Page 1

PG-C20XU

PG-C20XE

AN-Z7T

SERVICE MANUAL

SERVICE-ANLEITUNG

S31Q7PG-C20XU

LCD PROJECTOR

LCD PROJEKTOR

PG-C20XU

PG-C20XE

ATTACHMENT ADAPTOR

MODELS

ANSCHLUSSADAPTER

MODELLE

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

Im lnteresse der Benutzersicherheit (erforderliche Sicherheitsregeln in einigen Ländern) muß das Gerät in seinen

Originalzustand gebracht werden. Außerdem dürfen für die spezifizierten Bauteile nur identische Teile verwendet

werden.

AN-Z7T

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

1

Page 2

PG-C20XU

PG-C20XE

AN-Z7T

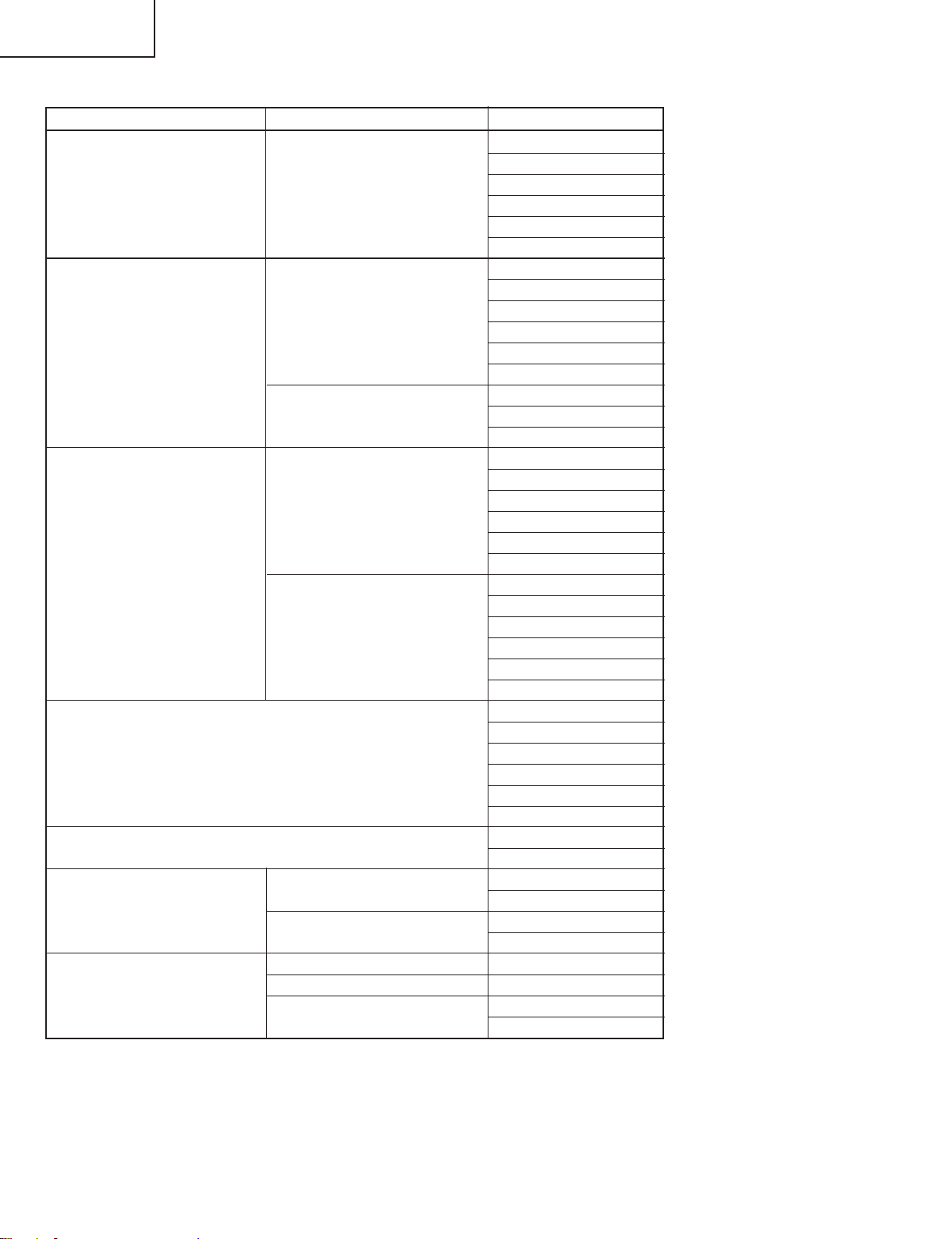

• SPECIFICATIONS ............................................. 3

• IMPORTANT SERVICE SAFETY

NOTES (for USA)............................................... 4

• NOTE TO SERVICE PERSONNEL ................... 5

• OPERATION MANUAL ...................................... 8

• REMOVING OF MAJOR PARTS ..................... 13

• RESETTING THE TOT AL LAMP TIMER ......... 19

• THE OPTICAL UNIT OUTLINE........................ 20

• ELECTRICAL ADJUSTMENT.......................... 23

• TROUBLE SHOOTING TABLE ........................ 31

• CHASSIS LAYOUT .......................................... 80

• BLOCK DIAGRAM ........................................... 82

• OVERALL WIRING DIAGRAM ........................ 84

CONTENTS

Page Page

• DESCRIPTION OF SCHEMATIC DIAGRAM ... 86

• WAVEFORMS .................................................. 87

• SCHEMATIC DIAGRAM .................................. 88

• PRINTED WIRING BOARD ASSEMBLIES ... 128

• P ARTS LIST

Ë

ELECTRICAL PARTS............................... 134

Ë

CABINET AND MECHANICAL PARTS .... 149

Ë

ACCESSORIES PARTS........................... 153

Ë

P ACKING PARTS..................................... 153

• PACKING OF THE SET ................................. 154

• A TT ACHMENT ADAPTOR............................. 155

Seite Seite

• TECHNISCHE DATEN..................................... 43

• HINWEISE FÜR DAS

WARTUNGSPERSONAL................................. 44

• BEDIENUNGSANLEITUNG............................. 45

• ENTFERNEN DER HAUPTTEILE ................... 50

• RÜCKSTELLEN DES

LAMPENBETRIEBSZEIT-TIMERS.................. 56

• BESCHREIBUNG DER OPTIK-EINHEIT ........ 57

• ELEKTRISCHE EINSTELLUNG ...................... 60

• FEHLERSUCHTABELLE ................................. 68

• CHASSIS-ANORDNUNG ................................ 80

• BLOCKSCHALTBILD ....................................... 82

• GESAMTSCHALTPLAN................................... 84

• BESCHREIBUNG DES SCHEMATISCHEN

INHAL T

• WELLENFORMEN........................................... 87

• SCHEMATISCHER SCHALTPLAN.................. 88

• LEITERPLATTENEINHEITEN ....................... 128

• ERSATZTEILLISTE

• VERPACKEN DES GERÄTS ......................... 154

• ANSCHLUSSADAPTER ................................ 155

SCHALTPLANS ............................................... 86

Ë

ELEKTRISCHE BAUTEILE ...................... 134

Ë

CEHÄUSE UND MECHANISCHE

BAUTEILE ................................................ 149

Ë

ZUBEHÖRTEILE...................................... 153

Ë

VERPACKUNGSTEILE ............................ 153

2

Page 3

Specifications

Product type LCD Projector

Video system PAL / PAL 60 / PAL- M / PAL- N / SECAM / NTSC 3.58 / NTSC 4.43 / DTV 480P

Display method LCD panel X 3,RGB optical shutter method

LCD panel Panel size:0.9" (22.9mm) (13.9 [H ] X 18.5 [W ] mm))

Projection lamp DC 150 W lamp

Contrast ratio 500:1

Video input signal RCA Connector:VIDEO,composite video,1.0 Vp-p,sync negative,75 Ω terminated

S-video input signal 4-pin Mini DIN connector

Horizontal resolution 580 TV lines (video input)

Audio output 1.0 W (monaural)

Computer RGB input signal 15-PIN MINI D-SUB CONNECTOR (COMPUTER INPUT 1 port,COMPUTER OUTPUT port):

Pixel clock 12 – 108 MHz

Vertical frequency 43 – 85 Hz

Horizontal frequency 15 – 80 kHz

Computer control signal 9-pin Mini DIN female connector (RS-232C port)

Speaker system 1 7⁄64" (2.8 cm) round

Rated voltage AC 100 – 240 V

Input current 2.6 A

Rated frequency 50/60 Hz

Power consumption 230 W (Selecting "OFF" in the "Power Save Mode".)

Operating temperature 41 °F to 95 °F (+ 5 °C to + 35 °C)

Storage temperature− 4 °F to 140 °F (− 20 °C to + 60 °C)

Cabinet Plastic

I/R carrier frequency 38 kHz

Dimensions (approx.) 10 15⁄64" (W) X 2 29⁄32" (H) X 8 5⁄32" (D)(260 X 74 X 207 mm)(main body only)

Weight (approx.) 5.73 lbs.(2.6 kg)

Supplied accessories Remote control, Two AAA size batteries, Power cord (11' 10" ,3.6 m), Computer RGB cable (9' 10"

Replacement parts Lamp unit (Lamp/cage module) (BQC-PGC20X//1), Remote control (RRMCG1613CESA), AAA

PG-C20XU

PG-C20XE

AN-Z7T

Model PG-C20XU/XE

Display method:Translucent TN liquid crystal panel

Drive method:TFT (Thin Film Transistor)Active Matrix panel

No.of dots:786,432 dots (1,024 [H ] X 768 [V ])

Lens 1 – 1.2X zoom lens, F2.3 – 2.6, f = 36.0 – 43.2 mm

RCA Connector:AUDIO,0.5 Vrms more than 22 kΩ (stereo)

Y (luminance signal):1.0 Vp-p,sync negative,75 Ω terminated

C (chrominance signal):Burst 0.286 Vp-p,75 Ω terminated

RGB separate/composite sync/sync on green type analog input:0 – 0.7 Vp-p,positive,

75 Ω terminated

STEREO MINIJACK:AUDIO,0.5 Vrms,more than 22 kΩ (stereo)

HORIZONTAL SYNC.SIGNAL:TTL level (positive/negative)or composite sync (Apple only)

VERTICAL SYNC.SIGNAL:Same as above

200 W (Selecting "ON" in the "Power Save Mode".)

10 15⁄64" (W) X 3 15⁄64" (H) X 8 5⁄32" (D)(260 X 82 X 207 mm)(including

adjustment feet and projecting parts)

,3 m), Computer audio cable (9' 10", 3 m), PS/2 mouse control cable (3' 3", 1 m), USB mouse

control cable (4' 1 1" ,1.5 m), DIN-D-sub RS-232C cable (6 45⁄64" ,15 cm), Remote mouse receiver,

Extra air filter, Lens cap (attached), Lens cap strap, CD-ROM,

size batteries, Power cord (CACCU5013DE01 (PG-C20XU), QACCV4002CEZZ (PG-C20XE),

QACCB5024CENA (PG-C20XE)), Computer RGB cable (QCNWG0002CEZZ), Computer audio

cable (QCNW-4870CEZZ), PS/2 mouse control cable (QCNW-5113CEZZ), USB mouse control

cable (QCNW-5680CEZZ), DIN-D-sub RS-232C cable (QCNW-5288CEZZ), Remote mouse receiver (RUNTK0694CEZZ), Air filter (PFILD0123CEZZ), Lens cap (PCOVZ1095CEKA), Lens cap

strap (UBNDT0013CEZZ), CD-ROM (UDSKA0029CEN1 (PG-C20XU), UDSKA0048CEN1 (PGC20XE)), LCD projector operation manual (TINS-7204CEZZ (PG-C20XU), TINS-7271CEZZ (PGC20XE)), LCD projector quick reference guide (TINS-7205CEZZ (PG-C20XU), TINS-7272CEZZ

(PG-C20XE), TINS-7284CEZZ (PG-C20XE), TINS-7285CEZZ (PG-C20XE))

This SHARP projector uses LCD (Liquid Crystal

Display)panels.These very sophisticated panels contain 786,432

pixels (RGB)TFTs (Thin Film Transistors).As with any high technology electronic equipment such as large screen TVs,video systems

and video cameras,there are certain acceptable tolerances that the

equipment must conform to.

Specifications are subject to change without notice.

This unit has some inactive TFT s within acceptable tolerances which

may result in illuminated or inactive dots on the picture screen.This

will not affect the picture quality or the life expectancy of the unit.

If you have any questions about this matter,please call toll free 1888-GO-SHARP (1-888-467-4277). U.S.A.ONLY

3

Page 4

PG-C20XU

2

2

2

PG-C20XE

AN-Z7T

IMPORTANT SERVICE SAFETY NOTES (for USA)

Ë Service work should be performed only by qualified service technicians who are

thoroughly familiar with all safety checks and servicing guidelines as follows:

WARNING

1. For continued safety, no modification of any circuit

should be attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE PROJECTOR:

(Fire & Shock Hazard)

Before returning the projector to the user, perform

the following safety checks:

1. Inspect lead wires are not pinched between the

chassis and other metal parts of the projector.

2. Inspect all protective devices such as non-metallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacity networks, mechanical

insulators, etc.

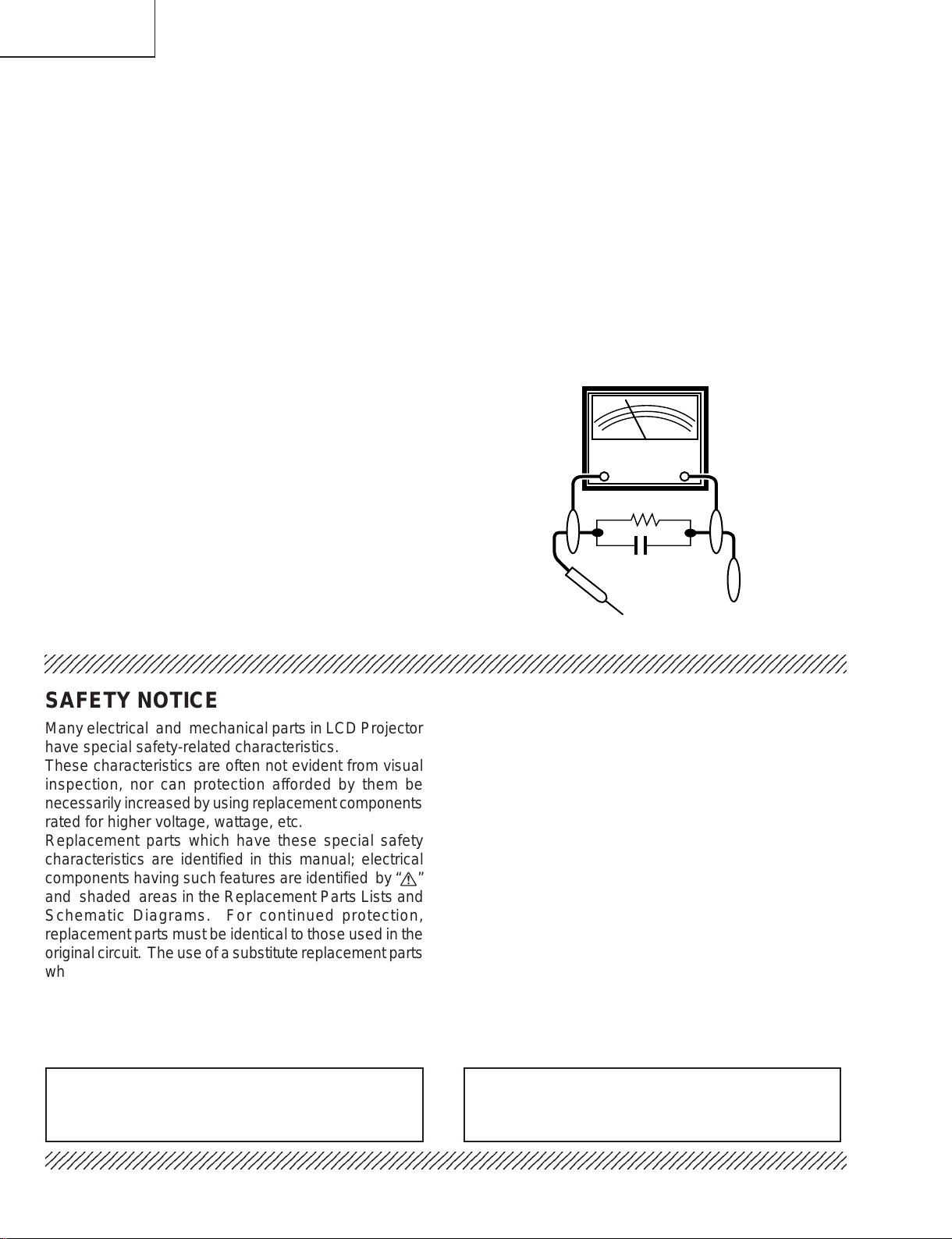

3. To be sure that no shock hazard exists, check for

current leakage in the following manner:

» Plug the AC cord directly into a 120-volt AC outlet,

(Do not use an isolation transformer for this test).

» Using two clip leads, connect a 1.5k ohm, 10 watt

resistor paralleled by a 0.15µF capacitor in parallel

between all exposed metal cabinet parts and earth

ground.

» Use an AC voltmeter with sensitivity of 5000 ohm per

volt., or higher, sensitivity to measure the AC voltage

drop across the resistor (See Diagram).

» All checks must be repeated with the AC plug

connection reversed. (If necessary , a non-polarized

adapter plug must be used only for the purpose of

completing these checks.)

Any reading of 0.3 volts RMS (this corresponds to

0.2 milliamp. AC.) or more is excessive and indicates

a potential shock hazard which must be corrected

before returning the unit to the owner.

AC

VOLTMETER

1.5k ohm (10W)

0.15µF

TEST PROBE

TO EXPOSED

METAL PARTS

CONNECT TO KNOWN

EARTH GROUND

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

SAFETY NOTICE

Many electrical and mechanical parts in LCD Projector

have special safety-related characteristics.

These characteristics are often not evident from visual

inspection, nor can protection afforded by them be

necessarily increased by using replacement components

rated for higher voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this manual; electrical

components having such features are identified by “å”

and shaded areas in the Replacement Parts Lists and

Schematic Diagrams. For continued protection,

replacement parts must be identical to those used in the

original circuit. The use of a substitute replacement parts

which do not have the same safety characteristics as

the factory recommended replacement parts shown in

this service manual, may create shock, fire or other

hazards.

AVIS POUR LA SECURITE

De nombreuses pièces, électriques et mécaniques, dans

les projecteur à LCD présentent des caractéristiques

spéciales relatives à la sécurité, qui ne sont souvent

pas évidentes à vue.

Le degré de protection ne peut pas être nécessairement

augmentée en utilisant des pièces de remplacement

étalonnées pour haute tension, puissance, etc.

Les pièces de remplacement qui présentent ces

caractéristiques sont identifiées dans ce manuel;

les pièces électriques qui présentent ces particularités

sont identifiées par la marque “å” et hachurées dans la

liste des pièces de remplacement et les diagrammes

schématiques. Pour assurer la protection, ces pièces

doivent être identiques à celles utilisées dans le circuit

d’origine. L’utilisation de pièces qui n’ont pas les mêmes

caractéristiques que les pièces recommandées par

l’usine, indiquées dans ce manuel, peut provoquer des

électrocutions, incendies ou autres accidents.

WARNING: The bimetallic component has the primary

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

conductive side exposed. Be very careful in

handling this component when the power is on.

AVERTISSEMENT: La composante bimétallique dispose du

conducteur primaire dénudé. Faire

attention lors de la manipulation de cette

composante sous tension.

4

Page 5

PG-C20XU

5

5

PG-C20XE

AN-Z7T

NOTE TO SERVICE

PERSONNEL

234567890123456789012345678901212345678901234

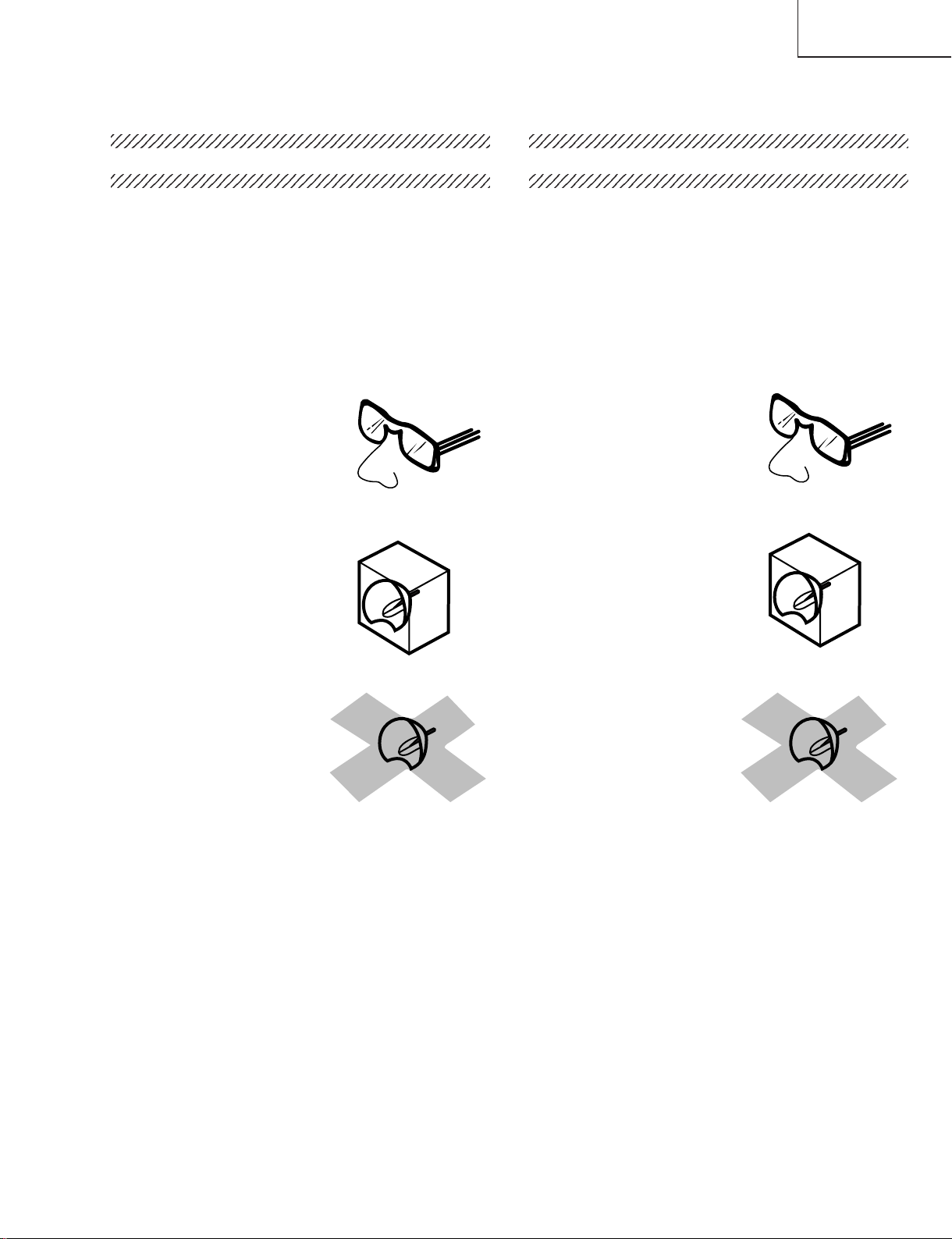

UV-RADIATION PRECAUTION

The light source, UHP lamp, in the LCD projector

emits small amounts of UV-Radiation.

A VOID DIRECT EYE AND SKIN EXPOSURE.

To ensure safety please adhere to the following:

1. Be sure to wear sun-glasses when servicing the

projector with the lamp

turned “on” and the top

enclosure removed.

2. Do not operate the lamp outside of the lamp housing.

NOTE POUR LE PERSONNEL

D’ENTRETIEN

234567890123456789012345678901212345678901234

PRECAUTION POUR LES RADIATIONS UV

La source de lumière, la lampe UHP, dans le

projecteur LCD émet de petites quantités de

radiation UV.

EVITEZ TOUTE EXPOSITION DIRECTE

DES YEUX ET DE LA PEAU.

Pour votre sécurité, nous vous prions de respecter

les points suivants:

1. Toujours porter des lunettes de soleil lors d’un

entretien du projecteur

avec la lampe allumée

et le haut du coffret retiré.

2. Ne pas faire fonctionner la lampe à l’extérieur du

boîtier de lampe.

3. Do not operate for more than 2 hours with the

enclosure removed.

UV-Radiation and Medium Pressure

Lamp Precautions

1. Be sure to disconnect the AC plug when replacing

the lamp.

2. Allow one hour for the unit to cool down before

servicing.

3. Replace only with same type lamp. Type BQCPGC20X//1 rated 100V/200W.

4. The lamp emits small amounts of UV-Radiation, avoid

direct-eye contact.

5. The medium pressure lamp involves a risk of

explosion. Be sure to follow installation instructions

described below and handle the lamp with care.

3. Ne pas faire fonctionner plus de 2 heures avec le

coffret retiré.

Précautions pour les radiations UV

et la lampe moyenne pression

1. Toujours débrancher la fiche AC lors du

remplacement de la lampe.

2. Laisser l’unité refroidir pendant une heure avant de

procéder à l’entretien.

3. Ne remplacer qu’avec une lampe du même type.

Type BQC-PGC20X//1, caractéristique 100V/200W.

4. La lampe émet de petites quantités de radiation UVéviter tout contact direct avec les yeux.

5. La lampe moyenne pression implique un risque

d’explosion. Toujours suivre les instructions

d’installation décrites ci-dessous et manipuler la

lampe avec soin.

5

Page 6

PG-C20XU

4

5

PG-C20XE

AN-Z7T

UV-RADIATION PRECAUTION (Continued)

23456789012345678901234567890121234567890123

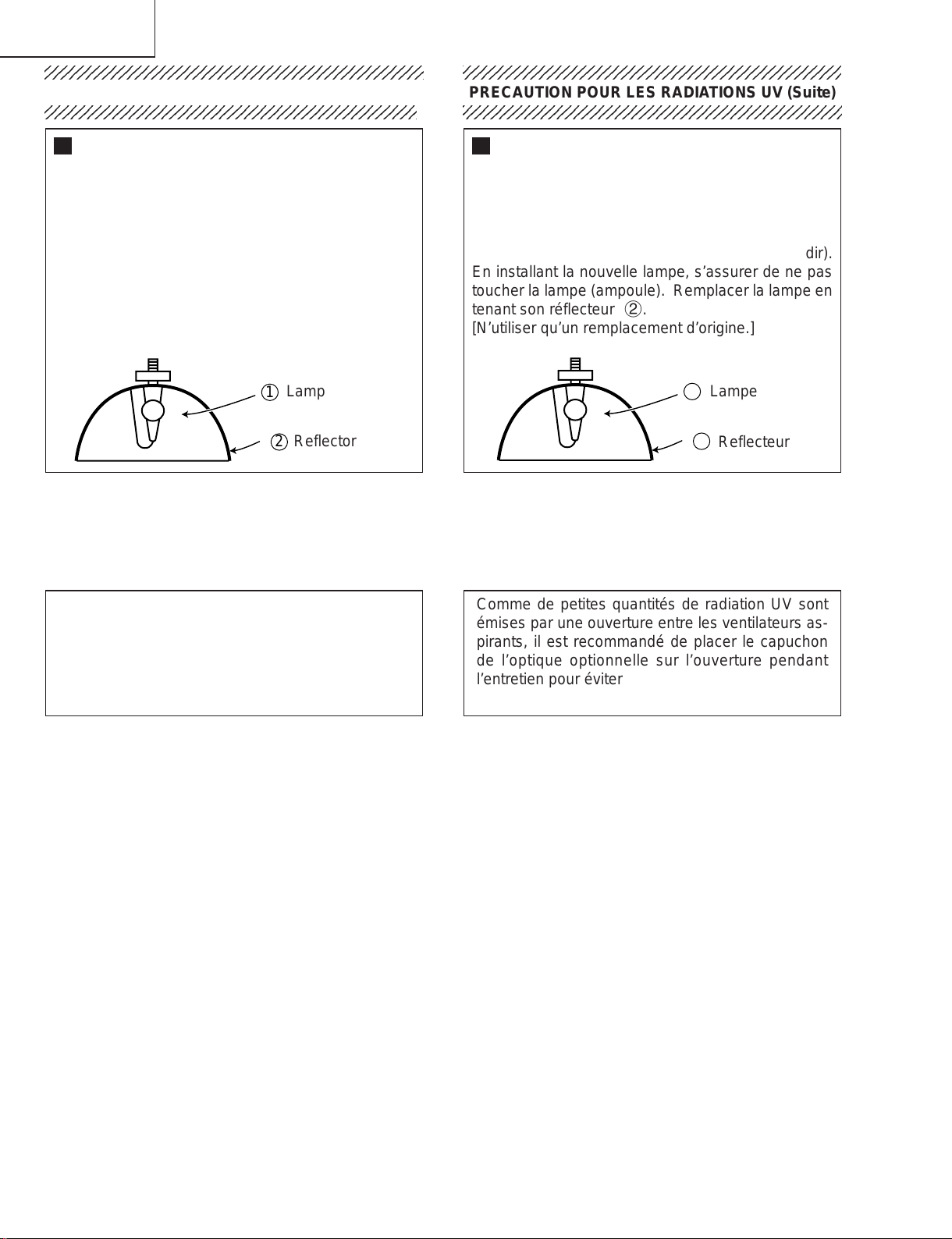

Lamp Replacement

Note:

Since the lamp reaches a very high temperature

during units operation replacement of the lamp

should be done at least one hour after the power

has been turned off. (to allow the lamp to cool off.)

Installing the new lamp, make sure not to touch the

lamp (bulb) replace the lamp by holding its reflector

2.

[Use original replacement only.]

Lamp

1

Reflector

2

DANGER ! –– Never turn the power on without the

lamp to avoid electric-shock or damage of the

devices since the stabilizer generates high voltages

at its start.

PRECAUTION POUR LES RADIATIONS UV (Suite)

234567890123456789012345678901212345678901234

Remplacement de la lampe

Remarque:

Comme la lampe devient très chaude pendant le

fonctionnement de l’unité, son remplacement ne doit

être effectué au moins une heure après avoir coupé

l’alimentation (pour permettre à la lampe de refroidir).

En installant la nouvelle lampe, s’assurer de ne pas

toucher la lampe (ampoule). Remplacer la lampe en

tenant son réflecteur 2.

[N’utiliser qu’un remplacement d’origine.]

1

Lampe

2

Reflecteur

DANGER ! –– Ne jamais mettre sous tension sans

la lampe pour éviter un choc électrique ou des

dommages des appareils car le stabilisateur génère

de hautes tensions à sa mise en route.

Since small amounts of UV-radiation are emitted from

an opening between the exhaust fans, it is recommended to place the cap of the optional lens on the

opening during servicing to avoid eye and skin exposure.

Comme de petites quantités de radiation UV sont

émises par une ouverture entre les ventilateurs aspirants, il est recommandé de placer le capuchon

de l’optique optionnelle sur l’ouverture pendant

l’entretien pour éviter une exposition des yeux et la

peau.

6

Page 7

PG-C20XU

2

PG-C20XE

AN-Z7T

WARNING: High brightness light source, do not stare into the beam of light, or view directly . Be especially

careful that children do not stare directly in to the beam of light.

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS UNIT TO

MOISTURE OR WET LOCATIONS.

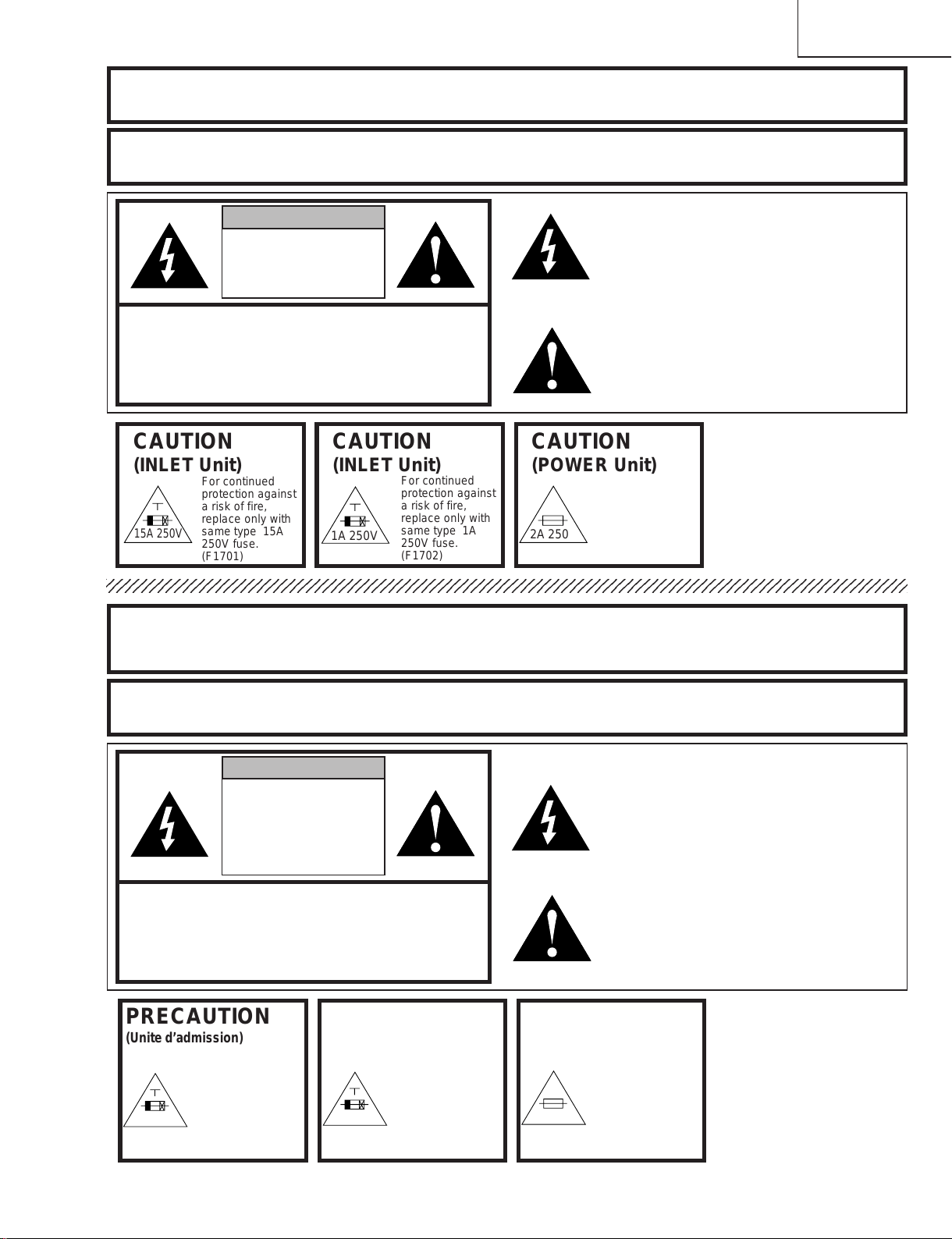

CAUTION

RISK OF ELECTRIC SHOCK.

DO NOT REMOVE SCREWS

EXCEPT SPECIFIED USER

SERVICE SCREW

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK,

NO USER-SERVICEABLE P ARTS EXCEPT LAMP UNIT.

CAUTION

(INLET Unit)

15A 250V

234567890123456789012345678901212345678901234567890123456789012123456789012345678901234567890121

DO NOT REMOVE CABINET.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

CAUTION

For continued

protection against

a risk of fire,

replace only with

same type 15A

250V fuse.

(F1701)

(INLET Unit)

1A 250V

For continued

protection against

a risk of fire,

replace only with

same type 1A

250V fuse.

(F1702)

CAUTION

(POWER Unit)

2A 250V

The lighting flash with arrowhead within a

triangle is intended to tell the user that

parts inside the product are risk of electric

shock to persons.

The exclamation point within a triangle is

intended to tell the user that important

operating and servicing instructions are in

the manual with the projector.

For continued

protection against a

risk of fire, replace

only with same type

P100A, ANZEN

DENGU, 2A, 250V

103°C fuse.(TF701)

A VERTISSEMENT : Source lumineuse de grande intensité. Ne pas fixer le faisceau lumineux ou le regarder

directement. Veiller particulièrement à éviter que les enfants ne fixent directement le

faisceau lumineux.

A VERTISSEMENT : AFIN D’EVITER TOUT RISQUE D’INCENDIE OU D’ELECTROCUTION, NE P AS PLACER

CET APPAREIL DANS UN ENDROIT HUMIDE OU MOUILLE.

ATTENTION

RISQUE

D’ELECTROCUTION NE

PASRETIRER LES VIS, A

L’EXCEPTION DES VIS DE

REPARATION UTILISATEUR

SPECIFIEES

L’éclair terminé d’une flèche à l’intérieur

d’un triangle indique à l’utilisateur que les

pi‘eces se trouvant dans l’appareil sont

susceptibles de provoquer une décharge

électrique.

Le point d’exclamation à l’intérieur d’un

ATTENTION: POUR EVITER TOUT RISQUE

D’ELECTROCUTION, NE PAS RETIRER LE CAPOT.

AUCUNE DES PIECES INTERIEURES N’EST REP ARABLE

PAR L’UTILISATEUR, A L’EXCEPTION DE L’UNITE DE

LAMPE. POUR TOUTE REP ARATION, S’ADRESSER A UN

PRECAUTION

(Unite d’admission)

15A 250V

TECHNICIEN D’ENTRETIEN QUALIFIE.

PRECAUTION

Pour une protection

continue contre les

risques d’incendie,

ne remplacer

qu’avec un fusible

15A 250V du même

type.

(F1701)

(Unite d’admission)

1A 250V

Pour une protection

continue contre les

risques d’incendie,

ne remplacer

qu’avec un fusible

1A 250V du même

type.

(F1702)

PRECAUTION

(Unité de PUTSSANCE)

2A 250V

triangle indique à l’utilisateur que les

instructions de fonctionnement et

d’entretien sont détaillées dans les

documents fournis avec le projecteur.

Pour une protection

continue contre un

risques d’incendie, ne

remplacer qu’avec un

fusible P100A, ANZEN

DENGU 2A 250V,

103°C du même type.

(TF701)

7

Page 8

PG-C20XU

PG-C20XE

AN-Z7T

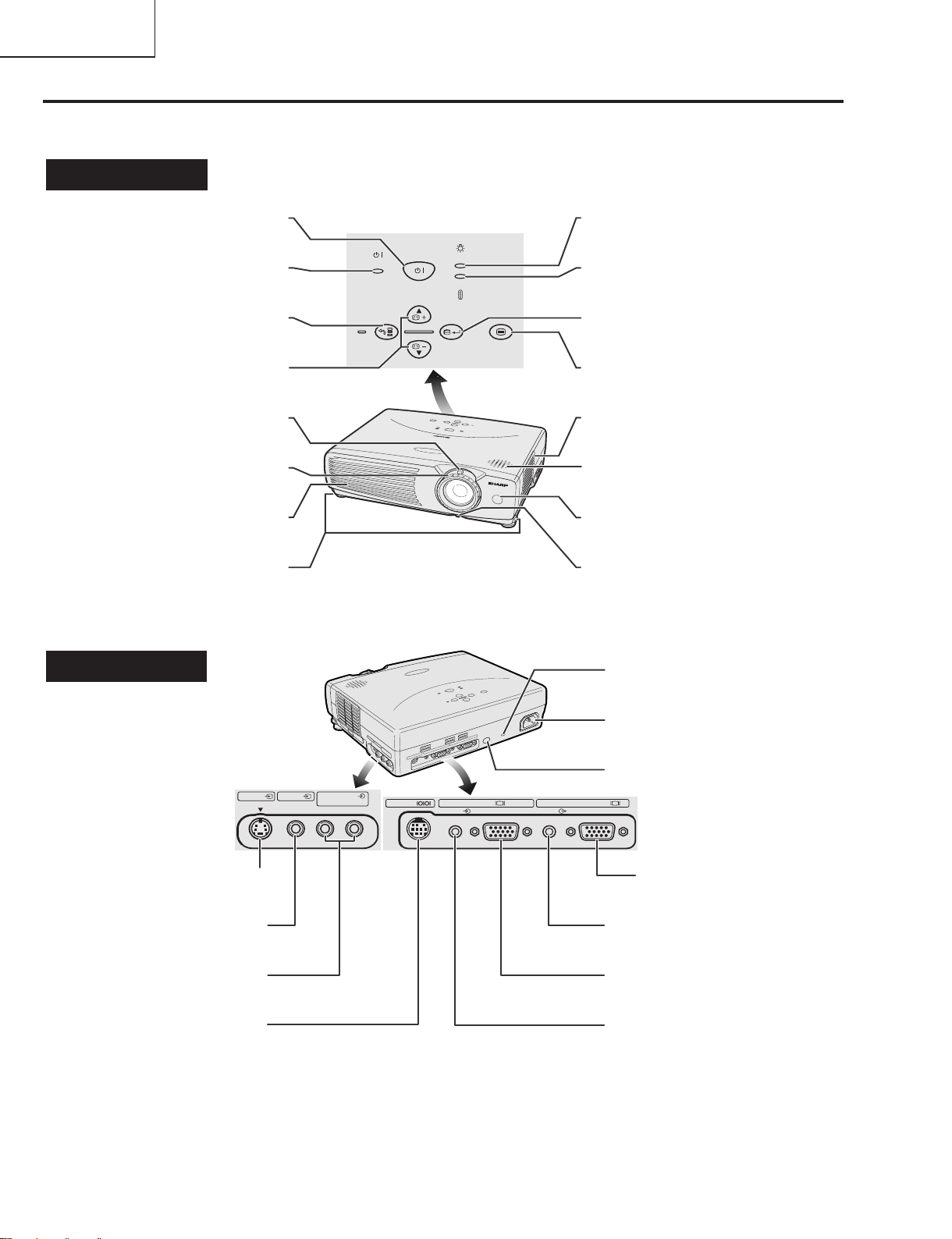

Location of Controls

Projector

Front and Top View

POWER indicator

INPUT/BACK button

KEYSTONE/Adjustment

Cooling fan (Exhaust vent)

Side and Rear View

ON/OFF button

(]/[ )buttons

ZOOM knob

FOCUS ring

Foot releases

POWER

INPUT

BACK

ON/OFF

KEYSTONE

LAMP

TEMP.

AUTO SYNC

ENTER

LAMP REPLACEMENT

indicator

TEMPERATURE WARNING

indicator

AUTO SYNC/ENTER button

MENU

MENU button

Air filter/Cooling fan

(Intake vent)

Speaker

Remote control sensor

Eyelet for

lens cap strap

Kensington Security

Standard connector

S-VIDEO INPUT 2 terminal

(4-pin Mini DIN)

VIDEO INPUT 3 terminal

(RCA)

AUDIO INPUT terminals

(RCA)

RS-232C port

(9-pin Mini DIN)

INPUT 2

S-VIDEO

INPUT 3 AUDIO INPUT

(S-VIDEO, VIDEO INPUT)

VIDEO

RS-232C

INPUT 1 OUTPUT (INPUT1)

AUDIO

COMPUTER

AUDIO

AC socket

Remote control sensor

COMPUTER

COMPUTER OUTPUT port

for INPUT 1

(HD 15)

AUDIO OUTPUT terminal

for INPUT 1

(3.5 mm stereo minijack)

COMPUTER INPUT 1 port

(HD 15)

AUDIO INPUT 1 terminal

(3.5 mm stereo minijack)

8

Page 9

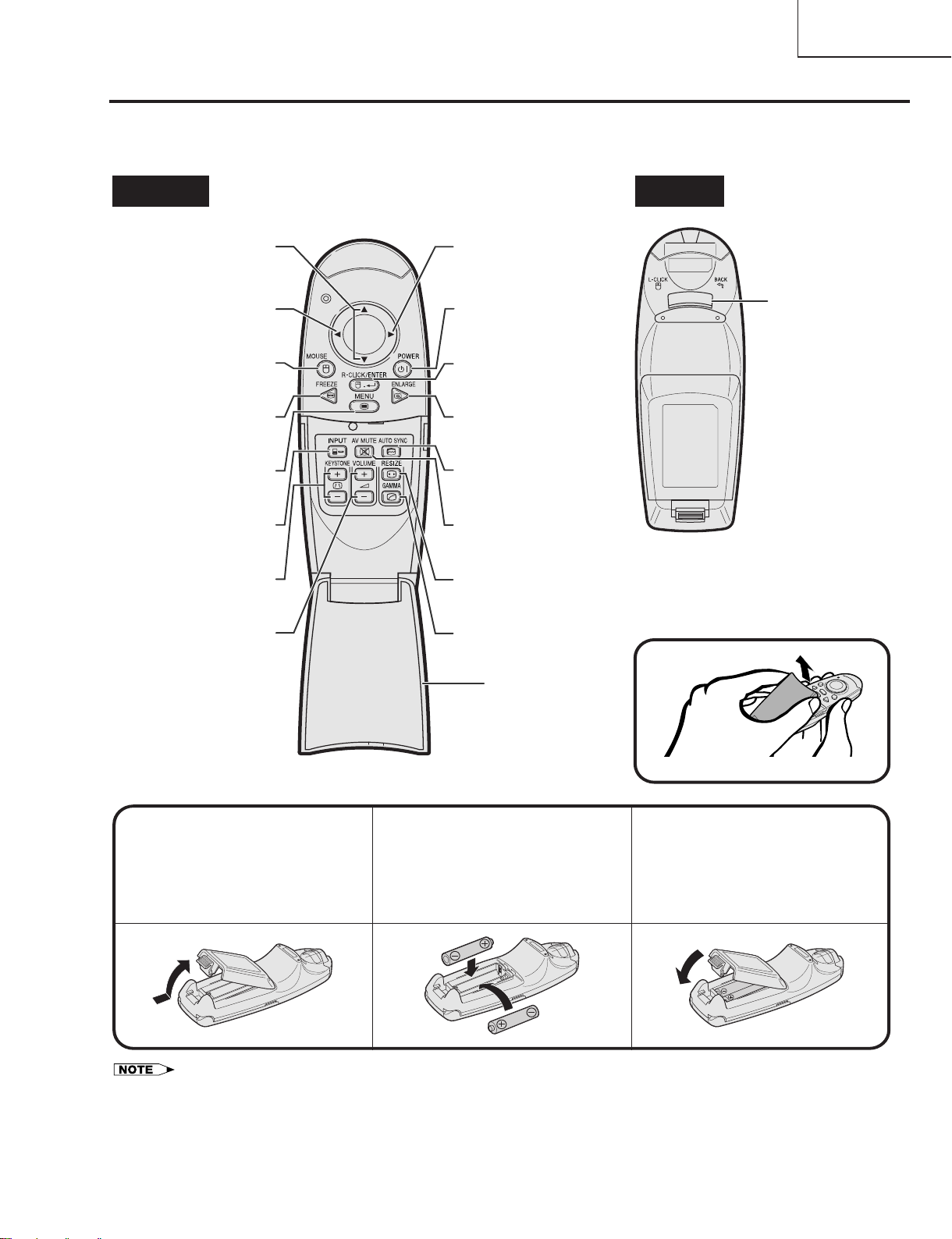

Remote Control

Front View

Rear View

Mouse (]/[)/

Adjustment (]/[)

buttons

Mouse (>)button

Mouse (<)button

MOUSE button

FREEZE button

MENU button

INPUT button

KEYSTONE buttons

VOLUME buttons

POWER button

RIGHT-CLICK/

ENTER button

ENLARGE button

AUTO SYNC button

AV MUTE button

RESIZE button

GAMMA button

Flip cover

LEFT-CLICK/

BACK button

Opening the Flip Cover

3

Press the tab and lift open

the battery cover in the

direction of the arrow.

Insert two AAA size

batteries,making sure

their polarities match the

+ and - marks inside

the battery compartment.

Inserting the Batteries

Insert the tabs on the

end of the battery cover

into their slots and press

the cover into position.

1

2

• If the remote control gets wet, wipe it dry immediately.

• Avoid excessive heat and humidity.

• If you will not be using the remote control for a long time, remove the batteries.

• Do not mix new and old or different types of batteries.

• There are operations that can only be carried out by remote control. Handle the remote control carefully.

PG-C20XU

PG-C20XE

AN-Z7T

9

Page 10

PG-C20XU

PG-C20XE

AN-Z7T

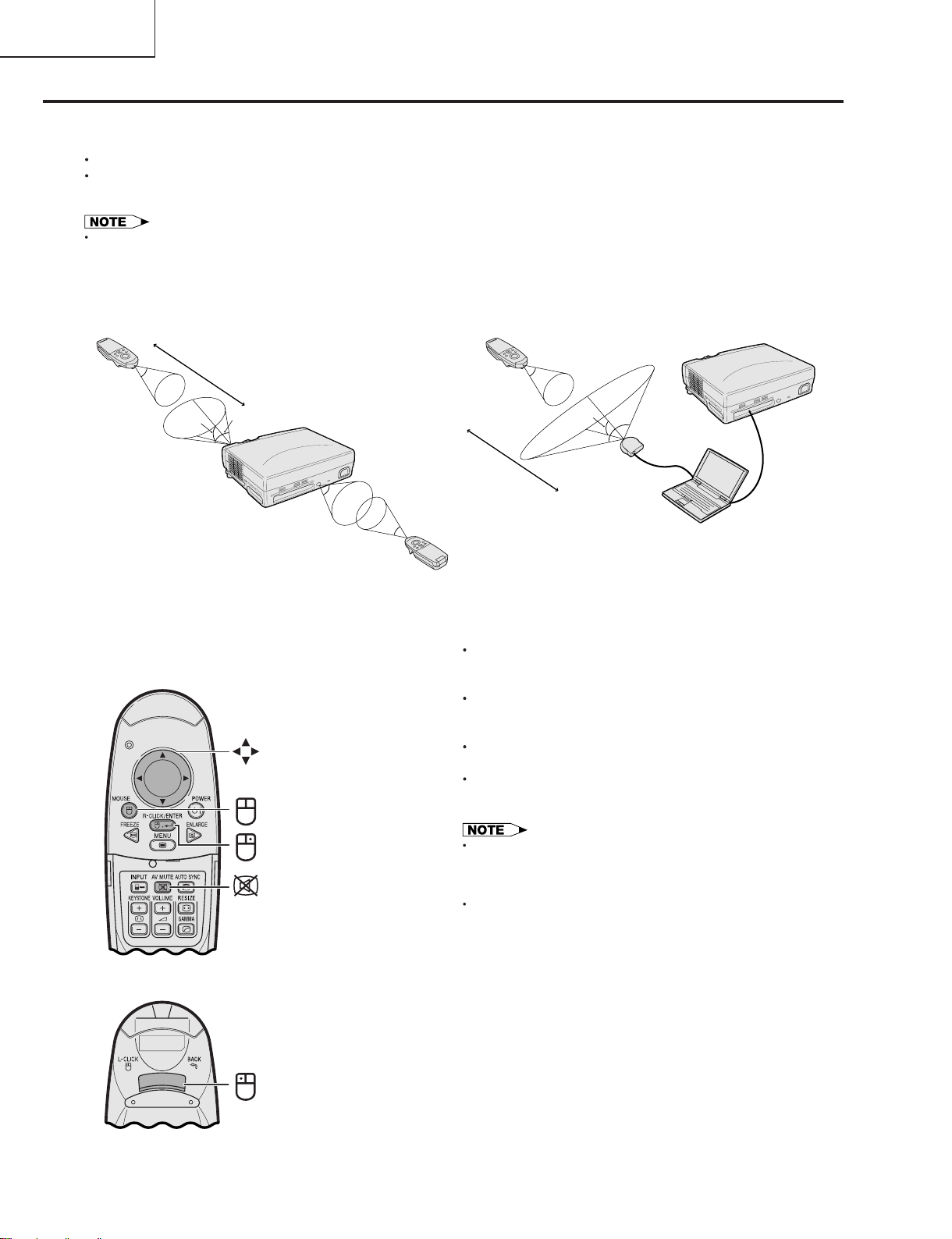

Remote Control/Mouse Receiver Positioning

The remote control can be used to control the projector within the ranges shown below.

The remote mouse receiver can be used with the remote control to control the mouse functions of a connected

computer within the ranges shown below.

The signal from the remote control can be reflected off a screen for easy operation. However, the effective distance of the

signal may differ due to the screen material.

Controlling the Projector

Remote control

23’ (7 m)

30ß

45ß

30ß

Effective buttons in MOUSE mode

Remote control

(Front view)

Mouse

MOUSE

45ß

30ß

Remote control

Using the Wireless Mouse

Remote control

30ß

30ß

120ß

13’(4 m)

Remote

mouse

receiver

Using as a Wireless Mouse

When MOUSE is pressed, the buttons on the remote

control light up and the remote control enters MOUSE

mode.

During MOUSE mode, the cursor can be used as the

pointer. MOUSE mode is for about ten seconds while

the buttons are lighting.

When MENU or ENLARGE is pressed, MOUSE mode

is released to the normal mode.

Be sure the supplied remote mouse receiver is

connected to your computer.

Remote control

(Rear view)

RIGHT-CLICK

AV MUTE

LEFT-CLICK

The wireless mouse may not operate correctly if your

computer serial port is not correctly set up. Refer to the

computer s operation manual for details of setting up/

installing the mouse driver.

For one-button mouse systems, use either the LEFT-CLICK

or RIGHT-CLICK button.

10

Page 11

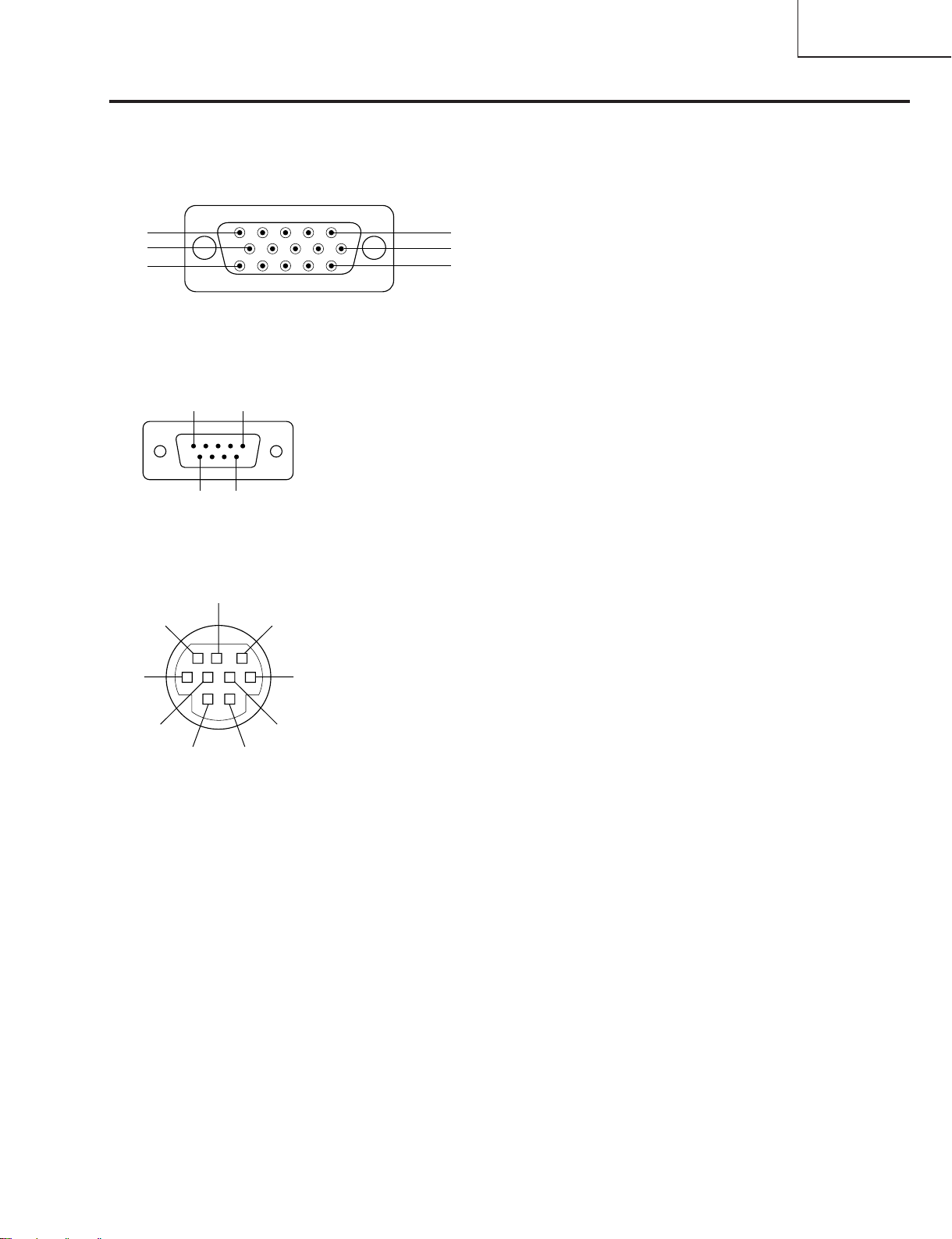

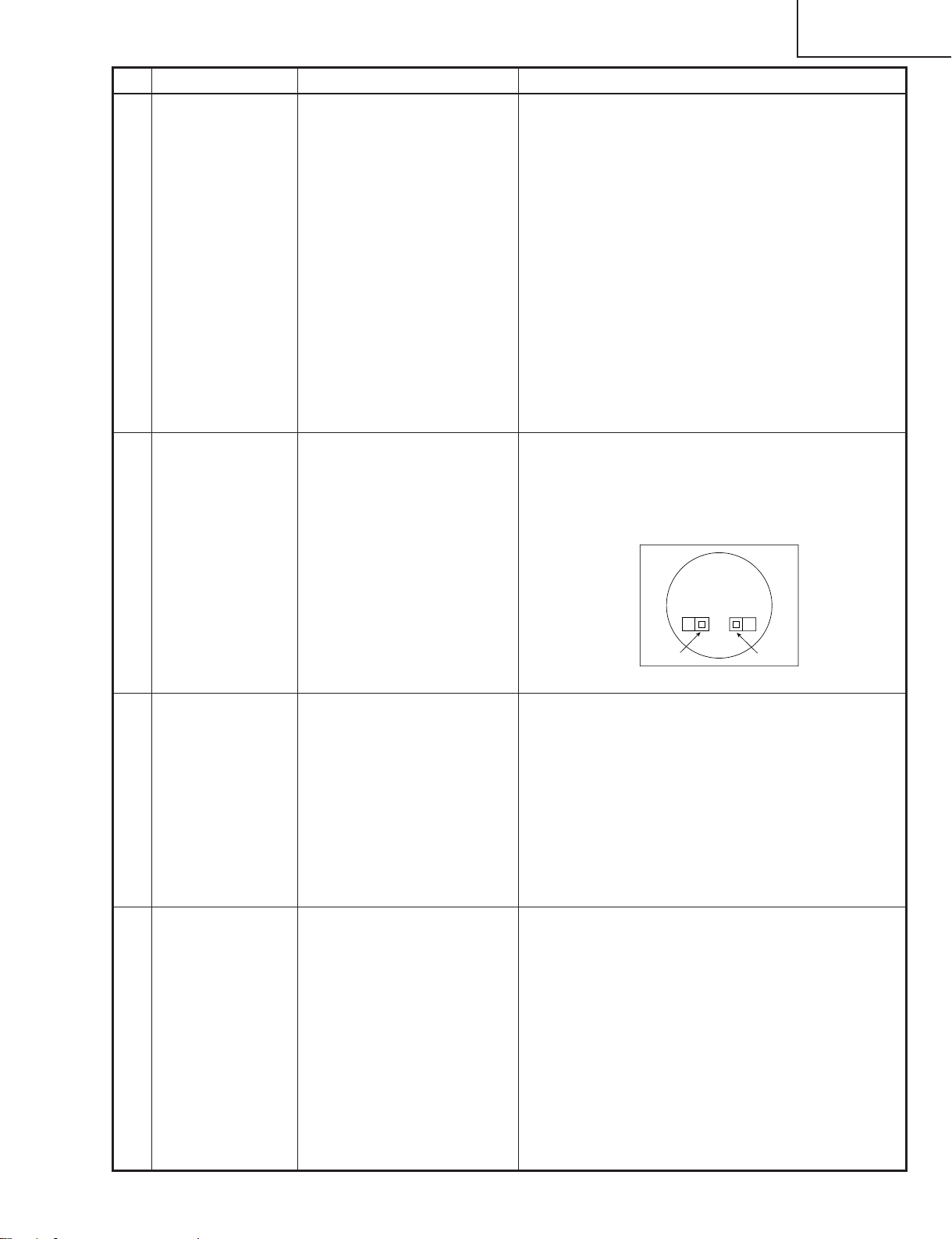

Connection Pin Assignments

COMPUTER INPUT 1 Port: 15-pin mini D-sub female connector

Computer Input

Analog

1. Video input (red)

2. Video input

(green/sync on green)

5

10

15

1

6

11

RS-232C Port: 9-pin D-sub male connector of the DIN-D-sub RS-232C cable

Pin No. Signal Name I/O Reference

1

5

69

1 Not connected

2 RD Receive Data Input Connected to internal circuit

3 SD Send Data Output Connected to internal circuit

4 Not connected

5 SG Signal Ground Connected to internal circuit

6 Not connected

7 Not connected

8 Not connected

9 Not connected

3. Video input (blue)

4. Not connected

5. Composite sync

6. GND (red)

7. GND (green/sync on green)

8. GND (blue)

PG-C20XU

PG-C20XE

AN-Z7T

9. Not connected

10.Not connected

11.GND

12.Bi-directional data

13.Horizontal sync signal

14.Vertical sync signal

15.Data clock

RS-232C Terminal: 9-pin Mini DIN female connector

8

9

6

5

2

7

4

1

Pin No. Signal Name I/O Reference

1 Not connected

2 RD Receive Data Input Connected to internal circuit

3 SD Send Data Output Connected to internal circuit

4 Not connected

3

5 SG Signal Ground Connected to internal circuit

6 Not connected

7 Not connected

8 Not connected

9 Not connected

11

Page 12

PG-C20XU

PG-C20XE

AN-Z7T

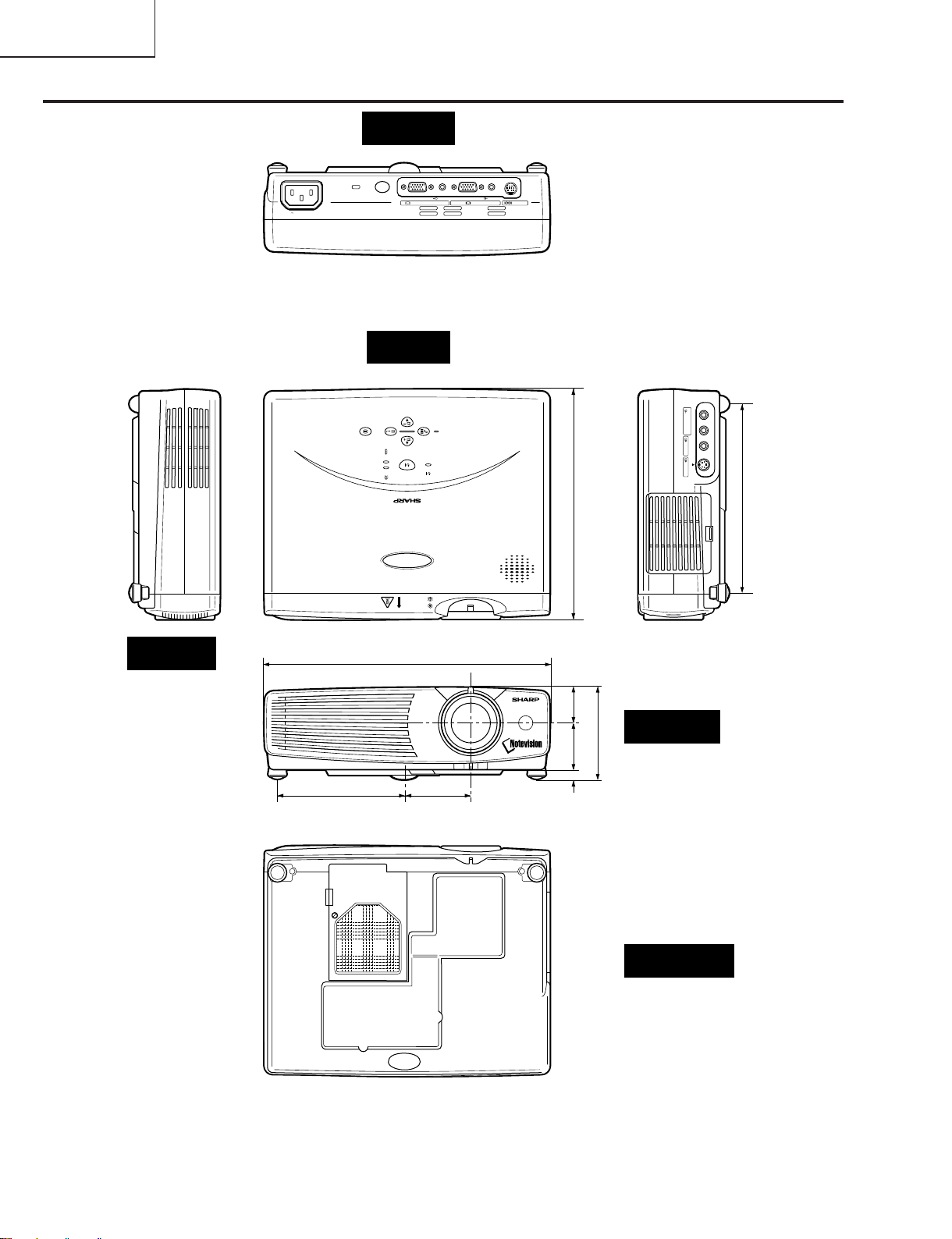

Dimensions

Rear View

Top View

Side View

21

4 / (118)

32

15

10 / (260)

64

9

32

2 / (58)

32

5

8 / (207)

64

17

1 / (32)

32

21

1 / (42)

16

5

/ (8)

Front View

64

15

3 / (82)

64

43

6 / (169.5)

12

Bottom View

Unit: inches (mm)

Page 13

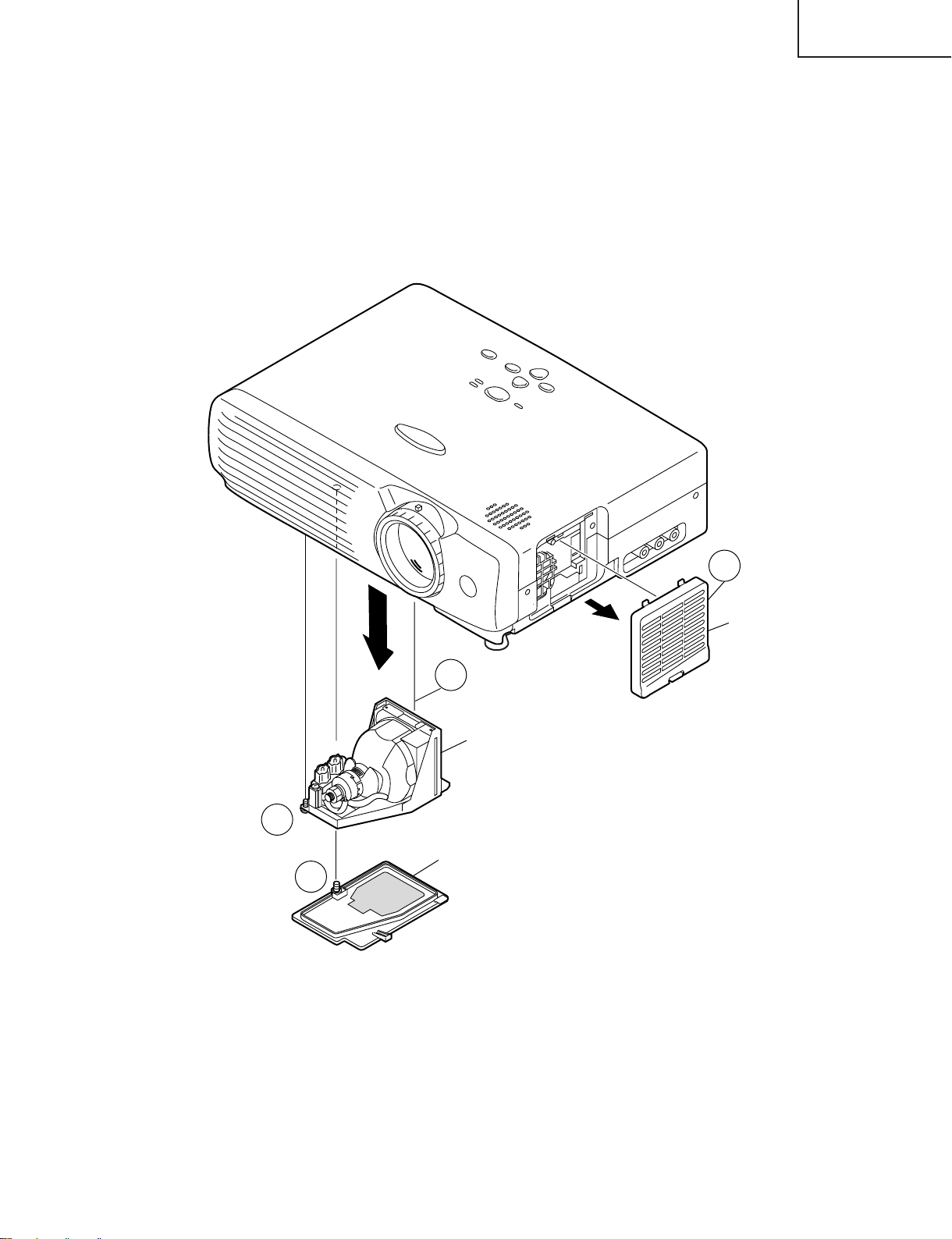

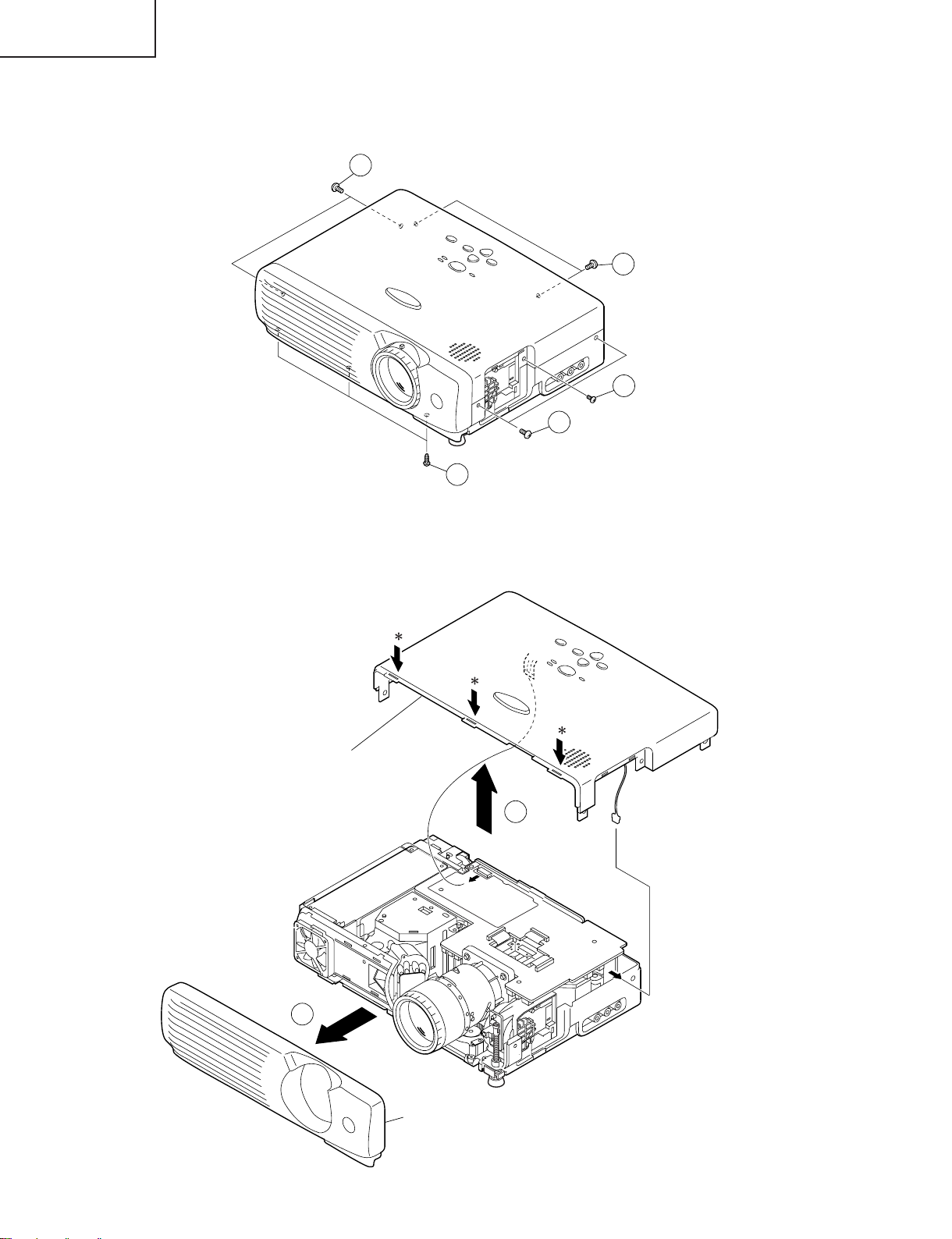

REMOVING OF MAJOR PARTS

1.Removing the intake cover and the lamp unit.

1-1. Detach the intake cover.

1-2. Remove the one lock screw (silver) from the lamp cover and detach the lamp cover.

1-3. Remove the two lock screws (silver) from the lamp unit and detach the lamp unit.

PG-C20XU

PG-C20XE

AN-Z7T

1-3

1-1

Intake cover

1-3

Lamp unit

Lamp cover

1-2

13

Page 14

PG-C20XU

PG-C20XE

AN-Z7T

2.Removing the front and top panels

2-1. Remove the three lock screws (silver) from the front panel.

2-2. Remove the seven lock screws (silver) from the top panel.

2-2

2-2

2-2

2-2

2-1

2-3. Press the ❈-marked spots of the top panel to unhook the claws, and detach the top panel.

2-4. Slowly lift the top panel, disconnect the connectors from the control panel and speaker, and lift up the top

panel.

Top panel

2-4

2-3

Front Panel

14

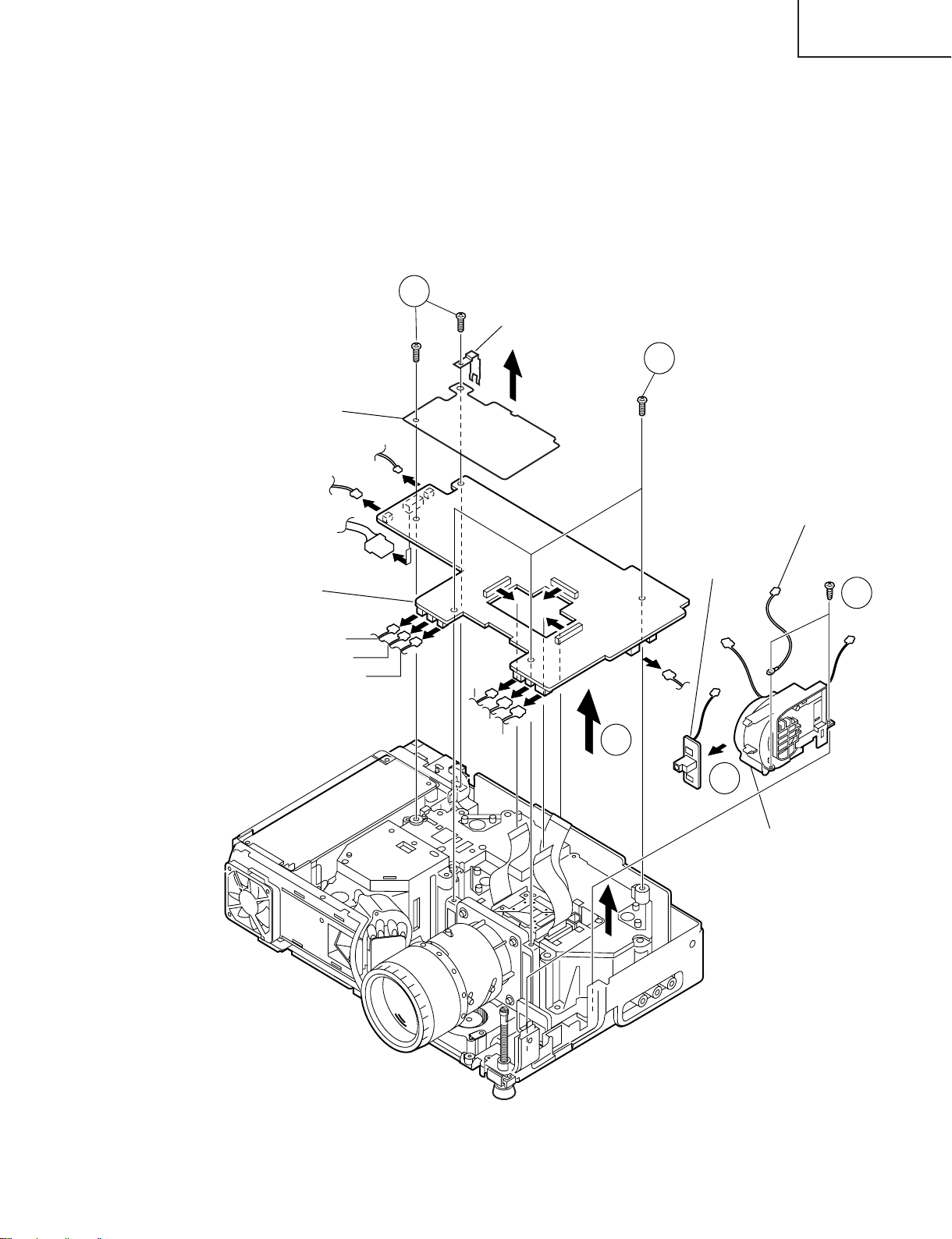

Page 15

PG-C20XU

Intake fan unit

Remote control

receiver PWB

Temperature sensor

Output PWB

Grounding spring

3-2

3-4

3-3

3-1

3-1

Electrostatic sheet

(PG-C20XU Only)

(P1702)

(P1707)

(P1703)

(P1705)

(SC1102)

(SC1202)

(SC1302)

(P1601)

(P1708)

(P1706)

(P1704)

(P1602)

(P1701)

PG-C20XE

AN-Z7T

3.Removing the output PWB unit, remote control receiver PWB unit and intake

fan unit

3-1. Remove the five lock screws (yellow) from the output PWB unit. Remove the grounding spring and the

electrostatic sheet (PG-C20XU only).

3-2. Lift the output PWB unit, disconnect the connectors and lift up the output PWB unit.

3-3. Remove the two lock screws (black) from the intake fan unit and detach both the intake fan unit and the

temperature sensor.

3-4. Unhook the claws of the intake fan unit off the remote control receiver PWB unit, and detach this unit.

15

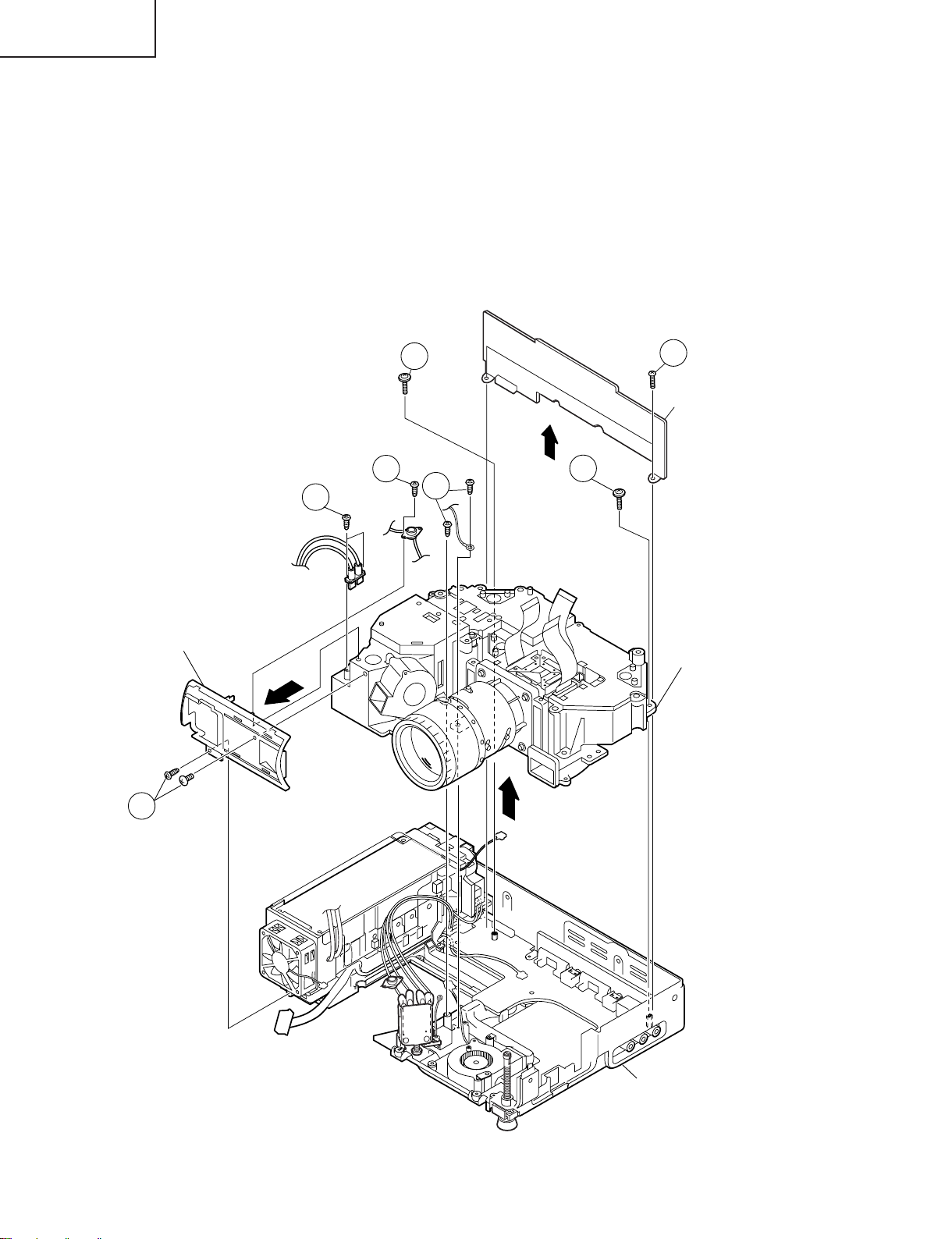

Page 16

PG-C20XU

PG-C20XE

AN-Z7T

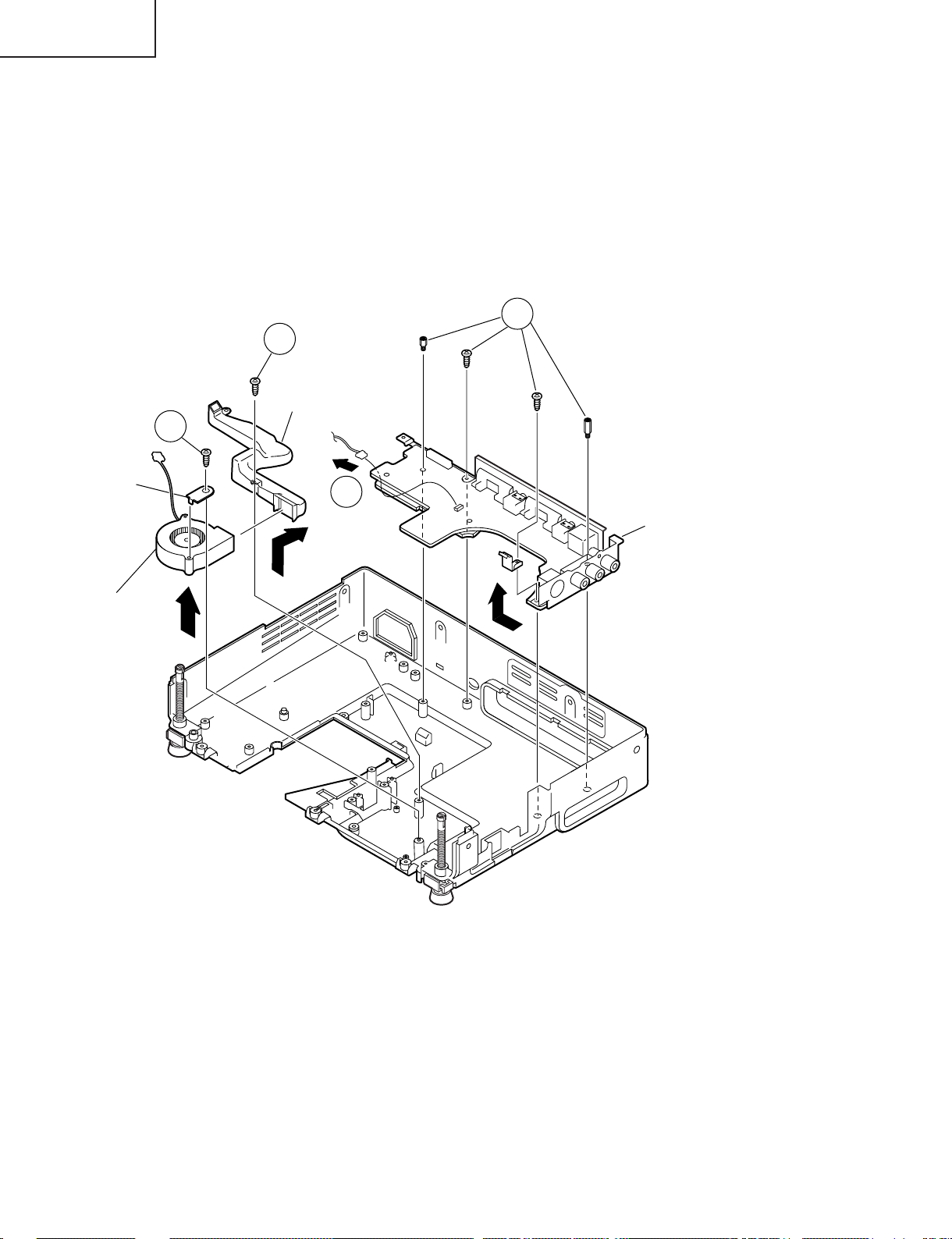

4.Removing the front duct unit, PC I/F PWB units, and optical mechanism unit

4-1. Remove the lock screw (silver) from the bimetal and detach the bimetal.

4-2. Remove the two lock screws (one in black, the other in silver) from the front duct unit and detach the front

duct unit.

4-3. Remove the two lock screws (yellow) from the PC I/F PWB unit. Detach this unit from above.

4-4. Remove the two lock screws (silver) from the lamp socket holder and detach the lamp socket holder.

4-5. Remove the four lock screws (two in black, two in yellow) from the optical mechanism unit and detach the

optical mechanism unit from above.

Front duct unit

4-4

4-1

4-5

4-3

PC I/F PWB

unit

4-5

4-5

Optical

mechanism

unit

4-2

Bottom panel

16

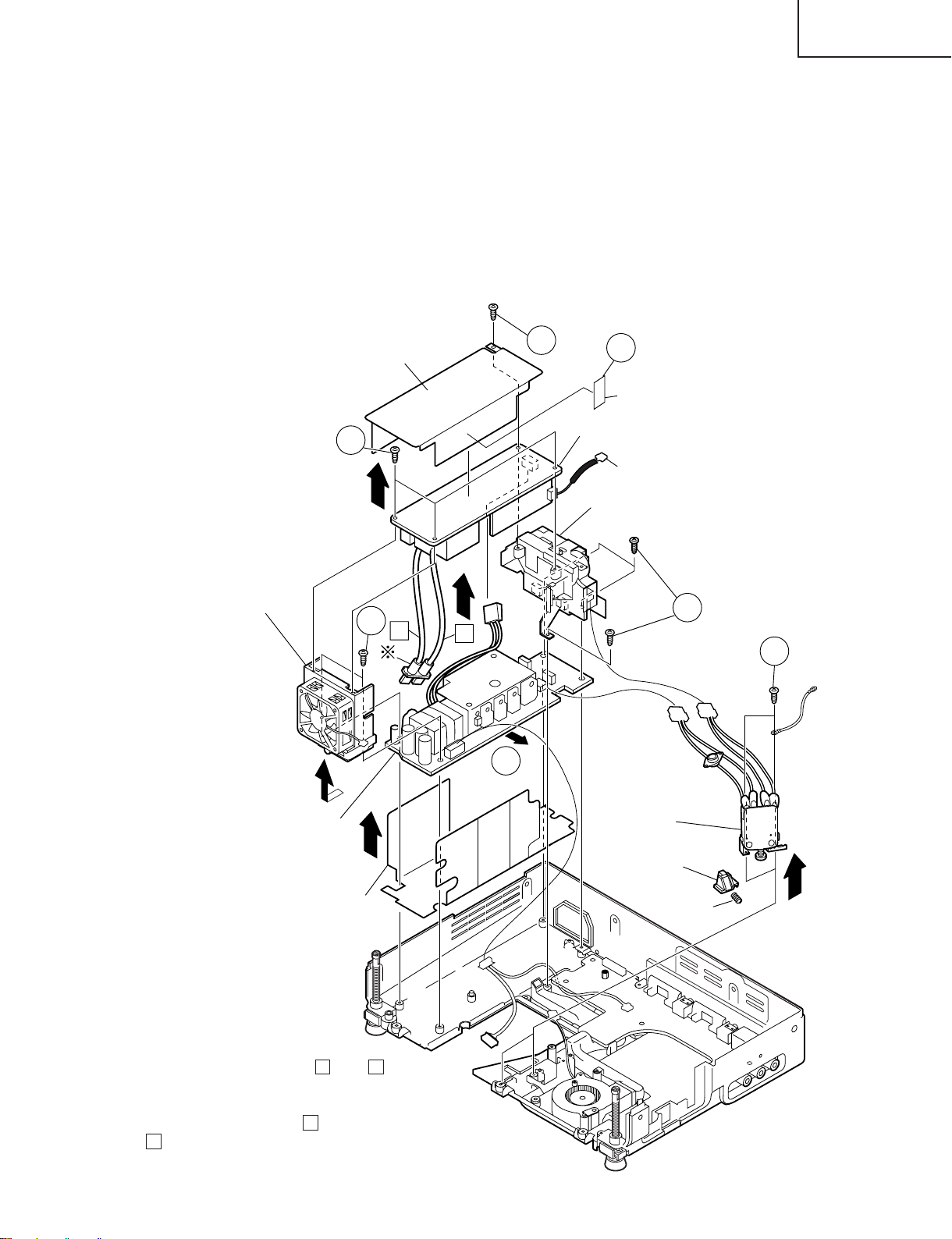

Page 17

PG-C20XU

PG-C20XE

AN-Z7T

5.Removing the ballast/power/AC inlet PWB unit, cooling fan and AC select

switch

5-1. Remove the lock screw (yellow or silver) from the ballast cover. Peel the Teflon tape that secures the lead

wires on the ballast cover. Detach the ballast cover.

5-2. Remove the three lock screws (yellow or silver) from the ballast PWB unit. Disconnect the connectors from

the power PWB unit and detach the ballast PWB unit.

5-3. Remove the two lock screws (silver) from the cooling fan/power PWB unit and detach the cooling fan unit.

5-4. Remove the three lock screws (silver) from the AC inlet/power PWB unit. Disconnect the AC select switch

connectors and the power PWB connector (EA). Detach the AC inlet PWB unit, power PWB unit and power

PWB unit cover.

5-5. Remove the two lock screws (yellow) from the AC select switch and detach the switch, slide and spring.

Cooling fan

Ballast cover

5-2

5-3

5-1

5-1

Teflon tape

Ballast PWB

Note: Be careful when connecting this

connector close to the live part of the

()

ballast PWB unit.

AC inlet PWB unit

5-4

B

A

5-5

5-4

Power PWB unit

Power PWB unit cover

❋ Precautions in reassembling

Keep the high-voltage leads ( A and B in

the figure) of the lamp socket on the

ballast PWB out of contact with the cooling

fan. To do this, lay the lead B behind the

lead A and dress them up in the cooling

fan holder notch.

AC select switch

Slide

Spring

(EA)

17

Page 18

PG-C20XU

PG-C20XE

AN-Z7T

6.Removing the connecting terminals/3-dimensional Y/C separation PWB unit

assembly

6-1. Remove the two lock screws (yellow) and the two supports from the connecting terminals/3-dimensional Y/

C separation PWB unit assembly. Slide the PWB unit and draw the terminals out of the bottom plate.

6-2. Disconnect the connector (EA) from the connecting terminals PWB unit.

7.Removing the center duct and the PBS fan

7-1. Remove the one lock screw (yellow) from the center duct and detach the center duct.

7-2. Remove the one lock screw (yellow) from the PBS fan and detach the angle and the PBS fan.

6-1

7-1

Center duct

Angle

PBS fan

7-2

(EA)

6-2

Connecting terminals/

3-dimensional

Y/C separation PWB

unit assembly

18

Page 19

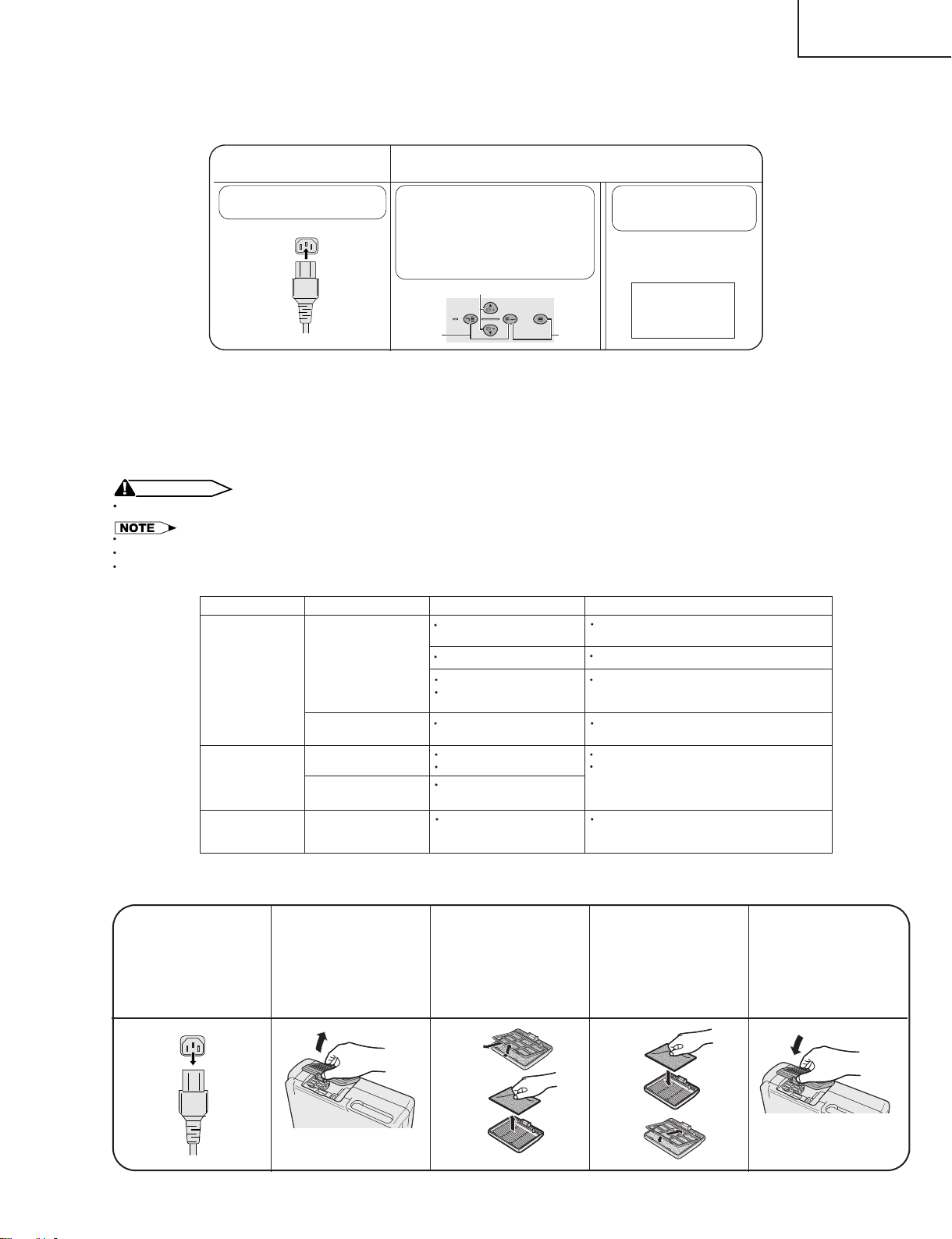

Resetting the TOTAL LAMP TIMER

CAUTION

Intense light hazard. Do not attempt to look into the aper ture and lens while the projector is operating.

As the usage environment can vary significantly, the projector lamp may not operate for 1,000 hours.

"1,000 hours" above indicates average life span and should be used for r eference only. This is different than the warranty period.

For safety, the power will not be turned on from the fourth times when turning on the power without changing the lamp after use for 1,000

hours.

● Resetting the total lamp timer

When replacing the lamp, reset the total lamp timer in the procedure below.

PG-C20XU

PG-C20XE

AN-Z7T

Connect the power cord.

1

Plug the power cord into the AC

socket of the projector.

Reset the lamp timer.

2

1 Press KEYSTONE ' and

KEYSTONE " on the projector at

the same time.

2 Press INPUT and AUTO SYNC on

the projector at the same time.

3Press AUTO SYNC and MENU at

the same time until unit comes on.

1

INPUT

AUTO SYNC

BACK ENTER MENU

2

3

LAMP 0000H

displayed, indicating that

the lamp timer is reset.

LAMP 0000H

is

● Light source (lamp)

The lamp used for light source has a service life of about 1,000 hours. If the total operating time exceeds 900

hours, replace the lamp with new one (separately sold) as soon as possible. However, if the image becomes

dim or the colors get less crisp even before the total operating time does not exceeds 900 hours, also replace

the lamp. The lamp's total operating time can be checked on the screen. If noticeable color irregularities are

found after replacing the lamp, make the color irregularity correction on page 28.

Maintenance Indicator

TEMPERATURE

WARNING

indicator

LAMP

REPLACEMENT

indicator

POWER indicator

Condition Possible Solution

The internal

temperature is

abnormally high.

The indicator flashes in

red.

The lamp does not

illuminate.

The lamp requires

replacement.

The indicator flashes in

red when the projector

is on.

Problem

Blocked air intake.

Clogged air filter.

Cooling fan breakdown.

Internal circuit failure.

Cooling down. Wait until the indicator stops flashing and

Burnt-out lamp.

Lamp circuit failure.

Lamp has been used for

over 900 hours.

The filter cover is open. Securely install the filter cover

Relocate the projector to an area with proper

ventilation.

Clean the filter.

Take the projector to your nearest Authorized

Sharp Industrial LCD Products Dealer or

Service Center for repair.

turns off.

Carefully replace the lamp.

Take the projector to your nearest Authorized

Sharp Industrial LCD Products Dealer or

Service Center for repair.

.

● Replacing the air filter

Just when replacing the lamp, replace also the air filter with the one that comes with the lamp replacement kit.

1.Disconnect the power

cord.

Unplug the power cord

from the AC socket.

r

2.Remove the filter cover.

Turn over the projector.

Press the tab and remove

the filter cover in the direction of the arrow.

3.Remove the air filter.

1 Remove the air filter

stopper.

2 Remove the air filter.

1

2

19

4.Replace the air filter.

1 Put the new air filter

into position.

2 Put the air filter stopper

back into position.

1

2

5.Replace the filter cover.

Insert the tab on the end of

the filter cover into the filter

cover opening and press

the filter cover into

position.

Page 20

PG-C20XU

PG-C20XE

AN-Z7T

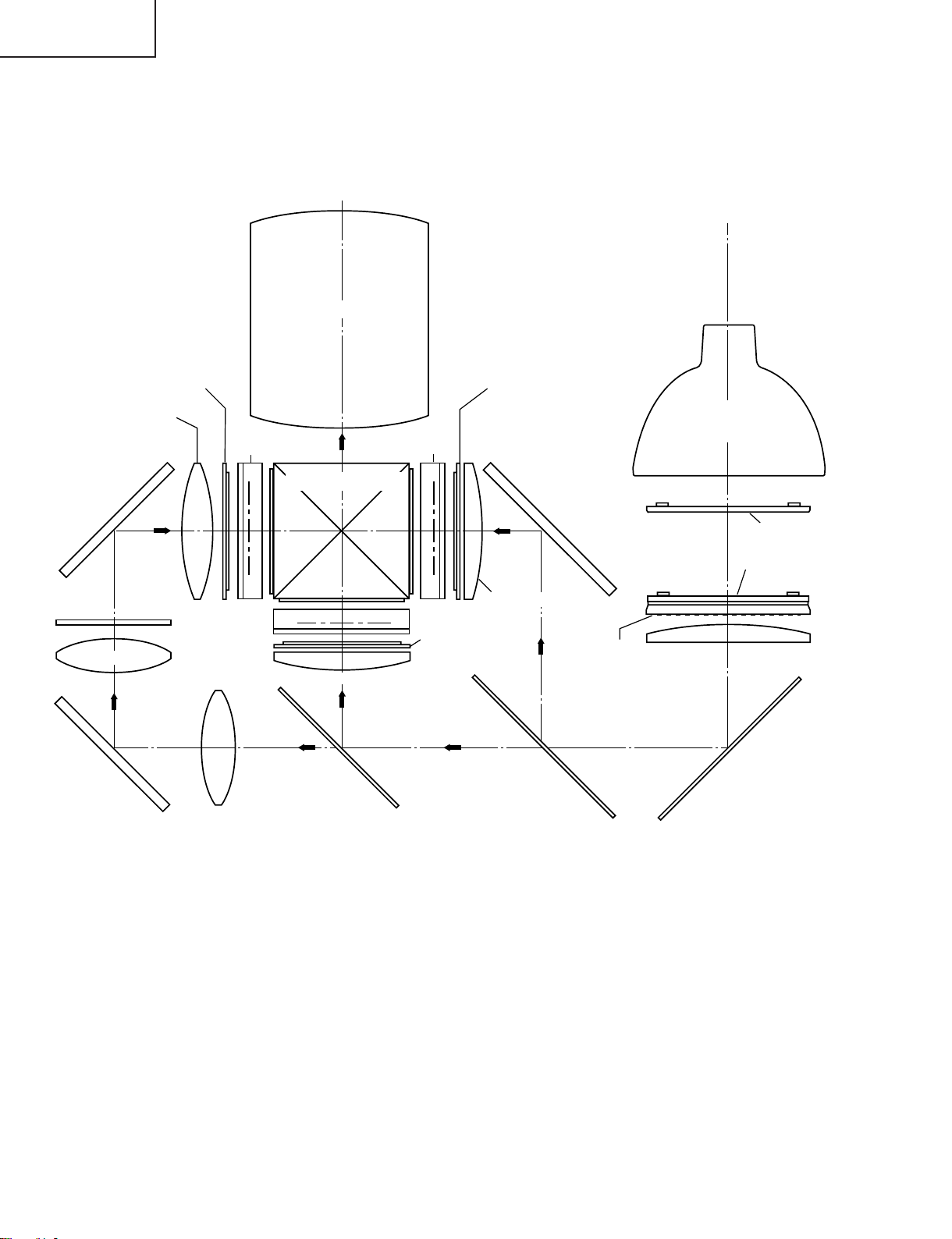

THE OPTICAL UNIT OUTLINE

Layout for proper setup of the optical components and parts (top view)

Projection Lens

Input polarizer B

Relay lens 3

M6

Mirror R, G, B

F1

Relay lens 2

Mirror R, G, B

G03

UV absorbing glass

G02

M4

Relay lens 1

LCD(B)

LCD(G)

L3

G01

Cross dichroic prism

Condencer lens G

Green

Blue

G reflector

M3

LCD(R)

Condencer lens R

Input polarizer G

Green/Blue

Input polarizer R

AL-coated mirror R

L2

Red

M2

M5

PBS

R reflector

Light source

(Lamp)

Fly-eye lens (Input)

Fly-eye lens (Output)

L1

AL-coated mirror R,G, B

M1

20

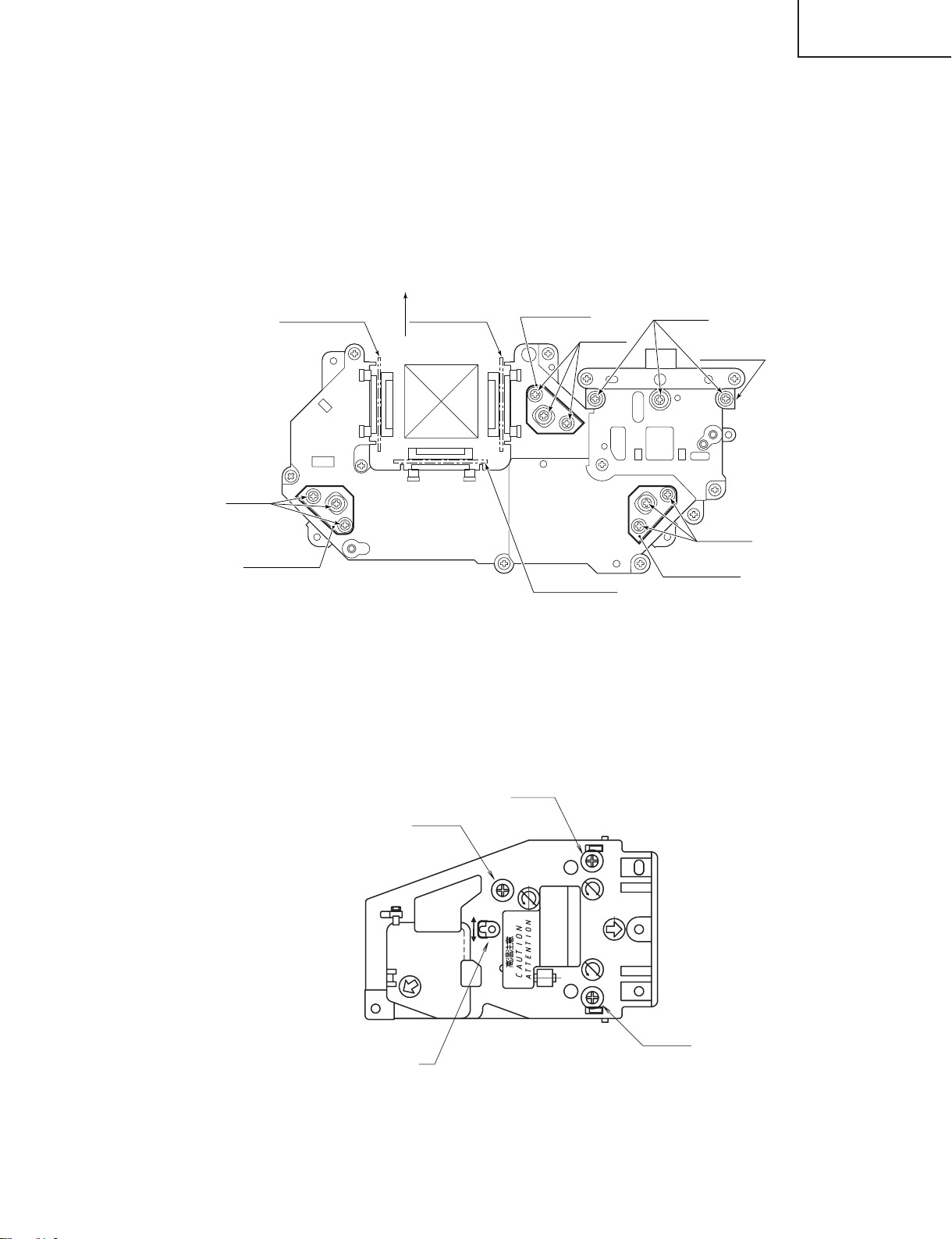

Page 21

PG-C20XU

Lamp assembly (bottom view)

Screw B

Screw A

Screw C

D

PG-C20XE

AN-Z7T

Adjusting the mirrors

This adjustment is needed when any of the optical parts of the optical mechanism has been replaced.

1. Disconnect the flat cables from all the LCD panels.

2. Light up the lamp.

3. Project a white-light image and check to see if there is any color tint in any direction. If any, loosen the incident-light

fly-eye adjusting plate lock screws and readjust the fly-eye to get the image uniformly whitish. Tighten up the lock

screws.

4. If by any chance the above step 3 fails, use the M1, M4 and M5 adjusting levers.

5. Before moving the M5 adjusting lever, shield the G and B color beams. (For shielding them, use reflective sheets

that reflect the incident lights.)

6. Loosen the adjusting lever lock screws, make adjustments, and tighten up the lock screws.

7. Before moving the M4 adjusting lever, shield the R and G color beams.

Lock screws

(yellow)

M4 Adjusting lever

Shielding plate for B

Front

Shielding plate for R

M5 Adjusting lever

Shielding plate for G

Lock screws

(yellow)

Lock screws

(yellow)

incident-light fly-eye

adjusting plate

Lock screws

(yellow)

M1 Adjusting lever

Correcting color irregularities on white-only screen when replacing the lamp

If color irregularities are found at the right and left on a white-only screen after replacing the lamp, it is necessary to

readjust the optical axis of the new lamp. Take the following steps.

1. Open the lamp cover and loosen the screws A, B and C at the bottom of the lamp.

2. Using a screwdriver or the like, move the U-shaped groove at the window D in the arrow direction.

3. Temporarily fix the screws A, B and C, close the lamp cover, and check the white-only screen again for color

irregularities.

4. Repeat the above steps 1, 2 and 3 until there will be no color irregularities. Now tighten up the screws A, B and C.

5. Finally secure the lamp cover back in position.

21

Page 22

PG-C20XU

PG-C20XE

AN-Z7T

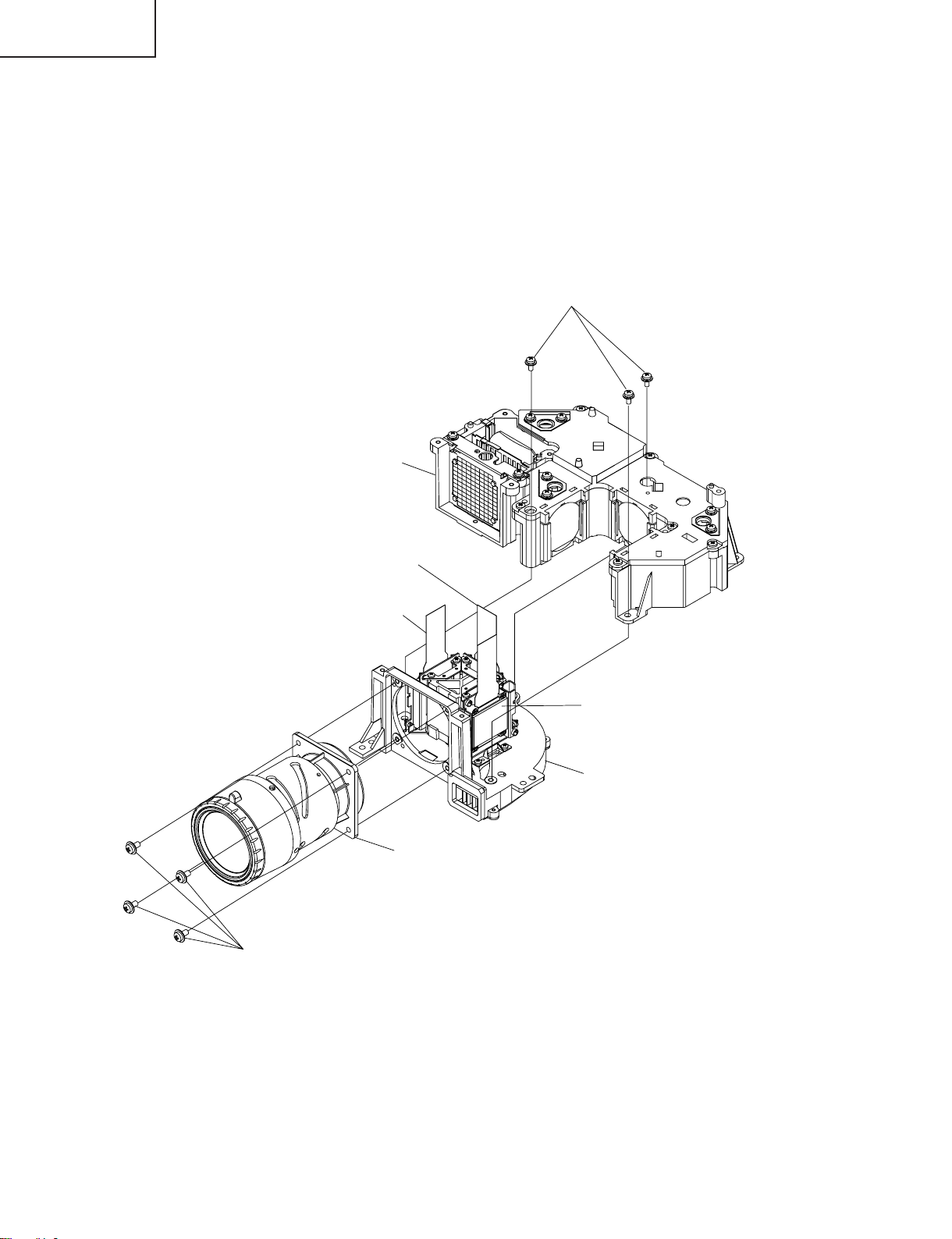

Replacing the prism holder unit

1. Remove the three lock screws, and take the prism holder unit and the projection lens assembly out of the optical

unit.

2. Remove the four lock screws, separate the prism holder unit and the projection lens assembly from each other.

3. Replace the prism holder unit with new one. Take the above steps 1 and 2 in reverse order.

Note: Even if just one of the LCD panels is defective, it is necessary to replace the entire prism holder unit. Do not

replace just the defective LCD panel only.

1Prism holder unit lock screws

(yellow)

Optical unit

G-LCD panel

R-LCD panel

Projection lens assembly

2Projection lens lock screws (yellow)

B-LCD panel

Prism holder unit

22

Page 23

PG-C20XU

PG-C20XE

ELECTRICAL ADJUSTMENT

Hook up a signal generator, or a DOSV or Mac personal computer to the projector in order to feed the

signals specified in the Adjusting conditions.

ADJUSTMENT PRECAUTIONS

1 Precautions for initializing

It takes 5 seconds to get the memory initialized and the initial settings rewritten. To go through the initialization, the

onscreen display background on the process menu screen turns red and the message "INITIALIZE" appears

onscreen for 5 seconds after pressing the specified key. Finally turn off the AC power (unplug the power cord).

2 Initial factory settings (S4, S5)

It takes 5 seconds to get the initial factory settings written. Do not turn off the main power during this procedure. To

ensure this waiting time, "S4" or "S5" appears on the onscreen display for 5 seconds. When this sign disappears,

you can keep on the power or turn it off.

3 Video adjustment

Be careful not to cut off the signals during the video adjustment.

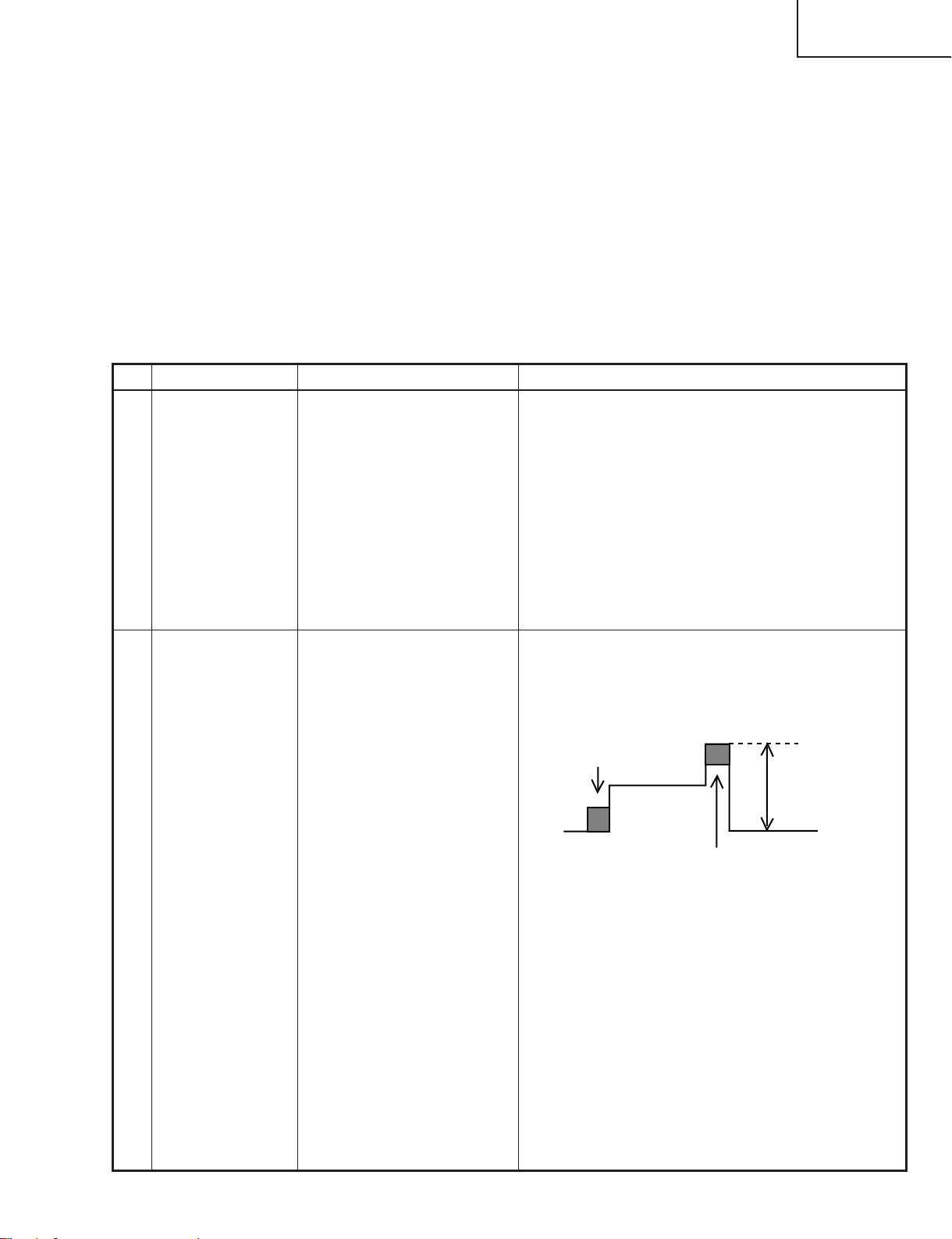

No. Adjusting point Adjusting conditions Adjusting procedure

AN-Z7T

1 EEPROM

initialization

2 Brightness

adjustment

1. Turn on the power (with the

lamp on) and warm up the

set for 15 minutes.

2. Select the following group,

sub-group and subject.

Group : Option

Sub-group:

EEPROM Initialize

Subject : Initialize Start

1. Feed the XGA 10-step signal.

2. Select the following group,

sub-group and subjects.

Group : Adjust PC Image

Sub-group: AD

Subject :

R-Bright (In R adjustment)

G-Bright (In G adjustment)

B-Bright (In B adjustment)

3. Connect the synchroscope

(0.2V/div.) to the following

TPs.

In R adjustment TP1403

In G adjustment TP1402

In B adjustment TP1401

» Make the following settings.

Press SW1601 to call the process mode. Initialize

the EEPROM by execution of Initialize Start. (After

the execution of Initialize Start, the EEPROM will not

be initialized unless the power is once turned off.)

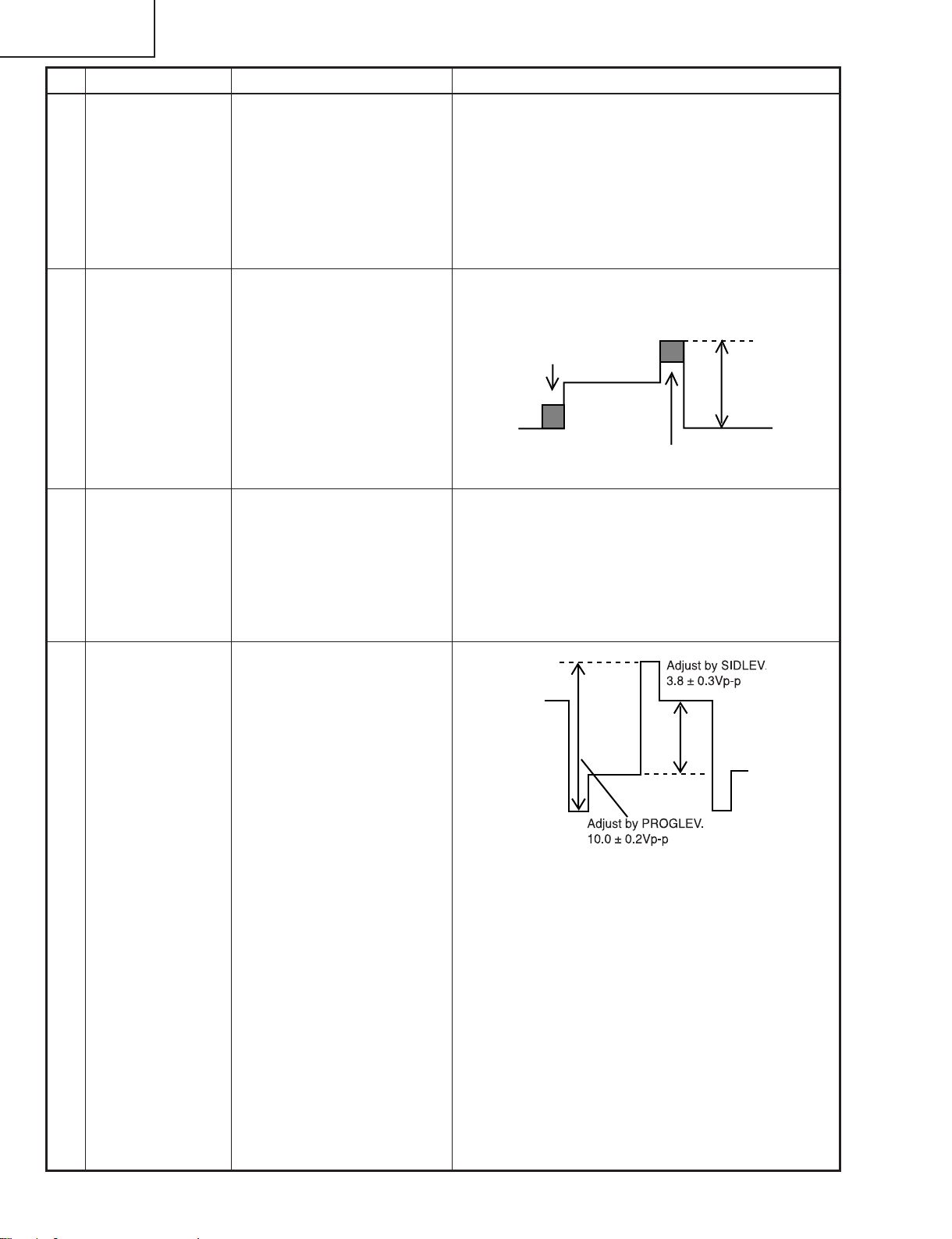

» Adjust the setting just until the color tone level 0 starts

moving.

0-gradation

0.8Vp-p

10-gradation

23

Page 24

PG-C20XU

PG-C20XE

AN-Z7T

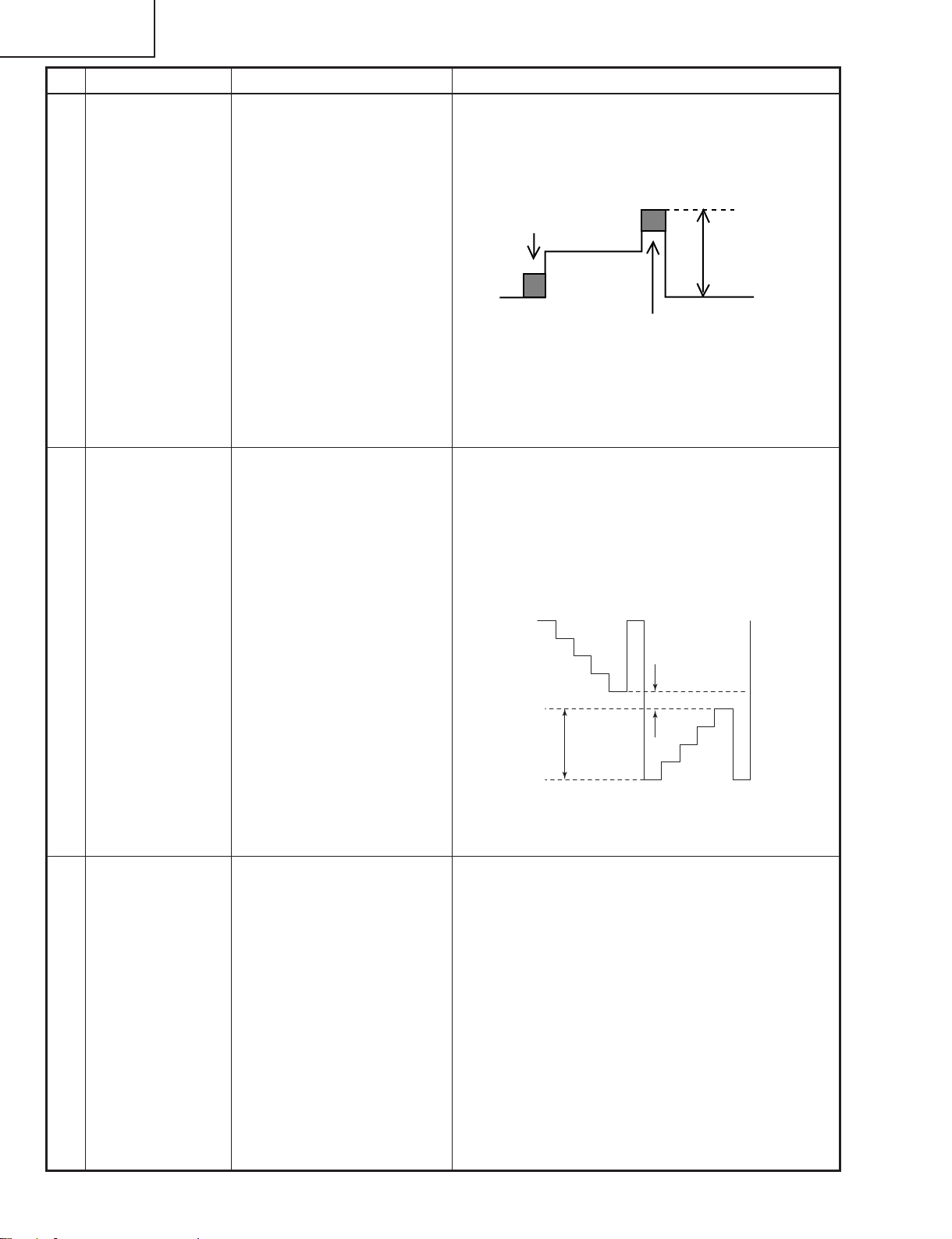

No. Adjusting point Adjusting conditions Adjusting procedure

3 Drive adjust-

ment

4 Panel input

signal amplitude

adjustment

1. Feed the XGA 10-step signal.

2. Select the following group,

sub-group and subjects.

Group : Adjust PC Image

Sub-group: AD

Subject :

R-Contrast (In R adjustment)

G-Contrast (In G adjustment)

B-Contrast (In B adjustment)

3. Connect the synchroscope

(0.2V/div.) to the following

TPs.

In R adjustment TP1403

In G adjustment TP1402

In B adjustment TP1401

1. Select the following group,

sub-group and subjects.

Group : Adjust PC image

Sub-group: CXA2111R

Subject :

AMP-R-GAIN (In R adjustment)

AMP-R-BLK (In R adjustment)

AMP-G-GAIN (In G adjustment)

AMP-G-BLK (In G adjustment)

AMP-B-GAIN (IN B adjustment)

AMP-B-BLK (IN B adjustment)

2. Connect the synchroscope

to the following TPs.

In R adjustment TP1101

In G adjustment TP1201

In B adjustment TP1301

3. Feed the XGA 10-step signal.

» First reach a setting where the color tone level 10

gets saturated. Then decrease the setting by one

point.

0-gradation

0.8Vp-p

10-gradation

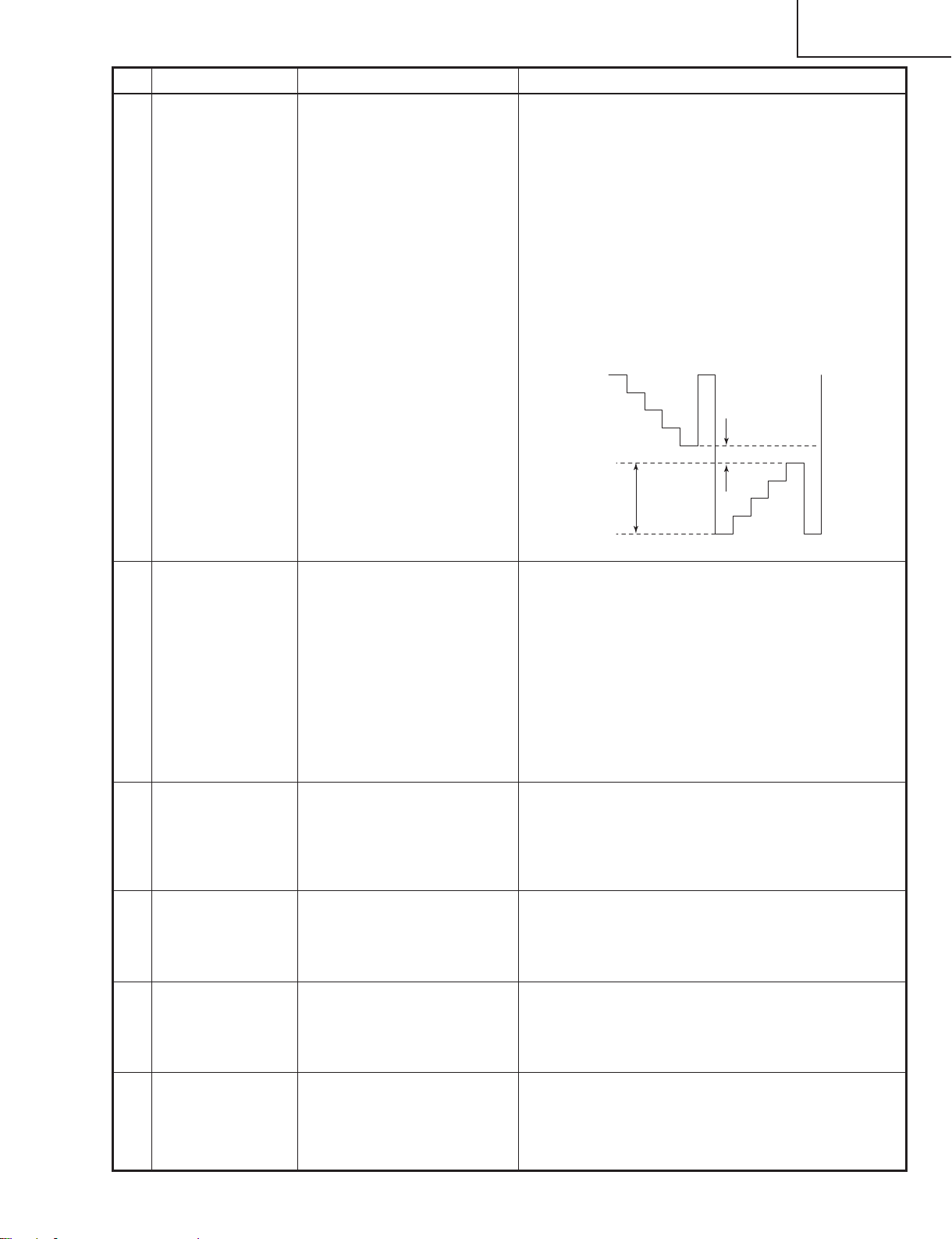

1.Select AMP-R-GAIN and adjust the signal amplitude

to 3.8 ± 0.1. Select 0.1Vp-p.

2.Select AMP-R-BLK and adjust the white-white signal amplitude to 2.1 ± 0.1Vp-p.

Note: Make sure that the black side does not interfere

in GAIN adjustment.

Adjust the amplitude as for G and B in the same

procedure.

2.1Vp-p

3.8Vp-p

5 Sample hold

pulse phase

checking

1. Feed the XGA mode monochrome signal.

2. Select the following group,

sub-group and subjects.

Group : LCD2(6050)

Sub-group: CLDLY

Subject : R_CLDLY

G_CLDLY

B_CLDLY

R_REVCLDLY

G_REVCLDLY

B_REVCLDLY

» Feed the G (30%) signal to see if there is no vertical

stripe visible on the screen. If it is visible, adjust the

setting to somewhere between 160 and 200.

Make also sure that the R and B settings are as follows.

R_CLDLY 171

R_REVCLDLY 175

B_CLDLY 175

B_REVCLDLY 178

24

Page 25

No. Adjusting point Adjusting conditions Adjusting procedure

PG-C20XU

PG-C20XE

AN-Z7T

6 RGB

countervoltage

adjustment

7 RGB tone

reproduction

adjustment

1. Feed the countervoltage

adjustment signal. (XGA)

2. Select the following group,

sub-group and subjects.

Group : LCD2 (6050)

Sub-group: COM

Subject :

R_LCCOM (In R adjustment)

G_LCCOM (In G adjustment)

B_LCCOM (In B adjustment)

R_REVLCCOM (In R reverse adjustment)

G_REVLCCOM (In G reverse adjustment)

B_REVLCCOM (In B reverse adjustment)

1. Feed the green-only

SMPTE pattern signal.

(XGA)

2. Select the following

group, sub-group and

subject.

Group : Adjust PC Image

Sub-group: CXA211 1R

Subject : AMP-BLK

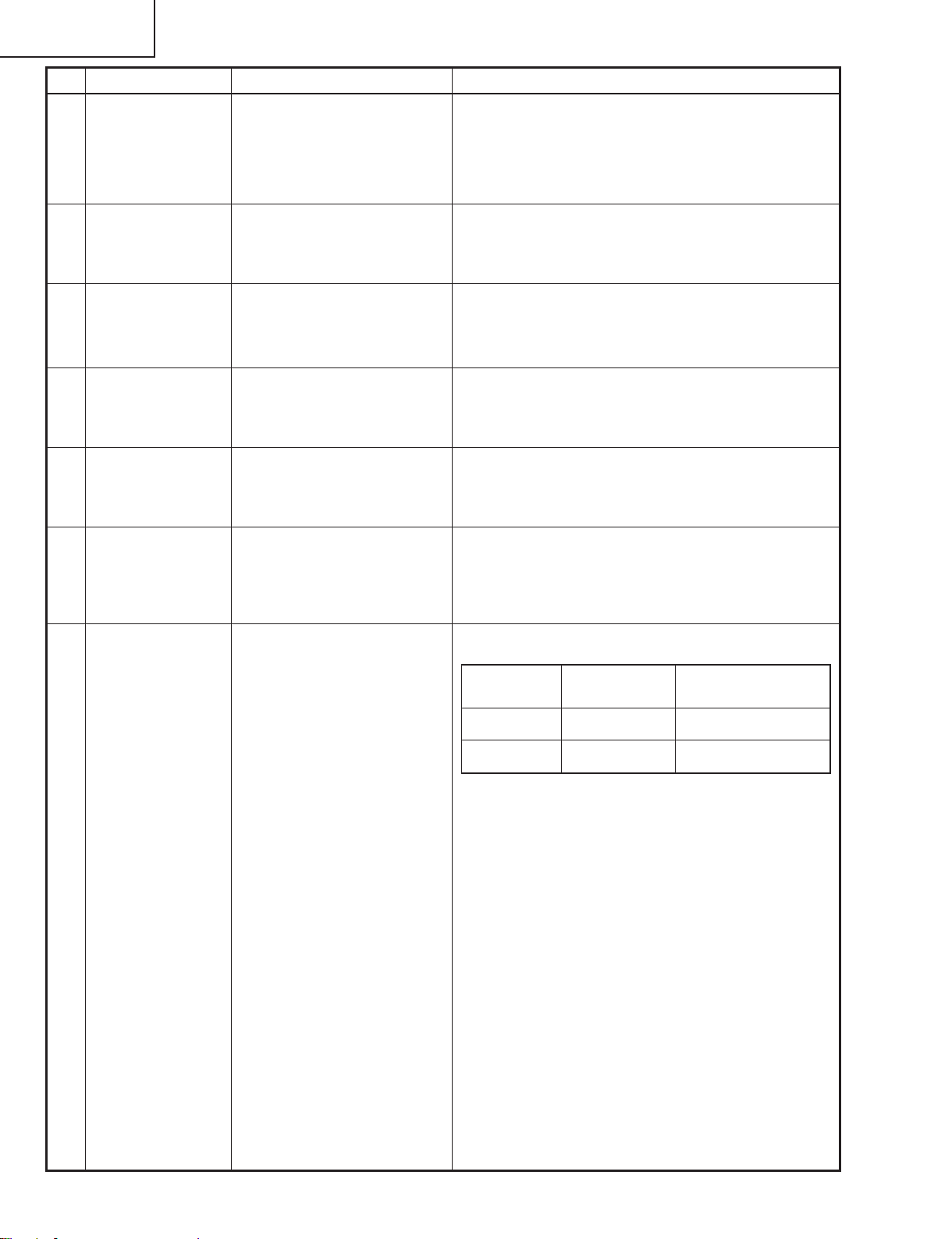

» Using the set's control switch or the remote control-

ler’s button, adjust the setting so that the flickering

be minimum.

» Adjust the setting so that the image comes to the

center of the screen.

» Adjust the AMP-BLK setting so that the gradation of

the part 1 (white 95% and 100%) as shown in the

figure below is barely discernible.

» Make sure that the gradation of the part 2 (black

0% and 5%) is also discernible.

8 RGB white

balance adjustment

9 Horizontal

center adjustment

1. Feed the 32-step grayscale signal. (XGA)

2. Select the following group,

sub-group and subjects.

Group : Adjust PC Image

Sub-group: CXA211 1R

Subject : AMP-R-BLK

(In R adjustment)

AMP-B-BLK

(In B adjustment)

1. Feed the NTSC

monoscope signal.

2. Select the following

group, sub-group and

subject.

Group :

Adjust VIDEO Image

Sub-group: VPC3230

Subject : H-Position

2

1

» Adjust the setting to achieve the best color tone

balance.

» Make sure the setting is 52.

25

Page 26

PG-C20XU

PG-C20XE

AN-Z7T

No. Adjusting point Adjusting conditions Adjusting procedure

10 Video BRIGHT-

NESS adjustment

11 Video CON-

TRAST adjustment

12 Color saturation

adjustment

1. Feed the NTSC 10-step

signal.

2. Select the following group,

sub-group and subject.

Group :

Adjust VIDEO Image

Sub-group: VPC3230

Subject : Bright

1. Feed the NTSC 10-step

signal.

2. Select the following group,

sub-group and subject.

Group :

Adjust VIDEO Image

Sub-group: VPC3230

Subject : Contrast

3. Connect the synchroscope

to TP1402.

1. Feed the color bar signal.

2. Select the following group,

sub-group and subject.

Group :

Adjust VIDEO Image

Sub-group: VPC3230

Subject : Color

» Make sure the setting is as shown below.

PG-C20XU ........142

PG-C20XE ........145

» First reach a setting where the color tone level 10

gets saturated. Then decrease the setting by one

point.

0-gradation

0.8Vp-p

10-gradation

» Make sure the setting is 128.

13 PSIG adjust-

ment

1. Select the following group,

sub-group and subjects.

Group :

Adjust VIDEO image

Sub-group: CXA2111R

Subject : PRGLEV

SIDLEV

2. Connect the synchroscope

to TP1210.

3. Using the NTSC 10-step

input signal, make sure that

there is no vertical stripes

appearing every 12 dots. (If

white or black vertical

stripes appear, fine-adjust

the SIDLEV setting.)

PSIG

» Make sure the setting is as shown below.

PRGLEV ...........61

SIDLEV .............170

26

Page 27

No. Adjusting point Adjusting conditions Adjusting procedure

14 VIDEO panel

input signal

amplitude

adjustment

1. Select the following group,

sub-group and subjects.

Group :

Adjust VIDEO image

Sub-group: CXA2111R

Subject :

AMP-R-Gain (In R adjustment)

AMP-R-BLK (In R adjustment)

AMP-G-Gain (In G adjustment)

AMP-G-BLK (In G adjustment)

AMP-B-Gain (IN B adjustment)

AMP-B-BLK (IN B adjustment)

2. Connect the synchroscope

to the following TPs.

In R adjustment TP1101

1.Select AMP-R-Gain and adjust the signal amplitude

to 3.8 ± 0.1Vp-p.

2.Select AMP-R-BLK and adjust the white-white signal amplitude to 2.1 ± 0.1Vp-p.

3.Select AMP-G-Gain and adjust the signal amplitude

to 3.5 ± 0.1Vp-p.

4.Select AMP-G-BLK and adjust the white-white signal amplitude to 2.6 ± 0.1Vp-p.

5.Select AMP-B-Gain and adjust the signal amplitude

to 3.5 ± 0.1Vp-p.

6.Select AMP-B-BLK and adjust the white-white signal

amplitude to 2.6 ± 0.1Vp-p.

Note: Make sure that the black side does not interfere

in Gain adjustment.

In G adjustment TP1201

In B adjustment TP1301

3. Feed the NTSC 10-step

signal.

2.1Vp-p(R)

PG-C20XU

PG-C20XE

AN-Z7T

15 Video white

balance adjustment

16 Automatic color

irregularity

correction

17 Color-related

performance

checking

3.8Vp-p(R)

1. Feed the 32-step grayscale signal. (VIDEO)

» Adjust the setting to achieve the best color tone bal-

ance.

2. Select the following group,

sub-group and subjects.

Group :

Adjust VIDEO Image

Sub-group: CXA2111R

Subject :

AMP-R-BLK (In R adjustment)

AMP-B-BLK (In B adjustment)

1. Apply the automatic color

correction using the auto-

» Make sure that no remarkable uneven color remains

on the screen.

matic color irregularity correction system.

1. Feed the color bar signal. » User adjustment:

Check the Color and Tint settings.

18 Video-related

performance

checking

19 Audio-related

performance

checking

1. Feed the monoscope pat-

tern signal.

» User adjustment:

Check the performance relating to Contrast, Brightness and Sharpness.

1. Feed the audio signal. » User adjustment:

Check the sound volume performance.

27

Page 28

PG-C20XU

PG-C20XE

AN-Z7T

No. Adjusting point Adjusting conditions Adjusting procedure

20 RGB-related

performance

checking

21 DVD perform-

ance checking

performance

checking

23 Auto sync

performance

checking

24 Keystone cor-

rection performance checking

25 Lamp power

changeover

performance

checking

1. Feed the RGB signal. » User adjustment:

Check the performance relating to Contrast, Brightness, Red, Blue, Clock, Phase, H-POS, and V-POS.

1. Receive the 480I signal. » User adjustment:

Check the performance relating to Contrast, Brightness, Color, Tint and Sharpness.

1. Heat the thermistor with a

» Make sure that the temperature is indicated.22 Thermistor

hair dryer.

1. Feed the phase check pat-

tern signal.

» In the VGA, SVGA, XGA, and SXGA modes, make

sure the Clock, Phase, H-Pos and V-Pos settings can

be automatically adjusted.

» Make sure that the keystone distortion can be cor-

rected.

» Make sure that the brightness can be changed with

the user lamp power control.

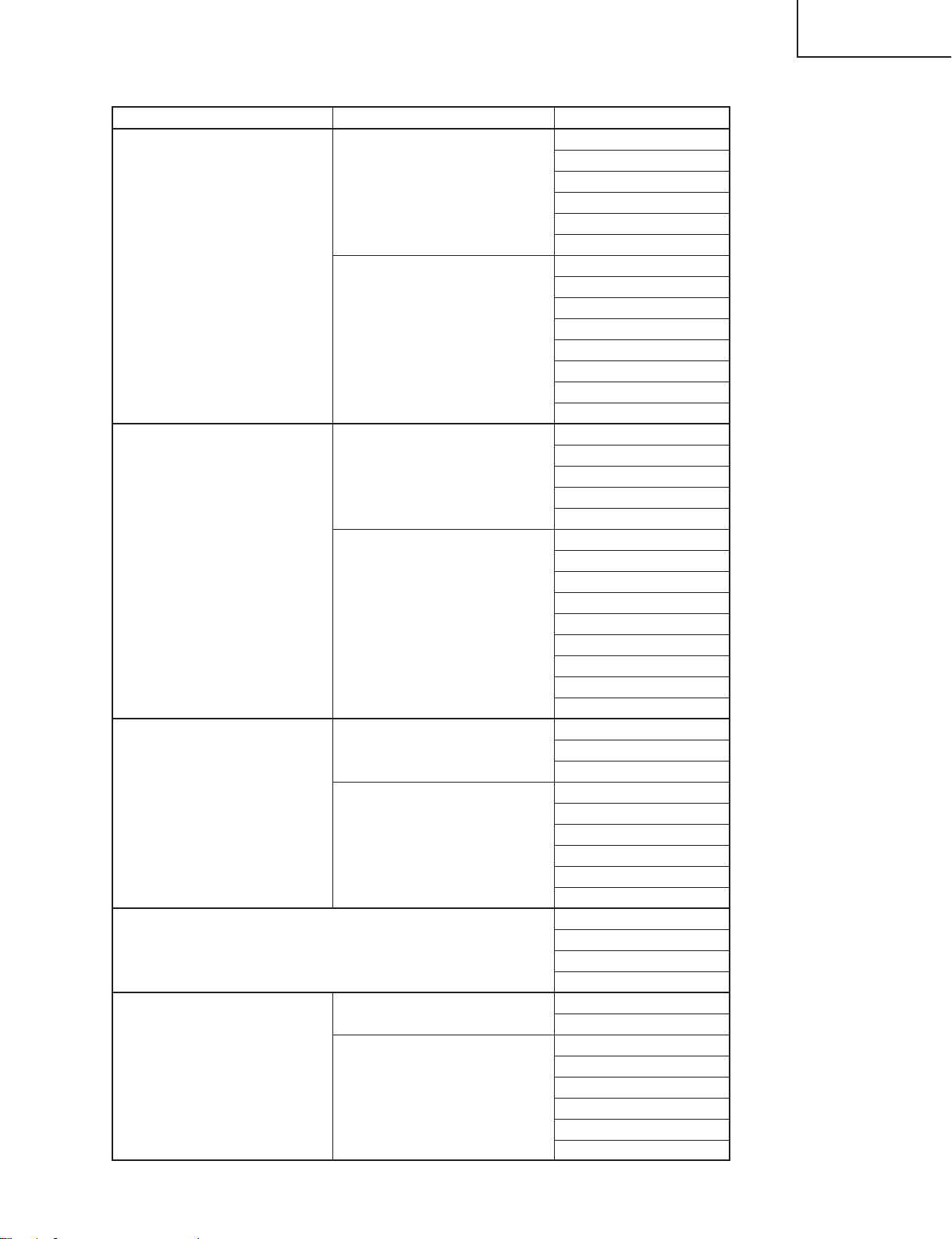

26 Delivery set-

tings

» Make the following settings.

Destination

Process adjustment Remote control adjustment

(Model)

US (XU) S4 Factory setting at 4

Europe (XE) S4 Factory setting at 4

28

Page 29

Process menu1

Group Sub group Subject

R-Bright

R-Contrast

AD

Adjust PC Image

CXA2111R

VPC3230 Color

Adjust VIDEO Image

CXA2111R AMP-B-BLK

VPC3230 Contrast

Adjust Component (480I) AMP-G-Gain

CXA2111R

LCD5(CXA1839)(480P)

(The menu appears on the screen. But do not use this menu because

this model is not equipped with the DTV function.)

NRS

LCD2 (6050)

COM

G-Bright

G-Contrast

B-Bright

B-Contrast

AMP-R-BLK

AMP-R-GAIN

AMP-G-BLK

AMP-G-GAIN

AMP-B-BLK

AMP-B-GAIN

AMP-BLK

AMP-GAIN

Bright

Contrast

H-Position

AGC

AMP-R-BLK

AMP-R-Gain

AMP-G-BLK

AMP-G-Gain

AMP-B-Gain

CLPLVL

PRGLEV

SIDLEV

Bright

Color

AMP-R-Gain

AMP-B-Gain

AMP-R-BLK

AMP-G-BLK

AMP-B-BLK

DTV_Bright

DTV_Contrast

DTV_Color

DTV_Tint

NRS-H

NRS-L

R_LCCOM

G_LCCOM

B_LCCOM

R_REVLCCOM

G_REVLCCOM

B_REVLCCOM

PG-C20XU

PG-C20XE

AN-Z7T

29

Page 30

PG-C20XU

PG-C20XE

AN-Z7T

Process menu2

Group Sub group Subject

R_CLDLY

G_CLDLY

LCD2 (6050) CLDLY

GHOST B_GHOST

LCD3 (Adjust GA4) G_GHOST_W

CK-PHASE GCK-PHASE

Adjust Horz. Conv

LCD4 (Adjust Conv)

Adjust Vert. Conv

Version

SS

Temp

Temp/Fan State

Fan Speed

Gamma Off on/off

Option

Revise Color Uneven on/off

EEPROM Initialize

B_CLDLY

R_REVCLDLY

G_REVCLDLY

B_REVCLDLY

R_GHOST

G_GHOST

R_GHOST_W

B_GHOST_W

RCK-PHASE

BCK-PHASE

R_HCONV

G_HCONV

B_HCONV

R_REVHCONV

G_REVHCONV

B_REVHCONV

R_VCONV

G_VCONV

B_VCONV

R_REVVCONV

G_REVVCONV

B_REVVCONV

Boot Code

Config

Sharp Table

Rom Code

GUI

Sub CPU

S4

S5

Inside Temp/ref

Outside Temp/ref

Lamp Fan

Other Fan

Cancel

Initialize Start

30

Page 31

YES

YES

NO

Checking the basic

performance

Is the POWER LED on or

flickering in red or green?

Go to "Checking the

power unit"

Go to "Checking the lamp

light-up"

NO

Is the set turned on by the

set’s or remote controller’s

power key?

Go to "Checking the

microcomputer

peripherals" and

"Checking the PLL circuit"

NO

Go to "Checking the

output line"

Go to "Checking the RGB

input"

Go to "Checking the

component input"

Go to "Checking the

video input"

Go to "Checking the

audio input"

Go to "Checking the RS232C"

End

NO

Is the cooling fan

running? Is the lamp on?

Is the user menu

displayed?

YES

YES

PG-C20XU

PG-C20XE

AN-Z7T

TROUBLE SHOOTING TABLE

31

Page 32

PG-C20XU

PG-C20XE

AN-Z7T

Checking the power unit

Are the connectors CN751,

P1707 and P3701 inserted

completely?

YES

Is the lamp cover closed

completely?

YES

Is the bimetal switch off?

YES

Is AC voltage (100-240V)

applied between pins (1)

and (3) of CN703?

YES

NO

Insert the connectors

CN751, P1707 and

P3701 tightly?

NO

Close the lamp cover

tightly.

NO

Replace the bimetal

NO

Replace F701.

Disconnect the CN751

connector (EA). Is there

13V output at pins (7), (8)

and (9)?

YES

Check the output PWB for

short-circuit. Check also

the UNT3701 on the

connection terminal PWB

and its peripheral circuits.

NO

Check Q706, Q708 and

Q710 for damage.

Replace as required.

32

Page 33

YES

YES

YES

YES

YES

YES

YES

NO

Checking the

microcomputer

peripherals

Is a voltage of about 3V

applied to pin (33) (RCS)

of IC1601?

Check the intake filter

cover for poor fitting and

the cooling fan for trouble.

Check IC1601, IC1606 and

their peripheral circuits.

Is the signal level at pin

(7) of IC8037 about 0V?

End

End

Set SW1602 to

"NORMAL" position.

NO

Is SW1602 set at

"NORMAL" position?

NO

NO

Check IC8018, IC8019,

IC8020 and their peripheral

circuits as well pin (26) of

IC1601 and its peripheral

circuits.

Check IC8021 and

IC8022. Replace the PC

interface as required.

NO

NO

Check all the ICs

connected with the

SDA3/SCL3 and

SDA5/SCL5 lines.

NO

Is there pulse signal at

pin (64) of IC1601?

Is there pulse signal at pin

(1) of IC1601?

Is there signal at pins (1),

(3), (4) and (6) of IC1802?

Check all the signals (A1

thru A17 and D1 thru D15)

of IC8021 with oscilloscope.

Are signal levels 0V and

3V?

PG-C20XU

PG-C20XE

AN-Z7T

33

Page 34

PG-C20XU

PG-C20XE

AN-Z7T

Checking the PLL circuit

Is there 120MHz clock

output at pin (8) of

IC8001?

YES

Is there 40MHz clock

output at pin (9) of

IC8001?

YES

Is there 16MHz or so

clock output at pin (7) of

IC8001?

YES

End

Checking the lamp

light-up

NO

NO

NO

IC8001 or its peripheral

circuit defective.

Turn on the power switch.

Is discharge sound heard

from the lamp?

NO

Are DC260-400V voltages

applied between the pins

of PL connector?

YES

Is the BA harness tightly

inserted? Is the harness

broken?

YES

Is voltage of over 1V

applied between pins (1)

and (2) of BA harness?

YES

YES

NO

NO

NO

Is the lamp socket

disconnected?

YES

Reconnect the lamp

socket tightly.

Go to "Checking the

power unit".

Insert the BA harness

tightly. Or replace it as

required.

Go to "Checking the

microcomputer

peripherals".

NO

Replace the lamp.

Replace the ballast unit.

34

Page 35

Checking the output line

PG-C20XU

PG-C20XE

AN-Z7T

Are there video input signals at

TP1401, TP1402 and TP1403?

YES

Are there video output signals at

pins (14), (16) and (18) of IC1405?

YES

Are there video input signals at pins

(45) of IC1101, IC1201, IC1301,

IC1102, IC1202 and IC1302?

YES

NO

Check P8001 and SC1701 for solder

cracks.

Are there video output signals at pins

(42), (44) and (46) of IC8024?

NO

Are there digital input signals at pins

(1) thru (33) of IC8024?

NO

IC8023 defective. Replace the PC

interface.

NO

Check IC1405, IC1403 and their

peripheral circuits.

Check IC1102, IC1202, IC1302 and

NO

their peripheral circuits as well as

pins (35) and (36) and the 15.5V

power line.

YES

YES

Check Q8013, Q8014,

Q8015 and their

peripheral circuits.

Check IC8024 and

IC8025.

Are there clock input signals (MCLK) at

pins (54) and (55) of IC1102, IC1202

NO

and IC1302?

YES

Are there output signals at pins (17),

(19), (21), (28), (30) and (32) of IC1101,

NO

IC1201, IC1301, IC1102, IC1202 and

IC1302?

YES

Are signals going to the control signal

NO

lines at pins (3) thru (21) of IC1103,

IC1203 and IC1303?

YES

Are signals coming from the control signal

lines at pins (11) thru (17) of IC1402 and

NO

IC1404?

YES

Are there input signals at SC1101,

NO

SC1201 and SC1301?

YES

Check the R, G and B panels.

Check P8001 and SC1701 for solder

cracks, and go to "Checking the

digital signal processing circuit".

Check IC1101, IC1201, IC1301,

IC1102, IC1202, IC1302, IC1401,

IC1403, IC1405 and their peripheral

circuits.

Check P8001 and SC1701 for solder

cracks, and go to "Checking the

digital signal processing circuit".

Check IC1402, IC1404 and their

peripheral circuits.

Check SC1101, SC1202, SC1301

and their peripheral circuits.

IC8023 defective.

Replace the PC

interface.

IC8023 defective.

Replace the PC

interface.

35

Page 36

PG-C20XU

PG-C20XE

AN-Z7T

1

2

Checking the RGB input

Feed the sync separation RGB

signal to INPUT1 terminal (pin

(15) of D-SUB).

Select INPUT1 (RGB) with the

set’s control or remote control

button.

Is the image disturbed? Does

NO SIGANL indication

appear?

YES

Do R, G and B colors appear?

YES

Does an image appears?

NO

Is the contour as specified?

YES

Are there disturbing vertical

stripes?

NO

Go to "Checking the sync signal".

NO

Go to "Checking the RGB input".

YES

Go to "Checking the input signal

setting input".

NO

YES

End

NO

IC8026 or peripheral circuit

defective.

36

Page 37

YES

YES

Checking the input signal

setting

Is the input signal setting

as specified?

Select the specified signal.

Is the connector properly

connected?

NO

Reconnect the connector.

End

NO

1

2

YES

YES

YES

YES

Checking the sync signal

Is there vertical sync signal

at TP8003?

Is there horizontal sync

signal at pin (3) of IC3008

connection terminal PWB?

IC3008 or its peripheral

circuit defective. Or

SC3003 in poor contact.

Is there horizontal sync

signal at pin (3) of IC3006

connection terminal PWB?

IC3006, IC3010 or their

peripheral circuit defective.

Or SC3003 in poor

contact.

Is there horizontal sync

signal at TP8002?

NO

End

SC3001 or its peripheral

circuit defective.

NO

NO

NO

PG-C20XU

PG-C20XE

AN-Z7T

37

Page 38

PG-C20XU

PG-C20XE

AN-Z7T

Checking the RGB signal

In order to check the input

signal, set the signal

generator to the gradation

signal.

Using the oscilloscope,

measure the lands (R, G

and B inputs of IC8026) of

C8204, C8208 and C8213.

Are there specified

NO

YES

IC8026 or its peripheral

circuit defective.

Are there gradation signals

at pins (8), (10) and (12) of

IC8012?

YES

IC8012 or its peripheral

circuit defective.

NO

Are there gradation signals

at pins (16), (18) and (20)

of IC3002 connection

terminal PWB?

YES

IC3002 or its peripheral

circuit defective. Or

SC3003 in poor contact.

NO

SC3001 or its peripheral

circuit defective.

38

Page 39

NO

YES

YES

Checking the SOG circuit

Using the oscilloscope,

measure the land of R8231

(pin (32) of IC8026). Is

there composite sync

signal?

NO

Using the oscilloscope,

measure the land of R8110

(base of Q8010). Does the

video signal contain the

sync signal?

Is there video signal with

sync signal at pin (18) of

IC3002 connection

terminal PWB?

NO

IC3002 connection

terminal PWB or its

peripheral circuit defective.

IC8008, IC8009, IC8031 or

their peripheral circuit

defective.

YES

SC3003 or its peripheral

circuit defective.

End

YES

NO

NO

YES

YES

NO

Checking the video input

Feed the specified video

signal.

Is there video signal at pin

(73) of IC8003?

Go to "Checking the

video sync signal".

Is there video signal at pin

(7) of IC3403 connection

terminal PWB?

IC3403 or its peripheral

circuit defective. Or

SC3003 in poor contact.

Is the image disturbed?

Does an image appear?

Are the colors as

specified?

End

IC8003 or its peripheral

circuit defective.

J3303 or its peripheral

circuit defective.

Select VIDEO with the

set’s key or remote control

button.

NO

NO

YES YES

PG-C20XU

PG-C20XE

AN-Z7T

39

Page 40

PG-C20XU

PG-C20XE

AN-Z7T

Checking the video sync

signal

Using the oscilloscope,

measure the signal at

TL8006. (Check the

vertical sync signal.)

Is the vertical sync signal

as specified?

YES

Using the oscilloscope,

measure the signal at

TL8009. (Check the

horizontal sync signal.)

Is the horizontal sync

signal as specified?

YES

Is there 15kHz or so signal

at TP8007?

YES

NO

NO

NO

Go to "Checking the input

signal setting".

If out of spec again,

IC8003 or its peripheral

circuit defective.

Is there signal with half the

vertical frequency at

TP8010?

YES

Is there 27MHz or so clock

signal at FL8034?

YES

Is there 13.5MHz or so

clock signal at FL8034?

YES

End

NO

NO

NO

IC8003 or its peripheral

circuit defective.

40

Page 41

Checking the digital signal

processing circuit

PG-C20XU

PG-C20XE

AN-Z7T

Is there 40MHz or so clock

signal at FL8024?

YES

Is there 38kHz or so pulse

(sync) signal at FL8026?

YES

Is there 60Hz or so pulse

(sync) signal at FL8025?

YES

End

NO

NO

NO

Go to "Checking the PLL

circuit".

IC8022, IC8021 or their

peripheral circuit defective.

41

Page 42

PG-C20XU

PG-C20XE

AN-Z7T

Checking the audio

signal

Are there audio output

signals at pins (7) of

IC3301 and IC3302?

YES

Is voltage applied to pin (4)

of IC1901?

YES

Using the remote control,

change VOL and cancel

MUTE. Does the voltage at

pin (7) of IC1901 vary

accordingly?

YES

Is there audio output signal

at pin (5) of IC1901?

YES

NO

NO

NO

NO

Check the audio cable.

Switch IC3301 and IC3302

to each other to check the

peripheral circuits.

Check R1914 first and

then the power circuit.

Check IC1403, IC1605 and

their peripheral circuits.

Check IC1901 and its

peripheral circuits.

Check the SP connector.

Checking the RS-232C

Using the communication

software ("TERA TERM"

recommended), make the

following settings:

Baud rate: 9600 bps

Bit length: 8 bits

Stop bit: 1 bit

Parity: None

Press the RETURN key on

the keyboard. Does "ERR"

reappear?

YES

NO

Check IC3601, IC1606,

IC1601, SW1602, IC8022,

communication circuit and

their peripheral circuits.

End

42

Page 43

Technische Daten

Produkttyp LCD Projector

Modell PG-C20XU/XE

Videosystem PAL/PAL 60/PAL-M/PAL-N/SECAM/NTSC 3.58/NTSC 4.43/DTV 480P

Wiedergabeverfahren LCD-Projektionspaneel x 3,optisches RGB-Verschlußverfahren

LCD-Projektionspaneel Panelgröße:22,9 mm (0,9") (13,9 mm [H ] x 18,5 mm [B ])

Wiedergabe-Verfahren:Durchl ä ssiges TN-Flüssigkristall-Paneel

Treiberverfahren:TFT (Dünnfilmtransistor) Aktivmatrix-Paneel

Anzahl der Bildpunkte:786.432 Bildpunkte (1.024 [H ] x 768 [V ])

Objektiv 1 –1,2 Zoomobjektiv, F2,3 –2,6, f =36,0 –43,2 mm

Projektionslampe 150 W Gleichstrom-Lampe

Kontrastverh ä ltnis 500:1

Videoeingangssignal RCA-Stecker:VIDEO, Gemischtes Video, 1,0 Vs-s, negatives Sync.-Signal, 75 Ω terminiert

RCA-Stecker:AUDIO, 0,5 Vrms mehr als 22 kΩ (Stereo)

S-Videoeingangssignal 4-Pin Mini DIN-Stecker

Y (Luminanz-Signal):1,0 Vs-s,negatives Sync.-Signal, 75 Ω terminiert

C (Chrominanz-Signal):Stoß 0,286 Vs-s, 75 Ω terminiert

Horizontale Aufl ö sung 580 Fernsehzeilen (Videoeingang)

Audioausgang 1,0 W (monaural)

RGB-Computereingangssignal 15-PIN MINI D-SUB STECKANSCHLUSS (Computer-Eingangsport 1 (COMPUTER INPUT 1),

Computer-Ausgangsport für Eingangs-Port 1 (COMPUTER OUTPUT für INPUT 1):

RGB getrennt/gemischte Sync./Sync.auf Grün-Typ analoger Eingang:0 –0,7 Vs-s,

positiv,75 Ω terminiert

STEREO-MINIBUCHSE:AUDIO,0,5 Vrms,mehr als 22 kΩ (Stereo)

HORIZONTALES SYNC.-SIGNAL:TTL-Pegelsignal (positiv/negativ)oder gemischtes Sync.-

Signal (nur Macintosh)

VERTIKALES SYNC.-SIGNAL:Wie oben

Punktetakt 12 –108 MHz

Vertikale Frequenz 43 –85 Hz

Horizontale Frequenz 15 –80 kHz

Computereingangs-Signal 9-Pin Mini DIN-Steckanschluß (RS-232C-Anschlußstelle)

Lautsprechersystem 2,8 cm (1 7 ⁄64" ) rund

Nennspannung 100 –240 V Wechselstromspannung

Eingangsspannung 2,6 A

Nennfrequenz 50/60 Hz

Nennaufnahme 230 W (Wahl von "OFF" im "Energiespar-Modus".)

200 W (Wahl von "ON" im "Energiespar-Modus".)

Betriebstemperatur +5°C bis +35°C

Lagertemperatur −20°C bis +60°C

Geh ä use Kunststoff

I/R-Tr ä gerfrequenz 38 kHz

Abmessungen (ca.) 260 x 74 x 207 mm (B x H x T) (nur Hauptgerät)

260 x 82 x 207 mm (B x H x T) (einschlie ß lich Drehfüße und vorstehende Teile)

Gewicht (ca.) 2,6 kg

Mitgeliefertes Zubehör Fernbedienung, Zwei Batterien der Größe AAA,Netzkabel (3,6 m), RGB-Computerkabel (3 m),

Computer-Audiokabel (3 m), PS/2-Maus-Steuerungskabel (1 m), USB-Maus-Steuerungskabel (1,5

m), DIN-D-Sub RS-232C-Kabel (15 cm), Fernbedienungs-Mausempfänger, Ersatz-Luftfilter,

Objektivkappe (angebracht), Objektivkappenband, CD-ROM, Bedienungsanleitung für LCDProjektor, Kurzanleitungen für den LCD-Projektor

Ersatzteile Lampensatz (Lampe/Käfigmodul)(BQC-PGC20X//1), Fernbedienung (RRMCG1613CESA),

Batterien der Größe AAA,Netzkabel (CACCU5013DE01 (PG-C20XU), QACCV4002CEZZ (PGC20XE), QACCB5024CENA (PG-C20XE)), RGB-Computerkabel (QCNWG0002EZZ), Computer-Audiokabel (QCNW-4870CEZZ), PS/2-Maus- Steuerungskabel (QCNW-5113CEZZ), USBMaus-Steuerungskabel (QCNW-5680CEZZ), DIN-D-Sub RS-232C-Kabel (QCNW-5288CEZZ),

Fernbedienungs-Mausempfänger (RUNTK0694CEZZ), Luftfilter (PFILD0123CEZZ), Objektivkappe

(PCOVZ1095CEKA), Objektivkappenband (UBNDT0013CEZZ), CD-ROM (UDSKA0029CEN1

(PG-C20XU), UDSKA0048CEN1 (PG-C20XE)), Bedienungsanleitung für LCD-Projektor (TINS7204CEZZ (PG-C20XU), TINS-7271CEZZ (PG-C20XE)), Kurzanleitungen für den LCD-Projektor

(TINS-7205CEZZ (PG-C20XU), TINS-7272CEZZ (PG-C20XE), TINS-7284CEZZ (PG-C20XE),

TINS-7285CEZZ (PG-C20XE))

Dieser Projektor von SHARP ist mit 3 LCD-(Flüssigkristallanzeige)

Projektionspaneels ausgestattet. Diese neuartigen Projektionspaneels

enthalten TFTs (Dünnfilmtransistoren) mit insgesamt 786.432

Bildpunkten (x RGB). Bei allen technologisch fortschrittlichen,

elektronischen Geräten, z.B.Großbild-Fernsehern, Videosystemen bzw.

Videokameras,sind bestimmte Toleranzgrenzen für die Funktionen

gegeben.

Ä nderungen der technischen Daten ohne vorherige Ank ü ndigung vorbehalten.

Dieses Gerät hat einige inaktive,innerhalb akzeptierter T oleranzgrenzen

liegende TFTs, die als beleuchtete oder als nicht aktive Punkte auf der

Bildwand wiedergegeben werden. Dies hat keinen Einfluß auf die

Bildqualität und die Lebensdauer des Gerätes.

PG-C20XU

PG-C20XE

AN-Z7T

43

Page 44

PG-C20XU

5

5

PG-C20XE

AN-Z7T

HINWEIS FÜR DAS

WARTUNGSPERSONAL

234567890123456789012345678901212345678901234

ACHTUNG: UV-STRAHLUNG

234567890123456789012345678901212345678901234

Die Beleuchtungsquelle des LCD-Projektors, eine

UHP-Lampe, emittiert eine geringe Menge

UV-Strahlung.

DIREKTE BESTRAHLUNG AUF AUGEN

UND HAUT MUSS VERMIEDEN WERDEN.

Zur Gewährleistung der Sicherheit muß folgendes

beachtet werden:

1. Bei Arbeiten am Projektor bei eingeschalteter

Lampe und abgenommenem oberen Gehäuse muß

unbedingt eine Sonnenbrille getragen werden.

Auswechseln der Lampe

Hinweis:

Da die Lampe während des Betriebs sehr heiß wird,

sollte die Lampe erst ausgewechselt werden, nachdem

das Gerät mindestens eine Stunde ausgeschaltet war ,

damit die Lampe ausreichend abkühlen kann.

Beim Installieren der neuen Lampe muß darauf

geachtet werden, die Lampe selbst (Glaskolben)

nicht zu berühren. Vielmehr muß die Lampe am

Reflektor 2 gehalten werden.

[Es darf nur ein Original-Ersatzteil verwendet

werden.]

Lampe

1

Reflektor

2

2. Die Lampe darf nicht außerhalb des

Lampengehäuses eingeschaltet werden.

3. Betrieb für länger als 2 Stunden bei

abgenommenem Gehäuse ist nicht zulässig.

Zur Beachtung bei UV-Strahlung

und Mitteldruck-Lampen

1. Vor dem Auswechseln der Lampe muß der

Netzstecker gezogen werden.

2. Vor Durchführung von Wartungsarbeiten muß das

Gerät eine Stunde abkühlen.

3. Die Lampe darf nur gegen eine der gleichen Art

ausgewechselt werden. T yp BQC-PGC20X//1,

bemessen für 100 V/200 W.

4. Die Lampe gibt eine geringe UV-Strahlung ab,

daher muß direkter Augenkontakt vermieden

werden.

5. Die Mitteldruck-Lampe weist ein Explosionsrisiko

auf. Daher müssen die nachstehenden

Installationsanweisungen beachtet werden, und die

Lampe muß vorsichtig behandelt werden.

GEFAHR! — Niemals die Spannungsversorgung

einschalten, ohne daß eine Lampe vorhanden ist,

um elektrische Schläge und Schäden am Gerät zu

vermeiden, da der Stabilisator anfangs hohe

Spannungen erzeugt.

Da eine geringe Menge UV-Strahlung an der Öf fnung

zwischen den Lüftern austritt, wird empfohlen,

während der Wartungsarbeiten die Abdeckkappe des

Zusatzobjektivs an dieser Öffnung anzubringen, um

Augen und Haut vor den UV-Strahlen zu schützen.

44

Page 45

Lage der Bedienelemente

Projektor

Ansicht von vorne und oben

PG-C20XU

PG-C20XE

AN-Z7T

Betriebs-Taste (ON/OFF)

Betriebs-anzeige

Eingang-/Zur ü ck-Taste

(INPUT/BACK)

Trapezverzeichnungs-/

Einstellungs-Tasten

(KEYSTONE/ ]/[)

Zoom-Knopf

Fokussierring

Kühlventilator (Luftauslaß)

Drehfuß-Feststeller

Seiten-und Rückansicht

ON/OFF

POWER

KEYSTONE

INPUT

BACK ENTER MENU

LAMP

TEMP.

AUTO SYNC

Lampenaustausch-Anzeige

Temperaturwarnanzeige

Automatische

Synchronisierung-/EingabeTaste (AUTO SYNC/ENTER)

Menü-Taste (MENU)

Luftfilter/Kühlventilator

(Lufteinlaß)

Lautsprecher

Fernbedienungs-Sensor

Öffnung für

Objektivkappenband

Standardanschluß für