50Hz

Chassis

Colour Television

DA100 and DW100

Colour Television – DA100/DW100 Chassis

Contents

POWER SUPPLIES...........................................................................................................................1

Switch Mode Power Supply......................................................................................................1

Start up operation...........................................................................................................1

Voltage regulation ..........................................................................................................2

Over-voltage Protection..................................................................................................2

Over-current control .......................................................................................................2

Slave Processor Power Supply.................................................................................................3

Degauss Circuit........................................................................................................................ 4

5v Regulator ............................................................................................................................5

DA100 (59ESD7H and 66ESD7H) 4:3 chassis................................................................ 5

DW100 (56FW53H to 6FW54H) 16:9 chassis.................................................................6

CLASS D OUTPUT STAGES............................................................................................................7

Tda7480 Pin Functions.............................................................................................................7

Pin 9 – Frequency..........................................................................................................7

Pin 12 – Mute/Standby function......................................................................................7

Audio Output............................................................................................................................8

Field Output.............................................................................................................................9

Vertical Fly-back...........................................................................................................10

VIDEO AND SYNC PROCESSOR...................................................................................................11

Description.............................................................................................................................11

Analogue front-end.......................................................................................................11

Input Selector............................................................................................................... 11

Clamping......................................................................................................................11

Automatic Gain Control ................................................................................................12

Analogue-to-Digital Converters..................................................................................... 12

Digitally Controlled Clock Oscillator .............................................................................. 12

Analogue Video Output ................................................................................................12

Average Beam Current Limiting.................................................................................... 12

Protection Circuitry.......................................................................................................12

Scan Velocity Modulation Output..................................................................................12

PICTURE ROTATION......................................................................................................................13

SCAN VELOCITY MODULATOR .................................................................................................... 14

LINE OUTPUT STAGE.................................................................................................................... 15

East West Circuit.................................................................................................................... 16

Circuit Description........................................................................................................16

MICROPROCESSOR CONTROL....................................................................................................17

Reset.....................................................................................................................................18

PROTECTION.................................................................................................................................19

Microprocessor....................................................................................................................... 19

Audio Output................................................................................................................19

Beam Current...............................................................................................................19

Horizontal Mute............................................................................................................19

Video/Sync Processor............................................................................................................20

Safety ..........................................................................................................................20

Vprot............................................................................................................................20

Sharp Electronics (UK) Ltd

September 99

Technical Support

Colour Television – DA100/DW100 Chassis

POWER SUPPLIES

This CTV employs two power supplies, which are similar in design to previous models. The Power

Supply located on the sub-board 'PWB-C' will supply the Dolby Prologic circuit and Audio Output

Stages that are also located on PWB-C. Similar to the CS, CA10 and CW100 chassis, when this

receiver is in standby mode, the outputs from the power supplies (including the supply to the Main

Microprocessor circuit) will be muted by removal of the FET gate voltage. The Slave Processor

(IC702) performs standby and timer on/off functions, additionally in this chassis the Slave Processor

will control the degauss circuit.

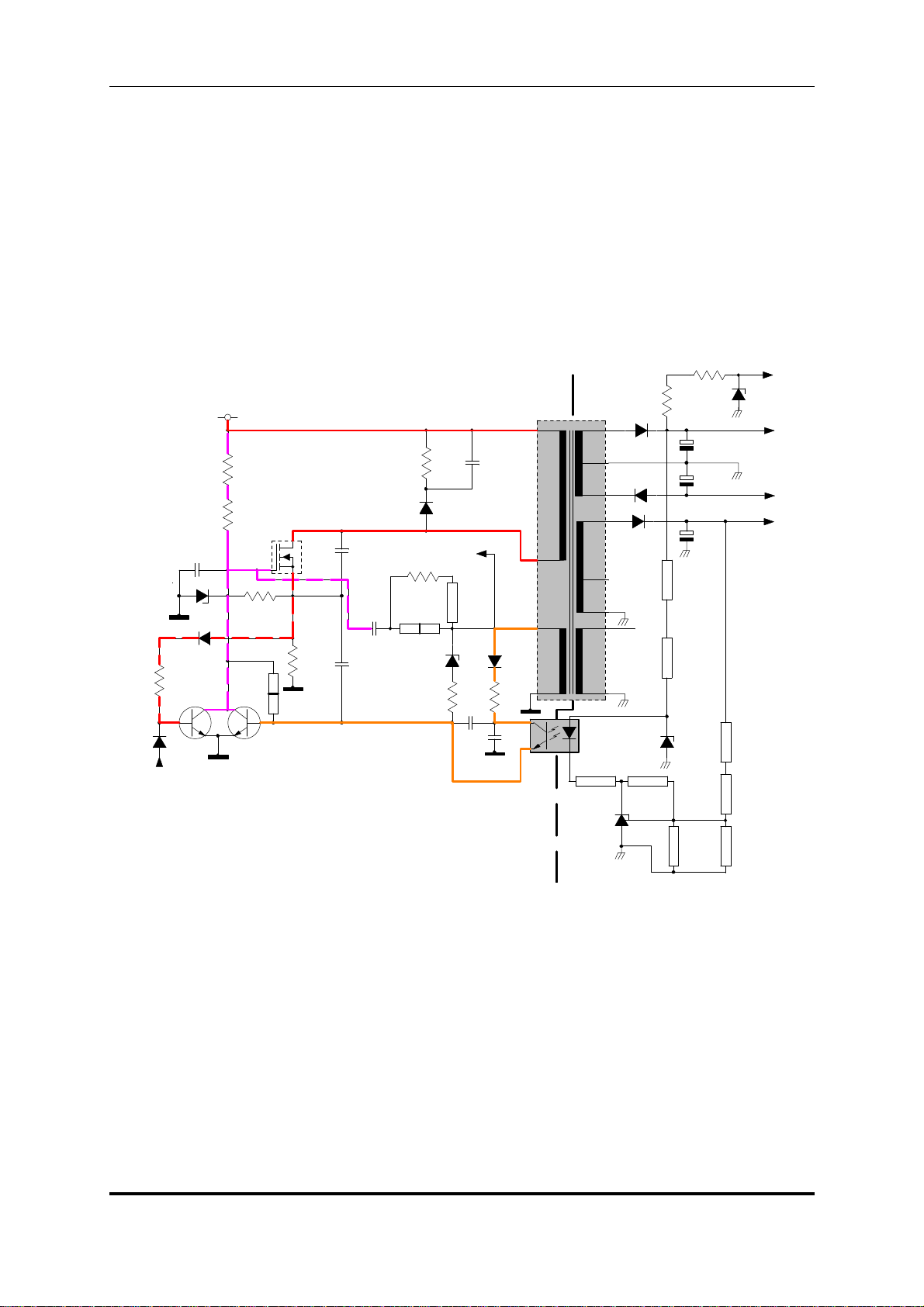

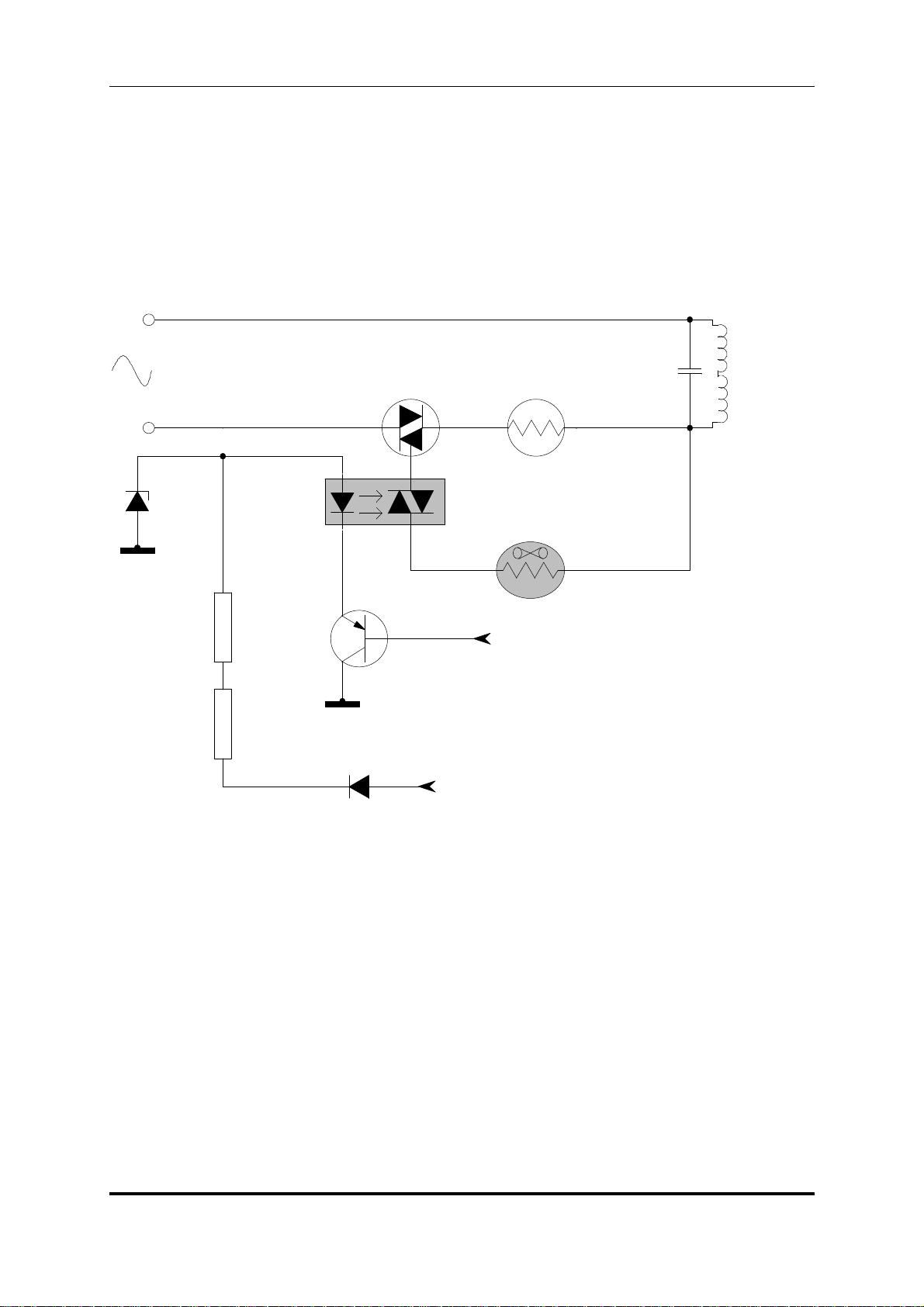

SWITCH MODE POWER SUPPLY

+8v

D721

8v2

+16v

-16v

150V

R743

47k

R744

47k

R746

47k

D730

Standby

R719

220

C712

100pF

D712

15v

D713

Q702

+HT

R713

560k

R714

560k Q701

R717

22k

Q703

C738

56pF

R716

0R47

C711

330pF

C714

82nF

C713

68nF

R730

82

C715

330pF

R723

270

R715

47k

D711

To Degauss

Circuit

R718

18

D716

5v6

C717

15nF

C718

3n3

C710

47nF

D715

R722

0R33

T701

17

12

14

8

7

3

4

5

6

115

2

IC705

R724

470

IC706

R728

180

D718

D719

D720

D726

12v

R750

1M

R727

180

C718

1000

C719

1000

C720

100

R766

220

R765

220

R745

1k8

START UP OPERATION

Rectified and smoothed mains voltage (+320VDC) is used to provide the start up voltage to the gate

of Q701. Current flows via R713 and R714 charging C714 (C714 earth return is via T701 secondary

winding pins 14 and 15). This allows a voltage at the gate of Q701 to rise slowly (Q701 will turn on

when the gate reaches 4.5V). D712 ensures that Q701 gate voltage will not exceed 15V, preventing

the FET being damage by voltage spikes.

When Q701 turns on, current will flow from the bridge rectifier, through T701 primary winding (pins 12

and 17), Q701 source/drain junction, returning to the bridge rectifier via, R716. The current flowing

through T701 primary will induce an e.m.f. into secondary windings

The e.m.f. produced at T701 pin 15 will flow through D715 and the collector emitter junction of the

opto-coupler (IC705), charging C713. Once the charge on C713 reaches 0.6V Q703 will turn on,

connecting Q701 gate to ground, turning Q701 off and discharging C714.

Sharp Electronics (UK) Ltd

September 99 Page 1

Technical Support

Colour Television – DA100/DW100 Chassis

At this point, the magnetic field within T701 will collapse causing the e.m.f at pin 15 to go negative

turning Q703 off.

Q701 will not turn on until sufficient charge has built up on C714. However, at this time the negative

plate of C714 is approximately -12V; due to the collapsing field within T701. This results in the time

period required to build sufficient charge on C714 to bias Q701 on increasing i.e. Q701 off time = the

time for the back 'e.m.f.' to decade to zero, plus C714 charge time form zero to 4.5V approx.).

VOLTAGE REGULATION

The feed back through the opto-coupler (IC705), provides voltage regulation. The +150V line is used

as the controlling source and a reference is provided from the +16v supply.

Increase in load

As the +150V rail falls due to an increase in load (high beam current), the trigger voltage of IC706 will

fall, increasing IC706 cathode voltage, reducing the current flowing through the LED section of IC705.

This has the effect of decreasing the conduction of the photo transistor part of IC705. This increases

the voltage drop across the collector/emitter junction; thereby increasing the time taken to charge

C713, delaying the point when Q703 turns on, turning Q701 off. Energy is transferred across T701 for

a longer period, increasing the HT rail; hence, the frequency of the power supply will fall.

Decrease in load

As the +150V rail increase due to a decreasing load (low beam current), the trigger voltage of IC706

will rise decreasing IC706 cathode voltage which increases the current flow through the LED section

of IC705. This has the effect of increase the conduction of the phototransistor within IC705. Thereby

decreasing the voltage drop across the collector/emitter junction; which will decrease C713 charge

time, advancing the point when Q703 turns off, turning off Q701 to turn on earlier. Energy is

transferred across T701 for a shorter period, decreasing the HT rail; hence, the frequency of the

power supply will increase.

It can now be seen that this is a variable frequency power supply, typically the frequency will vary

between 144kHz (no load) to 70kHz (high beam current).

OVER-VOLTAGE PROTECTION

D716 is used to prevent the secondary rails increasing beyond safe limits. If the e.m.f. at T701 pin 15

increases beyond safe limits D716 will conduct, increase the voltage across C713, thereby reducing

its charge time, turning on Q703 earlier, turning off Q701, allowing the HT rails to fall. Once the HT

starts to fall Q703 will turn off allowing the Power Supply to restart.

OVER-CURRENT CONTROL

Over current control is performed by monitoring the amount of current passing though the R716

(Q701 drain, earth return resistor). This resistor is an extremely low value, 0.47R, and Ohms Law

dictates that the current flowing through it must be proportional to the voltage across it. The base

voltage required for turning on Q702, is +0.6V then the voltage across R706 to ‘trip’ the circuit would

have to be approximately 1.2V (this includes 0.6V drop across D720). Therefore a current of 2.5amps

is required to operate the trip circuit.

The voltage developed across R716 will turn Q702 on via D713 and R719. Once Q702 turns on,

C714 will discharge rapidly, removing Q701 gate bias. Q701 will remain turn off until the current

through R716 decreases. At this point Q702 turns off allowing C714 to charge turning on Q701. If the

overload is still present then Q702 will turn on again, thus repeating the cycle. In the case of a short

circuit line output transistor the power supply will keep repeating this cycle. The HT rail and base of

Q702 (if measured with a standard DVM) would normally read zero volts and the power supply

appears not to be working. On some occasions when the short is not as heavy then a whistle may be

heard.

Sharp Electronics (UK) Ltd

September 99 Page 2

Technical Support

Colour Television – DA100/DW100 Chassis

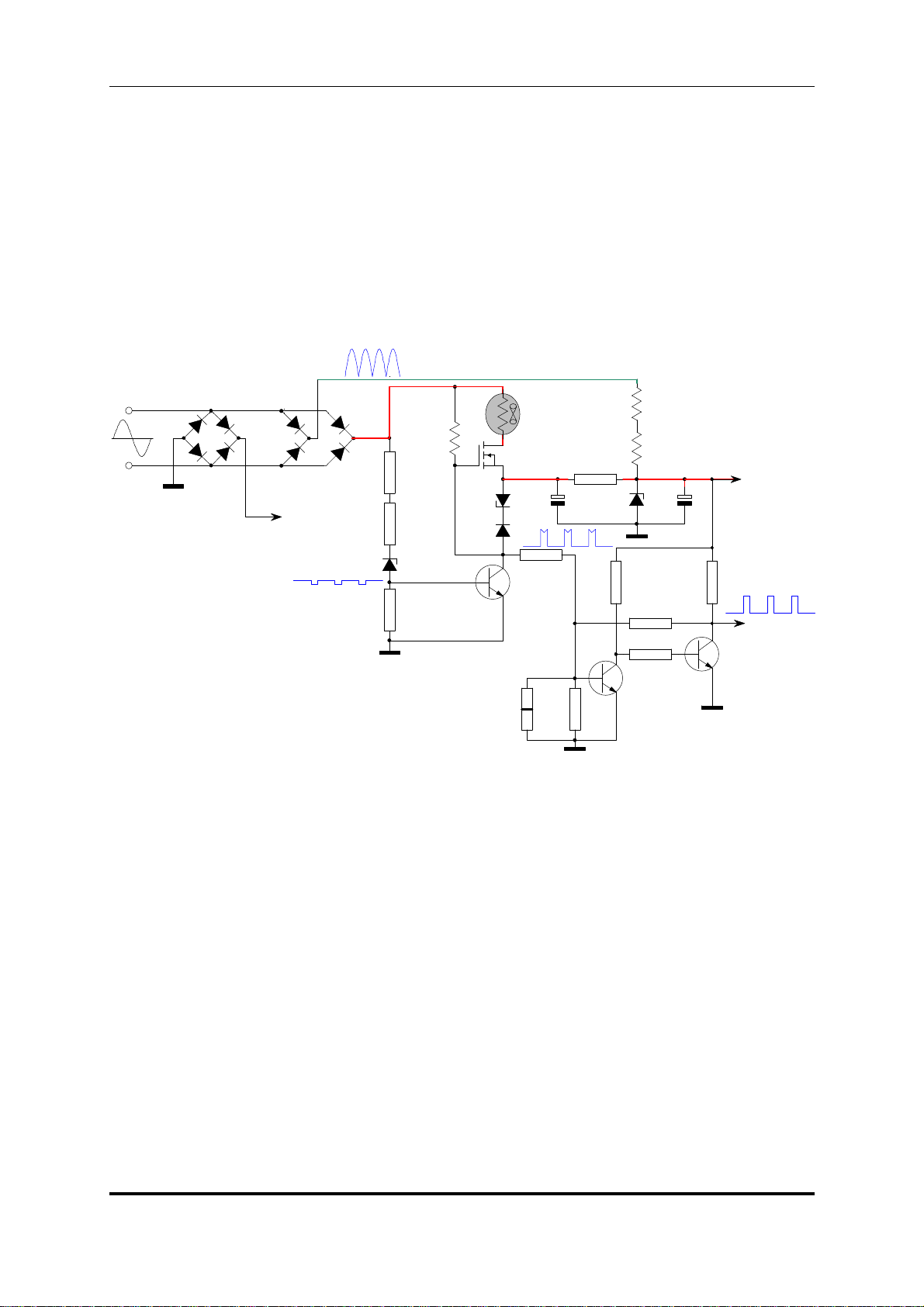

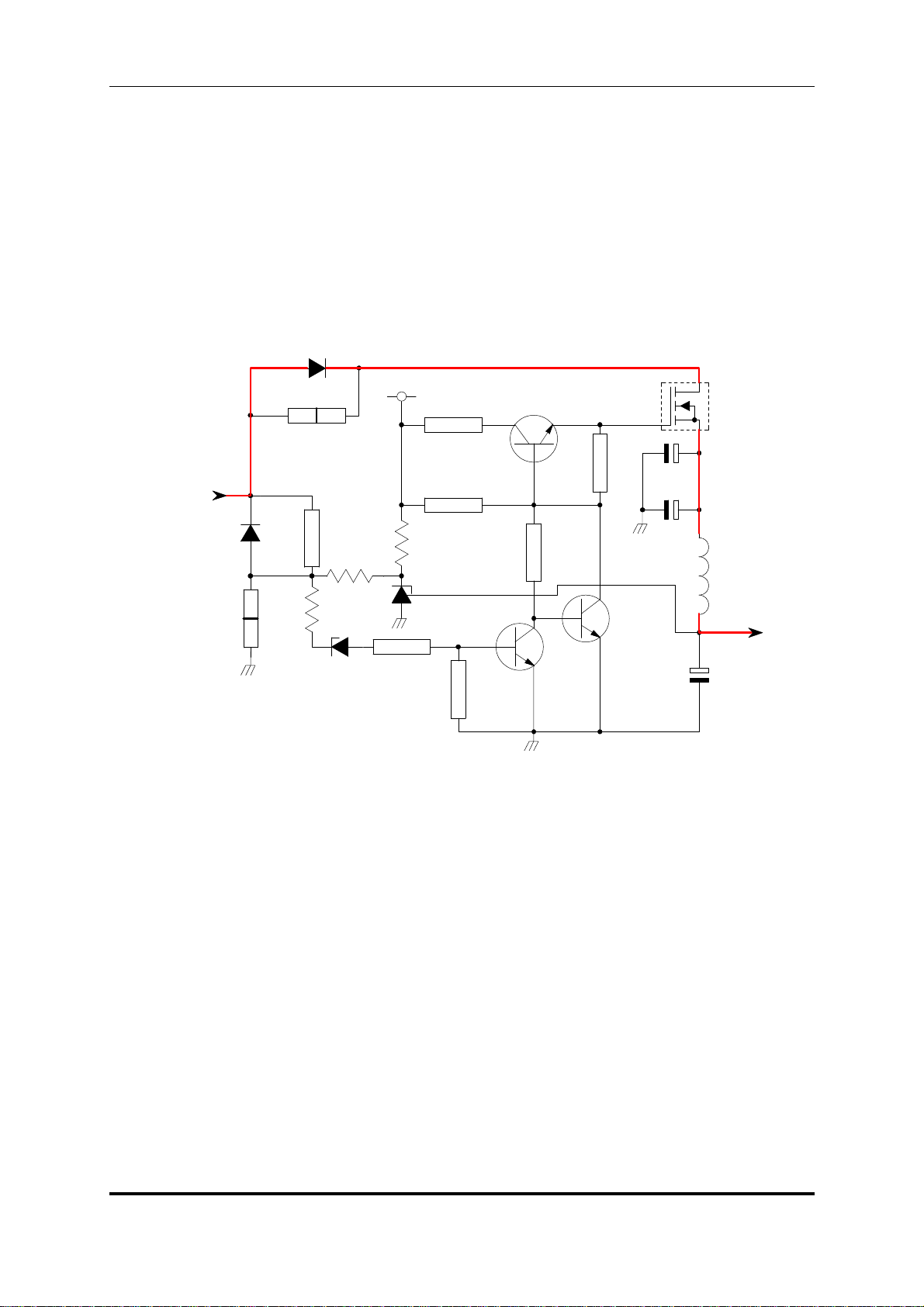

SLAVE PROCESSOR POWER SUPPLY

This part of the circuit has changed compared to previous chassis, where this supply was derived by

means of a bridge rectifier with two additional 68k resistors and a 5v1 zener diode to limit the voltage.

This has been replaced by a series regulator circuit, which is supplied from one side of the mains, with

an earth return via the bridge rectifier.

D708 and D707 forms part of a bridge rectifier, two diodes of the main bridge rectifier are used for the

other part. Therefore, at the junction of D707 and D708 there is a 100Hz signal comprising of positive

halve cycles at mains potential. Each time this signal exceeds 47v D729 will conduct, turning on

Q717.

D710

5v1

R738

47k

R737

180k

R721

150k

R703

150k

+5v

C724

220

R739

47k

R736

470k

Clock

D734

D731

HT

D707

D708

R774

470k

R775

470k

D729

47v

R776

82k

R771

470k

D732

15v

D733

Q717

Q715

C739

220

R770

220

R735

470k

C725

4n7

R777

47

Q708 Q709

R787

47k

When Q717 turns on the gate of Q715 is taken to ground. Since this is a N Channel MOSFET Q715 is

turned off and no current will flow through this device.

During the period when Q717 is turned off Q715 will turn on allowing C739 to charge to approximately

7v which is limited to 5v by R777 and D710.

It can now be seen that the period of Q715 conduction is very short (it is only turned on when the

100Hz signal at the junction of D707 and D708 is less than 47v). Therefore, a top-up supply from the

bridge rectifier circuit comprising of D734 and D731 is added to the cathode of D710 via R721 and

R703.

The 100Hz signal at the junction Q717 and D733 is also used as a timing signal for the real time clock

within the slave processor. However, before it can be used the signal is passed through a Schmitt

Trigger circuit (Q708 and Q709) to ensure that the signal free from noise.

Sharp Electronics (UK) Ltd

September 99 Page 3

Technical Support

Colour Television – DA100/DW100 Chassis

DEGAUSS CIRCUIT

This circuit is configured to ensure that the degauss circuit will not operated unless the switch mode

power supply is operating and IC702 pin 14 = low.

A positive bias is applied to the emitter of Q714 from T701 pin 15 (rectified by D727 and limited by

D728). Via the opto-coupler; IC708. Since Q714 is a pnp device once the base is taken low compared

to the emitter, Q714 will turn on allowing current to flow through IC708 (LED Section), turning on the

triac T702, allowing current to flow through the degauss coils.

N

L

D728

4v7

R768

220

R762

220

Q714

IC708

D727

T702

POR701

R763

100

From IC702

pin 14

From T701

pin15

C702

10nF

Degause

Coils

Current will continue to flow through the degauss coils until either the PTC (POR701) has increased in

value sufficiently to cut off the current flow, or IC702 pin 14 goes high, turning of Q714, preventing

current flow through IC708, turning the triac T702 off.

Since the default condition for IC702 = low, it can be seen that the degauss circuit should now operate

each time the CTV is turned on from the main on/off switch or switched from standby to normal

operation. Whether the main processor has set up communication with the slave processor or not.

Sharp Electronics (UK) Ltd

September 99 Page 4

Technical Support

Colour Television – DA100/DW100 Chassis

5V REGULATOR

This is another new circuit, but depending on whether you are dealing with the DA100 (4:3) chassis or

DW100 (16:9) chassis will determine the exact circuit.

DA100 (59ESD7H AND 66ESD7H) 4:3 CHASSIS

The FET Q704 is a series regulator producing 5v, which is controlled by Q713. A voltage is fed-back

from the output of Q704 (junction of L705 and C723) which will control the conduction of a variable

zener diode (IC707). D723, Q705 and Q706 provide protection against excessive supply voltage.

D722

From T701

pin 1

D714

C722

10nF

R707

1k5

R725

10k

C735

150pF

D723

2v7

R710

2k2

+16v

R731

10k

R726

22

R757

2k2

R706

8k2

IC707

R756

10k

Q713

R760

4k7

R729

4k7

Q705

Q704

C734

470

C721

470

L705

Q706

+5v

C723

2200

Sharp Electronics (UK) Ltd

September 99 Page 5

Technical Support