Page 1

64LHP5000

PROJECTOR UNIT

FINAL

SERVICE MANUAL

S29C764LHP5-P

REAR PROJECTION HDTV

MODEL

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored

to its original condition and only parts identical to those specified should be used.

64LHP5000

OUTLINE

1.This manual covers the 64LHP5000 Projector unit. The DTV Decoder is referred to in the DTV Unit Service

Manual that will be separately issued.

2.The Projector Unit Service Manual consists of two books: Issue No. S29C764LHP5-P and Issue No.

S29C864LHP5-P Use these two books together for serivicing.

CONTENTS

Page Page

〈

Issue No. S29C764LHP5-P

SPECIFICATIONS..............................................2

SAFETY INFORMATION...................................3

OPERATION MANUAL......................................6

ADJUSTMENT.................................................13

GENERAL INFORMATION..............................50

BLOCK DIAGRAMS.......................................102

SCHEMATIC DIAGRAM.................................108

PCB CONNECTION DIAGRAM.....................220

〉

〈

Issue No. S29C864LHP5-P

PARTS LIST

ELECTRICAL PARTS...............................244

CABINET AND MECHANICAL PARTS....320

PACKING OF THE SET.................................341

〉

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

1

Page 2

64LHP5000

PROJECTOR UNIT

Specifications

Display and amplifier section

Screen size ..................................................................... 64"

CRT.................................................. 7" High focus CRT x 3

Brightness (White peak) ......................... 400 Foot-Lamber t

[White window signal input contrast Max.]

without protective screen

Horizontal resolution.......................... More than 1400 lines

[Input digital test pattern (1400 lines resolution)]

Input terminals ...............................................4 video inputs

4 S-VIDEO input jacks (Y/C separate INPUT)

2 COMPONENT VIDEO INPUT jacks (Y, C

CENTER INPUT jack

Output terminals ..................................... MONITOR/AUDIO

Input terminal signal ratings

Input signal

Video signal:

Composite and S-VIDEO(Y): 1.0 Vp-p (75 ohms

load)

COMPONENT (Y):1.0 Vp-p (75 ohms load)

B/PB, CR/PR):0.7 Vp-p (75 ohms load)

(C

Audio signal (including CENTER): 500mV rms

Input impedance............................. Video input: 75 ohms

Audio input (including CENTER): 22 kilo-ohms

Input signal polarity (Video) ........ Synchronized negative

Output terminal signal ratings

Output signal .......... Video signal: 1 Vp-p (75 ohms load)

Audio signal: 500 mV rms (100 % modulation)

Output impedance ........................ Video output: 75 ohms

Audio output: Less than 1 kilo-ohms

Effective output

Front both channels driven............................. 15 W + 15 W

(THD. 1 % 1 kHz, 8 ohms)

Built-in speaker system ...... 16 cm (6-5/16 in) full range x 2

..............................................6.6 cm (2-9/16 in) tweeter x 2

DTV-OUT (NTSC)................... Audio: 2 Vrms (1 kHz, 0 dB)

Video: Composite Video; 1.0 Vp-p (Negative sync on), 75

Audio output

5.1 ch output..............................Front L/R, surround L/R,

center and subwoofer

Output connector: Pin-jack

Digital audio I/F . Optical digital output: Optical connector

Coaxial digital output........................................... Pin-jack

IR-MOUSE G-LINK Terminal x 1

Digital expansion port ............. For expansion input devices

B/PB, CR/PR)

4 audio inputs

or more

Tuner section

Circuit type...................................... Video signal detection:

PLL full synchronous detection

PLL digital synthesizer system

Audio multiplex: ATSC system

NTSC Reception channels

VHF; CH2–CH13, UHF; CH14–CH69

CATV (STANDARD, IRC or HRC)

CATV 1-125 CH

DTV reception channels

VHF: Low 54–88 MHz, High 174–216 MHz,

UHF: 470–806 MHz

Antenna terminals

................................... Antenna terminal, 75 ohms UNBAL,

F-type connector (VHF, UHF MIXED)

Electrical section, miscellaneous

Power requirements...................................120 V AC, 60 Hz

Power consumption ................................................... 400 W

External dimensions .... 1510 (W) x 698 (D) x 1425 (H) mm

59-7/16 (W) x 27-31/64 (D) x 56-1/8 (H) inch

Weight of main unit.............................. 167 kg (368 lb 4 oz)

NOTE:

Specifications and design are subject to possible modifications

without notice due to improvements.

2

Page 3

64LHP5000

PROJECTOR UNIT

SAFETY INFORMATION

This service manual is intended for qualified service technicians; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained to

properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the

warranty. If you are not qualified to perform the repair of this product properly and safely, you should not risk

trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of

California to cause cancer, birth defects or other reproductive harm.

Health & safety code section 25249.6—Proposition 65

NOTES

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must be

of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces de

remplacement doivent avoir la même désignation.

SAFETY PRECAUTIONS

NOTlCE: Comply with all cautions and safety related notes

located on or inside the cabinet and on the chassis or picture

tube.

The following precautions should be observed:

1. Do not install, remove, or handle the picture tube in any

manner unless shatterproof goggles are worn. People

not so equipped should be kept away while picture tubes

are handled.

Keep picture tube away from the body while handling.

2. When service is required, even though the PROJECTION MONITOR RECEIVER an isolation transformer

should be inserted between power line and the set in

safety before any service is performed.

3. When replacing a chassis in the set, all the protective

devices must be put back in place, such as barriers,

nonmetallic knobs, adjustment and compartment

covershields, isolation resistor-capacitor, etc.

4. When service is required, observe the original lead

dress.

Extra precaution should be taken to assure correct lead

dress in the high voltage circuitry area.

5. Always use the manufacturer’s replacement components. Especially critical components as indicated on the

circuit diagram should not be replaced by other

manufacture’s.

Furthermore where a short circuit has occurred, replace

those components that indicate evidence of overheating.

6. Before returning a serviced set to the customer, the service technician must thoroughly test the unit to be certain

that it is completely safe to operate without danger of

electrical shock, and be sure that no protective device

built into the set by the manufacturer has become defective, or inadvertently defeated during servicing.

Therefore, the following checks should be performed for the

continued protection of the customer and service technician.

Leakage Current Cold Check

With the AC plug removed from 120V AC 60Hz source,

place a jumper across the two plug prongs. Turn the AC

power switch on. Using an insulation tester (DC 500V), connect one lead to the jumpered AC plug and touch the other

lead to each exposed metal part (input/output terminals,

screwheads, metal overlays, control shafts, etc.), particularly any exposed metal part having a return path to the

chassis. Exposed metal parts having a return path to the

chassis should have a minimum resistor reading of 0.3MΩ

and a maximum resistor reading of 5MΩ. Any resistor value

below or above this range indicates an abnormality which

requires corrective action. Exposed metal parts not having a

return path to the chassis will indicate an open circuit.

3

Page 4

64LHP5000

PROJECTOR UNIT

Leakage Current Hot Check

Plug the AC line cord directly into a 120V AC 60Hz outlet ( do

not use an isolation transformer for this check). Turn the AC

power switch on.

Using a “Leakage Current Tester (Simpson Model 229

equivalent )”, measure for current from all exposed metal

parts of the cabinet ( input/output terminals, screwheads,

metal overlays, control shaft, etc. ), particularly any exposed

metal part having a return path to the chassis, to a known

earth ground (water pipe, conduit, etc.). Any current measured must not exceed 0.5mA.

Reading should

not be above

0.5 mA

Earth ground

Device

under

test

2-wire cord

Also test with

plug reversed

(Using AC adapter

plug as required)

Test all

exposed metal

surfaces

Leakage

current

tester

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS OUTLINED

ABOVE ARE INDICATIVE OF A POTENTIAL SHOCK HAZARD

AND MUST BE CORRECTED BEFORE RETURNING THE SET

TO THE CUSTOMER.

High V oltage

This set is provided with a X-ray protection for clearly indicating that voltage has increased in excess of a predetermined value. Comply with all notes described in this Service

Manual regarding this hold down circuit when servicing, so

that this X-ray protection may correctly by operated.

Serviceman Warning

In the status of the black picture ( video muting is being applied ) when no signal is input, high voltage of this set during

operation is less than 30.5kV. In case any component having some relation to the high voltage is replaced, confirm

that the high voltage is lower than 30.5kV in the status of the

black picture when no signal is input.

To measure H.V. use a high impedance H.V. meter.

Connect ( – ) to earth and ( + ) to the FBT anode cable connector.

(Refer to page 50)

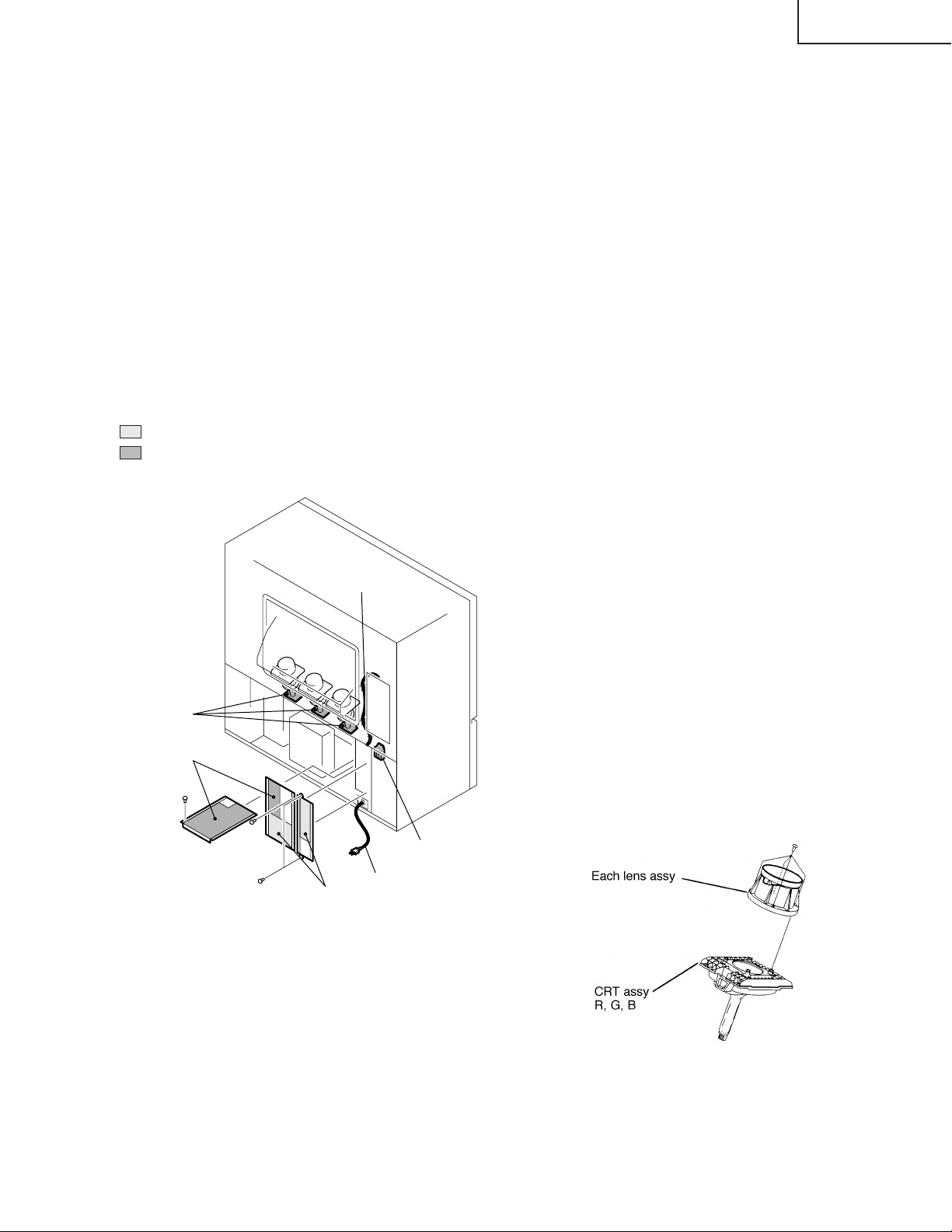

X-radiation

TUBE: The primary source of X-radiation in this set is the

picture tube.

For continued X-radiation protection, the replacement tube

must be the same type as the original, SHARP approved

type.

The picture tube (the CRT assy R, G, B ) use in this set

holds complete guarantee against X-ray radiation when the

X-ray is sealed (See page 5). Accordingly, when the current

in flowing to the picture tube (CRT assy R, G, B) be sure to

perform it by putting the tube into X-ray sealed applied state.

Avoid absolutely to flow the current to the picture tube (CRT

assy R, G, B) itself. Moreover, when the voltage of the high

voltage circuit becomes abnormally a little higher, the picture tube radiates X-rays. Accordingly, when servicing the

high voltage circuit be sure to replace as an assembly with

the DEFLECTION SERVICE assy in the manner in which

has been adjusted to perform normal operation.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in SHARP set have

special safety related characteristics. These are often not

evident from visual inspection nor the protection afforded by

them necessarily can be obtained by using replacement

components rated for higher voltage, wattage, etc. Replacement parts which have these special safety characteristics

are identified in this Service Manual.

Electrical components having such features are identified by

marking with a å on the schematics and on the parts list in

this Service Manual.

The use of a substitute replacement component which does

not have the same safety characteristics as the SHARP recommended replacement one, shown in the parts list in this

Service Manual, may create shock, fire, X-radiation, or other

hazards.

Product Safety is continuously under review and new instructions are issued from time to time. For the latest information, always consult the current SHARP Service Manual.

A subscription to, or additional copies of SHARP Service

Manual may be obtained at a nominal charge from SHARP.

4

Page 5

CHARGED SECTION, HIGH VOLTAGE GENERATING POINT

AND X-RAY PROTECTION

Ë

Charged section

The circuit in which the commercial AC power is used as it

is without passing through the power supply transformer. If

the charged section is touched, there is a risk of electric

shock. In addition, the measuring equipment can be damaged if it is connected to the GND of the charged section

and the GND of the non-charged section while connecting

the set directly to the commercial AC power supply. In this

case, be sure to connect the set via an insulated transformer

and supply the current.

Ë

Charged section

(Power supply primary side)

1. The primary side of the AC IN assy

2. AC power cord

3. The primary side of the POWER SUPPLY assy

4. AC power cord for DTV STB

: Part is the charged section.

: Part is the high voltage generating

points other than the charged section.

AC power cord for

DTV STB

High Voltage

generating point

High Voltage

generating point

Ë

High voltage generating point

The place where voltage is 100V is generated.

1. Charged seciton

DEFLECTION assy

(including FBT) (30.5kV, 1.2kV, 210V,135V)

2. POWER SUPPLY assy (135V)

3. R. CRT DRIVE assy (10.5kV, 210V)

4. G. CRT DRIVE assy (10.5kV, 210V)

5. B. CRT DRIVE assy (10.5kV, 210V)

6. CRT assy R (CRT service assy R) (30.5kV)

7. CRT assy G (CRT service assy G) (30.5kV)

8. CRT assy B (CRT service assy B) (30.5kV)

9. Focus variable resistor(VR1) (10.5kV)

10. Deflection yokes (L1, L2 and L3) Approx. (1100V at peak)

Ë

X-ray protection

• Regarding the parts which are relative to radiation of X-

rays (There is the danger to radiate X-ray from the individual CRT assy R, G, B), there are notifications of caution in the individual schematic diagrams. Be sure to read

them for safety’s sake.

• The component parts for X-ray protection are as follows :

When the current flows to the CRT assy R, G, B, be sure

to perform it with these parts being attached. Protection

from the X-ray radiation is maintained in the state in which

these parts have been installed to the CRT assy. R, G, B.

Accordingly, never supply current only to the CRT assy R,

G, B.

Moreover, the anode voltage of the CRT assy R, G, B

should always be kept not higher than the predetermined

value (in the minimum brightness and picture state when

non signal input is less than 30.5kV). Be sure to drive the

CRT assy R, G, B by using a completely functional DEFLECTION assy which have been adjusted completely in

the combined state. (When the voltage abnormally becomes high, the X-ray protection circuit will operate.)

1. CRT assy R, G, B (Do not dismantle CRT assemblies

under any circumastances)

2. Each Lens assy

64LHP5000

PROJECTOR UNIT

High Voltage

generating point

AC Power cord

Charged section

Fig. 1 Charged section and high voltage generating point

Fig. 2 Component parts for X-ray protection

5

Page 6

64LHP5000

POWER

STANDBY/ON

INPUT CH RETURN

POWER/

DOWN LOAD

TIMER OPC

PROJECTOR UNIT

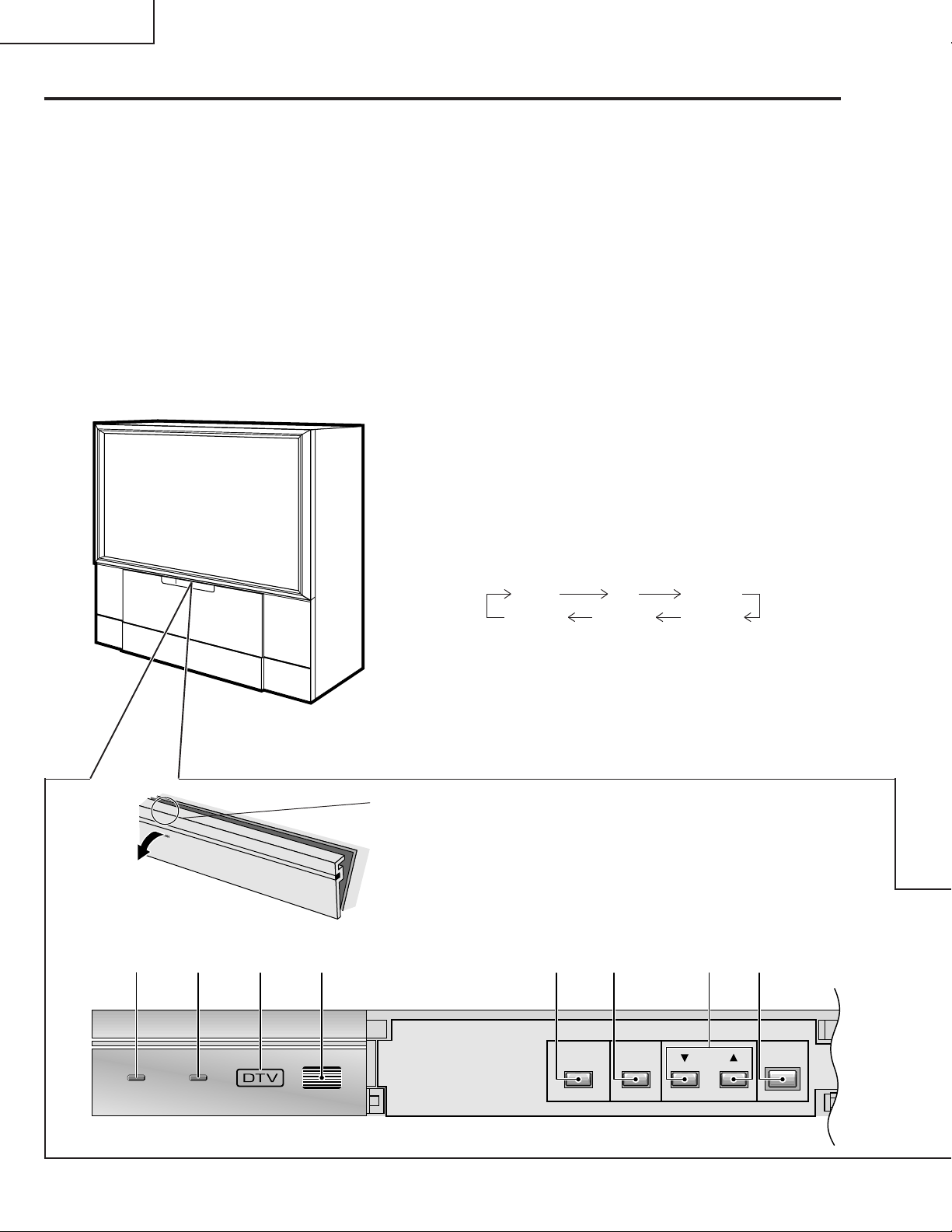

Front Panel Functions

A flip-down door conceals the control panel. Push gently

and release, to open the door. To close the door, lift it back

up into place.

NOTE:

If you accidentally pull the door, it may not shut properly. Push the

door back in to shut it.

1 POWER/DOWNLOAD indicator

Lights when power is on. Flashes when downloading the

GUIDE Plus+ program information.

2 Timer indicator

Lights GUIDE Plus+ timer is set.

3 DTV indicator

Lights when receiving a digital television broadcast.

Flashes when downloading the DTV program information.

(DTV indicator may still blink even when the power has

been turned off. This is not a defect.)

4 OPC sensor

Sensor to detect the room brightness.

5 POWER button (ST ANDBY/ON)

Press once to turn on the Rear Projection HDTV. Press

again to turn off the Rear Projection HDTV.

NOTE:

When the Rear Projection HDTV is turned on in DTV mode, it may take

several seconds before the DTV image is displayed. This is not a

malfunction.

6 INPUT button

Press to select your program source. Each press of the

INPUT changes the selection to the next source.

TV DTV INPUT 1

INPUT 4 INPUT 3 INPUT 2

7 CHANNEL b uttons

Press plus ' or minus " to tune to a higher or lower

channel. Only the preset channels can be tuned in using

these buttons.

8 RETURN b utton

Press to set the Rear Projection HDTV to its initial mode.

In some cases, the door may only open slightly when

pushed.

In such cases, open the door with your finger as shown in

the figure at left.

51 2 3 4 6 7 8

6

Page 7

64LHP5000

VOL

S-VIDEO

INPUT 4

VIDEO L-AUDIO-R

(MONO)

PROJECTOR UNIT

FRONT PANEL FUNCTIONS

Initial mode

Input selector: Set to TV.

TV channel: Remains at the last channel set.

VOLUME: Remains at the last setting.

MUTING: OFF

VIDEO

MODE: STD

Parameters: Set to 0.

3D Y/C LEVEL: 3

3D NR LEVEL: 3

CNR: OFF

FAV. COLOR: STD.

FLESH TONE: ON

AUDIO

MTS: MAIN

Parameters: Set to 0.

SURROUND: OFF

VIEW

AUT O VIEW: OFF

MODE: SMART STRETCH

V. POSITION: Set to 0.

CC: OFF

OPC: OFF

SYSTEM IN/OUT

SPEAKER: NORMAL

AUDIO OUT: FIXED

CAUTION:

Do not press any operation button on the Rear Projection

HDTV or the remote control unit while recording. Signals

from the MONITOR OUTPUT jacks may be temporarily

interrupted when a button is pressed.

ATTENTION

The Rear Projection HDTV Receiver will not function

properly in the following cases.

• An electrical discharge in the CRT.

• Lightning storms.

• High static electricity environment.

• Poor voltage regulation in the power source.

If the Rear Projection HDTV does not operate properly,

reset it as follows:

1. Unplug the AC cord.

2. After approximately 1 minute, turn on the power with

switch and 5 POWER button.

NOTE:

On rare occasions, an electrical discharge may occur inside the

CRT. It makes a short, sharp pop and either no sound is produced

or the volume level changes by itself. The TWIN PICTURE and

SEARCH SCREEN function will be cancelled automatically if an

electrical discharge occurs when this function is engaged.

• When this button is pressed while adjusting the

outer point convergence, the outer point

convergence returns to the initial mode.

9 VOLUME buttons

Press plus (+) button to increase the volume, press minus

(–) button to decrease it.

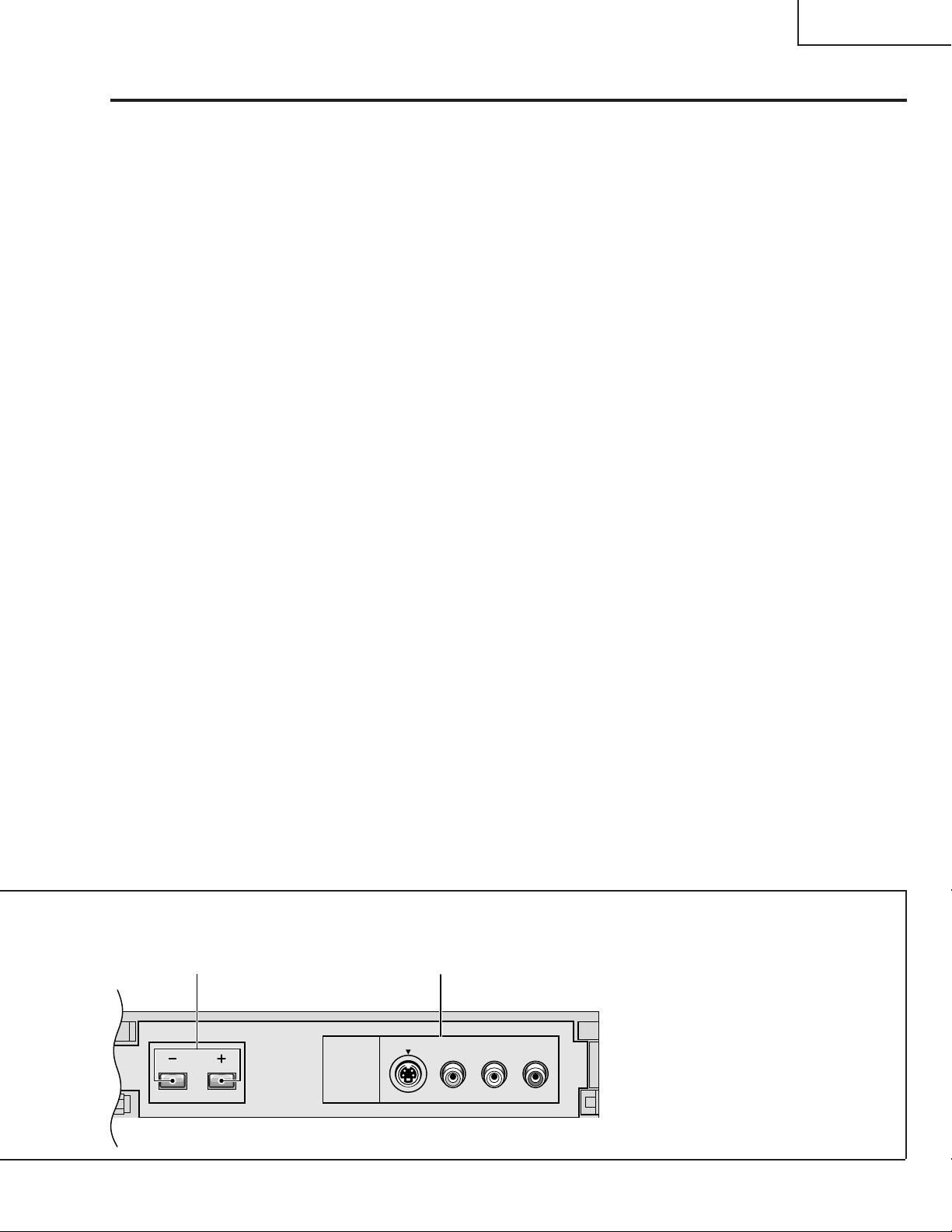

0 INPUT 4 jac ks

These inputs are for Video Movie and VCR. Use RCA-type

pin plug cords (the same as those used in Hi-Fi systems)

and S-VIDEO cords for connections. When the audio

source to be connected is monaural, connect the source to

the L-(MONO) jack.

9 0

7

Page 8

64LHP5000

PROJECTOR UNIT

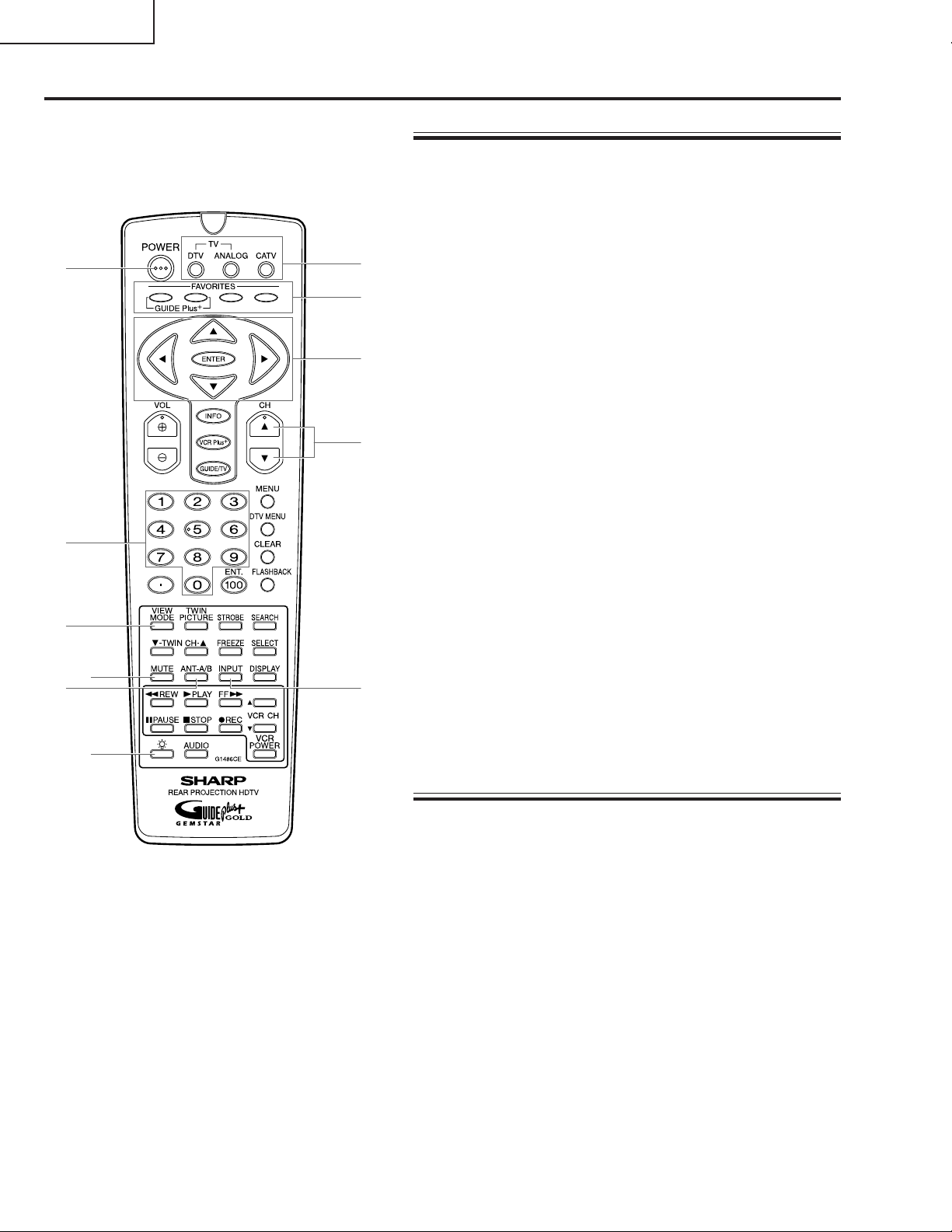

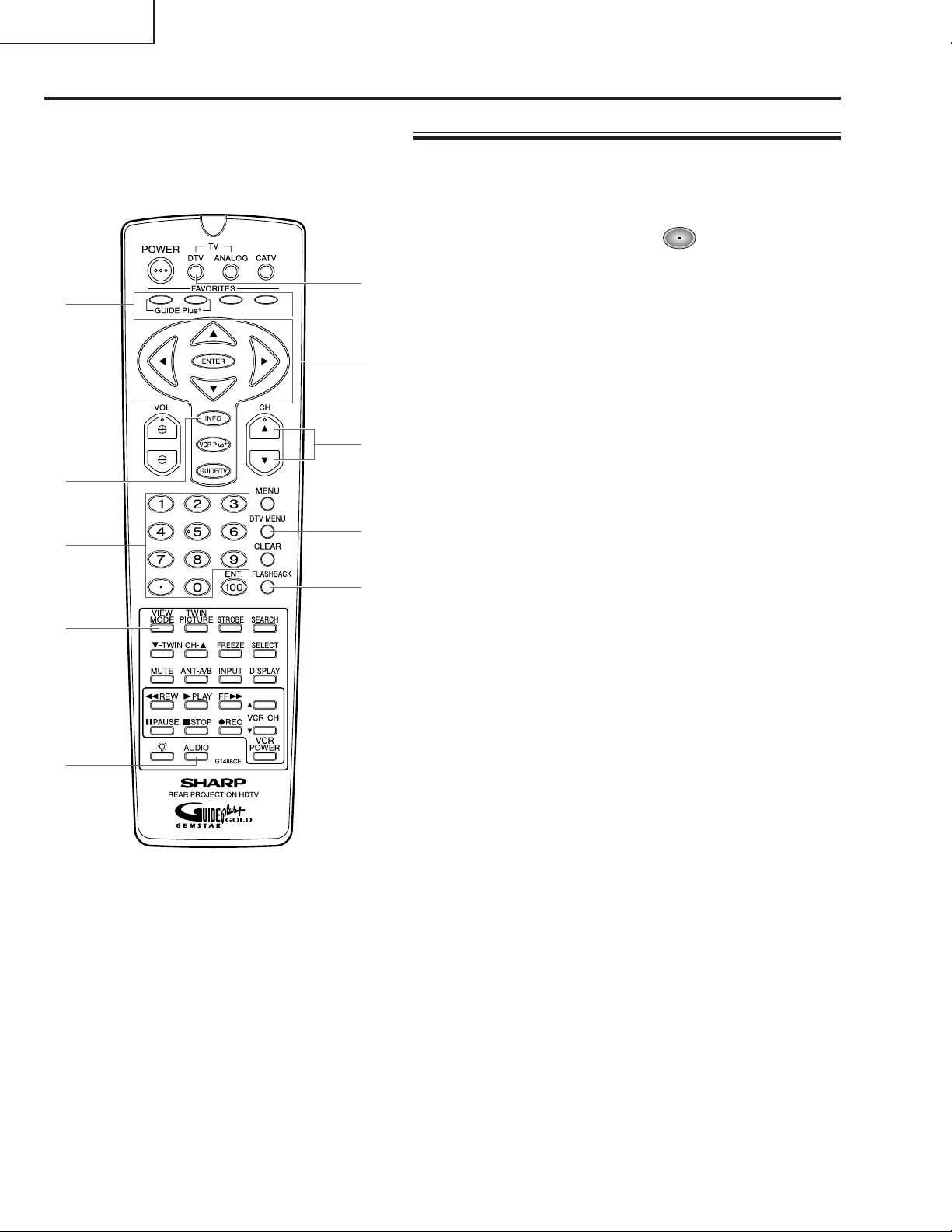

Remote Control Unit Functions

1

0

MONITOR (TV) CONTR OL B UTT ONS

1 POWER button

Turns the power of the Rear Projection HDTV on and off.

2 Input button (TV, DTV, INPUT 1 to INPUT 4)

Press the button to select the source you wish to watch. The screen

will display your selection.

5

3

4

7

9

8

6

2

3 VIEW MODE button

Press to select the VIEW MODE.

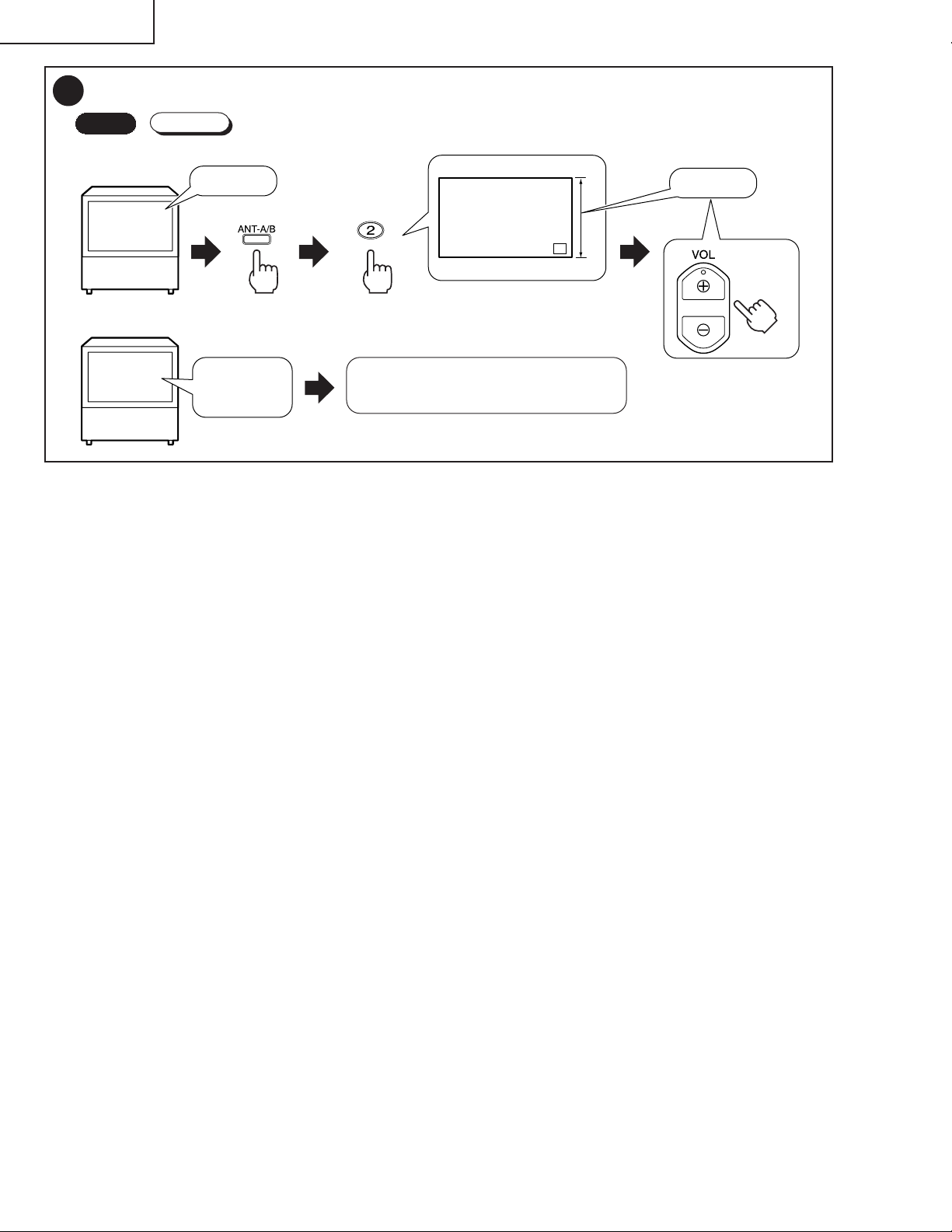

4 ANT-A/B button

Press to switch between ANTENNA-A and ANTENNA-B when you

wish to watch TV.

5 Direct channel selection buttons

Press the button (or buttons) that corresponds to the channel that

you wish to watch.

6 CH (channel) ', " button

Press plus ' or minus " to tune in a higher or lower channel. Only

the preset channels can be tuned in using these buttons.

7 MUTE button

Press to temporarily turn off the sound. Press again to return to the

previous volume level.

8 Cursor/ENTER buttons (ENTER, \, |, ', ")

\, |, ', ": Press to select or adjust items on the menu screen.

ENTER: Press to activate the selected function.

9 FAVORITES buttons

These buttons call up the channels that have been assigned to

them.

q

REMOTE CONTR OL UNIT SETTING BUTTONS

0 Remote control mode select buttons

Use to switch the remote control unit modes.

q Light button

When this button is pressed, some buttons on the remote control

unit will light. The lighting will tur n off if no operations are performed

within about six seconds.

This button is used for performing operations in dark places.

8

Page 9

a

t

s

p

i

o

u

64LHP5000

PROJECTOR UNIT

w TWIN PICTURE/SEARCH screen buttons

TWIN PICTURE: Press to turn the TWIN PICTURE screen function

on and off.

STROBE: Press to turn the STROBE screen on and off.

SEARCH: Press to select the SEARCH screen mode.

SELECT: Selects the screen for switching the channel or

input source.*

FREEZE: When this button is pressed with the regular

screen, the screen will change to the TWIN

PICTURE screen and the picture at the time the

button was pressed will become the sub-picture,

displayed as a frozen image.

"-TWIN CH-': Used to switch the channel for the sub-picture of

the TWIN PICTURE screen.

e DISPLAY button

Turns the screen indicators for the input source, channel, setting,

and they will appear for a few seconds.

r FLASHBACK button

Press to switch between the current channel and the channel you

were watching immediately before.

1

y

r

w

e

t VOL (volume) +, – buttons

Press plus (+) button to increase the volume, press minus (–) button

to decrease it.

Volume level will appear on the screen as numbers and a bar graph.

The maximum volume level is “63”.

The display will disappear from the screen after 2 seconds.

y MENU button

Press to turn on the menu screen for use in function selection.

Press again to return to normal TV screen.

u GUIDE/TV button

i INFO button

o VCR Plus+ button

p ENTER button

a ACTION button

s

The buttons of u-s listed above are GUIDE Plus+ buttons.

button

*1 With the 9-SEARCH screen, the search picture’s input source

and channel cannot be switched.

9

Page 10

64LHP5000

PROJECTOR UNIT

DTV CONTROL BUTT ONS

1 AUDIO button

Press to select the audio mode during multiaudio broadcasts.

5

9

2

0

6

4

3

8

7

2 Direct channel selection buttons,

Press the buttons that corresponds to the channel that you wish to

watch.

3 CH (channel) ', " button

Press plus ' or minus " to tune in a higher or lower channel.

4 Cursor/ENTER buttons (ENTER, \, |, ', ")

\, |, ', ": Press the button to select items on the DTV MENU

screen.

ENTER: Press to activate the selected function.

5 FAVORITE CH/Colored (blue, green, red and yellow) buttons

FAVORITE CH: Used for making FAVORITE CH settings for the

DTV.

Blue, Green, Red, Yellow: Used to make selections from the DTV

menu.

6 DTV button

Tur ns the TV to the DTV mode.

7 FLASHBACK button

Press to switch between the current channel and the channel you

were watching immediately before.

8 DTV MENU button

When this button is pressed, the DTV menu screen will be

displayed.

button

1

9 INFO button

When this button is pressed, information on DTV will be displayed.

0 VIEW MODE button

Adjust picture size.

10

Page 11

64LHP5000

PROJECTOR UNIT

CABLE CONTROL BUTT ONS

Cable converters which are made by other makers and are not

preset can also be operated using the remote control unit if buttons

1 to 2 have learnt the functions.

1 Direct channel selection buttons

Press the button (or buttons) that corresponds to the channel that

you wish to watch.

2 CH (channel) ', " buttons

Press plus ' or minus " to tune in a higher or lower channel.

3 ENTER button *

Fix the selected channel with the direct channel selection buttons.

1

2

3

* Some manufacturers do not preset ENTER.

11

Page 12

64LHP5000

PROJECTOR UNIT

VCR CONTROL BUTT ONS

If the VCR is preset by OPERATION OF REMOTE CONTROL, the

remote control unit button will function as follows when the mode

switch of the remote control unit is set to VCR.

When the input button having the same number as the input

terminal connecting the VCR is pressed, the VCR can be operated

using buttons 1 to 9.

VCR which are made by other makers and are not preset can also

be operated using the remote control unit if buttons 1 to 9 have

learnt the functions.

1 Numeric buttons

Use to enter two-digit code numbers when identifying your VCR.

2\\ REW

Press to rewind a tape. For some VCRs you may need to press

STOP first, then REWIND.

In Playback mode, hold button down to view picture moving

rapidly in reverse.

1

2

3

4

5

6

7

8

9

3| PLAY

Press to play back a tape.

4â PAUSE

Press to temporarily stop the tape during playback or recording.

Press again to release Pause.

5Ë STOP

Press to stop the tape.

6Æ REC

Press to begin recording.

7 FF ||

Press to rapidly advance the tape. For some VCRs, you may

need to press STOP first, then FF.

In Playback mode, hold button down to view the picture moving

rapidly in forward direction.

8 VCR CHANNEL UP (')/ DOWN (")

Press to scan up or down through the channels on the VCR.

9 VCR POWER Æ

Press to turn the VCR on and off.

12

Page 13

ADJUSTMENT

Ë

Key Indication of the Remote Control Unit

64LHP5000

PROJECTOR UNIT

CONVER GE:

GV (Green, Vertical)

GH (Green, Horizontal)

BV (Blue, Vertical)

• Adjustment Items

Adjustment

RANGE

OFFSET

Adjustment

Name

CUT-R

VOL0

Color

TINT

Contrast

Bright

Sharpness

3D YC,

3D NR Level

Detail

VOL20

S.V .M

VOL30

DRV-R

S.V .M

DRV-B

NU

MERIC

KEYS

Cyclically

ADJUSTMENT

ITEMS

STATIC

SKEW

3D SKEW

5D SKEW

BOW

4D BOW

6D BOW

SUB KEY

M S KEY

3S KEY

M 3S KEY

KEY

MID KEY

3D KEY

M 3D KEY

SUB PIN

M S PIN

4S PIN

M 4S PIN

PIN

MID PIN

4D PIN

M 4D PIN

LIN

MID LIN

6D LIN

SIZE

MID SIZE

5D SIZE

RANGE:

SRS ON/OFF

TRU ON/OFF

RH (Red, Horizontal)

RV (Red, Vertical)

BH (Blue, Horizontal)

TYPE

GH GV RH RV BH BV

OFFSET:

CUT-G

CUT-B

(Data Value)

VOL – VOL +

13

Page 14

64LHP5000

PROJECTOR UNIT

Ë

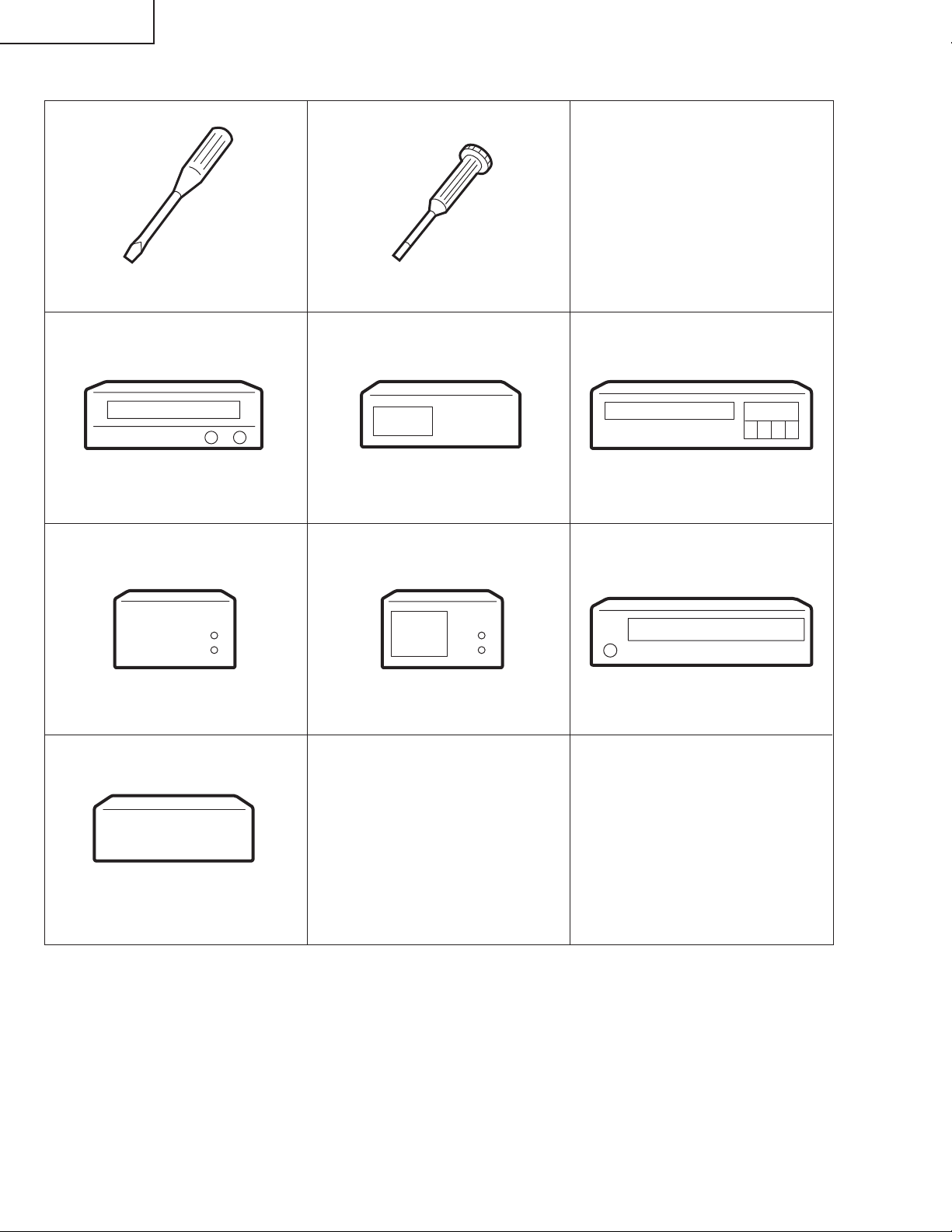

Jigs and Measuring Instruments

· Screwdriver · Adjustment screwdriver

Color bar generator D.DC. Volt meter LD player

Monoscope Dual trace oscilloscope Frequency counter

For HD Signal generator

14

Page 15

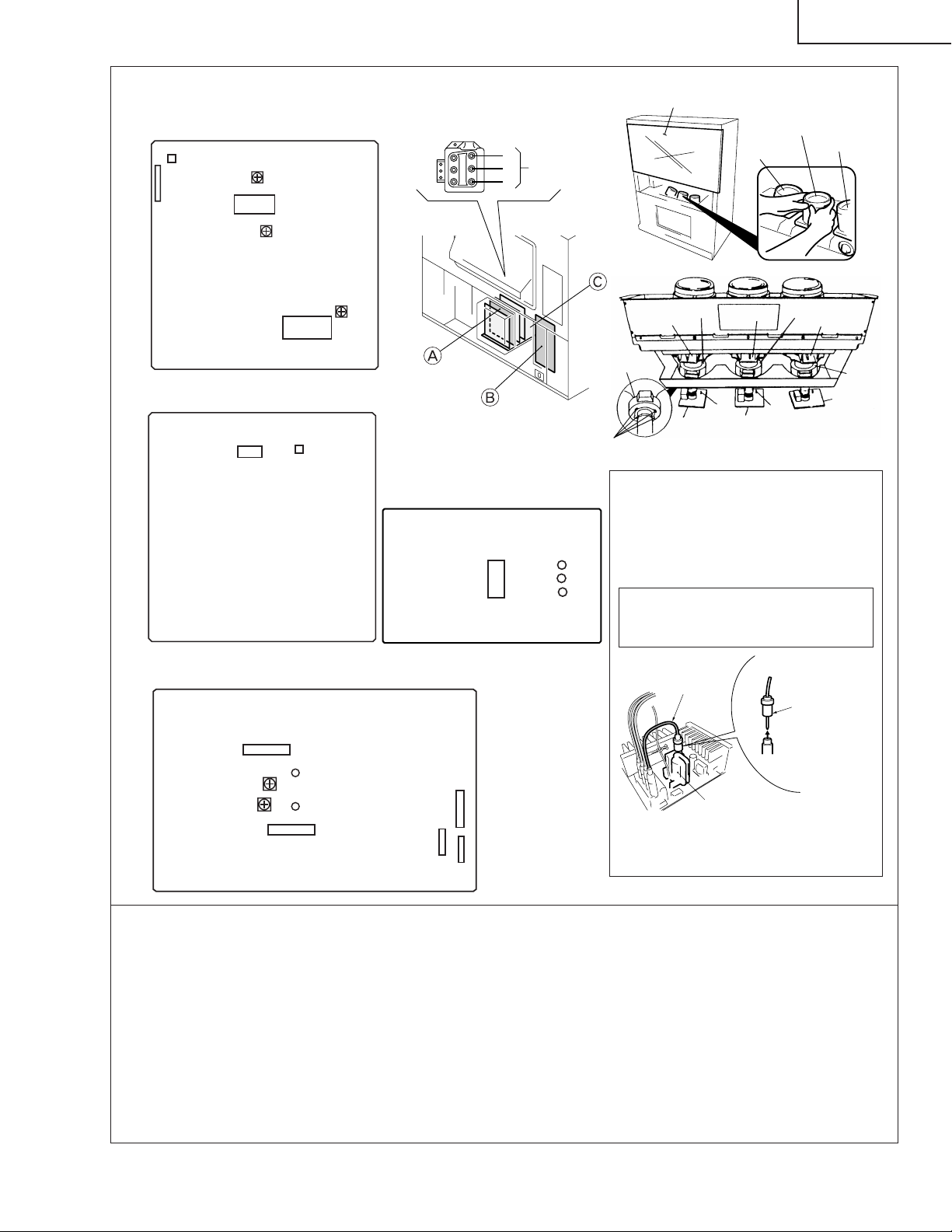

Ë

Assembly Adjustment Location and Items

A TUNER • µ-COM ASSY (A SIDE)

K2702

J2703

VR2701

916

IC2701

18

VR2801

FOCUS VR (VR1)

B

G FOCUS VR

R

Translucent paper such as tracing paper

Lens assy

(For Red)

64LHP5000

PROJECTOR UNIT

Lens assy

(For Green)

Lens assy

(For Blue)

52 27

IC2202

126

TUNER • µ-COM ASSY (B SIDE)

IC2702

14 8

71

Q2708

B POWER SUPPLY ASSY

IC207

91

VR201

VR202

TP201

TP204

91

IC201

L2202

C VIDEO ASSY (A SIDE)

IC5251

12856

15

1

1

1

11

10

P5252

29

P5254

Deflection

yoke (B)

CRT assy B

Deflection

yoke

B CRT DRIVE

Centering magnet

(Turn in either direction untill cross signal becomes white.)

assy

TP-BK

CRT assy G

G CRT DRIVE

assy

MEASURING METHOD

Disconnect the FBT anode cable as shown below.

Measure at the point where the cable enters the FBT.

Caution: Take extra precaution when measuring the

voltage. High voltage are also present in

surrounding circuit boards. (CRT DRIVE assy,

P5253

POWER SUPPLY assy).

SERVICEMAN W ARNING

Before removing the anode cable, turn off the power,

unplug the AC plug and let the unit discharge for more

than 1 minute.

Anode cable

FBT

Note:

When reconnecting the cable, proceed in the reverse

order. After reconnecting, tug on the cable to check

that it is secure.

TP-GK

Deflection

yoke (G)

CRT assy R

Pull straight up

Deflection

yoke (R)

R CRT DRIVE

assy

!Power supply adjustment

@Contrast coarse adjustment

#Brightness adjustment (PIONEER’s standard settings)

$Deflection yoke lean adjustment

%Screen center adjustment

^Focus adjustment of lens assy

&Focus VR adjustment

*Vertical size adjustment

(Horizontal size adjustment

)Convergence adjustment

QTest cross H-center position adjustment

WTuner block adjustment

EWhite balance adjustment

RPIONEER’s standard settings

TSide panel adjustment (Screen size 4:3)

YSPLIT screen adjustment

15

Page 16

64LHP5000

PROJECTOR UNIT

Ë

Assembly Adjustment Location Guide

If POWER SUPPLY ASSY

B

is repaired

1

Power supply adjustment

If DEFLECTION ASSY

If VIDEO ASSY

C

If TUNER µ-COM ASSY

A

If AMP ASSY

is repaired or replaced

is repaired or replaced

the µ-COM block

is repaired

(*1)

the tuner block

is repaired or replaced

is replaced

is replaced

No adjustment is required

7

Focus VR adjustment

8

Vertical size adjustment

9

Horizontal size adjustment

10

Convergence adjustment

13

White balance adjustment

3

Brightness adjustment

13

White balance adjustment

14

SHARP's standard settings

15

Side panel adjustment

2

Contrast coarse adjustment

3

Brightness adjustment

11

Test cross H-center position adjustment

14

SHARP's standard settings

12

Tuner block adjustment

All the above adjustments except for the test-cross H-center

11

position adjustment and tuner adjustment are required.

8

Vertical size adjustment

9

Horizontal size adjustment

10

Convergence adjustment

3

Brightness adjustment (SHARP's standard settings)

If R, G or B CRT DRIVE ASSY

If CRT ASSY

If LENS ASSY

is repaired or replaced

R, G, B or deflection yoke is replaced

is replaced

13

White balance adjustment

4

Deflection yoke lean adjustment

5

Screen center adjustment

7

Focus VR adjustment

10

Convergence adjustment

13

White balance adjustment

14

SHARP's standard settings

6

Focus adjustment of lens assy

10

Convergence adjustment

Check white balance. If the best screen is not obtained, adjust

If SIGNAL ASSY

If SUB VIDEO ASSY

If CONVER. DAC ASSY

If OTHER ASSY

is repaired or replaced

is repaired or replaced

is repaired or replaced

is repaired or replaced

13

White balance adjustment

16

SPLIT screen adjustment

13

White balance adjustment

14

SHARP's standard settings

10

Convergence adjustment

No adjustment is required

(*1) When replacing the tuner u-com assembly, mount the IC2204 (24LC32A:E2 PROM)on the current assembly to the new one to facilitate

adjustments.

16

Page 17

64LHP5000

PROJECTOR UNIT

Ë

Factory ADJ Mode

Select 1st FACTORY ADJ Mode

Start

“ON”

Front panel

Push the

switch with

thin rod.

Start

1st FAC

Selecting the mode for adjustment operations.

2

4

.................. Start adjusting

............ Select 1st factory adjustment mode, then adjust.

Normal

picture

Cyclically

2nd FACTORY ADJ

mode

picture

1

(MUTE) (MUTE)

STD OFFSET mode

(MUTE)

GENCE mode (ENTER)

(MUTE)

(∞ DOWN)

Telop : Blue

MANUAL CONVER-

Telop : White

AUTO ADJ mode

( LEFT)

Telop : White

1st FACTORY ADJ

mode

picture

RANGE CHECK mode

(MENU ON)

Telop : Red

The 2nd factory adjustment

mode is not used in the

adjustment.

PANEL ADJ mode

(FLASHBACK)

Telop : Yellow

(MUTE)

ADJUSTMENT SIZE

mode (ANT-A/B)

Telop : Green

(MUTE)

ADJUSTMENT MPX mode

(P IN P ON/OFF) (TWIN PICTURE)

Telop : Magenta

5

3

7

(MUTE)

Not used in the

adjustment

EPG CHECK mode

Note :

The brackets ( ) show the operation key.

TEST mode

( RIGHT)

Telop : Green

(GUIDE/TV)

Telop : Yellow

DTV PANEL mode

Telop : Yellow

(DTV)

SIGNAL ADJ mode

OTHERS OFFSET

(FF )

Telop : White

mode (XXXA)

Telop : -----

6

8

17

Page 18

64LHP5000

PROJECTOR UNIT

Adjustment Range Mode

1

Start

ADJUSTMENT

VOL 20

1st FAC

PD5462A RANGE

ADJUSTMENT

COLOR, BASS CNT

<VOLUME>

PD5462A RANGE

Telop : Red

: Vol 20

: Vol 30

: Vol 0

Picture quality, eyc., Change amount check made operating.

: COLOR,

BASS

: TINT,

TREBLE

: CONTRAST,

BALANCE

: BRIGHT

: SHARP-

NESS

: DETAIL

: S.V.M

TINT SHARPNESS

Center

CNT

The color to purple

MIN

The color to green

MAX

CNT

MIN

Cyclically

MAX

Center

Sharp

Soft

Adjustment OFFSET Mode

2

Start

1st FAC

STD

: STD OFFSET (NTSC)

: COMP (31kHz, 33kHz) OFFSET (HD)

: COMP (15kHz) OFFSET

(NTSC Component)

<Data value section>

COLOR

Telop : Blue

OFFSET

–24

Data value

This mode is to set the standard picture quality for a normal picture.

<Picture quality>

: COLOR (–64 to 63)

: TINT (–64 to 63)

: CONTRAST (–64 to 63)

: BRIGHT (–128 to 127)

: SHARPNESS (–128 to 127)

: DETAIL (–128 to 127)

: VM (–128 to 127)

: DRV-R (–64 to 63)

: DRV-B (–64 to 63)

: CUT-R (–128 to 127)

or

: CUT-G (–128 to 127)

18

: CUT-B (–128 to 127)

Page 19

3

64LHP5000

PROJECTOR UNIT

Size Mode

Start

1st FAC

<Size mode>

• Mode for roughly adjusting the horizontal and vertical sizes of the main deflection.

• In this mode, the color is green only, screen size is FULL and the contrast is

+10.

• The above settings are cleared when this mode is exited.

<Data value section>

ADJUSTMENT

H SIZE –24

Size mode

CH + : H PHA

or

(31 kHz)

CH – : H PHA

(33 kHz)

Telop : Green

: H Size

: V Size

: P HA

Screen mode

FULL SIZE

Data value

For

service

or

(–128 to 127)

Table on H SIZE and V SIZE data

Picture quality mode

NATURAL

ZOOM

CINEMA

FULL

FULL (MD)

A, B: are adjustment values.

D: Fixed value.

H SIZE

A

A

A

A

A+D

V SIZE

B

B

B

B

B

<View mode>

Table on H PHA data

: FULL (HD) H SIZE and

fixed value D can be

varied.

FULL ZOOM CINEMA WIDE

FULL (HD) NATURAL WIDE

PHA

Component input

(INPUT1, INPUT2)

DTV

(NTSC system)

15 kHz 31 kHz 33 kHz

CEFG C

C: Adjustment value

G: Fixed value

E, F: Fixed value + arbitrary service values

Others

19

Page 20

64LHP5000

PROJECTOR UNIT

4

Convergence Setting Mode

Start

1st FAC

<Variety section>

ADJUSTMENT

GV STATIC

Adjustment item

Variety

GV (Green, vertical)

GH (Green, horizontal)

BV (Blue, vertical)

Telop : White

Cyclically

Screen mode

FULL

–120

–128~127

Data value

RH (Red, horizontal)

RV (Red, vertical)

BH (Blue, horizontal)

<Data value section>

oror

ADJUSTMENT FULL

GV STATIC

–120

Data value

<Adjustment item section> <View mode>

STATIC (H, V)

SKEW 3D SKEW 5D SKEW

BOW 4D BOW 6D BOW

SUB KEY M S KEY 3S KEY

KEY MID KEY 3D KEY

SUB PIN M S PIN 4S PIN

PIN MID PIN 4D PIN

LIN MID LIN 6D LIN

SIZE MID SIZE 5D SIZE

M 3S KEY

M 3D KEY

M 4S PIN

M 4D PIN

<CRT control>

: Red ON/OFF

: Green ON/OFF

: Blue ON/OFF

FULL ZOOM CINEMA

WIDE

FULL (HD) NATURAL

WIDE

20

Page 21

5

Panel Adjustment Mode

64LHP5000

PROJECTOR UNIT

Start

1st FAC

• Mode for adjusting the brightness, width, and position of the gray part (panel) of

the 4:3 normal screen.

<Data value section>

ADJUSTMENT

Telop : Yellow

PANEL

–24

BRIGHT

Data value

<Adjustment item section>

6

DTV Panel Adjustment Mode (When option is mounted)

or

: BRIGHT (–64 to 63)

: CONTRAST (–64 to 63)

: WIDTH (–128 to 127)

: POSITION (–128 to 127)

Start

1st FAC

ADJUSTMENT

Telop : Yellow

DTV PANEL

–24

BRIGHT

Data value

• Mode for adjusting the brightness, width, and position of the gray part (panel) of

the 4:3 normal screen of the DTV tuner.

<Data value section>

or

<Adjustment item section>

: BRIGHT (–64 to 63)

: CONTRAST (–64 to 63)

: WIDTH (–128 to 127)

: POSITION (–128 to 127)

21

Page 22

64LHP5000

PROJECTOR UNIT

7

Adjustment MPX Mode

Start

1st FAC

For adjusting the TV tuner MPX decoder section

Auto adjust

(P IN P)

8

Others OFFSET Mode

Start

1st FAC

ADJUSTMENT

1 ATT

2 ST VCO

3 SAP VC

4 ST LPF

9

27

10

26

00001

MPX F.E 1

5 SAP LPF

6 WIDE BAN

7 SPECTRA

Telop : Magenta

Picture quality mode

MOVIE OFFSET

8

12

23

ADJUSTMENT

1 ATT

2 ST VCO

3 SAP VC

4 ST LPF

MPX F.E 1

9

5 SAP LPF

29

6 WIDE BAN

9

7 SPECTRA

30

00001

COMPLETE !

8

12

21

Yellow

“NG”

ADJUSTMENT

1 ATT

2 ST VCO

3 SAP VC

4 ST LPF

MPX F.E 1

9

5 SAP LPF

25

6 WIDE BAN

8

7 SPECTRA

30

00001

TRY AGAIN !!

8

12

23

Red

<Picture quality>

: COLOR (–64 to 63)

: TINT (–64 to 63)

–24

COLOR

Data value

OFFSET MODE

Direct Key Screen Display Picture quality mode

(Blue) MOVIE MOVIE OFFSET MODE

(Green) GAME GAME OFFSET MODE

(Red) TV TV OFFSET MODE

COLOR TEMP (STD) COLOR TEMP LOW for STD &

COLOR TEMP (MOVIE)

(GAME) OFFSET MODE

COLOR TEMP LOW for MOVIE

OFFSET MODE

: CONTRAST (–64 to 63)

: BRIGHT (–128 to 127)

: SHARPNESS (–128 to 127)

: DETAIL (–128 to 127)

: VM (–128 to 127)

: DRV-R (–64 to 63)

: DRV-B (–64 to 63)

: CUT-R (–128 to 127)

: CUT-G (–128 to 127)

: CUT-B (–128 to 127)

<Data value section>

or

22

Page 23

Ë

Adjustment

Power supply adjustment

1

-1

1

Start

64LHP5000

PROJECTOR UNIT

135V Power supply adjustment

Color-bar generator

D. DC voltmeter

Color bar

TP201

VR201

135.0V±1V

14.5V Power supply adjustment

-2

1

Start

Color bar

Contrast coarse adjustment

2

Start

1st FAC

POWER SUPPLY

ASSY

TP204

VR202

POWER SUPPLY

ASSY

VR201

Color-bar generator

D. DC voltmeter

14.5V ± 0.1V

VR202

ADJUSTMENT OFFSET

ADJUSTMENT OFFSET

COLOR

Telop : Blue

Data value

23

CONTRAST

or

Telop : 0

Page 24

64LHP5000

PROJECTOR UNIT

Brightness adjustment

3

Start

1st FAC

ADJUSTMENT OFFSET

CUTR

Telop : Blue

Data value

CUT-R

CUT-B

0

BRIGHT

or

Oscilloscope

or

G CRT DRIVE

assy

Cut of level

(180V DC)

TP-GK

GND

Deflection yoke lean adjustment

4

Start

Cross hatch

CRT assy B

Deflection

yoke

TP-GK

Deflection

yoke (G)

CRT assy R

R CRT DRIVE

assy

Deflection

yoke (R)

Deflection

yoke (B)

B CRT DRIVE assy

Centering magnet

(Turn in either direction untill cross signal becomes white.)

CRT assy G

TP-BK

G CRT DRIVE assy

24

Page 25

• For Red or Blue adjustment, turn 1st FACTORY ADJ mode ON

and then OFF to place the convergence POSITION at the center

of the adjustable range.

• Move the centering magnet of the deflection yoke for the

replaced color so that the horizontal and vertical lines at the

center of the screen align with the lines for a color not replaced.

Cross hatch

Screen center adjustment

5

Start

Focus adjustment of lens assy

6

Start

64LHP5000

PROJECTOR UNIT

Deflection yoke

Centering magnet

(Turn in either direction until cross signal becomes white.)

Translucent paper such as tracing paper

Focus VR adjustment

7

Start

Cross hatch

Cross hatch

FOCUS VR (VR1)

B

G FOCUS VR

R

“Best focusing”

Lens assy

(For Red)

Lens assy

(For Green)

Lens assy

(For Blue)

Turn the focus VR for best focusing.

25

Page 26

64LHP5000

PROJECTOR UNIT

Vertical size adjustment

8

Start

1st FAC

Monoscope

or

General

broadcasting

Green screen

V .SIZE

Adjust the size so that the picture is completely

displayed on the screen.

Note :

After the V. SIZE adjustment,

enter the H. SIZE adjustment by

pressing “1” key and readjust.

Screen mode : FULL

91% ± 2%

Note :

After the H. SIZE adjustment,

enter the V. SIZE adjustment by

pressing “2” key and readjust.

26

Page 27

Horizontal size adjustment

9

Start

1st FAC

Monoscope

64LHP5000

PROJECTOR UNIT

Note :

Screen mode : FULL

Green screen

H.SIZE

or

General

broadcasting

Adjust the size so that the picture is completely

displayed on the screen.

91% ± 2%

27

Page 28

64LHP5000

PROJECTOR UNIT

Convergence adjustment

10

10

Green line adjustment

-1

1st FAC

• Adjustment in the horizontal direction

Start

» Horizontal correction adjustment of the green line

• See 4 Convergence Setting Mode in the Factory ADJ mode.

• Input cross-hatch signals to this device’s video input terminal.

• The green line serves as the reference line in the adjustment of

red and blue. Perform this accurately.

Adjust the convergence of the green line using only green.

• Select the Adjustment item

GH - STATIC

or

In particular, be aware of the

setting before adjustment.

Adjustment Items

1

2

3

4

5

6

Center-line Adjustment

7

"

GH-STATIC

"

GH-SKEW

"

GH-BOW

"

(GH-3D SKEW)

"

(GH-4D BOW)

"

(GH-5D SKEW)

"

(GH-6D BOW)

Screen No.

1

2

5

3

6

4

7

• Adjust the center vertical line to the screen center position.

• Adjust so that the green vertical line at the center becomes a straight line with neither

Note: Do not adjust items 4 to 7.

• Adjust the Data value

distortion nor tilting.

Note :

The convergence for this device must be adjusted for each

screen size FULL (NTSC, 4:3 NORMAL), ZOOM (NTSC), CINEMA WIDE (NTSC), NATURAL WIDE (NTSC), FULL (HD)

(33.75 kHz, DTV).

RED

OFF

Green only

Note :

• Repeat the adjustments until you attain the

optimum state.

• Fine-adjust over the entire picture to obtain the

or

optimum picture.

• If the adjustment of H-STATIC is not possible

within the range of 010 to –010, set the data value

to 0, turn the centering magnet of the deflection

yoke and fine-adjust H-STATIC.

Adjustment Method

GREEN

ON

BLUE

OFF

1

2

3

4

5

6

Line-interval Adjustment

Ë

Screen

• STATIC

Key

No.

)

• SKEW

Key

No.

1

Key

No.

• BOW

2

"

GH-SIZE

"

GH-MID SIZE

"

GH-LIN

"

GH-MID LIN

"

(GH-5D SIZE)

"

(GH-6D LIN)

1

2

5

• 3D SKEW

• 4D BOW

8

9

A

B

0

C

• Adjust so that the intervals of the green vertical lines in the right and left sections of the

screen are symmetrical and correct.

Note: Do not adjust items 5 and 6.

» Screen’s changes in the horizontal direction when manual convergence

adjustment is mode

The changes at the arrow parts shown below are those implemented using

the Volume

key is used.

3

• 5D SKEW

4

Key

No.

± key. Changes are opposite to the arrow when the Volume —

= Fixed position

• SIZE

8

• MID SIZE

9

• 5D SIZE

8

6

• 6D BOW

7

Key

No.

• LIN

11

• MID LIN

12

7

Fig. 1. Horizontal correction (1)

• 6D LIN

10

13

28

Page 29

» Horizontal correction adjustment of the green line

• Select the Adjustment item

GH - SUB PIN

or

In particular, be aware of the

setting before adjustment.

• Adjust the Data value

Note :

• Repeat the adjustments until you attain the

optimum state.

• Fine-adjust over the entire picture to obtain the

or

optimum picture.

• If the adjustment of H-STATIC is not possible

within the range of 010 to –010, set the data value

to 0, turn the centering magnet of the deflection

yoke and fine-adjust H-STATIC.

64LHP5000

PROJECTOR UNIT

Adjustment Items

1

2

3

Lean Adjustment

4

1

2

3

4

5

6

7

8

Distortion Adjustment

9

10

11

12

*1 : Adjust taking note of the green vertical lines at 1/4 of the left and right sides of the screen.

"

GHKEY

"

GH-MID KEY

"

GH-SUB KEY

"

GH-M S KEY

"

GH-3D KEY

"

(GH-M 3D KEY)

"

GH-3DS KEY

"

(GH-M 3S KEY)

"

GH-PIN

"

GH-MID PIN

"

GH-SUB PIN

"

GH-M S PIN

"

GH-4D PIN

"

(GH-M 4D PIN)

"

GH-4DS PIN

"

(GH-M 4S PIN)

*1

*1

*1

*1

*1

*1

*1

*1

Screen No.

E

F

I

J

G

H

K

L

M

N

Q

R

O

P

S

T

• Adjust so that the vertical green lines on the left and right sides of the screen do not tilt.

• Adjust so that the vertical green lines on the left and right sides of the screen become

straight with no distortion.

Note: Do not adjust items 2, 4, 10 and 12.

Adjustment Method

Ë

Key

No.

4

Key

No.

3

Key

No.

6

Key

No.

5

Screen

• SUB KEY

• SUB PIN

• KEY

• PIN

15

19

23

27

• MID KEY

• M S KEY

• MID PIN

• M S PIN

16

20

24

28

Fig. 2. Horizontal correction (2)

• 3D KEY

• 3DS KEY

• 4D PIN

• 4DS PIN

17

21

25

29

29

• M 3D KEY

• M 3S KEY

• M 4D PIN

• M 4S PIN

» Screen’s changes in the horizontal direction when

18

manual convergence adjustment is mode

The changes at the arrow parts shown below are those

implemented using the Volume

opposite to the arrow when the Volume

± key. Changes are

— key is used.

22

26

30

= Fixed position

Page 30

64LHP5000

PROJECTOR UNIT

10

Green line adjustment

-2

1st FAC

• Adjustment in the vertical direction

Start

» Vertical correction adjustment of the green line

• Select the Adjustment item

GV - STATIC

or

In particular, be aware of the

setting before adjustment.

Adjustment Items

1

2

3

4

5

6

Center-line Adjustment

7

"

GV-STATIC

"

GV-SKEW

"

GV-BOW

"

(GV-3D SKEW)

"

(GV-4D BOW)

"

(GV-5D SKEW)

"

(GV-6D BOW)

Screen No.

1

2

5

3

6

4

7

• Adjust the center horizontal line to the center of the screen.

• Adjust so that the green vertical line at the center becomes a straight line with neither

Note: Do not adjust items 6 and 7.

• Adjust the Data value

distortion nor tilting.

Note :

• Repeat the adjustments until you attain the

optimum state.

• Fine-adjust over the entire picture to obtain the

or

optimum picture.

• If the adjustment of V-STATIC is not possible

within the range of 010 to –010, set the data value

to 0, turn the centering magnet of the deflection

yoke and fine-adjust V-STATIC.

Adjustment Method

1

2

3

4

5

6

Line-interval Adjustment

Ë

Screen

• STATIC

Key

No.

)

• SKEW

Key

No.

1

Key

No.

• BOW

2

"

GV-SIZE

"

GV-LIN

"

GV-MID SIZE

"

GV-MID LIN

"

(GV-5D SIZE)

"

(GV-6D LIN)

1

2

5

• 3D SKEW

• 4D BOW

8

A

9

B

0

C

• Adjust so that the intervals of the green horizontal lines at the top and bottom of the

screen are symmetrical and correct.

Note: Do not adjust items 5 and 6.

» Screen’s changes in the vertical direction when manual convergence

adjustment is mode

The changes at the arrow parts shown below are those implemented using

the Volume

key is used.

3

• 5D SKEW

4

± key. Changes are opposite to the arrow when the Volume —

• SIZE

8

• MID SIZE

9

• 5D SIZE

Key

No.

8

6

• 6D BOW

7

• LIN

11

• MID LIN

12

• 6D LIN

Key

No.

7

10

13

= Fixed position

Fig. 3. Vertical correction (1)

30

Page 31

» Vertical correction adjustment of the green line

• Select the Adjustment item

GV - SUB PIN

or

In particular, be aware of the

setting before adjustment.

• Adjust the Data value

Note :

• Repeat the adjustments until you attain the

optimum state.

• Fine-adjust over the entire picture to obtain the

or

optimum picture.

• If the adjustment of V-STATIC is not possible

within the range of 010 to –010, set the data value

to 0, turn the centering magnet of the deflection

yoke and fine-adjust V-STATIC.

64LHP5000

PROJECTOR UNIT

Adjustment Items

"

1

2

3

Lean Adjustment

4

1

2

3

4

5

6

7

8

9

Distortion Adjustment

10

11

12

*2 : Adjust taking note of the green horizontal lines at 1/4 of the left and right sides of the screen.

GV-KEY

"

GV-MID KEY

"

GV-SUB KEY

"

GV-M S KEY

"

GV-3D KEY

"

(GV-M 3D KEY)

"

GV-3DS KEY

"

(GV-M 3S KEY)

"

GV-PIN

"

GV-MID PIN

"

GV-4D PIN

"

(GV-M 4D PIN)

"

GV-SUB PIN

"

GV-M S PIN

"

GV-4DS PIN

"

(GV-M 4S PIN)

*2

*2

*2

*2

*2

*2

*2

*2

Screen No.

E

F

I

J

G

H

K

L

M

N

O

P

Q

R

S

T

• Adjust so that the green horizontal lines at the top and bottom of the screen do not tilt.

• Adjust so that the green horizontal lines at the top and bottom of the screen become

straight with no distortion.

Note: Do not adjust items 2, 4, 8 and 12.

Adjustment Method

Ë

Key

No.

4

Key

No.

3

Key

No.

6

Key

No.

5

Screen

• SUB KEY

• SUB PIN

• KEY

• PIN

15

19

23

27

• MID KEY

• M S KEY

• MID PIN

• M S PIN

16

20

24

28

Fig. 4. Vartical correction (2)

• 3D KEY

• 3DS KEY

• 4D PIN

• 4DS PIN

17

21

25

29

31

• M 3D KEY

• M 3S KEY

• M 4D PIN

• M 4S PIN

» Screen’s changes in the vertical direction when

18

manual convergence adjustment is mode

The changes at the arrow parts shown below are those

implemented using the Volume

opposite to the arrow when the Volume

± key. Changes are

— key is used.

22

26

30

= Fixed position

Page 32

64LHP5000

PROJECTOR UNIT

10

Red line adjustment

-3

1st FAC

• Adjustment in the horizontal direction

Start

» Horizontal correction adjustment of the red line

• See 4 Convergence Setting Mode in the Factory ADJ mode.

• Input cross-hatch signals to this device’s video input terminal.

• Adjust the convergence of the red line using the green and red

lines.

• Select the Adjustment item

• Adjust the Data value

RH - STATIC

or

In particular, be aware of the

setting before adjustment.

Adjustment Item

1

2

3

4

5

6

Center-line Adjustment

7

RH-STATIC

RH-SKEW

RH-BOW

(RH-3D SKEW)

(RH-4D BOW)

(RH-5D SKEW)

(RH-6D BOW)

"

"

"

"

"

"

"

Screen No.

1

2

5

3

6

4

7

• Adjust the red center to match the green center.

• Overlap the red vertical line at the center with the green vertical line.

Note: Do not adjust items 6 and 7.

RED

ON

RED + GREEN

Note :

• Ov erlap the green line with the red line, so that the line

becomes yellow .

• Repeat the adjustments until you attain the optimum

state.

or

• Fine-adjust ov er the entire picture to obtain the optimum

picture.

• If the adjustment is of H-STATICnot possible within the

range of 010 to –010, set the data value to 0, turn the

centering magnet of the deflection yoke and fine-adjust

H-STATIC.

Adjustment Method

GREEN

ON

BLUE

ON

1

2

3

4

5

6

Line-interval Adjustment

Ë

Screen

• STATIC

Key

No.

)

• SKEW

Key

No.

1

Key

No.

• BOW

2

"

RH-SIZE

"

RH-LIN

"

RH-MID SIZE

"

RH-MID LIN

"

(RH-5D SIZE)

"

(RH-6D LIN)

1

2

5

• 3D SKEW

• 4D BOW

8

A

9

B

0

C

• Adjust the interval at the center of the red vertical line to the interval of the green vertical

line.

Note: Do not adjust items 5 and 6.

» Screen’s changes in the horizontal direction when manual convergence

adjustment is mode

The changes at the arrow parts shown below are those implemented using

the Volume

key is used.

3

• 5D SKEW

4

Key

No.

± key. Changes are opposite to the arrow when the Volume —

= Fixed position

• SIZE

8

• MID SIZE

9

8

6

• 6D BOW

7

Key

No.

• LIN

11

• MID LIN

12

7

Fig. 5. Horizontal correction (1)

• 5D SIZE

• 6D LIN

10

13

32

Page 33

» Horizontal correction adjustment of the red line

• Select the Adjustment item

RH - SUB PIN

or

In particular, be aware of the

setting before adjustment.

• Adjust the Data value

Note :

• Repeat the adjustments until you attain the

optimum state.

• Fine-adjust over the entire picture to obtain the

or

optimum picture.

• If the adjustment of H-STATIC is not possible

within the range of 010 to –010, set the data value

to 0, turn the centering magnet of the deflection

yoke and fine-adjust H-STATIC.

64LHP5000

PROJECTOR UNIT

Adjustment Item

1

2

3

Lean Adjustment

4

1

2

3

4

5

6

7

8

9

Distortion Adjustment

10

11

12

*3 : Adjust taking note of the red horizontal lines at 1/4 of the left and right sides of the screen.

Ë

Screen

"

RH-KEY

"

RH-MID KEY

"

RH-SUB KEY

"

RH-M S KEY

"

RH-3D KEY

"

(RH-M 3D KEY)

"

RH-3DS KEY

"

(RH-M 3S KEY)

"

RH-PIN

"

RH-MID PIN

"

RH-4D PIN

"

(RH-M 4D PIN)

"

RH-SUB PIN

"

RH-M S PIN

"

(RH-4DS PIN)

"

RH-M 4S PIN

• KEY

*3

*3

*3

*3

15

*3

*3

*3

*3

• MID KEY

Screen No.

E

F

I

J

G

H

K

L

M

N

O

P

Q

R

S

T

16

• Adjust so that the red vertical lines at the top and bottom of the screen do not tilt.

• Adjust so that the red vertical line at the top and bottom of the screen overlap with the

green vertical lines, and becomes a straight line with no distortion.

Note: Do not adjust items 2, 4, 8 and 11.

17

• 3D KEY

• M 3D KEY

Key

No.

4

Adjustment Method

» Screen’s changes in the horizontal direction when

18

manual convergence adjustment is mode

The changes at the arrow parts shown below are those

implemented using the Volume

opposite to the arrow when the Volume

± key. Changes are

— key is used.

Key

No.

3

Key

No.

6

Key

No.

5

• SUB KEY

• PIN

• SUB PIN

19

23

27

• M S KEY

• MID PIN

• M S PIN

20

24

28

Fig. 6. Horizontal correction (2)

• 3DS KEY

• 4D PIN

• 4DS PIN

21

25

29

33

• M 3S KEY

• M 4D PIN

• M 4S PIN

22

26

30

= Fixed position

Page 34

64LHP5000

PROJECTOR UNIT

10

Red line adjustment

-4

1st FAC

• Adjustment in the vertical direction

Start

» Vertical correction adjustment of the red line

• Select the Adjustment item

RV - STATIC

or

In particular, be aware of the

setting before adjustment.

Adjustment Item

1

2

3

4

5

6

Center-line Adjustment

7

RV-STATIC

RV-SKEW

RV-BOW

RV-3D SKEW

RV-4D BOW

(RV-5D SKEW)

(RV-6D BOW)

"

"

"

"

"

"

"

Screen No.

1

2

5

3

6

4

7

• Adjust the red center to match the green center.

• Adjust so that the red horizontal line at the center overlaps with the green horizontal

line.

Note: Do not adjust items 6 to 7.

• Adjust the Data value

Note :

• Repeat the adjustments until you attain the

optimum state.

• Fine-adjust over the entire picture to obtain the

or

optimum picture.

• If the adjustment of V-STATIC is not possible

within the range of 010 to –010, set the data value

to 0, turn the centering magnet of the deflection

yoke and fine-adjust V-STATIC.

Adjustment Method

1

2

3

4

5

6

Line-interval Adjustment

Ë

Screen

• STATIC

Key

No.

)

• SKEW

Key

No.

1

Key

No.

• BOW

2

"

RV-SIZE

"

RV-LIN

"

RV-MID SIZE

"

RV-MID LIN

"

(RV-5D SKEW)

"

(RV-6D LIN)

1

2

5

• 3D SKEW

• 4D BOW

8

A

9

B

0

C

• Adjust the interval at the center of the red vertical line to the interval of the green vertical

line.

Note: Do not adjust items 5 and 6.

» Screen’s changes in the vertical direction when manual convergence

adjustment is mode

The changes at the arrow parts shown below are those implemented using

the Volume

key is used.

3

• 5D SKEW

4

± key. Changes are opposite to the arrow when the Volume —

• SIZE

8

• MID SIZE

9

Key

No.

8

6

• 6D BOW

7

• LIN

11

• MID LIN

12

Key

No.

7

• 5D SIZE

• 6D LIN

10

13

= Fixed position

Fig. 7. Vertical correction (1)

34

Page 35

» Vertical correction adjustment of the red line

• Select the Adjustment item

RV - SUB PIN

or

In particular, be aware of the

setting before adjustment.

• Adjust the Data value

Note :

• Repeat the adjustments until you attain the

optimum state.

• Fine-adjust over the entire picture to obtain the

or

optimum picture.

• If the adjustment of V-STATIC is not possible

within the range of 010 to –010, set the data value

to 0, turn the centering magnet of the deflection

yoke and fine-adjust V-STATIC.

64LHP5000

PROJECTOR UNIT

Adjustment Item

1

2

3

4

"

RV-KEY

"

RV-MID KEY

"

RV-SUB KEY

"

RV-M S KEY

*4

*4

Lean Adjustment

1

2

3

4

5

6

7

8

9

Distortion Adjustment

10

11

12

*4 : Adjust taking note of the red horizontal lines at 1/4 of the left and right sides of the screen.

"

RV-3D KEY

"

(RV-M 3D KEY)

"

RV-3DS KEY

"

(RV-M 3S KEY)

"

RV-PIN

"

RV-MID PIN

"

RV-4D PIN

"

(RV-M 4D PIN)

"

RV-SUB PIN

"

RV-M S PIN

"

RV-4DS PIN

"

(RV-M 4S PIN)

*4

*4

*4

*4

*4

*4

Screen No.

E

F

I

J

G

H

K

L

M

N

O

P

Q

R

S

T

• Adjust so that the red horizontal lines at the left and right of the screen do not tilt.

• Adjust so that the red horizontal lines at the left and right of the screen overlap with the

green horizontal lines, and become a straight line with no distortion.

Note: Do not adjust items 2, 4, 8 and 12.

Adjustment Method

Ë

Key

No.

4

Key

No.

3

Key

No.

6

Key

No.

5

Screen

• SUB KEY

• SUB PIN

• KEY

• PIN

15

19

23

27

• MID KEY

• M S KEY

• MID PIN

• M S PIN

16

20

24

28

Fig. 8. Vartical correction (2)

• 3D KEY

• 3DS KEY

• 4D PIN

• 4DS PIN

17

21

25

29

35

• M 3D KEY

• M 3S KEY

• M 4D PIN

• M 4S PIN

» Screen’s changes in the vertical direction when

18

manual convergence adjustment is mode

The changes at the arrow parts shown below are those

implemented using the Volume

opposite to the arrow when the Volume

± key. Changes are

— key is used.

22

26

30

= Fixed position

Page 36

64LHP5000

PROJECTOR UNIT

10

Blue line adjustment

-5

1st FAC

• Adjustment in the horizontal direction

Start

» Horizontal correction adjustment of the blue line

• See 4 Convergence Setting Mode in the Factory ADJ mode.

• Input cross-hatch signals to this device’s video input terminal.

• Select the Adjustment item

BH - STATIC

or

In particular, be aware of the

setting before adjustment.

Adjustment Item

1

2

3

4

1

6

Center-line Adjustment

7

"

BH-STATIC

"

BH-SKEW

"

BH-BOW

"

BH-3D SKEW

"

BH-4D BOW

"

BH-5D SKEW

"

BH-6D BOW

Screen No.

1

2

5

3

6

4

7

• Adjust the blue center to match the green center.

• Overlap the blue vertical line at the center with the green vertical line.

Note: Do not adjust items 6 and 7.

• Adjust the Data value

RED

OFF

GREEN + BLUE

Note :

• Repeat the adjustments until you attain the

optimum state.

• Fine-adjust over the entire picture to obtain the

or

optimum picture.

• If the adjustment of H-STATIC is not possible

within the range of 010 to –010, set the data value

to 0, turn the centering magnet of the deflection

yoke and fine-adjust H-STATIC.

Adjustment Method

GREEN

ON

BLUE

ON

1

2

3

4

5

6

Line-interval Adjustment

Ë

Screen

• STATIC

Key

No.

)

• SKEW

Key

No.

1

Key

No.

• BOW

2

"

BH-SIZE

"

BH-LIN

"

BH-MID SIZE

"

BH-MID LIN

"

(BH-5D SIZE)

"

(BH-6D LIN)

1

2

5

• 3D SKEW

• 4D BOW

8

A

9

B

0

C

• Adjust the interval at the center of the blue vertical line to the interval of the green

vertical line.

Note: Do not adjust items 5 and 6.

» Screen’s changes in the horizontal direction when manual convergence

adjustment is mode

The changes at the arrow parts shown below are those implemented using

the Volume

key is used.

3

• 5D SKEW

4

Key

No.

± key. Changes are opposite to the arrow when the Volume —

= Fixed position

• SIZE

8

• MID SIZE

9

• 5D SIZE

8

6

• 6D BOW

7

Key

No.

• LIN

11

• MID LIN

12

7

Fig. 9. Horizontal correction (1)

• 6D LIN

10

13

36

Page 37

» Horizontal correction and adjustment of blue line

• Select the Adjustment item

BH - SUB PIN

or

In particular, be aware of the

setting before adjustment.

• Adjust the Data value

Note :

• Repeat the adjustments until you attain the

optimum state.

• Fine-adjust over the entire picture to obtain the

or

optimum picture.

• If the adjustment of H-STATIC is not possible

within the range of 010 to –010, set the data value

to 0, turn the centering magnet of the deflection

yoke and fine-adjust H-STATIC.

64LHP5000

PROJECTOR UNIT

Adjustment Item

1

2

3

Lean Adjustment

4

1

2

3

4

5

6

7

8

9

Distortion Adjustment

10

11

12

*5 : Adjust taking note of the blue vertical lines at 1/4 of the left and right sides of the screen.

Ë

Screen

"

BH-KEY

"

BH-MID KEY

"

BH-SUB KEY

"

BH-M S KEY

"

BH-3D KEY

"

(BH-M 3D KEY)

"

BH-3DS KEY

"

(BH-M 3S KEY)

"

BH-PIN

"

BH-MID PIN

"

BH-4D PIN

"

(BH-M 4D PIN)

"

BH-SUB PIN

"

BH-M S PIN

"

BH-4DS PIN

"

(BH-M 4S PIN)

• KEY

*5

*5

*5

*5

15

*5

*5

*5

*5

• MID KEY

Screen No.

E

F

I

J

G

H

K

L

M

N

O

P

Q

R

S

T

16

• Adjust so that the blue vertical lines at the top and bottom of the screen do not tilt.

• Adjust so that the blue vertical lines at the top and bottom of the screen overlap with the

green vertical lines, and become a straight line with no distortion.

Note:Do not adjust items 2, 4, 8 and 12.

17

• 3D KEY

• M 3D KEY

Key

No.

4

Adjustment Method

» Screen’s changes in the horizontal direction when

18

manual convergence adjustment is mode

The changes at the arrow parts shown below are those

implemented using the Volume

opposite to the arrow when the Volume

± key. Changes are

— key is used.

Key

No.

3

Key

No.

6

Key

No.

5

• SUB KEY

• PIN

• SUB PIN

19

23

27

• M S KEY

• MID PIN

• M S PIN

20

24

28

• 3DS KEY

• 4DS PIN

Fig. 10. Horizontal correction (2)

• 4D PIN

21

25

29

37

• M 3S KEY

• M 4D PIN

• M 4S PIN

22

26

30

= Fixed position

Page 38

64LHP5000

PROJECTOR UNIT

10

Blue line adjustment

-6

1st FAC

• Adjustment in the vertical direction

Start

» Vertical correction adjustment of the blue line

• Select the Adjustment item

BV - STATIC

or

In particular, be aware of the

setting before adjustment.

Adjustment Item

1

2

3

4

5

6

Center-line Adjustment

7

BV-STATIC

BV-SKEW

BV-BOW

BV-3D SKEW

BV-4D BOW

BV-5D SKEW

BV-6D BOW

"

"

"

"

"

"

"

Screen No.

1

2

5

3

6

4

7

• Adjust the blue center to match the green center.

• Adjust so that the blue horizontal line at the center overlaps with the green horizontal

line.

• Adjust the Data value

Note :

• Repeat the adjustments until you attain the

optimum state.

• Fine-adjust over the entire picture to obtain the

or

optimum picture.

• If the adjustment of V-STATIC is not possible

within the range of 010 to –010, set the data value

to 0, turn the centering magnet of the deflection

yoke and fine-adjust V-STATIC.

Adjustment Method

1

2

3

4

5

6

Line-interval Adjustment

Ë

Screen

• STATIC

Key

No.

)

• SKEW

Key

No.

1

Key

No.

• BOW

2

"

BV-SIZE

"

BV-LIN

"

BV-MID SIZE

"

BV-MID LIN

"

(BV-5D SIZE)

"

(BV-6D LIN)

1

2

5

• 3D SKEW

• 4D BOW

8

A

9

B

0

C

• Adjust the interval at the center of the blue horizontal line to the interval of the green

horizontal line.

Note: Do not adjust items 5 and 6.

» Screen’s changes in the vertical direction when manual convergence

adjustment is mode

The changes at the arrow parts shown below are those implemented using

the Volume

key is used.

3

• 5D SKEW

4

± key. Changes are opposite to the arrow when the Volume —

• SIZE

8

• MID SIZE

9

Key

No.

8

6

• 6D BOW

7

• LIN

11

• MID LIN

12

Key

No.

7

• 5D SIZE

• 6D LIN

10

13

= Fixed position

Fig. 11. Vertical correction (1)

38

Page 39

» Vertical correction adjustment of the blue line

• Select the Adjustment item

BV - SUB PIN

or