Page 1

CODE: 00ZAR700//H1E

FIELD SERVICE HANDBOOK

DIGITAL LASER COPIER/PRINTER

DIGITAL MULTIFUNCTIONAL SYSTEM

AR-M550N/M550U

AR-M620N/M620U

MODEL AR-M700N/M700U

CONTENTS

[1] CONSUMABLE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] STRUCTURE OF EACH SECTION . . . . . . . . . . . . . . . . . 2-1

[3] SETTING AND ADJUSTMENTS. . . . . . . . . . . . . . . . . . . . 3-1

[4] SIMULATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[5] SELF DIAG MESSAGE AND TROUBLESHOOTING . . . .5-1

[6] ROM VERSION-UP METHOD . . . . . . . . . . . . . . . . . . . . . 6-1

[7] MAINTENANCE LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[8] OTHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[9] SIGNAL NAME LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Parts marked with “ ” are important for maintaining the safety of the set. Be sure to replace

these parts with specified ones for maintaining the safety and performance of the set.

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

Page 2

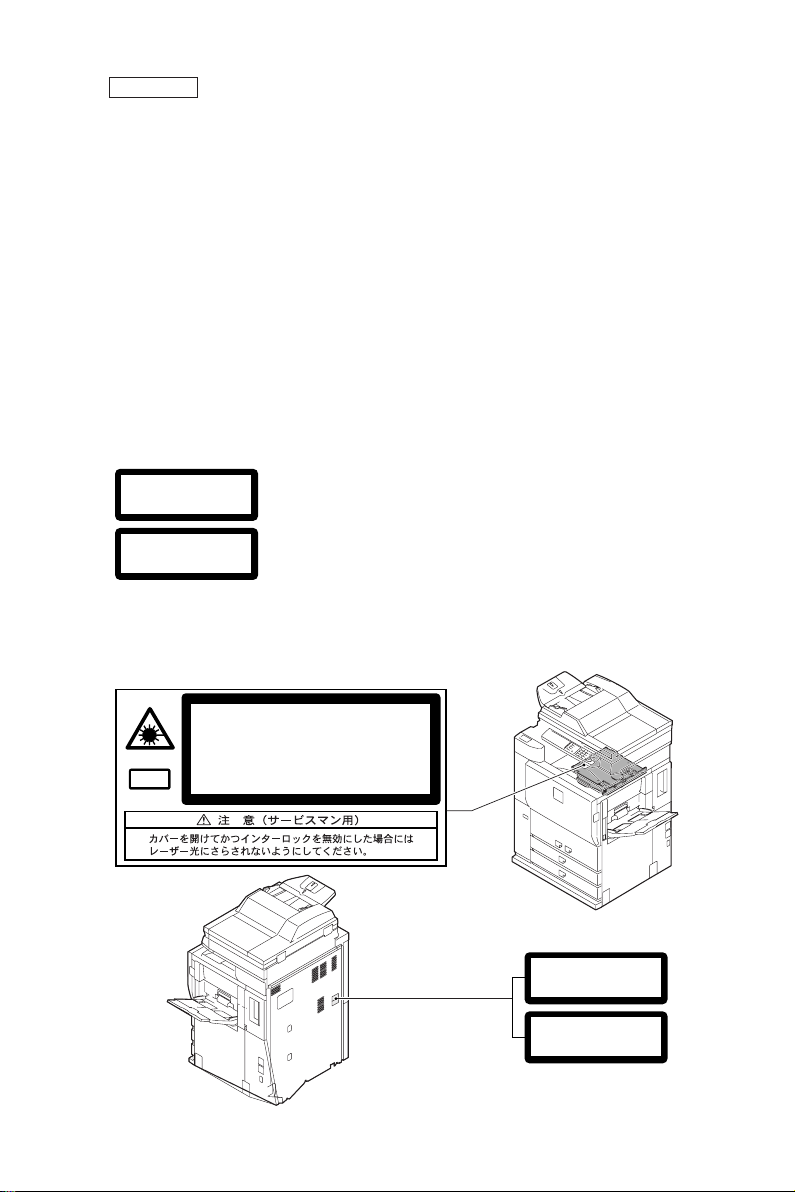

CAUTION

This product is a class 1 laser product that complies with 21CFR 1040 of the CDRH

standard and IEC825. This means that this machine does not produce hazardous laser

radiation. The use of controls, adjustments or performance of procedures other than

those specified herein may result in hazardous radiation exposure.

This laser radiation is not a danger to the skin, but when an exact focusing of the

laser beam is achieved on the eye’s retina, there is the danger of spot damage to the

The following cautions must be observed to avoid exposure of the laser beam to your

eyes at the time of servicing.

When a problem in the laser optical unit has occurred, the whole optical unit must

1)

be exchanged as a unit, not as individual parts.

Do not look into the machine with the main switch turned on after removing the

2)

developer unit, toner cartridge, and drum cartridge.

Do not look into the laser beam exposure slit of the laser optical unit with the

3)

connector connected when removing and installing the optical system.

The middle frame contains the safety interlock switch.

4)

Do not defeat the safety interlock by inserting wedges or other items into the

switch slot.

CLASS 1

LASER PRODUCT

LASER KLASSE 1

Wave length: 785 nm

Pulse times

North America: 55 cpm model (3.1 µs

Europe: 55 cpm model (3.7 µs

Output power: Max 0.8 mW

Laserstrahl

+10 nm

–15 nm

62 cpm model (3.1 µs

70 cpm model (2.7 µs

62 cpm model (3.7 µs

70 cpm model (3.2 µs

CAUTION

VORSICHT

ADVARSEL

ADVERSEL

VARNING

VAR O!

INVISIBLE LASER RADIATION,

WHEN OPEN AND INTERLOCKS DEFEATED.

AVOID EXPOSURE TO BEAM.

UNSICHTBARE LASERSTRAHLUNG,

WENN ABDECKUNG GEÖFFNET UND

SICHERHEITSVERRIEGELUNG ÜBERBRÜCKT.

NICHT DEM STRAHL AUSSETZEN.

± 3.1 ns)/7 mm

± 3.1 ns)/7 mm

± 2.7 ns)/7 mm

± 3.7 ns)/7 mm

± 3.7 ns)/7 mm

± 3.2 ns)/7 mm

INVISIBLE LASER RADIATION WHEN OPEN AND INTERLOCKS DEFEATED.

AVOID EXPOSURE TO BEAM.

UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET UND

SICHERHEITSVERRIEGELUNG ÜBERERÜCKT. NICHT DEM STRAHL AUSSETZEN.

USYNLIG LASERSTRÅLING VED ÅBNING, NÅR SIKKERHEDSAFBRYDERE ER

UDE AF FUNKTION. UNDGÅ UDSAETTELSE FOR STRÅLNING.

USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG SIKKERHEDSLÅS BRYTES.

UNNGÅ EKSPONERING FOR STRÅLEN.

OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄRRAR ÄR

URKOPPLADE. STRÅLEN ÄR FARLIG. BETRAKTA EJ STRÅLEN.

AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA NÄKYMÄTÖNTÄ

LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

CAUTION

VORSICHT

AVATTAESSA JA SUOJALUKITUS

OHITETTAESSA OLET ALTTIINA

NÄKYMÄTTÖMÄLLE LASERSÄTEILYLLE ÄLÄ

KATSO SÄTEESEEN.

USYNLIG LASERSTRÅLNING VED ÅBNING, NÅR

SIKKERHEDSBRYDERE ER UDE AF

FUNKTION. UNDGÅ UDSAETTELSE FOR

STRÅLNING.

OSYNLIG LASERSTRÅLNING NÄR DENNA DEL

ÄR ÖPPNAD OCH SPÄRREN ÄR URKOPPLAD.

BETRAKTA EJ STRÅLEN. – STRÅLEN ÄR

FARLIG.

VARO !

ADVARSEL

VARNING !

CLASS 1

LASER PRODUCT

LASER KLASSE 1

Page 3

CONTENTS

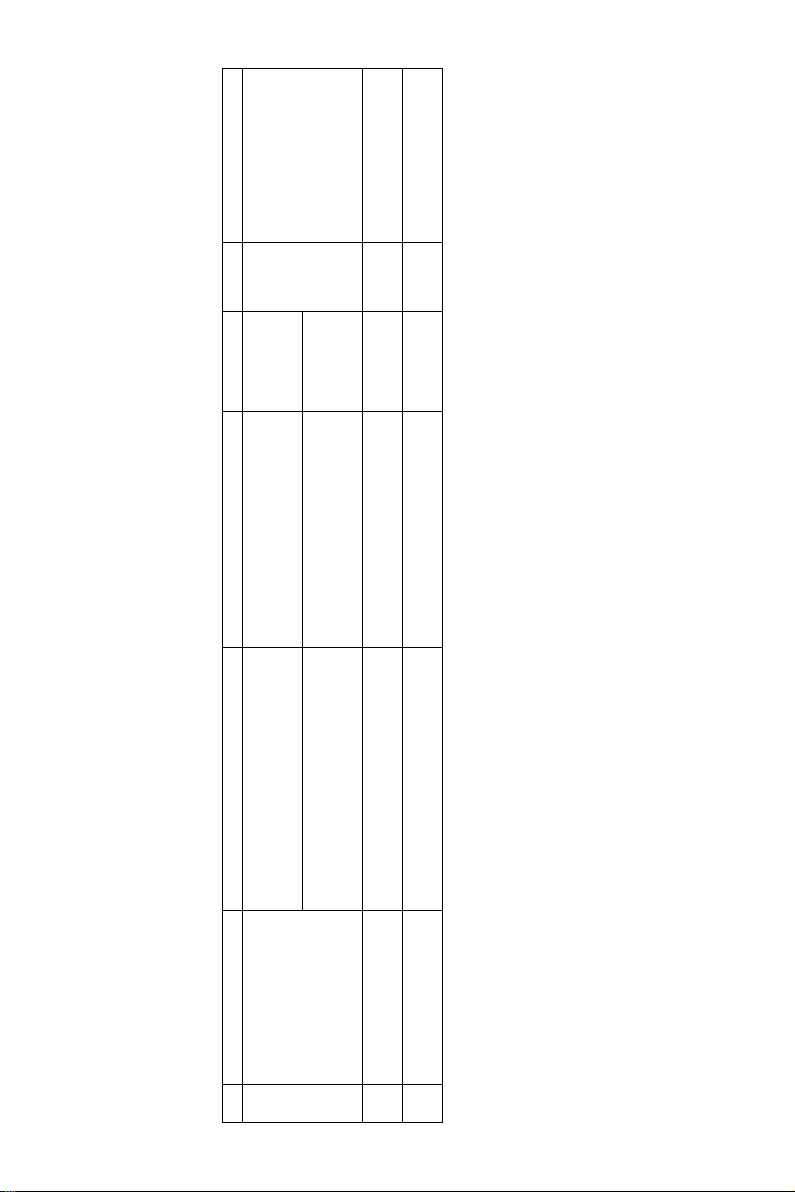

[1] CONSUMABLE PARTS

1. Supply system table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

A. USA, Canada, South and Central America . . . . . . . . . . . . . . . . . 1-1

B. Europe affiliates (Including East Europe, Russia)/Australia/

New Zealand/UK) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

C. Asia affiliates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

D. Hong Kong. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

E. China (AR-M620N/M700N) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

F. Middle East/Philippine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

G. Taiwan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

2. Maintenance parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

A. USA, Canada. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

B. Europe affiliates (Including East Europe, Russia) Australia/

New Zealand/UK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

C. Middle East/Asia/South and Central America . . . . . . . . . . . . . . 1-10

D. China. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

E. Taiwan. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

[2] STRUCTURE OF EACH SECTION

1. Operation panel section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2. Paper feed, paper transport, duplex,

and paper exit reverse sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

[Paper feed section] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

(Manual paper feed section) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

(Paper feed tray sections 1 and 2) . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

(Paper feed trays 3 and 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

[Paper Transport Section] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

(Vertical paper transport section 1) . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

(Vertical paper transport section 2) . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

(Horizontal transport section) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

[Paper exit and turning section] . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

(Duplex section) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

3. Laser scan unit (LSU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Page 4

4. Image process section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

[Developer tank section] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-26

[OPC drum section]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-28

[Transfer section] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-30

[Main charger section]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-32

5. Scanner section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

6. Fusing section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-36

7. SPF section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-42

[Paper feed tray section] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-44

[Paper feed/transport section]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-46

[CIS section] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

[Paper exit section] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-50

[3] SETTING AND ADJUSTMENTS

[ADJ 1] Adjusting high voltage values . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

[ADJ 2] Adjusting the developing unit. . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

[ADJ 3] Adjusting image distortions . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

[ADJ 4] Adjusting the SPF parallelism . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

[ADJ 5] Adjusting the image focus . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

[ADJ 6] Adjusting the image magnification . . . . . . . . . . . . . . . . . . . . . . 3-41

[ADJ 7] Adjusting the image off-center . . . . . . . . . . . . . . . . . . . . . . . . . 3-54

[ADJ 8] Adjusting the image position, image loss, and void area . . . . . 3-64

[ADJ 9] Adjusting the copied image quality . . . . . . . . . . . . . . . . . . . . . 3-77

[ADJ 10] Adjusting the print quality in fax mode . . . . . . . . . . . . . . . . . . . 3-87

[ADJ 11] Adjusting the image quality in scan mode . . . . . . . . . . . . . . . . 3-94

[ADJ 12] Common image quality adjustments for all of copy, scan,

and fax modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-99

[ADJ 13] Adjusting the fusing paper guide position . . . . . . . . . . . . . . . 3-103

[ADJ 14] Adjusting the paper size detection . . . . . . . . . . . . . . . . . . . . . 3-104

[ADJ 15] Adjusting the original size detection

(in original table mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-110

[ADJ 16] Adjusting the touch panel coordinates . . . . . . . . . . . . . . . . . . 3-112

[ADJ 17] Adjusting the supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . 3-113

[4] SIMULATION

1. Adjustment value/Simulation and storage data. . . . . . . . . . . . . . . . . 4-1

A. Simulation adjustment value/ Set value data. . . . . . . . . . . . . . . . 4-1

B. Each storage data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2. Simulation list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

3. Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-41

Page 5

[5] SELF DIAG MESSAGE AND TROUBLESHOOTING

[Error code] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

1. Breakdown sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

A. Breakdown mode process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

2. Trouble kind . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

3. Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

[6] ROM VERSION-UP METHOD

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

A. Version-up target ROM's . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

B. ROM version-up is required in the following cases:. . . . . . . . . . . 6-6

2. Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

A. Relationship between each ROM and version-up . . . . . . . . . . . . 6-7

3. Necessary items for Flash ROM version-up . . . . . . . . . . . . . . . . . . . 6-7

4. Flash ROM version-up method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

A. MFP control PWB ROM DIP switch selection and

Flash ROM slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

B. Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

C. Version-up procedure 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

D. Version-up procedure 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

E. Countermeasures against "Result: NG" . . . . . . . . . . . . . . . . . . 6-14

5. Turning OFF the power during the version-up procedure. . . . . . . . 6-14

[7] MAINTENANCE LIST

1. Maintenance list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

2. Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

A. Drum peripheral section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

B. Transfer section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

C. Developing section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-14

D. Fusing section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-16

E. Scanner section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

F. SPF section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-22

G. Paper feed section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

H. Transport section/paper exit reverse section/duplex section. . . 7-26

I. Drive section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-28

J. Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-30

3. Maintenance and disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-31

A. Necessary execution items in maintenance and servicing . . . . 7-31

Page 6

[8] OTHER

1. VARIOUS COUNTERS SPECIFICATIONS . . . . . . . . . . . . . . . . . . . 8-1

A. Count specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

B. Location and display of each counter data . . . . . . . . . . . . . . . . 8-12

2. Web setting service mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

A. Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

B. Operating procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

C. Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18

3. Paper jam code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-21

A. Paper jam judgment conditions . . . . . . . . . . . . . . . . . . . . . . . . . 8-21

B. Inserter (AR-CF2) paper jam judgment conditions . . . . . . . . . . 8-32

C. Finisher (AR-F15/F16) paper jam judgment conditions. . . . . . . 8-33

[9] SIGNAL NAME LIST

Page 7

6% document

MT = NT x 10

MD = ND x 10

AR-620MD 1 Used two bags.

55ppm: 250k

AR-620DR 10

55ppm: 250k

[1] CONSUMABLE PARTS

x 10 720k (72k x 10) AR-620MT 1 * Life setting by A4/LT

1 Toner cartridge (Black) Toner cartridge (Black)

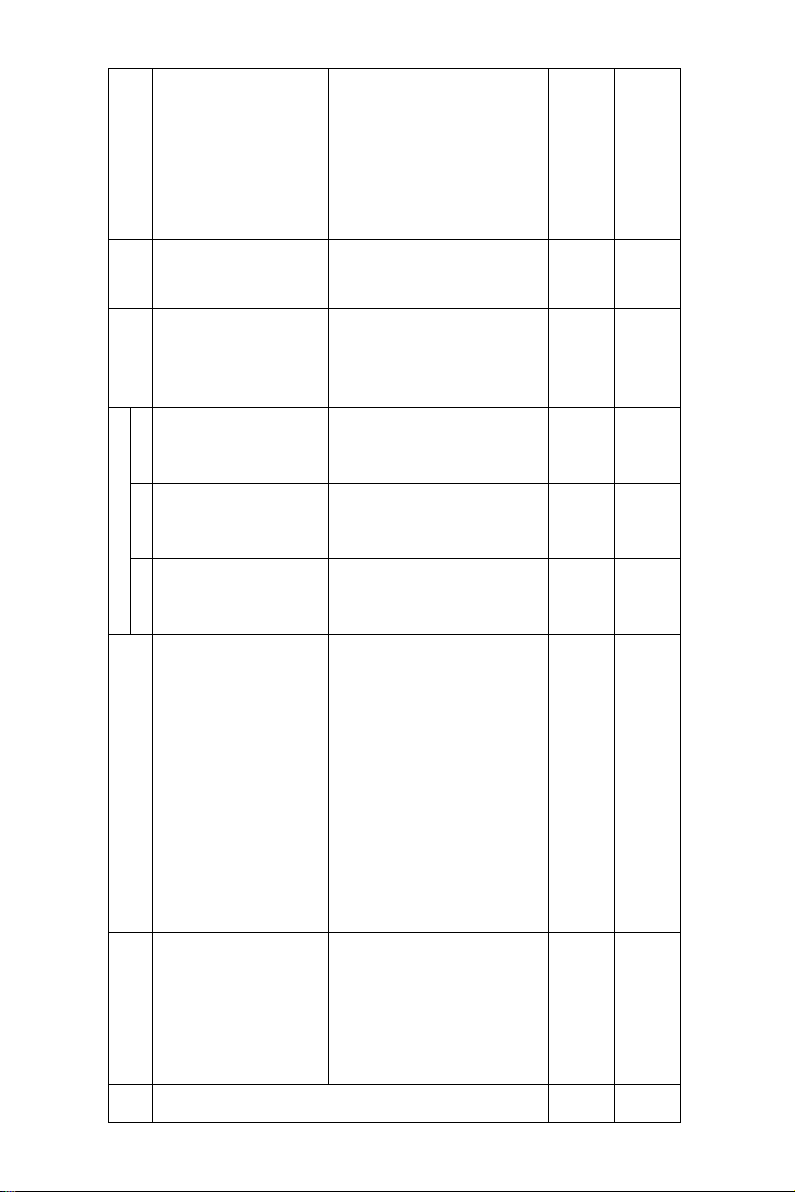

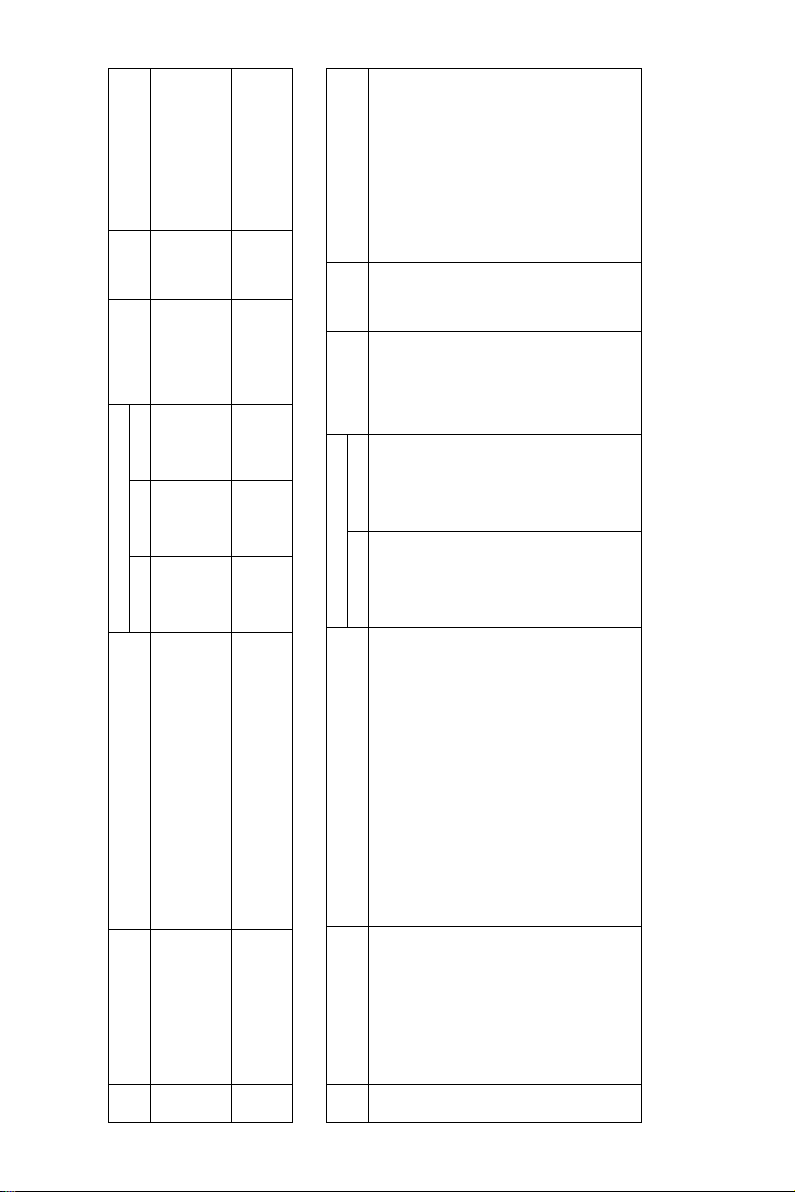

1. Supply system table

No. Part name Content Life Model name Packing Remark

A. USA, Canada, South and Central America

AR-M550/M620/M700 CONSUMABLE PARTS 1 - 1

(Toner; Net weight 1430g)

With IC chip

x 10 830k (83k x 10) AR-621MT

Toner cartridge (Black)

(Toner; Net weight 1650g)

With IC chip

x 10 62/70ppm: 300k

2 Developer (Black) Developer (Black)

(Developer; Net weight 725g)

3 Drum OPC drum x 1 62/70ppm: 300k

Page 8

6% document

LT = T x 10

LD = DV x 10

6% document

CT = ST x 10

CD = SD x 10

x 10 720k (72k x 10) AR-620LT 1 * Life setting by A4/LT

(Toner; Net weight 1430g)

With IC chip

x 10 830k (83k x 10) AR-621LT

Toner cartridge (Black)

(Toner; Net weight 1650g)

With IC chip

AR-620LD 1 Used two bags.

55ppm: 250k

x 10 62/70ppm: 300k

(Developer; Net weight 725g)

AR-620DM 10

55ppm: 250k

x 10 720k (72k x 10) AR-620CT 1 * Life setting by A4/LT

(Toner; Net weight 1430g)

With IC chip

x 10 830k (83k x 10) AR-621CT

Toner cartridge (Black)

(Toner; Net weight 1650g)

With IC chip

AR-620CD 1 Used two bags.

55ppm: 250k

x 10 62/70ppm: 300k

(Developer; Net weight 725g)

AR-620DR 10

55ppm: 250k

B. Europe affiliates (Including East Europe, Russia)/Australia/New Zealand/UK)

1 Toner cartridge (Black) Toner cartridge (Black)

No. Part name Content Life Model name Packing Remark

AR-M550/M620/M700 CONSUMABLE PARTS 1 - 2

2 Developer (Black) Developer (Black)

3 Drum OPC drum x 1 62/70ppm: 300k

1 Toner cartridge (Black) Toner cartridge (Black)

No. Part name Content Life Model name Packing Remark

C. Asia affiliates

2 Developer (Black) Developer (Black)

3 Drum OPC drum x 1 62/70ppm: 300k

Page 9

LT 6% document

CT-C = ST-C x 10

CD-C = SD-C x 10

AR-620CD-C 1 Used two bags.

55ppm: 250k

6% document

AR-620DR-C 10

55ppm: 250k

x 10 720k (72k x 10) AR-620CT-C 1 * Life setting by A4/

Toner cartridge (Black)

(Toner; Net weight 1430g)

With IC chip

For SRH

1 Toner cartridge (Black)

No. Part name Content Life Model name Packing Remark

D. Hong Kong

E. China (AR-M620N/M700N)

x 10 72k (72k x 1) AR-621ST-C 1 * Life setting by A4/LT

1 Toner cartridge (Black) Toner cartridge (Black)

No. Part name Content Life Model name Packing Remark

x 10 830k (83k x 10) AR-621CT-C

Toner cartridge (Black)

AR-M550/M620/M700 CONSUMABLE PARTS 1 - 3

(Toner; Net weight 1650g)

With IC chip

x 10 62/70ppm: 300k

(Developer; Net weight 725g)

2 Developer (Black) Developer (Black)

3 Drum OPC drum x 1 62/70ppm: 300k

(Toner; Net weight 1430g)

With IC chip

x 10 83k (83k x 1) AR-622ST-C

Toner cartridge (Black)

(Toner; Net weight 1650g)

x 10 62/70ppm: 300k AR-620SD-C 1 Used two bags.

With IC chip

(Developer; Net weight 725g)

2 Developer (Black) Developer (Black)

3 Drum OPC drum x 1 62/70ppm: 300k AR-620DR-C 1

Page 10

6% document

6% document

ET=FT x 10

CD = SD x 10

ET=FT x 10

LD = DV x 10

x 10 720k (72k x 10) AR-620ET 1 * Life setting by A4/LT

(Toner; Net weight 1430g)

With IC chip

x 10 830k (83k x 10) AR-621ET

Toner cartridge (Black)

(Toner; Net weight 1650g)

(Toner; Net weight 1650g)

With IC chip

AR-620LD 1 Used two bags.

55ppm: 250k

x 10 62/70ppm: 300k

(Developer; Net weight 725g)

AR-620DM 10

55ppm: 250k

AR-620CD 1 Used two bags.

AR-620DR 10

55ppm: 250k

55ppm: 250k

x 10 62/70ppm: 300k

With IC chip

(Developer; Net weight 725g)

x 10 720k (72k x 10) AR-620ET 1 * Life setting by A4/LT

(Toner; Net weight 1430g)

With IC chip

x 10 830k (83k x 10) AR-621ET

Toner cartridge (Black)

1 Toner cartridge (Black) Toner cartridge (Black)

No. Part name Content Life Model name Packing Remark

F. Middle East/Philippine

2 Developer (Black) Developer (Black)

3 Drum OPC drum x 1 62/70ppm: 300k

AR-M550/M620/M700 CONSUMABLE PARTS 1 - 4

1 Toner cartridge (Black) Toner cartridge (Black)

No. Part name Content Life Model name Packing Remark

G. Taiwan

3 Drum OPC drum x 1 62/70ppm: 300k

2 Developer (Black) Developer (Black)

Page 11

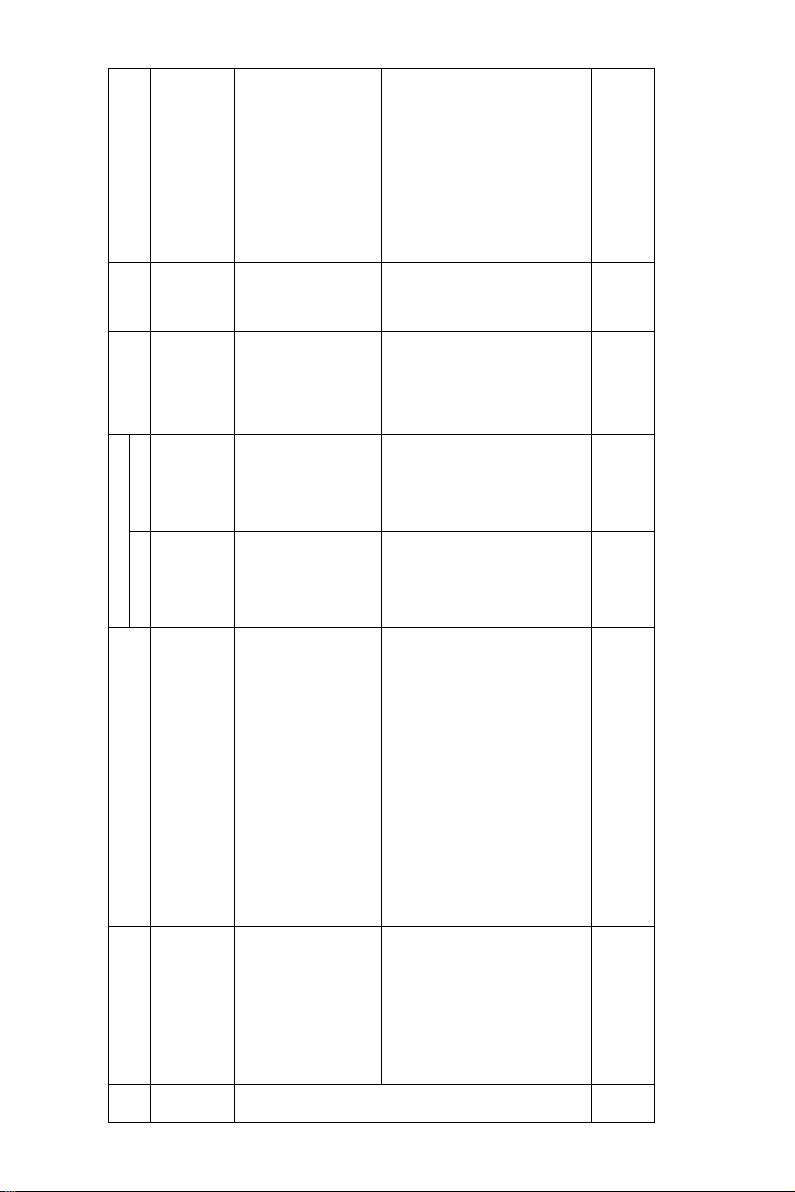

(AR-620BL) x 10

Model name Packing Remark

Life

55cpm 62cpm 70cpm

AR-620CB 1 AR-620CB =

300K

(x 10)

300K

(x 10)

(x 10)

Side seal R x 1

MC cleaning unit x 1

Cleaner blade x 1

Drum separation pawl x 4

Screen grid x 1

Toner reception seal x 1

Charging plate x 1

Paper dust removal unit x 1

DV seal x 1

DV side seal F x 1

DV side seal R x 1

Toner filter x 1

Transfer belt x 1

Transfer roller x 1

Transfer gear x 1

Fusing separation pawl (Upper) x 6

Fusing separation pawl (lower) x 2

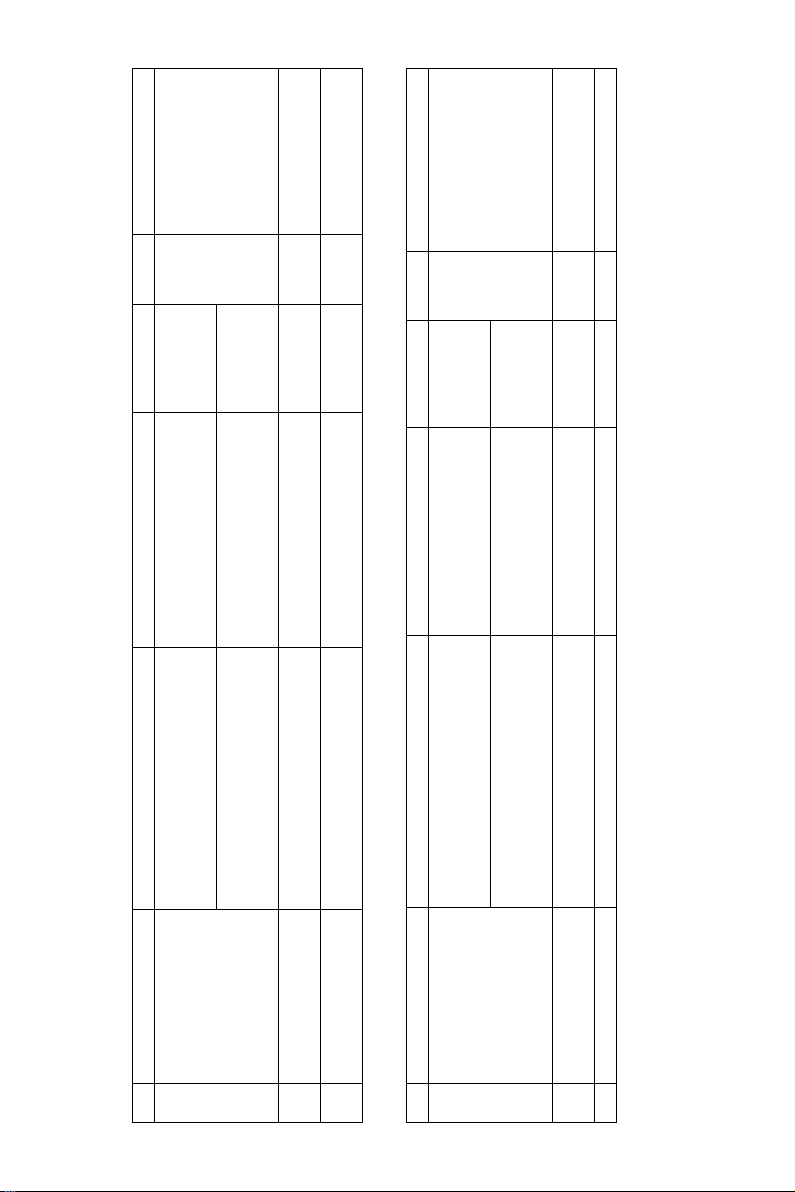

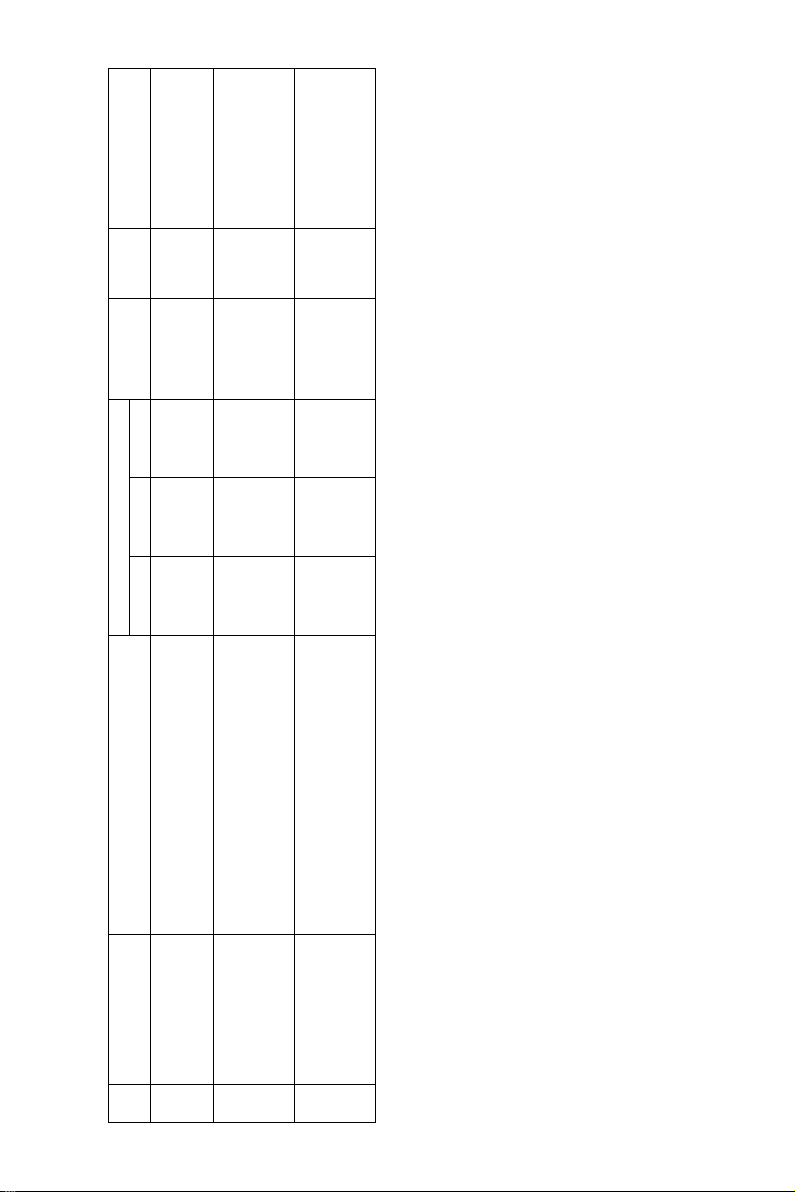

2. Maintenance parts list

No. Name Content

A. USA, Canada

1 Maintenance kit 1 Side seal F x 1 250K 300K 300K AR-620KA 10

AR-M550/M620/M700 CONSUMABLE PARTS 1 - 5

2 Maintenance kit 2 Transfer cleaning roller x 1 250K 300K 300K AR-620KB 10

3 Upper heat reoller kit Upper heat roller x 1 250K 300K 300K AR-620UH 10

4 Lower heat roller kit Lower heat roller x 1 250K 300K 300K AR-620LH 10

5 Cleaner blade Cleaner blade x 10 250K

Page 12

(AR-620RC) x 10

(Common with the

cartridge for AR-F11/

F12)

(Common with the

cartridge for AR-F12)

Model name Packing Remark

Life

55cpm 62cpm 70cpm

– AR-620CR 1 AR-620CR =

300K

(x 10)

(x 10)

Cleaning sheet x 10 ––300K AR-700CR 1

Scraper unit x 10 250K

Sub heat roller cleaning unit x 10

Oil roller x 10

Cleaning roller bearing x 20

Pressure cleaning plate x 10

SF-SC11 20 Cartridge for AR-F15

5,000

times x 3

5,000

times x 3

times x 3

Heat roller bearing x 2

SPF take-up roller x 1

SPF reverse roller x 1

Main unit paper feed take-up roller x 1

Main unit paper feed reverse roller x 1

AR-SC3 40 Cartridge for AR-F16

2,000

2,000

times x 3

times x 3

times x 3

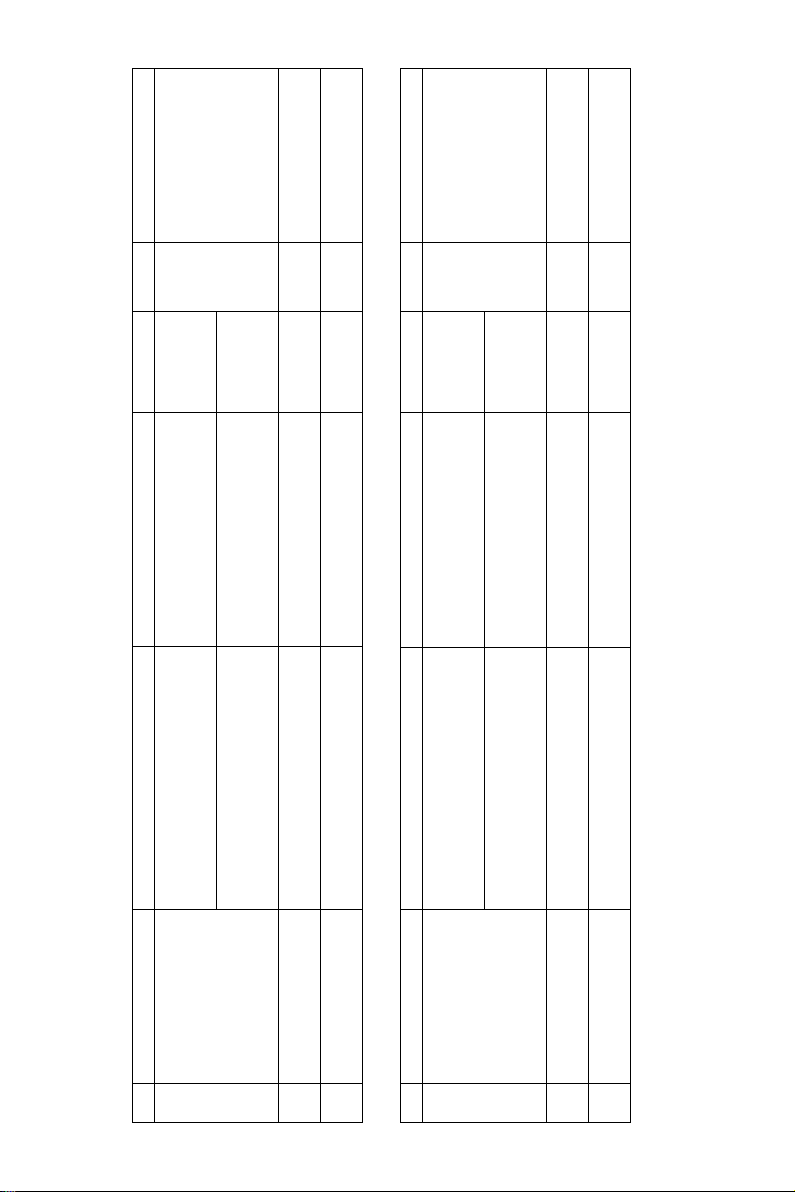

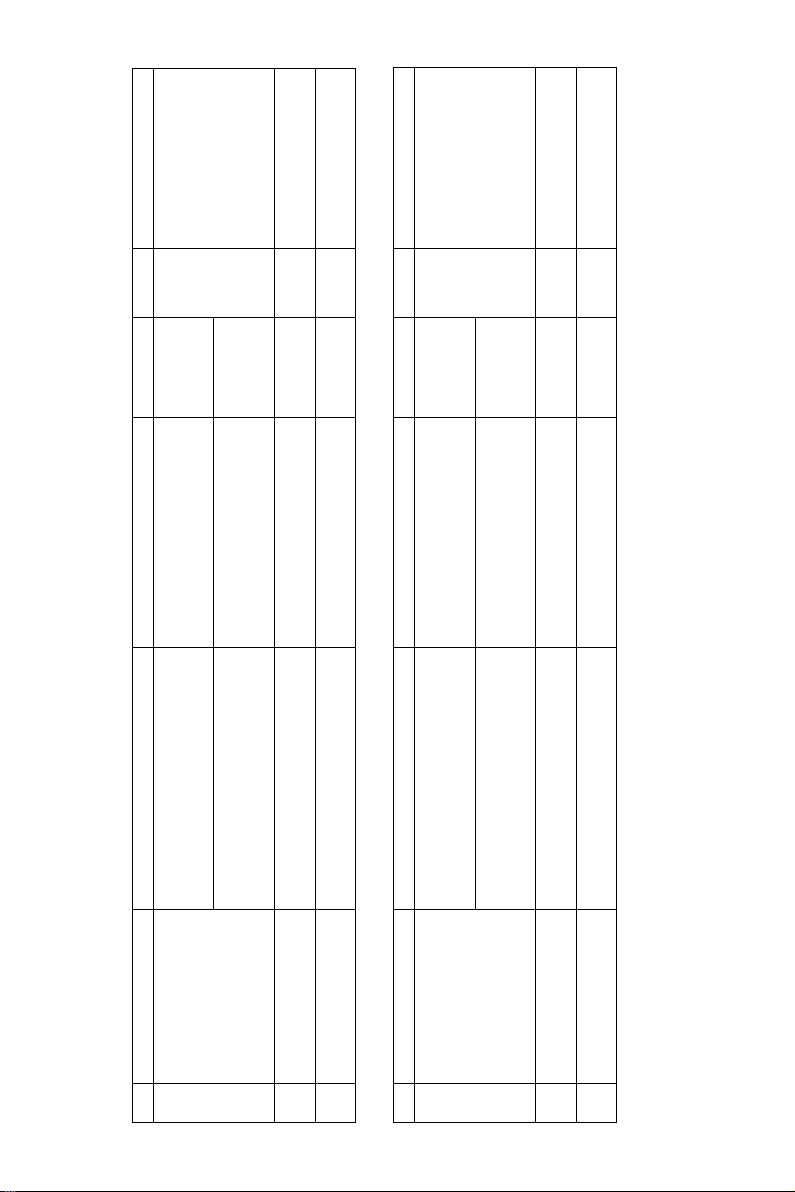

No. Name Content

6 Cleaning roller kit

(70cpm model)

(55/62cpm model)

8 Heat roller kit Sub heat roller x 1 250K 300K 300K AR-620HR 10

7 Maintenance kit 3

AR-M550/M620/M700 CONSUMABLE PARTS 1 - 6

9 DSPF roller kit SPF paper feed roller x 1 100K 100K 100K AR-620DF 10

10 Paper feed roller kit Main unit paper feed roller x 1 100K 100K 100K AR-620RT 10

11 Staple cartridge Finisher staple x 3 5,000

12 Staple cartridge Saddle finisher staple x 3 2,000

Page 13

Packing Remark

Model

Life

name

55cpm 62cpm 70cpm

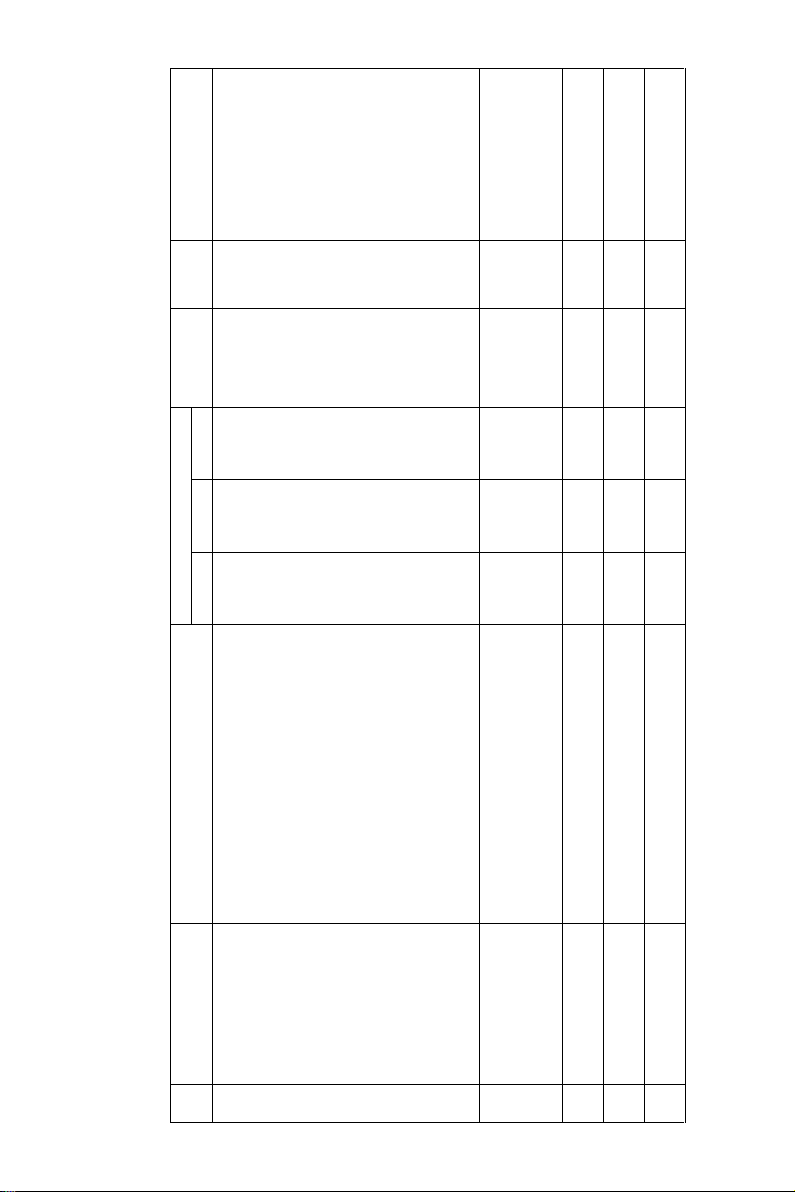

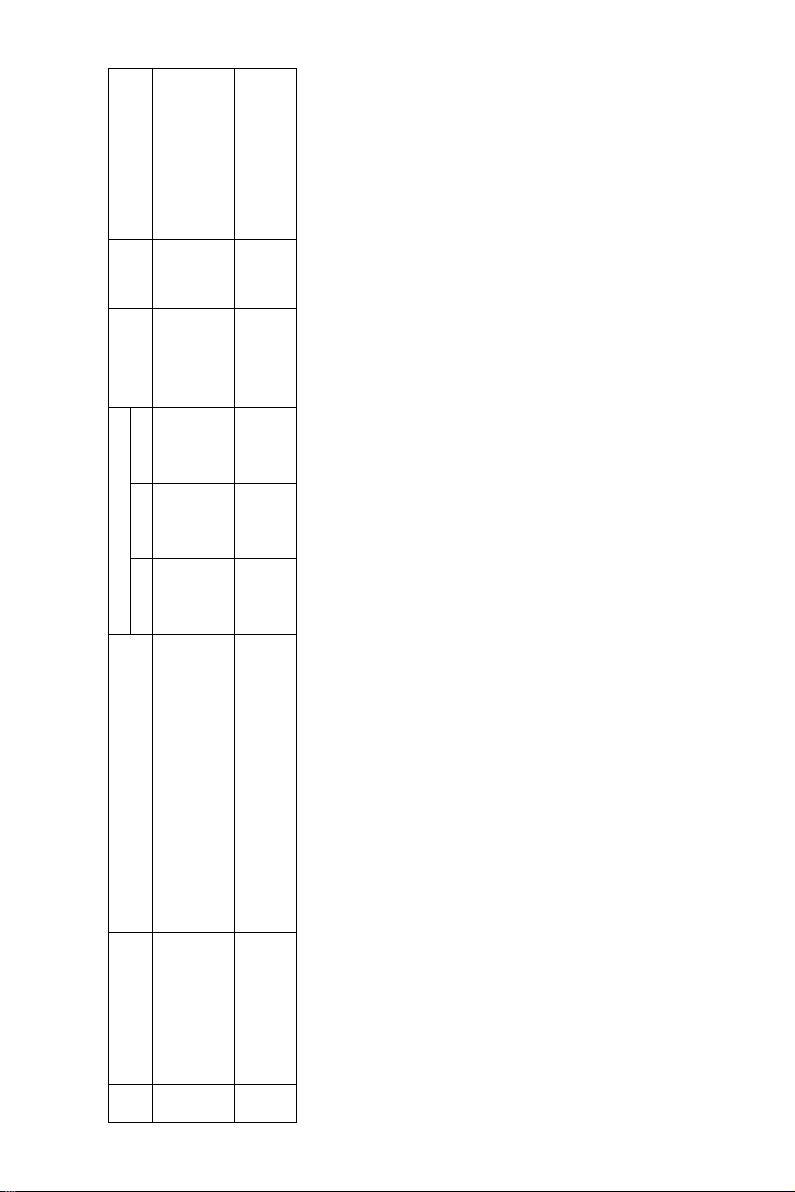

B. Europe affiliates (Including East Europe, Russia) Australia/New Zealand/UK

No. Part name Content

Side seal R x 1

MC cleaning unit x 1

Cleaner blade x 1

Drum separation pawl x 4

Screen grid x 1

Toner reception seal x 1

Charging plate x 1

Paper dust removal unit x 1

DV seal x 1

DV side seal F x 1

DV side seal R x 1

Toner filter x 1

1 Maintenance kit 1 Side seal F x 1 250K 300K 300K AR-620KA 10

AR-M550/M620/M700 CONSUMABLE PARTS 1 - 7

Transfer belt x 1

Transfer roller x 1

Transfer gear x 1

2 Maintenance kit 2 Transfer cleaning roller x 1 250K 300K 300K AR-620KB 10

Page 14

Packing Remark

Model

Life

name

55cpm 62cpm 70cpm

No. Part name Content

Upper heat roller x 1 250K 300K – AR-620KC 5

3 Maintenance kit 3

Lower heat roller x 1

Fusing separation pawl (Upper) x 6

Fusing separation pawl (lower) x 4

Scraper unit x 1

Sub heat roller cleaning unit x 1

Sub heat roller x 1

Heat roller bearing x 2

Upper heat roller x 1 ––300K AR-700KC 5

Lower heat roller x 1

Fusing separation pawl (Upper) x 6

Fusing separation pawl (lower) x 4

Cleaning sheet x 1

Oil roller x 1

(55/62cpm model)

AR-M550/M620/M700 CONSUMABLE PARTS 1 - 8

Maintenance kit 3

(70cpm model)

Cleaning roller bearing x 2

Pressure cleaning plate x 1

Sub heat roller x 1

Heat roller bearing x 2

SPF take-up roller x 1

SPF reverse roller x 1

Main unit paper feed take-up roller x 1

Main unit paper feed reverse roller x 1

4 DSPF roller kit SPF paper feed roller x 1 100K 100K 100K AR-620DF 10

5 Paper feed roller kit Main unit paper feed roller x 1 100K 100K 100K AR-620RT 10

Page 15

Packing Remark

Model

(Common with the

(Common with the

cartridge for AR-F11/

F12)

name

SF-SC11 20 Cartridge for AR-F15

cartridge for AR-F12)

AR-SC3 40 Cartridge for AR-F16

Life

5,000

5,000

55cpm 62cpm 70cpm

times x 3

times x 3

times x 3

2,000

2,000

times x 3

times x 3

times x 3

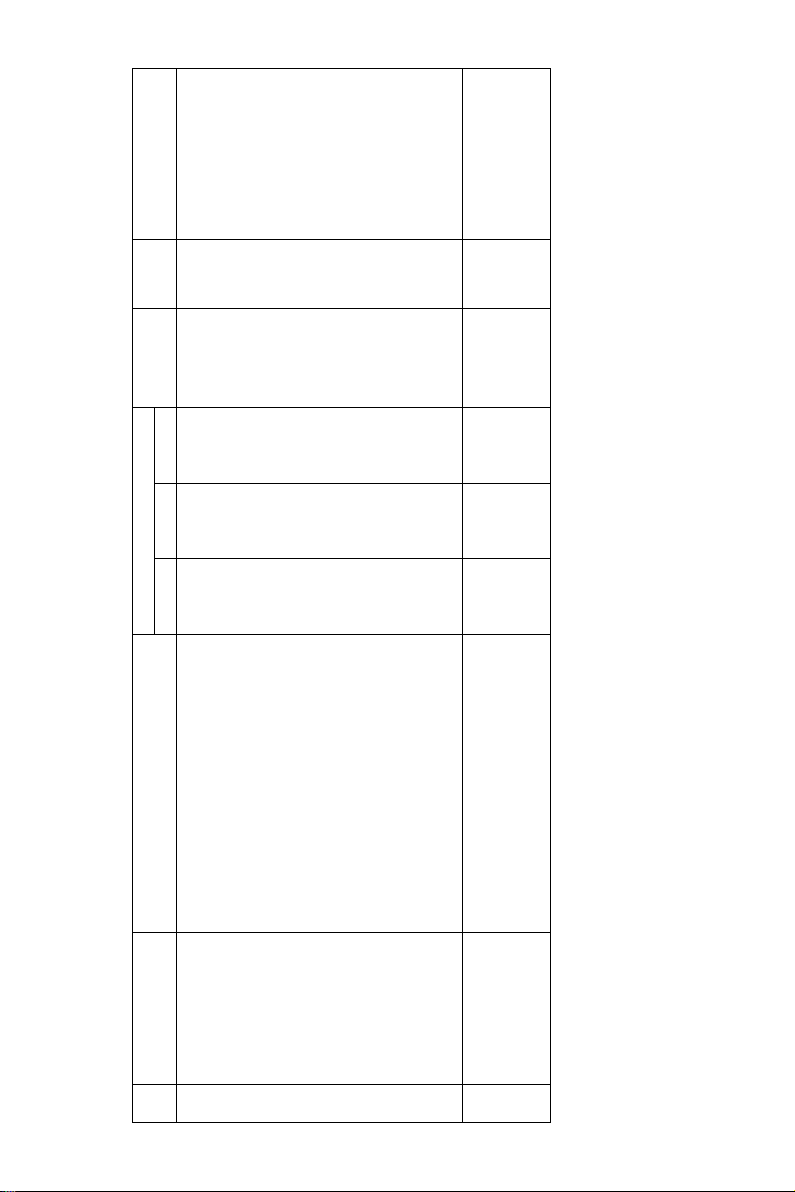

No. Part name Content

6 Staple cartridge Finisher staple x 3 5,000

7 Staple cartridge Saddle finisher staple x 3 2,000

AR-M550/M620/M700 CONSUMABLE PARTS 1 - 9

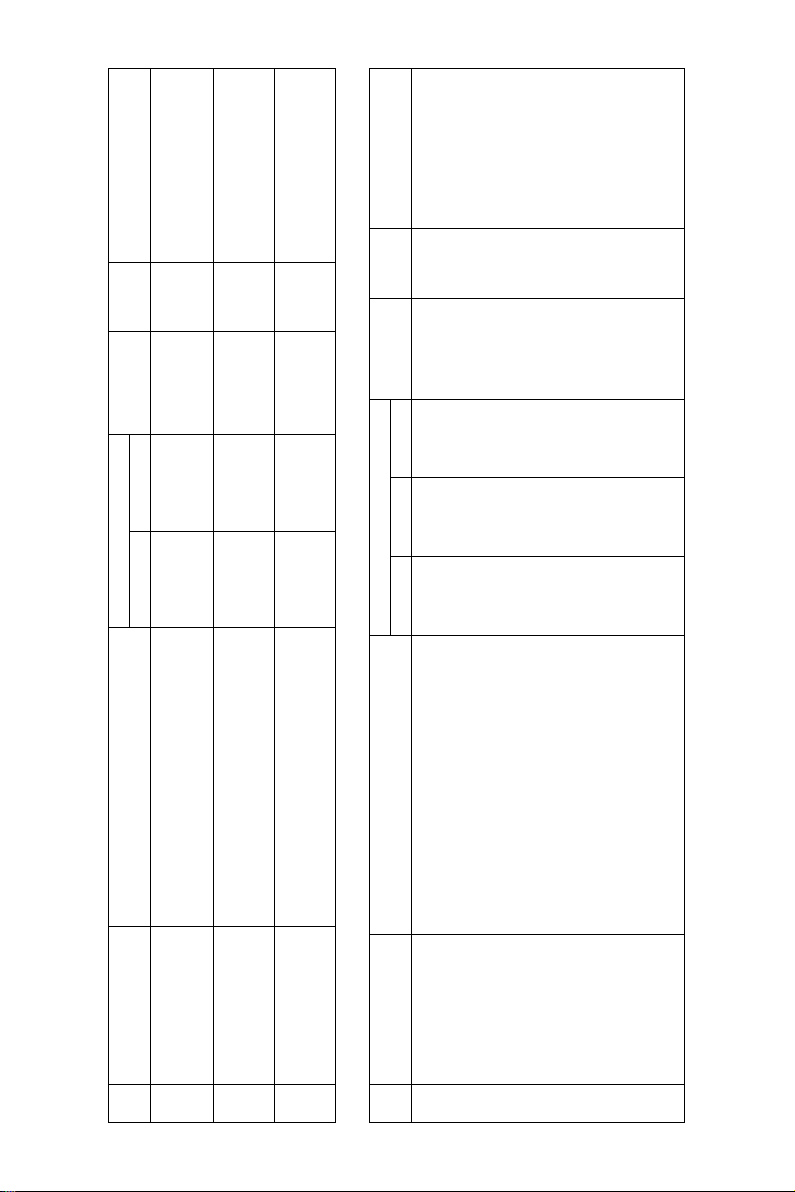

Page 16

Life

Model name Packing Remark

55cpm 62cpm 70cpm

Side seal R x 1

MC cleaning unit x 1

Cleaner blade x 1

Drum separation pawl x 4

Screen grid x 1

Toner reception seal x 1

Charging plate x 1

Paper dust removal unit x 1

DV seal x 1

DV side seal F x 1

DV side seal R x 1

Toner filter x 1

Transfer belt x 1

Transfer roller x 1

Transfer gear x 1

1 Maintenance kit 1 Side seal F x 1 250K 300K 300K AR-620KA 10

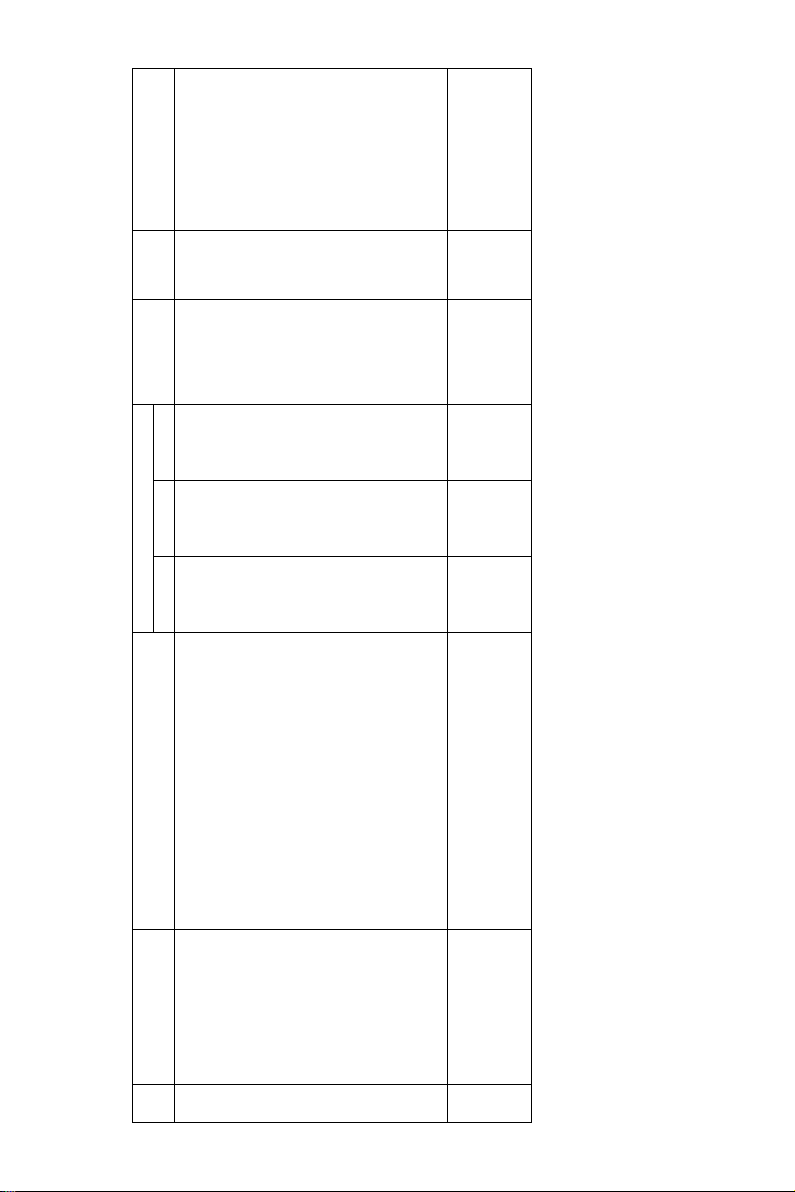

No. Part name Content

C. Middle East/Asia/South and Central America

AR-M550/M620/M700 CONSUMABLE PARTS 1 - 10

2 Maintenance kit 2 Transfer cleaning roller x 1 250K 300K 300K AR-620KB 10

Page 17

Model name Packing Remark

Life

55cpm 62cpm 70cpm

Upper heat roller x 1 250K 300K – AR-620KC 5

Lower heat roller x 1

Fusing separation pawl (Upper) x 6

Fusing separation pawl (lower) x 4

Scraper unit x 1

Sub heat roller cleaning unit x 1

Sub heat roller x 1

Heat roller bearing x 2

Upper heat roller x 1 ––300K AR-700KC 5

Lower heat roller x 1

Fusing separation pawl (Upper) x 6

Fusing separation pawl (lower) x 4

Cleaning sheet x 1

Oil roller x 1

Cleaning roller bearing x 2

Pressure cleaning plate x 1

Sub heat roller x 1

Heat roller bearing x 2

SPF take-up roller x 1

SPF reverse roller x 1

Main unit paper feed take-up roller x 1

Main unit paper feed reverse roller x 1

(55/62cpm model)

3 Maintenance kit 3

No. Part name Content

AR-M550/M620/M700 CONSUMABLE PARTS 1 - 11

Maintenance kit 3

(70cpm model)

4 DSPF roller kit SPF paper feed roller x 1 100K 100K 100K AR-620DF 10

5 Paper feed roller kit Main unit paper feed roller x 1 100K 100K 100K AR-620RT 10

Page 18

(Common with the

cartridge for AR-F11/

F12)

(Common with the

cartridge for AR-F12)

Model name Packing Remark

Life

SF-SC11 20 Cartridge for AR-F15

5,000

5,000

55cpm 62cpm 70cpm

times x 3

times x 3

times x 3

AR-SC3 40 Cartridge for AR-F16

2,000

2,000

times x 3

times x 3

times x 3

Model name Packing Packing

Life

62cpm 70cpm

Side seal R x 1

MC cleaning unit x 1

Cleaner blade x 1

Drum separation pawl x 4

Screen grid x 1

Toner reception seal x 1

Charging plate x 1

Paper dust removal unit x 1

DV seal x 1

DV side seal F x 1

DV side seal R x 1

Toner filter x 1

6 Staple cartridge Finisher staple x 3 5,000

No. Part name Content

7 Staple cartridge Saddle finisher staple x 3 2,000

AR-M550/M620/M700 CONSUMABLE PARTS 1 - 12

D. China

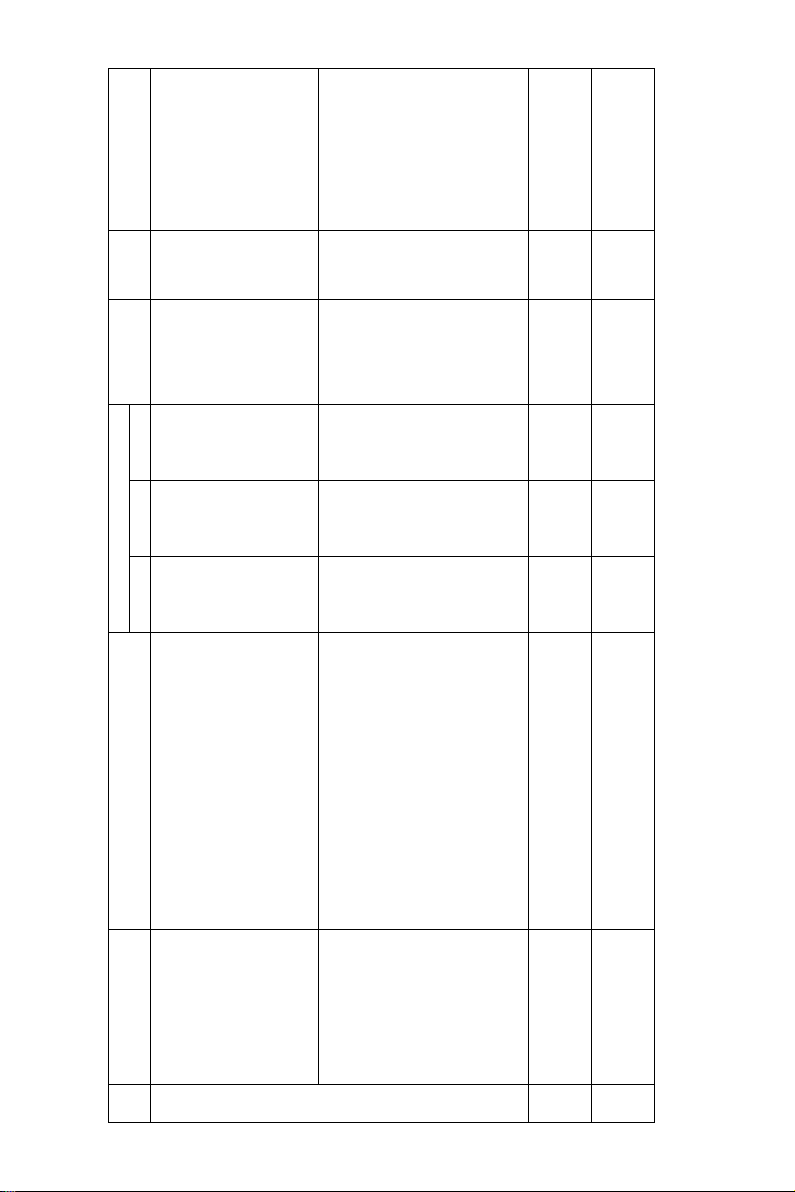

No. Part name Content

1 Maintenance kit 1 Side seal F x 1 300K 300K AR-620KA 10

Page 19

Model name Packing Packing

Life

62cpm 70cpm

Transfer belt x 1

Transfer roller x 1

Transfer gear x 1

Upper heat roller x 1 300K – AR-620KC 5

Lower heat roller x 1

Fusing separation pawl (Upper) x 6

Fusing separation pawl (lower) x 4

Scraper unit x 1

Sub heat roller cleaning unit x 1

Heat roller bearing x 2

Upper heat roller x 1 – 300K AR-700KC 5

Lower heat roller x 1

Fusing separation pawl (Upper) x 6

Fusing separation pawl (lower) x 4

Heat seal plate N assembly x 1

Oil roller x 1

Cleaning roller bearing x 2

Pressure cleaning plate x 1

Sub heat roller x 1

Heat roller bearing x 2

SPF take-up roller x 1

SPF reverse roller x 1

No. Part name Content

(55/62cpm model)

2 Maintenance kit 2 Transfer cleaning roller x 1 300K 300K AR-620KB 10

3 Maintenance kit 3

AR-M550/M620/M700 CONSUMABLE PARTS 1 - 13

Maintenance kit 3

(70cpm model)

4 DSPF roller kit SPF paper feed roller x 1 100K 100K AR-620DF 10

Page 20

(Common with the

cartridge for AR-F11/F12)

(Common with the

cartridge for AR-F12)

Model name Packing Packing

Life

62cpm 70cpm

Model name Packing Packing

Life

55cpm 62cpm 70cpm

Side seal R x 1

MC cleaning unit x 1

Cleaner blade x 1

Drum separation pawl x 4

Screen grid x 1

Toner reception seal x 1

Charging plate x 1

Paper dust removal unit x 1

DV seal x 1

DV side seal F x 1

DV side seal R x 1

Toner filter x 1

x 3

x 3

AR-SC3 40 Cartridge for AR-F16

x 3

2,000 times

x 3

SF-SC11 20 Cartridge for AR-F15

5,000 times

Main unit paper feed take-up roller x 1

Main unit paper feed reverse roller x 1

No. Part name Content

5 Paper feed roller kit Main unit paper feed roller x 1 100K 100K AR-620RT 10

6 Staple cartridge Finisher staple x 3 5,000 times

AR-M550/M620/M700 CONSUMABLE PARTS 1 - 14

7 Staple cartridge Saddle finisher staple x 3 2,000 times

E. Taiwan

No. Part name Content

1 Maintenance kit 1 Side seal F x 1 250K 300K 300K AR-620KA 10

Page 21

Model name Packing Packing

Life

55cpm 62cpm 70cpm

No. Part name Content

Transfer belt x 1

2 Maintenance kit 2 Transfer cleaning roller x 1 250K 300K 300K AR-620KB 10

Upper heat roller x 1 250K 300K – AR-620KC 5

Transfer roller x 1

Transfer gear x 1

Lower heat roller x 1

Fusing separation pawl (Upper) x 6

Fusing separation pawl (lower) x 4

Scraper unit x 1

Sub heat roller cleaning unit x 1

Heat roller bearing x 2

Upper heat roller x 1 ––300K AR-700KC 5

Lower heat roller x 1

Fusing separation pawl (Upper) x 6

Fusing separation pawl (lower) x 4

Cleaning sheet x 1

Oil roller x 1

(55/62cpm model)

Maintenance kit 3

(70cpm model)

3 Maintenance kit 3

AR-M550/M620/M700 CONSUMABLE PARTS 1 - 15

Cleaning roller bearing x 2

Pressure cleaning plate x 1

Sub heat roller x 1

Heat roller bearing x 2

SPF take-up roller x 1

SPF reverse roller x 1

4 DSPF roller kit SPF paper feed roller x 1 100K 100K 100K AR-620DF 10

Page 22

(Common with the

cartridge for AR-

F11/F12)

(Common with the

cartridge for AR-

F12)

Model name Packing Packing

Life

55cpm 62cpm 70cpm

Main unit paper feed take-up roller x 1

Main unit paper feed reverse roller x 1

SF-SC11 20 Cartridge for AR-F15

5,000

5,000

times x 3

times x 3

times x 3

AR-SC3 40 Cartridge for AR-F16

2,000

2,000

times x 3

times x 3

times x 3

No. Part name Content

5 Paper feed roller kit Main unit paper feed roller x 1 100K 100K 100K AR-620RT 10

6 Staple cartridge Finisher staple x 3 5,000

AR-M550/M620/M700 CONSUMABLE PARTS 1 - 16

7 Staple cartridge Saddle finisher staple x 3 2,000

Page 23

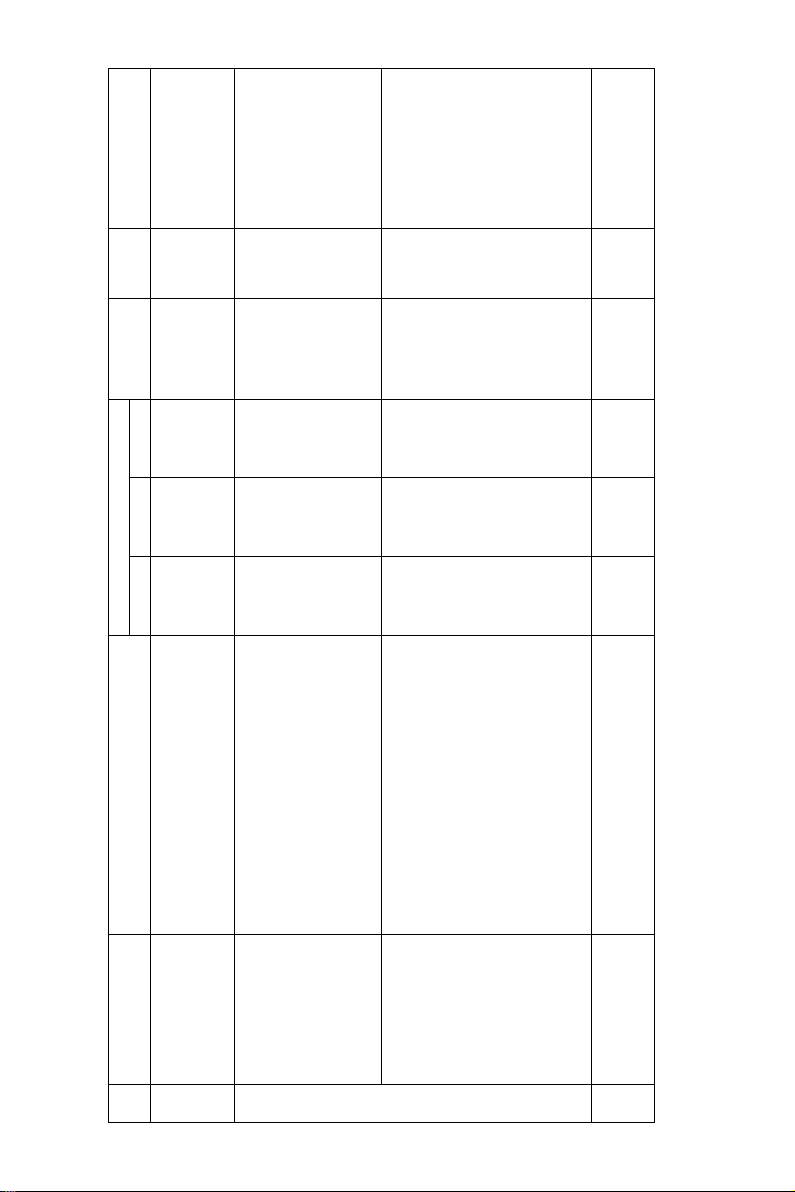

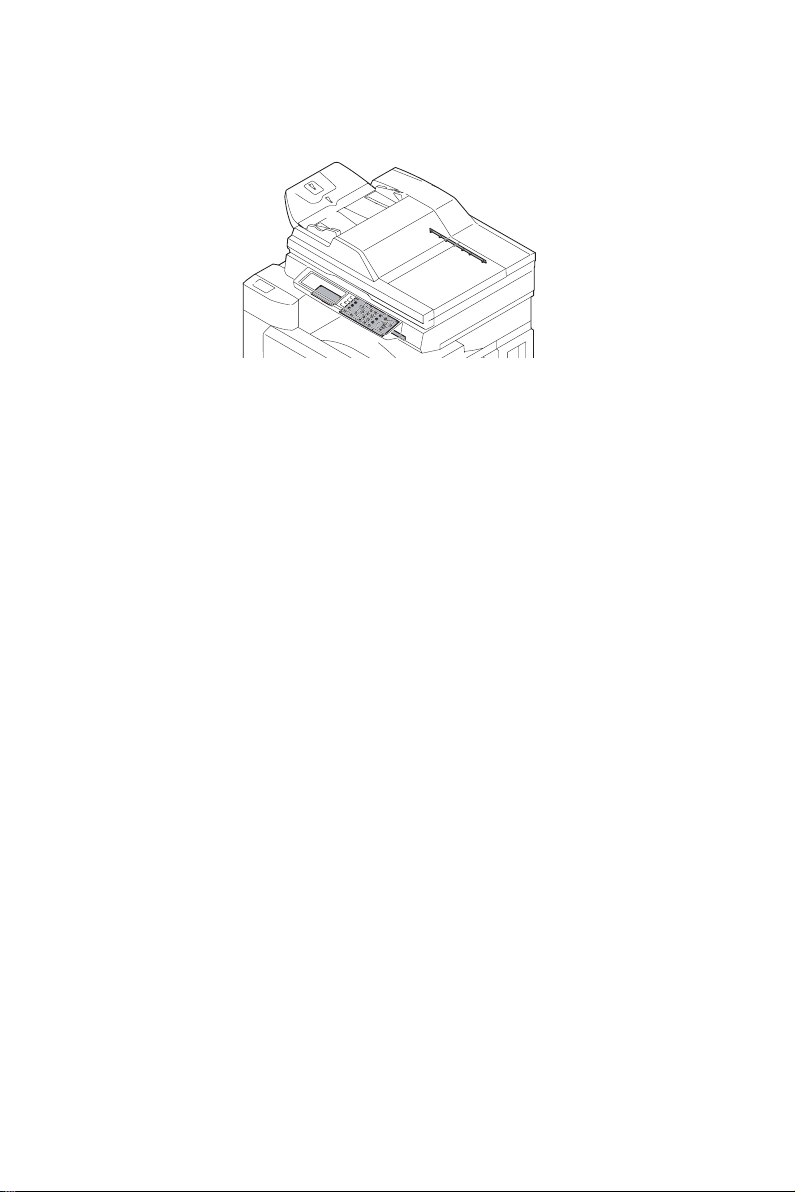

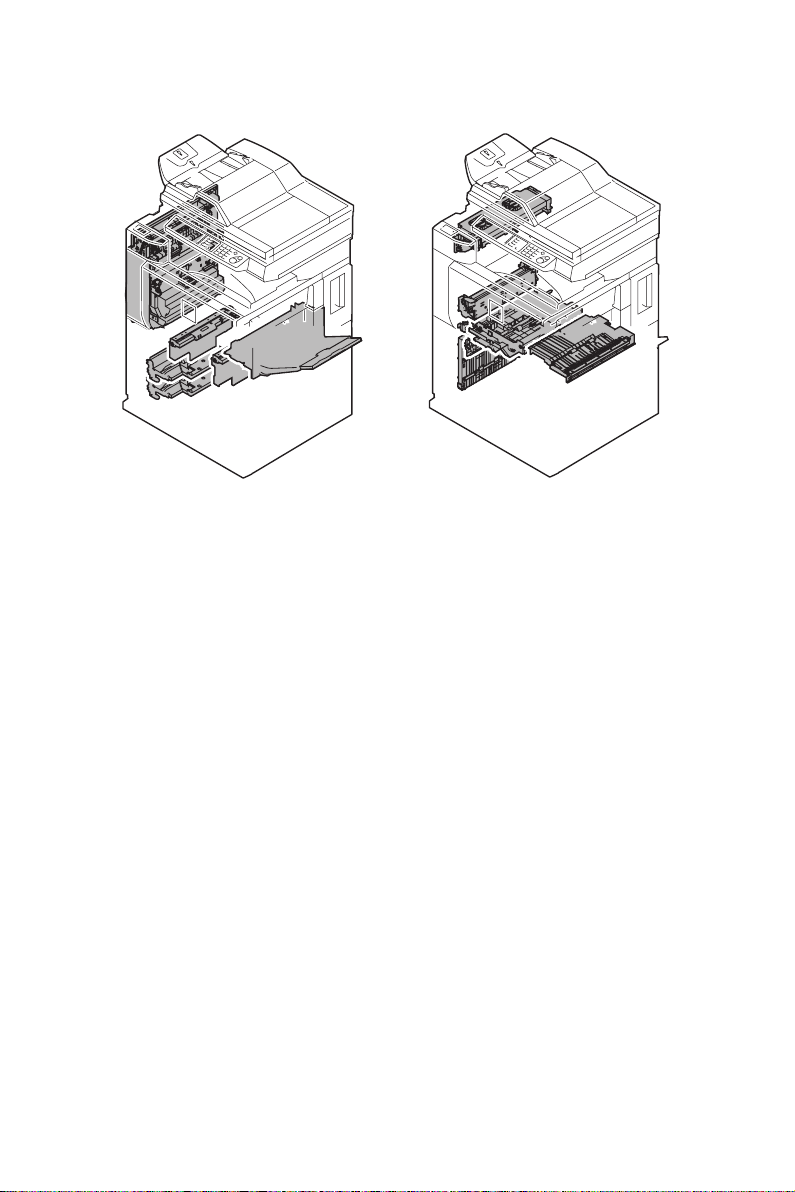

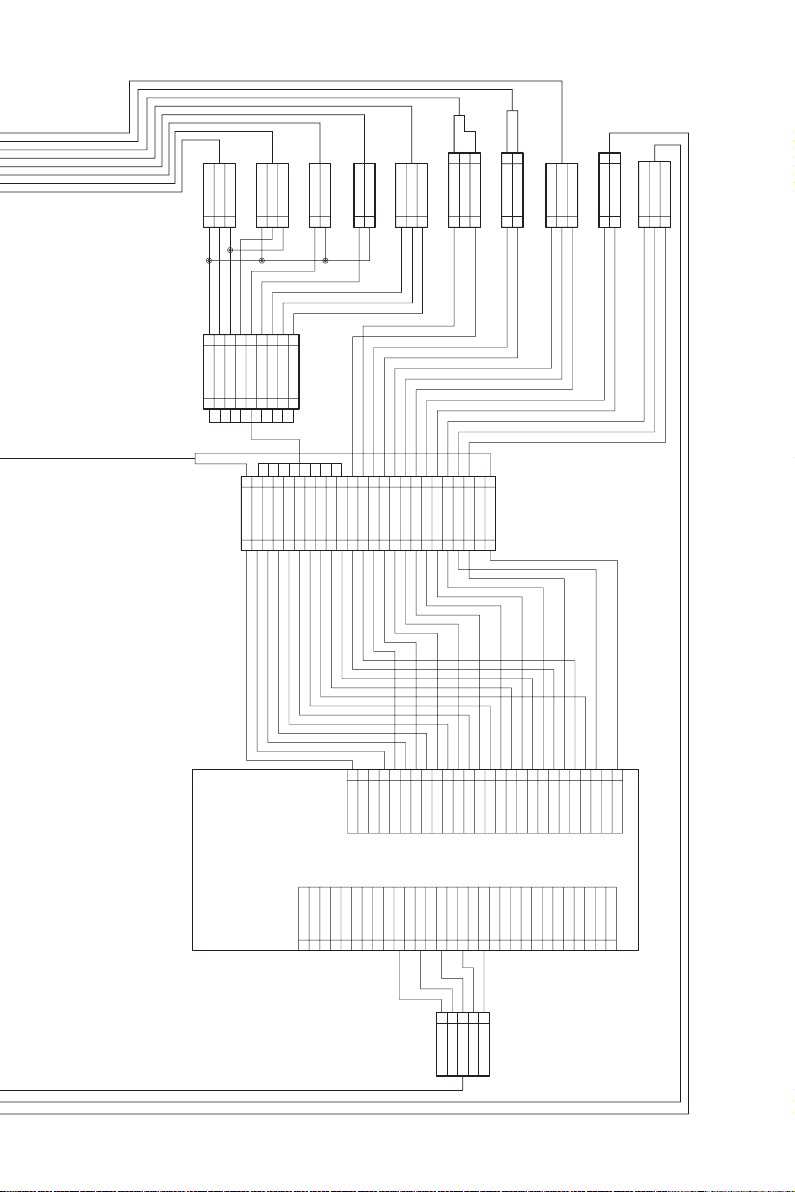

[2] STRUCTURE OF EACH SECTION

1. Operation panel section

A. General

This section describes various types of settings, display and operation.

The LCD display section is controlled by the MFP CONTROL PWB.

The touch panel, operation keys and LED display are controlled by the SCANNER

CONTROL PWB.

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 1

Page 24

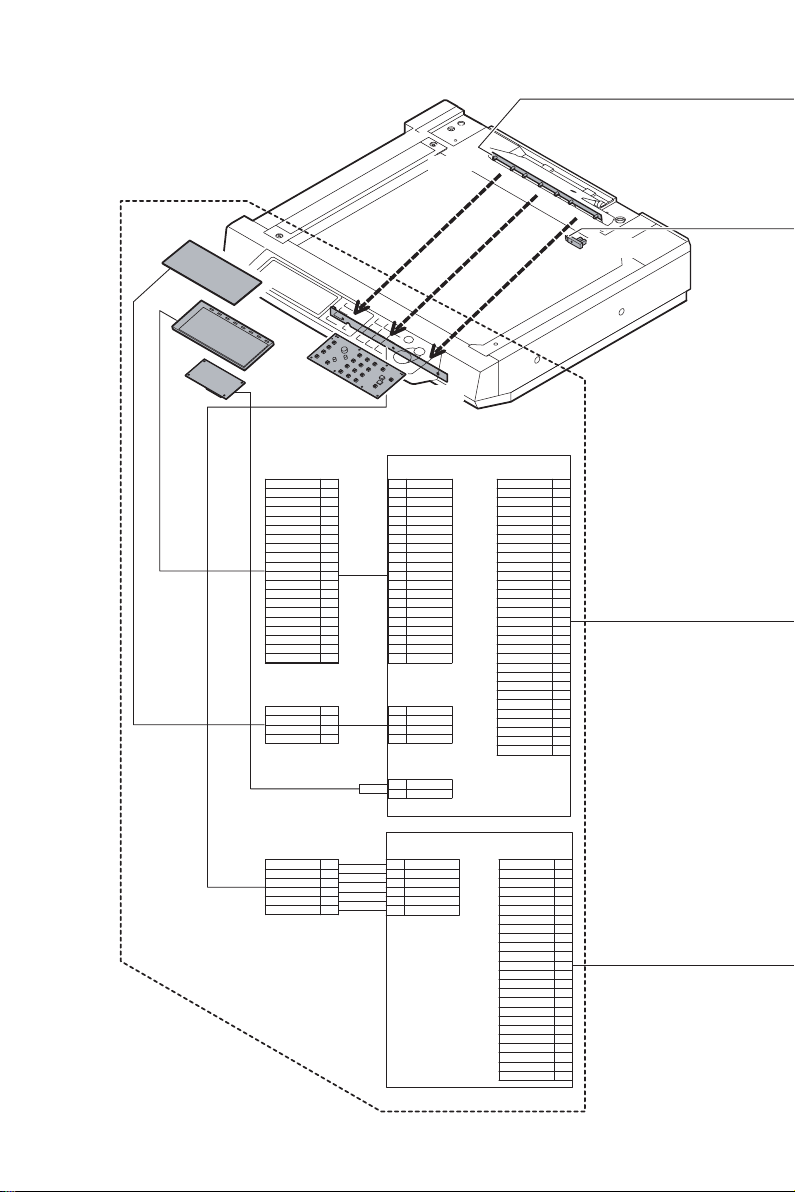

B. Major parts and signal functions

ORSLED

TOUCH

LCD

/CCFT

GND

N.C

N.C

N.C

N.C 16

GND

LCD D3

LCD D2

LCD D1

LCD D0

GND

LCD-VEE

3.3V3

lcd DIS

GND

CP2

GND

CP1

LCD M

LCD S

/YL

XH

YH

/XL

20

19

18

17

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

4

3

2

1

FFC-20Pin

FFC-4Pin

/ORSPD

CN4

20FLS-SM1-TB

1

GND

N.C

2

3

N.C

4

N.C

N.C

5

GND

6

7

LCD D3

LCD D2

8

9

LCD D1

10

LCD D0

GND

11

LCD-VEE

12

13

3.3V3

14

lcd DIS

GND

15

16

CP2

17

GND

18

CP1

19

LCD M

LCD S

20

CN2

04FM-1.0ST

/YL

1

XH

2

3

YH

/XL

4

CN3

S02(8.0)B-BHS-L

1

/CCFT

HV

2

CN1

30FMZ-BT

XH

/YL

/XL

YH

/CCFT

24V3

GND

TH

GND

lcdD3lcdD3+

lcdD2lcdD2+

lcdD1lcdD1+

lcdD0lcdD0+

LCD-VEE

3.3V3

lcdDIS

GND

lcdCP2lcdCP2+

GND

lcdCP1lcdCP1+

lcdMlcdM+

lcdSlcdS+

INVERTER

-LVDS PWB

OCSW

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

FFC-30Pin

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

PDSEL0

PDSEL1

PDSEL2

5V2

PD

GND

OPERATION PANEL

UNIT

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 2

B6B-PH-K-S

CN102

1

2

3

4

5

6

B6B-PH-SM3-TB

1

PDSEL0

2

PDSEL1

PDSEL2

3

4

5V2

5

PD

GND

6

MFP

OPE

PWB

CN101

T24FAZ-SMT-TF

GND

5V1

/BZR

N.C

N.C

GND

GND

GND

/F3

/F2

/F1

/F0

SEG2

SEG1

SEG0

/KEYIN

5V2

GND

PD

5V2

PDSEL2

PDSEL1

PDSEL0

GND

1

2

3

4

5

6

7

8

9

10

11

FFC-24Pin

12

13

14

15

16

17

18

19

20

21

22

23

24

Page 25

SCN JNT

PWB

CN6

30FMZ-BT

XH

1

2

/YL

3

/XL

4

YH

/CCFT

5

24V3

6

7

GND

8

TH

9

GND

lcdD3-

10

11

lcdD3+

lcdD2-

12

lcdD2+

13

14

lcdD1-

15

lcdD1+

16

lcdD0-

17

lcdD0+

18

LCD-VEE

19

3.3V3

lcdDIS

20

GND

21

22

lcdCP2-

23

lcdCP2+

GND

24

25

lcdCP1-

26

lcdCP1+

lcdM-

27

28

lcdM+

29

lcdSlcdS+

30

CN5

T24FAZ-SMT-TF

24

GND

23

5V1

22

/BZR

21

N.C

N.C

20

19

GND

18

GND

17

GND

16

/F3

15

/F2

/F1

14

13

/F0

SEG2

12

SEG1

11

10

SEG0

/KEYIN

9

5V2

8

7

GND

PD

6

5

5V2

4

PDSEL2

PDSEL1

3

2

PDSEL0

GND

1

CN4

TX25-100P-LT-H1

GND

GND

/1_DBL/1_DBL+

1_CLK1_CLK+

1_DATA01_DATA0+

1_DATA11_DATA1+

1_DATA21_DATA2+

1_DATA31_DATA3+

GND

GND

/CCDFAN

12V2

24V3

24V3

PDSEL1

PDSEL2

/KEYIN

SEG0

GND

GND

lcdS+

lcdSlcdM+

lcdMlcdCP1+

lcdCP1lcdCP2+

lcdCP2lcdD0+

lcdD0lcdD1+

lcdD1lcdD2+

lcdD2lcdD3+

lcdD3GND

GND

YH

/XL

/STSET

/STMPS

GND

GND

GND

GND

12V2

12V2

GND

5V2

GND

5V2

GND

3.3V3

FRM_CCD1

CLK_CCD1

TXD_CCD1

RES_CCD1

RXD_CCD1

ADD_CCD1

GND

PAGE1

GND

GND

/CL1

PDSEL0

5V2

PD

SEG1

SEG2

GND

/F0

GND

/F1

GND

/F2

GND

/F3

GND

/BZR

GND

5V1

lcdDIS

3.3V3

GND

LCD_VEE

TH

/CCFT

/YL

XH

24V3

24V3

GND

GND

H3P-SHF-AA

+B3P-SHF-1AA

5V1

1

GND

2

OCSW

3

CN1

TX24-100R-LT-H1

1

100

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

GND

GND

/1_DBL/1_DBL+

1_CLK1_CLK+

1_DATA01_DATA0+

1_DATA11_DATA1+

1_DATA21_DATA2+

1_DATA31_DATA3+

GND

GND

/CCDFAN

12V2

24V3

24V3

PDSEL1

PDSEL2

/KEYIN

SEG0

GND

GND

lcdS+

lcdSlcdM+

lcdMlcdCP1+

lcdCP1lcdCP2+

lcdCP2lcdD0+

lcdD0lcdD1+

lcdD1lcdD2+

lcdD2lcdD3+

lcdD3GND

GND

YH

/XL

/STSET

/STMPS

GND

GND

GND

GND

12V2

12V2

GND

5V2

GND

5V2

GND

3.3V3

FRM_CCD1

CLK_CCD1

TXD_CCD1

RES_CCD1

RXD_CCD1

ADD_CCD1

GND

PAGE1

GND

GND

/CL1

PDSEL0

5V2

PD

SEG1

SEG2

GND

/F0

GND

/F1

GND

/F2

GND

/F3

GND

/BZR

GND

5V1

lcdDIS

3.3V3

GND

LCD_VEE

TH

/CCFT

/YL

XH

24V3

24V3

GND

GND

CN3

B6B-PH-K-S

5V1

GND

OCSW13

24V3 4

/LED0

/LED1

SCN

CONTROL

PWB

2

5

6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 3

Page 26

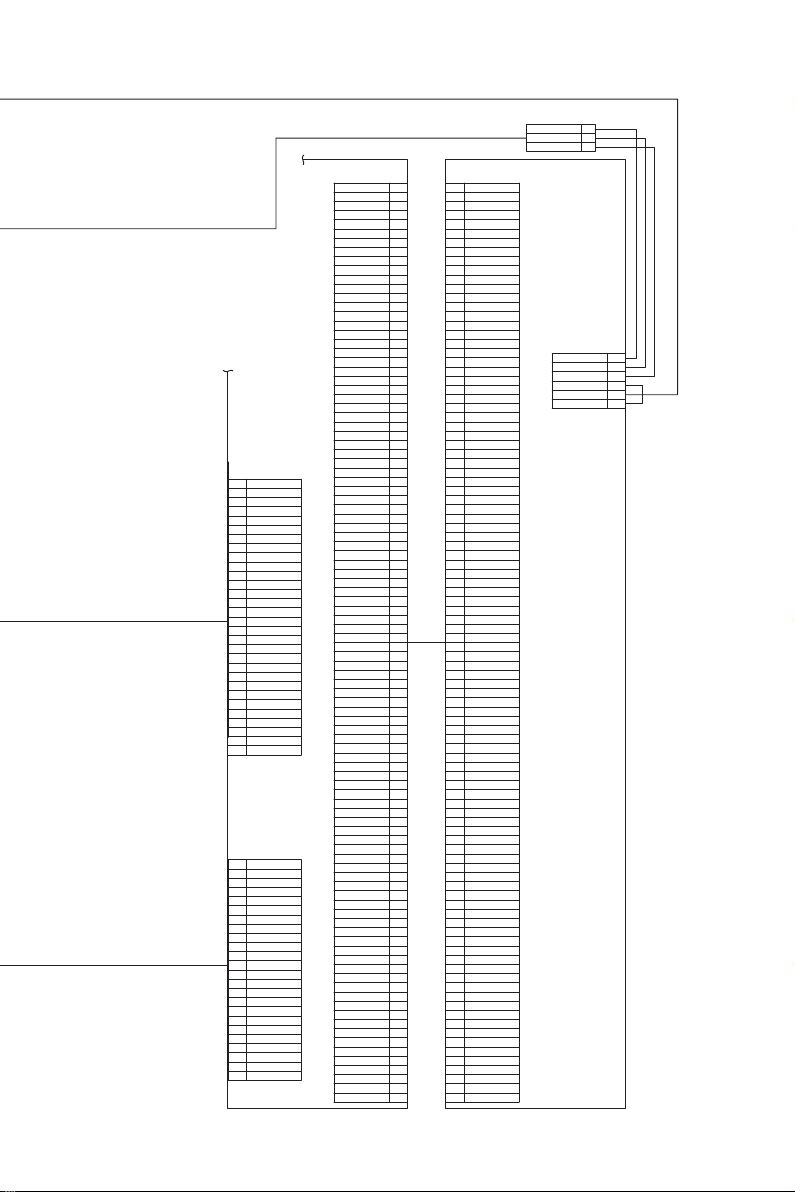

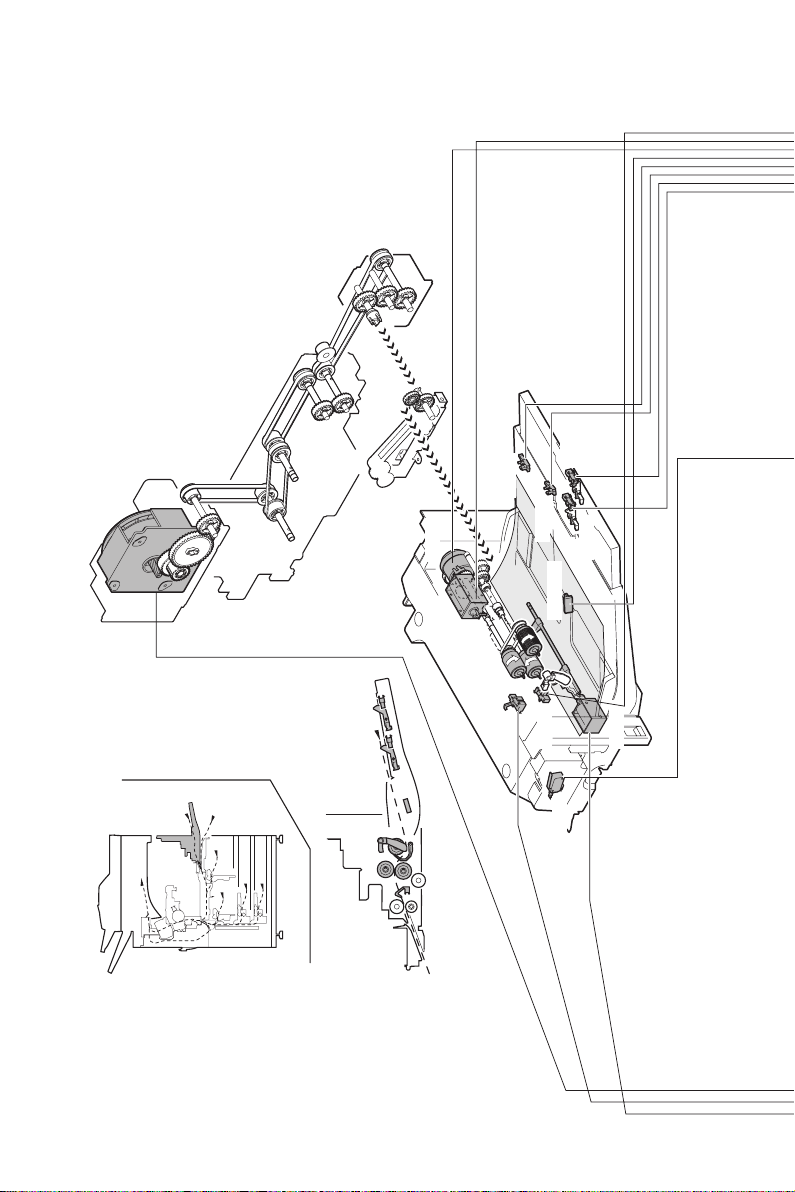

2. Paper feed, paper transport, duplex, and paper exit reverse sections

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 4

Page 27

[Paper feed section]

General

The paper feed tray 1 holds 900 sheets, the paper feed tray 2 holds 1,300 sheets,

the multi-purpose paper feed tray 3 holds 500 sheets, the paper feed tray 4 holds

500 sheets, and the manual paper feed tray holds 100 sheets. Those paper feed

units are standard provisions.

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 5

Page 28

(Manual paper feed section)

A. Major parts and signal functions

MM

MPFC

MTOP2

MTOP1

MPFPWS

MPLD2

MPLD1

MFPUS

MPFD1

MPED

DSW-R

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 6

MPFGS

Page 29

GND2

GND2

+5V2

+5V2

MPLD1

MPLD2

DF3-3S-2C

DF3-3S-2C

2

1

8

9

GND2

MPLD1

PHNR-09-H+BU09P-TR-P-H

3

65432

7

MPLD2

+5V2

MTOP1

MTOP2

321

GND2

MPFPWS

179228-2

1

Vref

987654321

MTOP1

GND2

212

MTOP2

179228-2

1

GND2

PHR-3

GND2

MPFPWS

1

2

Vref

3

2

113

+24V1

3

PHNR-03-H+BU03P-TR-P-H

2

1

(NC)

/MPFC

+24V1

/MFPUS

2

1

232

SMR-02V-N/SMP-02V-NC

GND2

MPED

DF3-3S-2C

1

+5V2

2

1

+24V1

/MPFGS

MPFD1

GND2

+5V-MPFD1

PHR-3

1

2

SMR-02V-N/SMP-02V-NC

321

MPLD1

+5V2

MPLD2

MTOP1

8765432

MTOP2

GND2

CN-13

9

MPFPWS

987654321

B26B-PHDSS-B

1

DSW-F(R)

GND2

DRAWER

QR/P4-24S-C(01)/QR/P4-24P-C(01)

PCU PWB

M2LUM

GND2

+24V1

/T1PFC

B30B-PHDSS-B

CN-17

1

2

10

Vref

/MPFC

1

DSW-F(R)

+24V1

+24V1

2

(NC)

+24V1

+24V1

(NC)

/M2PFC

/DSKPFC2

/MFPUS

GND2

GND2

+24V1

GND2

GND2

9876543

17161514131211

MPED

+5V2

16151413121110

76543

MPLD1

/MFPUS

TXD-FIN

+5V2

+24V1

/MPFGS

191817

9

8

+5V2

GND2

RXD-FIN

201918

21

GND2

+5V-MPFD1

20

21

MPLD2

MPED

/DTR-FIN

/MM

MMCLK

1413121110

15

MPFD1

(NC)

MTOP1

+5V2

/DSR-FIN

MM-T

54321

242322

DSW-R

242322

MTOP2

+24V1

TSW-LED

RES-FIN

MPFPWS

/MPFGS

TSW

(NC)

Vref

+5V-MPFD1

/MPFC

GND2

GND2

242322212019181716

MPFD1

+24V1

GND2

GND2

DSW-DSK

TANSET

+5V2

2526272829

242322212019181716151413121110

GND2

(NC)

25

(NC)

26

DSW-R

+5V2

30

GND2

+5V2

/MM

MMCLK

MM-T

S5B-PH-K-S

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 7

Page 30

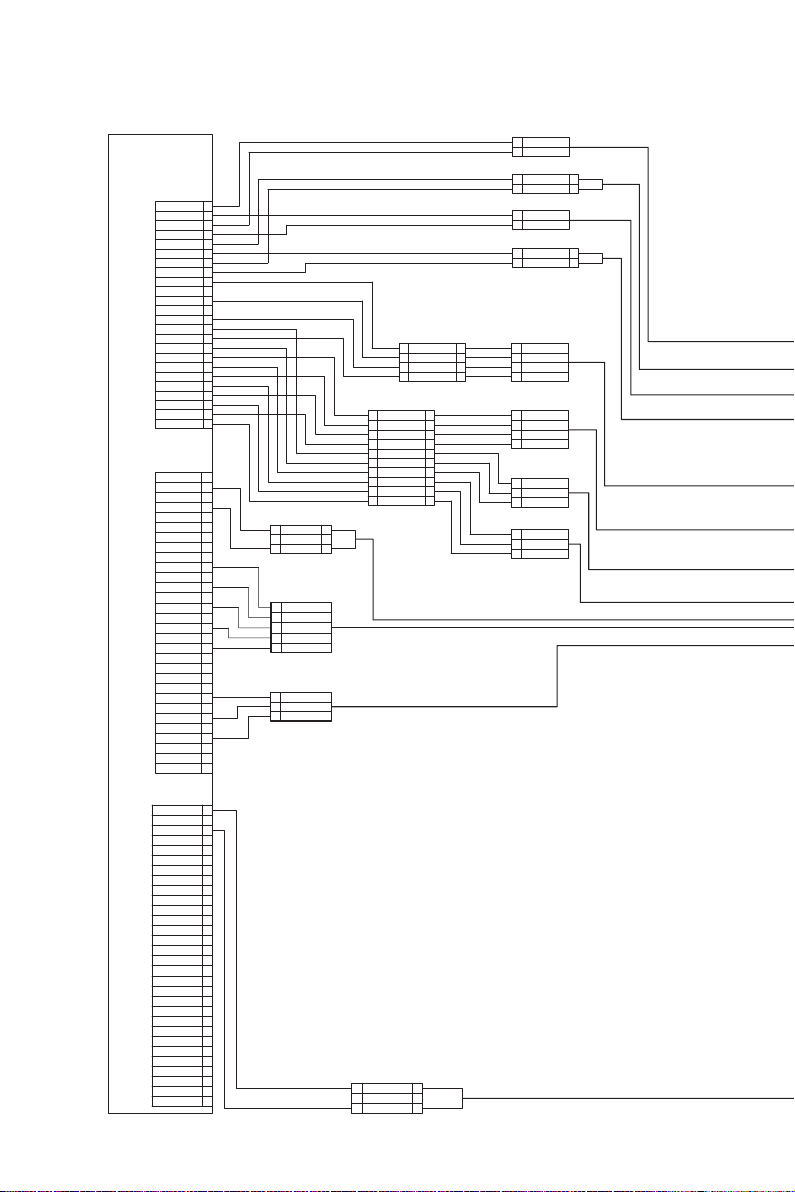

(Paper feed tray sections 1 and 2)

A. Major parts and signal functions

PCU PWB

CN-14

B24B-PHDSS-B

B30B-PHDSS-B

B30B-PHDSS-B

T1LUM

T2LUM

GND2

GND2

+24V1

+24V1

/T1PUS

/T2PUS

+5V2

+24V1

GND2

/DSKLS

T1LUD

GND2

T1PED

T1SPD

+5V2

+5V2

GND2

GND2

T2LUD

T2SPD

T2PED

+5V2

CN-17

M2LUM

+24V1

GND2

/T1PFC

+24V1

+24V1

/M2PFC

/DSKPFC2

GND2

GND2

TXD-FIN

+5V2

RXD-FIN

/MM

/DTR-FIN

MMCLK

/DSR-FIN

MM-T

RES-FIN

TSW-LED

(NC)

TSW

GND2

GND2

TANSET

GND2

+5V2

DSW-DSK

(NC)

+5V2

CN-12

+24V1

+24V1

/T2PFC

/HPLS

+24V1

DVCH1

/HPFC

DVCH2

+24V1

DVCH3

/PSBC

DVCH4

+5V2

+24V1

PPD

TCS

GND2

GND2

+5V-MPRD1

TSGOUT

GND2

GND2

MPRD1

+5V2

+5V-MPRD2

HUS-DV

GND2

GND2

MPRD2

TH-DV

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

PHNR-03-H+BU03P-TR-P-H

+24V1

(NC)

2

/T1PFC

1

S5B-PH-K-S

1

GND2

2

+5V2

3

/MM

4

MMCLK

5

MM-T

PHR-3

1

GND2

2

TANSET

3

+5V2

13

2

3

PHNR-03-H+BU03P-TR-P-H

SMR-04V-N/SMP-04V-NC

1

+5V2

2

GND2

3

T1LUD

4

T1PED

SMP-10V-NC/SMR-10V-N

1

1

+5V2

2

2

GND2

3

3

T2LUD

4

4

T2PED

5

5

GND2

6

6

T1SPD

7

7

+5V2

8

8

GND2

9

9

T2SPD

10

10

+5V2

32+24V1

1 3

(NC)

/T2PFC

1

2

SMR-02V-N/SMP-02V-NC

SMR-02V-N/SMP-02V-NC

1

2

3

4

PHR-2

1

T1LUM

GND2

2

1

+24V1

2

/T1PUS

PHR-2

1

T2LUM

2

GND2

1

+24V1

2

/T2PUS

S4B-PH-K-S

1

+5V2

2

GND2

3

T1LUD

4

T1PED

S4B-PH-K-S

1

+5V2

2

GND2

3

T2LUD

4

T2PED

PHR-3

1

GND2

2

T1SPD

3

+5V2

PHR-3

1

GND2

2

T2SPD

3

+5V2

1

2

1

2

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 8

Page 31

T1S PWB

MM

T1PUS

T1PFC

T1LUM

TANSET

T1SPD

T2S PWB

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 9

T2PFC

T2LUM

T2SPD

T2PUS

Page 32

(Paper feed trays 3 and 4)

A. Major parts and signal functions

MM

M1PFD

M2PFD

M1LUD

M1PED

M1PWS

M2LUD

M2PED

DSKPFC1

M1PUS

M2PUS

M1PFC

M1SPD

M2SPD

M1LUM

M2LUM

M2PFC

M1SS PWB

M2SS PWB

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 10

Page 33

PHR-2

M2LUM

GND2

PHNR-02-H+BU02P-TR-P-H

+24V1

1

/M2PFC

2

S6B-PH-K-S

(NC)

GND2

M1SS1

M1SS2

M1SS3

M1SS4

GND2

M1SPD

+5V2

S6B-PH-K-S

(NC)

GND2

M2SS1

M2SS2

M2SS3

M2SS4

GND2

M2SPD

+5V2

SMP-02V-NC/SMR-02V-N

+24V1

1

2

/M2PUS

PHR-3

GND2

M2PED

+5V2

PHR-3(RED)

GND2

M2LUD

+5V2

PHR-3

+5V-M2PFD

GND2

M2PFD

1

2

1

2

3

2

4

1

5

6

7

8

9

10 10

SMR-10V-N/SMP-10V-NC

1

2

3

4

5

6

PHR-3

PHR-3

SMP-02V-NC/SMR-02V-N

1

2

1

2

3

1

2

3

1

2

3

SMP-18V-NC/SMR-18V-N

1

2

3

1

2

3

4

5

6

1

2

3

+24V1

1

1

2

2

/M1PUS

PHR-3

GND2

1

2

M1PED

+5V2

3

PHR-3(RED)

GND2

1

2

M1LUD

+5V2

3

PHR-3

1

+5V-M1PFD

GND2

2

3

M1PFD

SMR-11V-N/SMP-11V-NC

+24V1

1

/M2PUS

2

GND2

3

M2PED

4

+5V2

5

6

GND2

M2LUD

7

+5V2

8

9

+5V-M2PFD

GND2

101110

11

M2PFD

PHNR-02-H+BU02P-TR-P-H

+24V1

1

/M1PFC

M1LUM

GND2

PHNR-02-H+BU02P-TR-P-H

1

+24V1

2

/DSKPFC1

Soldering

Vref

GND2

M1PWS

M2LUM

GND2

+24V1

/M2PFC

GND2

TXD-FIN

RXD-FIN

/DTR-FIN

/DSR-FIN

RES-FIN

1

GND2

2

M1SS1

3

M1SS2

4

M1SS3

5

M1SS4

6

GND2

M1SPD

7

8

+5V2

9

(NC)

10

GND2

11

M2SS1

12

M2SS2

13

M2SS3

14

M2SS4

15

GND2

16

M2SPD

17

+5V2

(NC)

18

SMR-11V-N/SMP-11V-NC

1

2

3

4

5

6

7

8

9

111011

1

2

3

4

5

6

7

8

9

2

12

PHR-2

1

2

2

1

3

1

2

1

2

3

4

5

6

7

8

9

S5B-PH-K-S

GND2

+5V2

/MM

MMCLK

MM-T

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

+24V1

1

/M1PUS

2

GND2

3

M1PED

4

+5V2

5

GND2

6

M1LUD

7

+5V2

8

9

+5V-M1PFD

GND2

10

M1PFD

SMR-03V-N/SMP-03V-NC

Vref

11

GND2

22

M1PWS

3

3

CN-17

B30B-PHDSS-B

M2LUM

1

+24V1

2

GND2

3

/T1PFC

4

+24V1

5

+24V1

6

/M2PFC

7

/DSKPFC2

8

GND2

9

GND2

10

TXD-FIN

11

+5V2

12

RXD-FIN

13

/MM

14

/DTR-FIN

15

MMCLK

16

/DSR-FIN

17

MM-T

18

RES-FIN

19

TSW-LED

20

(NC)

21

TSW

22

GND2

1

2

3

4

5

23

GND2

24

TANSET

25

GND2

26

+5V2

27

DSW-DSK

28

(NC)

29

+5V2

30

CN-15

B34B-PHDSS-B

DSW-F

1

2

(NC)

3

GND2

4

GND2

5

/GBPWM

6

/MHVREM

7

MHV-T

/THV+PWM

8

THV+REM

9

/CHV-PWM

10

/CHV-REM

11

12

/CHVACPWM

13

/CHVACREM

14

/DVPWM

15

/DVREM

16

HVREM

17

+24V1

18

(NC)

19

GND2

20

GND2

21

M1SS1

22

M2SS1

23

M1SS2

24

M2SS2

M1SS3

25

26

M2SS3

27

M1SS4

28

M2SS4

29

GND2

30

GND2

31

M1SPD

32

M2SPD

+5V2

33

+5V2

34

CN-16

B32B-PHDSS-B

+24V1

1

+24V1

2

/M1PUS

3

/M2PUS

4

GND2

5

GND2

6

M1PED

7

M2PED

8

+5V2

9

+5V2

10

GND2

11

12

GND2

M1LUD

13

M2LUD

14

+5V2

15

+5V2

16

+5V-M1PFD

17

18

+5V-M2PFD

19

GND2

20

GND2

21

M1PFD

22

M2PFD

23

+24V1

24

+24V1

/M1PFC

25

/DSKPFC1

26

27

M1LUM

Vref

28

GND2

29

GND2

30

(NC)

31

32

M1PWS

PCU PWB

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 11

Page 34

[Paper Transport Section]

Outline

The paper transport section serves the function of transferring paper from each

paper feed port to the registration roller section.

Paper from manual feed, paper feed tray units 1 and 2 (optional), and the right

paper feed tray of the paper feed tray units 1 and 2 is transported horizontally,

whereas paper from the left paper feed tray of the paper feed tray units 1 and 2,

paper feed tray 3 and paper feed tray 4 is transported vertically to the registration

roller section.

After the leading edge of the paper is synchronized with the leading edge of the

drum image in the registration roller section, the paper that is transfer printed with

the image in the transfer section passes through the fusing section and is discharged either face-down or face-up.

(Vertical paper transport section 1)

A. Major parts and signal functions

MM

DSKPFC2

VPM

PHNR-02-H+BU02P-TR-P-H

1

S5B-PH-K-S

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 12

+24V1

/DSKPFC2

GND2

+5V2

/MM

MMCLK

MM-T

2

12

1

2

3

4

5

Page 35

CN-17

B30B-PHDSS-B

M2LUM

1

+24V1

2

GND2

3

/T1PFC

4

+24V1

5

+24V1

6

7

/M2PFC

8

/DSKPFC2

9

GND2

10

GND2

11

TXD-FIN

12

+5V2

13

RXD-FIN

/MM

14

/DTR-FIN

15

MMCLK

16

/DSR-FIN

17

18

MM-T

RES-FIN

19

TSW-LED

20

21

(NC)

22

TSW

23

GND2

24

GND2

25

TANSET

GND2

26

27

+5V2

DSW-DSK

28

(NC)

29

+5V2

30

PCU PWB

CN-10

B26B-PHDSS-B

/POM1A

/POM1XA

/POM1B

/POM1XB

/POM2A

/POM2XA

/POM2B

/POM2XB

/ADM1A

/ADM1XA

/ADM1B

/ADM1XB

/ADM2A

/ADM2XA

/ADM2B

/ADM2XB

/TRMA

/TRMXA

/TRMB

/TRMXB

/VPMA

/VPMXA

/VPMB

/VPMXB

GND2

GND2

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

1

2

3

4

5

6

7

8

9

CN-4

B26B-PHDSS-B

/POM1A

1

/POM1XA

2

/POM1B

3

/POM1XB

4

/POM2A

5

6

/POM2XA

/POM2B

7

/POM2XB

8

/ADM1A

9

/ADM1XA

10

/ADM1B

11

/ADM1XB

12

/ADM2A

13

/ADM2XA

14

/ADM2B

15

/ADM2XB

16

/TRMA

17

/TRMXA

18

/TRMB

19

/TRMXB

20

/VPMA

21

/VPMXA

22

/VPMB

23

/VPMXB

24

GND2

25

GND2

26

DRIVER

PWB

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 13

CN-2

B12B-PH-K-S

/TRM/A

/TRMA

/TRMB

/TRM/B

+24V2

+24V2

/VPM/A

/VPMA

/VPMB

/VPM/B

+24V2

+24V2

1

2

3

4

5

SMR-06V-N/SMP-06V-NC

6

7

1

/VPM/A

8

/VPMA

2

9

/VPMB

3

10

4

/VPM/B

11

5

+24V2

12

+24V2

6

1

2

3

4

5

6

Page 36

(Vertical paper transport section 2)

A. Major parts and signal functions

PSBC

MM

RRC

TRM

S5B-PH-K-S

1

GND2

2

+5V2

3

/MM

4

MMCLK

5

MM-T

PHNR-02-H+BU02P-TR-P-H

+24V1

1

2

2

1

/RRC

CN-17

B30B-PHDSS-B

M2LUM

1

+24V1

2

GND2

3

/T1PFC

4

+24V1

5

+24V1

6

/M2PFC

7

/DSKPFC2

8

GND2

9

GND2

10

TXD-FIN

11

+5V2

12

RXD-FIN

13

/MM

14

/DTR-FIN

15

MMCLK

16

/DSR-FIN

17

MM-T

18

RES-FIN

19

TSW-LED

20

(NC)

21

TSW

22

23

GND2

GND2

24

TANSET

25

GND2

26

+5V2

27

DSW-DSK

28

(NC)

29

+5V2

30

CN-7

B32B-PHDSS-B

1

+24V1

2

+24V1

3

/CFM-DV

4

/RRC

5

GND2

6

(NC)

7

+24V1

8

+24V(DSW)

9

+5V-APPD1

PFD2

10

11

+5V-APPD2

/CFM-ADU

12

+5V-PFD2

13

14

THPS2

15

+5V-DSWD

16

TURM

+5V-AINPD

17

/TCBPWH

18

19

+5V-THPS1

20

(NC)

21

+5V-THPS2

/TCBIAS

22

23

/FBIAS

APPD1

24

DSWD

25

APPD2

26

27

/DGS

AINPD

28

29

GND2

GND2

30

(NC)

31

32

DSW-L

PPD

MPRD2

PCU PWB

CN-12

B30B-PHDSS-B

+24V1

+24V1

/T2PFC

/HPLS

+24V1

DVCH1

/HPFC

DVCH2

+24V1

DVCH3

/PSBC

DVCH4

+5V2

+24V1

PPD

TCS

GND2

GND2

+5V-MPRD1

TSGOUT

GND2

GND2

MPRD1

+5V2

+5V-MPRD2

HUS-DV

GND2

GND2

MPRD2

TH-DV

CN-10

B26B-PHDSS-B

/POM1A

/POM1XA

/POM1B

/POM1XB

/POM2A

/POM2XA

/POM2B

/POM2XB

/ADM1A

/ADM1XA

/ADM1B

/ADM1XB

/ADM2A

/ADM2XA

/ADM2B

/ADM2XB

/TRMA

/TRMXA

/TRMB

/TRMXB

/VPMA

/VPMXA

/VPMB

/VPMXB

GND2

GND2

VPM

MPRD1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 14

Page 37

+24V1

1

1

2

/PSBC

2

+5V2

3

3

PPD

4

4

5

GND2

5

+5V-MPRD1

6

6

7

GND2

7

8

MPRD1

8

9

9

+5V-MPRD2

10

10

GND2

11

11

MPRD2

12

12

+24V1

13

13

/HPLS

14

14

(NC)

15

15

(NC)

16

16

(NC)

17

17

(NC)

18

18

(NC)

SMR-18V-N/SMP-18V-NC

PHNR-06-H+BU06P-TR-P-H

+24V1

1

6

/PSBC

2

5

+5V2

3

4

PPD

4

3

GND2

5

2

(NC)

61

SMR-08V-N/SMP-08V-NC

+5V-MPRD1

1

1

GND2

2

2

MPRD1

3

3

+5V-MPRD2

4

4

GND2

5

5

MPRD2

6

6

+24V1

7

7

8

8

/HPLS

PHNR-02-H+BU02P-TR-P-H

+24V1

1

2

12

/PSBC

179228-3

+5V2

1

PPD

2

3

GND2

PHR-3(RED)

1

+5V-MPRD1

2

GND2

3

MPRD1

PHR-3

+5V-MPRD2

1

GND2

2

3

MPRD2

CN-4

B26B-PHDSS-B

/POM1A

1

/POM1XA

2

/POM1B

3

/POM1XB

4

/POM2A

5

/POM2XA

6

/POM2B

7

/POM2XB

8

/ADM1A

9

/ADM1XA

10

/ADM1B

11

/ADM1XB

12

/ADM2A

13

/ADM2XA

14

/ADM2B

15

/ADM2XB

16

/TRMA

17

/TRMXA

18

/TRMB

19

/TRMXB

20

/VPMA

21

22

/VPMXA

/VPMB

23

/VPMXB

24

GND2

25

GND2

26

DRIVER PWB

CN-2

B12B-PH-K-S

/TRM/A

/TRMA

/TRMB

/TRM/B

+24V2

+24V2

/VPM/A

/VPMA

/VPMB

/VPM/B

+24V2

+24V2

1

2

3

4

5

6

7

8

9

10

11

12

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 15

SMR-06V-N/SMP-06V-NC

/TRM/A

1

2

/TRMA

3

/TRMB

/TRM/B

4

5

+24V2

6

+24V2

SMR-06V-N/SMP-06V-NC

1

/VPM/A

2

/VPMA

3

/VPMB

4

/VPM/B

5

+24V2

6

+24V2

1

2

3

4

5

6

1

2

3

4

5

6

Page 38

(Horizontal transport section)

A. Major parts and signal functions

T1PPD

MPRD2

MPRD1

MPFD2

LPPD

HPFC

S5B-PH-K-S

GND2

+5V2

/MM

MMCLK

MM-T

1

2

3

4

5

MM

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 16

Page 39

CN-17

B30B-PHDSS-B

M2LUM

1

+24V1

2

3

GND2

4

/T1PFC

+24V1

5

+24V1

6

/M2PFC

7

/DSKPFC2

8

GND2

9

GND2

10

TXD-FIN

11

+5V2

12

RXD-FIN

13

/MM

14

15

/DTR-FIN

16

MMCLK

17

/DSR-FIN

18

MM-T

19

RES-FIN

20

TSW-LED

21

(NC)

22

TSW

23

GND2

24

GND2

25

TANSET

GND2

26

27

+5V2

28

DSW-DSK

29

(NC)

30

+5V2

PCU PWB

CN-12

B30B-PHDSS-B

+24V1

+24V1

/T2PFC

/HPLS

+24V1

DVCH1

/HPFC

DVCH2

+24V1

DVCH3

/PSBC

DVCH4

+5V2

+24V1

PPD

TCS

GND2

GND2

+5V-MPRD1

TSGOUT

GND2

GND2

MPRD1

+5V2

+5V-MPRD2

HUS-DV

GND2

GND2

MPRD2

TH-DV

CN-18

B14B-PHDSS-B

GND2

+5V-MPFD2

TXD-LCC

GND2

RXD-LCC

MPFD2

/DTR-LCC

+5V-LPPD

/DSR-LCC

GND2

RES-LCC

LPPD

/TRC-LCC

(NC)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

1

2

3

4

5

6

7

8

9

10

11

12

13

14

PHNR-02-H+BU02P-TR-P-H

2

+24V1

/HPFC

1

SMR-06V-N/SMP-06V-NC

+5V-MPFD2

1

2

3

4

5

6

GND2

MPFD2

+5V-LPPD

GND2

LPPD

1

2

3

4

5

6

1

2

SMP-06V-NC/SMR-06V-N

1

+5V-MPFD2

2

GND2

3

MPFD2

4

+5V-LPPD

5

GND2

6

LPPD

1

2

3

4

5

6

PHR-3

+5V-MPFD2

1

GND2

2

MPFD2

3

PHR-3

+5V-LPPD

1

GND2

2

LPPD

3

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 17

Page 40

[Paper exit and turning section]

A. Outline

The paper exit and turning section discharges paper which is transported from the

fusing section, and detects paper full. It also turns paper to transport it to the

duplex or the finisher.

B. Major parts and signal functions

CN-1

B12B-PH-K-S

/POM1/A

1

/POM1A

2

/POM1B

3

/POM1/B

4

+24V2

5

+24V2

6

/POM2/A

7

/POM2A

8

/POM2B

9

/POM2/B

10

+24V2

11

+24V2

12

CN-5

DRIVER PWB

B26B-PHDSS-B

/POM1A

/POM1XA

/POM1B

/POM1XB

/POM2A

/POM2XA

/POM2B

/POM2XB

/ADM1A

/ADM1XA

/ADM1B

/ADM1XB

/ADM2A

/ADM2XA

/ADM2B

/ADM2XB

/TRMA

/TRMXA

/TRMB

/TRMXB

/VPMA

/VPMXA

/VPMB

/VPMXB

GND2

GND2

CN-4

PCU PWB

CN-10

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

B26B-PHDSS-B

/POM1A

1

/POM1XA

2

/POM1B

3

/POM1XB

4

/POM2A

5

/POM2XA

6

/POM2B

7

/POM2XB

8

/ADM1A

9

/ADM1XA

10

/ADM1B

11

/ADM1XB

12

/ADM2A

13

/ADM2XA

14

/ADM2B

15

/ADM2XB

16

/TRMA

17

/TRMXA

18

/TRMB

19

/TRMXB

20

/VPMA

21

/VPMXA

22

/VPMB

23

/VPMXB

24

GND2

25

GND2

26

B32B-PHDSS-B

GND2

+24V1

POD1

/VFM-EX1

+5V2

GND2

GND2

+24V1

POD2

/VFM-EX2

+5V2

GND2

GND2

+24V1

POD3

/VFM-EX3

+5V2

GND2

+24V1

+24V1

/CFM-U1

/VFM-BKL

GND2

GND2

+24V

+24V1

/CFM-U3

/CFM-U2

GND2

GND2

TH-EX

GND2

CN-8

B20B-PHDSS-B

/PWM-RSV1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

20

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 18

Page 41

POM1

INTPWB

CFM-U1

SMP-02V-NC/SMR-02V-N

/PWM-RSV1

11

2

(NS)

2

CFM-U3

CFM-U4

DELIVERY UNIT

SMP-18V-NC/SMR-18V-N

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

GND2

POD1

+5V2

GND2

POD2

+5V2

GND2

POD3

+5V2

+24V1

/CFM-U1

GND2

+24V1

/CFM-U3

GND2

TH-EX

GND2

/PWM-RSV1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

POD1

POD2

POD3

SMR-06V-N/SMP-06V-NC

1

2

3

4

5

6

SMR-06V-N/SMP-06V-NC

1

2

3

4

5

6

1

2

3

1

2

3

1

2

3

SMR-03V-N/SMP-03V-NC

1

22

3

SMR-03V-N/SMP-03V-NC

1

22

3

PHNR-03-H+BU03P-TR-P-H

3

2

1

1

2

3

4

/POM1/A

/POM1A

/POM1B

/POM1/B

+24V2

+24V2

/POM2/A

/POM2A

/POM2B

/POM2/B

+24V2

+24V2

PHR-3

GND2

POD1

+5V2

PHR-3(RED)

GND2

POD2

+5V2

PHR-3

GND2

POD3

+5V2

+24V1

/CFM-U1

GND2

+24V1

/CFM-U3

GND2

+24V1

/PWM-RSV1

GND2

S4B-PH-K-S

(NC)

(NC)

TH-EX

GND2

POM2

1

2

3

4

5

6

1

2

3

4

5

6

1

3

1

3

1

2

3

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 19

Page 42

(Duplex section)

A. General

When duplex print is selected, paper one surface of which was printed is switched

back to feed to the duplex section to make duplex print.

B. Major parts and signal functions

DSW-L

ADM1

DSW-ADU

DGS

AINPD

ADM2

APPD1

TURM

APPD2

PFD2

THPS2

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 20

Page 43

PHR-3

+5V-APPD1

GND2

APPD1

321

PHR-3

GND

+5V-APPD2

PHR-3

GND2

PFD2

APPD2

+5V-PFD2

321

321

1

+5V-PFD2

PFD2

+5V-THPS2

1

SMR-12V-N/SMP-12V-NC

179228-3

THPS2

/TCB-PWM

THPS2

/TCBIAS

GND2

+5V-THPS2

321

8765432

DSW-L

DSW-L

8765432

9

GND2

9

PHR-2

101112

TURM

101112

GND2

TURM

2

1

+24V1

/CFM-ADU

TB PWB

/TCBIAS

DSW-L

DSW-L

B6B-PH-K-S

Bias

FPS-187

/TCB-PWM

GND2

F-GND

54321

6

SRA-21T-4

1

+24V2

/ADUM2/A

/ADUM2A

/ADUM2B

/ADUM2/B

21345

SMR-06V-N/SMP-06V-NC

SRA-21T-4

65432

+24V2

6

SMR-06V-N/SMP-06V-NC

1

/ADUM1/A

/ADUM1A

/ADUM1B

21345

65432

+24V2

+24V2

/ADUM1/B

179228-3

6

PHNR-03-H+BU03P-TR-P-H

AINPD

1223

AINPD

3

+5V-AINPD

GND2

321

GND2

+5V-AINPD

1

DSW-ADU

179228-3

+5V-DSWD

GND2

321

2

12

+24V1

1 DGS

PHNR-02-H+BU02P-TR-P-H

987654321

DRAWER

/ADUM2/A

/ADUM2A

/ADUM2B

/ADUM2/B

/ADUM1/A

/ADUM1A

/ADUM1B

+5V-AINPD

+5V-PFD2

+5V-DSW

987654321

CN-7

B32B-PHDSS-B

(NC)

1

+24V1

2

+24V1

/RRC

/CFM-DV

/ADUM1/B

+24V(DSW)

+24V1

GND2

(NC)

+24V1

PFD2

+24V(DSW)

432

1

DSW-L

DSW-L

GND2

(NC)

/FBIAS

432

1

55

SMP-05V-NC/SMR-05V-N

DRIVER

CN-5

B9B-PH-K-S

PWB

/ADM1/A

/ADM1A

/ADM1B

/ADM1/B

/ADM2/A

/ADM2A

/ADM2/B

/ADM2B

987654321

+24V2

DSW-L

+5V-APPD1

+5V-APPD2

PCU PWB

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 21

2019181716151413121110

21

TURM

THPS2

/CFM-ADU

2019181716151413121110

21

9876543

+5V-APPD1

+5V-APPD2

PFD2

242322

+5V-THPS2

/TCB-PWM

/TCBIAS

242322

+5V-PFD2

/CFM-ADU

THPS2

25262728293031

GND2

APPD1

APPD2

AINPD

GND2

25262728293031

+5V-DSWD

+5V-AINPD

+5V-THPS1

TURM

TCBWH

32

/DGS

+24V2

DSW-ADU

32

QR/P4-32S-C(01)/QR/P4-32P-C(01)

242322212019181716151413121110

25262728293031

+5V-THPS2

APPD1

APPD2

AINPD

/CFM-AM1

DSWD

/DGS

TCBIAS

(NC)

GND2

GND2

32

(NC)

DSW-L

LEFT DOOR UNIT

Page 44

3. Laser scan unit (LSU)

A. General

This section performs the following operations.

Image data sent from the MFP (image process circuit) through the mother board

and PCU are converted into laser beams to radiate onto the drum surface.

B. Major parts and signal functions

CN-8

MFP

CONTROL

PWB

CN-8

MOTHER

PWB

CN-6 CN-6

PCU PWB

B30B-PHDSS-B

GND2

+5VLD

GND2

GND2

/READY

/PMCLK

/START

+24V1

(NC)

+24V1

+5V2

GND2

+5V2

GND2

TEST

TEST2

VRB

GND2

TEST3

GND2

VIDEO

GND2

/VIDEO

GND2

LSU S/H

GND2

/LDON

GND2

/SYNC

GND2

CN-22

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

AR-M550/M620/M700 DETAILS OF EACH SECTION 2 - 22

Page 45

BD

PGM

CN-2

SMP-18V-NC/SMR-18V-N

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

1

2

3

4

5

6

7

8

9

10

11

12

SMP-12V-NC/SMR-12V-N

GND2

+5VLD

GND2

GND2

/READY

/PMCLK

/START

+24V1

(NC)

+24V1

+5V2

GND2

+5V2

GND2

TEST

TEST2

VRB

GND2

TEST3

GND2

/VIDEO

VIDEO

GND2

GND2

LSU S/H

GND2

/LDON

GND2

/SYNC

GND2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

10

11

12

1

2

3

4

5

6

7

8

9

B30B-PHDSS-B

GND2

1

+5VLD

2

3

GND2

4

GND2

5

/READY

6

/PMCLK

/START

7

8

+24V1

9

/BRAKE