Page 1

DIGITAL COPIER : AR-280

Date

:

Aug. 27, 1998

1. NEW ESTABLISHMENT OF THE ICU BASE PLATE AS CARRIED OUT AS A MEASURE TO ALLEVIATE

PROBLEMS OF NOISE.

2. NEW ESTABLISHMENT OF THE PCU PWB CARRIED OUT AS A MEASURE TO COMPLY WITH CE

STANDARDS.

3. CHANGE CARRIED OUT IN THE METHOD OF SECURING THE HARNESS IN THE FUSING UNIT.

4. ADDITION OF A FILTER PWB CARRIED OUT AS A MEASURE TO ALLEVIATE PROBLEMS OF NOISE.

No. : ARE-102

1. New establishment of the ICU base plate as carried out as a measure to alleviate

problems of noise.

1.Model Name: AR-280/285/335 (only for machines bound for the 200 V series destinations).

2.General: The ICU base plate has been newly established as the ICU base plate AS only for the

machines bound for the 200 V series destinations. This action has been carried out as

a measure to alleviate problems of noise. Please refer to the parts list for details

concerning the items for which changes have been carried out.

3.Action: From the start of 1998 June production.

2. New establishment of the PCU PWB carried out as a measure to comply with CE

standards.

1.Model Name: AR-280/285/335 (only for machines bound for the 200 V series destinations).

2.General: The PCU PWB has been carried out only for machines bound for the 200 V series

destinations. This action has been carried out as a measure to comply with CE

standards.

3.Action: From the start of 1998 June production.

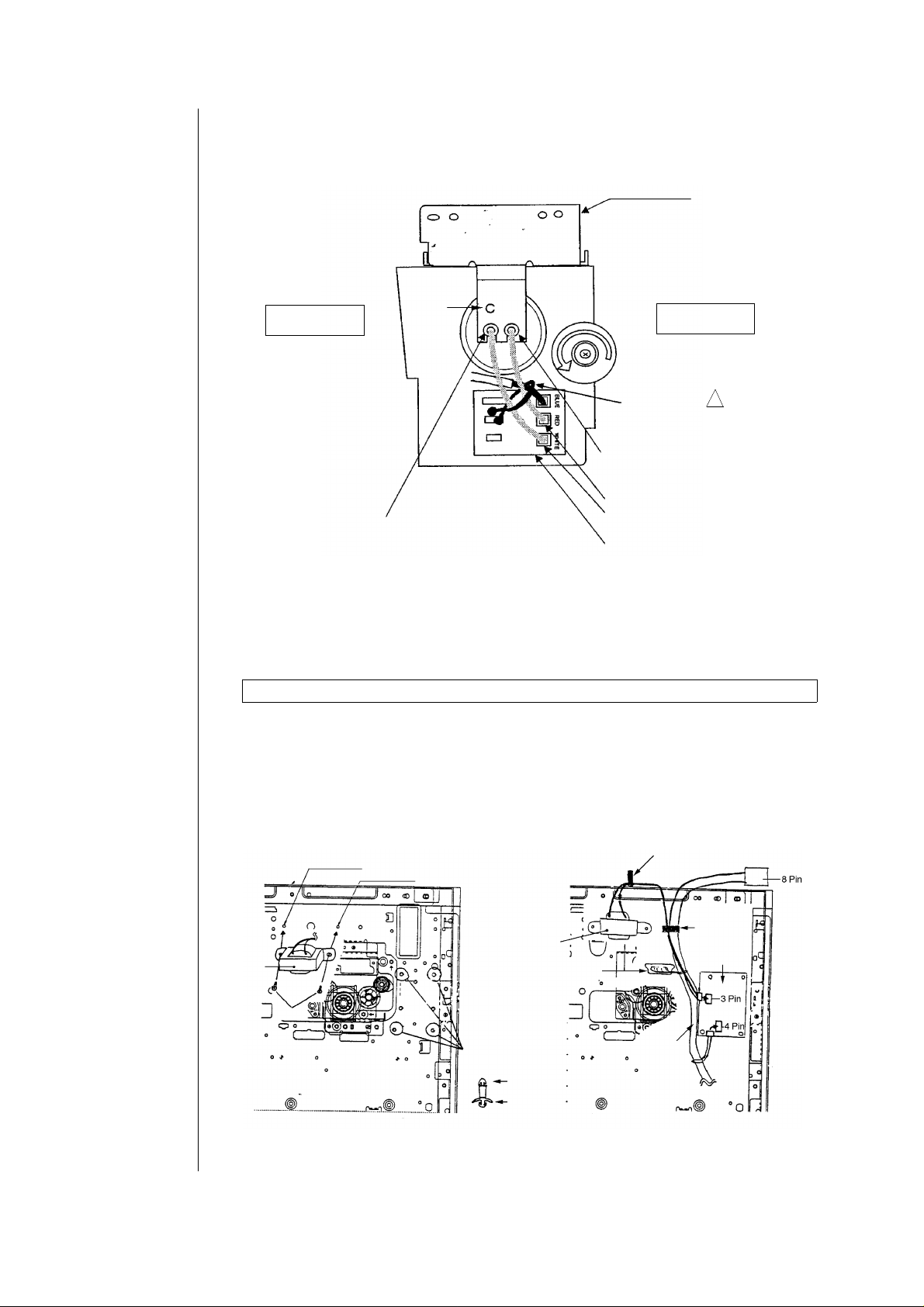

3. Change carried out in the method of securing the harness in the fusing unit.

1.Model Name: AR-280/285/335 (only for machines bound for the 200 V series destinations).

SHARP CORPORATION Reprography Division

1/3

Green

C

Page 2

2.General: The addition of a binding band (Omega Lock) has been carried out to insure the total

separation of the AC and DC lines of the harness in the fusing unit. This action has

been carried out as a measure to improve safety performance.

Lamp holder F

Engraved

Delivery side

Heater lamp main

* Related parts (please refer to the chart

for details concerning the related parts)

mark

Heater lamp sub

* Related parts (please refer to the chart

for details concerning the related parts)

Red fastener

White fastener

Fusing interface PWB

Suction side

Omega Lock 5

(only for the 200 V series)

3.Action: From the start of 1998 June production.

4. Addition of a filter PWB carried out as a measure to alleviate problems of noise.

1.Model Name: AR-280/285/335 (only for machines bound for the 200 V series destinations).

2.General: The addition of a reactor PWB and filter PWB has been carried out to the AC input line

of the DC power supply. This action has been carried out as a measure to alleviate

problems of noise.

Harness clamp

Transistor attachment hole

Reactor

M4 × 8

Transistor attachment hole

Reactor

Fusing drawer

4 locations

PWB supporter

attachment

PWB side

Frame side

Harness

clamp

Filter PWB

AC harness

3.Action: From the start of 1998 June production.

2/3

Page 3

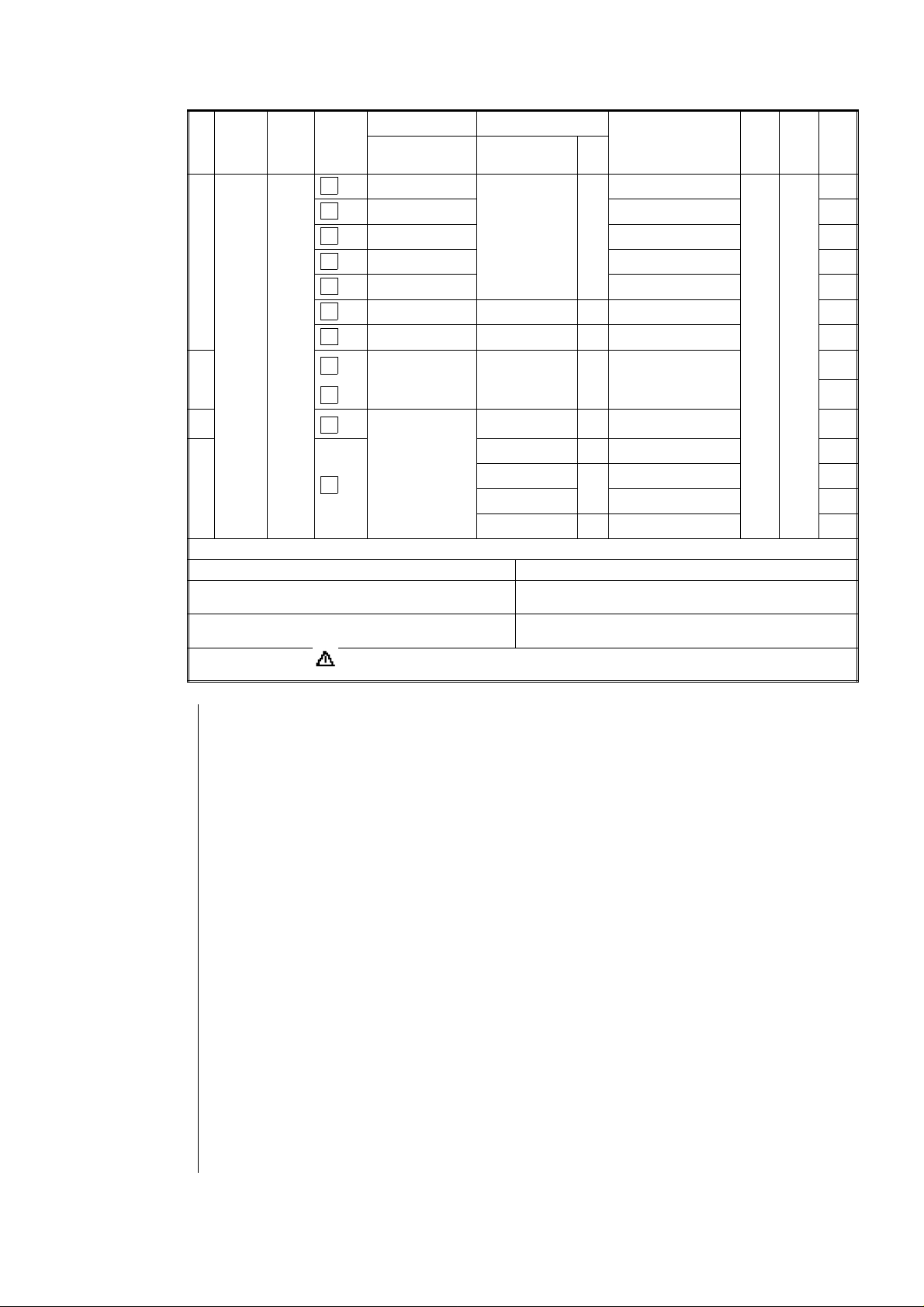

Ref.

No.

1

2

Model

name

AR-280

AR-285

AR-335

Version P/G No.

5 -55

5 -69

5 -58

5 -52

5 -57

5 -68

200V

series

5

10 -12

41 -901

Current parts New parts

Parts code Parts code

LPLTM5426FCZZ

LPLTM5596FCZZ ICU fixing plate

PGIDH1792FCZZ ICU sub PWB guide F

PGIDH1793FCZZ ICU sub PWB guide R

PGSK-2016HCZZ Gasket

PCOVP1470FCZZ PCOVP1508FCZZ AT ICU cover

---- CPLTM5628FC01 AU ICU base plate AS

CPWBN1267FC51 CPWBN1368FC51 CA PCU PWB

Discontinued ----

Price

rank

Parts name

ICU sub PWB fixing plate

Effec-

tive

time

1st lot

'98/6

Inter-

change-

ability

6

Note

3 16

----

4

<Interchange>

1. Interchangeable. 4. Not interchangeable.

2. Current type can be used in place of new type.

New type cannot be used in place of current type.

3. Current type cannot be used in place of new type.

New type can be used in place of current type.

Parts marked with " " is important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

10

LHLDW1334FCZZ AA Omega lock

RCILF0099FCZZ AY Reactor

XHBSE40P08000

LSUPP0060FCZZ PWB supporter Q'ty: 4

CPWBF1364FC51 AX Filter PWB

5. Interchangeable if replaced with same types of

related parts in use.

6. Others.

Screw (M4 × 8) Q'ty: 2

AA

3/3

Loading...

Loading...