Page 1

OPERATION MANUAL

INDOOR UNIT OUTDOOR UNIT

AH-PN10 AU-PN10

AH-PN10-GY AU-PN10

AH-PN13 AU-PN13

AH-PN13-GY AU-PN13

AH-PN19 AU-PN19

AH-PN24 AU-PN24

AH-L10 AU-L10

AH-L13 AU-L13

CONTENTS Page

IMPORTANT SAFETY

INSTRUCTIONS

1

PART NAMES 2

USING THE REMOTE

CONTROL

5

AUXILIARY MODE 5

TIPS ON SAVING

ENERGY

5

BASIC OPERATION 6

ADJUSTING THE AIR

FLOW DIRECTION

7

POWERFUL JET

OPERATION

7

GENTLE COOL AIR 8

PLASMACLUSTER

OPERATION

8

TIMER OPERATION 9

ONE-HOUR OFF TIMER 10

DISPLAY BUTTON 10

MAINTENANCE 11

OPERATING CONDITION 11

BEFORE CALLING FOR

SERVICE

12

INSTALLATION MANUAL 13

AH-PN10, 10GY AH-L10

AH-PN13, 13GY AH-L13

AH-PN19, AH-PN24

INSTALLATION MANUAL

Thank you for purchasing a SHARP air conditioner.

Please read this manual carefully before operating

the product

OM_AH-PN10 13GY_EN.indd 1OM_AH-PN10 13GY_EN.indd 1 12/22/11 6:30:07 PM12/22/11 6:30:07 PM

Page 2

OM_AH-PN10 13GY_EN.indd 2OM_AH-PN10 13GY_EN.indd 2 12/22/11 6:30:09 PM12/22/11 6:30:09 PM

Page 3

ENG-

E-1

ENGLISH

Please read this manual carefully before using

the product. This manual should be kept in a

safe place for handy reference.

IMPORTANT SAFETY

INSTRUCTIONS

WARNINGS

• Do not pull or deform the power supply cord.

Pulling and misuse of the power supply cord

can result in damage to the unit and cause

electrical shock.

• Be careful not to expose your body directly to

the outlet air for a long time. It may affect your

physical conditions.

• When using the air conditioner for infants,

children, elderly, bedridden, or disabled people

make sure the room temperature is suitable for

those in the room.

• Never insert objects into the unit. Inserting

objects can result in injury due to the high

speed rotation of internal fans.

• Ground the air conditioner without fail. Do not

connect the grounding wire to gas pipe, water

pipe, lightning rod or telephone grounding

wire. Incomplete grounding may cause electric

shock.

• If anything is abnormal with the air conditioner

(ex. a burning smell), stop the operation

immediately and turn the circuit breaker OFF.

• The appliance shall be installed in accordance

with national wiring regulations. Improper

cable connection can cause the power supply

cord, plug and the electrical outlet to overheat

and cause fire.

• If the supply cord is damaged, it must be

replaced by the manufacturer or its service

agent or a similarly qualified person in order

to avoid a hazard. Use only the manufacture

specified power cord for replacement.

• Do not splash or pour water directly on the

unit. Water can cause electrical shock or

equipment damage.

• Do not attempt to install/remove/repair the unit

by yourself. Incorrect work will cause electric

shock, water leak, fire etc. Consult your dealer

or other qualified service personnel for the

installation/removal/repair of the unit.

CAUTIONS

• Open a window or door periodically to

ventilate the room, especially when using gas

appliances. Insufficient ventilation may cause

oxygen shortage.

• Do not operate the buttons with wet hand. It

may cause electric shock.

• For safety, turn the circuit breaker off when not

using the unit for an extended period of time.

• Check the outdoor unit mounting rack

periodically for wear and to make sure it is

firmly in place.

• Do not put anything on the outdoor unit nor

step on it. The object or the person may fall

down or drop, causing injury.

• This unit is designed for residential use. Do

not use for other applications such as in a

kennel or greenhouse to raise animals or grow

plants.

• Do not place a vessel with water on the unit.

If water penetrates into the unit, electrical

insulations may deteriorate and cause electric

shock.

• Do not block the air inlets nor outlets of the

unit. It may cause insufficient performance or

troubles.

• Be sure to stop the operation and turn the

circuit breaker off before performing any

maintenance or cleaning. A fan is rotating

inside the unit and you may get injured.

• This appliance is not intended for use by

young children or infirm persons without

supervision. Young children should be

supervised to ensure that they do not play with

the appliance.

• Make sure to connect the air conditioner to

power supply of the rated voltage and frequency. Use of a power supply with improper

voltage and frequency can result in equipment

damage and possible fire.

• Do not install the unit in a place where inflammable gas may leak. It may cause fire.

Install the unit in a place with minimal dust,

fumes and moisture in the air.

• Arrange the drain hose to ensure smooth

drainage. Insufficient drainage may cause wetting of the room, furniture etc.

• Make sure a leak breaker or a circuit breaker

is installed, depending on the installation location, to avoid electrical shock.

OM_AH-PN10 13GY_EN.indd Sec1:1OM_AH-PN10 13GY_EN.indd Sec1:1 12/22/11 6:30:09 PM12/22/11 6:30:09 PM

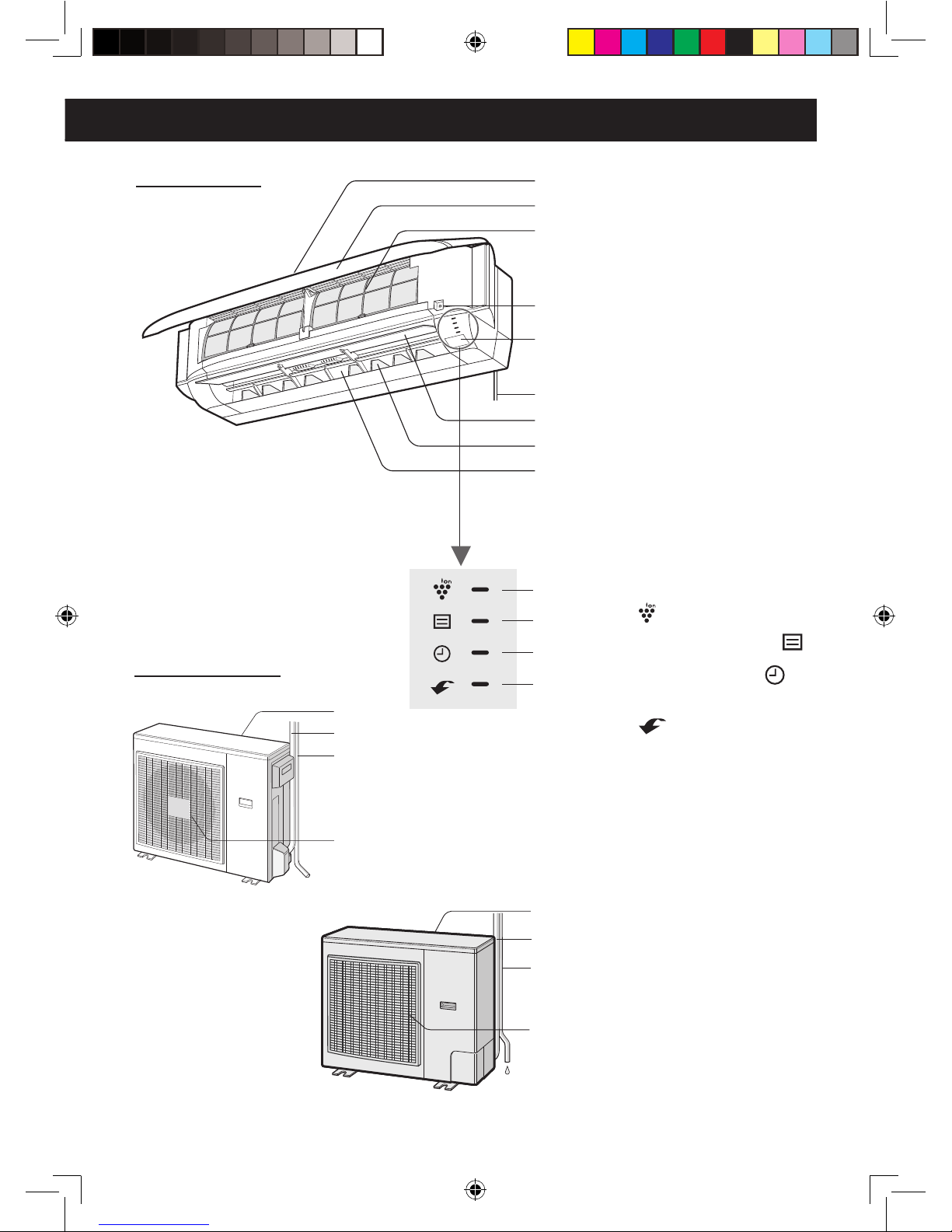

Page 4

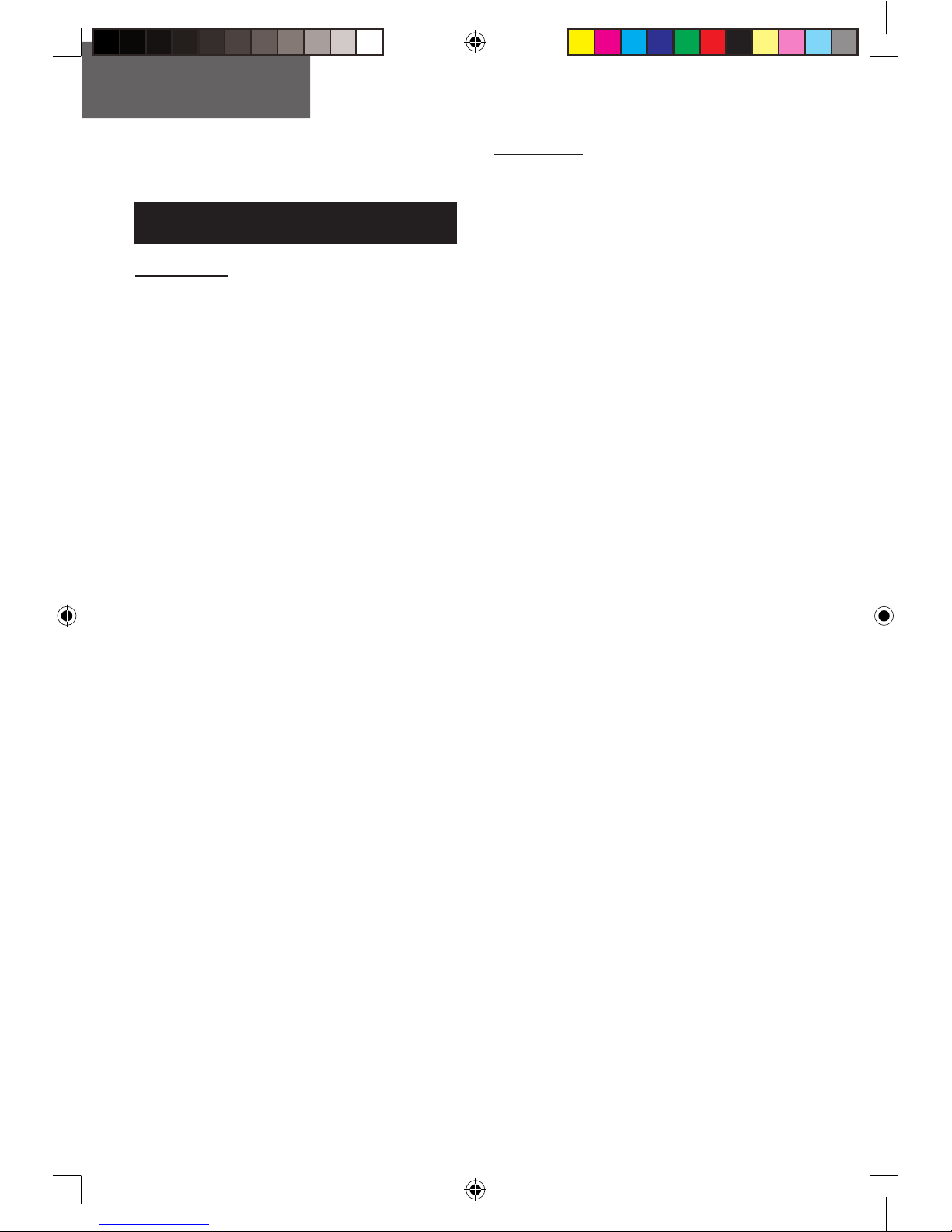

E-2

1

Inlet (Air)

2

Open Panel

3

Air Filter

4

AUX Button

5

Receiver Window

6

Vertical Airflow Louvre

7

Horizontal Airflow Louvre

8

Outlet (Air)

9

OPERATION Lamp (red

)

10

TIMER Lamp (orange

)

11

POWERFUL JET Lamp

(green

)

12

PLASMACLUSTER Lamp

(blue

)

PART NAMES

INDOOR UNIT

OUTDOOR UNIT

1

2

3

4

5

6

7

8

9

10

11

13

14

15

16

13

Inlet (Air)

14

Refrigerant Pipe and

Interconnecting Cord

15

Drainage Hose

16

Outlet (Air)

NOTE:

Actual units might vary slightly

from those shown above.

AH-L10

AH-L13

9

10

11

AH-PN10, AH-PN10-GY

AH-PN13, AH-PN13-GY

AU-PN10

AU-PN13

AU-L10

AU-L13

12

OM_AH-PN10 13GY_EN.indd Sec1:2OM_AH-PN10 13GY_EN.indd Sec1:2 12/22/11 6:30:10 PM12/22/11 6:30:10 PM

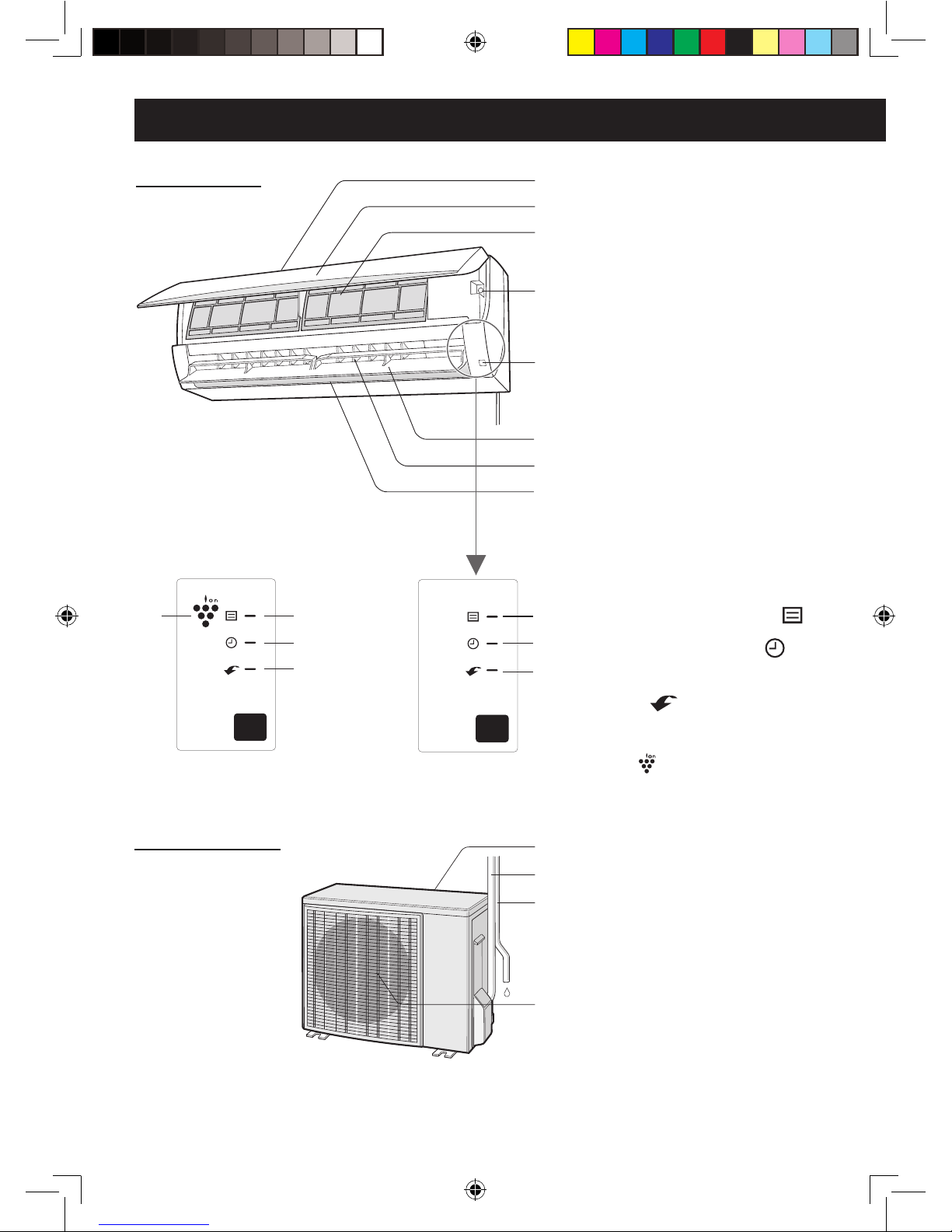

Page 5

ENG-

E-3

1 Inlet (Air)

2 Open Panel

3

Air Filter

4

AUX Button

5 Receiver Window

6 Power Supply Cord

7 Vertical Airflow Louvre

8 Horizontal Airflow Louvre

9 Outlet (Air)

10

PLASMACLUSTER Lamp

(blue

)

11

OPERATION Lamp (red

)

12

TIMER Lamp (orange

)

13

POWERFUL JET Lamp

(blue

)

14

Inlet (Air)

15

Refrigerant Pipe and

Interconnecting Cord

16

Drainage Hose

17

Outlet (Air)

NOTE:

Actual units might vary slightly

from those shown above.

INDOOR UNIT

OUTDOOR UNIT

1

2

3

4

5

6

7

8

9

14

15

16

17

14

15

16

17

AU-PN19

AU-PN24

10

11

12

13

AH-PN19, AH-PN24

OM_AH-PN10 13GY_EN.indd Sec1:3OM_AH-PN10 13GY_EN.indd Sec1:3 12/22/11 6:30:11 PM12/22/11 6:30:11 PM

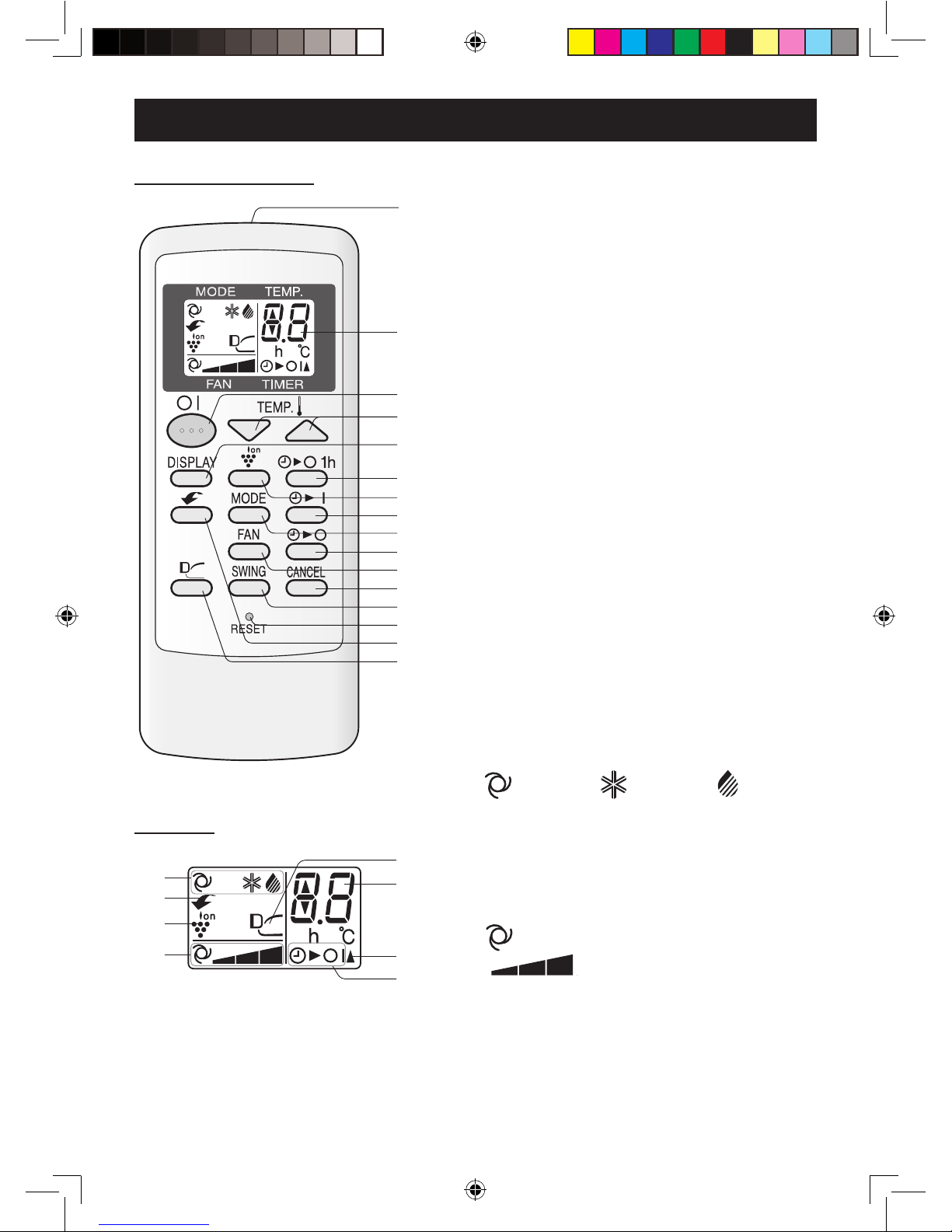

Page 6

E-4

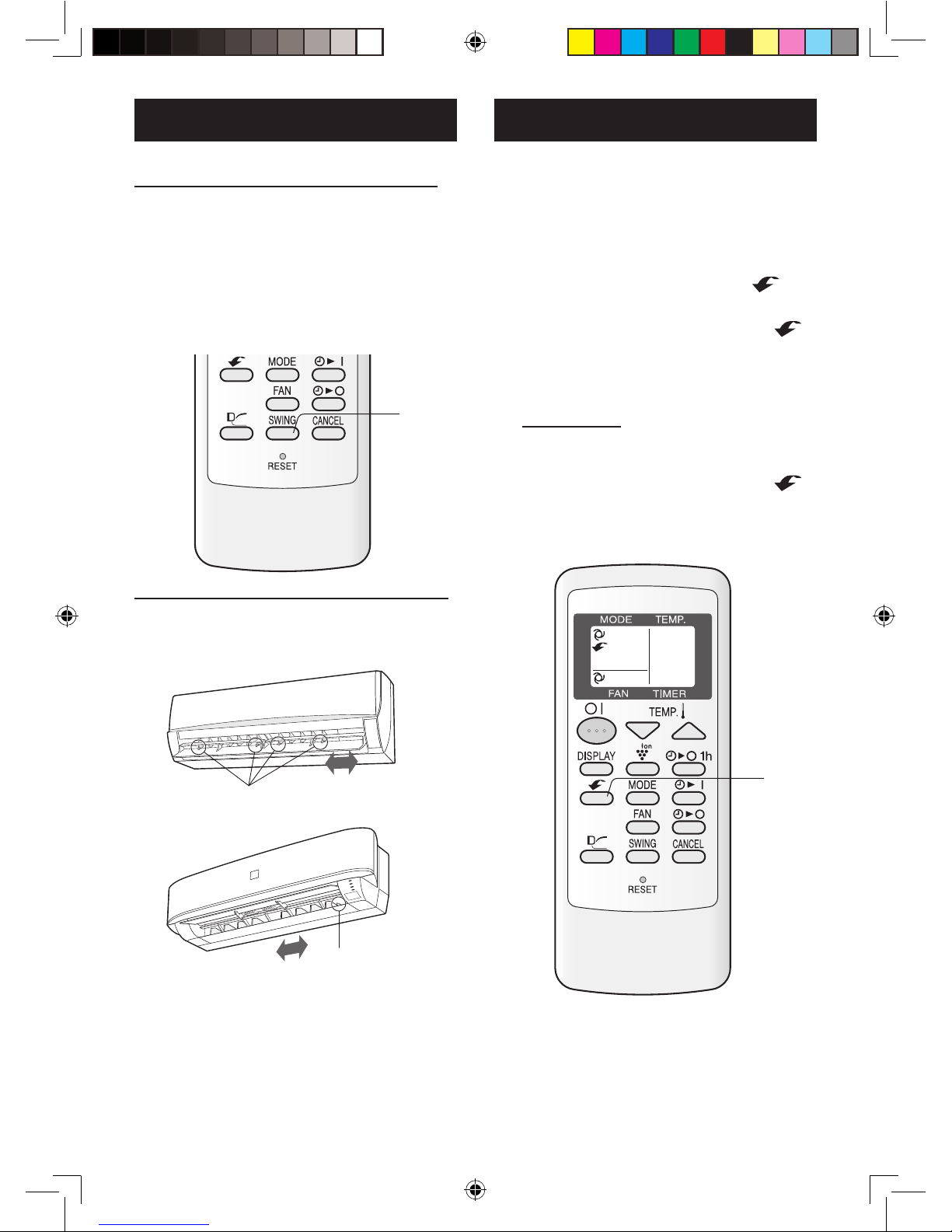

REMOTE CONTROL

1

TRANSMITTER

2

DISPLAY

3

ON/OFF Button

4

THERMOSTAT Button

5

DISPLAY Button

6

ONE-HOUR OFF TIMER Button

7

PLASMACLUSTER Button

8

TIMER ON Button

9

MODE Button

10

TIMER OFF Button

11

FAN Button

12

TIMER CANCEL Button

13

SWING Button

14

Reset Button

15

POWERFUL JET Button

16

GENTLE COOL AIR Button

DISPLAY

17

MODE Symbols

: AUTO : COOL : DRY

18

POWERFUL JET Symbol

19

PLASMACLUSTER Symbol

20

FAN SPEED Symbols

: AUTO

: Manual setting

21

GENTLE COOL AIR Symbol

22

TEMPERATURE AND TIMER COUNT DOWN

Indicator

23

TRANSMITTING Symbol

24

TIMER ON / TIMER OFF Indicator

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

PART NAMES

(AH-PN10, AH-PN10-GY

AH-PN13, AH-PN13-GY

AH-PN19, AH-PN24 ONLY)

(AH-PN10, AH-PN10-GY

AH-PN13, AH-PN13-GY

AH-PN19, AH-PN24 ONLY)

OM_AH-PN10 13GY_EN.indd Sec1:4OM_AH-PN10 13GY_EN.indd Sec1:4 12/22/11 6:30:13 PM12/22/11 6:30:13 PM

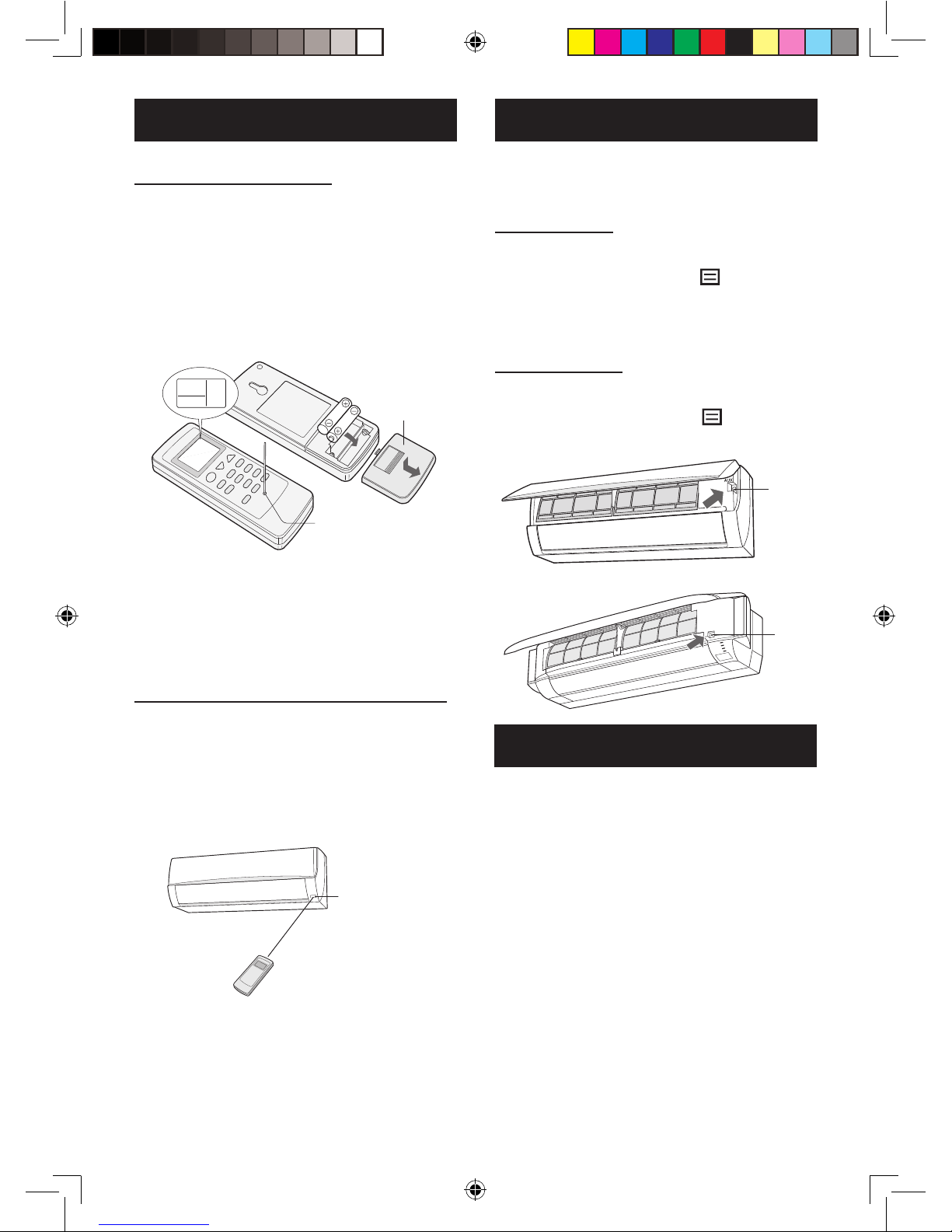

Page 7

ENG-

E-5

AUX

7 m

18,000/24,000 BTU

AUX

LOADING BATTERIES

1

Remove the battery cover.

2

Insert two batteries.

(AAA(R03))

Make sure the (+) and (-) polarities are

correctly aligned.

3

Reinstall the battery cover.

4

Press the RESET button using a

thin stick.

NOTE:

• The battery life is approximately 1 year in

normal use.

• When replacing the batteries, always change

both and use the same type.

• If you will not be using the unit for a long time,

remove the batteries from the remote control.

USING THE REMOTE CONTROL

Battery cover

HOW TO USE THE REMOTE CONTROL

Point the remote control towards the receiver

window and press the desired button. The

unit generates a beep when it receives the

signal.

• Make sure nothing, such as curtains, block the

signal receiver window.

• The signal effective distance is 7 m.

CAUTION:

•

Do not expose the receiver window to direct

sunlight. This may adversely affect its operation.

•

Use of certain fluorescent lamp in the same room

may interfere with transmission of the signal.

• Do not leave the remote control in direct

sunlight or near a heater. Protect the remote

control from moisture and shock.

Use this mode when the remote control is

not available.

TO TURN ON

Press the AUX button.

•

The red OPERATION lamp ( ) will light and

the unit will start operating in the AUTO mode.

• The fan speed and temperature setting are

set to AUTO.

TO TURN OFF

Press the AUX button again.

• The red OPERATION lamp ( ) will turn off.

AUXILIARY MODE

TIPS ON SAVING ENERGY

Below are some simple ways to save energy

when you use your air conditioner.

Set the proper temperature

• Setting the temperature lower than necessary during cooling operation will result in

increased power consumption.

Block direct sunlight and prevent drafts

•

Blocking direct sunlight during cooling operation

will reduce power consumption.

• Close the windows and doors during cooling

operation.

Keep filter clean to ensure the most efficient

operation

Disconnect the power cord or turn off the

circuit breaker when the unit is not used for an

extended period of time

• The indoor unit still consumes a small amount

of power when it is not operating.

Receiver window

RESET button

9,000/12,000 BTU

OM_AH-PN10 13GY_EN.indd Sec1:5OM_AH-PN10 13GY_EN.indd Sec1:5 12/22/11 6:30:14 PM12/22/11 6:30:14 PM

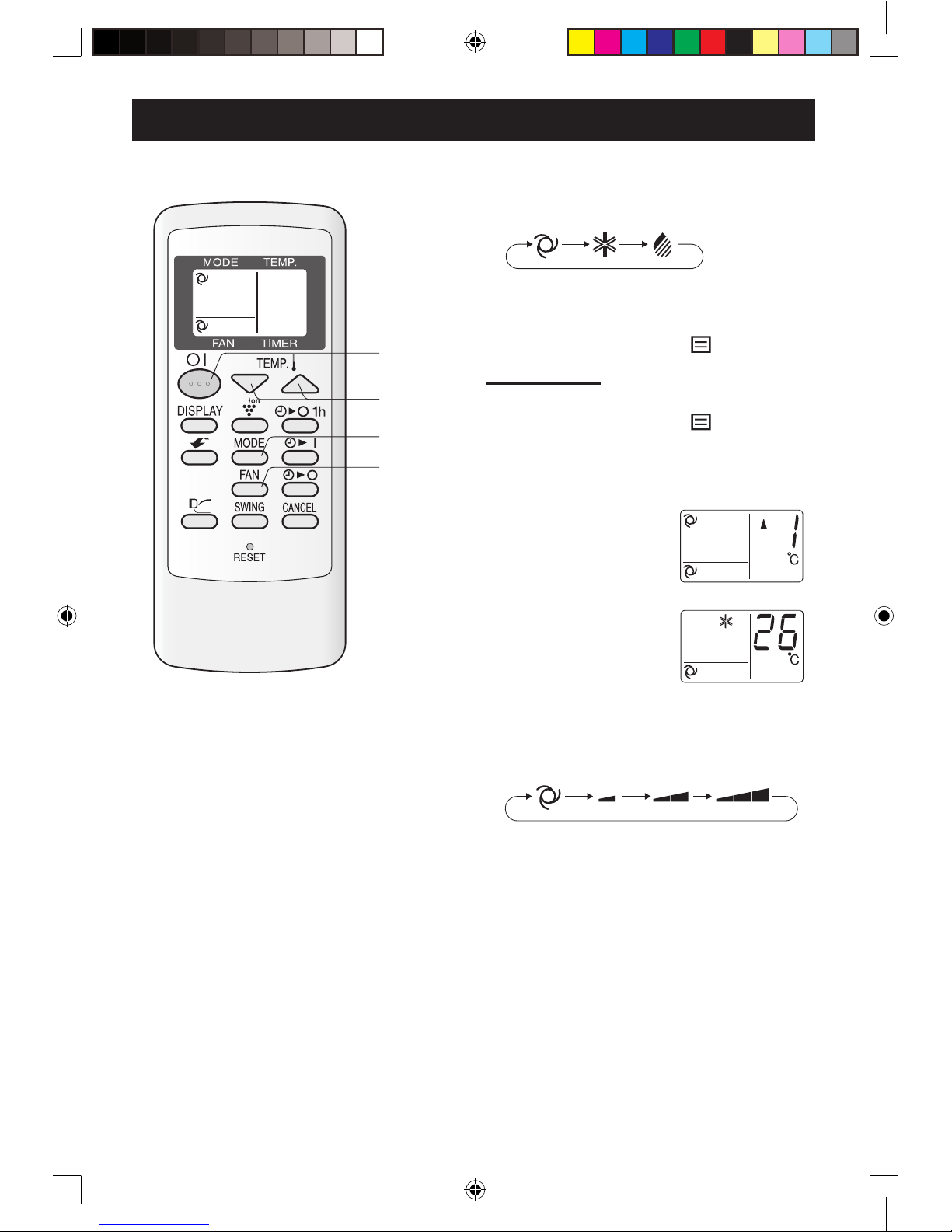

Page 8

E-6

2

3

1

4

1

Press the MODE button to select the

operation mode.

2

Press the ON/OFF button to start

operation.

• The red OPERATION lamp ( ) will light up.

TO TURN OFF

Press the ON/OFF button again.

• The red OPERATION lamp ( ) will turn off.

3

Press the THERMOSTAT button to

set the desired temperature.

(AUTO/DRY mode)

The temperature can

be changed up to ±2 °C

the automatically set of

temperature.

(COOL mode)

The temperature setting

range:

16-30°C.

4

Press the FAN button to set the

desired fan speed.

BASIC OPERATION

AUTO COOL DRY

AUTO SOFT LOW HIGH

NOTE:

AUTO MODE

In the AUTO mode, the temperature setting and mode are automatically selected according to the

room temperature when the unit is turned on.

DRY MODE

The fan speed is preset to AUTO and cannot be changed.

WHEN POWER FAILURE OCCURS

This air conditioner has a memory function to store settings when a power failure occurs.

After power recovery, the unit will automatically re-start in the same settings which were active before

the power failure, except for timer settings.

OM_AH-PN10 13GY_EN.indd Sec1:6OM_AH-PN10 13GY_EN.indd Sec1:6 12/22/11 6:30:16 PM12/22/11 6:30:16 PM

Page 9

ENG-

E-7

The air conditioner works at the maximum

power and optimum louvre direction to

makes the room cool rapidly.

1

During operation, press the

POWERFUL JET button.

• The remote control will display “ ”.

• The temperature display will go off.

• The green POWERFUL JET lamp (

)

will light up.

• The vertical airflow louvre will be set

obliquely downward.

TO CANCEL

Press the POWERFUL JET button

again.

• The green POWERFUL JET lamp ( )

will turn off.

• The vertical airflow louvre will return to

the original direction.

NOTE:

• The air conditioner will operate at “Extra

HIGH” fan speed for 30 minutes, and then

shift to “HIGH” fan speed.

• You can not set the temperature or fan speed

during the POWERFUL JET operation.

Louvre lever

1

2

1

9,000/12,000 BTU

18,000/24,000 BTU

CAUTION:

Never attempt to adjust the vertical airflow louvre manually.

• Manual adjustment of the vertical airflow louvre can cause the unit to malfunction.

• When the vertical adjustment louvre is positioned at the lowest position in the COOL or

DRY mode for an extended period of time,

condensation may result.

VERTICAL AIR FLOW DIRECTION

1

Press the SWING button.

• The vertical airflow louvre will swing.

2

Press the SWING button again

to stop the desired position.

• The adjustment range is narrower the

swing range in order to prevent condensation from dripping.

ADJUSTING THE AIR FLOW

DIRECTION

POWERFUL JET OPERATION

HORIZONTAL AIR FLOW DIRECTION

Hold the horizontal airflow louvre

levers and adjust the air flow direction.

Louvre lever

OM_AH-PN10 13GY_EN.indd Sec1:7OM_AH-PN10 13GY_EN.indd Sec1:7 12/22/11 6:30:17 PM12/22/11 6:30:17 PM

Page 10

E-8

The vertical airflow louvre is set obliquely

upward to deliver cool air to the ceiling in

order to avoid direct airflow.

1

During operation, press the

GENTLE COOL AIR button.

• The remote control will display “ ”.

TO CANCEL

Press the GENTLE COOL AIR button

again.

NOTE:

• If you want GENTLE COOL AIR operation

in POWERFUL JET mode, press GENTLE

COOL AIR button during POWERFUL JET

operation.

1

GENTLE COOL AIR

PLASMACLUSTER OPERATION

Plasmacluster ions released into the room

will reduce some airborne mold.

1

During operation, press the

PLASMACLUSTER button.

• The remote control will display “ ”.

• The blue PLASMACLUSTER lamp (

)

will light up.

TO CANCEL

Press the PLASMACLUSTER button

again.

• The blue PLASMACLUSTER lamp (

)

will turn off.

NOTE:

• Use of the PLASMACLUSTER operation will

be memorized, and it will be activated the next

time you turn on the unit.

• To perform Plasmacluster operation in FAN

only mode, press the PLASMACLUSTER button when the unit is not operating.

The mode symbol of the remote control will go

off and the fan speed cannot be set to AUTO.

1

(AH-PN10, AH-PN10-GY

AH-PN13, AH-PN13-GY

AH-PN19, AH-PN24 ONLY)

OM_AH-PN10 13GY_EN.indd Sec1:8OM_AH-PN10 13GY_EN.indd Sec1:8 12/22/11 6:30:18 PM12/22/11 6:30:18 PM

Page 11

ENG-

E-9

TIMER ON

1

Press the TIMER ON button and

set the time as desired.

•

The orange TIMER lamp ( ) will light up.

• The time setting will count down to show

the remaining time.

TO CANCEL

Press the CANCEL button.

•

The orange TIMER lamp ( ) will turn off.

TIMER OPERATION

1

TIMER OFF

1

Press the TIMER OFF button and

set the time as desired.

•

The orange TIMER lamp ( ) will light up.

• The time setting will count down to show

the remaining time.

TO CANCEL

Press the CANCEL button.

• The orange TIMER lamp ( ) will turn off.

0.5h 1.0h 1.5h 10h 11h 12h

0.5h 1.0h 1.5h 10h 11h 12h

CANCEL

1

NOTE:

• Timer duration can be set from a minimum of half an hour to a maximum of 12 hours. Up to 9.5

hours, you can set in half-hour increments, and from 10 to 12 hours, in 1-hour increments.

• The TIMER OFF and TIMER ON can not be set together.

• The ONE-HOUR OFF TIMER operation has priority over TIMER ON and TIMER OFF operations.

• When the temperature is set during timer setting, the temperature will show in the display for 5

seconds and then return to the timer display.

• If a power failure occurs while the TIMER is set, the TIMER setting will be cancelled and will not be

retrieved even after the power is restored.

TIMER OFF

• When the TIMER OFF is set, the temperature setting is automatically adjusted to prevent the room

from be coming excessively cold while you sleep. (Auto Sleep function) One hour after the time

operation begins, the temperature setting rises 1°C higher than the original temperature setting.

TIMER ON

• The unit will turn on prior to the set time to allow the room to reach the desired temperature by the

programmed time. (Awaking function)

CANCEL

OM_AH-PN10 13GY_EN.indd Sec1:9OM_AH-PN10 13GY_EN.indd Sec1:9 12/22/11 6:30:20 PM12/22/11 6:30:20 PM

Page 12

E-10

CANCEL

1

1

When the ONE-HOUR OFF TIMER is set, the

unit will automatically turn off after one hour.

1

Press the ONE-HOUR OFF TIMER

button.

• The remote control will displays “ ”.

•

The orange TIMER lamp ( ) will light up.

TO CANCEL

Press the CANCEL button.

• The orange TIMER lamp ( ) will turn off.

NOTE:

• The ONE-HOUR OFF TIMER operation has

priority over TIMER ON and TIMER OFF

operations.

• If the ONE-HOUR OFF TIMER is set while the

unit is not operating, the unit will operate for an

hour at the formerly set condition.

• If you wish to operate the unit for another

hour before the ONE-HOUR OFF TIMER is

activated, press the ONE-HOUR OFF TIMER

button again during operation.

ONE-HOUR OFF TIMER

Use when the lamps on the unit are too

bright. (The red OPERATION lamp and the

orange TIMER lamp cannot be turned off.)

1

During operation, press the

DISPLAY button.

• The blue PLASMACLUSTER lamp ( )

and/or the green POWERFULL JET lamp

(

) will turn off.

TO LIGHT UP

Press the DISPLAY button again.

DISPLAY BUTTON

OM_AH-PN10 13GY_EN.indd Sec1:10OM_AH-PN10 13GY_EN.indd Sec1:10 12/22/11 6:30:21 PM12/22/11 6:30:21 PM

Page 13

ENG-

E-11

9,000/12,000 BTU

18,000/24,000 BTU

Be sure to disconnect the power cord from

the wall outlet or turn off the circuit breaker

before performing any maintenance.

CLEANING THE FILTERS

1

Turn off the unit.

2

Remove the filters.

1

Lift the open panel.

2

Pull the air filters down to remove them.

MAINTENANCE

OPERATING CONDITION

Mode

Indoor

Temp.

Outdoor

Te mp .

Cooling

Upper limit 32˚C43˚C

Lower limit 21˚C21˚C

• The built-in safety device may prevent the unit

from operating when used out of this range.

• Condensation may form on the air outlet if the

unit operates continuously in the COOL or

DRY mode when humidity is over 80 %.

MAINTENANCE AFTER AIR

CONDITIONER SEASON

1

Operate the unit in the COOL

mode, temperature setting 30˚C,

to thoroughly dry inside the unit.

2

Stop the operation and unplug the

unit. Turn off the circuit breaker,

if you have one exclusively for

the air conditioner.

3

Clean the filters, then reinstall

them.

MAINTENANCE BEFORE AIR

CONDITIONER SEASON

1

Make sure that the air filters are

not dirty.

2

Make sure that nothing obstructs

the air inlet or outlet.

3

Clean the filters.

Use a vacuum cleaner to remove dust. If

the filters are dirty, wash them with warm

water and a mild detergent. Dry filters in the

shade before reinstalling.

4

Reinstall the filters and close

the open panel.

CLEANING THE UNIT AND THE

REMOTE CONTROL

• Wipe them with a soft cloth.

• Do not directly splash or pour water on them.

It can cause electrical shock or equipment

damage.

• Do not use hot water, thinner, abrasive powders or strong solvents.

OM_AH-PN10 13GY_EN.indd Sec1:11OM_AH-PN10 13GY_EN.indd Sec1:11 12/22/11 6:30:22 PM12/22/11 6:30:22 PM

Page 14

E-12

Check the following points before calling for

service.

The unit does not operate

• Check if the circuit breaker has tripped or the

fuse has blown.

The unit does not cool effectively

•

Check the filters. If dirty, clean them.

• Check the outdoor unit to make sure nothing

is blocking the air inlet or outlet.

• Check the thermostat is proper setting.

• Make sure windows and doors are closed

tightly.

The unit does not receive the remote

control signal

• Check whether the remote control batteries

have become old and weak.

• Try to send the signal again with the remote

control pointed properly towards the unit’s

signal receiver window.

• Check whether the remote control batteries

are installed properly.

Please call for service when

OPERATION lamp, TIMER lamp and/or

PLASMACLUSTER lamp on the unit blink.

The following conditions do not denote

equipment malfunctions

UNIT DOES NOT OPERATE

The unit will not operate if it is turned on immediately after it is turned off.

The unit will not

operate immediately

after the mode is changed.

This is to protect the unit.

Wait 3 minutes before

operating the unit.

ODORS

Carpet and furniture odors that entered into

theunit may be sent out from the unit.

CRACKING NOISE

This sound is generated by the friction of the

unit expanding or connecting due to a temperature change.

SWISHING NOISE

The soft, swishing noise is the sound of the

refrigerant flowing inside the unit.

MIST SEEN AT INDOOR AIR OUTLET

In cooling operation,

this is caused by the difference between the room air temperature and the

air discharged.

ODOR EMITTED FROM THE

PLASMACLUSTER AIR OUTLET

(AH-PN10, AH-PN10-GY

AH-PN13, AH-PN13-GY

AH-PN19, AH-PN24 ONLY)

This is the smell of ozone generated from

the

Plasmacluster Ion generator. The ozone

concentration is very small, posing no adverse

effect on your health.

The ozone discharged

into the air rapidly decomposes, and its density

in the room will not increase.

A LOW BUZZING NOISE

(AH-PN10, AH-PN10-GY

AH-PN13, AH-PN13-GY

AH-PN19, AH-PN24 ONLY)

This is a sound of the unit generating Plasmacluster ions.

BEFORE CALLING FOR SERVICE

(AH-PN10, AH-PN10-GY

AH-PN13, AH-PN13-GY

AH-PN19, AH-PN24 ONLY)

OM_AH-PN10 13GY_EN.indd Sec1:12OM_AH-PN10 13GY_EN.indd Sec1:12 12/22/11 6:30:23 PM12/22/11 6:30:23 PM

Page 15

ENG-

E-13

INSTALLATION MANUAL

SAFETY PRECAUTIONS

SPLIT TYPE ROOM AIR CONDITIONER

ACCESSORIES

ITEMS Q’ty ITEMS Q’ty ITEMS Q’ty

1

MOUNTING PLATE

1

3

DRY BATTERY

2

5

CABLE COVER

1

2

REMOTE CONTROL

1

4

REMOTE CONTROL

HOLDER

1

6

OPERATION AND

INSTALLATION MANUAL

1

9K, 12K BTU

18K, 24K BTU

9K, 12K BTU

18K, 24K BTU

•

Installation must be made in accordance with the installation manual by qualified service

personnel.

Incorrect work will cause electric shock, water leak, fire.

•

Be sure to use the attached accessories parts and specified parts for installation.

Use of other parts will cause electric shock, water leak, fire, the unit falling.

• The appliance shall be installed in accordance with national wiring regulations.

Wrong connection can cause overheating or fire.

•

After installation has complete, check that there is no leakage of refrigerant gas.

If the refrigerant gas contact with fire, it may generate toxic gas.

• Ventilate the room if refrigerant gas leakes during installation.

If the refrigerant gas contact with fire, it may generate toxic gas.

• Use the specified electrical cable.

Make sure the cable is secured in place and that the terminals are free of any excess force from

the cable.

Otherwise overheating or fire may result.

•

Form the cable so that the control box cover, the cord holder and cable holder are not loose.

Otherwise overheating, fire or electric shock may result.

• Tighten the flare nut with a torque wrench according to the specified method.

If the flare nut is tightened too hard, the flare nut may be broken after a long time and cause

refrigerant gas leakage.

• When installing the unit, take care not to enter air substance other than the specified

refrigerant (R22) in the refrigerant cycle.

Otherwise, it will cause burst and injury as a result of abnormal high pressure in the refrigerant cycle.

• Be sure to connect the refrigerant pipe before running the compressor.

Otherwise, it will cause burst and injury as a result of abnormal high pressure in the refrigerant cycle.

• Earth the unit.

Incomplete earth may cause electrical shock.

• Install an earth leakage breaker to avoid electric shock in case of leak.

Use the current-activated, high-sensitivity, high-speed type breaker with a rated sensitivity current

of below 30 mA and an operating time of below 0.1 second.

• Arrange the drain hose to ensure smooth drainage.

Insufficient drainage may cause wetting of the room, furniture etc.

OM_AH-PN10 13GY_EN.indd Sec1:13OM_AH-PN10 13GY_EN.indd Sec1:13 12/22/11 6:30:25 PM12/22/11 6:30:25 PM

Page 16

E-14

NOTES ON LOCATIONS

INDOOR UNIT

1. Keep the air outlet clear of any obstacle so that outgoing air flows smoothly in the entire room.

2. Make a drain hose hole for easy drainage.

3. Provide sufficient space on both sides and above the unit.

4. The air filters should be easily taken in and out.

5. Keep TV set, radio and the like 1 m or more away from the unit and the remote control.

6. Keep the air inlet clear of obstacles that could block incoming air.

7. The remote control may not function properly in a room equipped with an electronic simultaneous-start or rapid-start fluorescent lighting.

8. Select a location that does not cause loud operation noise and extreme vibrations.

OUTDOOR UNIT

1. Place the outdoor unit on a stable base.

2. Provided sufficient space around the unit. It should also be well ventilated.

3. The unit should not be exposed to strong wind nor splashed with rain water.

4. Water drain from the unit should be let out without problem. Lay a drain hose if required. In cold

regions, installation of the drain pipe is not advisable as freezing could result.

5. Keep TV set, radio and the like 1 m or more away from the unit.

6. Avoid locations exposed to machine oil vapor, salty air (facing the seashore, for example), hot

spring vapor sulfur gas, etc. Such location can cause breakdown.

7. Avoid locations exposed to muddy water (along a road, for example) or where the unit can be

tampered with.

8. Select a location where the outgoing air or operating noise cannot annoy others.

9. Keep the air outlet opening free of any obstacle. This could affect the performance of the unit

and create loud noises.

INSTALLATION DIAGRAM

Provide as much installation space as possible for efficient air-conditioning.

50 mm or more

50 mm

or more

50 mm

or more

70 mm or more

Coating tape

(Commercially

available)

50 mm or more

200 mm

or more

100 mm

or more

200 mm

or more

Fix the remote control holder to the wall

with the short screws.

4

REMOTE CONTROL HOLDER

SHORT SCREW

2

REMOTE CONTROL

Coating tape (Commercially available)

50 mm or more

50 mm

or more

70 mm or more

50 mm

or more

300 mm

or more

1000 mm

or more

400 mm

or more

9000/12000 BTU 24000 BTU 18000 BTU

300 mm or more

400 mm

or more

300 mm

or more

1000 mm

or more

300 mm

or more

OM_AH-PN10 13GY_EN.indd Sec1:14OM_AH-PN10 13GY_EN.indd Sec1:14 12/22/11 6:30:27 PM12/22/11 6:30:27 PM

Page 17

ENG-

E-15

INSTALLATION DIMENSION OF INDOOR UNIT

860

108

A

125

J

175

115

I

F

E

D

J

E

A

F

I

D

292

45

30

Length unit: mm

Center of wall hole

Center of

wall hole

Outline of indoor unit

(Unit size)

965 (Unit size)

Model

Max. piping

length:A

Max. height

difference:B

Min. piping

length

Additional refrigerant

(piping length exceeds 7.5m)

9K-Btu/h type 10 m 5 m

1 m

15 g/m

12K-Btu/h type 15 m 7 m

10 g/m

18K 24K-Btu/h type

15 m 10 m

• Standard piping length is 7.5m.

• When the outdoor unit is placed at a higher level than the indoor

unit, provide a trap near the hose’s lead-in port.

Use the refrigerant pipes shown in the table below.

Pipe size

Pipe

thickness

Thermal insulation

Liquid side 1/4" (ø 6.35 mm)

0.8 mm

Thickness: 6 mm or

thicker

Material: Polyethylene

foam

Gas side

9K-Btu/h type

3/8" (ø 9.52 mm)

12K-Btu/h type

1/2" (ø 12.7 mm)

18K 24K-Btu/h type

5/8" (ø 15.88 mm)

1.0 mm

• The thermal insulation should cover both the gas and liquid pipes.

Trap

PIPES

A

B

B

3

13

05

05

80

A

J

I

80

88 88

F

42

E

E E

C

A

B

J

H

G

F

0

0

I

D

D

Length unit: mm

Center of wall hole

Center of wall hole

Outline of indoor unit

(Unit size)

965 (Unit size)

9000/12000 BTU

18000/24000 BTU

OM_AH-PN10 13GY_EN.indd Sec1:15OM_AH-PN10 13GY_EN.indd Sec1:15 12/22/11 6:30:28 PM12/22/11 6:30:28 PM

Page 18

E-16

Installing the mounting plate

(1) Referring to the “

INSTALLATION DIMEN-

SION OF INDOOR UNIT

”, mark the location

for the fixing holes and the piping hole.

•

Recommended fixing holes are marked in

circle around the hole. (7 points)

• Make sure that the mounting plate is horizontally.

(2) Secure the mounting plate to the wall with

the long screws and check the stiffness.

Wall

Making a piping hole

(1)

Drill a piping hole with 70mm diameter concrete

drill or a hole saw with a 5mm down ward

slant to the outside.

(2) Set the sleeve and caps.

1

MOUNTING PLATE

LONG SCREW

Indoor Outdoor

Cut with a saw.

Cap

5 mm

Sleeve

(Downward to outdoor)

PLACING THE MOUNTING PLATE AND MAKING A PIPING HOLE

LONG SCREW

1

MOUNTING PLATE

SETTING UP THE INDOOR UNIT

1

2

3

4

5

Mounting the indoor unit

For right side piping

(1)

Pass the pipes and the drain hose through the piping hole.

(2) Hook the unit onto the mounting plate.

(3) Pull the connecting cable into the indoor unit.

(4) Push the unit and apply the bottom hooks to the

mounting plate's support.

(5) Pull the bottom of the unit to check that the unit is

fixed in place.

For left side piping

(1)

Reverse the positions of the drain hose and drain cap.

Refer to “

Exchange the drain hose

”

(2)

Connect the pipes and wrap tape around the insula-

tion of the piping joints tightly not to become thick.

(3) Bind the pipes and connecting cable with tape.

(4) Set the pipes and connecting cable along the back

of the unit, and attach the piping holder.

(5) Pass the pipes, connecting cable and the drain

hose through the piping hole.

(6) Hook the unit onto the mounting plate.

(7) Push the unit and apply the bottom hooks to the

mounting plate's support.

(8) Pull the bottom of the unit to check that the unit is

fixed in place.

NOTES:

• Bend the pipes carefully as not to damage them.

• Lay the drain hose below the pipes.

Drain Hose

MOUNTING PLATE

Taping

Drain Cap

Piping route

For directions 1, 2 , 4 and 5, cut out the specific

zone without leaving any sharp edge.

(Keep the cut-out plate for possible future use.)

PLATE

Cut the plate

along notch.

Hook

MOUNTING PLATE

Tape

Pipes

Drain Hose

Insulation

Tape

Model 9000/12000 BTU Model 18000/2400 BTU

Model 9000/12000 BTU

PLATE

PLATE

Piping holder

OM_AH-PN10 13GY_EN.indd Sec1:16OM_AH-PN10 13GY_EN.indd Sec1:16 12/22/11 6:30:29 PM12/22/11 6:30:29 PM

Page 19

ENG-

E-17

1

2

3

4

5

(1)

Remove the screw and pull out the drain hose.

(2) Pull out the drain cap.

(3) Reconnect the drain hose to the right and

insert the drain cap to the left.

• Fully insert the drain hose until it stops

and fix the screw removed in (1).

• Insert a hexagon wrench (4 mm diagonal)

into the drain cap, and press it fully.

Drain Hose

Hexagon wrench

Drain Cap

Drain Hose

Drain Cap

Screw

Exchange the drain hose

Screw

CONNECTING THE CABLE TO THE INDOOR UNIT

Use a copper cable. (Cross-section area: 2.0 mm2 ) 9,000-12,000-18,000 BTU only

Use a cable which is not lighter than polychloroprene sheathed flexible cord (Code designation 60245 IEC 57).

Use a copper cable. (Cross-section area: 2.0 mm2) 24,000 BTU only

8

8

40

50

Earth wire

Connecting cable

Length unit: mm

8

8

80

90

8

8

80

90

Drain Hose

MOUNTING PLATE

Taping

Drain Cap

Hook

MOUNTING PLATE

Piping holder

Tape

Pipes

Drain Hose

Insulation

Tape

Earth wire Earth wire

Plate

Cut the plate along notch.

Piping route

For directions 1, 2 , 4 and 5, cut out the specific

zone without leaving any sharp edge.

(Keep the cut-out plate for possible future use.)

Model 18000/24000 BTU

Model 9000/12000 BTU Model 18000 BTU Model 24000 BTU

Plate

Plate

Plate

WARNING:

After replacing, make sure that both the drain

hose and drain cap are firmly inserted.

OM_AH-PN10 13GY_EN.indd Sec1:17OM_AH-PN10 13GY_EN.indd Sec1:17 12/22/11 6:30:32 PM12/22/11 6:30:32 PM

Page 20

E-18

SHORT SCREW

5

CABLE COVER

CAUTIONS:

• Be very careful not to confuse the terminal connections. Wrong cabling may damage the internal

control circuit.

• Be sure to connect the cable to match the markings on the indoor unit’s terminal board and those of

the outdoor unit.

(1) Process the end of the connecting

cable for the indoor side.

(2) Open the open panel.

(3) Connect the cable.

(4) Fix the cable with the cable cover

and the short screw.

(5) Close the open panel.

N1

N1

OUTDOOR UNIT

NL

POWER SUPPLY

NL1

NLL1

OUTDOOR UNIT

NL

POWER SUPPLY

SHORT SCREW

5

CABLE COVER

18K-Btu/h type

24K-Btu/h type

CONNECTING THE DRAIN HOSE

Not running wavy.

Not left

in water.

No trap

allowed.

Not to rise.

Connecting the drain hose

(1) Connect a drain hose.

(2) Tape over the connecting part.

Drain Hose (Commercially available)

ø16 mm

No trap allowed.

NOTE:

• Be sure to lay the drain hose downward for smooth drainflow.

•

Be careful not to allow the drain hose to rise, form a trap or

leave its end in water, as shown below.

• Coil thermal insulation around a drain hose extension, if running in the room.

Checking drainage

(1) Open the open panel.

(2) Remove the air filters.

(3) Pour some water into the drain pan.

(4) Check the water drains smoothly.

Connect to

outdoor

Power supply

cable

Earth wire

Connect to

outdoor

Power supply

cable

Cable

holder

Cable

holder

Model 9000/12000 BTU

Model 18000/24000 BTU

Connecting

cable

Earth wire

Power supply

cable

Earth wire

OM_AH-PN10 13GY_EN.indd Sec1:18OM_AH-PN10 13GY_EN.indd Sec1:18 12/22/11 6:30:33 PM12/22/11 6:30:33 PM

Page 21

ENG-

E-19

OUTDOOR UNIT INSTALLATION

A

B

Referring to the figure, firmly fasten the outdoor unit with bolts.

ระยะหางของขาตั้งตัวเคร องปรับอากาศ

ระยะหางของขาตั้งตัวเคร องปรับอากาศ

Model A B

9K/12K Btu/h 515 299

18K Btu/h 557 379

24K Btu/h 590 361

Length unit: mm

Unit size

AH-PN10

AH-PN10GY

AH-PN13

AH-PN13GY

AH-L10

AH-L13

AH-PN19

AH-PN24

AU-PN10

AU-PN13

AU-L10

AU-L13

AU-PN19 AU-PN24

WIDTH 223 250 250 330 357

HEIGHT 292 313 540 710 800

DEPTH 860 965 730 850 940

Connecting the refrigerant pipes

Connecting the pipes

Connect the pipes for the indoor unit first and then

for the outdoor unit.

(1) Tighten the flare nuts by hand for the first 3-4

turns.

(2) Use a wrench and torque wrench to tighten up

the pipes.

• Do not over tighten the pipes. It may be de

formed or damaged.

Flaring the pipe end

(1) Cutting with a pipe cutter.

Cut at a right angle.

(2) Deburring.

Allow no cuttings in the pipe.

(3) Putting in the flare nut

(4) Flaring the pipe end

Flare processing dimensions (A)

Tool A

R22 tool 0.5 - 1.0 mm

(5) Checking

To be flared perfectly circular.

Flare nut not missing.

90°

A

Flare nut tightening torque

Flare nut

Wrench

Torque wrench

Pipe size Torque

Liquid size 1/4" 16 ± 2 N·m (1.6 ± 0.2 kgf·m)

Gas side 3/8" 9K-Btu/h type 38 ± 4 N·m (3.8 ± 0.4 kgf·m)

1/2"

12K 18K-Btu/h type

55 ± 5 N·m (5.5 ± 0.5 kgf·m)

5/8" 24K-Btu/h type 70 ± 7 N·m (7.0 ± 0.7 kgf·m)

OM_AH-PN10 13GY_EN.indd Sec1:19OM_AH-PN10 13GY_EN.indd Sec1:19 12/22/11 6:30:35 PM12/22/11 6:30:35 PM

Page 22

E-20

CONNECTING THE PIPES TO THE OUTDOOR UNIT

Piping can be made in four directions, choose whichever direction convenient according to unit’s

installation condition.

1. Remove 3 screws of service panel.

Slide the panel downward and detach it.

Screw

Pipe cover

2. Remove the knock out hole of pipe cover or unit base pan, depending on the piping direction intended.

After removing the knock out hole, remove burrs and attach BUSHING B on the knock out hole to

protect the edge.

Knock out hole for refrigerant pipe

Knock out hole for refrigerant pipe and cable

3. Remove the pipe cover.

Pipe cover (front)

4. Connect the pipes.

Align the center of the pipes and tighten the flare nuts by hand for the first 3-4 turns.

Use two wrenches to tighten up the pipes.

• Take care so that the connecting pipes will not touch the internal refrigerant piping.

• Be sure to cover the pipe connection area thoroughly with pipe thermal insulation.

Slit

6. Fill up the clearance between the knock out hole and the pipes with putty.

Slit

Slit

Pipe cover (rear)

5. Replace the pipe cover.

Cut off the remaining portion of the pipe cover slit to widen the pipe opening and replace the pipe cover.

OM_AH-PN10 13GY_EN.indd Sec1:20OM_AH-PN10 13GY_EN.indd Sec1:20 12/22/11 6:30:37 PM12/22/11 6:30:37 PM

Page 23

ENG-

E-21

AIR REMOVAL

Lo Hi

Valve shaft cap tightening torque

Pipe size Torque

รุนเคร องปรับอากาศ

รุนเคร องปรับอากาศ

Liquid side 1/4" 24±3N · m (2.4±0.3 kgf · m) AH/AU-PN10, 13, 19 and 24

AH/AU-L10, 13

Gas side 3/8" 9K-Btu/h type 31±3 N · m (3.1±0.3 kgf · m) AH/AU-PN10 and L10

1/2" 12K 18K-Btu/h type 31±3 N · m (3.1±0.3 kgf · m) AH/AU-PN13, 19 and L13

5/8" 24K-Btu/h type 31±3 N · m (3.1±0.3 kgf · m) AH/AU-PN24

Service port cap tightening torque

Torque

11±1 N · m (1.1±0.1 kgf · m)

(1) Remove both valve shaft caps of the 2 and 3-way valves.

(2) Remove the service port cap of the 3-way valve.

(3)

Connect the gauge manifold hose to the service port and the vacuum pump.

Be sure that the hose end to be connected to the service port has a valve core pusher.

(4) Open the gauge manifold low-pressure valve(Lo) and operate the vacuum pump for 10-15 minutes.

Make sure the compound gauge reads -0.1 MPa(-76 cmHg).

(5) Close the gauge manifold valve.

(6) Turn off the vacuum pump.

Leave as it for 1-2 minutes and make sure the needle of the compound gauge does not go back.

(7)

Open the 2-way valve 90° counterclockwise by turning the hexagon wrench. Close it after 5 second,

and check for gas leakage.*

(8) Disconnect the gauge manifold hose from the service port.

(9) Fully open the 2-way valve with hexagon wrench.

(10)

Fully open the 3-way valve with hexagon wrench.

(11)

Firmly tighten the service port cap and both valve shaft caps with a torque wrench at the specified

tightening torque.

*

Check the pipe connections for gas leak using a leakage detector or soapy water.

Gauge manifold

Compound gauge

Vacuum pump

Service port cap

3-way valve

Valve shaft cap

2-way valve

Hexagon wrench

(Diagonally 4 mm)

OPEN

Service port

CLOSE

OM_AH-PN10 13GY_EN.indd Sec1:21OM_AH-PN10 13GY_EN.indd Sec1:21 12/22/11 6:30:37 PM12/22/11 6:30:37 PM

Page 24

E-22

CONNECTING THE CABLE TO THE OUTDOOR UNIT

9K 12K-Btu/h type

(1) Process the end of the connecting cable for the

outdoor unit.

(2) Remove the control box cover.

(3) Connect the cable.

(4) Put back the control box cover.

(5) Double-check that the cable is securely in place.

N

1

Earth wire

Control box cover

Connecting cable

Terminal board

Cable holder

8

8

40

50

Terminal cover

Earth wire

Length unit: mm

Connecting cable 9K 12K 18K-Btu/h type

18K-Btu/h type

(1) Process the end of the connecting cable for the

outdoor unit.

(2) Remove the control box cover and the terminal cover.

(3) Remove the cable holder and connect the cable.

(4) Fix the cable sheath with the cable holder and the

screw.

(5) Double-check that the cable is securely in place.

(6) Put back the terminal cover and the control box cover.

24K-Btu/h type

(1)

ถอดรูสําหรับตอสายไฟออก โดยกระแทกที่แผนเหล็กของถอดฝาชุดครอบทอออก

ถอดรูสําหรับตอสายไฟออก โดยกระแทกที่แผนเหล็กของถอดฝาชุดครอบทอออก

(2) ตอสายไฟเขากับชุดควบคุมโดยตอใหตรงกับที่ตอกับชุดภายในบาน

(2) ตอสายไฟเขากับชุดควบคุมโดยตอใหตรงกับที่ตอกับชุดภายในบาน

(3) ยึดสายไฟใหแนนดวยตัวยึดสายไฟ

(3) ยึดสายไฟใหแนนดวยตัวยึดสายไฟ

(4) Double-check that the cable is securely in place.

(5)

ปดชองวางระหวางสายไฟและรูของแผนใหหมดเพ อปองกันสิ่งแปลกปลอมเขาไปในตัวเคร อง

ปดชองวางระหวางสายไฟและรูของแผนใหหมดเพ อปองกันสิ่งแปลกปลอมเขาไปในตัวเคร อง

(6)

ประกอบฝาปดเขาที่เดิม

ประกอบฝาปดเขาที่เดิม

45 mm

8 mm

รูสำหรับตอสายไฟ

รูสำหรับตอสายไฟ

รูสำหรับตอสายไฟ

รูสำหรับตอสายไฟ

Cable holder

Terminal cover

CAUTIONS:

• Be sure to put the cable leads deep into the terminal board and tighten up the screws. Poor contact

can cause overheating or fire, or malfunction.

• Be sure to connect the cable to match the markings on the indoor unit’s terminal board and those of

the outdoor unit.

.

24 -Btu/h type

OM_AH-PN10 13GY_EN.indd Sec1:22OM_AH-PN10 13GY_EN.indd Sec1:22 12/22/11 6:30:39 PM12/22/11 6:30:39 PM

Page 25

ENG-

E-23

POWER CABLING

Power supply cable

Blue

Brown

Green/Yellow-striped

Power supply

Blue

Live

Green/Yellow-striped

Prepare a dedicated power supply circuit.

9K-Btu/h type 12K-Btu/h type 18K-Btu/h type 24K-Btu/h type

Power supply 220 V - 240 V, single-phase

Circuit breaker 10 A 15 A 20 A 25 A

• Fit a disconnect switch, having a contact separation of at least 3mm in all poles, to the electricity

power line.

TEST RUN

(1) Start the operation with the remote control.

(2) To start test run in cooling, hold down the

AUX button on the unit for over 5 seconds

until a beep sound is heard and an operation

lamp flashes.

(3) Make sure the system runs well.

To stop the operation, press the AUX button

again.

ITEMS TO CHECK

Is the specified power supply voltage used?

Is the connecting cable fixed to terminal board firmly?

Is the earth wire connected properly arranged?

Is the drainage properly?

Is the indoor unit hooked to the mounting plate firmly?

Is there any gas leakage at the pipe connection?

EXPLANATION TO CUSTOMER

• Explain to the customer how to use and maintain the system, referring to the operation manual.

• Ask the customer to carefully read the operation manual.

• When the system has been set up, hand the installation manual to the customer.

Model 18000/24000 BTUModel 9000/12000 BTU

AUX

AUX

OM_AH-PN10 13GY_EN.indd Sec1:23OM_AH-PN10 13GY_EN.indd Sec1:23 12/22/11 6:30:40 PM12/22/11 6:30:40 PM

Page 26

E-24

DETACHING THE UNIT FROM THE MOUNTING PLATE

“ ” mark.

Push the “

” marks at the bottom of the indoor unit

and pull the bottom of the unit. When the hooks are

released from the mounting plate, support the bottom

of the unit and lift the unit upwards.

PUMP DOWN

Pump down is adopted in the case of unit removal for re-installation, abandonment, repair etc.

Pump down is to collect the refrigerant into the outdoor unit.

PROCEDURE USING GAUGE MANIFOLD

(Recommended procedure)

(1) Connect the gauge manifold hose to the service

port of the 3-way valve.

(2) Run the air conditioner at cooling test run mode

(Refer to 10 TEST RUN).

(3) After 5-10 minutes, close the 2-way valve.

(4) Close the 3-way valve when the compound gauge

reading becomes almost 0 MPa(0 cmHg).

(5) Stop the test run operation.

(6) Disconnect the gauge manifold hose from the service port.

(7) Disconnect both refrigerant pipes.

PROCEDURE WITHOUT USING GAUGE MANIFOLD

(1) Run the air conditioner at cooling test run mode (Refer to TEST RUN).

(2) After 5-10 minutes, fully close the 2-way valve by turning the hexagon wrench.

(3) After 2-3 minutes, immediately close the 3-way valve fully.

(4) Stop the test run operation.

(5) Disconnect both refrigerant pipes.

CUTIONS:

• Make sure that the compressor is turned off before removing the refrigerant pipes. Otherwise, it will

cause burst and injury.

•

Do not perform PUMP DOWN when refrigerant is leaking or there is no refrigerant in the refrigerant cycle.

Otherwise, it will cause burst and injury.

Lo Hi

Gauge manifold

Compound

gauge

3-way valve

2-way valve

Service port

OM_AH-PN10 13GY_EN.indd Sec1:24OM_AH-PN10 13GY_EN.indd Sec1:24 12/22/11 6:30:41 PM12/22/11 6:30:41 PM

Page 27

OM_AH-PN10 13GY_EN.indd Sec1:25OM_AH-PN10 13GY_EN.indd Sec1:25 12/22/11 6:30:42 PM12/22/11 6:30:42 PM

Page 28

Printed in Thailand

TINSEA720JBRZ 11M- TH 2

OM_AH-PN10 13GY_EN.indd Sec1:26OM_AH-PN10 13GY_EN.indd Sec1:26 12/22/11 6:30:42 PM12/22/11 6:30:42 PM

Loading...

Loading...