Page 1

m

Service Manual

PAL SYSTEM

COLOUR

TELEWSION

ELECTRICAL SPECIFICATIONS

Aerial Input

Imp’edance

..................

75 ohm

Convergence.

...............

Self Converging System

Focus

...................

Bi-potential

electrostatic

Audio Power Output Rating

..........

2.0 Watt (max.)

Intermediate Frequencies

Picture IF Carrier Frequency.

......... 36,875 MHz

Sound IF Carrier Frequency

..........

31,375 MHz

Colour

Sub-Carrie;-Frequency . . 32,445 MHz (Nominal)

Powerlnput .................

.240VoltsAC50Hz

Power Rating

........................

165 Watt

Speaker Size.

................. 19 x

10cm

Dynamic

Voice Coil Impedance

...........

.8

ohms (at 400 Hz)

Sweep Deflection

.....................

.Magnetic

Tuning Ranges

.............

VHF-Channels 0 thru 11

UH

F Channels 28

thru

63

I

IMPORTANT SERVICE NOTES

Maintenance and repair of this receiver should be down by

qualified service

persona4

only.

SERVICING OF HIGH VOLTAGE SYSTEM AND

PICTURE TUBE

When servicing the high voltage system, remove static

charge from it by connecting a 1 OK ohm Resistor in series

with an insulated wire (such as a test probe) between picture

tube

dag

and 2nd anode lead. (AC

line

cord

shodd

be

disconnected from AC outlet.)

1. Picture tube in this receiver employs

ixitegral

implosion

protection.

,\

3. Replace with tube of the same type number for continued safety.

3. Do not lift picture tube by the neck.

4. Handle the picture tube only when wearing shatter-proof

goggles and after discharging the high voltage completely.

X-RAY

This receiver is designed so that any X-ray radiation is

kept to an absolute minimum. Since certain malfunctions

or servicing may produce potentially hazardous radiation

with prolonged exposure at close range, the following

precautions should be observed:

1. Do not adjust the high voltage level above 27.5 KV at

1

.lmA.

2. Do not substitute a picture tube with unauthorized

types and/or brands which may cause excess X-ray

radiation.

BEFORE RETURNING THE RECEIVER

Before returning the receiver to the user, perform the

following safety checks.

1. Inspect all lead dress to make certain that leads are nol

pinched or that hardware is not lodged between the

chassis and other metal parts in the receiver.

2. Inspect

al4

protective devices such as

non-metal4ic

control

knobs, insulating fishpapers, cabinet backs, adjustment

and compartment covers or shields, isolation

resistor-

capacity networks, mechanical insulators etc.

The manufacturer reserves the right to vary specifications or use alternative materials as may be deemed necessary or desirable

at any time, any such change or variation being of a kind as not to reduce the quality performance or appearance substantially.

SHARP CORPORATION OF

AUSTRALLA

PTY.

LTD.

64-80 SEVILLE ST.,

FAIRFIELD, 2165

N.S.W.

TEL: 02-728-9111

Page 2

INSTALLATION AND SERVICE ADJUSTMENTS

INSTALLATION OF NEW COLOUR TELEVISION

RECEIVER

Adjust the receiver for a black and white picture. Check

the horizontal oscillator adjustment, focus, vertical size

and linearity.

Observe the picture for good

black-and-

white reproduction over all areas of the screen. No ob-

jectionable

colour

shading should be evident. If shading

is evident, demagnetize the receiver. It is seldom necessary

to go through a complete “set-up” routine when installing

a new colour receiver. In the majority of cases a technician

needs only to

degauss

the face plate area of the picture

tube and touch up the static convergence.

Colour

television receivers leaving the factory are adjusted

by experts who specialize in the set-up of

colour

receivers.

Normally, readjustment of picture tube temperature or

even dynamic convergence should not be required upon

delivery. However, since a receiver or parts of it, may

become magnetized as it is transported from one location

to another, it is very important to demagnetize the picture

tube face plate area once the receiver is set in its final

operating position.

DEGAUSSING

This receiver is equipped with an automatic

degaussing

coil

which effectively demagnetizes the picture tube each time

the receiver is turned on. The

degaussing

coil will operate

at any time the set is turned on after having been off for at

least five minutes.

Since this

degaussing

effect is confined to the picture tube,

should any part of the chassis or cabinet become magnetized,

it will be necessary to

degauss

the affected area by means of

a manual

degaussing

coil. Move the coil slowly around the

parts to be demagnetized, then slowly withdraw for a

distance of six feet before disconnecting the coil from

the AC power supply.

Note:

Degaussing

(or

demagnetising)

is an important

function in the setting up and installation of

colour

T.V.

receivers.

The receiver should be positioned in its foal

location before

degaussing

because of possible loss of

purity due to the

re-location

of the receiver.

Because of possible loss of purity caused by the

re-location

of the receiver, the cabinet should be positioned in its

final location before

degaussing.

MODULE SERVICE PERCAUTIONS

1.

DO NOT remove or insert module units whilst the set is

switched on.

2.

Semiconductor heat sinks should be regarded as potential

shock hazards when the receiver is operation.

HOWTOADJUSTTHECHANNELSETTING(UHF/VHF)

(1)

Touch the Channel Selector Button corresponding to

the channel, that you wish to select.

(2)

Adjust the Band Selector switch to either of 3

positions

(VL,

VH

, U) as shown below, depending on

what channel you now wish to select.

BAND

VL

. . . . . . . . .

VHF 0 - Sch.

BANDVH

. . . . . . . . .

VHF5A-llch.

BANDU

. . . . . . . . .

UHF21-69ch.

(3)

Note the number on the Channel Selector Button and

relate it to the Preset Tuning knob and Band Selector

switch with corresponding number.

(4)

Tune in the desired channel by turning the Preset

Tuning knob clockwise or counterclockwise until the

channel is properly tuned.

Note:

Whenever the ON-OFF switch is turned on, No. 1 program

will always be selected. However, when you want to change

this No. 1 program to another program by depressing the

channel selector button, it sometimes occurs that the

corresponding indicator lamp does not light up - this

means that your desired program has not been selected.

In this case, set the ON-OFF switch to “OFF” position and

reverse the polarity of power cord. Then, the unit will

function normally, assuring a proper program selection. The

aforesaid, however, may take place only when the antenna

terminal is grounded or a separate transformer is used as a

power supply source and, therefore, this is out of the

question as long as you operate the unit in a normal

receiv-

ing

condition.

Preset Channel Table

(at factory setting)

No. 1

A2

No.2

Al

No. 3 ASA

No.4 A6

No. 5

A2

No. 6

E23

No. 7 E34

No. 8 E68

Figure 1. Front Panel Controls

7

Page 3

HIGHVOLTAGECHECK

High voltage is not adjustable but must be checked to

verify that the receiver is operating within safe and efficient

design limitations

as

specified:

1.

2.

3.

4.

If

Remove cabinet back.

Operate receiver for at least 15 minutes, with strong air

signal or test signal properly tuned in.

Set Brightness and contrast controls to maximum

position.

Connect an accurate high voltage meter to CRT anode.

Reading should be

24.5 + 1 SW.

(at 1

.15mA)

correct reading cannot be obtained, check circuitry for

malfunctioning components.

FOCUS

Adjust the Focus control(R667), located on the rear of the

TV chassis, for maximum over-alldefinition and fine picture

detail with Brightness and Contrast controls set at normal

viewing levels.

VERTICAL SIZE AND LINEARITY

The Vertical Linearity control

(RS 15)

primarily affects the

top of the raster while the Vertical Size control

(R517)

primarily affects the bottom of the raster. However,

there is some interaction between these two controls.

Vertical Centering properly positioned and Brightness and

Contrast controls adjusted for normal picture, alternately

adjust Vertical Linearity and Vertical Size controls to

obtain a linear picture.

HORIZONTAL OSCILLATOR ADJUSTMENT

The receiver should be operating for at least 10 minutes

before proceeding.

1.

Tune in a local station and set the Horizontal Hold

control

(R618)

at the center of its rotation.

2.

Connect a short clip lead between test point

TP401

and ground.

3.

Adjust the Horizontal Frequency Control

(R617)

to

obtain minimum horizontal movement of the picture.

4.

Remove a short clip lead between test point

TP401

and

ground.

5.

Check the operation of the Horizontal Hold control to

verify that the picture is porperly synchronized with the

control set at the mechanical

centre

of its range.

RF AGC ADJUSTMENT

The receiver should be operating for at least 10 minutes

before proceeding.

1.

Connect a

58db

input signal to the antenna terminal.

2.

Connect

VTVM

to

TP204.

3.

Fully turn RF

AGC

control

(R206)

counter-clock-

wise.

4.

Observing the indication of

VTVM,

slowly turn RF

AGC

control

(R206)

clockwise and fix it when the

voltage starts to fall.

+13OV

ADJUSTMENT

The

+13OV Adj.

control

(R724)

is adjusted at the factory.

However, should readjustment be required, proceed as

follows:

1.

Operate receiver for at least 15 minutes.

2.

Connect positive lead of

VTVM

to

TWO 1,

negative lead

to

chass

is ground.

3.

Rotate

+13OV

Adjust control

(R724)

to clockwise and/

or counter clockwise until a

VTVM

reading of DC

13OV.

4.

Remove

VTVM

to

TP?Ol.

CAUTION:

Do not exceed

130

volt for protecting

the set from failure.

H-SIZE ADJUSTMENT

Since the horizontal amplitude of receiver has been completely adjusted before delivery from the factory, normally

readjustment should not be required.

However, if it

becomes necessary for any reasons, take the following steps.

1.

Receive cross-hatch pattern.

2.

Rotate H-Size coil

(L608)

until over scanning is more

than 6 percent.

CENTERING ADJUSTMENT

H-Center Adjustment:

If the picture is one-sided from right to left of the screen,

rotate H-CENT adjust control

(R627)

until the picture is

centered.

V-Centre

Adjustment:

If the picture is one-sided from top lo bottom of the

screen, change V-CENT adjust tip to adjust so that the

picture is centered.

PINCUSHION ADJUSTMENT

The pin-cushion adjustments are

preset

at the factory and

normally need no further adjustment. However, if necessary,

corrections can be made by adjusting for straight horizontal

lines at the top and bottom of the rester.

The receiver should be allowed to operate for at least five

minutes with a cross-hatch pattern displayed on the screen.

Top and Bottom Pincushion Adjustment

1.

Adjust the Pincushion coil

(LSO 1)

to move the maximum

curvature of the horizontal lines to the center of the

screen.

2.

Adjust the Pincushion Transformer Magnet

(TSOl)

so as

to straighten out the horizontal lines at both the top and

bottom of the screen.

Side Pincushion Adjustment

1.

Rotate the Side Pin. Phase control

(R638)

until the pin-

cushion distortion is at the

centre

of screen.

2.

Rotate the Side Pin. Amp. control

(R639)

to compensate

for pincushion distortion until vertical lines at both sides

of screen are straight .

3

Page 4

WHITEBALANCE ADJUSTMENT

The purpose of this procedure is to

optimize

the picture

tube to obtain good black and white picture at all brightness

levels while at the same time achieving maximum usable

brightness. Normal RF

AGC

setting and purity adjustments

must

procede

this procedure.

This adjustment is to be made only after a warm-up

operation is provided for 5 minutes at least.

With antenna connected to the receiver, tune in picture

on a strong channel.

Rotate the

Colour

control

(R839)

to maximum

CCW

position and misadjust

pre-set

Tuning so that the receiver

will not produce a color picture while the following

adjustments are being performed.

1.

Set the Green Drive

(R1015)

and Blue Drive

(R1016)

controls to mid-position.

2.

Rotate the Red, Green and Blue Bias controls to the full

CCW

end of their rotation ranges.

3.

Set the Service Switch, on

PWB-B,

to Service position.

4.

Rotate the Screen control

(R1032),

to the full

CCW

end of its rotation range. Then, rotate it CW until a

dim raster of one pronounced color (Red, Green or

Blue) is obtained.

5.

The other two color Bias controls must be rotated

CW

until a dim white raster is obtained.

6.

Set the Service switch to Normal position

7.

Set the Brightness control (R480) to maximum.

8.

Set the two Drive controls to obtain best white uni-

formity on the picture tube screen.

9.

Rotate the Brightness control to minimum.

10.

Rotate the Brightness control to clockwise until a dim

raster is obtained.

11.

Touch-up adjustment of the three Bias Controls to

obtain best white uniformity on the screen.

BEAMCURRENTADJUSTMENT

Black and white tracking procedure must have been completed before attempting this adjustment.

Operate receiver for at least 15 minutes and with antenna

connected to the receiver, tune in picture on a strong

channel.

1.

Connect voltmeter positive probe to

TP603

and negative

probe to

TP602,

on

PWB-B.

2.

Rotate Brightness and Contrast controls to maximum.

3.

Adjust

s-lb

contrast control

(R671)

to obtain a reading

of

1.15v.

PURITYADJUSTMENT

Before purity adjustment can be made, the receiver

should be demagnetized and allow to run with full brightness (without bloom) for a minimum of 10 minutes and

static convergence must be correct.

1.

With antenna connected receiver.

2.

Fully turn the R-Bias

(R1007)

and B-Bias

(R1009)

controls counterclockwise to get green alone.

3.

Loosen the clamp screw for deflection yoke and draw it

back as much as possible.

4.

Turn the purity magnet rings and fn them so that a

green band is produced and that red and blue bands are

made at the right and left.

5.

Slowly slide the deflection yoke forward and

fuc

it by

tightening up the clamp screw when the best over-all

green is obtained in the screen.

6.

When purity is not achieved, repeat the steps 3, 4 and

5,

then the best purity can be obtained.

7.

Fully turn the G-Bias control

(R1008)

counterclockwise

and then the R-Bias control clockwise. Check if the

purity of red has been achieved. After that, check

the purity of blue as well.

DEFLECTLON

YOKE

H-SIZE COIL

6-POLE

MAGNET

PURITY MAGNET

Figure

2.

CONVERGENCEADJUSTMENT

Any

colour

impurity induced as a result of relocation of

the receiver normally will be removed by the Automatic

Degaussing

Operation.

The

degaussing

recurs any time

the receiver is turned on, after being off for at least 5

minutes.

The receiver, with the Brightness and Contrast controls

in normal position, should be operated for minimum of

10

minutes before proceeding. Also, adjustments such as

purity, vertical size and vertical linearity must be made,

as directed in this manual, before attempting convergence

adjustment.

Connect the cross

hach

pattern Generator to the VHF

antenna terminals of the receiver and turn the receiver to a

channel suitable for operation with the particular generator

being used.

4

Page 5

Static Convergence Adjustment

1.

Rotate two pieces of

4-pole

magnet in different directions reverse to each other so as to make the same the

vertical lines of red beam and blue beam.

2.

Rotate both magnets in combination without changing

the created angle between them and fix them when the

vertical line and horizontal line for both red beam and

blue beam are the nearest.

3.

Rotate both magnets gradually in different direction

until the red line and Blue line are

focussed

upon

one to another producing a mazenta line.

4.

Rotate two pieces of

6-pole

magnets to bring the green

line onto the mazenta line.

CHASSIS REMOVAL

1.

Loosen the back cover retaining screws and separate the

back cover from cabinet.

2.

In this position the chassis can be inspect from all sides.

3.

Remove

PWB-B

chassis (deflection

PWB)

retaining

screws.

4.

After all plug connections on

PWB-B

and picture tube

anode cap have been disconnection the

PWB-B

chassis

can be pulled out of the cabinet.

5.

Remove

PWB-E

chassis (power

PWB)

retaining screws.

6.

After all plug connections on

PWB-E

have been discon-

nection the

PWB-E

chassis can be pulled out of the

cabinet.

7.

When remove the

PWB-A

chassis (signal

PWB)

after pull

out of the all connections on

PWB-A

and pull out the

PWB-A

chassis.

PICTURE TUBE ASSEMBLY REMOVAL AND REPLACEMENT

1.

2.

3.

4.

5.

6.

7.

8.

Remove

PWB-B

and

PWB-E

chassis from cabinet.

(Refer to CHASSIS REMOVAL procedure)

Disconnect picture tube coating earth tip from the

PWBC.

Unplug picture tube socket board

(PWB-C)

from picture

tube.

Spread a heavy pad on blanket on the

wark

surface to be

used to prevent scratching the cabinet and carefully

place cabinet face down on this protective covering.

Remove the four nuts that secure the picture tube

mounting tubs to the front frame.

Carefully grasp the picture tube assembly by its mounting

tubs and lift from the cabinet front.

The picture tube must be handled with care.

Remove the picture tube

dag

ground harness assembly.

Carefully seat the new picture tube assembly in place on

the cabinet front and install all hardware in reverse other

sequence.

5

Page 6

GENERALALIGNMENTINSTRLJCTION

Equipment

The test equipment specified on page 7 or its equivalent,

is required to properly perform the alignment procedures

which are outlined on the following pages. Use of equipment which does not meet these requirements may result

in the inability to properly align the instrument.

A warm-up period of at least fifteen minutes should be

allowed for proper stabilization of equipments such as

Marker and Sweep Generators.

It is essential that the proper bias values, as specified,

are maintained during alignment to insure the proper

results.

Equipment Terminations

The alignment pads and the input lead are designed for

correct matching of the equipment to the circuits involved.

Failure to use proper matching will result in responses

which cannot be depended upon as representing the true

operation of the receiver.

The pads should be constructed

as compactly as possible and all unshielded leads at the end

of the test equipment cables should be as short as possible,

preferably not in excess of one inch long. In many

instances a small ceramic capacitor, approximately

lOOOPF,

connected from the oscilloscope probe to ground will

eliminate stray pick-up of unwanted signals. If used, make

sure the capacitor does not affect the shape of the response

being observed.

Signal Overload

Use of excessive signal from the Sweep Generator can cause

overloading of the receiver circuits. To determine that this

condition is not present and that the response curve is true,

turn the Sweep Generator output to zero and then gradually

increase the output until a response is obtained. Further

increase of the sweep output should not change the configuration of the response except in amplitude. If the

response changes in configuration, such as flattening at the

top or dropping below the base line at the bottom, decrease

the sweep output to restore the proper configuration. The

oscilloscope gain should be run as high as possible to maintain a usable pattern with the peak-to-peak values specified,

thus requiring a lower output from the Sweep Generator

and less chance of overload.

Insertion of markers from the Marker Generator should

not cause distortion of the response curve. The markers

should be kept as small as possible and still remain visible.

6

Page 7

TESTEQUIPMENT

To facilitate service and alignment for this chassis, it is

recomended

that the following test equipments should be

used.

VARIABLE POWER SUPPLY . . . .

Range: DC 0 . .

.25V

TEST PATTERN GENERATOR

VOLT METER . . . . . . . . . . .

High input

inpeadance

type.

SWEEP GENERATOR.

MARKER GENERATOR . . . . . . . With crystal

caliblated

accuracy.

OSCOLLOSCOPE

IF-TEST BLOCKS . . . . . . . . . . . . . . . .

Shown in Fig.

3.

VIDEO DETECTOR TEST BLOCK . . . Shown in Fig.

4.

OUTPUT PADS

. . . . . . . . .

Shown in Fig.

5 (A)

(B) (C).

(A)

TO

TEST POINT

loop

I

N60

47K --

I5000

.

CHASSIS

Figure 3. IF Test Block

Figure 4. Video Detector Test

Blodc

TO TEST POINT

I

001

5.6K

CHASSIS

SWEEP

GENERATOR

CHUSi

(A)

SIF

Sweep Generator Output Pad

(B)

PIF

Sweep Geneator Output Pad

SWEEP

GENERATOR

SWEEP

GENERATOR

CHfiSIS

ICI Chroma

Sweep Generator Output Pad

Figure 5. Output Pad

7

Page 8

TUNER PERFORMANCE CHECK

Preliminary Information

Unless there is evidence of tempering or if electrical repairs

have been made tuner alignment is normally not required.

Response Curve

“A”

is an indicator of the quality of tuner

performance. If the response curve is obviously bad on all

channels, repair, rather than alignment, is indicated.

Also check for bad solder connections and contacts.

Visually inspect the circuits for overheated components

and obvious wiring defects.

Test Equipment Connections:

Refer to Figure

6.

GENERAL . . . .

The set under

-test

should be correctly

fine

tuned,

fine

tuning should not be adjusted while

performing this tuner check.

OSCILLOSCOPE . . . With at 1

.OV

P-P calibration, connect

to terminal

TP203.

SWEEP GENERATOR

. . .

..Connect

output to the tuner

aerial terminals using proper matching pad.

MARKER GENERATOR

. . . . . . . . Connect markers at loosely

to Sweep Generator output lead.

BIAS SUPPLY

. . . . . . . . . . . . . . . .

Apply

+7.S

volts bias to

TP204.

Performance Check

Starting with the tuner placed in the Channel 12 position

and the Sweep Generator

.set

at the proper frequency, check

the overall response curve as viewed on the Oscilloscope.

This viewed curve should match, approximately, Response

Curve “A”.

The same procedure should be used for

Channels 11 through

0.

.

31.375

Response Curve “A”

Figure 6. Tuner Performance Check

Page 9

PICTURE IF TRANSFORMER & TRAP ALIGNMENT

Test Equipment Connections:

Refer to Figure

7.

GENERAL

. . . . . . . . . . . . . . . .

Connect AC power plug through

isolation transformer to power supply.

BIAS SUPPLY

. . . . . . . . . . . .

Apply t8V volts bias to

TP204.

OSCILLOSCOPE

. . . . . . Connect to

TP203

through “IF TEST

BLOCK” shown in Figure 3. Detector terminal B

is connected to

TP201.

SWEEP GENERATOR

. . . . . . .

Connect

IF/VF

output in

series with “Out Put Pad” shown in Figure 5 to

TP201.

MARKER GENERATOR

. . . . . . Couple

loosely

to

Sweep

Generator Output Cable to provide markers.

VTVM

. . . . . . . . . . . . .

Used to check bias voltage.

Note:

. . . . . . .

Preset RF

AGC

control to mid-position. Set

Channel Selector to Channel

10.

Alignment Procedure

. . . . . . . . .

See “General Alignment

In-

struction” before attempting alignment.

STEP

4

5

6

7

8

Recheck adjustment of Tl on tuner and

T201

for correct response as shown in

“B”

of Figure

7.

9

10

11

12

Reset RF

AGC

control

(R206)

for normal operation.

ADJUSTMENT

WEEP

GENERATOR

MARKER

GENERATOR

COMPONENT

PROCEDURE

Detector stage

30-42MHz

36.875MHq

32.445MHz

3

1.375MHz

T206

(bottom core)

Adjust as shown on response curve “A” of

Figure

7.

Adjust 3

1.375MHz

attenuation of

PIF

Same as Step 1 31.375MHz

T206

Adjust

T206

(Top core) alternately for

(Top

co=)

maximum attenuation of

31.375MHz

as

Det.

transformer.

shown on response curve “A” of Figure

7.

Recheck adjustment of

I206

(Bottom core) for response as shown in “A” Figure

7.

Remove the Sweep Generator lead from

TP201

and reconnect it

to test point on tuner.

Remove the IF Test Block terminal A from the

TP203

and reconnect it to

TP201

of IF Test Block terminal

B.

Apply

+8.0

volts

ACC

bias to

TP204.

Set channel selector to channel

10.

Check 31.375MHz

38.375MHz

Adjacent channel

trap & sound trap

transformers

Same as Step 1

Adjust mixer collector

coil

in VHF

tuner

Same as Step 1

Adjust

1st

PIF

transformer

Same as Step 1

31.375MHz

T202

Adjust for minimum dip at

31.375

MHz,

38.375MHz

T203

38.375MHz.

3

1.375MHz

32.445MHz

36.875MHz

38.375MHz

Tl

on

Adjust for maximum gain and the response

VHF Tuner

curve

“B”

in Figure

7.

Same as Step 6

T201

Remove the IF Test Block terminal B from the

TP201

and reconnect it to

TP203

of IF Test Block terminal A.

Apply

+8.0

volts

ACC

bias to

TP204.

Adjust for proper

PIF

curve

Same as Step 1

Same as Step 6

T204

T205

Align T204 and T205 for maximum gain and

obtain the response as shown in

“C”

Figure

7.

Recheck adjustment

T204, T205

and for correct response as shown in

“C”

Figure

7.

9

Page 10

3

1.375

Response Curve “A”

31.376

38.376

Response Curve

%”

Figure 7. PIF Transformer and Trap Alignment

10

Page 11

RF AFT ALIGNMENT

Test Equipment Connections*

Refer to Figure 9 .

GENERAL

. . . . . . . . . . . . . . . .

Set channel selector to the highest

unused channel.

Read the General Alignment

Instruction (Page

6)

Connect.

AC

power plug through the isolation

trans-

former to power supply.

oscILLOscoPE

. . . . . . . .

Connect through a direct probe to

TP201.

Calibrate for a two inch equal

OSV

P-P

display.

Note:

Set base line in

centre

of CRT for reference.

SWEEP

GENERATOR

. . . . . . .

Connect the IF video output

through the Output Pad A or B. (Figure 5 ) Set

for a 1 V P-P output.

MARKER GENERATOR . . . Adjust to produce

36.875

MHz couple loosely to Sweep Generator output cable

to provide marker.

ALIGNMENT PROCEDURE

Before attempting this alignment, check the PIF response and realign if necessary.

Make sure that the signal appearing at the

output of the video detector has an amplitude of 1V P-P.

STEP

ADJUSTMENT

SWEEP

MARKER

GENERATOR GENERATOR

COMPONENT

PROCEDURE

1

I

Readjust Marker Generator for visible

36,875MHz

marker, if necessary, without distorting the response

cuIye.

2

Move the core of

T201

to its bottom end of range.

3

AFT

Transformer

35 - 40MHz

36.875MHz

1208

Adjust

T208

to obtain the maximum amplitude

I

and response

cuve

“A” as shown in Figure

8.

4

AFT Discriminator

35 - 40MHz.

36.875MHz

T209

Adjust

T209

to bring

36.875MHz

marker to the

centre of S curve “B” as shown in Figure

8.

5

APT Transformer

35 - 4OMHz.

36875MHz

T208

Adjust

T208

to make the S curve symmetrical

as shown in Figure

8.

6

(

Repeat Steps 3 through 5 so that the final response curve matches Response Curve,

“B”.

When property aligned maximum allowable amplitude ratio above and below zero reference is approximately

A=B.

7

(See Response Curve “B”).

Check all channels for same response, if response is not the same, adjust

T208, T209

for each

charmeL

With the tuner set to an outside signal, observe whether or not the AFT locks in a black and white station and a colour station.

8

Note:

If AFT is found to lock in

B/W

but not colour, perform the Burst Alignment. If AFT does not B/W or colour, repeat this

AFT alignment.

36.875MHz

Respmse

Curve “A”

Response Curve

“B”

1%

Figure 8.

Page 12

T3Ol

T206

cl 0

Q 0207

1200

T205

-0

TP206

cl

0

0 0206

0

TP205

0

0

T203

0

0

0

T202

Q202

0

Q 00205

0204

cl

0

TPOI

( ouT,:, /---

Figure 9. RF AFT Alignment

12

Page 13

SOUNDIFDETECTORALIGNMENT

The following alignment procedures are accomplished with

the receiver operating normally while connected to an

antenna and tuned to receiver a local telecast.

STEP

I

ADJUSTMENT

I

COMPONENT

I

PROCEDURE

1

Transformer Input

2

Discriminator

T301

T302

Adjust the input transformer for maximum sound.

Adjust the discriminator for least distortion with maximum

sound and minimum buzz.

VIDEO

TRAP(4.43MHz)ALlGNMENT

GENERAL

. . . . . . . . . . .

Connect AC power plug through the isolation transformer to power supply.

STEP

1

PROCEDURE

Connect

Colour

Bar Generator to receiver antenna terminals. Switch Pattern control to

Colour

Bar Position. Adjust receiver

for normal colour reception.

2

Connect Oscilloscope to

TP404.

3

I

Adjust the Video Trap

(T401)

for minimum

chroma carria

in the Video signal.

R454

R436

ADJUST

VIDEO

RB24

-

I

SUB CONTRAST

“T401 f

“2 E-l

n

TPL

I 0

0

n”

II

I, IuLo”‘l

I I

TP402

w

l-l

YU

0413 0412

D

“‘“‘0

17 O

yip808

0

I

I

r

Lj

,

Figure

10.

Video Trap Alignment

13

Page 14

PEDESTAL LEVEL ALIGNMENT

Tune in a black and White Signal. The receiver should

have been operating at least 10 minutes before proceeding

with Pedestal Level Alignment.

Connect AC power plug through the isolation transformer

to power supply.

STEP

PROCEDURE

1

Set the Brightness control to mid. positions.

2

Set the R-Drive, G-Drive and B-Drive controls to mid range.

3

Set the R, G and B Bias controls to minimum (fully

CCW)

4

Connect oscilloscope to collector of red output transistor

((21001)

5

Connect a short clip lead between

TP402

and

TP403.

6

Adjust the Pedestal control

(R436)

to make the pedestal level be aligned with the pulse level (A) of the waveform drawn on an

oscilloscope.

7

Adjust the white balance in such manners as in page

4.

/

J-J-

(A)

______--______1- -_____________ DC130V

Waveform “A”

q

T6Ol

0

0 0

TP

TP

810

809

TP806

SUB-COLORu SUB-CONT

1

L40

0’4’0

OTP

402

0

TP401

-

0 TP404

PEDESTAL LEVEL

0

@

R436

PEDESTAL

RI032

RI015

RIO07

Figure

11.

Pedestal Level Alignment

14

Page 15

CHROMABANDPASSALIGNMENT

Test Equipment Connections:

Refer to Figure

12.

OSCILLOSCOPE

. . . . . .

GENERAL

Connect to

TP802

through “Video

. . . . . . . .

Connect AC power plug through the

Detector Test Block” shown in Figure

4.

isolation transformer to power supply.

SWEEP GENERATOR

. . . . . . . . . . .

Connect the IF Video

Out-

Set Channel selector to the highest unused channel.

put through the Out Put Pad. (Refer to Figure 5

).

Preset

Colour

control to approximately midposition.

MARKER GENERATOR

. . . . . . . .

Connect as shown.

Set the Contrast control to maximum. Connect a

SIGNAL GENERATOR . . . . . . . . . . . .

Connect as shown Produce

short clip lead between

TP806

and

807.

of

36.875MHz

signal.

BIAS

SUPPLY . . . . . . . . . . .

Apply t7.5 volts bias to

TP204.

RF MODULATOR

. . . . . . . . . . . . . . . . . .

Connect as shown.

OUT PUT PAD

. . . . . . . . . . . . . . . . . . . . . . . . .

Connect as shown.

VTVM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check to bias voltage.

STEP

ADJUSTMENT

SWEEP

MARKER

GENERATOR

GENERATOR

COMPONENT

PROCEDURE

1

Set the

Colour

control to

centre

of its range.

2

Apply output of Sweep Generator to the RF

Modulater.

Set the

Colour

control to the

centre

of it range.

3

Apply

7.W

bias to

TP204.

4

Bandpass Trans.

4.4MHz

TZOS

6466

TC601g

0

0207

(TCI

1202

I-J

DL6Ol

(TS)

r-1

T206

1205

0

TP206

(TA)

[I

Figure 12. Chroma Bandpass

Alignment

Page 16

4.43MHz OSCILLATOR AND

COLOUR SYNC. ALIGNMENT

Test

Equipment Connections:

Refer to Figure

13.

OSCILLOSCOPE

. . . . . . . . . . . .

Connect through direct probe

GENERAL

. . . . . . .

Connect AC power plug through the

isola-

described. The frequency response of vertical input

tion

framsformer to power supply.

should be flat to at least

MHz.

Set the Colour control to the centre of its range.

COLOUR BAR GENERATOR

. . . . . . . . .

..Connect to

receiver

Set the receiver to normal operation.

antenna terminals. Switch Pattern control to Colour

Bar position. Adjust receiver for normal colour

reception.

4.43MHz

OSCILLATOR ALIGNMENT

STEP

ADJUSTMENT

COMPONENT

PROCEDURE

1

Connect Oscilloscope to

TP805

(Vertical range

O.SV/cm)

2

Adjust

4.43MHz

T803

Adjust

T803

for maximum deflection on scope.

(CW

Trans.)

(Output level 1 .l * 0.3V p-p)

COLOUR SYNC. ALIGNMENT

STEP

ADJUSTMENT

COMPONENT

I

PROCEDURE

1

Connect a short clip lead between

TP806

and

TP807.

Turn the

Colour

Killer control to fully counter

cloc!:wise

position.

2

Adjust

APC

Trans.

T802

Adjust

APC Trans (T802)

to obtain

colour

sync.

3

Remove a short clip lead between

TP806

and

TP807.

Chedc

whether colour sync. obtain or not.

R454

R436

ADJUST

SUB CARRIER

ADJUST

AR

C

TRANSFORM

ER

0407

-

R824

T801

-

COLOR

--\-

tot

0

0408

SUB

CONTRAST

0

0’

0

0

w

9802

3 TP802

m)TP

PEDESTAL

040g

0

T 401

0

0

0402

8

TP

0

TP403

0410

‘04

0 0

no

rP402

[-I

@&Ap

TP80

L

T804

n-

:K)

l-J

0

TP803s0

DL801

rl

0

0404

1821

Figure 13.

4.43MHz

Oscillator and

Colour

Sync.

Alignment

Page 17

PALDELAYCIRCUITALIGNMENT

STEP

1

ADJUSTMENT

COMPONENT

Set the

Colour

control to

centre

of its range.

Connect Oscilloscope to

TP803.

PROCEDURE

2

Adjust Delay Time

control

R821

Adjust

R821

to the response curve “A” shown in Figure

14.

3

Adjust Phase trans.

T804

Adjust

T804

to the response curve

“B”

shown in Figure

14.

4

Remove Oscilloscope to

TP804.

SOUNDTRAPALIGNMENT

STEP

I

ADJUSTMENT

COMPONENT

PROCEDURE

1

Connect Oscilloscope to

TP802.

Fine tune until sound appears in the

chroma

signal.

2

Adjust

5.5MHz

Sound

Trap trans.

T207

Adjust the

5.5MHz

sound trap

(T207)

for minimum sound in the

chroma signal.

CORRECT IN CORRECT

Response “A”

CORRECT IN CORRECT

Response

“6”

Figure

14. H-l

Delay Circuit Alignment

Page 18

TROUBLE SHOOTING GUIDE

Methods of Checking

Repairs will be considerably simplified by careful observation of the defect and its location to a specific part of the

circuit. Once this has been done it can be said that

90%

of the repair has been completed.

To do this an understanding of the outline of the

ICs

used

in solid state colour T.V. will be of great assistance in

quickly diagnosing the cause of trouble.

When checking, the following procedure is

recommended:-

1)

Carefully note the symptoms of the trouble. Ensure

that the defect is in fact caused by the receiver and not

by a fault in transmission, by switching to alternative

channels.

2)

If the fault is present on all channels locate the defective

circuit in the receiver.

3)

Where the defective circuit has adjustable controls

ensure that these are correctly set. If adjustments have

no effect on the fault be sure to

re-set

to the original

positions.

4)

Measure voltages and waveforms of the suspected circuit

block and, if defects are found, replace the transistors,

ICs

or other components.

(a) Check the collector voltage and waveform of

transistors.

(b)

Check voltage between base and emitter of

transistors. (Generally

0.3 -

1 v for silicon

transistors and

0.1

- 0.5

v for germanium tran-

sistors).

(c)

Measure the terminal voltages and waveforms of

ICS.

(d) Check resistors, capacitors and coils.

Note:

When removing components from the

PWB

dis-

connect the leads by heating the soldered portions

with a soldering iron, removing surplus solder

with a

desoldering

tool.

PART

r==h

PWB

COPPER FOIL

- OESOLDERING

TOOL

Melt the solder

and suck it

up by the

desoldering

tool.

Figure

15.

PRECAUTIONS TO BE TAKEN DURING REPLAIR

In servicing, some of the methods used for valve systems

do not work on solid state colour T.V. receivers. Keep in

mind

that:-

1)

Transistors and KS MUST NOT be overloaded, even

momentarily.

In the case of valves, damage is rarely caused even if the

anodes and screens are severely overloaded, provided

that this condition is not maintained for very long.

Transistors and

ICs,

however, should not be subjected

to overload even for a moment.

Be sure to switch off the power source when removing

or soldering leads or measuring resistance.

2)

Essential Conditions in Checking Transistors

The test and replacement of power transistors must be

carried out in such a way that the transistor is kept in

its heat-sink.

Valve checking is simple but with transistors testing is complicated by the fact that screws and

solder must be removed. Never test a power transistor

which is not securely fixed in its heat-sink otherwise

damage will be caused by overheating as power transistors consume large current.

To check small transistors, remove as quickly as possible

with a soldering iron avoiding excessive heating of the

transistor.

3)

Avoiding short-circuits

When checking voltages or waveforms take care not to

produce shortcircuits with the test probes or test clips

of the meter or oscilloscope.

During operation:

-

DO NOT short the emitter resistor.

DO NOT short or open circuit the bias resistor.

DO NOT short the collector resistor.

DO NOT allow adjacent legs of

ICs

to come into contact

with each other.

4)

Do Not Operate Vertical Output Circuit With Parts

Removed.

If the vertical output circuit is operated with parts

removed a large flyback pulse may be produced which

can cause short-circuting or deterioration of transistors.

5)

In checking the horizontal deflection circuit, abnormal

oscillation such, as sparking the high voltage circuit and

stopping the oscillator circuit must be avoided.

If the high voltage circuit is checked by sparking the

driver or the input pulse is cut off abruptly with the

horizontal output circuit operated, the output transistor

may be damaged. The output transistor is designed to

withstand high voltages but if it is heated or subjected

to abnormal conditions for long periods the resistance

against voltages’ will be considerably reduced, and the

transistor may be damaged if subjected to an input

circuit shock (cutting off the input instantly) or output

circuit shock (sparking the high voltage circuit).

6)

Others

Wires must be carefully arranged after check and repair.

(Be sure to connect them to the original places taking

care not to induce high voltages or other circuitry).

18

Page 19

These notes may give the impression that the repair of

IC

and transistorised sets is a complicated procedure.

,

However, no difficulties should be encountered provided

that it is remembered that extra care must be taken in

comparision to valve-operated receivers.

EXAMPLES OF DEFECTIVE PARTS

1)

Transistors

(a) Short-circuit of connections . . . Continuity in

both forward and backward directions when

measured by an ohmmeter.

(b)

Burn-out of connections (open) . . . No continuity

in both forward and backward directions when

measured by an ohmmeter.

(c)

Deterioration of characteristics.

2)

Capacitors

(a)

Change of capacity

(b)

No capacity (open)

(c)

Defective insulation (leak)

(d) Short-circuit

3)

Resistors

(a) Increase of resistance value

Generally, resistances tend to increase in value

during use. This often occurs in cases of higher

resistances than

1OOK

ohms.

(b)

Bum-out

Resistance value is extremely increased.

4)

Coil, Transformers

(a) Burn-out

(b)

Layer short - line short - iron core short . . . etc.

CHECKING OF TRANSISTORS BY OHMMETER

Transistors can be checked by measuring the forward

backward resistances between collector and base,

emitter and base.

and

and

Since the function of a diode exists between emitter

and

base, collector and base, low and high resistances

are

indicated by polarity when measured with a test meter.

The former is the

for.ward

resistance and the latter is the

backward resistance.

Attention must be paid to the range of the ohmmeter.

In the case of an ordinary transistor, the range can be

found by

X1000,

but the range of a power transistor must

be reduced for the measurement. Alteration of resistance

values measured by tester.

(1)

Short-circuit of connections . . . Both forward and

backward resistances become zero.

(2)

Burn-out of connections (OPEN) . . . Both forward

and backward resistances become infinite.

(3) Deterioration of characteristic . . . Difference between

forward and backward becomes small.

Note: It is desirable to measure the transistor whilst

disconnected from the

PWB.

R

I-----

-----1

,

:--,';-.C.L,

,

-----+A

‘d+-----

R : LEAK

RESJSTOR

I

1

LAYER SHORT

LAYER LEAK

-1

I

I

-_.- ----_-

-I

SHORT

Figure

16

$6

LAYER SHORT

Figure

17

-4&k-

BURN-OUT

19

Page 20

EXPLANATION OF CODES FOR RESISTOR AND CAPACITOR

RESISTOR

I

A, B

I

C

I

D

COLOR

SIGNIFICANT FIGURES

DECIMAL MULTIPLIER EXAMPLE

(POWER OF 10)

TOLERANCE

(RESISTANCE)

I

I

I

I

I

I

0

loo

BROWN

I

1

I

10’

I

XlOfi

I

-

RED

I

2

I

102

I

XlOOR

I

-

ORANGE

3

103

Xl&!

-

YELLOW

4

lo4

XlOKfi

GREEN

5

lo5

XlOOKR

-

BLUE

6

10”

XlMa

-

VIOLET

7

10’

XlOMR

-

GRAY

I

8

I

lo8

I

XlOOMa

I

-

WHITE

I

9

I

lo9

I

XlOOOMfi

I

-

GOLD

-

SILVER

-

COLORLESS

EXAMPLE

A : RED

B : VIOLET

27

x

lo3

C : ORANGE

=

27,OOOa

D :

CX)LD

27Kfi2+5%

CAPACITOR

I

I

I

(A)

CAPACITY

(B)

(0

TOLERANCE

WITHSTAND VOLTAGE

A

B

EXAMPLE

1RO

1PF

G

+

2%

1B

12v

3A

1KV

100

1OPF

J

+, 5%

1E

25V

3D

2KV

101

1OOPF

K

+10%

1H

5ov

3F

3.15KV

102

1OOOPF

M

+20%

2E

250V

3G

4KV

103 O.OljfF

P

+100-O%

2F

315v

2u

104

O.lpF S

+150-O%

2H

5oov

Except for the

T

*200-O%

WITH UNDER LINE

above, the

indica-

tion methode

2s

Z

+80-20%

WITHOUT UNDER LINE

25V or

SOOV

,

direct indicated to

Except for the above, the indication methode

as

capacity.

direct indicated to withstand value.

A

8

2OOOPF f 5%

5ov

O.Ol@ + 10%

630V

20

Page 21

TROUBLE SHOOTING TABLE

Ctdmd

Circuits

l

Power

Regulator Circuit

l Horizontal Deflection Circuit

l

Picture Tube Bias Circuit

l

Protector

l

Video Circuit

l Picture

Tube

*

6

1s

the fuse

(F701, 702,

703)

blown out?

I

4

Replace the fuse

Check for the collector

with new one.

voltage of

0705.

l

,

.

F703

blown out

F701,

or

702

blown

again

Normal(266V)

our again

I--

----

-

--w--w

1

r-m---

J

i

Check for

Q705

-----1

:

c701

I

1

I

I

:

POR701

i

I

I

I

I ,

D701,0702

,

L

------w-w--

l i

-----------

i

I

I Q704

I

i

0701 ;

; 0702 !

y--------B-

I

-i

I

Picture Tube

i‘

0

c

----

J

Yes

L

w-B--

---,-J

t

Firstly turn off the power

switch and about 15 seconds

thereafter turn on the power

switch. At this moment, is

horizontal oscillation sound

heard?

I

I

When SCR

(0613)

is disconnected

and the power switch is turned on,

?

i

20704,

T701

Yes

;

Q602, Q603

I

; Q606

I

r

R747

I

I

L

I

--- -

--mm-- A

!-----

-w-w-

I

, SCR

(0613)

,

p-w---I

--- ----

I

Check +Bz line

i

L

I

--‘-----------J

i 0611

I

20602

I

I

I

L--w-,

w-v-

J

c

Check for the bias circuit of

picture

tube. Check high

voltage rectifier unit.

Normal

T

6

1

When

TP804

is grounded,

is there caused a raster?

No

Yes

r---

L

-7 r--

-f

----I

;

Q411

L

se--

I circuits,

L

-v--

LA

Page 22

l P-l F Circuit

’

AGC

Circuit

. Tuner

’ B power supply circuit for

the tuner

M’hen

click noise is given

to the pin 1 of 1201, does

1

noise appear on the screen?

$

Yes

t

Make the pin 9 of

I201 be grounded

and check for the

voltage of

TP205.

\

Normal

(&. 3.6V)

,fl,

Check for the

voltage at B4

I

terminal.

1

No

Check for the voltage at the

base, collector and emitter

of

Q207.

Normal

9

Abnormal

9

[F’l

‘“*I’““’

r--i-

-,

r-i-,-,

I

1201 I

I

ZD201

I

I

Q203

I

I

Q204 i

L

B-B--J

I

R463

L

e---B

:

A

22

Page 23

NO PICTURE (SOUND IS NORMAL)

/

Checked Circuit

l Video A 7plifier

t

Check for the voltage at the

collector, emitter and base

of

Q208

and

Q209.

,

Normal

Make

TP804

be

grounded.

c

1

’

I

I

If the both legs

of

R457

are

L,-,,-

r::

shorted, does

picture appear?

r

3

--

“‘7

I

I

D301

;

I

T301 ,

T302

I

I

1301 :

La---,

A

Checked Circuits

l

Sound

Circuit

l Audio Output Circuit

I

Hum is created

When the pin 6 of

1301

is

grounded, does sound

come out?

I

I

No

t

Check for the

voltage at the

-

pin 5 of 1301.

I

C306

I

c305

I

I

R304

I-

I

-----J

c+

Normal

(12.5V)

--VW-

:

0208 7

’ 0209 i

I

I

D201

1

I

I

I

Apply main ripple to the

1

pin 1 of

1302

via

0.1/S

capacitor and

47K

ohm

resistor.

r.-L-

7

I 1302

i)Speaker

I

L

--e-e-

-l

r-L--

~

I

D706 I

I

R710

I

I

I

f

L-w-,-

J

23

Page 24

Checked

Circuits

l

2nd

Video Amp.

l

Horiz., Vert.

Circuit.

Are both vertical and horizontal

synchronizations not possible?

No

7

c

Check for the voltage at

the collector, base and

emitter of

09.

Check for the voltage at the

collector, base and emitter

of Q401.

Normal

Abnormal

t

r---

---

I

Q402 i

t

r--

--

I

Q401 f

L---w-, 4

L-----J

synchronization

Is it impossible even

if V-HOLD

(R506)

J

r----

----I

I

Q501 -i

r

Q502 :

t

c503

I

:

I

----------a

Only horizontal

synchronization

I

I

I

I

Is it impossible

aven

if H-HOLD

(R618)

and H-FREQ

(R617)

controls are adjusted?

.

1

Check

Q613

I

D601 ;

I

0602 I

t

Q601 ;

I

L C601

_I

--e-w-

1

24

Page 25

I

NO VERTICAL SCAN

I

set at SERVICE posItIon?

Is

the yrvice

ST

0:

!‘WB-B

pq

(c/

1]At

“NORM;L”

position

I

r

-- ---

L

1

0506 ;

Normal

I

Q507

I

I

I

I

I

I

:

CheckQ504

base

I

L ------

Voltage

Normal:

11.6V

L ,

--- --

; C511,C512

I

1 C509, R519 ;

I

R520a

R52’

I

; R522, R523

,

I

L----l

I

I

I

Check

Q503

base voltage.

Normal:

2V,-,

1 C506 ;

I

I

I

I

I-

1

--

-----a--

I

1

I

i

Deflection coil

L---- -

-I

T501

I

I

I

L501

I

1

I

I------,-,--,

J

r

I

I

r--f

---7

I

0503

I

I

c507

I

I

c509

I

I

I

I

I

I-- - ----J

I

DEFECTIVE VERTICAL AMPLITUDE AND VERTICAL LINEARITY

I

I

Adjust the controls

W-LIN,

V-SIZE)

4

9

[T

[ Top

con!pression ] l?

7

--em-__-- ----------------

I

w---s-

------- -- ---- ------ ----

I

Check for Vertical oscillator, driver and output circuit.

L-----------------------------

-----

I

-------------------------------

-I

25

Page 26

NO COLOUR OR PALE COLOUR

r

Checked Circuits

l

1801

and its Adjacent Circuit

l

1802

and its Adjacent Circuit

2.

Set colour contrast control to

3.

Set contrast control to maximum.

4.

Check aerial cable.

No colour

I

When the junction bet.

TP806

and

TP807

is

shorted, does colour

No colour

P

i

1801 ’

I,--,

,:

I

51

Yes

1

Is there chroma signal at

TP802?

,

I

I

Check for the voltage at the

collector, emitter and base

of

0801.

When the emitter-collector junction

of

Q802

is shorted, does colour

1

I---

--

-I

J

r-- ---1

I

I

1802 ;

Q802

I

------a

t---i

26

Page 27

NO SPECIFIC COLOUR

Specific

colours

are not

Checked Circuits

b

produced in colour broad-

l 1802 and its Adjacent Circuit

cast reception.

l

R.G.8

Output Circuit

Is some colour produced

in

B/W

broadcast reception?

,

No

,

I- a

--

B-M

1

I

1802

I

I

I

L809 :

I

l-808 f

L807

f Is04

t

1

i

0

a- --w-M

Is the white balance properly adjusted?

No

r-----

-

-------1

$x+djust

the white balance.:

L

-------m.--------M-

J

f

r

*

*

The picture coloured red

The picture coloured green

The picture coloured blue

or cyan.

or magenta.

or yellow.

I

7

A

L

7

r--

--

; QlOOl ;

c

------

J

:

-- --

c

1

I

[ Q1003 ;

L

-----A

.-----a-J

Checked Circuits

l

1801

and its Adjacent

Circuit

I-

t

-m-- ---

I

1801

Cl306

:

I

I

X801 C808 ;

f

T802 C807

I

L803

I

I

C811

I

I

C812

I

f

C810

I

I

R805

1

I

L-----A

27

Page 28

PRINTED WIRING BOARD ASSEMBLIES

I

Figure

18.

PWB-A Component Side

28

Page 29

Figure 19.

PWBA

Wiring Side

29

Page 30

Figure 20.

FWB-B

Component Side

30

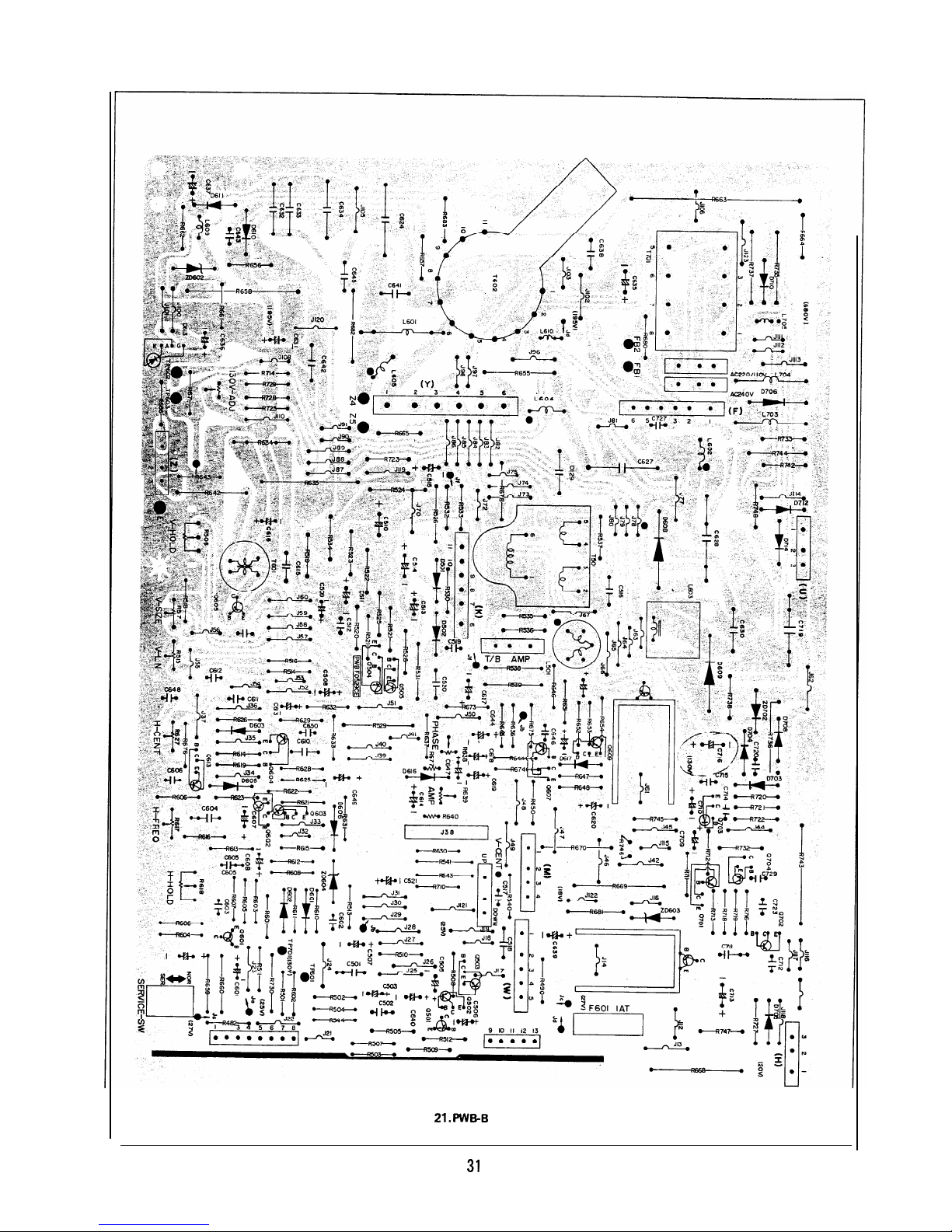

Page 31

Figure

21. PWB-B

Wiring Side

31

Page 32

( PWBF0491CE)

Page 33

Figure 26.

PWB-E

Component Side

Figure 27.

PWB-E

Wiring Side

33

Page 34

Figure 28. PWM-A Component Side

Figure 29. PWM-A Wiring Side

34

Page 35

CHASSIS I

D-L-AMP-AD J

.

R821

DUNTK0499

T207

T3Ol

C)

T209

cl

0

T200

TP3OI

0

0 TP206

T206

cl

0

0 0207

T205

l-a

0 0206

0 TP205

0203

0

“6 o Oo205

0204

(TC)

c-1

(TB)

l-1

(TN

11

0

0

0

0

cl

0

Q 0201

R?06

RF-AGC

T203

T202

T201

EL

SELECTOR BUT TON

ESE7 FINE TUNING KNOB

DUNTK0487

r-

L

BAND SELEGTaS

SWITCH

R454 R436

SUB-CONTRAST

PEDESTAL LEVEL SET

.

Figure 30.

1:

35

Page 36

4YOUT

R70

0

C70GfA.) (A)

0702

R70l

R702

OD

POR701

DUNT

KOS25

TP70l

R6lB

R617

R627 1

R5b

RSl7

RS06

I I

DUNTKOSP 7

RIOIS

co

G-DRIVE

RI016

B-DRIVE

G%S

I

ssis

Layout

36

Page 37

BLO

TOUCH

BUTTON

I

CHANNEL

INDECATOR

I,

SENSOR

PWB-

A

SP3Ol

SPEAKER

PIglO-IISA

S

-AMP

Irt-

VIDEO

2nd-VIDEO

CORRECTION

TlON

REGULATOR

Ii-AFC

SIDE PIN AMP

Page 38

<

DIAGRAM

I

rt

ACC

a

CHROMA

d

9

URST

KILLER

‘+

14

AMP

DE1

AMP

!

I

f

2nd

KILLER

i

CHROMA -

PULSE

AMP

AMP

AMP

I

APC-

ADJ

u(T]

1

I.PHASE

DL-PHASE

.OR.DC

I

VIDEO

PEDESTAL BRIGHTNESS

AMP

5 th VIDEO AMP

06,407,

Q409,0410 1

041 I

08

L

w

373,372(O)

,L

2SC373 2SA509(0)

4

th

VIDE

AMP - BLANKING A MP

l5V. 25V

REGULATOI;

_ 0404

,C’412

25v,

80

2SC 372(0 1

b

o

Q40S,Q413

-

:ONTRAST

--

2SA495fY)

t A

‘=“-

2SD235(Y)

PWB-

E

c

0701

0702

240V

Block Diagram

38

Page 39

Tuner

Figure

32.

Tuner Schematic

SAFETY NOTE:

1.

DISCONNECT THE AC PLUG FROM THE

AC OUTLET BEFORE REPLACING

PARTS

2.

SEMICONDUCTOR

HEA T

SINKS

SHOULD BE REGARDED AS PO-

TENT/AL SHOCK HAZARDS WHEN

THE CHASSIS IS OPERATING.

- us2

BOTTOM VIEW

BOTTOM VIEW

r

‘YTrc"

NOTE

1.

The unit of n&stance

‘ohm”is

omitted (K-1000 ohms

M-l

Megvhml.

2

All resistors are

l/4

watt, unless

othenvise

noted.

3 All capacitors MFO, unless otherwise noted P-MMFO.

’’

’

Voltage Measurement Conditions

1.

Voltaps

in parenthesis measured with no Signal.

2

Voltay?s

without parenthesis measured with

1000/N

8 &

w or

colour-Signal.

9

All the voltages in each point an?

measunzd

with

Vacuum Tube Volt Meter..

Waveform Measurement Conditions

1.

Colour

bar generator signal of 2 V peak to

paak

applied

at base of

1st

Video Amplifier (Q208).

2.

Apptvximetely 8V

AGC

bias

-Pi-TIC”

BOTTOM VIEW

BOTTOM VIEW

.

L

P

CA-

-L

BOTTOM VIEW

39

Page 40

.I.8

VPP

W)1(2) ~.WXJ

(H)

I(3) 3.4Vpp

(H)1(4)6.4Vpp

U-I)

I(51

~.WPP (t-0 1

Page 41

REPLACEMENT

PARTS

LIST

____

_-- __-_

-----

-

It is recommanded to use genuine factory SHARP replacement parts to assure fine performance.

“How to order Replacement Parts”

To have your order filled promptly and correctly, please furnish the following information-s.

1.

Model Number

2.

Ref. No.

3.

Part No.

4.

Description

REF. NO.

PART NO.

DESCRIPTION

REF. NO. PART NO.

DESCRIPTION

CRT

01

02

03

Q4

Q5

Ql71

Q172

QlOl

0102

Q103

Q104

Q201

Q202

Q203

Q204

Q205

Q206

Q207

Q208

Q209

Q401

Q402

0403

0404

Q405

Q406

Q407

Q408

Q409

Picture Tube and Semiconductor Complement

VB560AUTCOl RS

Picture Tube

(560AUB22-TCOI (RI)

(Incl.

Deflection Yoke &

Static Conv. Assy.)

2sc1070

Transistor, RF-Amplifier

(UHF)

2SC288A

Transistor, Local

oscillator (UHF)

2sc1393

Transistor, UHF

Amplifier

2SC535B

Transistor, Mixer

2SC535B

Transistor, Mixer

2sc1393

Transistor, RF Amplifier

(VHF)

2SC717

Transistor, Local

oscillator (VHF)

2SC373

Transistor, AFT Muting

2SC373

Transistor, AFT Muting

2SC373

Transistor, AFT Voltage

amplifier

2SC458A

(Cl

Transistor, Tuning

voltage amplifier

2SC373

Transistor,

UHFNHF-

Band switcher

2SC372 (0)

Transistor,

UHFNHF-

Band switcher

2SA495 (Y)

Transistor,

UHF-

Switcher

(+I 5V)

2SC372 (Y)

Transistor,

VHF-

Switcher

(+I 5V)

2SA495 (Y)

Transistor,

AGC

Amplifier

2SC373

Transistor,

AGC

Amplifier (VHF)

2SC383

(WI

Transistor, P-l F Amplifier

2SC380 (VI

Transistor, 1 st Video

Amplifier

2SC380 (Y)

Transistor, 2nd Video

Amplifier

2SA495 (Y)

Transistor, Sync.

Separator

2SC372 (Y)

Transistor, Sync.

Amplifier

2SC372 (0)

Transistor, Pulse

Amplifier

2SC372 (0)

Transistor, Pulse

Amplifier

2SD235 (Y)

Transistor, Voltage

Regulator

(+I 5V)

2SC373

Transistor, 3rd Video

Amplifier

2SC372

Transistor, 3rd Video

Amplifier

2SC373

Transistor, 3rd Video

Amplifier

2SC373

Transistor,

4th

Video

Amplifier

0410

0411

Q412

Q413

Q501

Q502

Q503

Q504

Q505

Q506

0507

0601

Q602

0603

Q604

0605

Q606

0607

0609

0610

0613

0701

Q702

Q703

0704

0705

0801

0802

01001

Q1002

Q1003

1101

1102

1201

1202

1301

2SC373

2SA509

(01

2SA495

(Y)

2SD235

(Y)

2SC380A (0)

2SA495 (0)

2SC373

2SA495

(Y)

2SC983

(Y)

2SC2168

2SA958

2SA495

(Y)

2SC380A (0)

2SA495 (0)

2SC373

2SC1569

2SC1172

2SC372

(Y)

2SA495 (0)

2SD235 (Y)

2SC372 (0)

2SC734

(Y)

2SC372

(Y)

2SC372 (Y)

2SA743A (C)

2SCl578

2SC380 (0)

2SA495

(Y)

2SC1722

2SCl722

2SCl722

RH-IX0053CEZZ

RH-IX0053CEZZ

RH-IX0004CEZz

RH-IX0034CEZZ

RH-IX0043CEZZ

Transistor, 4th Video

Amplifier

Transistor, 5th Video

Amplifier

Transistor, Blanking

Transistor, Voltage

Regulator

(+25V)

Transistor, Vertical

Oscillator

Transistor, Vertical

Oscillator

Transistor, Vertical

Amplifier

iransistor,

Vertical

Amplifier

Transistor, Vertical

Drive

Transistor, Vertical

output

Transistor, Vertical

output

Transistor, Horizontal

AFC

Transistor, Horizontal

Oscillator

Transistor, Horizontal

Oscillator

Transistor, Horizontal

Oscillator

Transistor, Horizontal Drive

Transistor, Horizontal

output

Transistor, Side-pin

Amplifier

Transistor, Side-pin Drive

Transistor, Side-pin

output

Transistor, Horiz.

Centering Amplifier

Transistor, Pulse Amplifier

Transistor, Pulse Former

Transistor, Error Amplifier

Transistor, Power Regulator

Drive

Transistor, Power Regulator

Output

Transistor, Chroma

Amplifier

Transistor, Colour Gain

Control

Transistor, Red Output

Transistor, Green Output

Transistor, Blue Output

IC, Sensor, Channel

Selector

IC, Sensor, Channel

Selector

IC, P-IF Amplifier,

AGC

IC, AFT

IC, S-l F, Demodulator

41

Page 42

REF. NO.

PART NO.

DESCRIPTION

REF. NO.

PART NO.

DESCRIPTION

1302

RH-IX0054CEZZ

IC, Audio Output

D603

RH-DX0048CEZZ

Diode, Protector

1801

RH-IX0050CEZZ

IC, Chroma Amplifier,

D605

1

s1555

Diode, Temperature

ACC, APC,

Colour Killer

Compensation

1802

RH-IX0051CEZZ

IC, Demod., Matrix,

D607

RH-DX0052CEZZ

Diode, Damper

PAL-Switch

D608

RH-DX0086CEZZ

Diode, Side-pin.

Dl

1

S2208

Variable capacitance

D609

RH-DX0086CEZZ

Diode, Side-pin.

Diode

D610

RH-DX0073CEZZ

Rectifier 19OV

D2

1

S2208

Variable Capacitance D611

RH-DX0048CEZZ

Diode, Rectification

Diode

D616

R H-DX0048CEZZ

Diode, Clamping

D3

1

S2208

Variable Capacitance

D617

RH-DX0048CEZZ

Diode, Protector

Diode

D701

RH-DX0070CEZZ

Rectifier (Power)

D4

1

S2208

Variable Capacitance

0702 RH-DX0069CEZZ

Rectifier (Power)

Diode

D703

RH-DX0048CEZZ

Diode, Temperature

D5

lS2198

Diode

Compensation

D6

HZ-l 1 A

Zener Diode

D704

RH-DX0048CEZZ

Diode, Temperature

07

lS1555

Diode

Compensation

D172

1

s2222

Diode

D705

RH-DX0055CEZZ

Diode, Stater

D173

1

s2209

Diode

D706 RH-DX0071 CEZZ

Diode, Damper

D174

BB109B

Variable Capacitance

D708

1

S2095A

Diode, Protector

Diode

D710

lS184A

Diode

D175

1

s1555

Diode

D712

RH-DX0073CEZZ

Diode Clamper

D176

BB109B

Diode

D714

R H-DX0062CEZZ

Diode

D177

lS2186GR

Diode

0720

lS1834

Diode

D178

1

S2186GR

Diode

ZDlOl

RH-IX0037CEZZ

Zener Diode

D179

BB109B

Variable Capacitance

ZD201

RH-EX0017CEZZ

Zener Diode

(12.5V)

Diode

ZD401

RH-EX0028CEZZ

Zener Diode

(25V)

D180

1

S2186GR

Diode

ZD402

RH-EX001.7CEZZ

Zener Diode

(12.5V)

D181

BB109B

Variable Capacitance

ZD602 RH-EX0050CEZZ

Zener Diode

(18V)

Diode

ZD604

RH-EX0017CEZ.Z

Zener Diode

(12V)

D182

lS2186GR

Diode

ZD701

RH-EX0037CEZZ

Zener Diode (2OV)

DlOl

RH-PX0007CEZZ

LED, Channel Indicator

ZD702

RH-EX0048CEZZ

Zener Diode

(6.3V)

0102

RH-PX0007CEZZ

LED, Channel Indicator

D613

VHSSFl R3G411

E SCR Protector

D103

RH-PX0007CEZZ

LED, Channel Indicator

DlOOl

RH-DXOO55CEZZ

Diode, Protector

D104

RH-PX0007CEZZ

LED, Channel Indicator

POR701

RMPTPOO18CEZZ

Positive Coefficient

0105

RH-PX0007CEZZ

LED, Channel Indicator

Thermistor,

Degaussing

D106 RH-PX0007CEZZ

LED, Channel Indicator

X801

RCRSAOOl

1

CEZZ

Crystal,

4.43MHz

D107

RH-PX0007CEZZ

LED, Channel Indicator

D108

RH-PX0007CEZZ

LED, Channel Indicator

D109

R H-DX0048CEZZ

Diode

DllO

RH-DX0048CEZZ

Diode

Dill

RH-DX0048CEZZ

Diode

Coils

D112

RH-DX0048CEZZ

Diode

0113

RH-DX0048CEZZ

Diode L201

VP-LK2R2KOOOO Choke

2.2pH

D114

RH-DX0048CEZZ

Diode

L202

VP-LKl OOKOOOO

Choke 10pH

D115

RH-DX0048CEZZ

Diode

L203

VP-LK2R2KOOOO Choke

2.2~H

D116

RH-DX0048CEZZ

Diode

L204

VP-LKl51 KOOOO

Choke

150pH

D117

RH-DX0048CEZZ

Diode

L301

VP-LKl20KOOOO

Choke 12pH

D118

RH-DX0048CEZZ

Diode

L302

VP-LK390KOOOO

Choke

39pH

D119

RH-DX0048CEZZ

Diode

L305

VP-LK6R8KOOOO Choke

6.81~.H

D120

RH-DX0048CEZZ

Diode

L401

VP-LK390KOOOO Peaking

39pH

0121

RH-DX0048CEZZ

Diode

L403

VP-LK180KOOOO Peaking

18/.4H

D122

RH-DX0048CEZZ

Diode L501

RCI

LZ0230CEZZ

T/B Pincushion Phase

D123

RH-DX0048CEZZ

Diode

L601

RC

I LPOO45C

EZZ

Choke

~/LH

D124

RH-DX0048CEZZ

Diode

L602

RCI

LZ0250CEZZ

Choke

170pH

0125

RH-DX0048CEZZ

Protective Diode

L603

RTRNC0030CEZZ

Choke

3mH

D126

RH-DX0048CEZZ

Diode

L604

RCI LZ0247CEZZ

Horizontal Linearity

D127

RH-DX0048CEZZ

Diode

L605 RCI LZ0249CEZZ

Choke