Sharp AR-M355N, AR-M455N Service Manual

SERVICE MANUAL

CODE: 00ZAR455N/A1E

DIGITAL MULTIFUNCTIONAL

SYSTEM

AR-M355N

MODEL

CONTENTS

[1] GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[3] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[4] CONSUMABLE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[5] EXTERNAL VIEWS AND INTERNAL STRUCTURES . . . . . . . . . . 5-1

[6] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] DISASSEMBLY AND ASSEMBLY, MAINTENANCE . . . . . . . . . . . 7-1

[8] ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[9] SIMULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

AR-M455N

[10] TROUBLE CODES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

[11] MACHINE OPERATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

[12] ROM VERSION-UP METHOD . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

[13] ELECTRICAL SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

Parts marked with “ ” are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

This document has been published to be used

SHARP CORPORATION

for after sales service only.

The contents are subject to change without notice.

CAUTION

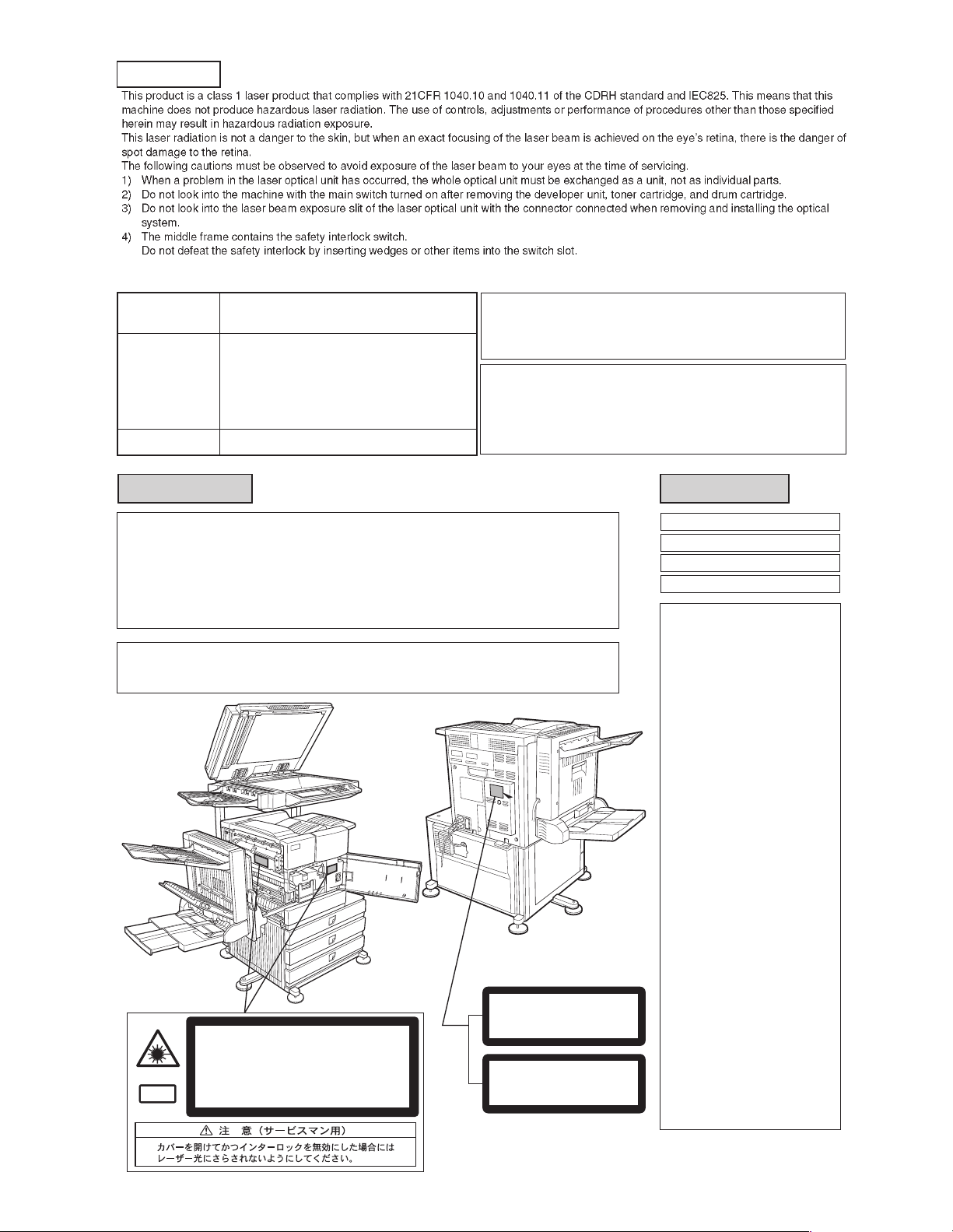

Cautions on laser

Wave length

Pulse times

Output power

North America:

Europe:

785 nm

+10 nm

−15 nm

35 cpm model: (4.1 µs ± 4.1 ns)/7 mm

45 cpm model: (5.7 µs ± 5.7 ns)/7 mm

35 cpm model: (3.8 µs ± 3.8 ns)/7 mm

45 cpm model: (4.4 µs ± 4.4 ns)/7 mm

0.2 mW - 0.4 mW

At the production line, the output power of the scanner unit

is adjusted to 0.4 MILLIWATT PLUS 8 % and is maintained

constant by the operation of the Automatic Power Control (APC).

Caution

This product contains a low power laser device. To ensure

safety do not remove any cover or attempt to gain access

to the inside of the product. Refer all servicing to qualified

personnel.

For North America:

SAFETY PRECAUTIONS

This Digital Equipment is rated Class 1 and complies with 21 CFR 1040.10 and 1040.11 of the

CDRH standards. This means that the equipment does not produce hazardous laser radiation. For

your safety, observe the precautions below.

●

Do not remove the cabinet, operation panel or any other covers.

●

The equipment's exterior covers contain several safety interlock switches. Do not bypass any

safety interlock by inserting wedges or other items into switch slots.

Caution

Use of controls or adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

CLASS 1

LASER PRODUCT

LASER KLASSE 1

Laserstrahl

INVISIBLE LASER RADIATION WHEN OPEN AND INTERLOCKS DEFEATED.

AVOID EXPOSURE TO BEAM.

CAUTION

UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET UND

SICHERHEITSVERRIEGELUNG ÜBERERÜCKT. NICHT DEM STRAHL AUSSETZEN.

VORSICHT

USYNLIG LASERSTRÅLING VED ÅBNING, NÅR SIKKERHEDSAFBRYDERE ER

UDE AF FUNKTION. UNDGÅ UDSAETTELSE FOR STRÅLNING.

ADVARSEL

USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES OG SIKKERHEDSLÅS BRYTES.

UNNGÅ EKSPONERING FOR STRÅLEN.

ADVERSEL

OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD OCH SPÄRRAR ÄR

URKOPPLADE. STRÅLEN ÄR FARLIG. BETRAKTA EJ STRÅLEN.

VARNING

AVATTAESSA JA SUOJALUKITUS OHITETTAESSA OLET ALTTIINA NÄKYMÄTÖNT

LASERSÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN.

VARO !

For Europe:

CLASS 1 LASER PRODUCT

LASER KLASSE 1

LUOKAN 1 LASERLAITE

KLASS 1 LASERAPPARAT

CAUTION

INVISIBLE LASER RADIATION

WHEN OPEN INTERLOCKS

DEFEATED. AVOID EXPOSURE

TO BEAM.

VORSICHT

UNSICHTBARE

LASERSTRAHLUNG WENN

ABDECKUNG GEÖFFNET UND

SICHERHEITSVERRIEGELUNG

ÜBERBRÜCKT. NICHT DEM

STRAHL AUSSETZEN.

ADVARSEL

USYNLIG LASERSTRÅLNING

VED ÅBNING, NÅR

SIKKERHEDSBRYDERE ER

UDE AF FUNKTION. UNDGÅ

UDSAETTELSE FOR

STRÅLNING.

VAROITUS!

LAITTEEN KÄYTTÄMINEN

MUULLA KUIN TÄSSÄ

KÄYTTÖOHJEESSA

MAINITULLA TAVALLA SAATTAA

ALTISTAA KÄYTTÄJÄN

TURVALLISUUSLUOKAN 1

YLITTÄVÄLLE

NÄKYMÄTTÖMÄLLE

LASERSÄTEILYLLE.

VARNING

OM APPARATEN ANVÄNDS PÅ

ANNAT SÄTT ÄN I DENNA

BRUKSANVISNING

SPECIFICERATS, KAN

ANVÄNDAREN UTSÄTTAS FÖR

OSYNLIG LASERSTRÅLNING,

SOM ÖVERSKRIDER GRÄNSEN

FÖR LASERKLASS 1.

[1] GENERAL

1. Note for servicing

Pictogram

This Service Manual uses some pictographs to assure safe operation.

Please understand the meanings of pictographs before servicing.

CAUTION: If this CAUTION is ignored, an injury or damage to

A. Cautions for servicing

1) Do not touch the photoconductive drum. Scratches or

2) The fusing unit is extremely hot. Exercise care in this area.

3) Do not look directly at the light source of the scanner module.

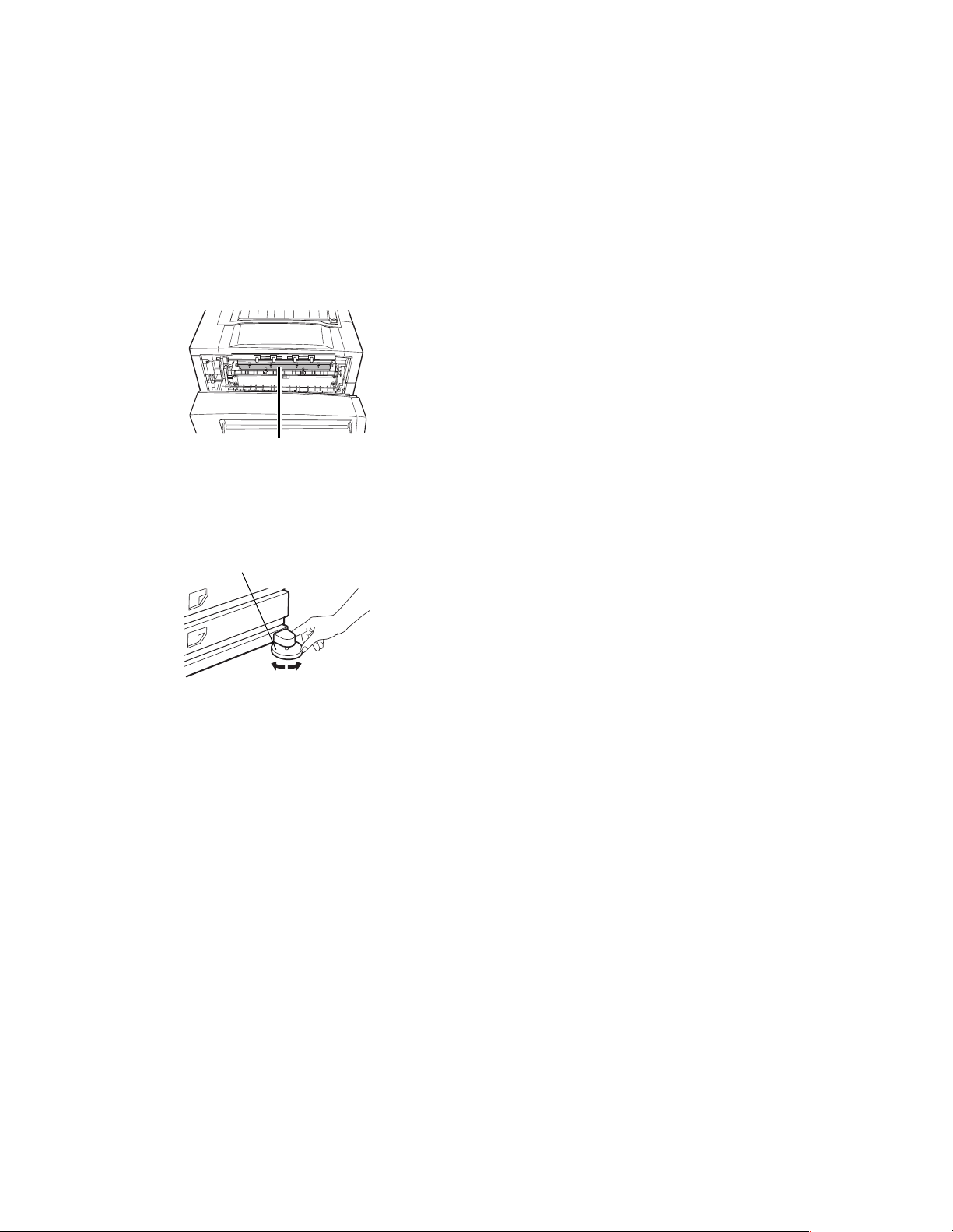

4) Five adjusters are provided on all optional stand/paper drawer

property could occur.

smudges on the drum will cause dirty printouts.

Fusing unit

Doing so may damage your eyes.

units. These adjusters should be lowered until they contact the

floor.

Adjuster

Lock

5) Do not make any modifications to this machine. Doing so may

result in personal injury or damage to the machine.

6) Since this machine is heavy, it is recommended that it be

moved by more than one person to prevent injury.

7) When connecting this machine to a computer, be sure to first

turn both the computer and the machine off.

8) Do not print anything which is prohibited from printing by law.

The following items are normally prohibited from printing by

national law. Other items may be prohibited by local law.

• Money

• Stamps

• Bonds

• Stocks

• Bank drafts

• Checks

• Passports

• Driver's licenses

9) Do not throw toner or a toner cartridge into fire. Toner may be

spattered, causing a burn.

10) Store toner or toner cartridges in a hard-to-reach place for children.

Release

AR-M355N/M455N GENERAL 1 - 1

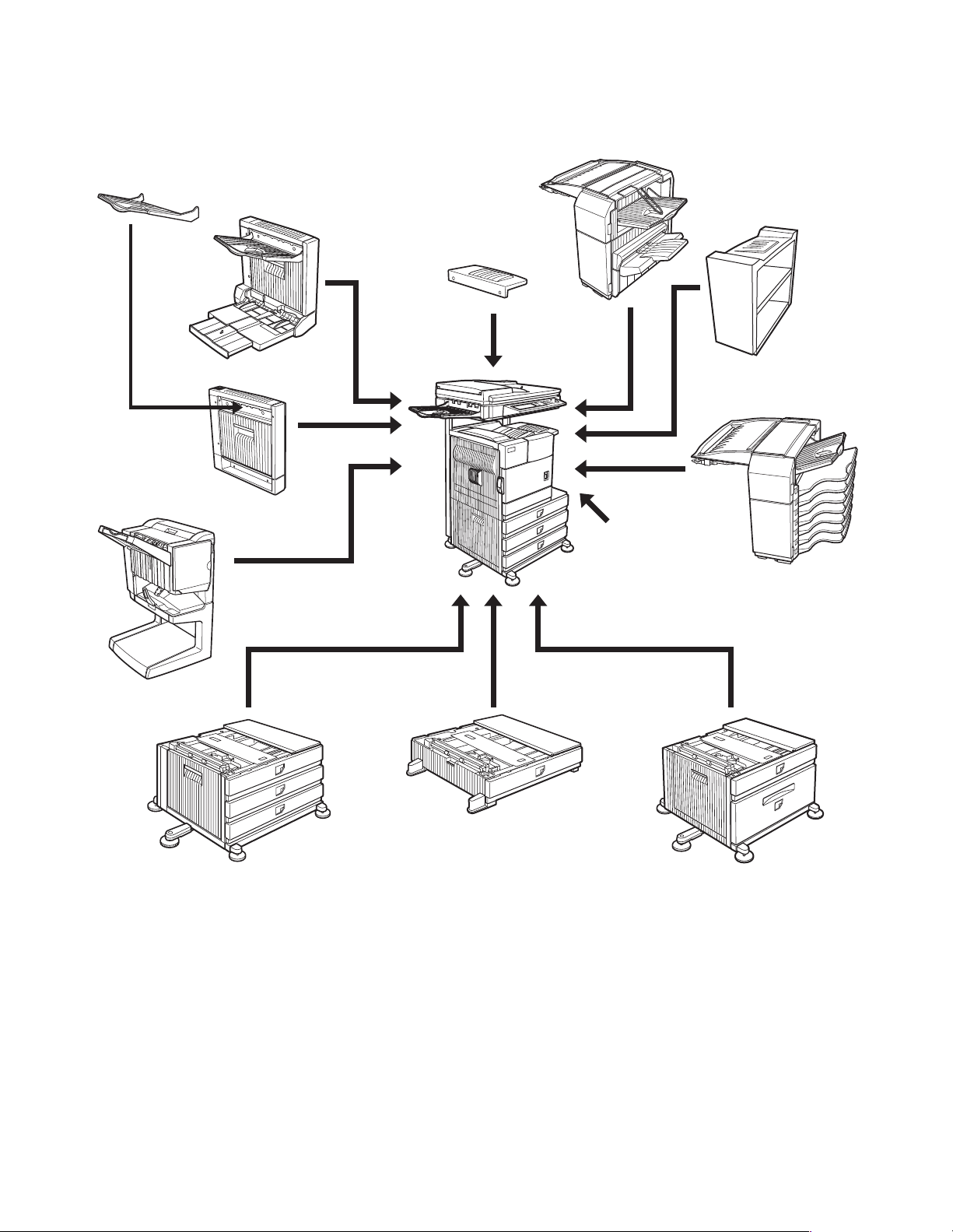

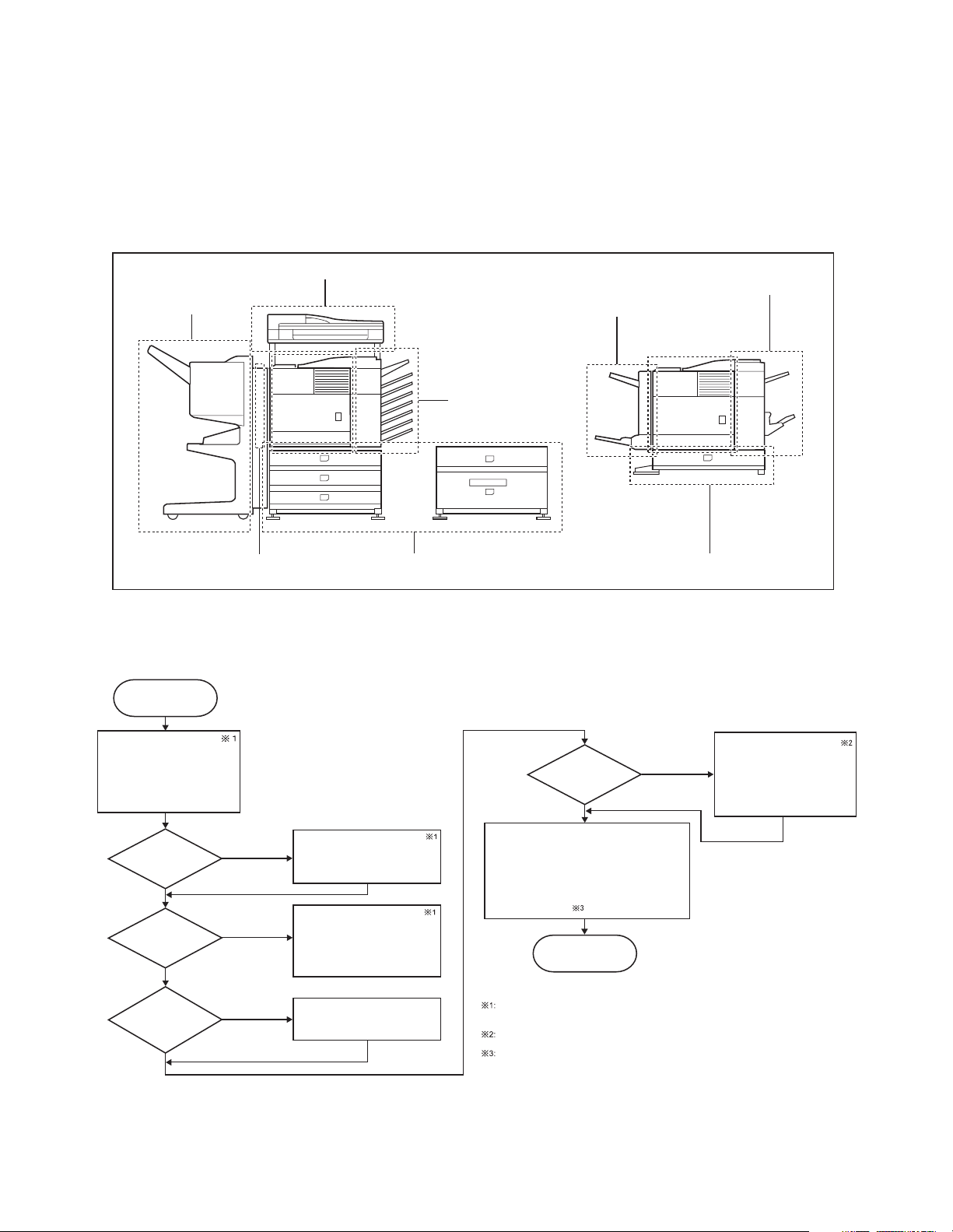

[2] CONFIGURATION

1. System configuration

A. Basic system

AR-M355N/M455N

(Copier/Network printer model)

Necessary options

• B/W scanner module/DSPF (AR-EF3)

• Scanner Rack (AR-RK2)

• Any one of the stand/MPD & 2000 sheet paper drawer (AR-

D28), the stand/3 x 500 sheet paper drawer (AR-D27), or the

multi purpose drawer (AR-MU2)

• Any one of the upper exit tray extension (AR-TE4), the finisher (AR-FN6), the mail-bin stacker (AR-MS1), or the cover

option at right side (AR-TE5)

AR-M355N/M455N CONFIGURATION 2 - 1

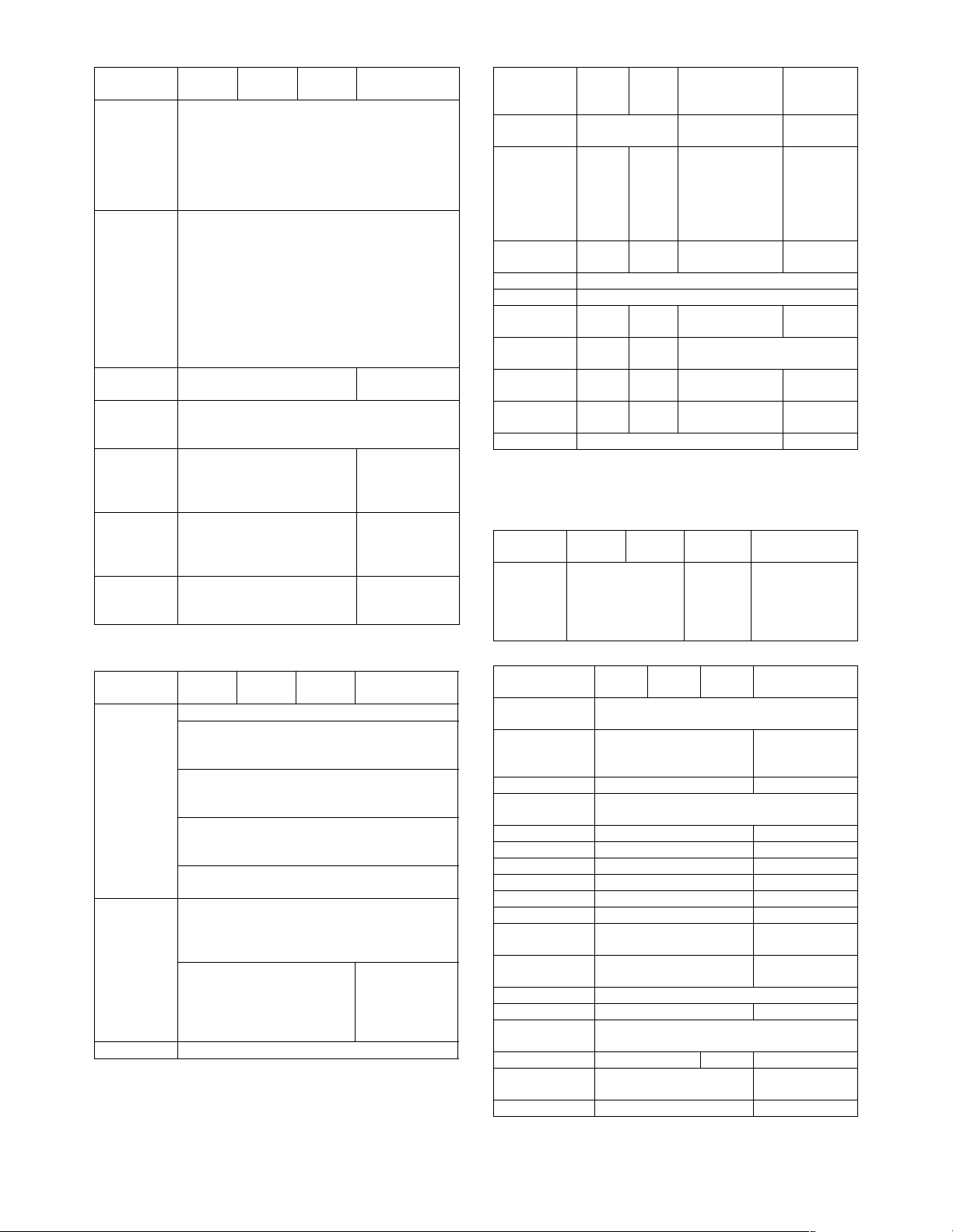

B. Option lineup

For combinations of options, refer to "C. List of combination of peripheral devices" described later.

(1) Major options

11. Finisher

(AR-FN6)

7. Exit tray

10. Saddle stitch

finisher

(AR-FN7)

8. Duplex

module/bypass tray

(AR-DU4)

9. Duplex module

(AR-DU3)

5. Upper exit tray

extension

(AR-TE4)

6. Cover option

at right side

(AR-TE5)

12. Mail-bin stacker

(AR-MS1)

13. Fax expansion kit

(AR-FX12)

3. Stand/3 x 500 sheet

paper drawer

(AR-D27)

4. Multi purpose drawer

(AR-MU2)

2. Stand/MPD & 2000 sheet

paper drawer

(AR-D28)

AR-M355N/M455N CONFIGURATION 2 - 2

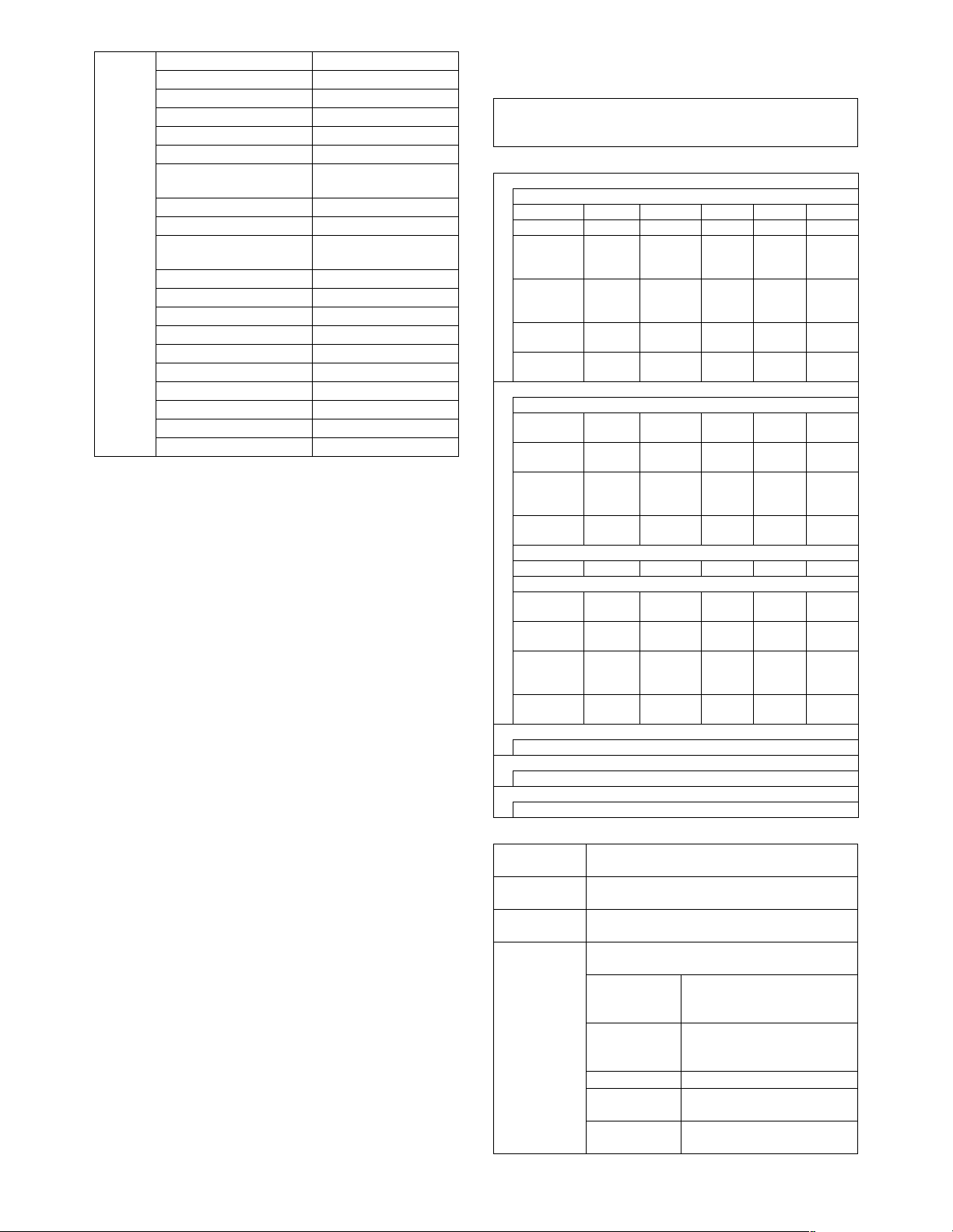

No. Option name Installing conditions

1 B/W scanner module/DSPF AR-EF3 • The scanner rack (AR-RK2) is required.

• Either of the stand/3 x 500 sheet paper drawer (AR-D27) or the

stand/MPD & 2000 sheet paper drawer (AR-D28) is required.

2 Stand/MPD & 2000 sheet paper drawer AR-D28 • Simultaneous installation with the large capacity paper feed

3 Stand/3 x 500 sheet paper drawer AR-D27

4 Multi purpose drawer AR-MU2

5 Upper exit tray extension AR-TE4 • Required when the finisher (AR-FN6) or the mail-bin stacker

6 Cover option at right side AR-TE5

7 Exit tray AR-TE3 • Required when the duplex module (AR-DU3) is installed and the

8 Duplex module/bypass tray AR-DU4 • Any one of the multi purpose drawer (AR-MU2), the stand/3 x

9 Duplex module AR-DU3

10 Saddle stitch finisher AR-FN7 • Simultaneous installation with the finisher (AR-FN6) is inhibited.

11 Finisher AR-FN6 • Simultaneous installation with the saddle finisher (AR-FN7) is

12 Mail-bin stacker AR-MS1 • Any one of the multi paper drawer (AR-MU2), the stand/3 x 500

13 Fax expansion kit AR-FX12 • The scanner rack (AR-RK2) and the stand/3 x 500 sheet paper

desk (AR-D28) or the 3-stage paper feed desk (AR-D27) is

inhibited.

(AR-MS1) is not installed.

saddle stitch finisher (AR-FN7) is not installed.

500 sheet paper drawer (AR-D27), or the stand/MPD & 2000

sheet paper drawer (AR-D28) is required.

• The duplex module/bypass tray (AR-DU4) cannot be installed

with the exit tray (AR-TE3) or the saddle stitch finisher (ARFN7).

• When the duplex module (AR-DU3) is installed, the exit tray

(AR-TE3) or the saddle stitch finisher (AR-FN7) is required.

• The duplex module (AR-DU3) is required.

• The stand/3 x 500 sheet paper drawer (AR-D27) or the stand/

MPD & 2000 sheet paper drawer (AR-D28) is required.

inhibited.

• Any one of the multi paper drawer (AR-MU2), the stand/3 x 500

sheet paper drawer (AR-D27), or the stand/MPD & 2000 sheet

paper drawer (AR-D28) is required.

sheet paper drawer (AR-D27), or the stand/MPD & 2000 sheet

paper drawer (AR-D28) is required.

drawer (AR-D27), or the stand/MPD & 2000 sheet paper drawer

is required.

• The B/W scanner module/DSPF (AR-EF3) is required.

(2) Other options

Option Installing conditions

Paper exit unit Punch unit AR-PN1 For saddle stitch finisher (AR-FN7)

Function

expansion

options

FAX-related

option

PS3 expansion kit AR-PK6

Network scanner expansion kit AR-NS3

Sharpdesk 1 licence kit AR-U11M For network scanner expansion kit (AR-NS3)

Sharpdesk 5 licence kit AR-U15M

Sharpdesk 50 licence kit AR-U1AM

Sharpdesk 100 licence kit AR-U1BM

Data security kit (CC version ) AR-FR21

Data security kit (Commercial version ) AR-FR21U

Bar code font AR-PF1

Flash ROM kit AR-PF2

Fax memory (8 MB) AR-MM9 For fax expansion kit (AR-FX12)

AR-M355N/M455N CONFIGURATION 2 - 3

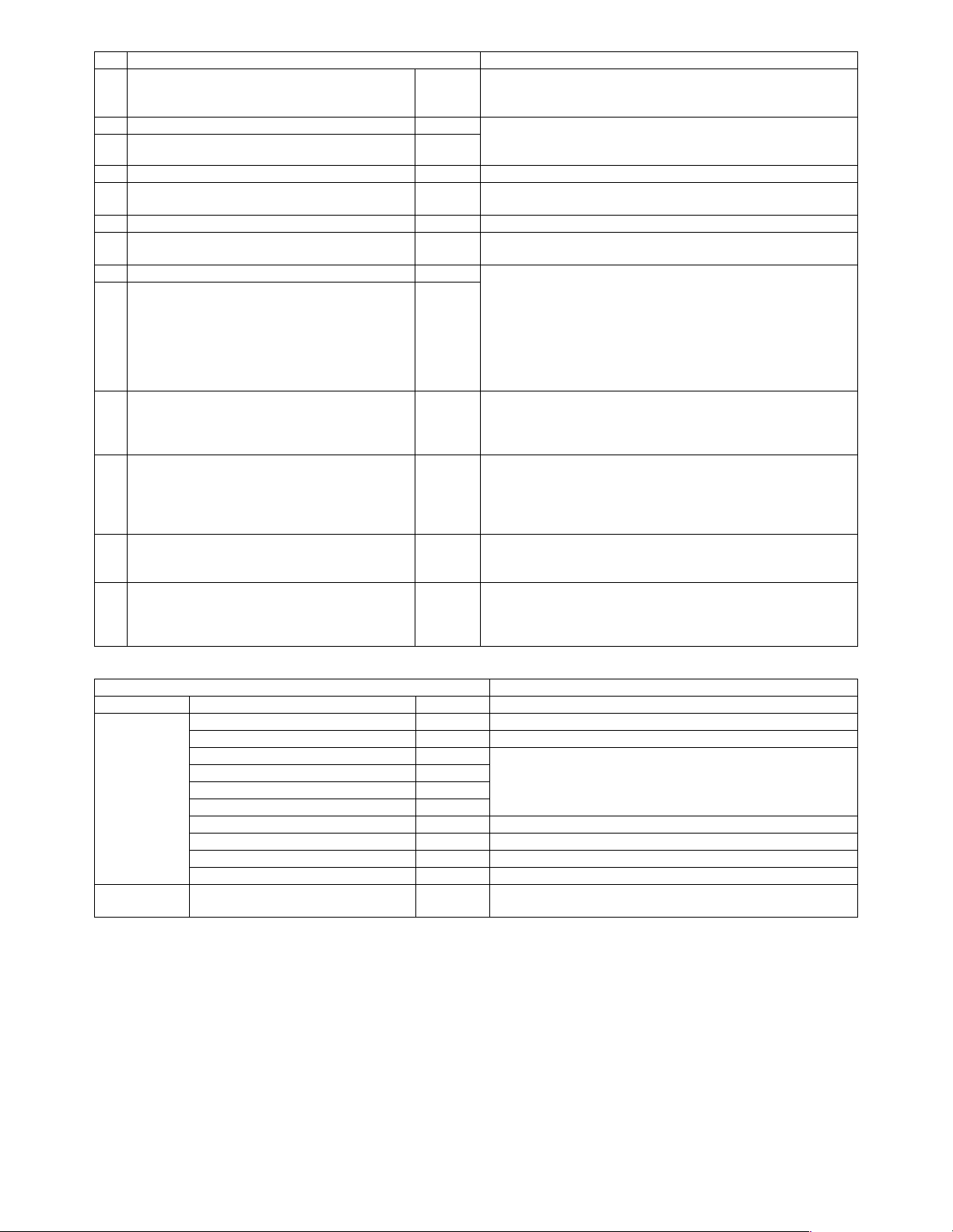

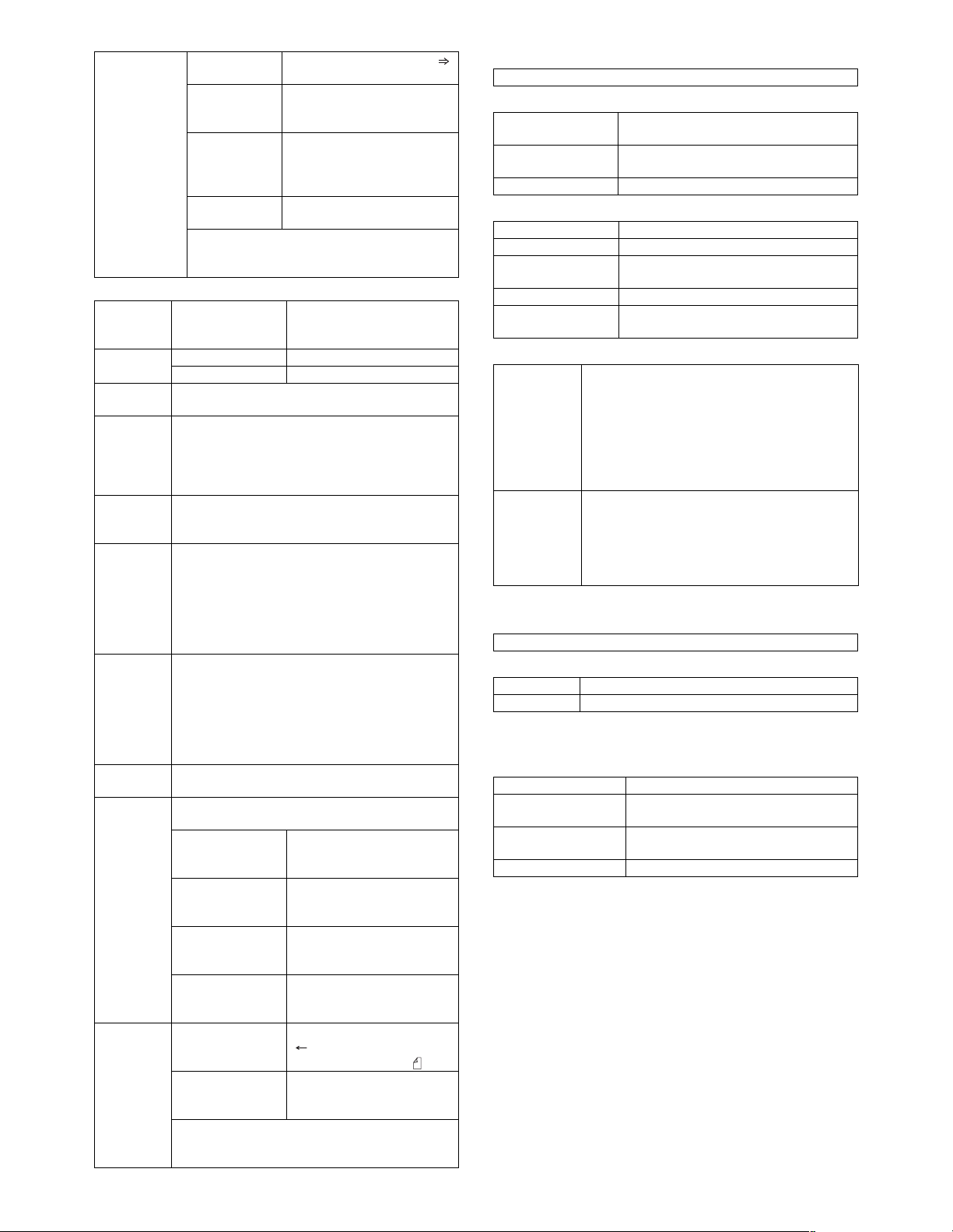

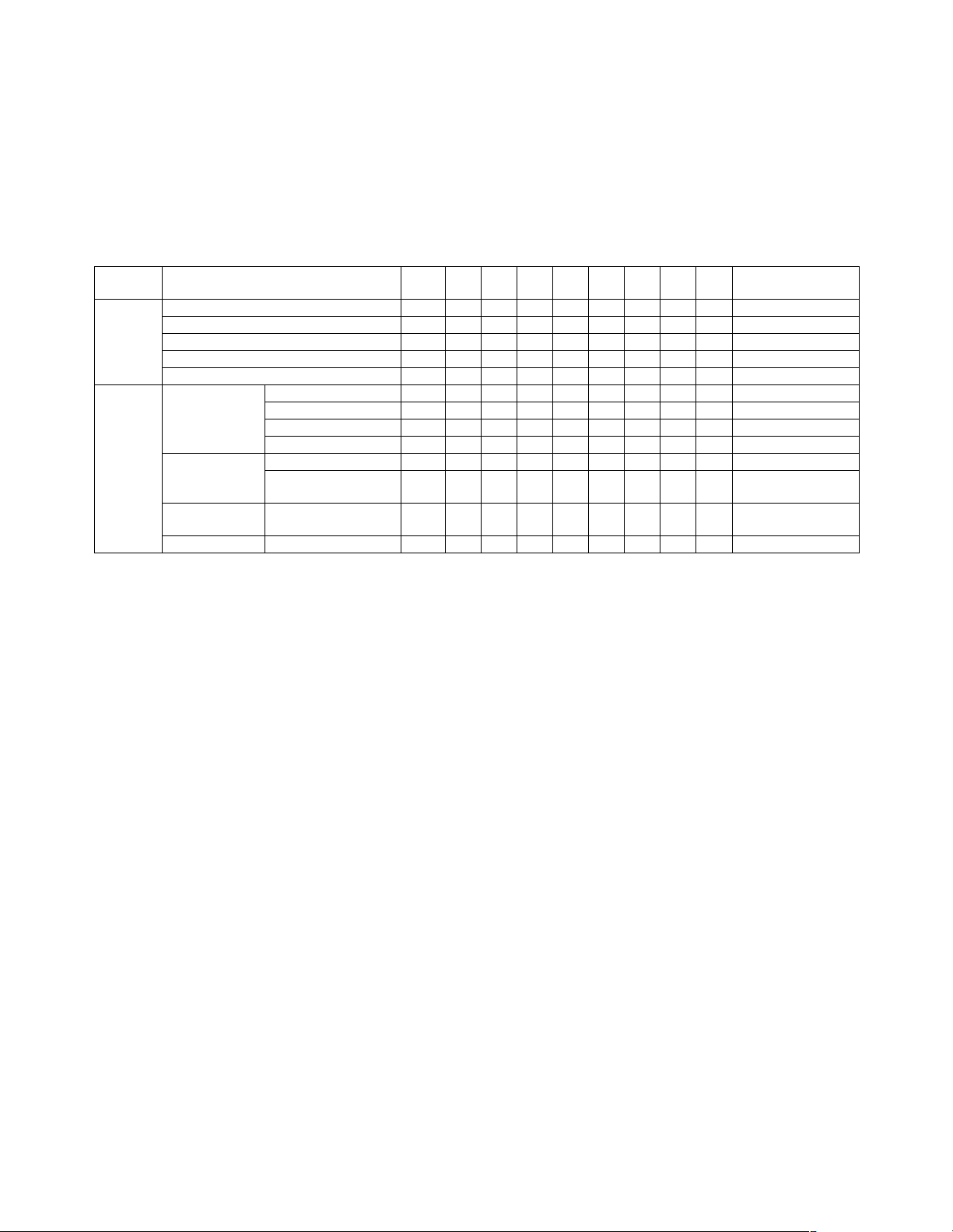

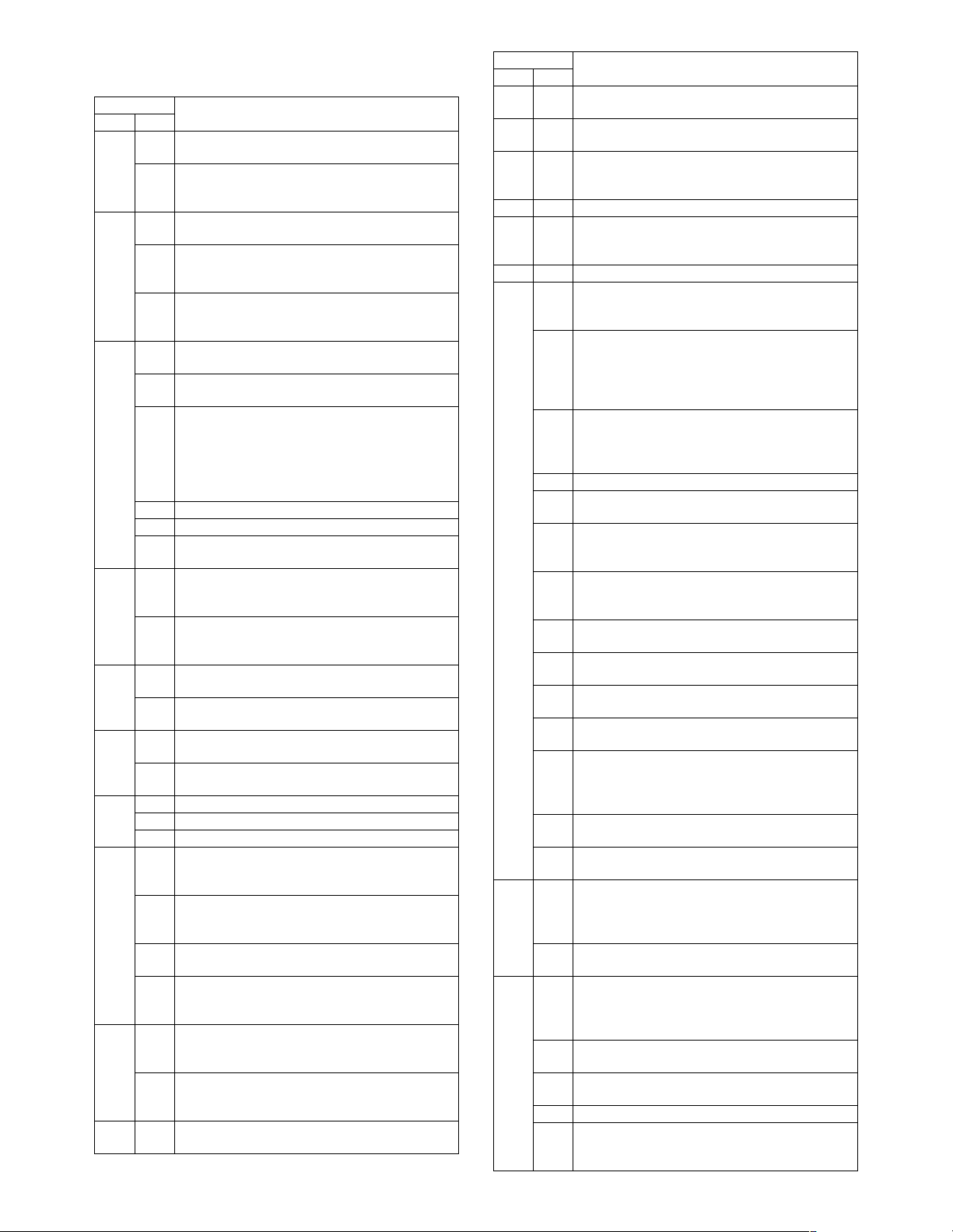

C. List of combination of peripheral devices

As shown in the table below, some other peripheral devices ( B ) may be needed for installation of a peripheral device ( A ) and some

peripheral devices cannot be installed together.

B

Related to scanner feature

B/W scanner module/DSPF AR-EF3

Scanner rack

Related to paper feed unit

Multi purpose drawer

Stand/3 x 500 sheet

paper drawer

Stand/MPD & 2000 sheet

paper drawer

Duplex module/bypass tray

Duplex module

Output units

Saddle stitch finisher

Finisher

A

Mail-bin stacker

Exit tray

Upper e

Cover option at right side

Punch unit

Related to extension of

functions and others

PS3 expansion kit

Network scanner

expansion kit

Facsimile expansion kit

Fax memory (8 MB)

Bar code font

Flash ROM kit

Data security kit (CC version)

Data security kit (Commercial version)

xit tray extension

AR-RK2

AR-MU2

AR-D27

AR-D28

AR-DU4

AR-DU3

AR-FN7

AR-FN6

AR-MS1

AR-TE3

AR-TE4

AR-TE5

AR-PN1

AR-PK6

AR-NS3

AR-FX12

AR-MM9

AR-PF1

AR-PF2

AR-FR21

AR-FR21U

B/W scanner module/DSPF

Scanner rack

Multi purpose drawer

Stand/3 x 500 sheet paper drawer

Stand/MPD & 2000 sheet

Duplex module/bypass tray

1

1

*

1

*

1

*

1

*

*

1

*

1

*

1

*

1

*

1

*

1

*

1

*

1

*

1

*

1

*

Duplex module

1

*

Saddle stitch finisher

Finisher

Mail-bin stacker

Exit tray

Punch unit

Upper exit tray extension

Multi-function controller board

Cover option at right side

PS3 expansion kit

Print server card

Fax memory (8 MB)

Network scanner expansion kit

Facsimile expansion kit

Bar code font

Flash ROM kit

Data security kit (CC version)

Data security kit (Commercial version)

= Must be installed together.

1

*

= Any of the units must be installed together.

= Cannot be installed together.

AR-M355N/M455N CONFIGURATION 2 - 4

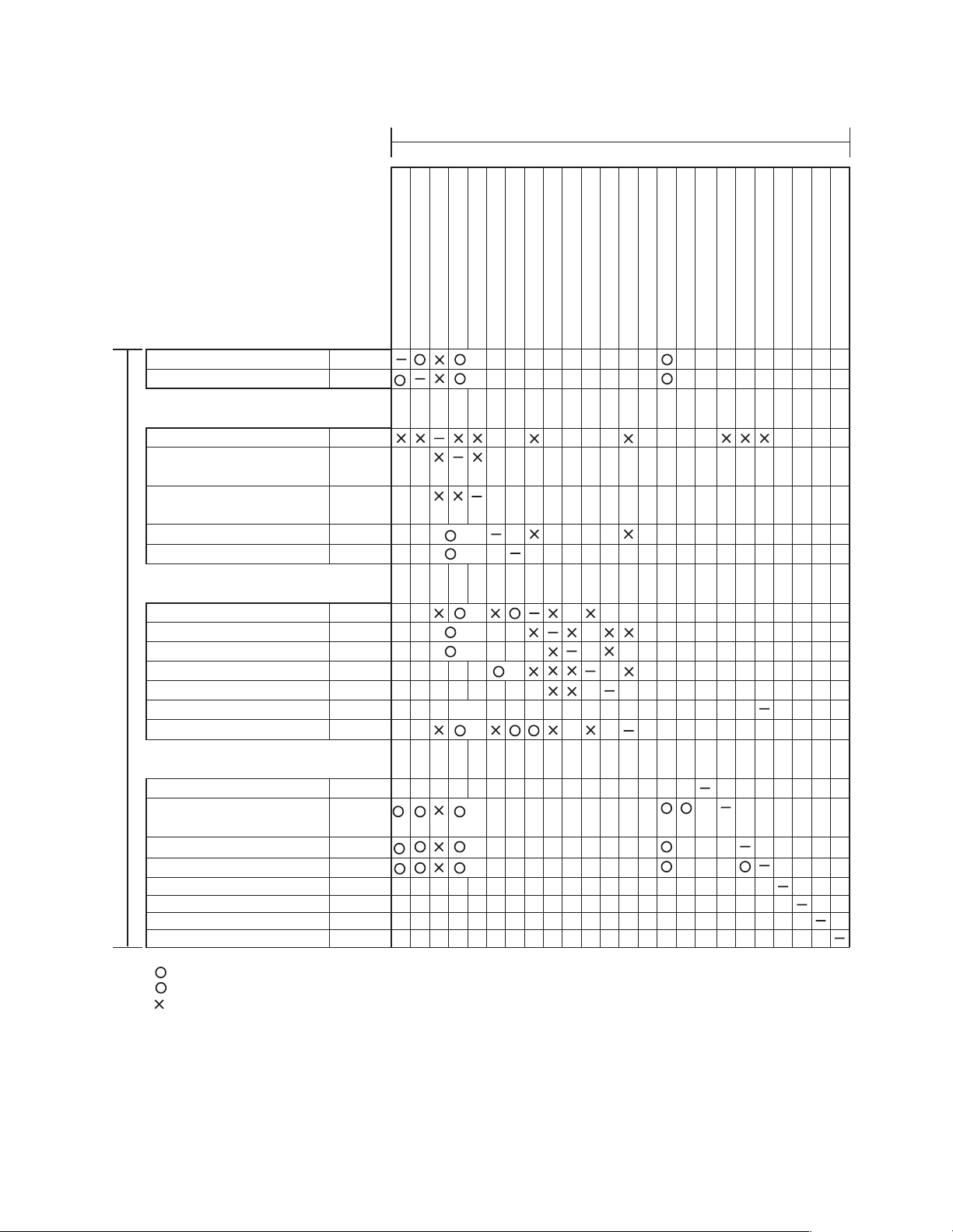

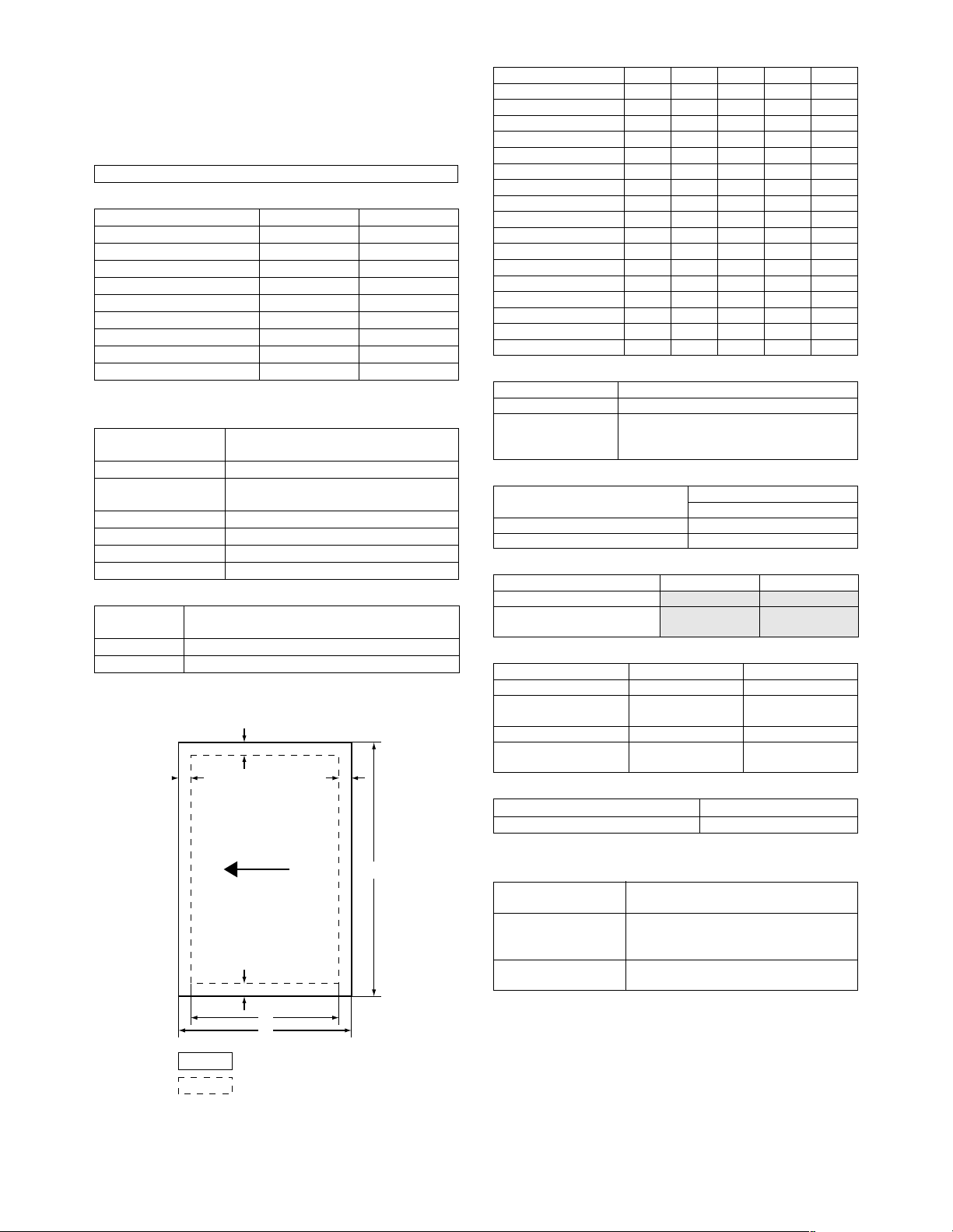

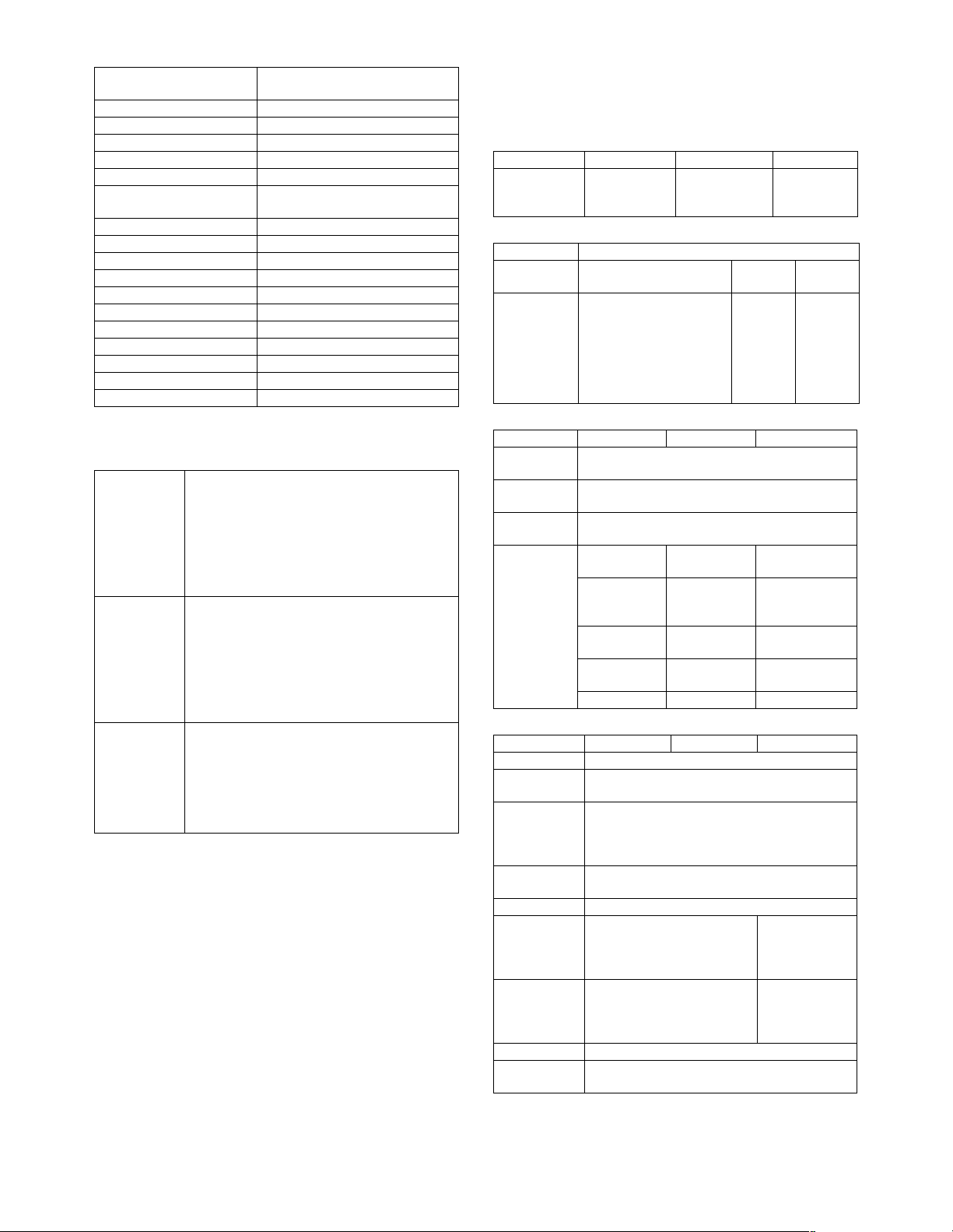

[3] SPECIFICATIONS

1. Basic Specification

A. Base Engine

(1) Form

Console type

(2) Engine speed

Paper size AR-M355N AR-M455N

A4, 8.5" x 11" 35ppm (31ppm*) 45ppm (40ppm*)

A4R, 8.5" x 11"R 25ppm 30ppm

A5R/5.5" x 8.5"R, Invoice-R 35ppm 45ppm

B5 35ppm 45ppm

B5R, Exective-R 25ppm 30ppm

B4/8.5" x 14 20ppm 22ppm

A3/11" x 17" 17ppm 20ppm

8K 17ppm 20ppm

16K 35ppm 45ppm

* Paper feed from Manual bypass tray

(3) Engine composition

Photoconductor type OPC

Record method Electrophotograph (laser)

Development

method

Charge method Charged saw-tooth method

Transfer method Transfer roller

Cleaning method Counter blade

Fusing method Heat roller

(4) Engine resolution

Resolution Read: 600dpi

Smoothing Write :1200dpi equivalent

Gradation Write :2 levels

(5) Printable area

The print area of this product is shown below.

(diameter of photoconductor : ø30mm)

Dry-type dual-component magnetic

brush development

Write :600dpi

E

C

E

D

C

A

B

(in mm)

Paper size A B C D E

A3 297 420 4 289 4

B4 257 364 4 242 4

A4 210 297 4 202 4

B5 182 257 4 168 4

A5 148 210 4 140 4

Japanese postcard 100 148 4 92 4

Ledger 279 432 4 271 4

Legal 216 356 4 208 4

Foolscap 216 330 4 208 4

Letter 216 279 4 208 4

Executive 184 267 4 183 4

Invoice 140 2162 4 132 4

Com-10 (envelope) 105 241 4 97 4

C5 (envelope) 162 229 4 154 4

Monarch (envelope) 98 191 4 90 4

DL (envelope) 110 220 4 102 4

ISO B5(envelope) 176 250 4 168 4

(6) Warm-up

Warm-up time less than 80 seconds

Pre-heat requirement Required

Jam recovery time Target: about 30 seconds

(Under standard condition of 60 seconds left

after side cover opening, polygon motor halt)

(7) Power source

Voltage 100V system

Frequency 50/60Hz

Power cord Inlet type

100-127V

(8) Power consumption

Max. Power consumption

Energy consumption

efficiency

AR-M355N AR-M455N

(9) Energy Star benchmark

Low power mode 184.75W 223.25W

Recovery time from

low power mode

Sleep mode Less than 80W Less than 95W

Transition time to

sleep mode

AR-M355N AR-M455N

Max. 30 sec. Max. 30 sec.

60 min.

(Max. 240 min.)

(Recommendation)

90 min.

(Max. 240 min.)

(10) Noise

At working less than 6.8B

At waiting mode less than 5.0B

∗ Showing noise benchmark in each model as a whole system.

(11) Dimensions

External dimensions

(W x D x H)

Occupied space

dimensions

(W x D)

Weight Approx. 85.7 lb (38.9kg)

*1: With multi purpose tray (AR-MU1)

16.9" x 21.7" x 18.5"

(428 x 552 x 475 mm) (Only main unit)

25.7" x 22.3" (654 x 567 mm) *1

(include developer and controller board)

Paper size

Printable area

If a printer driver for Windows or Macintosh is used for printing, the

printable area will be smaller. The actual printable area depends

on the printer driver to be used.

AR-M355N/M455N SPECIFICATIONS 3 - 1

B. Document Feeding Equipment

(1) One-drawer tray (included in the base engine)

Paper feed method One-drawer tray

Sizes to be fed A4, B5, 8.5" x 11"

Paper capacity 500 sheets (at 80g/m²)

Media available for

paper feeding

Paper type Plain, recycled, pre-printed, pre-

Paper size switching To be switched by user

Dehumidification

heater

Balance detection Provided (paper empty and 3 steps)

Default size setting 100V system

Mounting/demounting

of the tray

Plain paper 60 - 105g/m², 16 - 28lbs

punched, color, letter head

(paper size to be entered from the

operation panel).

Not provided

8.5" x 11"

Provided

C. Output Equipment

(1) Face-down Exit Tray (included in the base engine)

Output position/method Face-down output at the upper side of main

unit

Output paper capacity 400 sheets (80g/m² sheet)

Output paper size A3, B4, A4, A4R, B5, B5R, A5R

Spec of media for

paper output

Remaining paper

detection

Exit tray full detection Provided

11 " x 17", 8.5" x 14", 8.5" x 13", 8.5" x 11 ",

8.5" x 11 "R, 5.5" x 8.5"R

Executive, postal card, Monarch (98 x 191),

8K, 16K, 16KR

Com-10 (105 x 241), DL (110 x 220),

C5 (162 x 229), ISO B5 (176 x 250)

Tracing paper : 52 ~ 59g/m² / 14 ~ 15lbs

Plain paper : 60 ~ 128g/m² / 16 ~ 34lbs

Index paper : 176g/m² / 47lbs

Cover paper : 205g/m² / 54 ~ 55lbs

Transparency firm

Not provided

2. Specific Function

A. Printer Function

(1) Platform

IBM PC/AT (Include compatible machine)

Macintosh

(2) Support OS

Custom PS Windows 95/98/Me

Windows NT 4.0

Windows 2003 server

Windows 2000 server

Windows 2000

Windows XP

Custom

PCL5e/6(XL)

PPD Windows 95/98/Me

Windows 95/98/Me

Windows NT 4.0

Windows 2003 server

Windows 2000 server

Windows 2000

Windows XP

Windows NT 4.0

Windows 2003 server

Windows 2000 server

Windows 2000

Windows XP

MacOS 8.6 - 9.x, 10.1.5, 10.2 - 10.2.8

(except for Mac OS 10.2.2), 10.3-10.3.3

(3) PDL emulation

PCL6 compatible, PCL5e compatible, PostScript 3 compatible

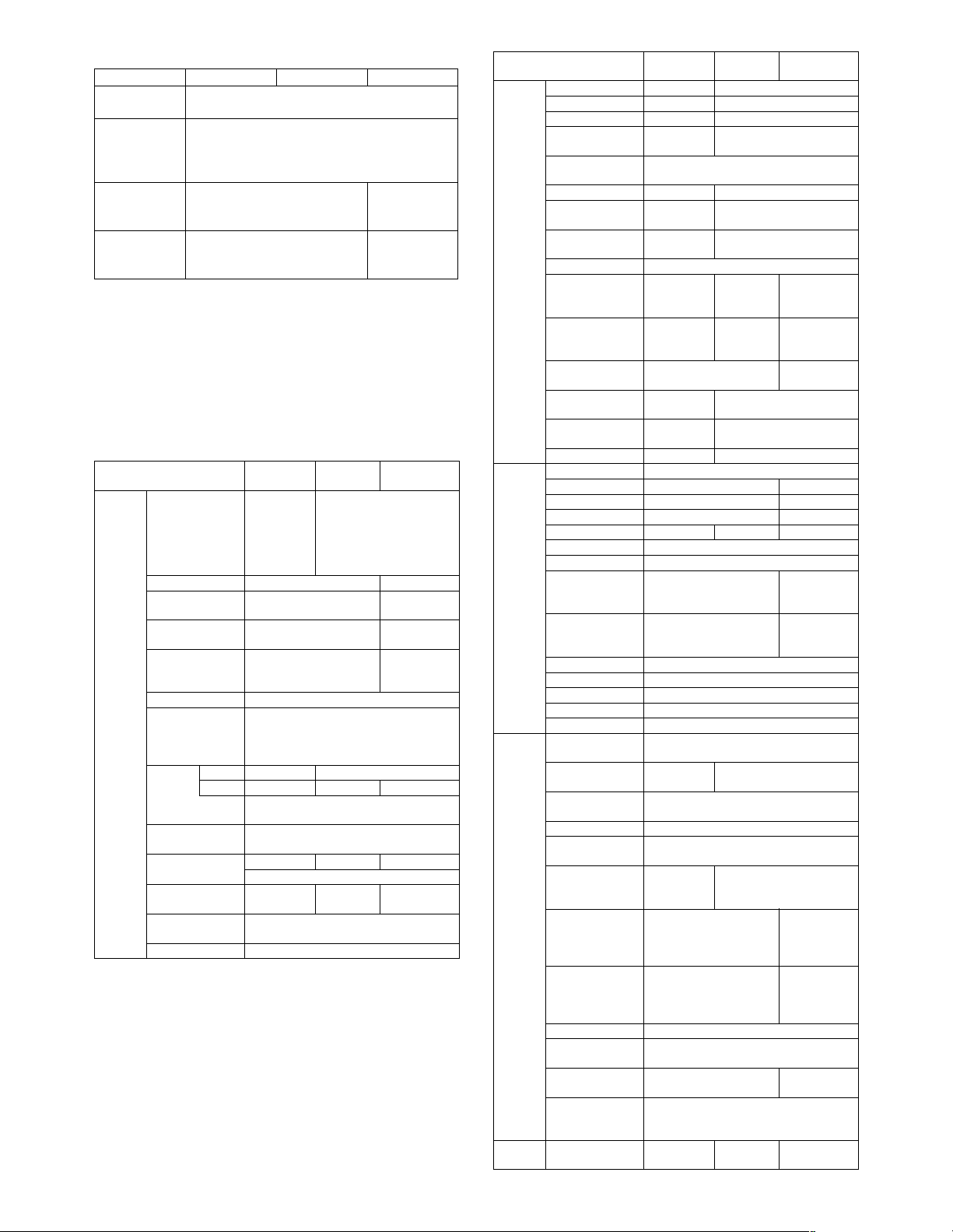

(4) Windows driver function

a. General

Function PCL5e PCL6 PS

Copies 1-999

Orientation Portrait

Landscape

Duplex 1-sided

2-sided

(Left /top/ right

binding)

Booklet Invoice on Letter

Letter on Ledger

A5 on A4

A4 on A3

B5 on B4

Letter on Letter

Ledger on Ledger

A4 on A4

A3 on A3

B4 on B4

Binding edge Left / top / right –

N-up 2/4/6/8/9/16 2 / 4 / 6 / 9 / 16

N-up order Z / Reversed Z /

N / Reversed N

N-up border Yes / No Always Yes (*2)

*1: For printing, PS driver bundled with the Windows is required.

*2: Since the function is of PS driver bundled with Windows, spec-

ification may vary according to the OS.

PPD file *1

(for Windows XP)

Portrait

Landscape-A

Landscape-B

(*2)

1-sided

2-sided

(Long / short

binding)

(*2)

Yes

(2up booklet only)

(*2)

(*2)

Z (*2)

AR-M355N/M455N SPECIFICATIONS 3 - 2

b. Paper Input

Function PCL5e PCL6 PS

Paper size A3 / B4 / A4 / B5 /

Paper type Plain

Custom

paper type

Source

selection

Cover Yes/No

Insert page Yes/No

Transparency

inserts

*1: For printing, PS driver bundled with the Windows is required.

c. Paper Output

Function PCL5e PCL6 PS

Output tray

selection

Staple Finisher

Offset cancel Yes/No

*1: For printing, PS driver bundled with the Windows is required.

A5 / Ledger /

Legal / Foolscap /

Letter / Executive

/Invoice/8k / 16k

/COM10/C5/

Monarch/DL

Letter Head

Pre-Print

Pre-Punch

Recycle

Color

Label

Heavy Paper

Transparency

Envelope

7 type –

Automatic

Tray 1/2/3/4

Bypass-tray

User can select from

1-sided/2-sided/

No print

User can select from

1-sided/2-sided/

No print

No

Yes (Blank)

Yes (Printed)

Center tray

Finisher

• Top tray

• Offset tray

Saddle Stitch

Finisher

• Offset tray

Mailbin stacker

• Mailbin top tray

• Mailbin (1-7)

Duplex module

• Left tray

• No staple

• 1 staple

• 2 staples

Saddle Stitch

Finisher

• No staple

• 1 staple

• 2 staples

PPD file *1

(for Windows XP)

–

–

–

PPD file *1

(for Windows XP)

Saddle Stitch

Finisher

• No staple

• 1 staple

• 2 staples

d. Graphic

Function PCL5e PCL6 PS

Resolution

setting

Halftone

setting

Graphics

mode

Smoothing Yes/No

Toner save Yes / No

Photo

enhancement

Negative

image

Mirror image ––Horizontal

Zoom ––25-400%

Fit to page Yes / No –

*1: For printing, PS driver bundled with the Windows is required.

*2: Since the function is of PS driver bundled with Windows, spec-

ification may vary according to the OS.

e. Font

Function PCL5e PCL6 PS

Download

font

f. Others

Function PCL5e PCL6 PS

Configuration

setting

Watermark Yes Yes

Edge to edge Yes –

Line width

setting

Form overlay Yes –

Print hold Yes –

Confidential print Yes –

Sample print Yes –

Print accounting Yes –

Quick sets Yes –

Auto

configuration

Job end

notification

Tandem print Yes

Carbon print Yes –

Multienlargement

XY zoom – Yes –

Cover insert +

pamphlet

Document filing Yes –

*1: For printing, PS driver bundled with the Windows is required.

*2: Since the function is of PS driver bundled with Windows, spec-

ification may vary according to the OS.

600/300 dpi 600dpi 600dpi

– No Screen frequency

Raster

HP-GL2

Bitmap

TrueType

Raster

Vector

– Yes/No ––

––Yes / No

Yes

Yes –

Yes –

Yes –

8.0 to 360.0

in 0.1 steps

Screen angle

0.0 to 360.0

in 0.1 steps

––

Vertical

(XY zoom)

Bitmap

Type1

TrueType

–

–

PPD file *1

(for Windows

XP)

–

Horizontal

(*2)

1-1000%

(*2)

PPD file *1

(for Windows XP)

Auto

Outline

Bitmap

Native TrueType

(*2)

PPD file *1

(for Windows XP)

(functionality is

limited)

AR-M355N/M455N SPECIFICATIONS 3 - 3

(5) Macintosh driver functions

a. General

Function

Copies 1-999

Orientation Portrait

Duplex 1-sided

Booklet Yes

N-up 2/4/6/9/16 (*1)

N-up order Z / reversed Z / N / reversed N (*1)

N-up border None / Single hairline / Single thin line /

*1: Since the function is of PS driver bundled with Macintosh,

specification may vary according to the OS.

b. Paper input

Function

Paper size A3 / B4 / A4 / B5 / A5 /

Paper type Plain / Letter Head / Pre-Print /

Custom paper

type

Source selection Automatic

Different 1st

page

Cover / insert

page

Transparency

inserts

*1: Since the function is of PS driver bundled with Macintosh,

specification may vary according to the OS.

Landscape-A

Landscape-B (*1)

2-sided

Pamphlet

(Right /left /top binding)

Double hairline / Double thin line (*1)

Japanese Postcard /

Ledger / Legal / Foolscap / Letter /

Executive / Invoice/ 8K / 16K/

COM10/C5/Monarch/DL

Pre-Punch / Recycle / Color /

Label / Heavy Paper / Transparency /

Envelope

7

Tray 1/2/3/4

Bypass-tray

Yes / No (*1)

–

(On OS9, user can select from: No/First

Page/Last Page)

(*1)

No

Yes (Blank)

Yes (Printed)

Macintosh PPD file

(for Mac OS X ver10.2.8)

Macintosh PPD file

(for Mac OS X ver10.2.8)

c. Paper output

Function

Output tray

selection

Staple Finisher

Offset Yes/No

d. Graphic

Function

Resolution

setting

Halftone setting –

Graphics mode –

Smoothing Yes/No

Toner save Yes / No

Photo

enhancement

Negative image –

Mirror image –

Zoom 1-100000 (*1)

Fit to page –

*1: Since the function is of PS driver bundled with Macintosh,

specification may vary according to the OS.

e. Font

Function

Download font –

Center tray

Finisher

• Top tray

• Offset tray

Saddle Stitch Finisher

• Offset tray

Mailbin stacker

• Mailbin top tray

• Mailbin (1-7)

Duplex module

• Left tray

• No staple

• 1 staple

• 2 staples

Saddle Stitch Finisher

• No staple

• 1 staple

• 2 staples

600dpi

Yes/No

(Selectable only on MacOS9.x.x LaserWriter) (*1)

Macintosh PPD file

(for Mac OS X ver10.2.8)

Macintosh PPD file

(for Mac OS X ver10.2.8)

Macintosh PPD file

(for Mac OS X ver10.2.8)

AR-M355N/M455N SPECIFICATIONS 3 - 4

f. Others

Function

Configuration setting Yes

Watermark Yes

Edge to edge Yes

Form overlay –

Print hold Yes

Confidential print Yes

Sample print Yes

Print accounting Yes

Quick sets –

Auto configuration – (OS9: Yes)

Job end notification –

Tandem print Yes

Carbon print –

Multi-enlargement –

XY zoom –

Cover insert + pamphlet –

Document filing Yes (*1)

*1: Since the function is of PS driver bundled with Macintosh,

specification may vary according to the OS.

Macintosh PPD file

(for Mac OS X ver10.2.8)

(PIN selection)

(6) Compatibility

PCL 5e

compatibility

PCL6

compatibility

PostScript

Compatibility

Target for PCL5e is to be compatible with HP

LaserJet 4050.

Small margin difference, rendering difference

by different font family, default and transfer

function difference is not to be included in the

compatibility.

All the PJL commands are not necessarily

included in the compatibility.

Target for PCL6 is to be compatible with HP

LaserJet 4050.

Small margin difference, rendering difference

by different font family, default and transfer

function difference is not to be included in the

compatibility.

All the PJL commands are not necessarily

included in the compatibility.

PostScript is targeted to be compatible with

Adobe PostScript as performed in HP LaserJet

4050.

Small margin difference, rendering difference

by different font family, default and transfer

function difference is not to be included in the

compatibility.

B. Image send function

(1) Mode

Scanner (Scan to E-mail, Scan to Sharpdesk, Scan to FTP, Scan

to HDD), FAX, Internet FAX

(2) Support system

Mode Scanner Internet FAX FAX

Supported

server

(3) Support image

Format TIFF, PDF, TIFF-F, TIFF-FX

Compression

method

(4) Image process

Mode Scanner Internet FAX FAX

Half tone

reproduction

Exposure

adjustment

Quality

selection

Resolution

(Varies with

the file type/

transmission

method)

(5) Specified destination

Mode Scanner Internet FAX FAX

LDAP Yes (Also can be stored in one-touch address.)

Specified

destination

One-touch

keys (Max.

number of keys

to be stored.)

Group* To be registered from one-touch and manual

Program Yes

Manual

destination

entry

Chain dialing

(Manual

destination

entry)

Resend This is used to recall the last destination.

Speed dialing This is used to recall address control number by

SMTP server

FTP server

Scanner Internet

Uncompressed,

G3 (1-dimension) *1,

G4 *3

*1 G3 (1-dimension) = MH

(Modified Huffman)

*3 G4 = MMR (Modified

MR)

Half-tone ON/OFF (It's not effective for the

following resolution with *.)

200 x 200dpi * 200 x 100dpi * Normal (203.2 x

300 x 300dpi 200 x 200dpi Small letter

400 x 400dpi 200 x 400dpi Fine (203.2 x

600 x 600dpi 400 x 400dpi Extra fine (406.4

– 600 x 600dpi –

Specifying by one-touch or group, manual

In this, FTP and Desktop are 200 destinations.

Soft Keyboard Input via the

POP server

SMTP server

ESMTP server

FAX

MH, MMR MH, MR,

Equivalent to 256 levels

Auto + 5 steps

97.8dpi) *

(203.2 x

195.6dpi)

391dpi)

x 391dpi)

destination entry

Max. 999 destinations

destination entry 500

numeric

keys, # key and *

key.

– Up to 64-digit

with pause

key

using numeric keys.

–

FAX

MMR,

JBIG

AR-M355N/M455N SPECIFICATIONS 3 - 5

(6) Specified multiple destinations

Mode Scanner Internet FAX FAX

Specified

destination

Max. number

of Manual

Specifying by one-touch or group, manual

destination entry.

Total of 5000 destinations including group and

relay broadcast.

destination

entry*

Sequential

broadcasting

Yes (E-mail only. It is not

available for

Yes

FTP/Desktop.)

Simultaneous

– Yes

FAX

transmission

* Manual destination entry: Entry other than One-touch, using

numeric keys or soft keyboard.

* In the case of broadcast transmission including fax destina-

tion, the resolution level for fax mode is applied.

* In the case of broadcast transmission with Internet FAX and

Scanner destinations, the resolution level of Internet FAX

mode is applied.

* In the case of broadcast transmission, the compression format

set with the key operator programs is applied.

(7) Functions

Internet

FAX

–

–

–

–

size only.

transmit)

program.

Yes

Max. 800mm

Yes

FAX

Yes

Yes

Yes

At on-hook

only

Yes: A3 → B4,

A3 → A4,

B4 → A4

Yes

Yes

–

Transmit

function

Mode Scanner

Memory transmit

On-fook

Quick online

transmit

Direct transmit

Auto reduction

transmit

Rotation transmit Yes

Scaling transmit Yes (Scaling from regular size to regular

Re-call

mode

Book original

transmit

Long length

original transmit

Specified pages

per file

Maximum number

of send data

Sender name Max.999 destinations

Error

Busy

–

Data is sent

by memory

transmit

when upper

limit is set.

Some functions does not allow rotation

–

––

No. of times/interval is set via key operator

Yes Yes Yes

Yes Yes

Mode Scanner

Receive

function

Special

function

Report/

List

function

Others PC-facsimile

Auto receive

Manual receive

Memory receive

Reduction receive

for standard size

Scaling receive for

specified size

Rotation receive – Yes

Divided receive

Duplex receive

2 in 1 receive

Address/Domainspecified reception

is enabled.

Address/Domainspecified reception

is disabled.

External phone

connection

Answering phone

connection

Transfer function

at output trouble

Auto startup mode

Time setting Yes

Transmit request

Remote transmit

Cover function

Print at sender

Page division Yes

Page combination No

Confidential

(machine at the

other end)

Transmit

broadcast

direction

Transmit message

Edge erase Yes

Center erase Yes

2 in 1 Yes

Card shot Yes

Transmit/receive

record

Transmit/receive

result

Address/phone

directory list

Group list Yes

ID/Sender's

address list)

Sender list Print

Confidential box

check list

Transmit group list

Program list Yes

Reserved transmit

list

Memory box list

Memory clear

notice list

transmission

Internet

FAX

–

–

FAX

Yes

Yes

– Yes

– Yes

–

–

Yes: To be defined by key

operator program

– Yes: To be defined by key

operator program

–

Yes 50

address

Yes 50

address

–

–

No (Remedy for PAT)

-

Only the

specified

number

Yes

– Yes

–

–

–

Yes

Yes

Yes

– No

–

Yes

–

–

Yes (F code

method)

Yes (F code

method)

–

Yes

No Yes

Yes

–

administrator

address.

–

–

No

Described in the key

operation list

Yes

(Integrated to

the memory

box list)

Yes

(Integrated to

the memory

box list)

–

–

Yes (FAX

mode only)

–

(It's possible that this is output in case of

–

errors.)

PC-iFAX PC-FAX

AR-M355N/M455N SPECIFICATIONS 3 - 6

(8) Transmission method

Mode Scanner Internet FAX FAX

Transmission time – 2 seconds (level:

Super G3/JBIG)

6 seconds (G3

ECM)

Modem speed – 33.6kbps →

2.4kbps

automatic fallback

Intercommunication – Super G3/G3

Communication line – General

telephone line

(PSTN), Private

branch

exchange(PBX),

FAX line

ECM – Yes

(9) Record size

Mode Scanner Internet FAX FAX

Max. record

293mm

width

Record size – A3-A5,

11" x 17"-

5.5" x 8.5"

A3-A5,

11" x 17"-

5.5" x 8.5"

(10) F code transmission

Mode Scanner Internet FAX FAX

Sub address – Yes

Passcode – Yes

C. Copy function

(1) Copy Speed

AR-M355N AR-M455N

Actual Reduction Enlargement Actual Reduction Enlargement

A4,

8.5" x 11"

A4R,

8.5" x 11"R

A5R,

5.5" x 8.5"R,

Invoice-R

B5 35 35 35 45 45 45

B5R,

Exective-R

B4,

8.5" x 14"

A3,

11" x 17"

Extra,

Envelope

∗ Figures in reduction/enlargement are represented by those at

the ratio to show slowest speed

(2) First copy time

Conditions: A4 or 8.5"x11" from front tray of PPC, with polygon

Document glass *1 Less than 5.3

DSPF Less than 6.0

*1: During OC mode

35 35 35 45 45 45

25 25 25 30 30 30

35 35 35 45 45 45

25 25 25 30 30 30

20 20 20 22 22 22

17 17 17 20 20 20

17 17 17 20 20 20

motor running.

AR-M355N AR-M455N

Less than 4.6

seconds

seconds

Less than 5.3

seconds

seconds

(3) Job speed

AR-M355N AR-M455N

S→ S *1 33 cpm (94%) 42 cpm (93%)

S→ D *2 32 cpm (91%) 40 cpm (88%)

D→ D *3 32 cpm (91%) 40 cpm (88%)

*1: S → S : A4 / 8.5" x 11" original 5 sheets copy 5sets

D : A4 / 8.5" x 11" original 10 sheets copy 5sets

*2: S

→

*3: D

D : A4 / 8.5" x 11" original 5 sheets (10 pages) copy 5sets

→

(4) Continuous copy

Max. multiple number 999 pages

(5) Copy Ratio

Copy ratio AB series :

Zoom 25 - 400%

Independent

scaling

25%, 50%, 70%, 81%, 86%, 100%, 115%, 122%,

141%, 200%, 400%

Inch series :

25%, 50%, 64%, 77%, 100%, 121%, 129%, 200%,

400%

25 - 200% (Copy from DSPF)

4

(6) Exposure/Copy Quality Process

Exposure mode Binary: Text(auto/manual), Text/photo, Photo

256 levels: Not provided

Manual steps 9 steps

Toner save mode Standard

(7) Copy Function

Function APS Yes

AMS Yes

XY zoom Yes

Paper type select Yes (By type setting)

Auto tray switching Yes

Rotation copy Yes

Electronic sort Yes

Rotation sort Yes

Reserved copy Yes

Prior tray setting No

Recall/register of program Yes

Document filing Yes

Proof copy No

Preheat function Yes (To be set up by the

key operator program)

Auto power shut-off

function

Account control Yes 500 accounts

Process control Yes

Tandem copy Yes (via network)

Tab copy No

Book copy Yes

Irregular original size input Yes

Irregular paper size input Yes

Yes (To be set up by the

key operator program)

AR-M355N/M455N SPECIFICATIONS 3 - 7

Special

function

Margin shift Yes

Edge erase/Center erase Yes

Dual page copying Yes

Covers/Inserts/Tab Inserts Yes

Transparency insert Yes

Centering No

Multi shot (Nin1) Yes (2 in 1 / 4 in 1)

Card shot Yes

Pamphlet copy Yes (Centering: Yes)

2-sided copy orientation

change

Job build Yes (max.10000 sheets)

Negative image Yes

Shading No

Mirror image Yes

Multi-page enlargement No

Repeat No

Date stamp Yes

Stamp Yes

Character stamp Yes

Page stamp Yes

Yes: Standard Function

No: Not provided

(Centering: Yes)

Yes

3. B/W Scanner Module (DSPF)

(1) Form

Scanner (Document glass) / DSPF standard

Operation panel integral type

(common hardware for all the destinations)

(2) Resolution / Gradation

Reading resolution (dpi)

Magnification 25 - 99 100 101 - 200 201 - 400 –

OC 600x600 600x600 600x600 600x600 –

OC

(High speed):

Text/Auto

OC

(High speed):

Others

DSPF/SPF

(standard)

DSPF/SPF

(high quality)

Input and transmitting resolution (dpi)

FAX transmit mode and scanner/fax multicasting mode

Selection

mode

Input

resolution: OC

Input

resolution:

DSPF

Transmitting

resolution

Internet-FAX

Scanner mode

Selection

mode

Input

resolution: OC

Input

resolution:

DSPF

Transmitting

resolution

Reading level

256 tones

Exposure lamp

Electrodeless xenon lamp

Output level

Binary

600x600 600x300 600x600 600x600 –

600x600 600x300 600x600 600x600 –

600x300 600x300 600x600 - –

600x600 600x600 600x600 - –

Standard Fine Super fine Ultra fine 600dpi

600 x391.2 600x391.2 600x391.2 600x391.2 –

600x300 600x300 600x300 600x300 –

203.2x97.8 203.2x195.6 203.2x391 406.4x391 –

200x100 200x200 200x400 400x400 600x600

Standard Fine Super fine Ultra fine –

600x391.2 600x391.2 600x391.2 600x600 –

600x300 600x300 600x300 600x300 –

200x200 300x300 400x400 600x600 –

(3) Document Glass

Reading area 297 x 431.8 (mm)

Original

alignment

Original size

detection

Sizes to be

detected

11.7" x 17"

Left edge / Rear corner alignment

Provided

(Standard size only)

Automatic (one detection unit to be used with

software modification by destination)

Inch-1 11" x 17", 8.5" x 14",

Inch-2 11" x 17", 8.5" x 13",

AB-1 A3, B4, A4, A4R, B5, B5R, A5

AB-2 A3, A4, A4R, A5, B5, B5R,

AB-3 8K, A4, A4R, A5, B4, 16K,

Copy mode

8.5" x 11", 8.5" x 11"R,

5.5" x 8.5"

8.5" x 11", 8.5" x 11"R, 5.5" x

8.5"

216 x 330 mm

16KR

sending

AR-M355N/M455N SPECIFICATIONS 3 - 8

OR guide

display

Rear left side

(Print display)

Left side OR

guide

(Print display)

Interior side OR

guide

(Print display)

Interior side OR

guide

The position available to attach the staple

position guide label when the optional finisher

(desktop console type) is equipped.

Original reference position " "

(From the Interior side)

5-1/2, A5R, B5R, A4R/A5,

8.5", B4R/B5, 11", A3R/A4

(From the left side)

5-1/2, A5, B5, A4/A5R, 8-1/2,

B5R, 11", A4R, 13", 14", B4R,

A3R, 17"

Book marks are at A4 and

8-1/2 positions.

(4) DSPF/SPF

Type DSPF One-scan-dual-side scanning

method DSPF with OC

integrated

Scan speed Standard mode 45 opm

High quality mode 22.5 opm

Original

alignment

Original size A3, B4, A4, A4R, B5, B5R, A5, A5R

Original

paper

weight

Original

stack

capacity

Not

transportable

original type

Original size

detection

Sizes to be

detected

Original tray

guide

display

Center alignment

11"x17", 8.5"x14", 8.5"x13", 8.5"x11",

8.5"x11"R,5.5"x8.5", 5.5"x8.5"R, 8K, 16K, 16KR

(Long size original up to 800mm in FAX, e-mail and

iFAX mode)

50~128g/m², 15~34lbs

Max. 50 sheets

(Max. 30 sheets for A3, B4,11" x 17",8.5" x 14")

(Max. 15 sheets for A3, B4, 11" x 17", 8.5" x 14"

over 105g/m²)

or, Total thickness less than

Max. 6.5mm (at 50 to 80g/m², 15 to 21lbs)

Max. 5.0mm (at 80 to 128g/m², 21 to 34lbs)

Transparency film, secondary original paper,

tracing paper, carbon paper, thermal paper,

original with crumple/crimp/rip,

original with attachment/clipping,

original with many punch holes

(with 2 or 3 holes acceptable),

original preprinted with ink-ribbon.

Provided

Automatic (one detection unit to be used with

software modification by destination)

Inch-1 11" x 17", 8.5" x 14",

Inch-2 11" x 17", 8.5" x 13",

AB-1 A3, B4, A4, A4R, B5, B5R,

AB-2 A3, B4, A4, A4R, B5, B5R,

Center of the tray

(inscribeddisplay)

Original Guide

(inscribed display)

The position available to attach the staple position

guide label when the optional finisher (desktop

console type) is equipped.

8.5" x 11", 8.5" x 11"R,

5.5" x 8.5", A4, A3

8.5" x 11", 8.5" x 11"R,

5.5" x 8.5", A4, A3

A5, A3, 8.5" x 11", 11" x 17"

216 x 330 mm

A5, 8.5" x 11", 11" x 17",

216 x 330 mm

Original reference position

" " Original face-down

placement indication " "

(From Center)

B5R, A4R/A5, 8.5",

B4R/B5, 11", A3R/A4

(5) Power Source

Supplied from the main unit

(6) Dimensions

External dimensions

(WxDxH)

Occupied space

dimensions (WxD)

Weight Approx. 19.5 kg

808 x 619x180 mm

945 x 619 mm

(When the tray is extended)

(7) Display device at scanner part

Type Dot map LCD, touch panel

Display dot number 640 x 240 dots (dot pitch 0.24x0.24 mm)

LCD operating

dimension

LCD back-light Fluorescent tube method

LCD brightness

adjustment

153.5 x 57.5 mm

Provided

(8) Key

Mode

selection area

Basic input

area

* For pirnter

Job status key

Document filing key

(* online display LED/data in-memory display

LED)

Image send key

(busy display LED/data in-memory display LED)

Copy mode key

User definition key

Start key

CA key

10-key

Clear key

∗ key

#/P key

(9) Touch sense method

Resistive film method

(10) Used character in the LCD

Dot 8 x 16 , 16 x 16 dots

Bold display O

4. Rack for Scanner

(1) Dimensions

Strength 60 kg

External dimensions

(W x D x H)

Occupied space

dimensions (W x D)

Weight Approx.5 kg (2pieces)

30 x 415 x 860 mm (Single goods)

575 x 415 mm (State of installation)

(2pieces)

AR-M355N/M455N SPECIFICATIONS 3 - 9

[4] CONSUMABLE PARTS

1. Supply system table

A. USA/CANADA

NO Name Content Life Product name Remark

1 Toner cartridge (Black) Toner cartridge (with IC)

(Toner : Net weight 750 g)

2 Developer (Black) Developer

(Developer : Net weight 500 g)

3 Drum OPC drum x1 200k AR-455DR

4 50K maintenance kit Cleaner blade

Drum separation pawl

Screen grid

Toner reception seal

Side malt F

Side malt R

Charging plate

5 100K maintenance kit Transfer roller

Discharging plate

Paper dust removing unit

DV blade

DV side seal F

DV side seal R

6 Upper heat roller kit Upper heat roller

Fusing separation pawl (Upper)

7 Lower heat roller kit Lower heat roller

Fusing separation pawl (Lower)

8 Cleaner blade Cleaner blade x10 50K(x10) AR-450CB AR-450CB=(AR-450BL)x10

9 Cleaning roller Cleaning roller

Bearing

10 Staple cartridge Staple cartridge x3 3000x3 AR-SC1 Common with cartridge for AR-

11 Staple cartridge Staple cartridge x3 5000x3 AR-SC2

Note 1: Print on Master/individual carton:Toner/Developer in 2 languages (English/French), DR in 4 languages (English/French/German/

Spanish).

Note 2: Packed with machine: DR 50K/Developer UN/Process UN

Note 3: The other maintenance parts which are not listed above are registered as service parts.

x 10 350k (35k

x 10)

x 10 1000k

(100k x 10)

x1

50K AR-450KC1

x4

x1

x1

x1

x1

x1

x1

100K AR-450KA1

x1

x1

x1

x1

x1

x1x4200K AR-450UH

x1x2200K AR-450LH

x10

200K(x10) AR-450CR AR-450CR=(AR-450RC)x10

x20

AR-455MT *Life setup is based on A4 6%

AR-455MD

FN4 & AR-FN6

Common with cartridge for AR-FN7

AR-M355N/M455N CONSUMABLE PARTS 4 - 1

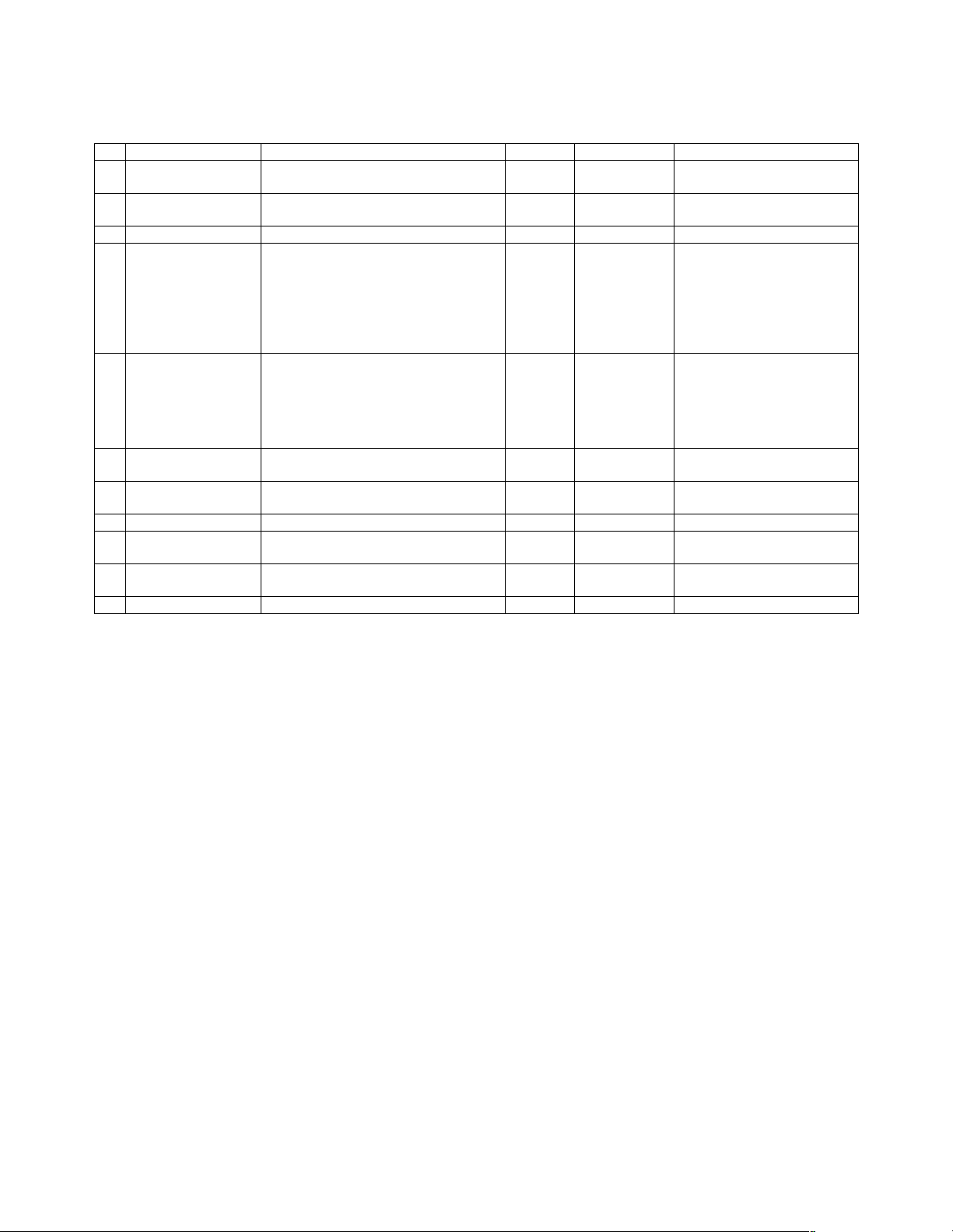

2. Production number identification

A. Drum cartridge

The lot number, printed on the front side flange, is composed of 10

digits, each digit showing the following content:

C. Developer cartridge

The lot number is of 8 digit, and each digit indicates as follows.

The lot number shall be printed on the bag.

12345678

12345678910

1 Number

For this model, this digit is 2.

2 Alphabet

Indicates the model conformity code. T for this model.

3 Number

Indicates the end digit of the production year.

4 Number or X, Y, Z

Indicates the production month.

X stands for October, Y November, and Z December.

5/6 Number

Indicates the production day on the month.

7 Number or X, Y, Z

Indicates the month of packing.

X stands for October, Y November, and Z December.

8/9 Number

Indicates the day of the month of packing.

10 Alphabet

Indicates the production factory. "A" for Nara Plant.

B. Toner cartridge

The lot number is of 7 digits, and each digit indicates as follows.

The lot number shall be printed in the position shown in the figure.

12 34567

1 Version number (A - sequentially revised)

2 Numeral figure

Indicates the end digit of the production year.

3 Alphabet

Indicates the production factory. (B for SOCC)

4 Destination code

5,6 Numeral figures

Indicates the production day.

7 Numeral figure or X, Y, Z

Indicates the production month.

X stands for October, Y November, and Z December.

1 Alphabet

Indicates the production factory.

2 Number

Indicates the production year.

3/4 Number

Indicates the production month.

5/6 Number

Indicates the production day.

7 Hyphen

8 Number

Indicates the production lot.

3. Environmental conditions

A. Operating conditions

85%

85

Humidity (%)

20

10 35

Temperature

B. Storage conditions

90

30

35

(Without dew condensation)

60%

Aluminum bag

Serial No. attachment

Serial No. attachment

AR-M355N/M455N CONSUMABLE PARTS 4 - 2

Heat seal

Humidity (%)

20

-10 40

Temperature

(Without dew condensation)

[6] UNPACKING AND INSTALLATION

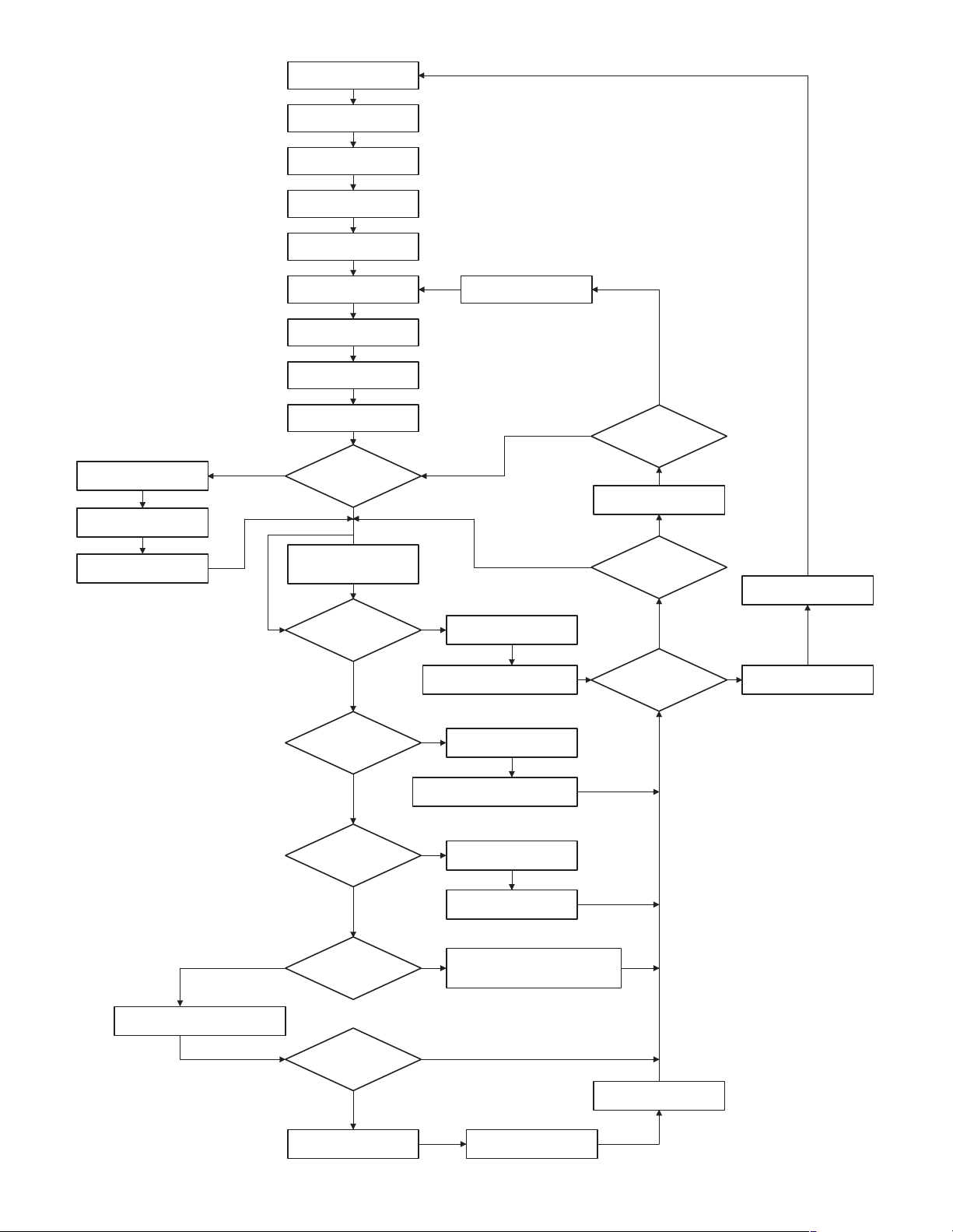

1. Installing procedure flowchart

There are many combinations between this machine and option

units. For installing option units, observe the following procedures

for efficiency.

To install the devices effciently, follow the procedure below.

Some peripheral devices may have been installed as standard

devices depending on the main unit model.

Part of descriptions and illustrations may be different.

Finishing device

Start of installation

Scanner/document feeder device

Main unit

Paper feeding deviceDuplex device Paper feeding device

Finishing device

Finishing device

Duplex/bypass device

Main unit

Main unit, paper feeding

device, and power supply

unit.

AR-MU2

AR-D27

AR-D28

Main unit

[Electrical setting/adjustment]

1) Installation of driver software, setting,

and operation check

Main unit/AR-EF3/AR-FX12/AR-PK6/AR-NS3

2)

Paper guide position adjustment/off center adjustment

AR-MU2/AR-D27/AR-D28/

AR-DU3/AR-DU4

When installing a paper feeding device or a duplex/bypass device, be sure to reattach

the rear cabinet, the AC inlet cover, and the harness cover of the main unit at the end

of installation as needed.

When installing a controller board, a facsimile unit, and other electric devices, be sure to install them

at a time.

Only off center adjustment is needed for AR-DU3.

Duplex/bypass

device installed?

No

Finishing device

installed?

No

Scanner/document

feeder installed?

No

Yes

Yes

Yes

Install duplex/pypass device.

AR-DU3

AR-DU4

Install finishing device.

AR-MS1

AR-FN6

AR-FN7

AR-PN1A / B / C / D

Install scanner/document feeder.

AR-EF3/AR-RK2

∗ For installation of an option unit, refer to the Service Manual of the option unit.

Controller board,

facsimile unit or other

electric devices

installed?

No

End

Yes

Install controller board,

facsimile unit or other electric

devices.

AR-FX12/AR-MM9

AR-PK6

AR-NS3

Extended memory

AR-M355N/M455N UNPACKING AND INSTALLATION 6 - 1

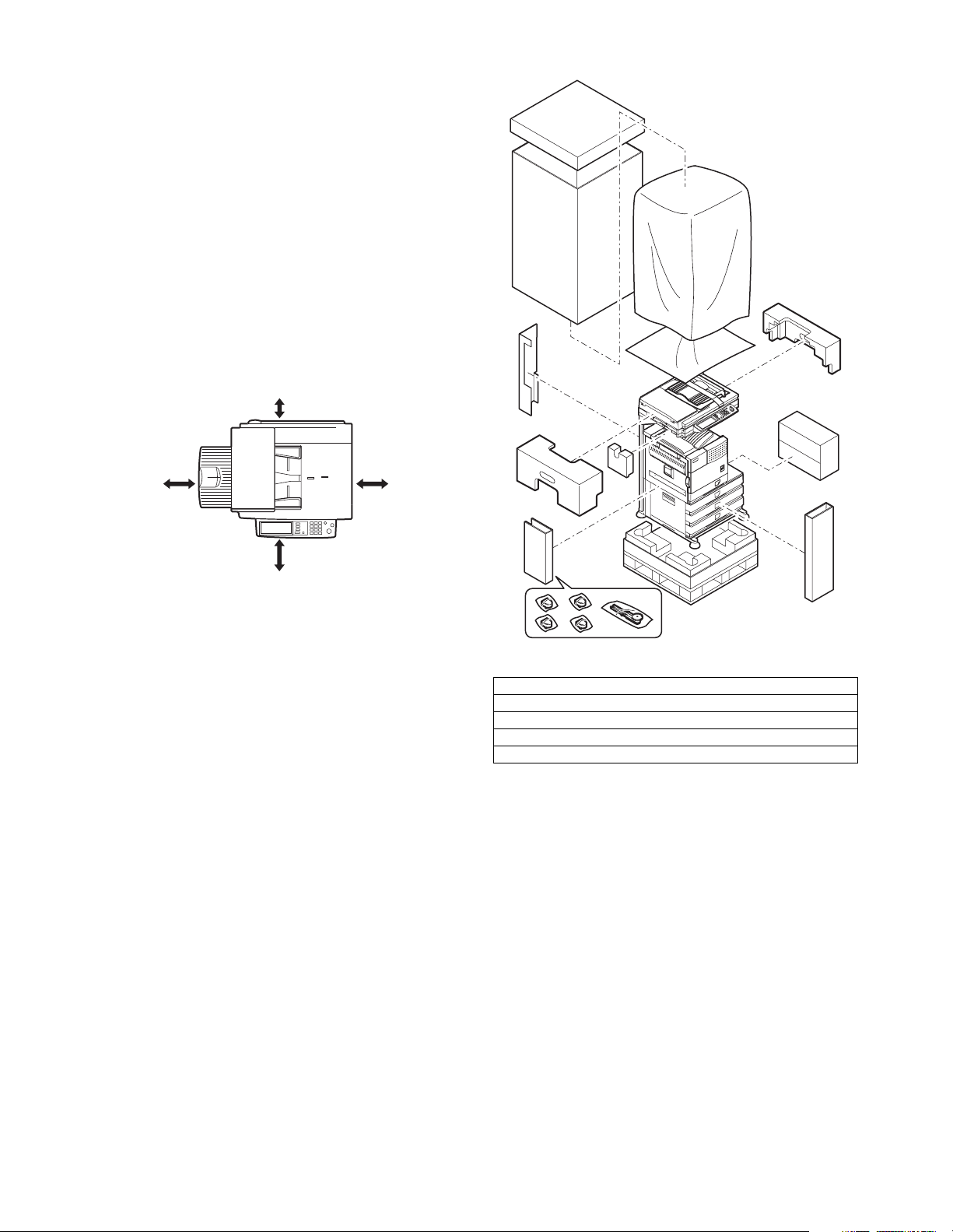

2. Note for installation place

Improper installation may damage this product. Please note the

following during initial installation and whenever the machine is

moved.

1) The machine should be installed near an accessible power

outlet for easy connection.

2) Be sure to connect the power cord only to a power outlet that

meets the specified voltage and current requirements. Also

make certain the outlet is properly grounded.

• For the power supply requirements, see the name plate of

the main unit.

3) Do not install your machine in areas that are:

• damp, humid, or very dusty

• exposed to direct sunlight

• poorly ventilated

• subject to extreme temperature or humidity

changes, e.g., near an air conditioner or heater.

4) Be sure to allow the required space around the machine for

servicing and proper ventilation.

11-13/16" (30cm)

3. Unpacking procedure

31-1/2"

(80cm)

23-5/8"

(60cm)

23-5/8" (60cm)

Check the following items are included in the package.

Operating Manual (Common/Copier/Key Operation)

Install Guide

CD-ROM for Printer

CD-ROM for Network Interface

Maintenance card/Maintenance case

AR-M355N/M455N UNPACKING AND INSTALLATION 6 - 2

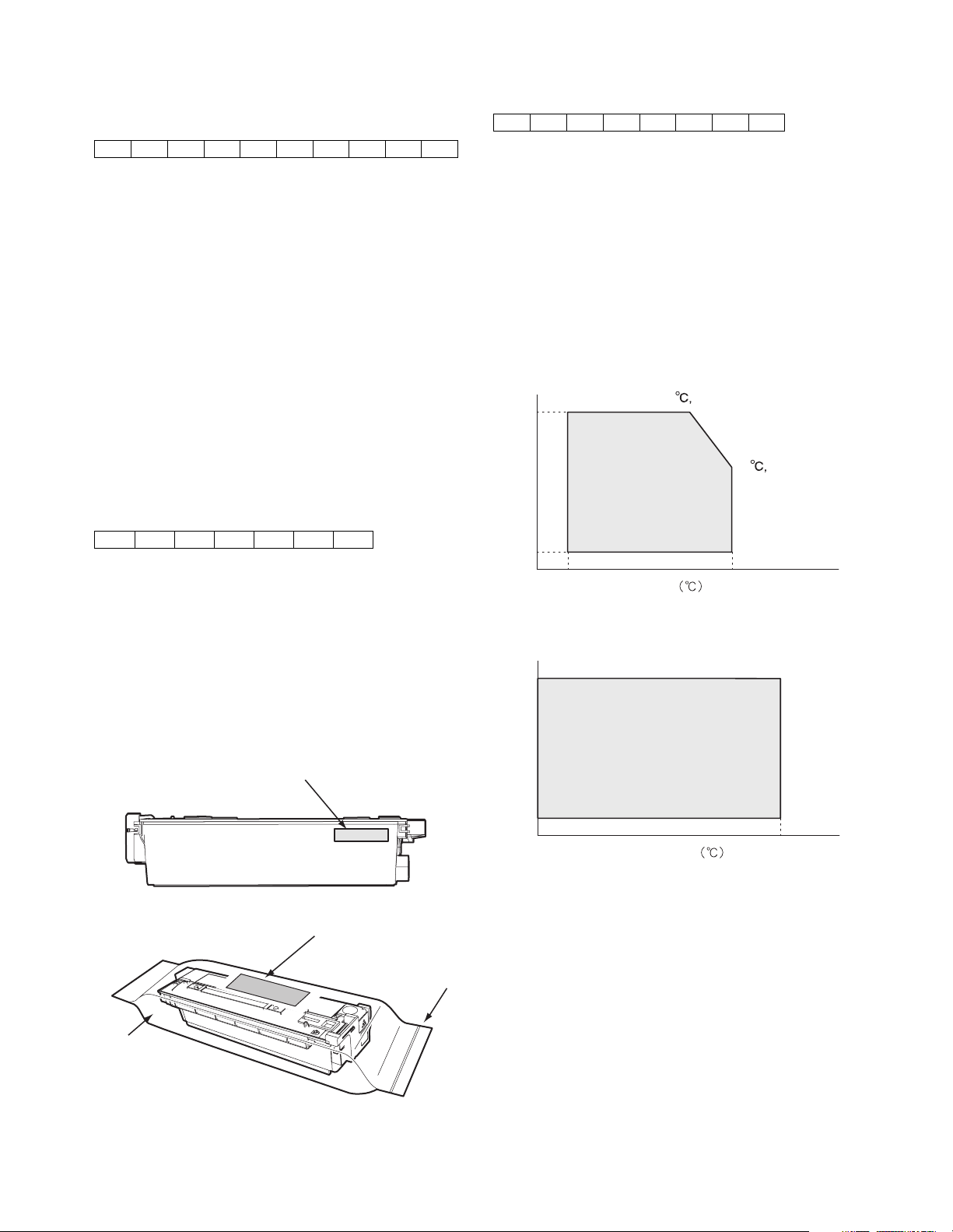

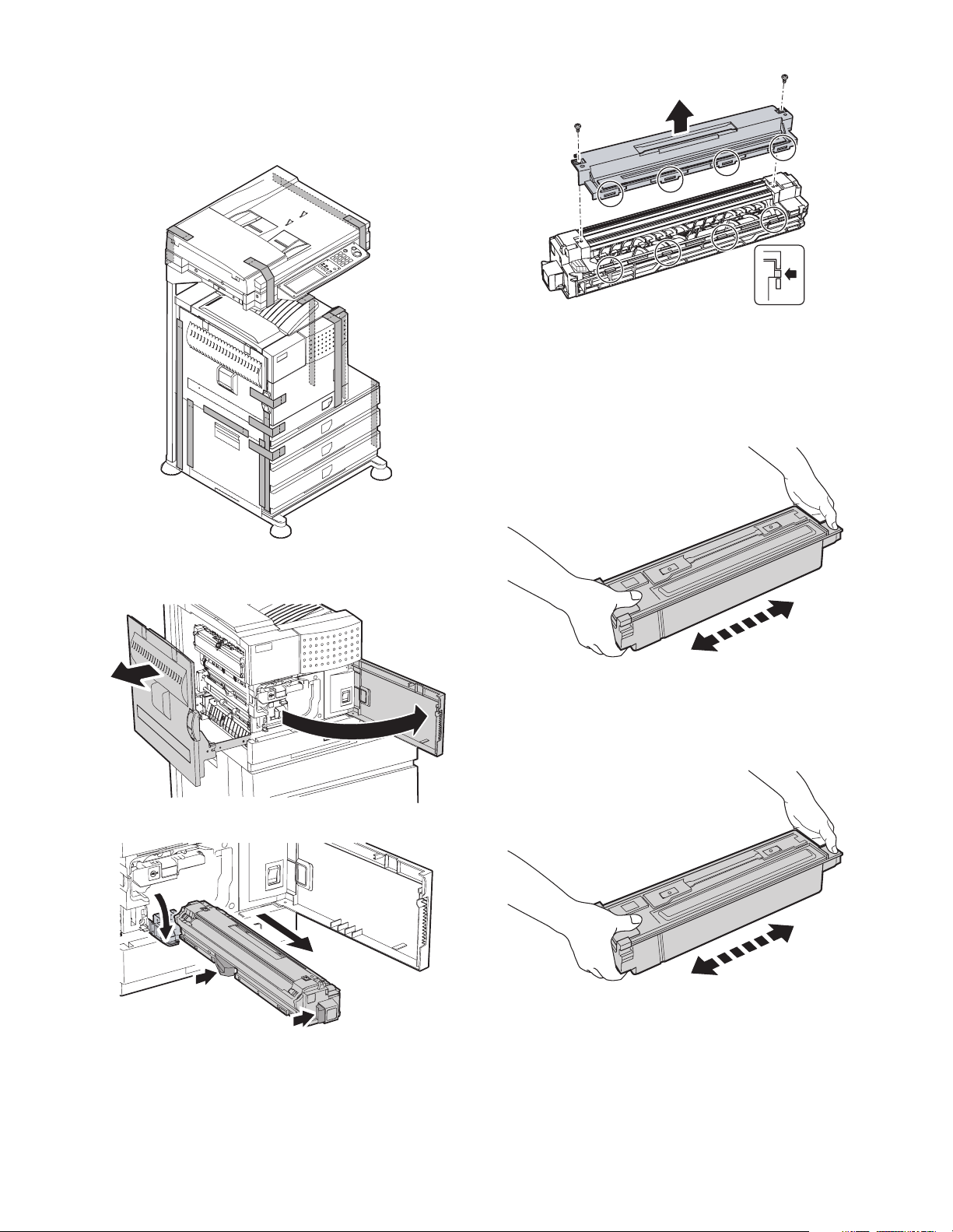

4. Machine installing procedure

Note: In advance to installation of the machine, the paper feed

option units (AR-D27/AR-D28/AR-MU2) should have been

installed.

A. Remove the locking tape

3) Remove the top cover of the developer cartridge.

4) While rotating the MG roller, supply developer into the developer cartridge evenly.

Note that the MG roller must be rotated in the arrow direction

as shown in the figure below.

Use of a metal scale or a screwdriver (-) facilitates the procedure.

Note: Before opening the developer seal, shake it 4 or 5 times.

B. Setting related to process

1) Open the left door and the front door.

2) Remove the developer cartridge from the machine.

5) Attach the top cover to the developer cartridge and install the

cartridge to the machine.

C. Toner cartridge settings

1) Remove a new toner cartridge from the package and shake it

horizontally five or six times.

AR-M355N/M455N UNPACKING AND INSTALLATION 6 - 3

2) Insert a new toner cartridge.

Push the cartridge in until it locks securely into place.

3) Gently remove the sealing tape from the cartridge.

D. Setting related to fusing

1) Put down the right and the left levers of the fusing unit in the

arrow direction.

E. Paper setting

1) Pull out the first stage paper feed tray.

Slowly pull out the tray until it stops.

4) Return the cartridge lock lever.

2) While pressing the paper holding plate, remove the fixing pin.

AR-M355N/M455N UNPACKING AND INSTALLATION 6 - 4

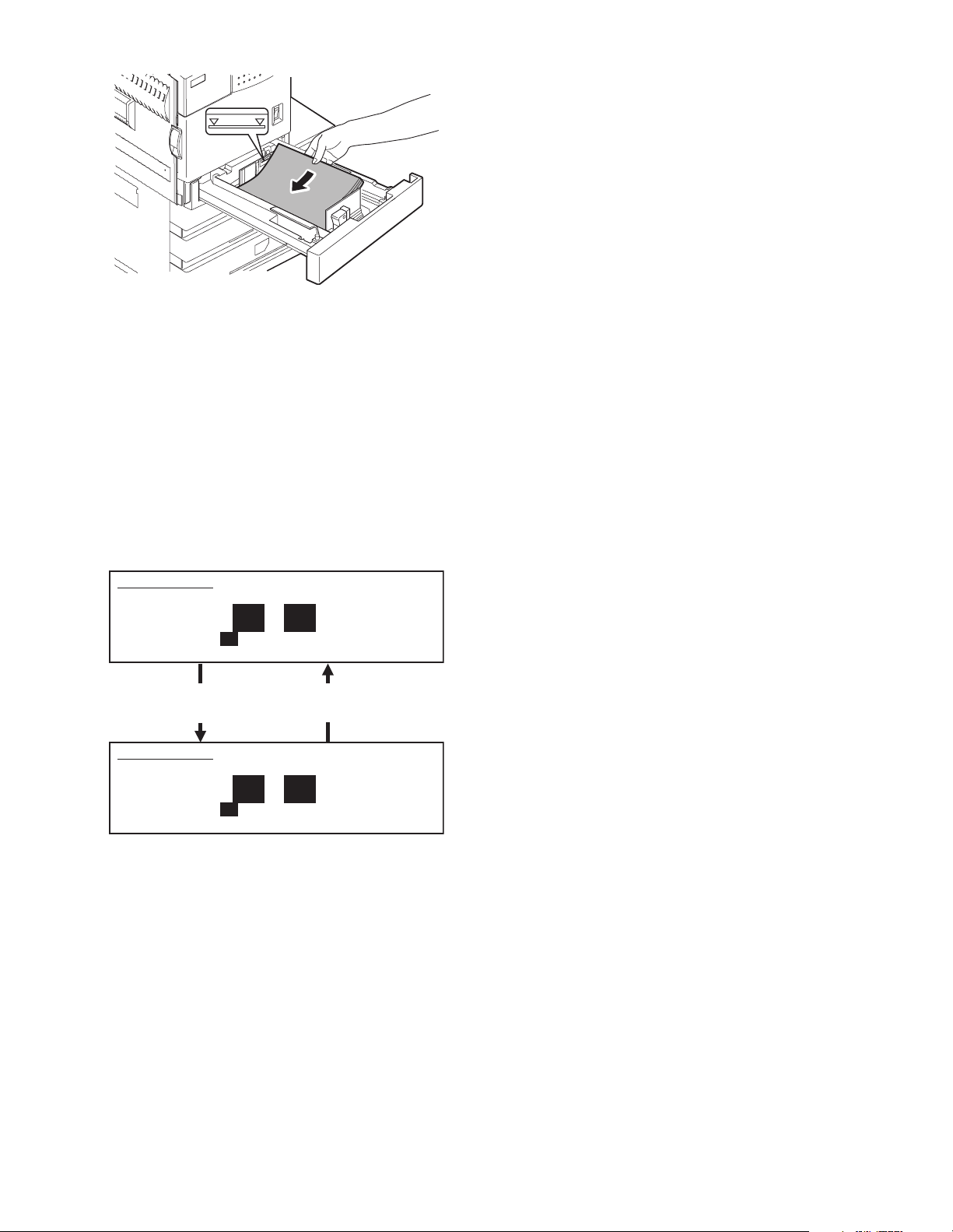

3) Put paper in the tray, and close the paper feed tray.

5. Automatic developer adjustment

1) Attach the cabinets which were removed.

2) Close the left door.

At that time, keep the front door open.

Note: The automatic developer adjustment must be performed by

entering the simulation mode with the front door open. If the

power is turned on with the front door closed, warm-up is

performed to supply toner to the developing unit. As a

result, the reference toner density cannot be obtained.

3) Insert the power plug into the power outlet.

4) Go through the modes specified in Simulation 25-2.

5) Close the front door.

(LCD Display)

6. Print test

1) After completion of warm-up (normal mode), select [CUSTOM

SETTINGS]

2) Print [ALL SETUP LIST] to check and confirm the print quality.

3) Press the [CUSTOM SETTINGS] key again to return to the

normal menu.

→ [Data list up] to display the menu.

SIMULATION 25-2

AUTOMATIC DV ADJUSTMENT. PRESS START.

HUMIDITY AREA: 70.0 - 72.5

TEMPERATURE AREA: 70.0 - 72.5

DEVE REFERENCE: 128

Press [START] key. Press [CUSTOM SETTINGS] key, and the

SIMULATION 25-2

AUTOMATIC DV ADJUSTMENT. EXECUTING···.

HUMIDITY AREA: 70.0 - 72.5

TEMPERATURE AREA: 70.0 - 72.5

DEVE REFERENCE: 118

operation is stopped immediately or after 3 min.

6) Press the [START] key, and the automatic developer adjustment will be performed.

During execution of the automatic developer adjustment,

“EXECUTING...” is displayed and the toner sensor value is

indicated on the LCD. (DEVE REFERENCE)

7) After about 2 min, the adjustment value is stored in the

machine. Check that the mode was normally completed.

Normal end: Returns to the initial window (PRESS

START display).

Abnormal end: Returns to the initial window (PRESS

START display), and indicates the trouble

display (TROUBLE! EE-**).

In case of an error end, remove the cause of the error, and

execute the automatic developer adjustment again.

8) Turn off/on the power, and the machine returns to the normal

mode and enters the warm-up mode.

AR-M355N/M455N UNPACKING AND INSTALLATION 6 - 5

[7] DISASSEMBLY AND ASSEMBLY, MAINTENANCE

1. Self print of set values

Use of SIM 22-6 allows to print the set values and the jam history of the machine.

These values must be printed before execution of maintenance or disassembly procedures.

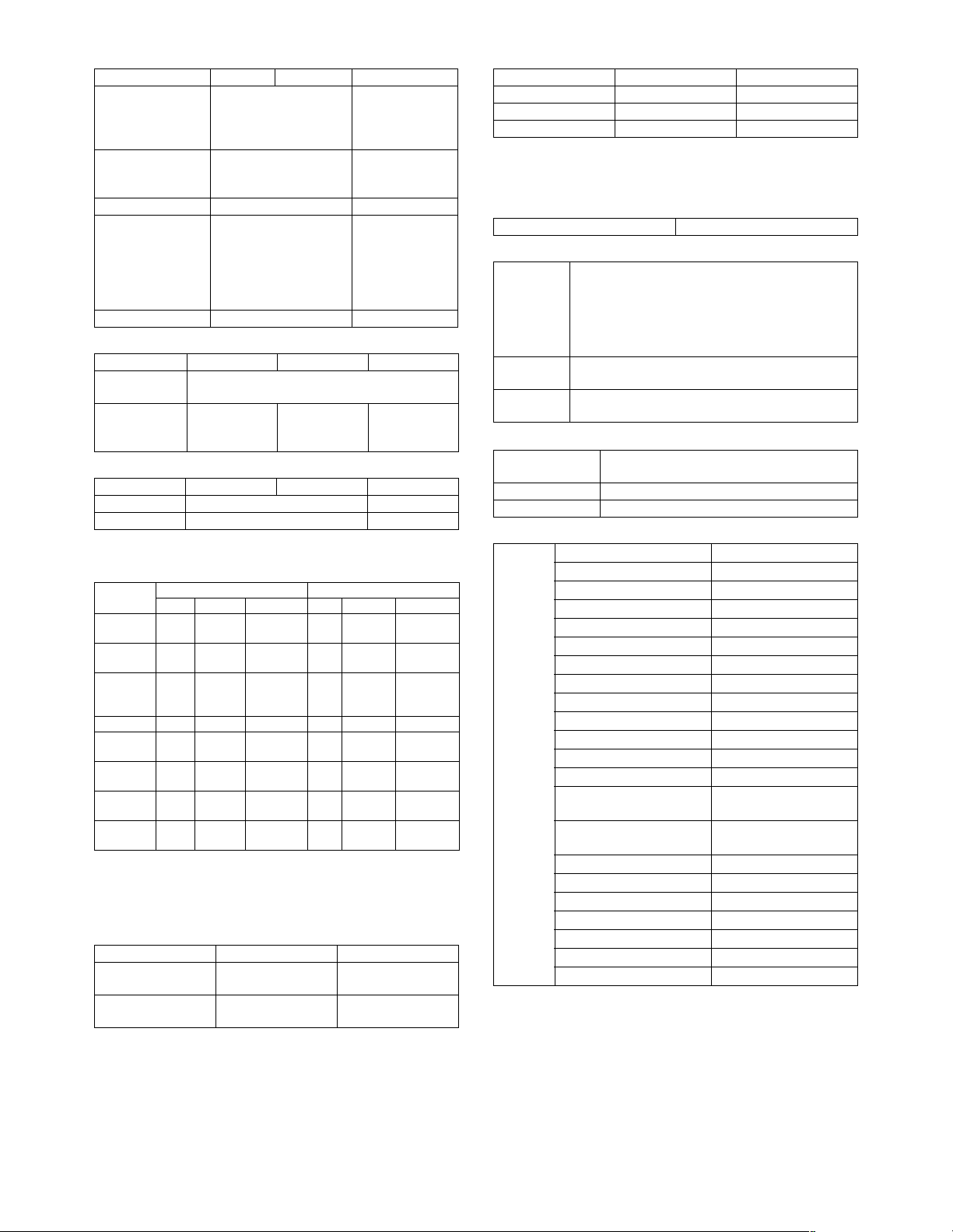

2. Maintenance System Table

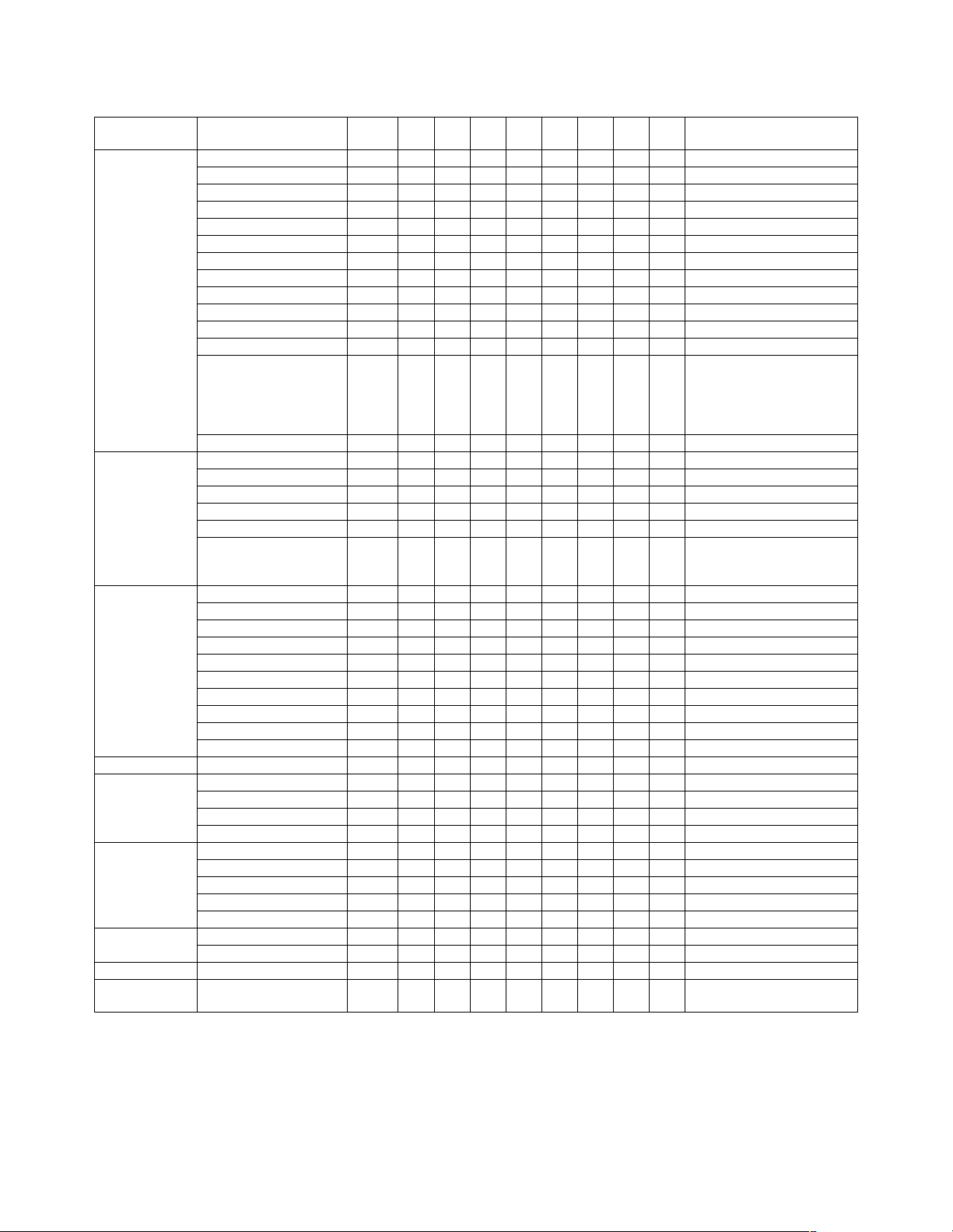

A. Scanner / DSPF

Maintenance cycle : 200K

✕ Check (Clean, replace, or adjust as necessary.) ❍ Clean ▲ Replace ∆ Adjust ✩ Lubricate ❏ Move position

Unit name Part name

Optical

section

DSPF Paper feed

Note 2: Replacement reference: Replace by using the SPF counter value as an indication.

Mirror/Lens/Reflector/Sensors ❍ ❍❍❍❍❍❍❍❍

Table glass/Dust-proof glass/OC ❍ ❍❍❍❍❍❍❍❍

White reference glass ❍ ❍❍❍❍❍❍❍❍

Rails ✩✩✩✩✩✩✩✩

Drive belt/Drive wire/Pulley ✕✕✕✕✕✕✕✕

Pick-up roller ❍ ❍❍❍❍❍❍❍❍Note 2

section

Transport section PS roller ❍ ❍❍❍❍❍❍❍❍

Paper exit

section

Other Sensors ❍❍❍❍❍❍❍❍For cleaning, blow air.

Paper feed roller ❍ ❍❍❍❍❍❍❍❍Note 2

Separation mylar lower ❍ ❍❍❍❍❍❍❍❍Note 2

Separation pad ❍ ❍❍❍❍❍❍❍❍Note 2

Exposure section

(Dust-proof glass)

Paper exit roller ❍ ❍❍❍❍❍❍❍❍

Paper feed section pickup roller, paper feed roller, separation pad, separation lower mylar lower:

100K or 1 year

When

100K 200K 300K 400K 500K 600K 700K 800K Remark

calling

❍ ❍❍❍❍❍❍❍❍

AR-M355N/M455N DISASSEMBLY AND ASSEMBLY, MAINTENANCE 7 - 1

B. Engine section

Maintenance cycle : 200K

✕ Check (Clean, replace, or adjust as necessary.) ❍ Clean ▲ Replace ∆ Adjust ✩ Lubricate ❏ Move position

Unit name Part name

Drum peripheral Drum ✕▲✕▲✕▲✕▲Replace at 200K or 1 year.

Cleaner blade ✕▲✕▲✕▲✕▲

Toner reception seal ✕▲✕▲✕▲✕▲

Side molt F ✕▲✕▲✕▲✕▲

Side molt R ✕▲✕▲✕▲✕▲

Transfer roller ✕ ✕▲✕▲✕▲✕▲

Discharge plate ✕ ✕▲✕▲✕▲✕▲

TR bearing (F/R) ✕✕✕▲✕✕✕▲

Transfer roller collar ✕✕✕▲✕✕✕▲

After-transfer star ring ✕✕✕✕✕✕✕✕

TR gear ✕ ✕▲✕▲✕▲✕▲

Drum separation pawl unit ✕▲✕▲✕▲✕▲

MC unit ✕ ❍▲❍▲❍▲❍▲Includes the screen grid, the

Paper guide ❍ ❍❍❍❍❍❍❍❍

Developing

section

Fusing section Upper heat roller ✕ ✕▲✕▲✕▲✕▲

Filters Ozone filter ▲▲▲▲▲▲▲▲

Paper feed

section

Transport section

Paper exit

reverse section

Drive section Gears (Specified position) ✕ ✩✩✩✩✩✩✩✩

Image quality ✕ ✕✕✕✕✕✕✕✕

Other Sensors ✕✕✕✕✕✕✕✕Cleaning is performed by air

Developer ▲▲▲▲▲▲▲▲Supplied when installing

DV blade ✕▲✕▲✕▲✕▲

DSD collar ❍❍❍❍❍❍❍❍

DV side seal F ✕▲✕▲✕▲✕▲

DV side seal R ✕▲✕▲✕▲✕▲

Toner cartridge ––––––––

Lower heat roller ✕ ✕▲✕▲✕▲✕▲

Upper separation pawl ❍ ❍▲❍▲❍▲❍▲

Lower separation pawl ❍ ❍▲❍▲❍▲❍▲

Thermistor ✕ ✕✕✕✕✕✕✕✕Clean and remove paper dust.

Upper heat roller gear ✕▲✕▲✕▲✕▲

Paper guides ❍ ❍❍❍❍❍❍❍❍

Gears ✩✩✩✩✩✩✩✩

CL roller ✕ ✕▲✕▲✕▲✕▲

CL roller bearing ✕ ✕▲✕▲✕▲✕▲

Pick-up roller ✕ ✕✕✕✕✕✕✕✕Note 1

Paper feed roller ✕ ✕✕✕✕✕✕✕✕Note 1

Separation roller ✕ ✕✕✕✕✕✕✕✕Note 1

Torque limiter ✕ ✕✕✕✕✕✕✕✕Note 1

PS follower roller ✕ ❍❍❍❍❍❍❍❍

Transport rollers ✕ ❍❍❍❍❍❍❍❍

Transport paper guides ❍ ❍❍❍❍❍❍❍❍

Paper dust remover unit ❍ ❍▲❍▲❍▲❍▲

Optical reflection sensor ❍ ❍❍❍❍❍❍❍❍PS roller unit section

Belts ✕ ✕✕✕✕✕✕✕✕

When

100K 200K 300K 400K 500K 600K 700K 800K Remark

calling

charging plate, and the MC

cleaner.

❍: Charging plate cleaning by

the MC cleaner

Attached when installing./

750g, user replacement for

every 35K.

blowing.

Note 1: Replacement reference:Use the counter value of each paper feed port as the replacement reference.

Paper feed roller/Separation pad/Torque limiter section (Include Desk, Multi purpose): 100K or 1 years

AR-M355N/M455N DISASSEMBLY AND ASSEMBLY, MAINTENANCE 7 - 2

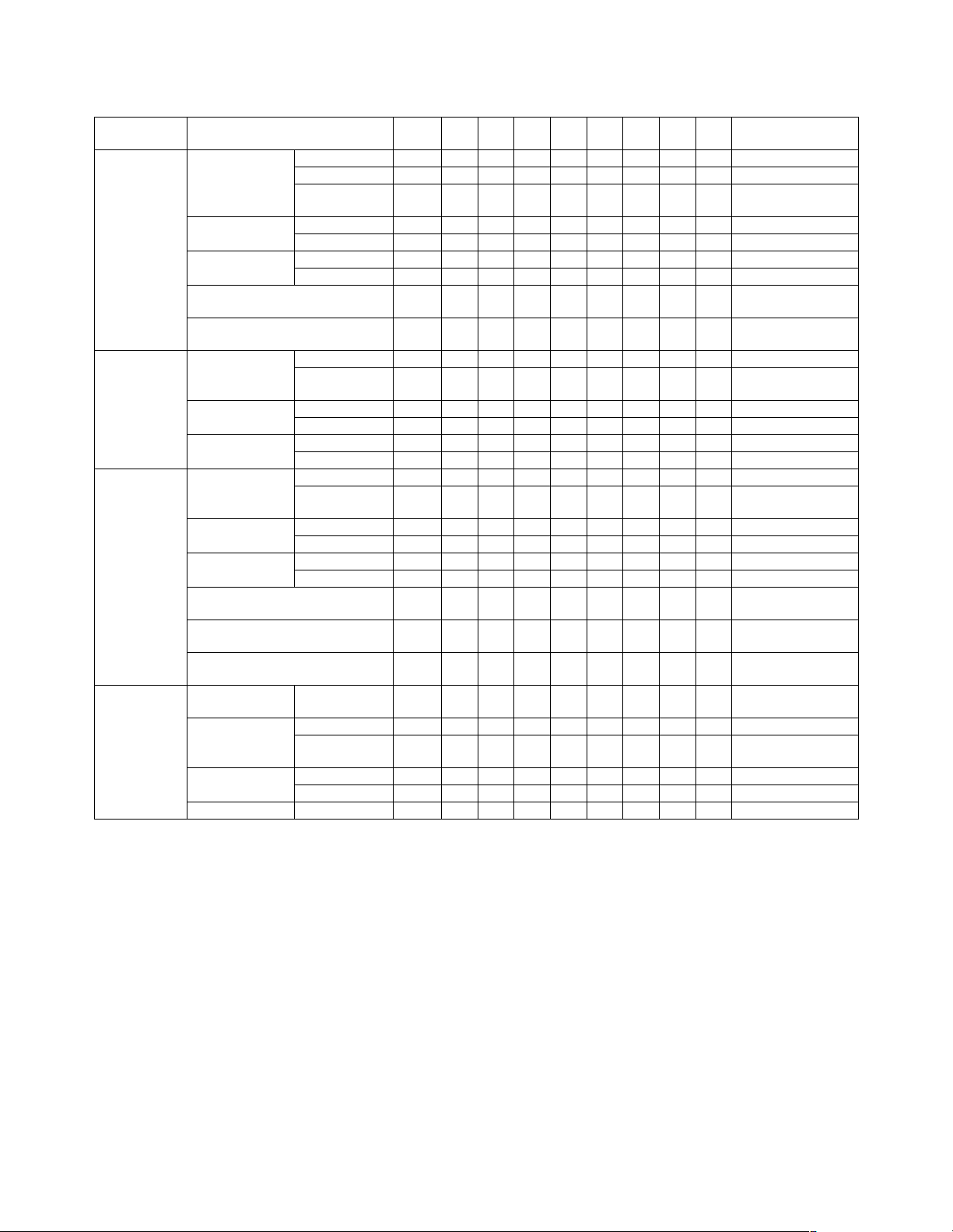

C. Peripheral devices

Maintenance cycle : 50K

✕ Check (Clean, replace, or adjust as necessary.) ❍ Clean ▲ Replace ∆ Adjust ✩ Lubricate ❏ Move position

Option name Part name

Finisher Transport section Transport rollers ❍ ❍❍❍❍❍❍❍❍

De-curler roller (❍)✕❍❍❍❍❍❍❍❍

Transport paper

guides

Drive section Gears ✕ ✩✩✩✩✩✩✩✩(Specified position)

Belts ✕ ✕✕✕✕✕✕✕✕

Other Sensors ✕ ✕✕✕✕✕✕✕✕

Discharge brush ✕ ✕✕✕✕✕✕✕✕

Staple unit Replace unit

Staple cartridge User replacement

Mail-bin

stacker

Saddle finisher,

punch unit

ADU

+ Manual feed

Note 3: Replacement reference: Use the counter value of each paper feed port as the replacement reference.

Transport section Transport rollers ✕ ❍❍❍❍❍❍❍❍

Transport paper

guides

Drive section Gears ✕ ✩✩✩✩✩✩✩✩(Specified position)

Belts ✕ ✕✕✕✕✕✕✕✕

Other Sensors ✕ ✕✕✕✕✕✕✕✕

Discharge brush ✕ ✕✕✕✕✕✕✕✕

Transport section Transport rollers ✕ ❍❍❍❍❍❍❍❍

Transport paper

guides

Drive section Gears ✕ ✩✩✩✩✩✩✩✩(Specified position)

Belts ✕ ✕✕✕✕✕✕✕✕

Other Sensors ✕ ✕✕✕✕✕✕✕✕

Discharge brush ✕ ✕✕✕✕✕✕✕✕

Staple unit Replace unit at 300K

Staple cartridge User replacement

Punch unit Replace unit at

Paper feed

separation section

Transport section Transport rollers ✕ ❍❍❍❍❍❍❍❍

Drive section Gears ✕ ✩✩✩✩✩✩✩✩(Specified position)

Other Sensors ✕ ✕✕✕✕✕✕✕✕

Paper feed

rollers

Transport paper

guides

Belts ✕ ✕✕✕✕✕✕✕✕

Paper feed section pickup roller, paper feed roller, separation pad: 100K or 1 year

When

100K 200K 300K 400K 500K 600K 700K 800K Remark

calling

✕ ❍❍❍❍❍❍❍❍

✕ ❍❍❍❍❍❍❍❍

✕ ❍❍❍❍❍❍❍❍

(❍)✕ (❍)✕ (❍)✕ (❍)✕ (❍ )✕ (❍)✕ (❍)✕ (❍)✕ (❍)✕ Note 3

✕ ❍❍❍❍❍❍❍❍

at 200K staple.

for every 3000 pcs.

staple.

for every 5000 pcs.

1000K.

AR-M355N/M455N DISASSEMBLY AND ASSEMBLY, MAINTENANCE 7 - 3

[9] SIMULATION

1. Outline and purpose

The simulation has the following functions to grasp the machine

operating status, identify the trouble position and causes in an earlier stage, and make various setups and adjustments speedily for

improving the serviceability of the machine.

1) Various adjustments

2) Setup of specifications and functions

3) Canceling troubles

4) Operation check

5) Various counters check, setup, and clear

6) Machine operating status (operation history) data check, clear

7) Transfer of various data (adjustments, setup, operations,

counters)

The operating procedures and the displays differ depending on the

form of the operation panel of the machine.

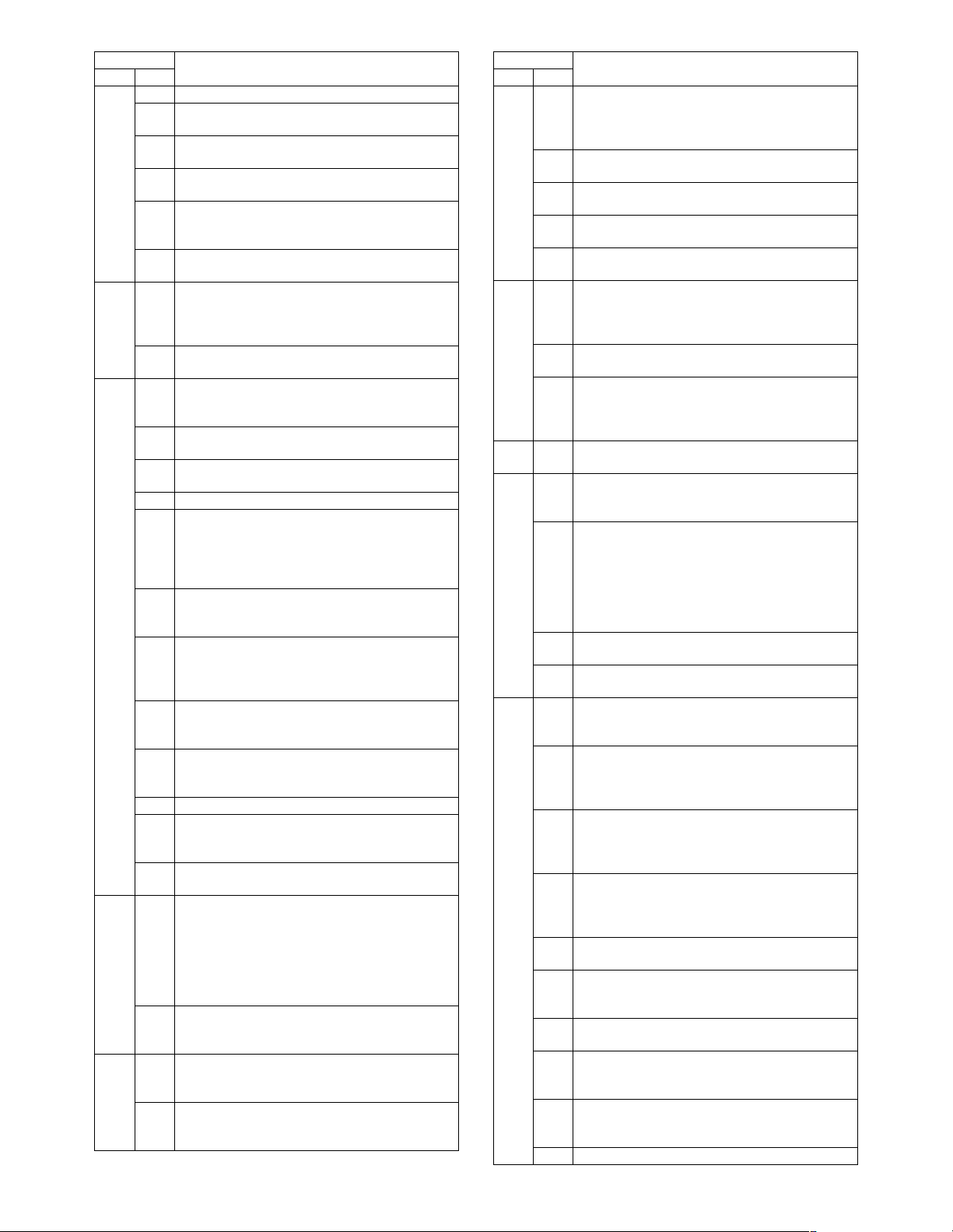

2. Code-type simulation

A. Operating procedures and operations

∗ Entering the simulation mode

Program key ON → Asterisk (*) key ON

1) Copy mode key ON

CLEAR key ON → Asterisk (*) key ON → Ready for input of

→

a main code of simulation

2) Entering a main code with the 10-key

3) Entering a sub code with the 10-key

4) Select an item with the scroll key and the item key.

5) The machine enters the mode corresponding to the selected

item.

Press START key or EXECUTE key to start the simulation

operation.

To cancel the current simulation mode or to change the main

code and the sub code, press the user setup key.

∗ Canceling the simulation mode to return to the normal mode

1) Press CA key.

→

START key ON

→

START key ON

→

AR-M355N/M455N SIMULATION 9 - 1

START (Copy mode)

Press the Program key.

Press the asterisk (*) key.

Press the clear key.

Press the asterisk (*) key.

Standby for entry of SIM

sub code

Enter SIM sub code with

the 10-key.

Press the START button.

Standby for entry of

SIM code.

Enter the main code of

SIM with the 10-key.

The main code of SIM

is displayed.

Press the START button.

YES

Is there a sub code ?

Select the mode and the

item with the scroll key

and the item key.

Operation check ?

Operating conditions

check ?

NO

NO

NO

Press the CUSTOM

SETTINGS key

he

YES

Press the EXECUTE button

and OK button.

Operation is made according

to the selected mode and item.

YES

Press the EXECUTE button

and OK button.

The display is made according to

the selected some and the item.

YES

Press the CUSTOM

NO

to perform another

NO

Is it the same

simulation ?

SETTINGS key

YES

Do you want

simulation ?

NO

Do you

want to end the

simulation ?

The simulation mode

is canceled.

YES

Press the clear all key.

YES

The display is made according

to the selected mode and the item.

Data clear ?

NO

Adjustments

or setting (counter data

change) ?

Do you

want to change the

content ?

YES

Enter the new setting and

adjustment values.

AR-M355N/M455N SIMULATION 9 - 2

YES

Press the EXECUTE button

and OK button.

The selected mode and

the item are cleared.

Operation is made according

NO

to the selected mode and the item.

NO

(Other modes)

Press the EXECUTE button

and OK button.

The changed content

is stored.

B. Simulation list

(1) Main/ Sub

Code

Main Sub

1 1 Used to check the operations of the scanner

(read) unit and its control circuit.

2 Used to check the operation of sensor and

detector in the scanning (read) section and the

related circuit.

2 1 Used to check the operations of the automatic

document feeder unit and the control circuit.

2 Used to check the operations of the sensors and

detectors in the automatic document feeder unit

and the related circuits.

3 Used to check the operations of the loads in the

automatic document feeder unit and the control

circuits.

3 2 Used to check the operation of sensor and

detector in the finisher and the related circuit.

3 Used to check the operation of the load in the

finisher and the control circuit.

6 Used to adjust the stacking capacity of the

finisher. (Used to adjust the alignment plate

(jogger) stop position in the finisher paper width

direction. The adjustment is made by changing

the alignment plate home position in the paper

width direction by software.)

10 Console finisher adjustment

20 Used to check the mail bin stacker sensor.

21 Used to check the operations of the mail bin

stacker loads.

4 2 Used to check the operations of the sensors and

detectors in the paper feed section (desk paper

feed/large capacity tray) and the related circuit.

3 Used to check the operations of the loads in the

paper feed section (desk paper feed/large

capacity tray) and the related circuit.

5 1 Used to check the operation of the display, LCD

in the operation panel, and control circuit.

2 Used to check the operation of the heater lamp

and the control circuit.

6 1 Used to check the operation of the paper

transport system loads and the control circuit.

2 Used to check the operations of each fan motor

and its control circuit.

7 1 Used to set the operating conditions of aging.

6 Used to set the intermittent aging cycle.

8 Used to set the warm-up time display YES/NO.

8 1 Used to check and adjust the operations of the

developing voltage of each color and the control

circuit.

2 Used to check and adjust the operation of the

main charger grid voltage in each printer mode

and the control circuit.

6 Used to check and adjust the operation of the

transfer voltage and the control circuit.

17 Used to check and adjust the operation of the

transfer voltage and the related circuit. (Transfer

belt cleaning mode)

9 1 Used to check and adjust the operation of the

load (clutch/solenoid) in the duplex section and

the control circuit.

2 Used to check the operations of the sensors and

detectors in the duplex section and its control

circuit.

10 1 Used to check the operations of the toner motor

and the related circuit.

Function (Purpose)

Code

Main Sub

13 0 Used to cancel the self-diag "U1" trouble. (Only

when FAX is installed.)

14 0 Used to cancel excluding the self-diag U1/LCC/

U2/PF troubles.

15 0 Used to cancel the self-diag "U6-09, F3-12, 22"

(large capacity paper feed tray, paper feed trays

1, 2) troubles.

16 0 Used to cancel the self-diag U2 troubles.

17 0 Used to cancel the PF troubles (when the copy

inhibit command from the host computer is

received).

21 1 Used to set the maintenance cycle.

22 1 Used to check the print count value in each

section and each operation mode. (Used to check

the maintenance timing.)

2 Used to check the total numbers of misfeed and

troubles. (When the number of misfeed is

considerably great, it is judged as necessary for

repair. The misfeed rate is obtained by dividing

this count value with the total counter value.)

3 Used to check misfeed positions and the misfeed

count of each position. (If the misfeed count is

considerably great, it may be judged as

necessary to repair.)

4 Used to check the trouble (self diag) history.

5 Used to check the ROM version of each unit

(section).

6 Used to output the list of the setting and

adjustment data (simulations, FAX soft switch,

counters).

7 Used to display the key operator code. (This

simulation is used when the customer forgets the

key operator code.)

8 Used to check the number of use of the finisher,

the SPF, and the scan (reading) unit.

9 Used to check the number of use (print quantity)

of each paper feed section.

10 Used to check the system configuration (option,

internal hardware).

11 Used to check the use frequency (send/receive)

of FAX. (Only when FAX is installed)

12 Used to check the SPF misfeed positions and the

number of misfeed at each position. (When the

number of misfeed is considerably great, it can be

judged as necessary for repair.)

13 Used to check the operating time of the process

section (OPC drum, DV unit, toner bottle).

19 Used to check the values of the counters related

to the scan mode and the internet FAX mode.

23 2 Used to check the trouble history of paper jam

and misfeed. (If the number of misfeed and

troubles is considerably great, it may be judged

as necessary to repair.)

80 Used to check the operations of the sensors and

detectors in the paper feed and transport section.

24 1 Used to clear the misfeed counter, the misfeed

history, the trouble counter, and the trouble

history. (The counters are cleared after

completion of maintenance.)

2 Used to clear the number of use (the number of

prints) of each paper feed section.

3 Used to clear the number of use of the finisher,

SPF, and the scan (reading) unit.

4 Used to reset the maintenance counter.

5 Used to reset the developer counter. (The

developer counter of the DV unit which is

installed is reset.)

Function (Purpose)

AR-M355N/M455N SIMULATION 9 - 3

Code

Main Sub

24 6 Used to reset the copy counter.

7 Used to clear the OPC drum counter. (Perform

this simulation when the OPC drum is replaced.)

9 Used clear the printer mode print counter and the

self print mode print counter.

10 Used to clear the FAX counter. (Only when FAX

is installed)

11 Used to reset the OPC drum rotation time, and

the DV unit rotation time counter. The developer

counter in the DV unit installed is reset.

15 Used to clear the counters related to the scan

mode and the internet FAX mode.

25 1 Used to check the operations of the developing

section (toner concentration, humidity and toner

concentration sensor, humidity sensor,

temperature sensor output can be monitored.)

2 Used to make the initial setting of toner

concentration when replacing developer.

26 3 Used to set the specifications of the auditor.

Setting must be made according to the auditor

use conditions.

5 Used to set the count mode of the total counter

and the maintenance counter.

6 Used to set the specifications (paper, fixed

magnification ratio, etc.) of the destination.

10 Used to set the network scanner trial mode.

18 Used to set YES/NO of toner save operation.

(This function is valid only in Japan and UK

versions. (Depends on the destination setting of

SIM26-6.) For the other destinations, the same

setting can be made by the user program P22.)

30 Used to set the operation mode conforming to the

CE mark (Europe safety standards). (Conforming

to soft start when driving the fusing heater lamp.)

35 Used to set whether the same continuous

troubles are displayed as one trouble or the

series of troubles with SIM 22-4 when the same

troubles occur continuously.

38 Used to set CONTINUE/STOP of printing when

maintenance timing is over and the count value

reaches 110% of replacement timing (life).

41 Used to set YES/NO of the automatic

magnification ratio selection (AMS) in the

pamphlet mode.

50 Black-White reverse YES/NO setting

52 Used to set whether non-print paper (insertion

paper, cover paper) (blank image print paper) is

counted up or not.

68 Used to set ENABLE/DISABLE of the CA key

cancel function of print stop.

27 1 Used to set the specifications for operations in

case of communication trouble between the host

computer and MODEM (machine side). (When

communication trouble occurs between the host

computer MODEM and the machine, the self diag

display (U7-00) is printed and setting for inhibition

of print or not is made.)

5 Used to enter the machine tag No. (This function

allows to check the tag No. of the machine with

the host computer.)

30 1 Used to check the operation of sensors and

detectors in other than the paper feed section and

the operations of the related circuits.

2 Used to check the operation of sensors and

detectors in the paper feed section and the

related circuits.

Function (Purpose)

Code

Main Sub

40 1 Used to check the operation of the manual feed

tray paper size detector and the related circuit.

(The operation of the manual feed tray paper size

detector can be monitored with the LCD display.)

2 Used to adjust the manual paper feed tray paper

width detector detection level.

7 Used to enter the manual paper feed tray paper

width adjustment value.

11 Used to check the multi-purpose tray width

detection adjustment value.

12 Used to check the multi-purpose tray width

detection adjustment value.

41 1 Used to check the operation of the document size

sensor and the related circuit. (The operation of

the document size sensor can be monitored with