Page 1

DIGITAL COPIER : AR-280

Date

:

Aug. 27, 1998

1. ADDITION OF GASKETS CARRIED OUT AS A MEASURE TO ALLEVIATE

PROBLEMS OF NOISE.

2. ADDITION OF A FERRITE CORE CARRIED OUT AS A MEASURE TO

ALLEVIATE PROBLEMS OF NOISE.

No. : ARE-104

1. Addition of a gasket carried out as a measure to alleviate problems of noise.

1.Model Name: AR-280/285/335 (only for machines bound for the 200 V series destinations)

2.General: The addition of the parts described below has been carried out. This action has been

carried out as a measure to alleviate problems of electrical noise.

3.Description: • The addition of an EMI absorption sheet and a gasket has been carried out to the ICU

attachment plate.

• The addition of gaskets has been carried out to the chassis of the machine.

EMI absorption sheet

ICU cover EX

Standard

Standard

F side

Contact

standard

Width

Gasket

Gasket

Gasket

Standard

SHARP CORPORATION Reprography Division

1/5

Green

C

Page 2

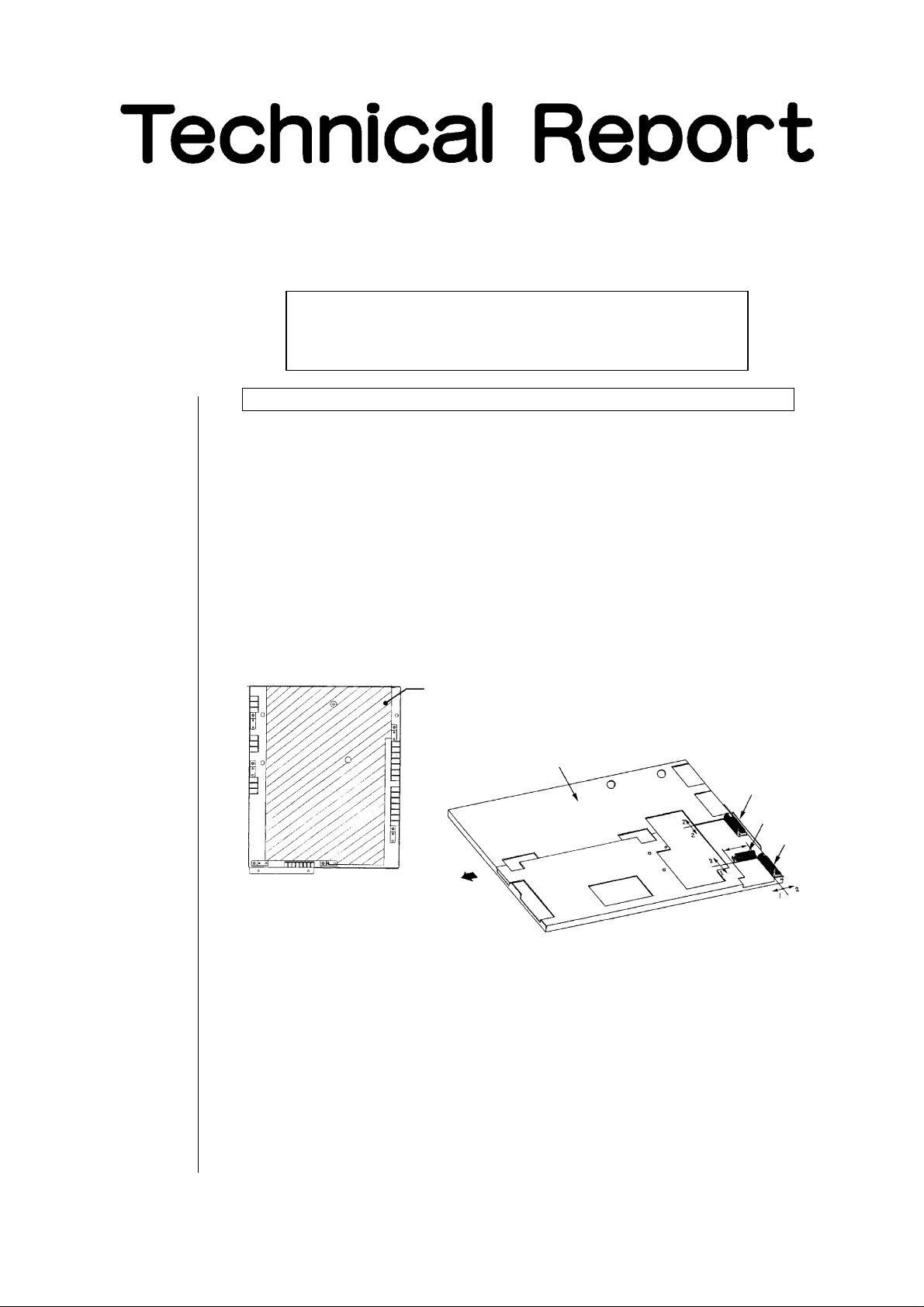

Rear frame

Lower base plate

Cross section diagram

4.Action: From the start of 1998 June production.

2. Addition of a ferrite core carried out as a measure to alleviate problems of noise.

1.Model Name: AR-280/285/335

2.General: The addition of a ferrite core has been carried out to each of the parts described below.

This action has been carried out as a measure to alleviate problems of electrical noise.

Attachment of the ferrite core to the ICU connection harness.

ICU PWB

2/5

To the operation panel

Page 3

Attachment of the ferrite core to the CCD flat cable.

To the CCD PWB

ICU PWB

Attachment of the ferrite core to the original

document detection harness line.

To the original document detection lamp PWB.

3 pin interface connector

Machine GND

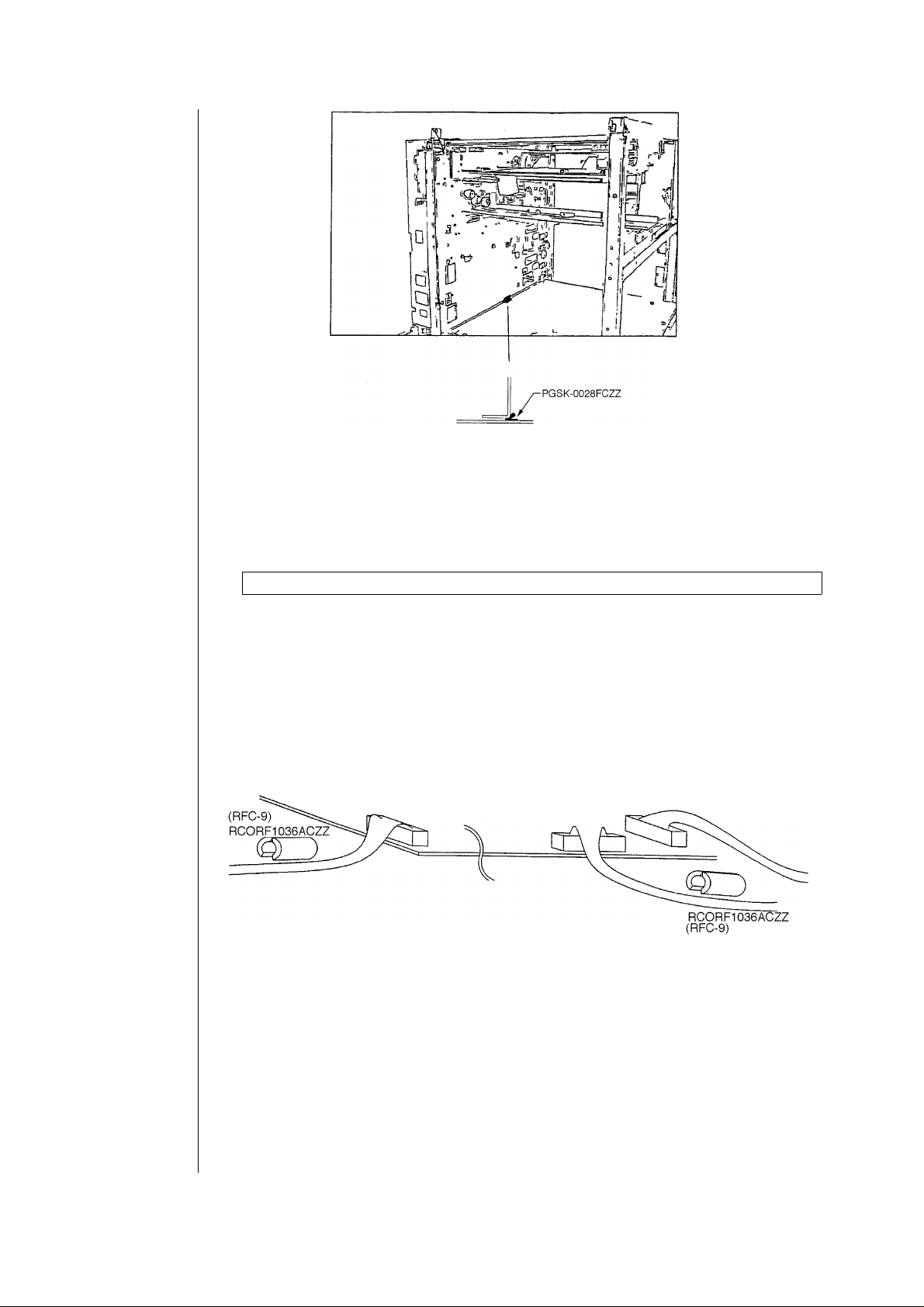

Attachment of the ferrite core to the RADF

and SPF interface harness line.

Attachment of the ferrite core to the MSW harness line.

Harness lifter

MSW line interface connector

Attachment of the ferrite core

to the manual harness.

Main harness

To the scanner UN

RADF and SPF

interface connector.

To the frame of

the machine.

(Side view)

Attachment of the ferrite core to the original

document detection harness line.

Original document

detection lamp PWB

Wire saddle

12 pin interface connector

8 pin interface connector

To the manual UN

Attachment of the ferrite core to the

paper delivery drawer harness line.

To the rear frame

Drawer connector

3/5

Page 4

Attachment of the ferrite core to the high voltage AC harness.

To the AC terminal

Tube

To the high voltage PWB

Attachment of the ferrite core to the FIN and desk harness line.

Attachment of the ferrite core to the LCC interface harness line.

To the frame of the machine

LCC interface connector

Wire saddle

FIN interface connector

Desk interface connector

3.Action: From the start of 1998 June production.

4/5

Page 5

Ref.

No.

1

Model

name

Version P/G No.

5

10 PGSK-0028FCZZ AF

Current parts New parts

Parts code Parts code

PSHEZ4677FCZZ BF

PGSK-0030FCZZ AH

Price

rank

Parts name

EMI absorption

sheet

Gasket

Effec-

tive

time

Inter-

change-

ability

Note

AR-280

AR-285

AR-335

2 ----

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with " " is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

200V

Series

----

RCORF0035FCZZ AM

RCORF1036ACZZ AP

RCORF5010BCZZ AD

RCORF6693RCZZ AK

RCORF1039LCZZ AN

RCORF0034FCZZ AR

RCORF0037FCZZ AS

RCORF0029FCZZ AN

5. Interchangeable if replaced with same types of

related parts in use.

6. Others.

'98/6

1st lot

Ferrite core

6

5/5

Loading...

Loading...