Sharp AR-M550U,AR-M620U,AR-M700U Technical Manual

AR-M550U

AR-M620U AR-M700U

Technical Handy Guide

HANDY GUIDE

The information contained within this guide is subject to change

without prior notice.

For the latest technical and fault finding information,

Please follow the SharpSearch link which can be found on the

Technical Website.

http://www.tradenet.sharp.co.uk/tech/

The Handy Guide is not a substitute for the official Sharp Service manuals.

It is for use by Sharp qualified field service engineers with the intention of

improving the efficiency of Sharp Photocopiers.

Should you have relevant information, which is not included within this guide

please contact the Sharp Copier Hotline by e-mail :

copier.hotline@sharp-uk.co.uk

SHARP ELECTRONICS (UK) LTD.

Document Systems Support

Technical Services Group

2

February 2005

HANDY GUIDE

Contents – February 2005

1. Machine Specification 4

2. Machine Options 6

3. Consumables 7

Page

4. Initial Setup Procedure 8

5. Routine Maintenance 11

Updated

Revised

6. Minimum Call Procedure 15

7. Coin Vendor I/F 16

8. Product Key Registration 18

9. Firmware Update 20

10. FlashRom Recovery 23

11. Firmware Revision

Engine 24

Updated

Printer I/F 25 Updated

Facsimile 25

12. Technical Update 26

Updated

13. Test Simulations 28

14. Trouble Codes 34

15. Network Scanner Trouble Codes 37

16. Jam Cause Codes 38

17. PWB Data Storage Location 44

18. Notes 47

3

February 2005

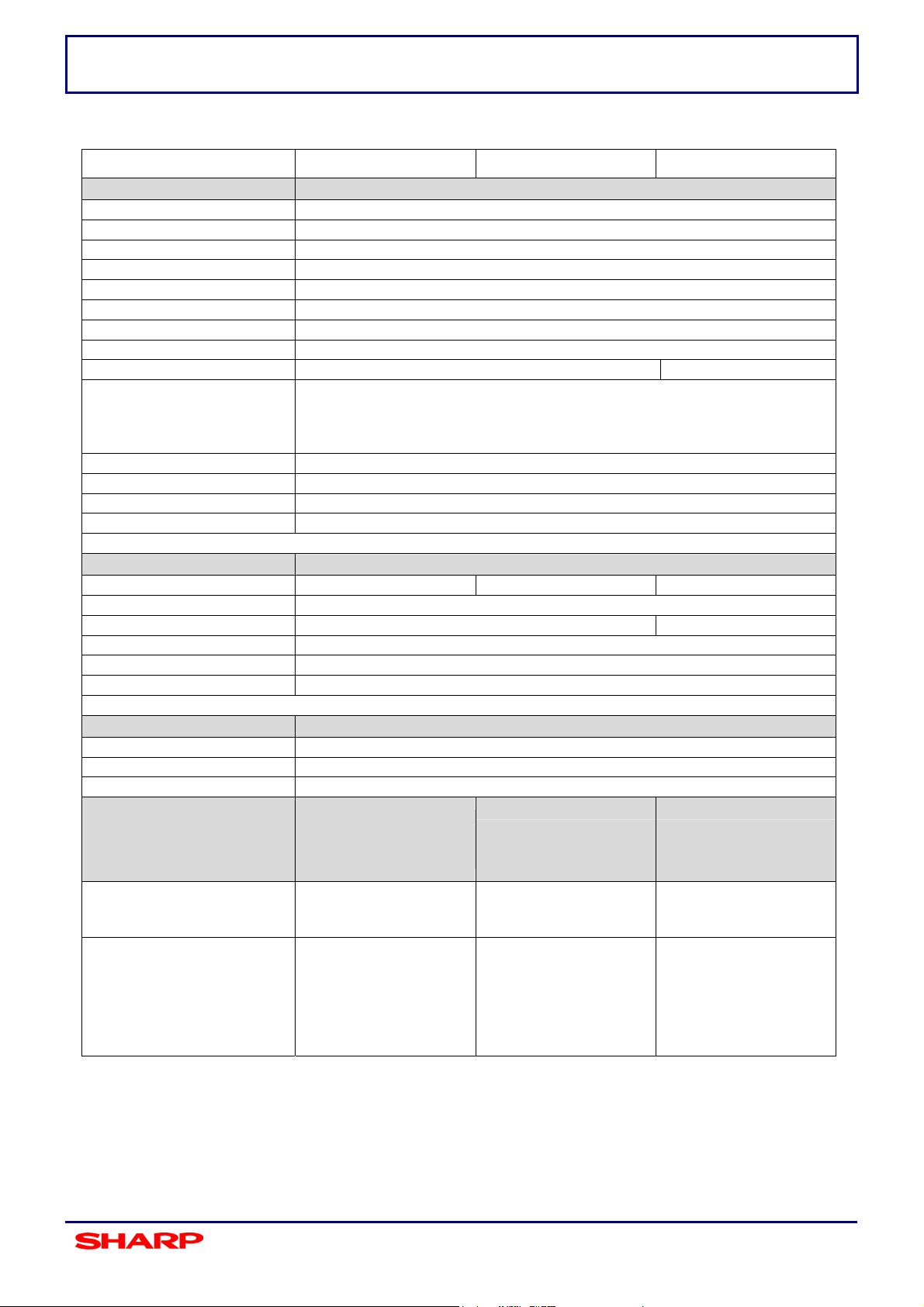

MACHINE SPECIFICATIONS

General

Type Console

Original paper size Max. A3

Printed paper size Max. A3 – Min. A5R

Standard paper capacity 1x 2000 (800+1200) + 2x500 + MB(100) sheets

Maximum paper capacity 1x 2000 (800+1200) + 2x 500 + 3500 + MB(100) sheets

Paper weight Tray 1,2 : 60-105 g/m2 Tray 3,4 : 60-205 g/m2 (Bypass : 52-205 g/m2)

Output capacity 250 sheets (Face down)

Warm-up time Less than 120 sec.

Resolution (Equivalent) 600 dpi (600 x 1200 dpi in printing) 600dpi

Memory/HDD

Duplex Std

Power consumption 1.84KW

Dimensions (W-D-H) 728x679x1192

Weight 185Kg

Copier

Copy speed(A4:continuous) 55 cpm 62 cpm 70 cpm

E-sort Yes

First copy time 3.9 sec. 3.3 sec.

Continuous copy Max. 999

Scan resolution 600 dpi

Zoom range Platen : 25 - 400 %, DF : 25 - 200 %

Document Feeder

Original capacity 150 sheets

Original replacement speed 65 opm (simplex), 76 opm (duplex) for copying

AR-M550 AR-M620 AR-M700

128MB + 40 GB HDD (Opt. 64MB/128MB/256MB)

(Actual capacity of HDD is 40GB. Quick folder can store up to 10,000 pages or

1000 files. Main folder and custom folder combined can store up to 20,000

pages or 3000 files.)

Std (DSPF)

Opt. Inserter AR-CF2

Finishing

Output capacity -----

Functionality

(AR-CF2 requires

AR-F15 or 16)

100 sheets insertion

60-256 g/m

Off-line finishing

2

4

Opt. AR-F15

Staple Finisher

Upper : 2,000

Lower : 2,000

50 sheets multi-staple,

Off-set shifting,

Hole punch

(requires

AR-PN4A/C/D)

Opt. AR-F16

Saddle Stitch Finisher

Upper : 2,000

Lower : 2,000

50 sheets multi-staple,

Booklet with Saddle

stitch, Off-set shifting

Hole punch

(requires

AR-PN4A/C/D)

February 2005

MACHINE SPECIFICATIONS

Network Printer

Print speed(A4:continuous) 55 ppm 62 ppm 70 ppm

PDL (Emulation)

Interface

Memory 128MB + 40 GB HDD (Opt. 64MB/128MB/256MB)

Supported OS

Bundled Utility Software Sharp Printer Administrator Utility, Status Monitor

Scanning

Resolution 200dpi, 300 dpi, 400dpi, 600 dpi

Duplex Yes

Destination Sharpdesk, FTP, E-mail

Bundled Utility software Network Scan Tool, Sharpdesk 3.0 (10 licenses), TWAIN driver

Fax

Communication Formula Super G3, Max. 33,600 bps

Document size Max. A3 – Min. A5

Compression MH, MR, MMR, JBIG

Dial Registration Up to 999 destinations (including e-mail address)

Broadcast transmission Yes, Max. 5000 destinations

PC-Fax Yes

AR-M550 AR-M620 AR-M700

Opt. AR-P19 for AR-M550U/620U/700U,

Std : PCL5e, PCL6

Opt : Post Script3 (AR-PK5)

IEEE1284, USB 1.1/2.0,

10/100BaseTX, Opt. for AR-MxxxU (AR-P19)

Win/95/98/Me, WinNT4.0/2000/XP

Mac OS 8.6 - 9.2.2, Mac OS X10.1.5 and 10.2-10.2.8 (excluding10.2.2)

with Opt. AR-PK5)

Opt. AR-NS3

Opt. AR-FX8

5

February 2005

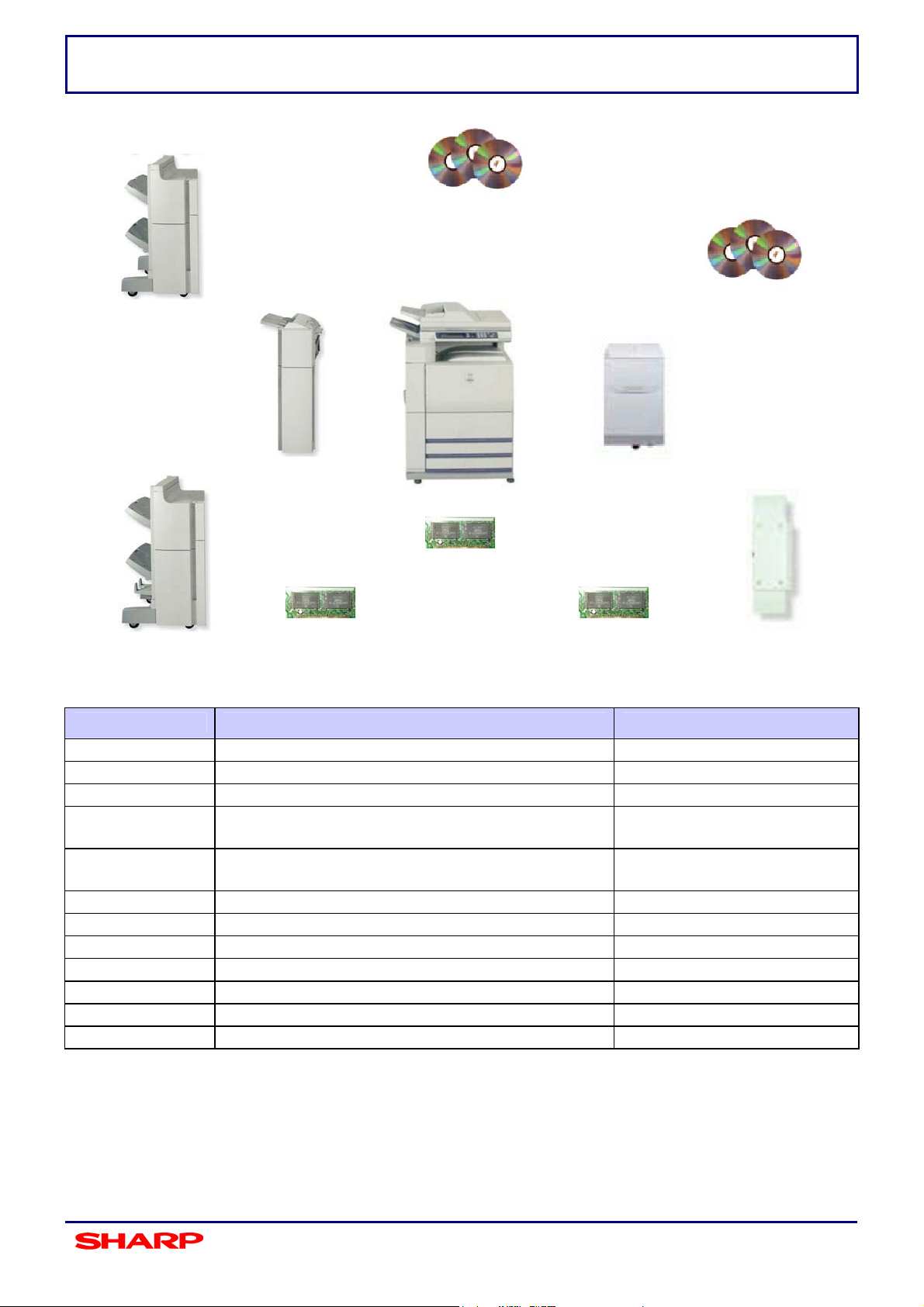

MACHINE OPTIONS

AR-PK5

AR-NS3

AR-F15

AR-CF2 AR-LC6

AR-FR11

AR-F16 AR-PF1 AR-MM9 AR-FX8

AR-P19

Model Name Description Comments

AR-LC6

AR-F15

AR-F16

AR-PN4A/C/D

AR-CF2

AR-P19

AR-PK5

AR-PF1

AR-FR11

AR-NS3

AR-FX8

AR-MM9

3,500 sheet large capacity tray Option

Finisher Option

Saddle Stitch Finisher Option

A:2 hole, C:4 hole, D:4 hole wide punch unit

Inserter

(AR-F15 or AR-F16 required)

(AR-F15 or AR-F16 required)

Option

Option

Network printer board with NIC Option

Postscript 3 Kit Option

Barcode Font Kit Option (AR-P19 is required)

Data Security Kit Option

Network Scanner Expansion Kit Option (AR-P19 is required)

Fax Expansion Kit Option

Fax Memory (8MB) Option

Note: Items in Blue require “Soft Key” Activation

6

February 2005

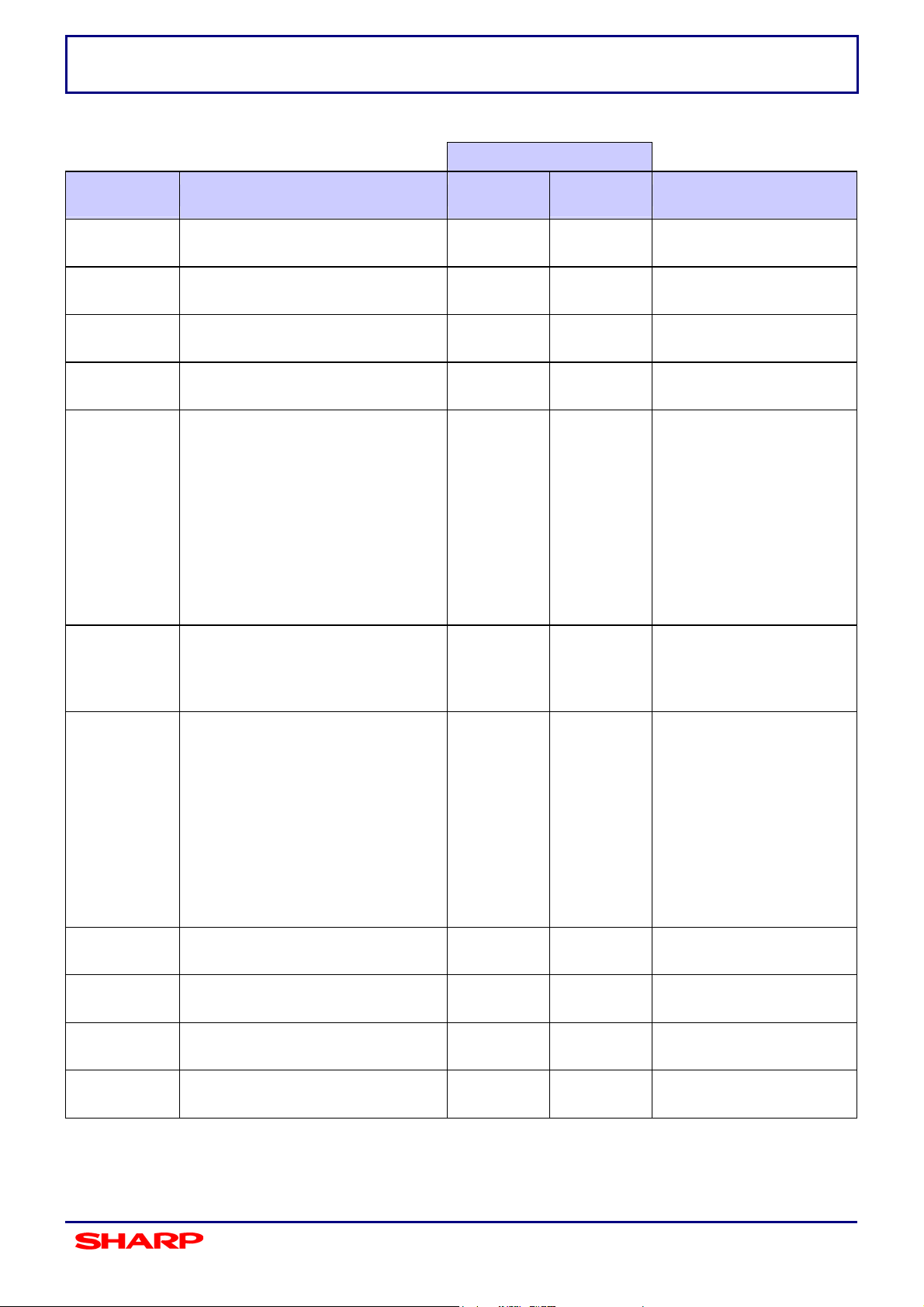

CONSUMABLES

Life (Approx)

Model

Name

Contents AR-M550

AR-M620

AR-M700

Comment

AR-620LT Toner Cartridge with IC chip 72K 72K A4 @ 6% coverage

AR-621LT Toner Cartridge with IC chip 83K 83K

AR-620LD

AR-620DM

Developer 25K 300K Use 2 bags

OPC Drum 250K 300K

A4 @ 6% coverage

From Apr Production

The drum is supplied

with the machine

Cleaner Blade

Drum Separation Pawl x 4

Screen Grid

Toner Receiving Seal

AR-620KA

Charger Plate

Paper Dust Cleaning Unit

250K 300K

Maintenance Kit 1

DV Seal

DV Side Seal R

DV Side Seal F

MC Cleaner Unit

Transfer Belt

AR-620KB

Transfer Roller

Transfer Gear

250K 300K

Maintenance Kit 2

Transfer CL Roller

Upper Fuser Roller

Lower Fuser Roller

Fuser Pawls Upper x 6

Fuser Pawls Lower x 4

AR-700KC

Heat Seal Base Assembly

Oil Roller

250K 300K

Maintenance Kit 3

CL Roller Bearing

CL Plate

Heat Roller

Heat Roller Bearing x 2

AR-620DF

AR-620RT

SF-SC11

AR-SC3

Main Unit Feeding Roller Kit 100K 100K

Saddle Staple cartridge (2 k) 2K x 3 2K x 3

DSPF Roller Kit 100K 100K

Staple cartridge (5 k) 5K x 3 5K x 3

Note: AR-620LT has been superseded by AR-621LT

7

For AR-F15/16

Common with AR-F11/F12

For AR-F16

Common with AR-F12

February 2005

INITIAL SETUP PROCEDURE

Cont’d

REMOVAL OF MACHINE FROM CARTON

It is recommended to use a fork lift truck however, if a fork

lift truck is not available, it will require 4 people to lift

the machine from the carton

LOCK & PACKING REMOVAL

Number 2/3 mirror base lock screw.

Tray rotation release plate lock.

Fuser pressure release screws (turn fully anticlockwise

DEVELOPER SETUP

Sim 25-01 Developer Stir

Sim 25-02 Developer level setting

PROCESS CONTROL

Sim 44-02 ID & DM Sensor adjustment

TONER INSTALLATION

Before installing the toner cartridge ensure the cartridge

is shaken horizontally several times.

Be careful not to rotate the toner cartridge.

CASSETTE SETUP & PAPER TYPE

Set cassette sizes by adjusting the guides in the cassette.

Paper Type Setting

Custom Settings – Tray Settings

8

February 2005

INITIAL SETUP PROCEDURE

Sim 21-01 Maintenance Cycle Setting

ARM550U set 250k

ARM620U set 300k

ARM700U set 300k

Sim 26-02 LCC Paper Size Set-up

Sim 26-05 A3 paper count ( set 1or 2 counts)

Sim 26-06 Destination setup.

Sim 26-35 Set Multi Error Counter

Set to 1 (Multi Count

IMAGE WRITING DISTORTION (SKEW)

Sim 64-01 Print Area adjust

Pattern 71

Density 100

Level 3

IMAGE POSITION & OFF CENTRE

Sim 50-05 Print Area adjust (Sub scan)

Image Off-Centre adjustment.

Adjust (All Cassettes)

Sim 50-12 OC & RADF Off Centre Adjust

Sim 50-01 OR

Sim 50-02 Lead/Rear Edge, Image Loss & Void Adjustment

Sim 46-02 Copy Density Adjustment.

Cont’d

INITIAL SETTINGS

COPY IMAGE POSITION

COPY DENSITY

9

February 2005

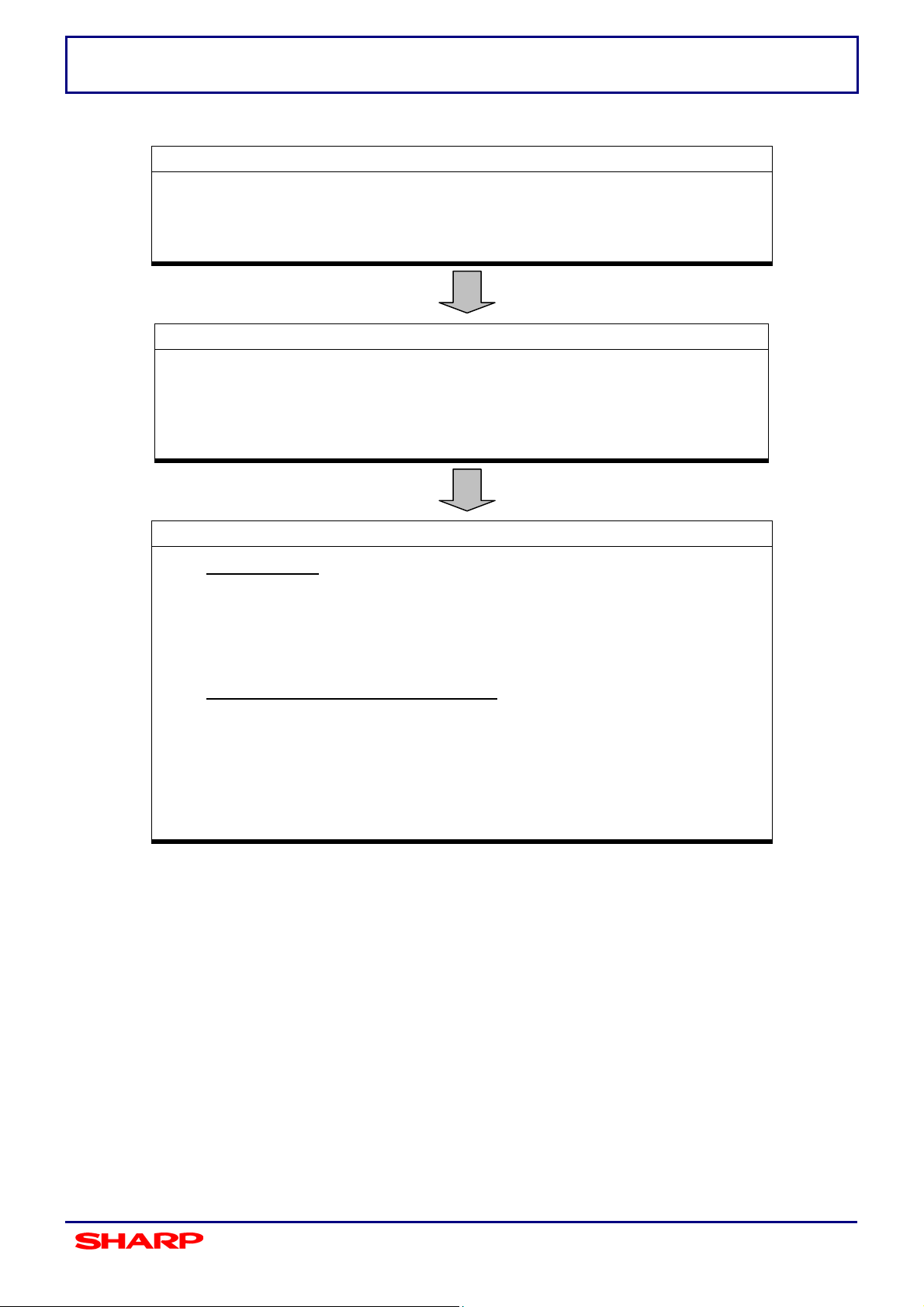

INITIAL SETUP PROCEDURE

Sim 26-10 Trial Mode activation – Network Scanner

Sim 22-06 Print All Simulation Data

Sim 66-02 Fax Destination

Sim 66-10 Image Memory Clear

(only perform when AR-MM9 is installed)

Entry Mode :

Press Custom Settings key

Press KEY OPERATOR PRG.

Enter Key Operator code (DEFAULT – 00000)

Change Key Operator Password:

Enter Key Operator mode, using procedure listed above

Press Key operator code change

Enter new 5-digit code

Press OK key.

CUSTOM SETTINGS

OTHER

FAX – AR-FX8

10

February 2005

ROUTINE MAINTENANCE

Consumable System

For AR-M550/AR-M620/AR-M700

The AR-M550/620/700 consumable system is SRU – Service Replaceable Units. The toner unit

is supplied as a cartridge that the customer can change, and the engineer changes the Drum

and Developer at 250/300K copies.

DV / Process Replacement Schedule

USER REPLACEABLE Toner Cartridge - AR-621LT, life = 83k (A4 @ 6%)

Developer (AR-620LD) - Life: AR-M550 =250K, AR-M620/700 =300k

Drum (AR-620DM) - Life: AR-M550 =250K, AR-M620/700 =300k

(Transfer belt, Transfer roller, Transfer gear, Transfer CL Roller)

(DSPF paper feed roller, DSPF take up roller, DSPF reverse roller)

(Main unit paper feed roller, takes up roller, reverse roller)

Maintenance Kit 1 (AR-620KA) Life: AR-M550 =250K, AR-M620/700 =300k

(Blade, sep pawls, grid, toner seal, cleaning brush, charge plate, paper dust

removal unit, DV seal, DV side seal f/r, toner filter, Side seal F, Side seal R,

MC Cleaner unit)

Maintenance Kit 2 (AR-620KB) Life: AR-M550 =250K, AR-M620/700 =300k

Maintenance Kit 3 (AR-700KC) Life: AR-M550 =250K, AR-M620/700 =300k

(Upper heat roller, lower heat roller, Fuser sep pawls upper and lower, Heat roller,

Heat roller bearing, Heat seal Base Assembly, Cleaner roller, Cleaning plate)

DSPF Roller Kit (AR-620DF) Life 100k

Feed Roller Kit (AR-620RT) Life 100k

Staple Cartridge (AR-SC11) Life 5k

Saddle Stitch (AR-SC3) Life 2k

11

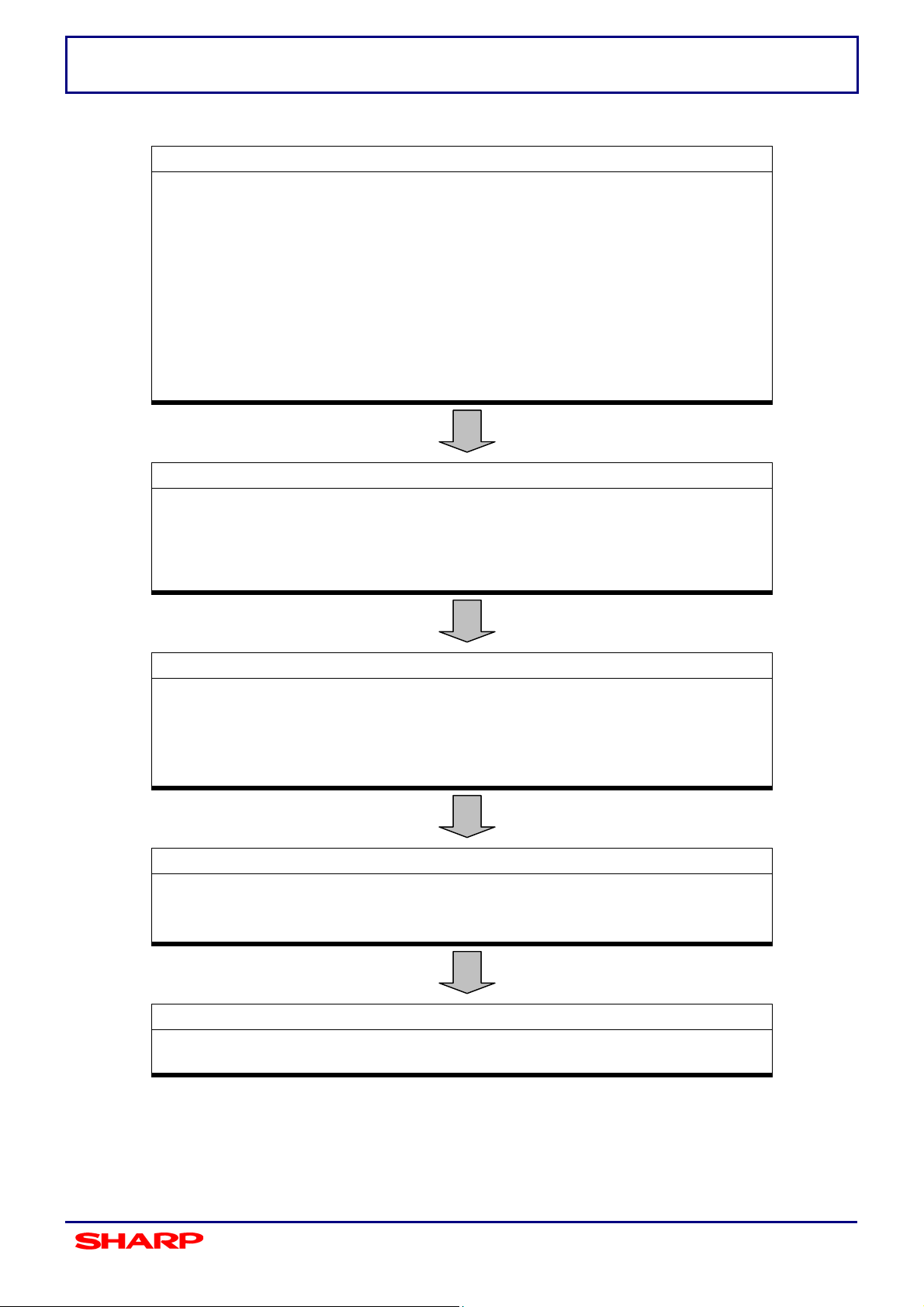

February 2005

ROUTINE MAINTENANCE

MAINTENANCE

COMPLETED

DRUM

REPLACEMENT

DEVELOPER

REPLACEMENT

COPY DENSITY

JAM &

TROUBLE

COUNTER

FEED ROLLER

REPLACEMENT

SIMULATION

DATA PRINT

Sim 24-04 Maintenance Counter Reset

Sim 21-01 Maintenance Setting Check

(Default set to 0)

Sim 24-07 Drum Membrane Counter Reset

Sim 24-11 Developer rotation time reset

Sim 24-05 Developer counter reset

Sim 25-02 Toner concentration setting

Sim 24-11 Developer rotation time reset

Sim 44-02 ID & DM Sensor adjustment

Sim 46-02 Copy density adjust

Sim 24-01 Jam/Trouble Counter Reset

Sim 24-02 Individual Tray Counter Reset

Sim 22-06 Print All Simulation Data

12

February 2005

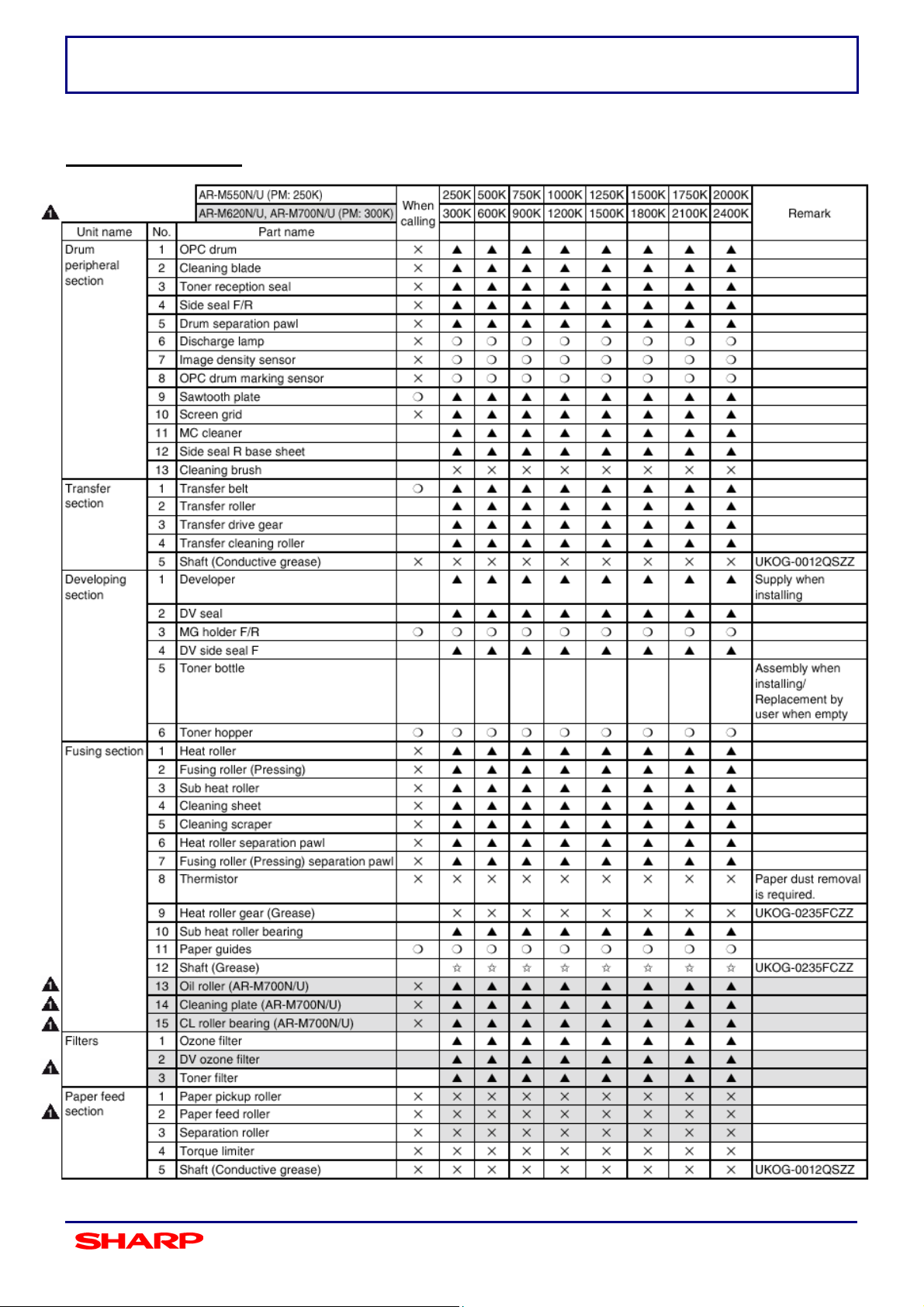

Maintenance List

ROUTINE MAINTENANCE

13

February 2005

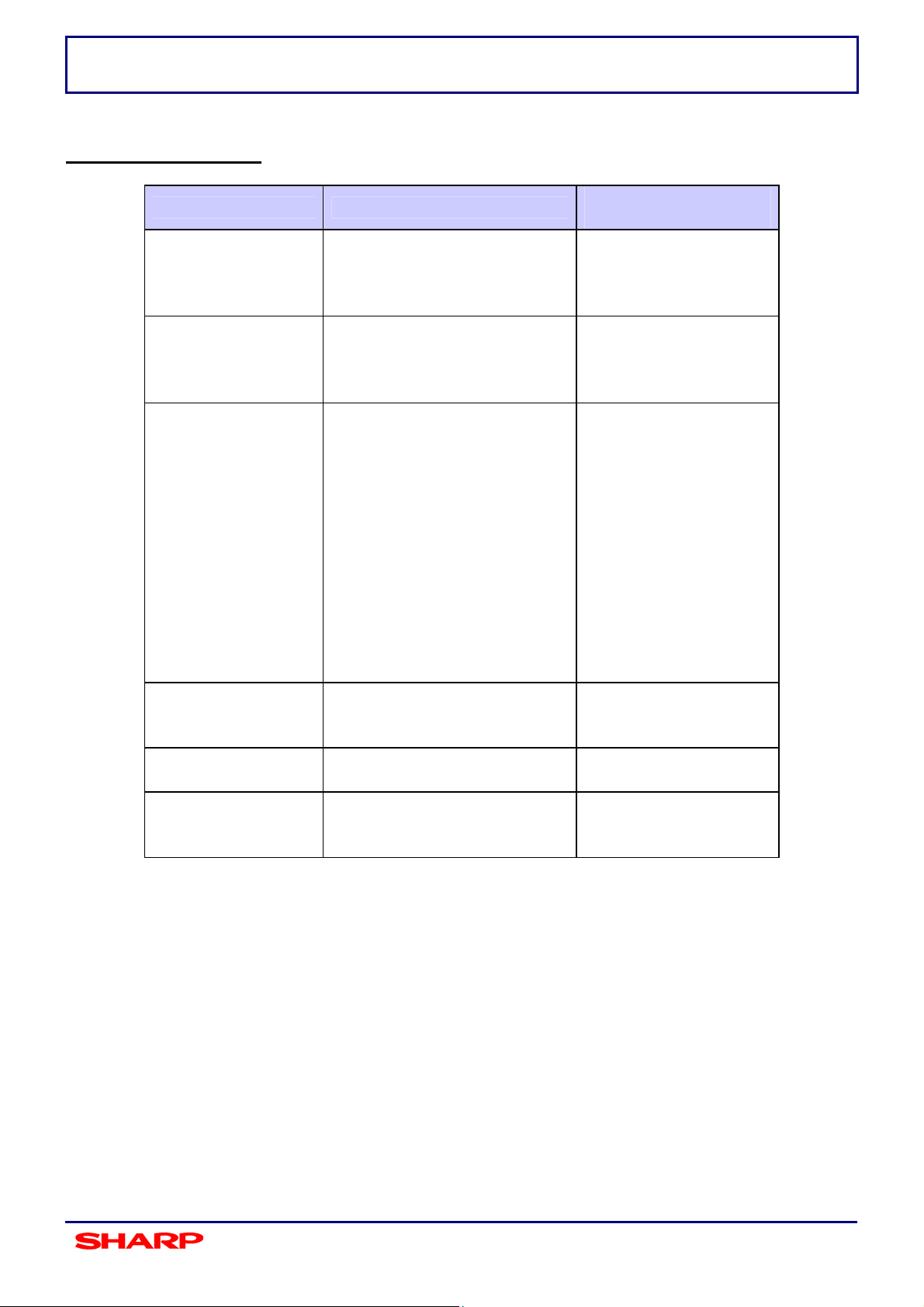

Other Adjustments

Section Adjustment Item

Process

Laser scanner

Scanner

Original sensor

Copy Quality

Paper Trans

ROUTINE MAINTENANCE

Adjustment

Procedure

1 Developer doctor gap Refer to section 7 of

Service Manual

2 MG roller main pole position

1 Horizontal image distortion Sim 50-10

2 Print off centre

1 Vertical image distortion

balance

2 Vertical image distortion

balance

3 Vertical image distortion Winding pulley

4 Horizontal image distortion F rail height adjust

5 Main scan magnification

ratio

6 Main scan magnification

ratio

7 Original off centre Sim 50 - 12

1 Size sensor adjust

1 Copy mode Sim 46 - 02

1 Resist Roller Pressure

adjust

Copy lamp unit

installing position

No2/3 mirror base

installing position

position

CCD unit position

Sim 48 - 01

Sim 41 - 3

Sim 51-2

14

February 2005

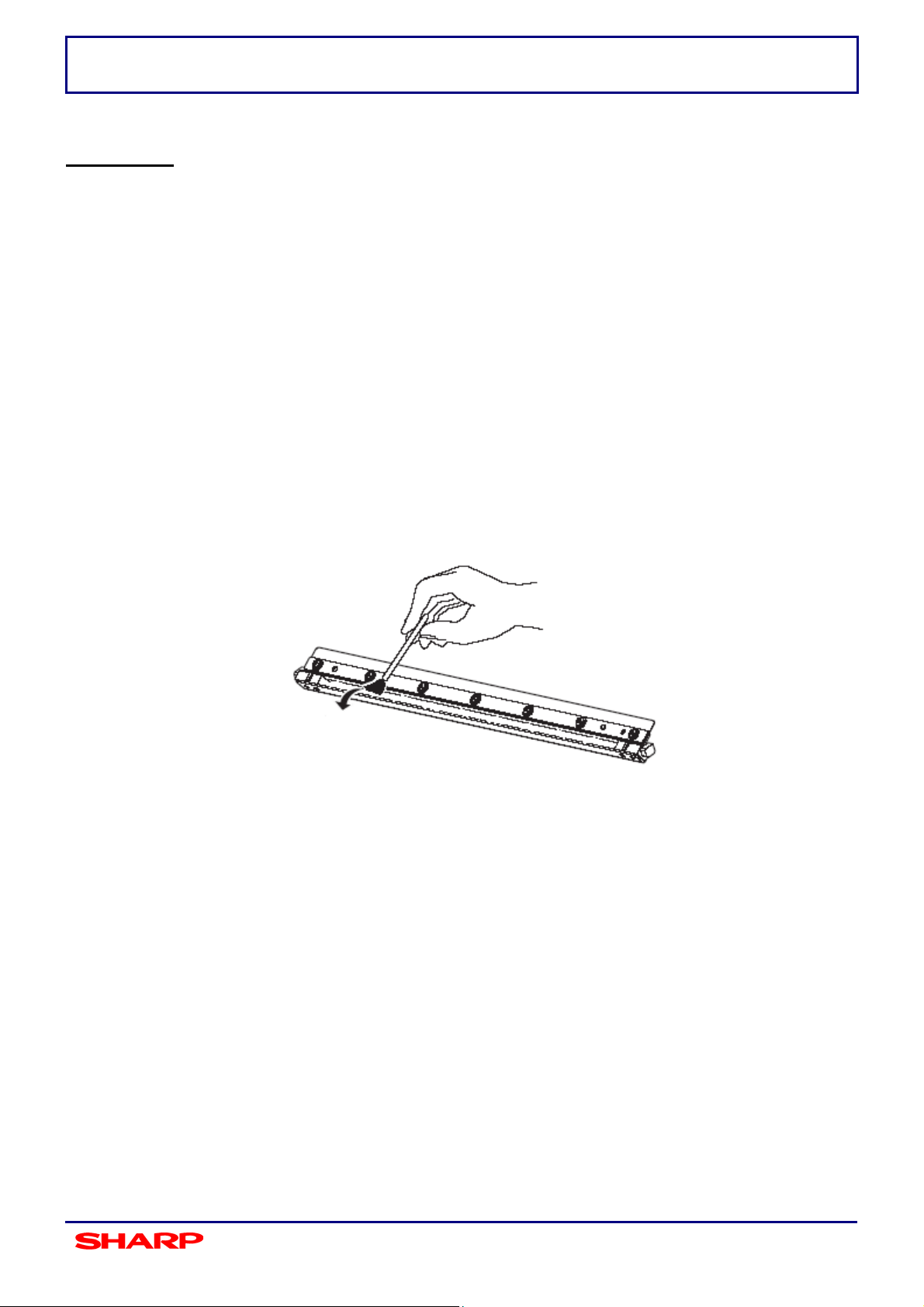

MINIMUM CALL PROCEDURE

Fuser Unit

It is recommended that if the AR-M550/620/700 is visited during the service period, the fuser

unit should be cleaned out in accordance with the Service Manual.

1 Move away the finisher/inserter (AR-F15, AR-F16 and AR-CF2) if fitted.

2 Open the upper left hand door.

3 Remove the cover from the fuser unit (three silver screws).

4 Clean out excess paper dust with brush.

15

February 2005

Loading...

Loading...