Page 1

SERVICE MANUAL

Page

SPLIT SYSTEM

ROOM AIR CONDITIONER

INDOOR UNIT OUTDOOR UNIT

AH-129 AU-129

AH-MP14 AU-MP14

CONTENTS

SPECIFICATIONS..............................................................................................................................................2

EXTERNAL DIMENSIONS.................................................................................................................................4

WIRING DIAGRAMS..........................................................................................................................................5

ELECTRICAL PARTS........................................................................................................................................6

MICROCOMPUTER CONTROL SYSTEM.........................................................................................................7

PRINTED WIRING DIAGRAM............................................................................................................................8

FUNTIONS........................................................................................................................................................10

TROUBLESHOOTING......................................................................................................................................14

REFRIGERATION CYCLE AND PERFORMANCE CURVES..........................................................................16

DISASSEMBLING PROCEDURE.....................................................................................................................17

REPLACEMENT PARTS LIST..........................................................................................................................25

SHARP CORPORATION

SHARP CORPORATION

1

Page 2

CHAPTER 1. PRODUCT SPECIFICATION

A

y

g

g

g

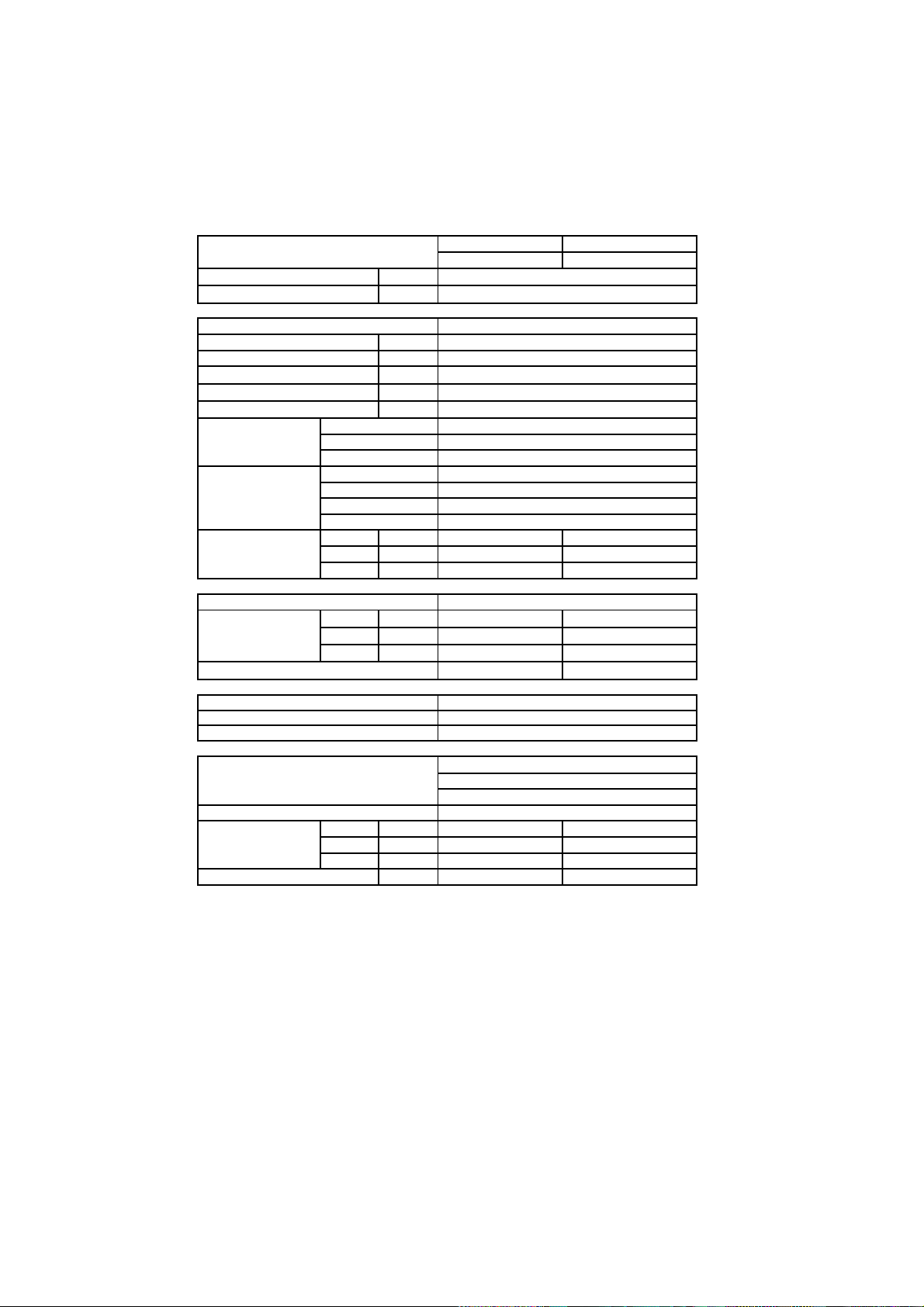

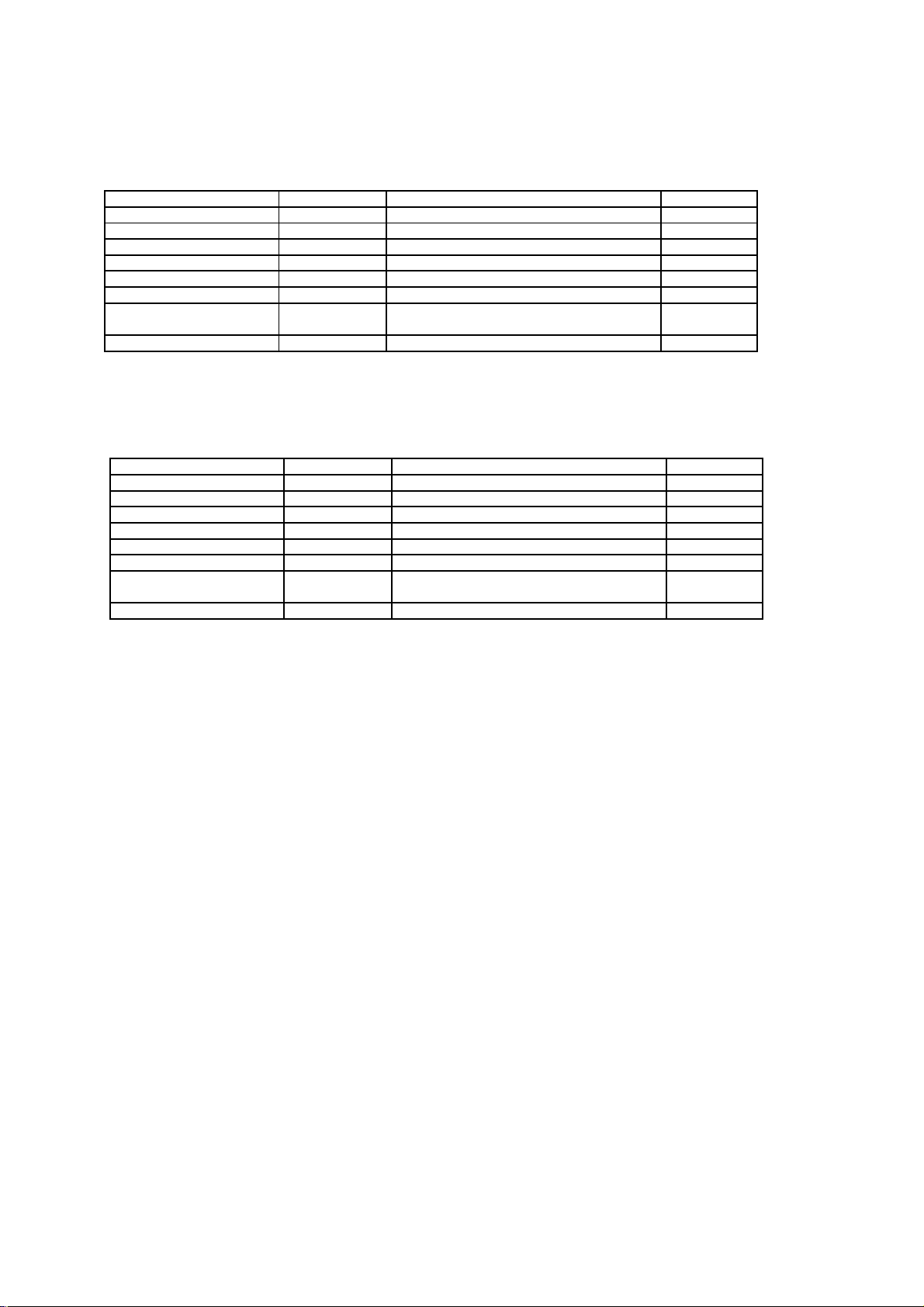

[1] SPECIFICATION

1. AH-129 / AU-129

ITEMS

Cooling capacity kW 3.50

Moisture removal Liters/h

Electrical data

Phase Single

Rated frequency Hz

Rated voltage V 220

Rated current

Rated input * W 1090

Power factor % 97 - 99

Compressor Type Hermetically sealed rotary type

Model RH207VXGT

Oil charge 520cc (DIAMOND MS56)

Refrigerant system Evaporator Slit fin and Grooved tube type

Condenser Slit fin and Grooved tube type

Control Capillary tube

Refrigerant volume 960g

Noise level

stem

Fan s

Drive Direct drive

Air flow quantity

Fan

Connections

erant couplin

Refri

erant tube size Gas, Liquid 3/8" , 1/4"

Refri

Drain piping

Others

Safety device Compressor : Internal protector

Air filters Polypropylene net (Washable)

Net dimensions

Net weight

High

Mid.

Low

High

Mid.

Low

Width

Height

Depth

A5.1

dB(A)

dB(A)

dB(A)

m3/min.

m3/min.

m3/min.

mm O.D 18

mm

mm

mm

kg

INDOOR UNIT

H-129

–

50

39

33

29

10.2

9.6 –

8.7

Cross flow fan

Flare type

φ

Fan motor : Thermal fuse / Protector

Fuse, Micro computer control

790

278

198

10

OUTDOOR UNIT

48

–

–

27

–

Propeller fan

730

540

250

34

AU-129

2

Page 3

2. AH-MP14 / AU-MP14

A

y

/

g

g

g

ITEMS

INDOOR UNIT

H-MP14

OUTDOOR UNIT

Cooling capacity kW 3.50

Moisture removal Liters/h

–

Electrical data

Phase

Rated frequency Hz

Single

50

Rated voltage V 220

Rated current A5.1

Rated input * W 1090

Power factor % 97 - 99

Compressor Type Hermetic al l y sealed rotary type

Model RH207VXGT

Oil charge 520cc (DIAMOND MS56)

Refrigerant system Evaporator Slit fin and Grooved tube type

Condenser Slit fin and Grooved tube type

Control Capillary tube

Refrigerant volume 960g

Noise level

stem

Fan s

Drive

Air flow quantity

Fan

High

Mid.

Low

High

Mid.

Low

dB(A)

dB(A)

dB(A)

m3/min.

m3/min.

m3

min.

39

33

29

Direct drive

10.2

9.6

8.7

Cross flow fan

48

–

–

27

–

–

Propeller fan

Connections

erant couplin

Refri

erant tube size Gas, Liquid 3/8" , 1/4"

Refri

Drain piping

mm O.D 18

Flare type

φ

φφ

Others

Safety device

Compressor : Internal protector

Fan motor : Thermal fuse / Protector

Fuse, Micro computer cont rol

Air filters Polypropylene net (Was habl e)

Net dimensions

Net weight

Width

Height

Depth

mm

mm

mm

kg

790

278

198

10

730

540

250

34

AU-MP14

3

Page 4

[2] EXTERNAL DIMENSION

1. Indoor unit (AH-129 / AH-MP14)

2. Outdoor unit (AU-129 / AU-MP14)

198790

278

540

515

730

37.5

12

58

135

4.5

72

299

324

14

250

165

167.5

81

136

4

Page 5

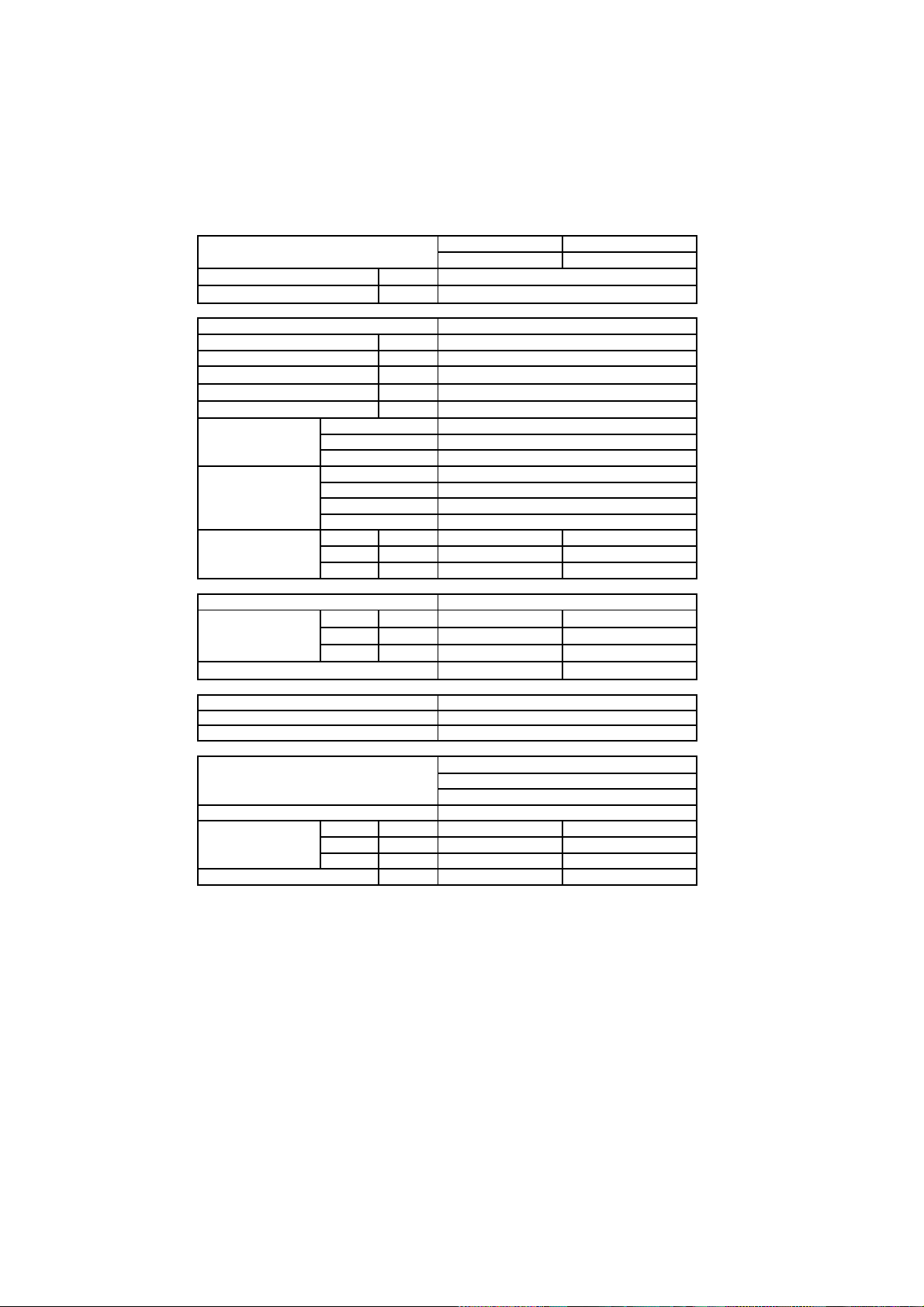

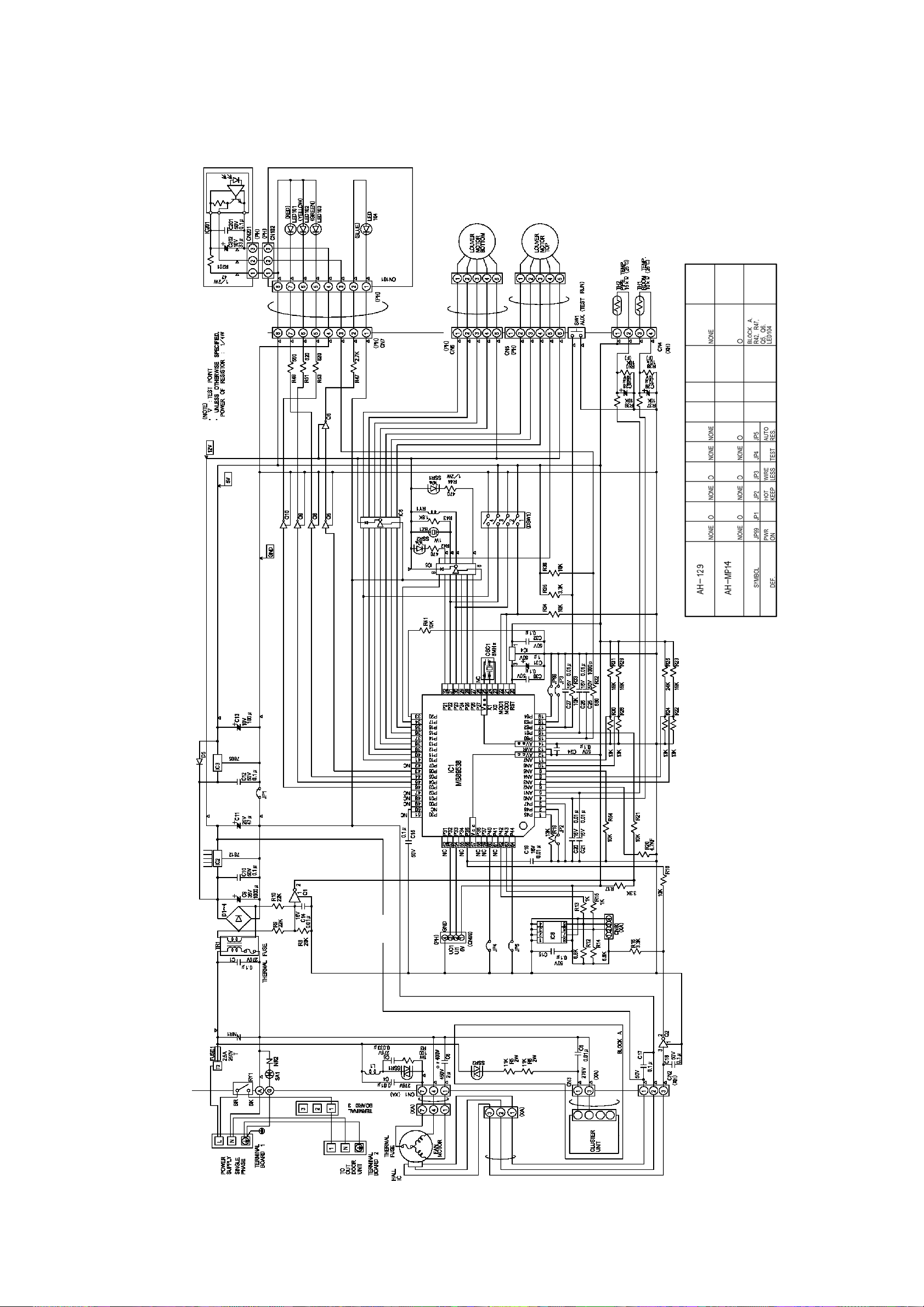

[3] WIRING DIAGRAM

Indoor Unit (AH-129)

4'%'+8'4

70+6

&+52.#;

70+6

Indoor Unit (AH-MP14)

4'%'+8'4

70+6

&+52.#;

70+6

%0

%0

%0

%0

%0

(#0/1614

%0

%0

%0

%0

%0

%0

1WV

6'4/+0#.

$1#4&

.'(6

#

8

(75'

6

+P

#

04

8

5#

)

.

6'4/+0#.

$1#4&

.'(6

4+)*6

%%

04

5#

1WV

6'4/+0#.

$1#4&

.'(6

6'4/+0#.

$1#4&

.'(6

.

4+)*6

#

8

6

+P

(75'

#

8

)

(#0/1614

Outdoor (AU-129 / AU-MP14)

$-$.#%$.$.7'

$4$4190

4'4'&

9*9*+6'

);)4''0;'..19

%%

4'

$-

$.

Ǵ(

$-

4'

$4

9*

Ǵ(

$.

%%

5

Page 6

CHAPTER 2. ELECTRIC CIRCUIT

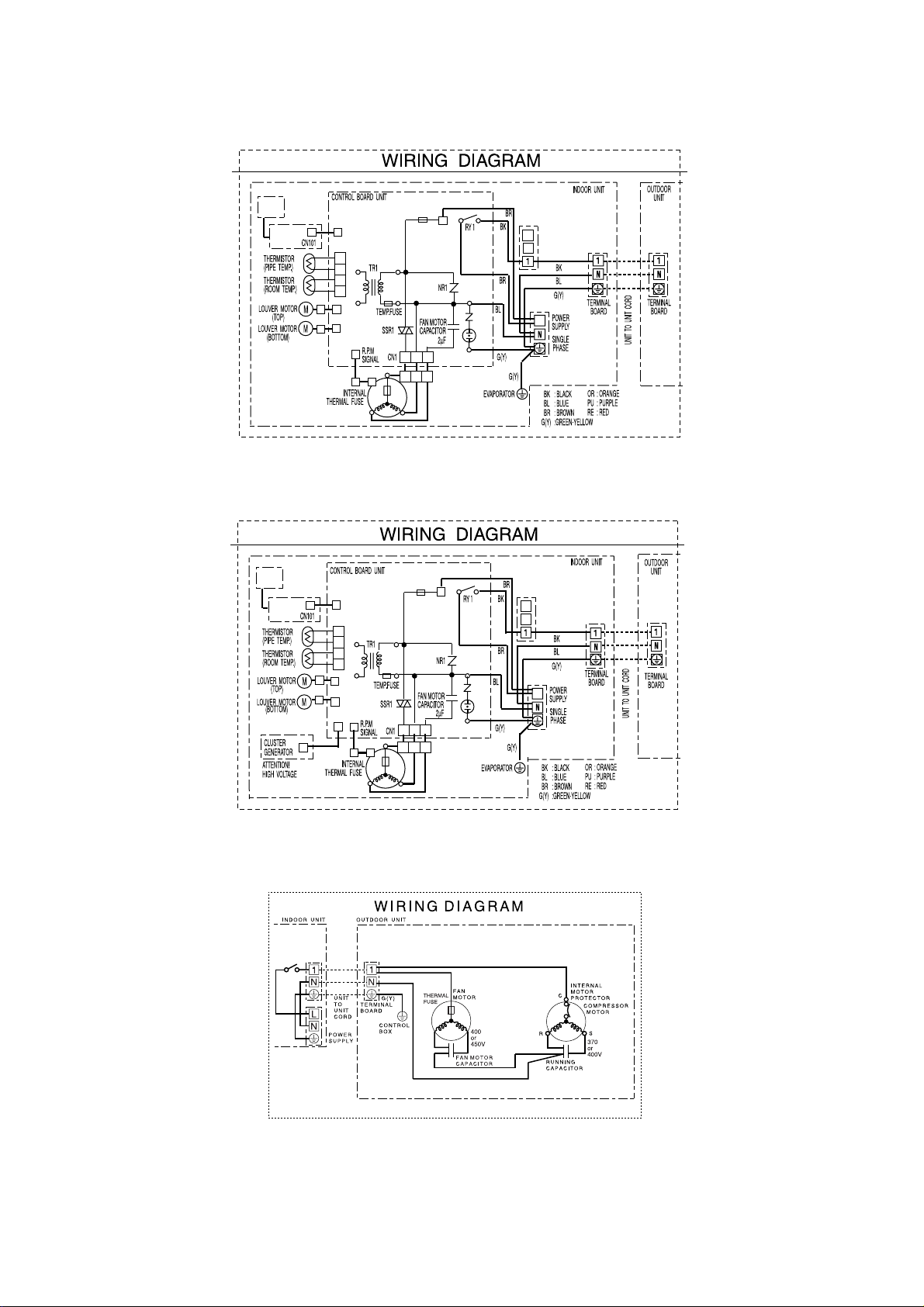

[1] ELECTRIC PARTS

1. AH-129 / AU-129

DESCRIPTION

Compressor

Indoor fan motor CMOT-A448JBKZ 220 - 240V , 50Hz INDOOR

Outdoor fan motor

Indoor fan motor capacitor

Outdoor fan motor capacitor

Running capacitor

Transformer — Primary ; AC 220 / 240V 50Hz

Fuse — 250V, 2.5A INDOOR

2. AH-MP14 / AU-MP14

DESCRIPTION

Compressor

Indoor fan motor CMOT-A448JBKZ 220 - 240V , 50Hz INDOOR

Outdoor fan motor

Indoor fan motor capacitor

Outdoor fan motor capacitor

Running capacitor

Transformer — Primary ; AC 220 / 240V 50Hz

Fuse

MODEL

RH207VXGT 220V, 50Hz, 1120W

CMOTLB182JBEZ 220 - 240V , 50/60Hz

— 450V, 2

— 400V, 2

— 400V, 30µF

—

MODEL

RH207VXGT 220V, 50Hz, 1120W

CMOTLB182JBEZ 220 - 240V , 50/60Hz

— 450V, 2

— 400V, 2

— 400V, 30µF

—

— 250V, 2.5A INDOOR

µF INDOOR

µF

Secondary ; AC15.3V , 50Hz

µF INDOOR

µF

Secondary ; AC15.3V , 50Hz

REMARKS

REMARKS

SITE

OUTDOOR

OUTDOOR

OUTDOOR

OUTDOOR

INDOOR

SITE

OUTDOOR

OUTDOOR

OUTDOOR

OUTDOOR

INDOOR

6

Page 7

[2] MICRO-COMPUTER CONTROL SYSTEM

1. Electronic Control Diagram

Indoor unit (AH-129 / AH-MP14)

7

Page 8

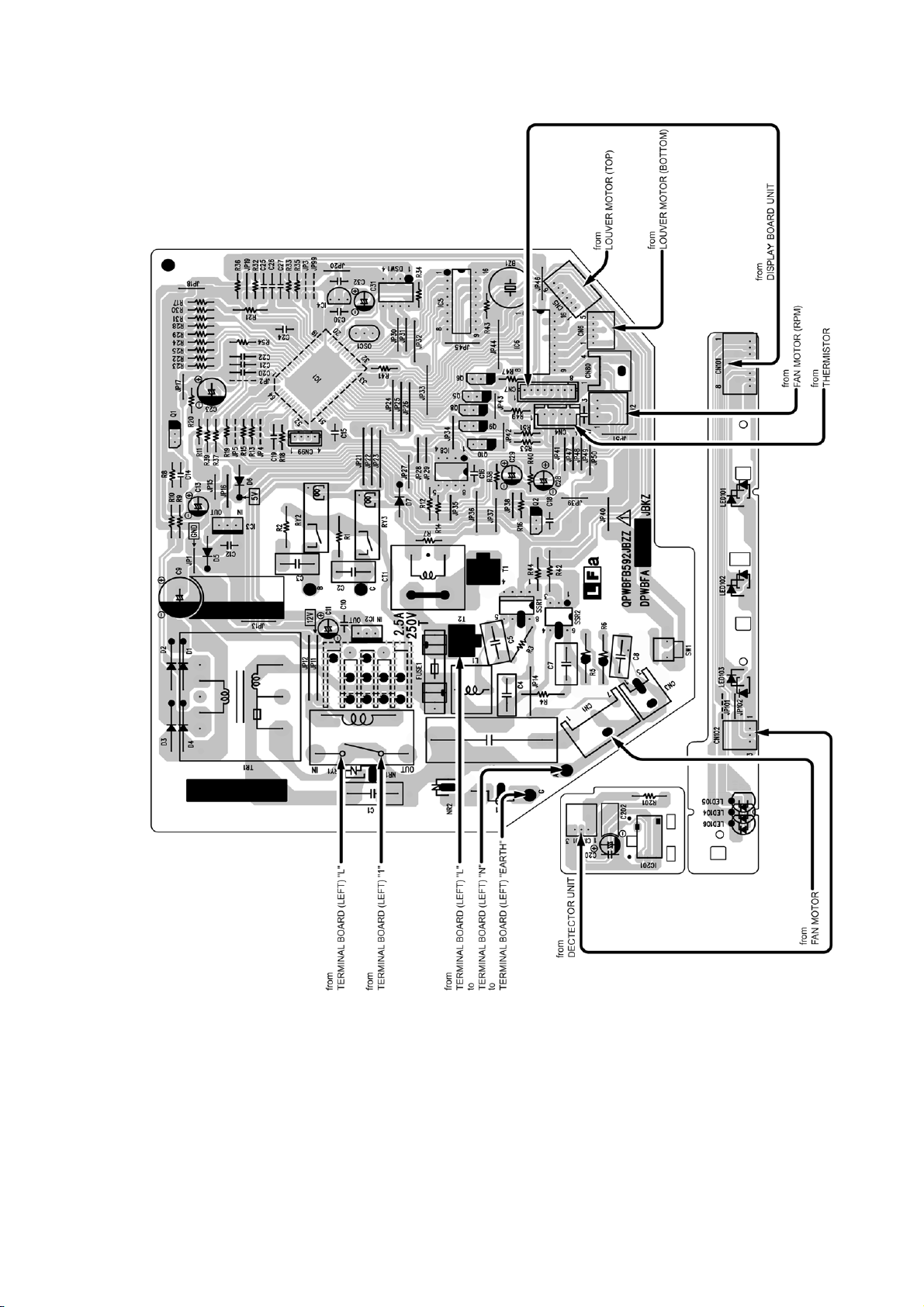

2. PRINTED WIRING DIAGRAM

2.1 Indoor (AH-129)

8

Page 9

2.2 Indoor (AH-MP14)

9

Page 10

CHAPTER 3. FUNCTIONS

p

)

p

)

p

)

[1] FUNCTION

TEMPERATURE CONTROL

CHARACTERISTIC

In the "COOL" mode, the thermostat circuit is controlled by five

thermostat lines (C1 thru C5).

1.2. DRY

In the "DRY" mode, the thermostat circuit is controlled by three

thermostat lines (D1 thru D3).

1.1. COOL operation

18 32

Preset temperature (C )

2.2. DRY

On the switch on, the compressor always starts to operate for 2

minutes with fan speed "DL".

The microcomputer reads the room temperature 2 minutes after

this first compressor operation.

This room temperature is set as the preset temperature

The preset temperature ranges from 18 C to 32 C. When the room

temperature is below 18 C, the preset temperature is set to 18 C,

and when the room temperature is over 32 C, the preset

temperature is set to 32 C.

Dry operation is divided into three zones (Cooling zone,

Dehumidifying zone and Circulating zone) by thermostat lines (D1

to D3), and the compressor and the fan motor are controlled in

each zone as shown in Table.

°°

18 32

Preset tem

erature (C

OPERATION MODES

2.1. COOL operation

The compressor turns on or off, at the thermostat lines C3 and

C4. The outdoor fan motor is also controlled with the compressor.

18 32

Preset tem

Cooling zone (1) & (5) ON "DH"

Dehumidifying zone (2) & (4) ON "DL"

Circulating zone (3) OFF "DL" or OFF

erature (C

Compressor Fan speed

FAN SPEED

Fan speeds are given by the indoor fan motor, "DL"~"CH" which

are available in the following operation mode.

NOTE: Fan speed may be changed, without warning.

Fan

Fan switch Fan switch

speed

DL

DH

CL

CAL

CM

CAH

CH

—

—

COOL LOW — 800

—

COOL MID

—

COOL HIGH — 1170

(AUTO)

DRY

COOL

AH-129 / AH-MP14

(r.p.m)

800

890

840

980

1020

FREEZE PREVENTIVE

When the indoor pipe temperature falls below 3 C cool or dry

operation for 3 minutes or more, the compressor is turned off.

When the indoor pipe temperature rises above 7 C in cool or dry

operation for 3 minutes or more, the compressor is turned on.

°

18 32

Preset tem

erature (C

10

Page 11

TEST RUN OUTPUTS IN EACH OPERATION MODE

p

)

p

If the "AUX" button on the unit is pressed for 5 seconds or more

during operation, cool test operation starts. The operation LED (red)

flickers during tes t run.

In cool mode continuous compressor on operation is performed. In

dry mode the operation is in dehumidifying zone.

TIMER

6.1. ON/OFF Timer

When the unit operates duri ng one hour after the OFF-time is s et, tem-

°°°

+0.33 C +0.66 C +1 C

erature setting is automatically shifted ( in

(After 1H) (After 1.5H) (Aft er 2H)

operation and dry operation). When the ON-timer is set in cool

operation, operation starts before 0 to 30 minutes(depends on the

room temperature

so that preset tem perat ure i s obtaind at set time.

6.2. 1 hour timer

When ONE-HOUR timer is set, the unit turns off automatically afte

one hour. The one hour timer operation has priority over other time

r

operation, such as the TIMER ON and TIMER OFF. If the

ONE-HOUR TIMER button is pressed again duri ng operation, the unit

AUTOMATIC AIR CONDITIONING

When autom atic air conditioning is selected, the operation mode and

preset temperature are set automatically according to the room

temperature on starting operation.

Room temperature

eration start

at o

Above 28

26

24

Below 24

°C26°C

°C > 28°C COOL 25°C

°C > 26°C24°C

°C DRY Room temperature at

When DRY mode is selected by the micro computer with AUTO

operation, the fan speed lamps on the indoor unit panel will indicate

identically with the fan speed symbols on the remote control dispaly,

as the FAN speed setting i s changed accordingly. Despit e,

Operation Mode Preset Temperature

operation start

Mode

Cooling ON ON ON OFF

O

Circulat-

O

ing

U

Cooling ON

}

Dehumidiflying

o

Circulating

POWER ON START

If the connecting wire "POWER ON" (JP99) is cut on the PWB

ass'y, when the power is supplied by t urning on a circuit breaker,

the air conditioner automat i c al l y s tarts of operation in "AUTO".

(Refer to Printed Wiring Board.)

AUTO RESTART

11.1. When JP5 is ON

Power failuer occurs during operation, the unit will restart in the

same operation mode as bef ore recovery.

11.2. When JP5 is OFF

Auto restart funct i on i s not available.

Compres-

sor

Outdoor

Fan Motor

Indoor

Fan Motor

OFF OFF ON OFF

ON L/UL

ON ON UL/D OFF

OFF OFF D/OFF OFF

Valve Coil

OFF

AUTOMATIC FAN SPEED

When the automatic fan speed is selected in cool operation, the fan

speed is automatically changed by the thermostat lines C1 to C3 in

cool operation.

11

Page 12

[2] TEST MODE

1. AH-129

Keep pushing the "AUX." buttons and supply the power, the system will go to the test mode. In this mode, the output of operation is switched by

pushing the ""AUX." button in the unit or the "OI" button in the remote controller. Normal outputs are shown in Table.

STEP No.

BUZZER

STEP0

STEP1

STEP2

STEP3

STEP4

STEP5

STEP6

STEP7

STEP8

STEP9

STEP10

BEEP2

BEEP1

BEEP1

BEEP1

BEEP1

BEEP1

BEEP1

BEEP1

BEEP1

BEEP1

BEEP1

OUTPUT "-" : NO CHECK, "O" : ON, "X" : OFF

LED 101 LED 102 LED 103

RED YELLOW GREEN

O *1O*2O

X X O

O RPM X O

O *4 X

O IC8 O O

OOO

X R.C. X O

XXX

XXO

O X O

O O O

LED 104

BLUE

X

X

X

X

X

X

X

X

X

X

X

FAN

LOUVER OUTDOOR

MOTOR

XXX

O OPEN O

O X X

O X O

O X X

OXO

O X X

OXO

OXX

O X O

X CLOSE O

*1 : 7°C<(ROOM TEMP.)<42°C

°C<(PIPE TEMP.)<45°C

*2 : -2

*4 : O --- POWER ON INVALIDITY

*4 : X --- POWER ON VALIDITY

1. AH-MP14

STEP No. OUTPUT "-" : NO CHECK, "O" : ON, "X" : OFF

BUZZER

STEP0

STEP1

STEP2

STEP3

STEP4

BEEP2

BEEP1

BEEP1

BEEP1

BEEP1

LED 101 LED 102 LED 103

RED YELLOW GREEN

O *1O*2O

X X O

O RPMO O

O *4 X

O IC8O O

LED 104

BLUE

O

X

O

X

X

STEP5BEEP1 X O O X OXOX

STEP6

STEP7

STEP8

STEP9

STEP10

BEEP1

BEEP1

BEEP1

BEEP1

BEEP1

X R.C.X O

X X X

XXO

O X O

O O O

X

X

X

X

X

FAN

LOUVER OUTDOOR PLASMA

MOTOR

CLUSTER

XXXX

O OPEN O X

OXXO

O X O O *4 : O --- POWER ON INVALIDITY

OXXX

OXXX

OXOX

OXXX

OXOX

X CLOSE O X

*1 : 7°C<(ROOM TEMP.)<42°C

°C<(PIPE TEMP.)<45°C

*2 : -2

*4 : X --- POWER ON VALIDITY

12

Page 13

[3] DIAGNOSIS PROCEDURE

1. AH-129 / AH-MP14

When indoor fan m ot or i s out of order occurs, indoor fan motor and louver are all stopped and the operation LED(red) turns on or off

synchronously with the tim i mg of the timer LED.

When the therm i stor for room tem perat ure or pipe temperature is open or short state, the operation LED t urns on or off synchrnoously with the

timing of the timer LED by pushing continous l y f or more than 5 seconds "AUX." but ton during suspension of operati

Timing chart of Tim er LED and Operation LED of DIAGNOSIS P ROCE DURE .

When "OI" button the remote controll er or " A UX." but ton in the unit is pushed, the unit is free from DIAGNOSIS

When the louver unit is not properly inst alled, all lamps on the indicator panel will blink operation are all stop and Remote signal is not acc ept .

13

Page 14

CHAPTER 4. TROUBLESHOOTING

14

Page 15

CHAPTER 4. TROUBLESHOOTING

15

Page 16

16

Page 17

DISASSEMBLING PROCEDURE MODEL: AH-129 ,AH-MP14

[1] INDOOR UNIT

Be sure to disconnect t he power supply cord from the AC power outlet before starting the disass embly procedure. W hen reassembling the unitafter repairing, besure to install screws to their original positions.

The screws used are not the same i n specifications s uch as corrosion-resist ant treatment, ti p shape and length.

After the air conditioner i s repaired or parts or replaced, measure insulation resist ance of the equipment using and i nsulation resistanc e meter.

if the measured resistance is lower than 1M , inspect parts and repair or replace defective parts.

1) Open the open panel. 5) Pushing the 2 hooks, dis connect the louver base(2)

2) Remove screw fixing the cord clamp.

Ω

6) Remove 2 air filters.

3) Remove the cord clam p. 7) Remove the Screw cover (use the(-)driver).

4) Remove the unit-to-unit wiring from the terminal board(4). 8) Remove the cover.

17

Page 18

9) Remove 5 screws fixing the front panel. 14) Remove the control box.

10) Pull the front panel up.

11) Remove a screw fixing the Control box cover,

and remove it 15) Remove the LED guide.

16) Pushing the 2 hooks of the hol der, remove the display

12) Remove the 2 screws fixing the cont rol box. board

13) Disconnect the thermistor. 17) Remove a screw fixing the holder.

18

Page 19

18) Remove the holder. 21) Remove the screw fixing the evaporator ass 'y and -

evaporator.

22) Remove the drain guide.

19) Remove 2 screws fixing the holder. (AH-MP14)

23) Remove 2 screws fixing the evaporator.

20) Remove 2 screws fixing the PC cover. (AH-MP14)

24) Remove 2 screw fixing the evaporator and bushing holder.

19

Page 20

25) Pull the evaporator ass'y up. 28) Remove the screw fixing cross flow fan.

26) Take out the left side of the drain pan.

29) Hold up the left side of evaporator, pull out cross flow

fan

Attention: In cas e of assembly.

Part A is inserted into the drain part of the drain pan.

27) Take out the right side of t he drai n pan l eavi ng drai n-

hose in cabinet.

20

Page 21

MODEL: AU-129 ,AU-MP14

[2] OUTDOOR UNIT

1) Loose a screw fixing the side cover 3) Loose the unit-to-unit cord.

2) Loose 2 screws fixing the terminal cover and 1 screw- 4) Loose 6 screws fixing the top panel.

fixing the cord clamp. ( Right side view )

21

Page 22

( Left side view ) 5) Loose 5 screws fixing the front panel. (Ri ght side view)

( Left side view )

( Front view )

( Front view )

22

Page 23

6) Cut 3 plastic bands. 9) Remove 3 terminals of compressor.

7) Remove 2 terminals. (connecting with fan condenser) 10) Loose 4 screw fixing the control box.

8) Remove the terminal cover.

11) Take out the control box

23

Page 24

1. DISASSEMBLING PROCEDURE OF THE FAN 2. ASSEMBLING PROCEDURE OF COMPRESSOR

COVER

1) Loose the fan nut and take out f an. 1) Remove: Unlace the fastenner and pull the compress or cover

out from left side. [a) b)]

2) Assembly: Insert the compressor cover from left side, cover

the tube and fasten. [b) a)]

2) Loose 4 screws fixing fan motor.

24

Loading...

Loading...