Page 1

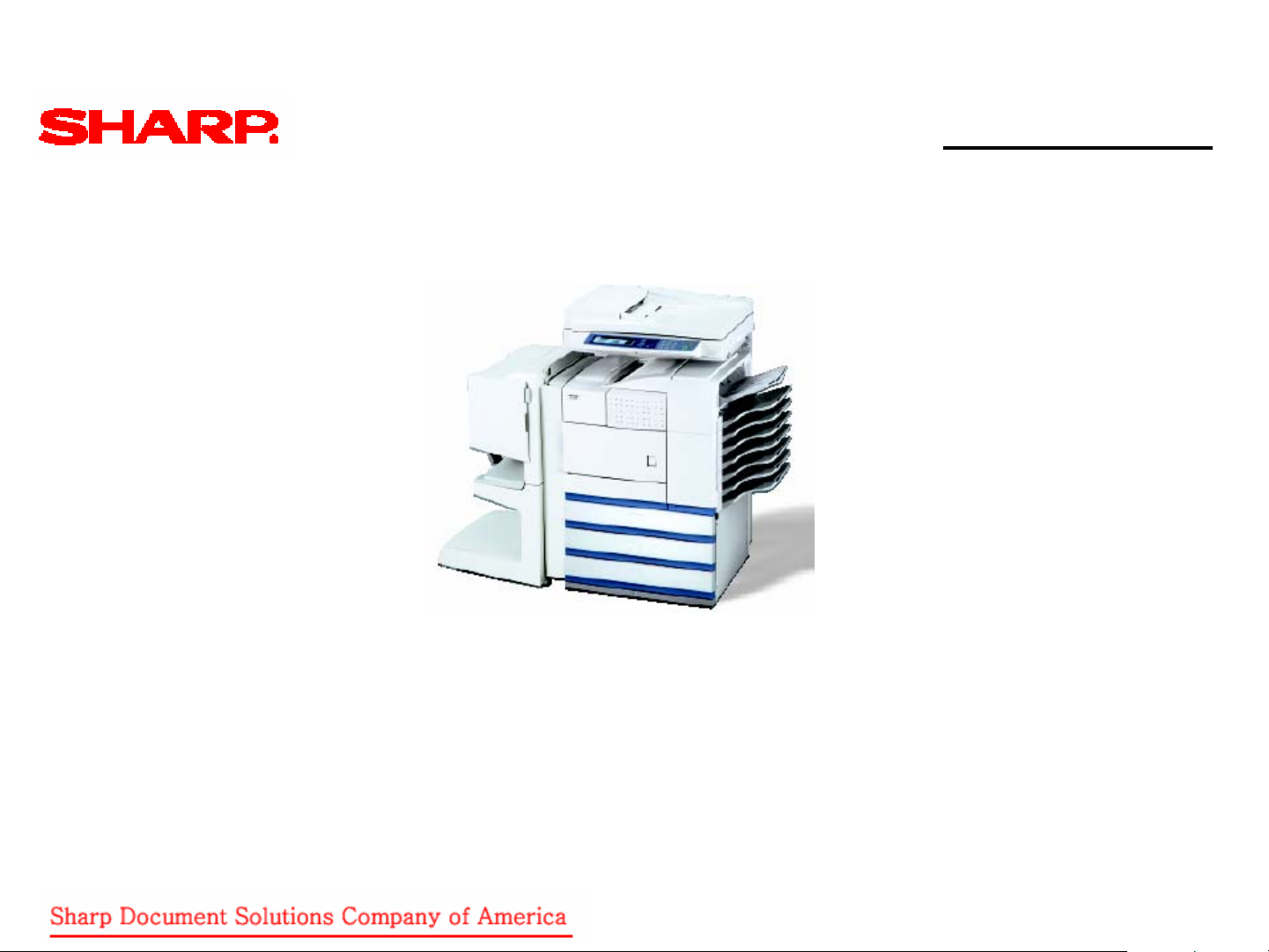

Quick Reference Guide: AR-M355N/M455N

Description: Features & Options

Why the AR-M355N/M455N …

Targeted for busy mid-volume environments, the

AR-M335N/M445N Digital Multifunctional IMAGERs

offer powerful Multitasking, Advanced Application

Integration and Leading Edge Security. The base

model is comprised of a newly engineered 300 MHz

Multi-tasking Controller, an integrated PCL6

Network Printing System, and 40 GB Hard Disk

Drive that include Sharp’s Document Filing System

combined with a Duplex Single Pass Document

Feeder (DSPF) and on-line paper capacity of up to

3100 sheets.

Each of the host machines is available in three

different configurations:

Package A, AR-M355NA / AR-M455NA

Package B, AR-M355NB / AR-M455NB

Package C, AR-M355NC / AR-M455NC

Base N Model machines include 35/45 PPM engine,

300 MHz multitasking controller, 128 MB memory,

PCL6 printing system, 40 GB hard disk drive (with

document filing), 500-sheet letter size tray, USB2

port, IEEE parallel port, and RJ-45 network

interface.

Scan2 Technology

The new technology enables users to scan both

sides of a 2-sided document in one pass, autoduplex documents on paper stocks up to 97 lbs

Index, and offer an array of convenience

features.

The AR-M335N/M445N Digital

Multifunctional IMAGER

Features

9 35/45 ppm print speed

9 True multi-tasking engine controller

9 50-sheet Duplex Single Pass Feeder

9 Document filing system

9 Permanent Font and Form storage

9 Carbon Copy Print mode

9 Auto Duplexing on stocks up to 97 lb. index

9 IP/MAC Address Filtering (secure NIC card)

9 LDAP support with optional Network Scanner

Expansion Kit

9 Standard IEEE 1284 and USB 2.0 ports

9 New Card Shot feature (copies both sides of

an ID card onto a single sheet of paper)

Performance, Flexibility,

Productivity, and Security

Powerful Network Connectivity

300 MHz PCL6 Printing System

40 GB Hard Drive

Network Tandem Printing

Flexible Network Scanning

Ability to end to 6 different destinations

allows for a truly digital workflow

¾Send to Desktop

¾Sent to E-mail

¾Send to FTP

¾Send to Group

¾Send to FAX

¾Send to I-FAX

Professional Finishing

Two-Tray Finisher

Saddle-Stitch Finisher

Mail Bin Stacker

Scalable Security Offerings

Confidential Print Feature

User Authentication (E-mail)

IP/MAC Address Filtering

Data Security Kit (128 bit

encryption)

1

Page 2

Quick Reference Guide: AR-M355N/M455N

Pre-Setup: Tools, Documentation, & Admonitions

Toolbox Basics

Mechanical

• Screwdriver, Phillips #2

• Screwdriver, Flat #1

• Wrench, 1.5mm Hex head

• Feeler gauges

Electrical

• Voltmeter

• ESD wrist or ankle strap

• Approved surge suppressor

• 30x lighted viewing device

Miscellaneous

• Clean, soft, lint-free cloths

• Alcohol

Special Tools & Service Documentation

AR-M355N/AR-M455N, Service Manual, Circuit Diagram,

and Parts Guide

*AR-TE3, Exit Tray

or

*AR-TE5, Exit Tray/Cabinet

* Optional equipment

Laser Admonition

Part NumberDescription

SM-ARC355N/ARM455N

Code: 00ZARM455NA1E

SM-AR-DU3*AR-DU3/DU4, Duplex Unit

N/A

SM-AR-D28*AR-D27, Stand/3 x 500 Sheet Paper Drawer

SM-AR-D28*AR-D28, Stand/MPD & 2000 Sheet Paper Drawer

SM-AR-D28*AR-MU2, Multi-purpose Drawer

SM-AR-FN7*AR-FN6, Finisher

SM-AR-MS1*AR-MS1, Mail-bin Stacker

SM-AR-FN6*AR-FN7, Saddle Stitch Finisher

For your protection, do

not remove protective

covers or bypass safety

interlocks.

Material Safety Data Sheets

(MSDSs)*

DescriptionProduct Code

AR-455MT

(Black)

* Download MSDSs at http://www.sharp-service.com

MSDS

No.

F-01331Toner cartridge

F-31331Developer (Black)AR-455MD

n/aDrumAR-455DR

Electrical/Electronic Component

Admonitions

WARNING: Electrical hazard.

Employ proper precautions when

working with high-voltage electrical

equipment.

CAUTION: Improper handling of

electronic components can damage

!

the equipment.

Properly ground and wear an

electro-static device (ESD) on your

E

wrist or ankle when working with

electronic modules. Similarly, use

S

anti-static bags to protect electronic

components during storage or

D

shipping.

2

Page 3

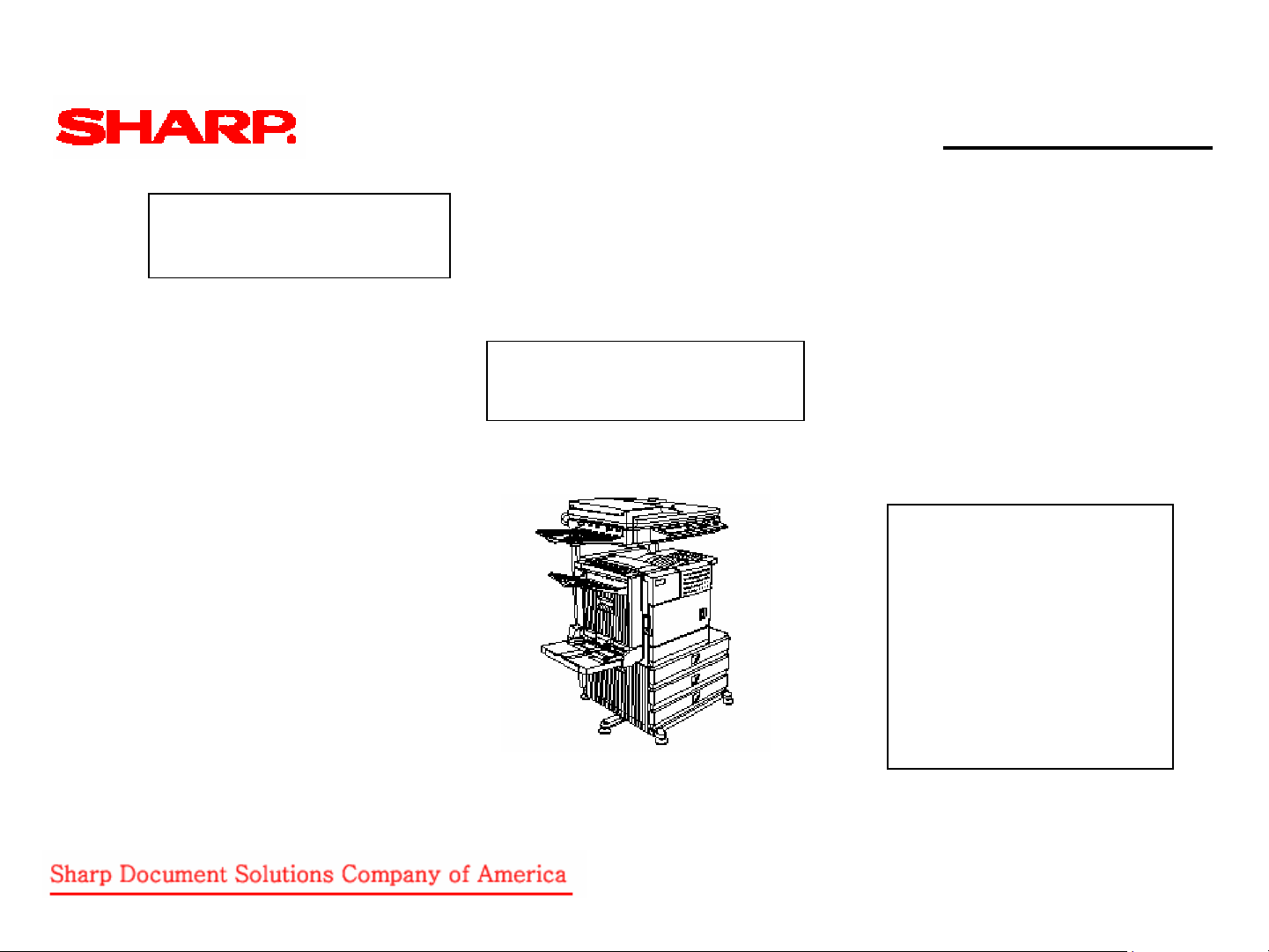

System configuration

Basic system

Quick Reference Guide: AR-M355N/M455N

Basic System Configuration

AR-M355N/AR-M455N

(Copier/Network printer model)

Necessary options:

Any one of the stand/MPD & 2000

sheet paper drawer (AR-D28), the

stand/3x 500 sheet paper drawer (ARD27), or the multi-purpose drawer

(AR-MU)*

Any one of the upper exit tray

extensions (AR-TE4 or AR-TE5), the

finisher (AR-FN6), the mail-bin stacker

(AR-MS1)

AR-EF3

AR-RK2

* To install the AR-MU2, the exclusive use desk is required.

3

Page 4

Quick Reference Guide: AR-M355N/M455N

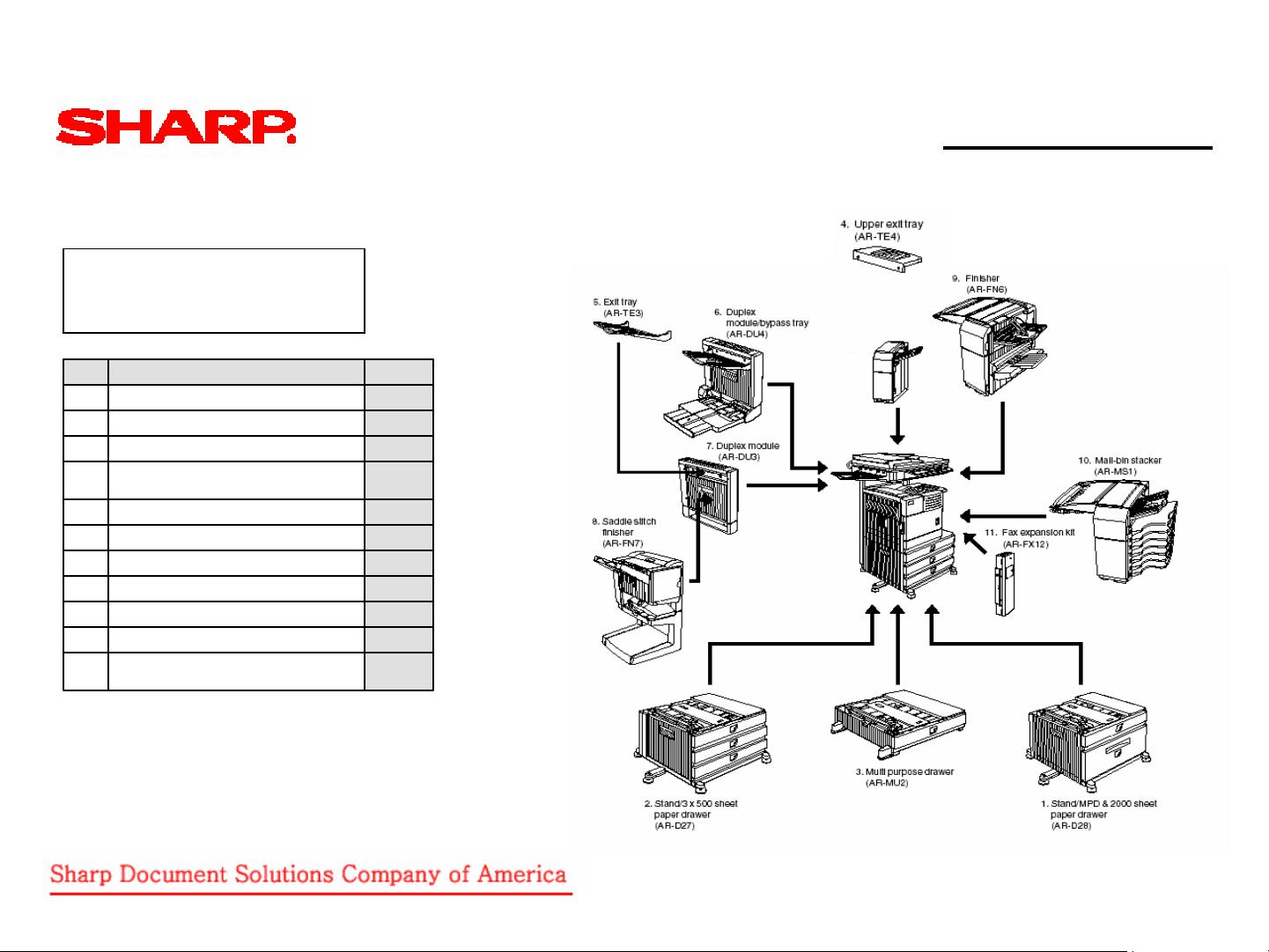

Optional Equipment

Option lineup

Major options

Upper exit tray extension

4

or Cabinet exit tray

Fax expansion kit11

ModelOption NameNo.

AR-D28Stand/MPD & 2000 sheet paper drawer1

AR-D27Stand/3 x 500 sheet paper drawer2

AR-MU2Multi-purpose drawer3

AR-TE4

AR-TE5

AR-TE3Exit tray5

AR-DU4Duplex module/bypass tray6

AR-DU3Duplex module7

AR-FN7Saddle stitch finisher8

AR-FN6Finisher9

AR-MS1Mail-bin stacker10

ARFX12

or

Exit Tray/Cabinet

(AR-TE5)

4

Page 5

Quick Reference Guide: AR-M355N/M455N

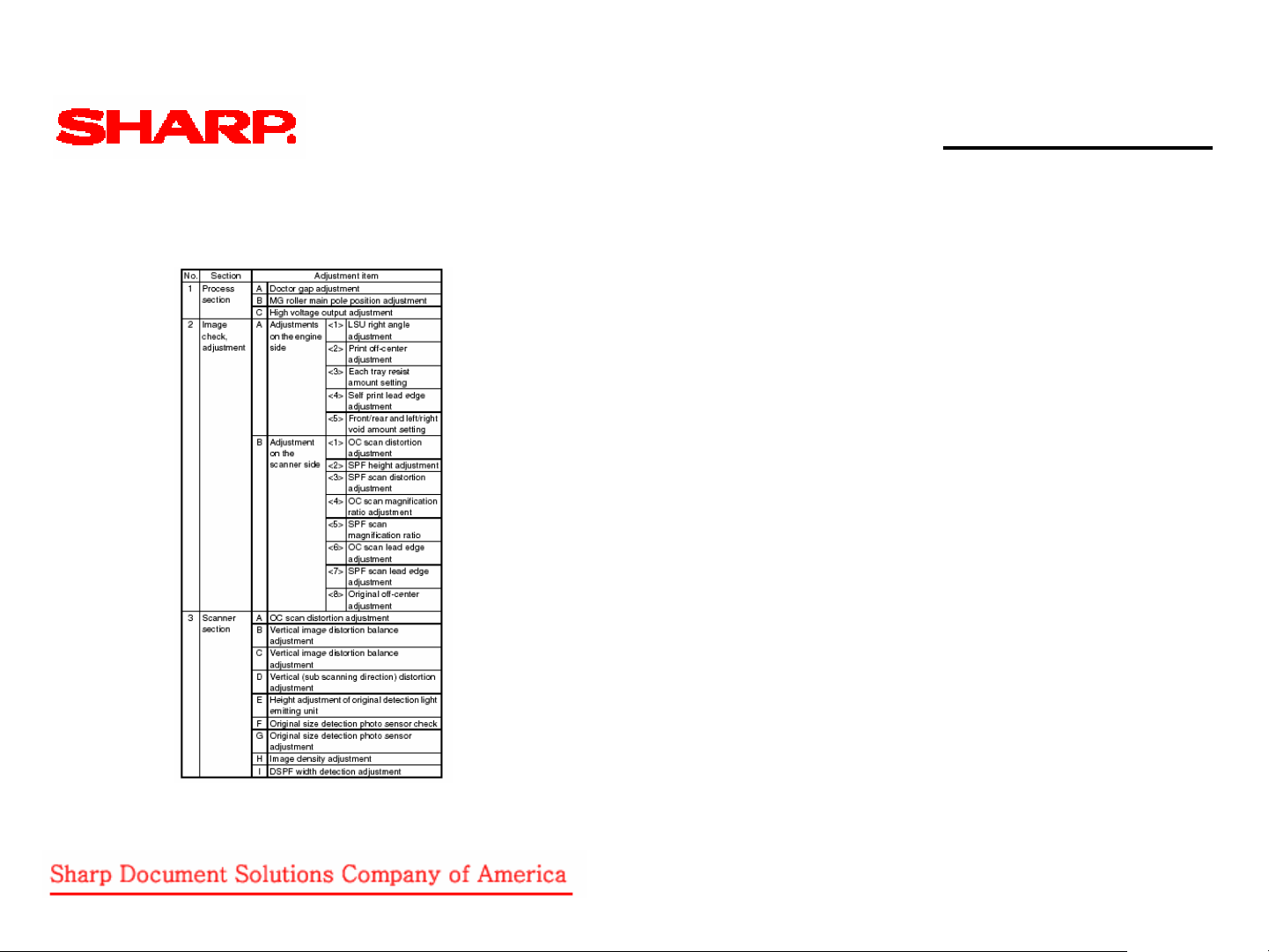

Adjustment and Simulation

Adjustment Checklist

Simulation

Entering the Simulation Mode

1. Copy mode key ON → Program key ON → Asterisk (*) key

ON → CLEAR key ON →Asterisk key ON → Ready for

input of a main code of simulation

2. Entering a main code with the 10-key → START key ON

3. Entering a sub-code with the 10-key → START key ON

4. Select an item with the scroll key and the item key.

5. The machine enters the mode corresponding to the

selected item.

a) Press START key or EXECUTE key to start

the simulation operation.

b) To cancel the current simulation mode or to

change the main code or the sub code, press

the user setup key.

*Canceling the simulation mode to return to the

normal mode:

6. Press CA key.

Simulation List

Please refer to the Simulation List (pages 1 through 10) that follows.

Note: For detailed instructions, refer to Section 8

of the AR-M355N/M455N Service Manual.

5

Page 6

Simulation List (Main/Sub)

SubMain

Used to check the operations of the scanner (read) unit and its control circuit.11

Used to check the operation of sensor and detector in the scanning (read) section and the related circuit.2

Used to check the operations of the automatic document feeder unit and the control circuit.12

Used to check the operations of the sensors and detectors in the automatic document feeder unit and the related circuits.2

Used to check the operations of the loads in the automatic document feeder unit and the control circuits.3

Used to check the operation of sensor and detector in the finisher and the related circuit.23

Used to check the operation of the load in the finisher and the control circuit.3

6

24

Used to adjust the stacking capacity of the finisher. (Used to adjust the alignment plate [jogger] stop position in the finisher

paper width direction. The adjustment is made by changing the alignment plate home position in the paper width direction by

software.)

Console finisher (AR-FN7) adjustment.10

Used to check the mail bin stacker sensor.20

Used to check the operations of the mail bin stacker loads.21

Used to check the operations of the sensors and detectors in the paper feed section (desk paper feed/large capacity tray) and

the related circuit.

Used to check the operations of the loads in the paper feed section (desk paper feed/large capacity tray) and the related circuit.3

Used to check the operation of the display, LCD in the operation panel and control circuit.15

Used to check the operation of the heater lamp and the control circuit.2

Used to check the operation of the paper transport system loads and the control circuit.16

Used to check the operations of each fan motor and its control circuit.2

Used to set the operating conditions of aging.17

Used to set the intermittent aging cycle.6

Used to set the warm-up time display YES/NO.8

Quick Reference Guide: AR-M355N/M455N

Simulation List (Pg. 1 of 10)

Function (Purpose)Code

6

Page 7

Simulation List (Main/Sub)

Used to check and adjust the operations of the developing voltage of each color and the control circuit.18

Used to check and adjust the operation of the main charger grid voltage in each printer mode and the control circuit.2

Used to check and adjust the operation of the transfer voltage and the control circuit.6

Used to check and adjust the operation of the transfer voltage and the related circuit. (Transfer belt cleaning mode.)17

Used to check and adjust the operation of the load (clutch/solenoid) in the duplex section and the control circuit.19

Used to check the operations of the sensors and detectors in the duplex section and its control circuit.2

Used to check the operations of the toner motor and the related circuit.110

Used to cancel the self-diag “U!” trouble. (Only when FAX is installed.)013

Used to cancel excluding the self-diag U1/LCC/U2/PF troubles.014

Used to cancel the self-diag “U6-01, 02, 03, F3-12, 22” (large capacity paper feed tray, paper feed trays 1, 2) troubles.015

Used to cancel the self-diag U2 troubles.016

Used to cancel the PF troubles (when the copy inhibit command from the host computer is received).017

Used to set the maintenance cycle.121

Used to check the print count value in each section an each operation mode. (Used to check the maintenance timing.)122

2

3

Used to check the total numbers of misfeed and troubles. (When the number of misfeed is considerably great, it is judged as

necessary for repair. The misfeed rate is obtained by dividing this count value with the total counter value.)

Used to check misfeed positions and the misfeed count of each position. (if the misfeed count is considerably great, it may be

judged as necessary to repair.)

Used to check the trouble (self-diag) history.4

Used to check the ROM version of each unit (section).5

Used to output the list of the setting and adjustment data (simulations, FAX soft switch, counters).6

Used to display the key operator code. (This simulation is used when the customer forgets the key operator code.)7

Used to check the number of use of the finisher, the SPF, and the scan (reading) unit.8

Used to check the number of use (print quantity) of each paper feed section.9

Used to check the system configuration (options, internal hardware).10

Quick Reference Guide: AR-M355N/M455N

Simulation List (Pg. 2 of 10)

7

Page 8

Simulation List (Main/Sub) (cont’d)

Used to check the use frequency (send/receive) of FAX. (Only when FAX is installed.)1122

12

223

Used to check the SPF misfeed positions and the number of misfeed at each position. (When the number of misfeed is

considerably great, it can be used as necessary for repair.)

Used to check the operating time of the process section (OPC drum, DV unit, toner bottle).13

Used to check the values of the counters related to the scan mode and the internet FAX mode.19

Used to check the trouble history of paper jam and misfeed. (If the number of misfeed and troubles is considerably great, it may

be judged as necessary to repair.)

Used o check the operations of the sensors and detectors in the paper feed and transport sections.80

Quick Reference Guide: AR-M355N/M455N

Simulation List (Pg. 3 of 10)

1`24

11

125

Used to clear the misfeed counter, the misfeed history, the trouble counter and the trouble history. The counters are cleared

after completion of maintenance.)

Used to clear the number of use (the number of prints) of each paper feed section.2

Used to clear the number of use of the finisher, SPF, and the scan (reading) unit.3

Used to reset the maintenance counter.4

Used to reset the developer counter. (The developer counter of the DV unit which is installed is reset.)5

Used to reset the copy counter.6

Used to clear the OPC drum counter. (Perform this simulation when the OPC drum is replaced.)7

Used clear the printer mode print counter and the self print mode print counter.9

Used to clear the FAX counter. (Only when FAX is installed.)10

Used to reset the OPC drum rotation time, and the DV unit rotation time counter. ; The developer counter in the DV unit installed

Is reset.

Used to clear the counters related to the scan mode and the internet FAX mode.15

Used to check the operations of the developing section (toner concentration, humidity and toner concentration sensor, humidity

sensor, temperature sensor output can be monitored.)

Used to make the initial setting of toner concentration when replacing developer.2

8

Page 9

Simulation List (Main/Sub) (cont’d)

Used to set the specification of the auditor. Setting must be made according to the auditor use conditions.326

Used to set the count mode of the total counter and the maintenance counter.5

Used to set the specifications (paper, document detection, etc.) of the destination.6

Used to set the network scanner trial mode.10

18

130

140

141

3

9

Used to set YEZ/NO of toner save operation. (This function is valid only in Japan and UK versions. [Depends on the destination

setting of SIM26-6.] For the other destinations, the same setting can be made by the user program P22.)

Used to check the operation of sensors and detectors in other than the paper feed section and the operations of the related

circuits.

Used to check the operation of sensors and detectors in the paper feed section and the related circuits.2

Used to check the operation of the manual feed tray paper size detector and the related circuit. (The operation of the manual

feed tray paper size detector can be monitored with the LCD display.

Used to adjust the manual paper feed tray paper width detector detection level.2

Used to enter the manual paper feed tray paper width adjustment value.7

Used to check the multi-purpose tray width detection adjustment value.11

Used to check the multi-purpose tray width detection adjustment value.12

Used to check the operation of the document size sensor and the related circuit. (The operation of the document size sensor

can be monitored with the LCD display.)

Used to adjust the document size sensor sensing level.2

Used to check the operation of the document size sensor and the related circuit. (The document size sensor output level can be

monitored with the LCD display.)

Used to set the fusing temperature in each operation mode.143

Used to set enable/disable of correction operations in the image forming (process) section.144

Used to check the data related to the image forming section correction (process correction) result (corrected main charger grid

voltage, the developing bias voltage, and the laser power voltage in each print mode). (This simulation allows to check that

correction is performed normally or not.)

Used to check the output level of the temperature sensor and the humidity sensor.14

Quick Reference Guide: AR-M355N/M455N

Simulation List (Pg. 4 of 10)

9

Page 10

Simulation List (Main/Sub) (cont’d)

Used to check the output level of the temperature sensor and the humidity sensor.1444

Used to check the toner concentration control data.16

Used to adjust the copy density in all the copy modes (Auto, Text, Text/Photo, and Photo mode.246

9

11

20

Used to adjust the print density for each density level (display value) in the copy mode (binary-Text mode). An optional print

density can be set for each density level (display value).

Used to adjust the print density for each density level (display value) in the copy mode (binary-Photo m ode). An optional print

density can be set for each density level (display value).

Used to adjust the print density into eh FAX mode (all models).12

Used to adjust the print density in the FAX mode (each normal mode). (Only when FAX is installed.)13

Used to adjust the print density in the FAX mode (each fin mode). (Only when FAX is installed.)14

Used to adjust the print density in the FAX mode (each super fine mode). (Only when FAX is installed.)15

Used to adjust the print density in the FAX mode (each ultra fine mode). (Only when FAX is installed.)16

Used to set the gain in shading correction.17

Used to adjust the gamma (density gradient) in the copy mode.18

Used to set the auto mode operation specifications in ach mode (copy, scan, FAX).19

Used to adjust the copy density correction into eh SPF copy mode for the document table copy mode. The adjustment is made

so that the copy density becomes the same as that of the document table copy mode.

Unused to adjust the scanner exposure level in all the scanner modes.21

Used to adjust the scanner exposure level in the normal text mode.22

Used to adjust the scanner exposure level in the fine text mode.23

Used to adjust the scanner exposure level (in the super fine text mode).24

Used to adjust the scanner exposure level in the ultra fine text mode.25

Used to adjust the gamma (density gradient) of the network scanner mode.27

Used to adjust sharpness of the copy mode.31

Quick Reference Guide: AR-M355N/M455N

Simulation List (Pg. 5 of 10)

10

Page 11

Simulation List (Main/Sub) (cont’d)

Used to adjust sharpness of the FAX mode.3946

Used to adjust the image density in the FAX mode (600dpi).45

Used to adjust sharpness of the scanner mode.46

Used to adjust the copy magnification ratio (in the main scanning and the sub scanning directions).148

Used to adjust the copy magnification ratio in the sub scanning direction.5

HSYNC cycle adjustment.6

150

2

5

6

7

251

Used to adjust the copy image position and the void area (image loss) adjustment on print paper in the copy mode. (The similar

adjustment can be performed with SIM 50-5 and 50-2 (Simplified method].) (Document table mode.)

Used to adjust the document scan position, the image print position, and the void area (image loss). (Simple adjustment) (This

adjustment is the simple method of SIM 50-1.) (Document table mode.)

Used to adjust the print image position and the void area (image loss) on print paper. (Adjustment as the print engine.) (This

adjustment is reflected on all the FAX/printer/copy modes.)

Used to adjust the copy image position and void area (image loss) on print paper in the copy mode. (The similar adjustment can

e performed with SIM 50-7 [simple method].) (SPF mode).

Used to adjust the copy image position and void area (image loss) on print prepare in the copy mode. (The similar adjustment

can be performed with SIM 50-6). (SPF mode.)

Used to adjust the print image off-center position. (Adjusted separately for each paper feed section.)10

Used to adjust the scan image off-center position. (Adjusted separately for each scan mode.)12

Used to adjust the image loss of the scan image in the FAX/scan mode.27

Used to adjust the contact pressure of paper on the resist roller of each section (each paper feed, duplex feed and SPF paper

feed of the copier). (This adjustment is required when the print image position variations are considerably great or when paper

jams occur too frequently.)

Used to adjust the DSPF width detection level.653

Used to enter the SPF width detection adjustment value.7

Used to adjust the document scan start position. (Used to adjust the scanner scan position into eh SPF mode front scan.)8

Quick Reference Guide: AR-M355N/M455N

Simulation List (Pg. 6 of 10)

11

Page 12

Simulation List (Main/Sub) (cont’d)

Used to set the specifications of the engine control operations. (PCU-PWB).155

Used to set the specifications of the scanner control operations. (Scanner control PWB).2

Used to set the specifications of the controller operations. (MFP control PWB).3

Used to transfer the MFP controller data. (Used to repair the PWB.)156

Used to check the MFP control (DRAM) operations (read/write).160

Used to check the operation of the scanner (write) unit (LSU).161

Used to adjust the laser power (absolute value) in the copy mode.2

Used to adjust the laser power (absolute value) in the FAX mode.3

Used to adjust the laser power (absolute value) in the printer mode.4

Used to format the hard disk.162

Used to check the operation of the hard disk (read/write). (Only in the model with a disk installed). (Partial check.)2

Used to check the operations of the hard disk (read/write). (All areas check.)3

Used to check the operations of the hard disk. (The self-diag operation of the SMART function I executed.6

Used to check the operation soft the hard disk. (/The result of the self-diag operation of the SMART function is printed out.)7

Used to format the hard disk (the system area excluded).8

Used to delete a job complete list (also to delete job log data).10

Used to delete document filing data. (The mana gement area (standard folder, user folder) is cleared.)11

Used to check the result of shading correction. (The shading correction data are displayed.)163

Used to execute shading.2

Used to adjust the white plate scan start position for shading. (Document table mode.)7

164

Used to check the operation of the printer section (self-print operation). (The print pattern, the paper feed mode, the print mode,

the print quantity, and the density can be optionally set).

Quick Reference Guide: AR-M355N/M455N

Simulation List (Pg. 7 of 10)

12

Page 13

Simulation List (Main/Sub) (cont’d)

Used to adjust the touch panel (LCS display section) detection position.165

Used to check the result of the touch panel (LCD display) detection position adjustment. (The coordinates are displayed.)2

Quick Reference Guide: AR-M355N/M455N

Simulation List (Pg. 8 of 10)

166

2

3

4

5

8

9

10

11

12

13

14

Used to change and check the FAX soft switch functions. (Used to change and check the functions provided for the FAX soft

switches.) (Only when FAX is installed.)

Used to clear the FAX soft switch function data and to set to the default. (Excluding the adjustment values.) (Only when FAX is

installed.)

Used to check the operation of the FAX PWB memory (read/write). (This adjustment is required when the PWB is replaced with

a new one.) (Only when FAX is installed.)

Used to check the output operation of data signals in each data output mode of FAX. (Used to check the operation of MODEM.)

Send level: Max. (Only when FAX is installed.)

Used to check the output operation of data signals in ach data output mode of FAX. (Used to check the operation of MODEM.)

An output is sent at the send level set by the soft switch. (Only when FAX is installed.)

Used to print the confidential pass code. (Used when the confidential pass code is forgotten.) (Only when FAX is installed.)6

Used to print the mage memory data (memory send/receive). (Only when FAX is installed.)7

Used to check the output operation of various sound signals of FAX. (Used to check the operation of the sound output IC.)

Send level: Max. (Only when FAX is installed.)

Used to check the output operation of various sound signals of FAX. (Used to check the operation of the sound output IC.) An

output is sent at the send level set by the soft switch. (Only when FAX is installed.)

Used to clear all data of the image memory (memory send/receive). The confidential data are also cleared at the same time.

(Only when FAX is installed.)

Used to check the output operation of FAX G3 mode 300bps. (Used to check the operation of MODEM.) Send level: Max.

(Only when FAX is installed.)

Used to check the output operation of FAX G3 mode 300bps. (Used to check the operation of MODEM.) An output is send at

the send level set by the soft switch. (Only when FAX is installed.)

Used to enter (set) the number of FAX dial signal output test. (The dial number set by this simulation is outputted when the dial

signal output test is made by SIM 66-14-16.) (Only when FAX is installed.)

Used to set the make time in the FAX pulse dial mode (10pps) and to test the dial signal output. (The dial number signals et by

SIM 66-13 is outputted.) Used to check troubles in dialing and to check the operation. (Only when FAX is installed.

13

Page 14

Simulation List (Main/Sub) (cont’d)

Used to set the make time in the FAX pulse dial mode (20pps) and to test the dial signal output. (The dial number signal set by SIM 66-

1566

13 is outputted.) The send level can be set to an optional level. Used to check troubles in dialing and to check the operation. (Only

when FAX is installed.)

Used to check the dial signal (DTMF) output in the FAX tone dial mode. (The dial number signal set by SIM 66-13 is outputted. The

16

send level can be set to an optional level. Used to check troubles in dialing and to check the operation. (Only when FAX is installed.)

Used to check the dial signal (DTMF) output in the FAX tone dial mode. Send level: Max. Used to check the operation. (Only when

17

FAX is installed.)

Used to check the dial signal (DTMF) output in the FAX tone dial mode. An output is sent at the send level set by the soft switch. Used

18

to check the operation. (Only when FAX is installed.)

Used to back-up the HDD data into the Flash memory (optional FAX expansion memory: AR-MM9). (Only when FAX is installed.)19

Used to read the back-up data by SIM 66-19 to the SRAM/HDD. (Only when FAX is installed.)20

Used to print information related to FAX (various registrations, communication management, file management, system error protocol).

21

(Only when FAX is installed.)

Used to adjust the handset volume. (Only when the FAX is installed.)22

Quick Reference Guide: AR-M355N/M455N

Simulation List (Pg. 9 of 10)

Used to download the FAX program. (Only when FAX is installed.) Not used in the market. (For development.)23

Used to clear the FAST memory data. (Only when FAX is installed.)24

Used to register the FAX number for Model dial-in. (Only when FAX is installed.) Not used in the market. (For development.)25

14

Page 15

Simulation List (Main/Sub) (cont’d)

Used to register external telephone numbers for Modem dial-in. (Only when FAX is

2666

installed.) Not used in the market. (For development.)

Used to register the transfer number for voice warp. (Only when FAX is installed.) Not

27

used in the market. (For development.)

Used to clear data related to an address book (one-touch registration, program

29

registration/expansion, relay memory box registration, each table content.)

Used to check the change in the TEL/LIU status. (Only7 when FAX is installed.)30

Quick Reference Guide: AR-M355N/M455N

Simulation List (Pg. 10 of 10)

Used to set the destination specifications. (Only when FAX is installed.)3966

PIC program rewriting. (Only when FAX is installed.)42

PIC adjustment value writing. (Only when FAX is installed.)43

Used to check the operation of the parallel I/F o the printer. (This simulation is for

267

production only, and requires a special tool for execution.) (Not used in the market.)

Used to set YES/NO of the parallel I/F select signal of the printer.11

Used to check the relay operation. (Only when FAX is installed.)31

Used to check the receive data (fixed data) from the line. (Only when FAX is installed.)32

Used to check the signal (BUSY TONE / CNG / CED / FNET / DTMF) detection. (Only

33

when FAX is installed.)

Used to measure the communication time of test image data. (Only when FAX is

34

installed.)

Modem program rewriting. (Only when FAX is installed.) Not used in the market. (For

35

development.)

Used to check interface between MFPC controller and MDMC. (Check of the data line or

36

the command line.) (Only when FAX is installed.)

Used to set the destination specifications. (Only when FAX is installed.)39

Used to check the operation of the network card.16

15

Page 16

Supply System Table

Quick Reference Guide: AR-M355N/M455N

Supplies

Product Code / MSDS No.LifeContentDescription

Toner cartridge (Black)

Developer (Black)

Note 1: The other maintenance parts which are not listed above are registered as service parts.

Toner cartridge (with IC)

(x 10)

(Toner: Net weight 750

g)

Developer

(Developer: Net weight

500 g) (x 10)

AR-455MT / MSDS No. F-01331350K

(35K x 10)

AR-455MD / MSDS No. F-313311000K

(100K x

10)

AR-455DR (No MSDS required)200KOPC drum (x 1)Drum

16

Page 17

Maintenance Parts List

Quick Reference Guide: AR-M355N/M455N

Supplies (cont’d)

RemarksModel NameLifeContentItem

200K Maintenance Kit

Upper heat roller kit

Lower heat roller kit

Drum separation pawl (x 4)

MC unit *1 (x 1)

Toner receiving seat (x 1)

Side malt F (x 1)

Side malt R (x 1)

Transfer roller (x 1)

Discharge blade (x 1)

Paper dust removing unit (x 1)

DV blade (x 1)

DV side seal F (x 1)

DV side seal R (x 1)

Fusing separation pawl (Upper) (x 4)

Fusing separation pawl (Lower) (x 2)

Cleaner blade (x 10)Cleaner blade

Staple cartridge (x 3)Staple cartridge

Staple cartridge (x 3)Staple cartridge

(x 10)

times

(x 3)

times

(x 3)

AR-455KA1200KCleaner blade (x 1)

AR-455UH200KUpper heat roller (x 1)

AR-455LH200KLower heat roller (x 1)

AR-SC13000

*1: Screen grid, charging plate,

MC cleaner unit are included.

AR-455CB = (AR-455BL) x 10AR-455CB200K

Cartridge for AR-FN4

Common with cartridge for ARFN6

Cartridge for AR-FN7AR-SC25000

Note: The other maintenance parts which are not listed above are registered as service parts.

17

Page 18

Engine Copy Speeds (PPM)

Invoice-R

* Paper feed from Manual Bypass Tray

Quick Reference Guide: AR-M355N/M455N

Basic Specifications

AR-M455NAR-M355NPaper Size

45ppm (40ppm*)35ppm (31ppm*)A4 (8.5” x 11”)

30ppm25ppmA4R (8.5”x 11”R)

45ppm35ppmA5R/5.5” x 8.5”R,

45ppm35ppmB5

30ppm25ppmB5R, Executive-R

20ppm17ppmA3/(11” x 17”)

20ppm17ppm8K

45ppm35ppm16K

18

Page 19

Functional Speeds

Quick Reference Guide: AR-M355N/M455N

Basic Specifications (cont’d)

Warm Up Time:

First Copy Times:

Jam Recovery Times:

Multi-Copy Max:

Void Width:

Image Loss (Normal)

External Dimensions:

W x D x H:

Occupied Space

Dimensions: W X D:

Weight:

Engine:

Desk:

Rack:

DSPF:

< 80 secs.

10.5 sec. (Color)

15.5 sec. (B&W)

About 30 sec. (Under standard condition of 60 seconds left

after side cover opening, polygon motor halt)

999 sheets

Lead Edge: 5mm or less

Rear Edge: 5mm or less

5mm or less

826 x 665 x 1127mm (32.5” x 26.2” x 44.4”) including

automatic document feeder.

963 x 665mm (37.9” x 26.2”) including automatic document

feeder

Approximately 41.4kg (91 lbs)

Approximately 31.4kg (69 lbs)

Approximately 7.4kg (16 lbs)

Approximately 2lkg (46 lbs)

Power Source

100V system (100-127V), 50/60 Hz, Inlet type power cord

AR-M355N = 1440W; AR-M455N = 1440WPower Consumption

19

Page 20

Quick Reference Guide: AR-M355N/M455N

Cautions for Servicing & Prohibited Printing List

Cautions for Servicing

□ Do not touch the photoconductive drum. Scratches or

smudges on the drum will cause dirty printouts.

□ The fusing unit is extremely hot. Exercise care in this area.

□ Do not look directly at the light source of the scanner

module. Doing so may damage your eyes.

□ Five adjusters are provided on all optional stand/paper

drawer u nits. These adjusters should be lowered until they

contact the floor.

□ Do not make any modifications to this machine. Doing so

may result in personal injury or damage to the machine.

□ Since this machine is heavy, it is recommended that it be

moved by more than one person to prevent injury.

□ When connecting this machine to a computer, be sure to first

turn both the computer and the machine off.

□ Do not throw toner or a toner cartridge into fire. Toner may

be spattered, causing a burn.

□ Store toner or toner cartridges in a hard-to-reach place for

child safety.

Prohibited from Printing by Law

□ Do not print anything that is prohibited from printing by

law.

The following items are normally prohibited from printing

by national law. Other items may be prohibited by local

law.

• Money

•Stamps

• Bonds

• Stocks

• Bank drafts

• Checks

• Passports

• Driver’s licenses

20

Page 21

Quick Reference Guide: AR-M355N/M455N

PWB Repair

The PWBs listed below can be forwarded to the following

address for repair.

Sharp Electronics Corporation

Product and Board Repair

Department 650

1300 Naperville Drive

Romeoville, IL 60446

except Japan]

except Japan]

[except Japan]

[Japan]

PWB, 100

PWB Repair

Repair PWBs

Price RankPart NumberDescription

BLCPWBN1633FCE1Mother board PWB

BXCPWBX1637DS53PCU PWB [AR-M355N

BXCPWBX1637DS56PCU PWB [AR-M455N

AYCPWBF1629FC1MFP Control PWB, Relay

AUCPWBF1626FCE1MFP Control PWB, Fuse

AVCPWBF1625FCE1MFP Control PWB, Fuse

BXRDENC0036FCZ1AC/DC Power Supply

BVCPWBX1635DS51Scanner Control PWB

BACPWBN1632FCE1Scanner Interface PWB

BACPWBF1628FCE1MFP OPE PWB

BNCPWBN1567DS53CIS Control PWB

Important: When returning the MFP Control PWB or Scanner Control PWB, be sure to remove the

EEPROMs from the PWBs and install them on the new PWBs) that you receive. The

EEPROM contains machine settings and most importantly the machine serial number.

21

Page 22

AR-M355N

Quick Reference Guide: AR-M355N/M455N

Environmental Data

Power Consumption

Operating NoiseOzone PeakWatts

(5.0 dB) (6.8 dB)< 0.1< 184 W< 80 W1440wh184.75wh

AR-M455N

Operating NoiseOzone PeakWatts

Power Consumption

(5.0 dB) (6.8 dB)< 0.1< 223 W< 95 W1440wh223.25wh

Note: ASTM Standard Test Data is available through your Regional Service Office.

OperationStandby(PPM)OperationStandbyOperationStandby

OperationStandby(PPM)OperationStandbyOperationStandby

22

Page 23

Quick Reference Guide: AR-M355N/M455N

Flash ROM Version Up (Firmware ROM Upgrade) Procedures

General Information

The Flash ROM Version Up procedures enable writing of the program data from a PC to the target PWBs which

becomes source ROM. Target PWBs and ROMs include:

• Control PWB

- Boot/Main Flash ROM

- PCU Flash ROM

• MFP Control PW

- Boot Flash RO

- Main Flash ROM

• Scanner / Fax PW

- Scanner Flash ROM

- Fax Flash ROM

Two Procedures are Available to Write to ROM

1. Procedure 1 (Collectively Writing to “Batch”)

2. Procedure 2 (Using the CN6 of the Controller PWB to Write ROMs Individually)

After choosing the applicable procedure, make sure you have the necessary items on hand for upgrading as listed

under Preparation.

Preparation

Flash ROM

The following items are required to perform an update procedure.

• Host machine with operating ROM in it

• Windows/Personal computer (operating in MS-DOS mode) with a USB or parallel port

• USB cable or Centronics cable (to connect the PC and the Controller PWB)

• Software for upgrading (SFU collective file or SFU unit-specific files)

• Spare Flash ROMs for PCU, Controller Boot, and Scanner)

• Updated Firmware of FCOPY.EXE and/or File2PRN.EXE. (latest version downloaded from Sharpnet©)

23

Page 24

Quick Reference Guide: AR-M355N/M455N

Flash ROM Version Up (Firmware ROM Upgrade) Procedures (cont’d)

DIP Switches

Flash ROM (cont’d)

Note: When updating the ROM, the DIP switches on the back of the

Setting the DIP Switches

1. Remove the screw marked with an asterisk (*) from the Controller

Note: There are two DIP switches on the Controller: the Diag Mode

2. Upon completion of the upgrade procedure, remember to return

machine must be set properly. Follow the Setting the DIP Switches

procedure below.

PWB at the back of the machine and rotate the plate part to access

the DIP switches. See illustration.

Switch (on the left) and the Write Protect Switch (on the right).

The switches are set to the Protect mode (switches are in the Up

position) during normal operation. Protect mode is the default. In

order to write to the ROM, the switches must be changed to the

down position (Diag Mode). This releases the write protection.

the switches to the Up position (Write Protect), and then rotate the

plate back over the DIP switches to the original position, and

tighten down the screw.

24

Page 25

Quick Reference Guide: AR-M355N/M455N

Flash ROM Version Up (Firmware ROM Upgrade) Procedures (cont’d)

Upgrade Procedure 1: Collectively Writing with Each ROM Inserted into the Specified Slot

Flash ROM (cont’d)

Note: Make certain all of the ROMs on the PCU, FAX, and scanner are operating ROMs. An empty ROM (a ROM that cannot boot the machine)

Setup

1. Set the Diag Mode Switch DIP switch (located on the left side on the back of the machine) to the diag mode. (See Setting the DIP Switches.)

2. Make certain the scanner unit is connected to the machine.

3. When a FAX is installed, make certain the FAX unit is connected to the machine.

4. Connect the PC and Controller PWB with the Centronics cable or USB cable.

5. Power ON the PC.

6. Power ON the machine to be updated.

Update Procedures

1. When the machine is booted, the following display is shown.

2. Press the MENU key a few times to display the following windows.

Note: If using File2PRN.EXE, select the connection type (USB or

cannot be used for writing.

3. Press OK key, and the following window is displayed.

Note 1: The LED flashes and the display is changed

sequentially (as shown below) when files are

transferred from the PC by Fcopy.EXE or

File2PRN.EXE.

parallel) with the Up/Down select key.

25

Page 26

Quick Reference Guide: AR-M355N/M455N

Flash ROM Version Up (Firmware ROM Upgrade) Procedures (cont’d)

Upgrade Procedure 1: Collectively Writing to “Batch” (cont’d)

Flash ROM (cont’d)

Note 2: The backlight of the LCD is instantaneously

Note 3: On machines that do not

4. Reboot the machine. Use the Up/Down key on

5. Power OFF and reset the DIP switches to the Up

End of Procedure 1.

turned OFF when the scanner is updated. Do

not power OFF since it is not a breakdown.

Wait several minutes until “Result: OK” displays,

then press the Up/Down key to make certain

there is no “Result: NG” for each ROM.

have a FAX installed,

when the collective files are updated, the

display is “Result: NG”. “Result: NG” is

displayed in this instance for FAX.

In all other “Result: NG” displays, see the

section titled Troubleshooting “Result:NG”.

window 1) to verify that the version of the updated

software has been updated correctly.

position (Write Protect default).

26

Page 27

Quick Reference Guide: AR-M355N/M455N

Flash ROM Version Up (Firmware ROM Upgrade) Procedures (cont’d)

Upgrade Procedure 2: Using the CN6 of the Controller PWB to Write ROMs Individually

Note: By using an empty slot of the Controller PWB, writing can be

made to an empty ROM that is not operating.

Setup

Flash ROM (cont’d)

1. Set the Diag Mode Switch DIP switch (located on the left side on

the back of the machine) to the diag mode. (See Setting the DIP

Switches.)

2. Insert the applicable ROM of the PCU, the SCN or the FAX into

the empty slot (CN6) on the Controller PWB.

3. Make certain the scanner unit is connected to the machine.

4. When a FAX is installed, make certain the FAX unit is connected

to the machine.

5. Connect the PC and Controller PWB with the Centronics cable or

USB cable.

6. Power ON the PC.

7. Power ON the machine to be updated.

Update Procedures

8. When the machine is booted, the following display is shown.

9. Press the MENU key a few times to display the following window.

Note: When using File2PRN.EXE, press the Up/Down key to

select the appropriate connection type (either USB or

parallel).

10. Press OK key, and the following window is displayed.

Note: The LED flashes and the display is changed sequentially (as

shown below) when files are transferred from the PC by

Fcopy.EXE or File2PRN.EXE.

27

Page 28

Quick Reference Guide: AR-M355N/M455N

Flash ROM Version Up (Firmware ROM Upgrade) Procedures (cont’d)

Upgrade Procedure 2: Using the CN6 of the Controller PWB to Write ROMs Individually

11. Press OK key, and the following window is displayed.

12. Use the Up/Down key to select the slot No. where

the ROM is inserted and press the OK key.

Note: The LED flashes and the display is changed

sequentially (as shown below). Wait several minutes

until “Result: OK” displays.

Flash ROM (cont’d)

A13. After turning OFF the power, replace the newly written

ROM with the ROM of the specified slot of the PWB.

14. Power ON and reboot the machine. Use the Up/Down key on

window 1) to verify that the version of the updated software has

been updated correctly.

15. Power OFF and reset the DIP switches to the Up position (Write

Protect default).

End of Procedure 2.

28

Page 29

Quick Reference Guide: AR-M355N/M455N

Operation Panel

When the machine is booted by the diag mode, each operation is performed with the hard

keys of the scanner. The window display is made by the LCD panel. The keys used in the

diag mode are assigned as follows:

START key → OK key

Document filing key → Up/Down select key

FAX/Image send key → Up/Down select key

Job status key → Menu key

Clear key → BACK key

Troubleshooting “Result:NG”

If a “Result:NG” is displayed, check for the following possible causes.

Operation Panel and Troubleshooting “Result:NG”

Event: The Write Protect DIP switch setting is incorrect.

Action: Make sure that the Write Protect switch of the Controller PWB is not set to the

release side (down).

Note: Data cannot be written to the ROM if the Write Protect switch is not set to Release

(down). Set the DIP switch properly and retry updating.

Event: The FAX cable is not connected. (The FAX is NG.) Writing cannot occur.

Action: Connect the cable properly and retry writing.

29

Page 30

File Transfer Process Flow Chart

Quick Reference Guide: AR-M355N/M455N

File Transfer

File Transfer Procedures

File Transfer by Fcopy.EXE

1. For file transfer by Fcopy, put Fcopy.exe and the files in the same

directory, and boot the MS-DOS.

2. Go to the directory of the files, and type “Fcopy file name and the

transfer is occurs.

Note: In the following example, the SFU file is in

the C:\ROM directory and it is transferred.

File Transfer by File2PRN.EXE

1. Set the machine to which the files are to be transferred as a printer.

(The connection types as a printer are parallel port, network, and USB.)

Note: An IP address setting is required for transfer by the network

connection.

2. Execute File2PRN.EXE to transfer the files. The follow window displays.

30

Loading...

Loading...