Page 1

14T1-L

conventional analog manner. The adjustments via the I2C bus control include preset-only items and

(c) Using the VOLUME UP/ DOWN key on the remote controller, the data can be modified.

TV14T1-LService Manual14T1-LMarketE

CHAPTER 5. ADJUSTMENT METHOD

[1] ADJUSTMENT METHOD

ADJUSTMENT PRECAUTIONS

This model's setting are adjusted in two different ways: through the I2C bus control and in the

variable data.

1. Setting the service mode by the microprocessor.

(a) Press and hold the local key "VOL DOWN" & "CH UP" and power on the main switch,

TV will enter into the SERVICE MODE. Or Key in service key of 40 (HEX) will enter the

service mode. The initial value of EEPROM are automatically preset when new EEPROM

is used. However, after the 1st time it will not be able to preset unless do the precedure

in section 2 as below.

(b) Press the CH DOWN / UP key on the remote controller to select the setting items

one by one.

(d) When press the local key "VOL DOWN" & "CH UP" at the same time or press service

key 40 (HEX), it will be released from the service mode.

2. Factory Presetting.

(1) Press remote controller key of code "B7" for 4 seconds, the initial values are

automatically preset.

(2) The initial data are preset as listed in page 2 until 7.

(3) Please modify the bus setup data.

Precaution

: If haven't done this initialization, malfunction might be happen.

3. For reference, please check with memory map RH-IXC227WJZZQ (See Attachment)

5 – 1

Page 2

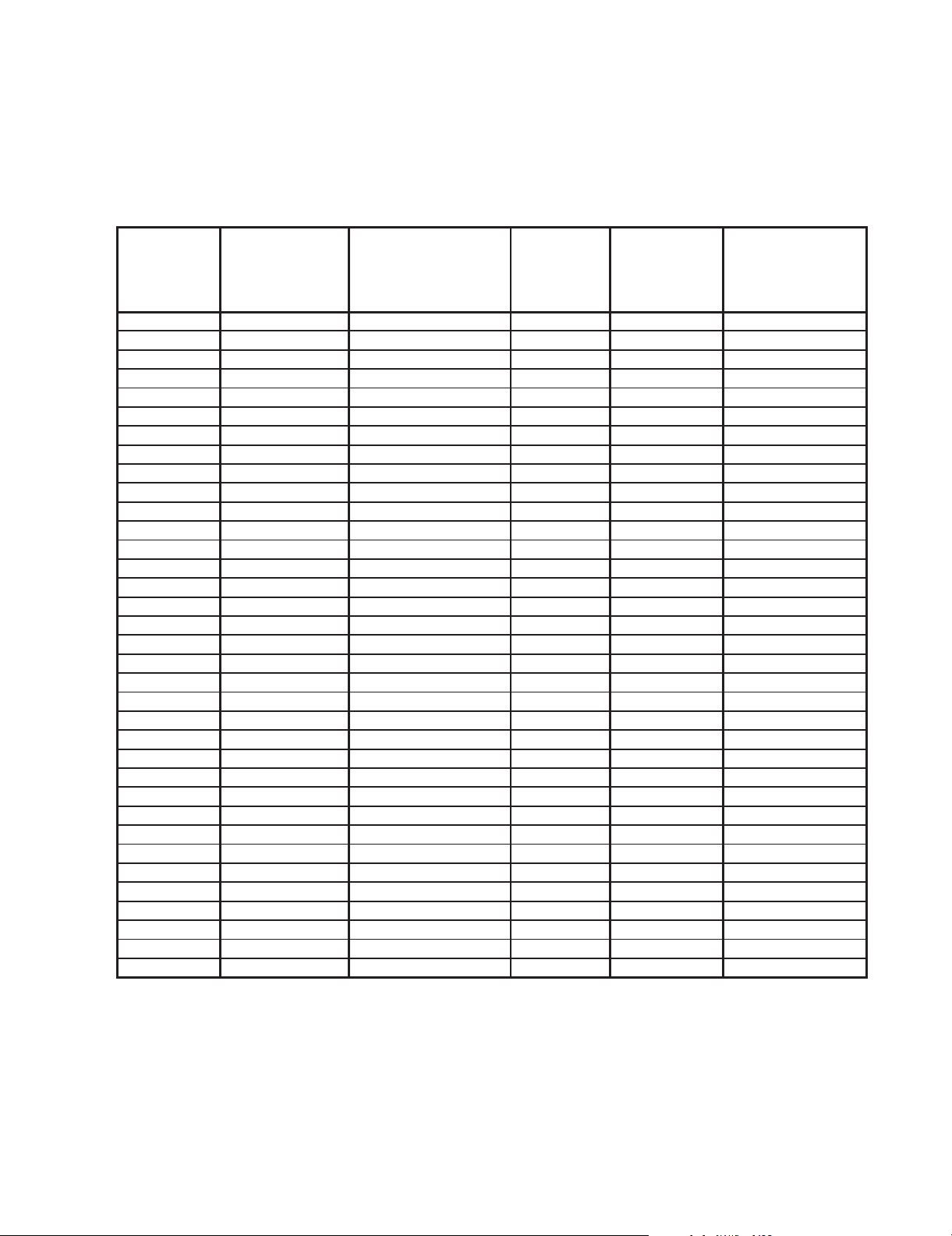

There is three stage of Service Mode data

Setting Data (DEC)

Item

Setting Item

Setting Range

Default

IC

First stage data from V01 ~ V35

to go into second stage of service mode data, press MENU key

Second stage data from 008 ~ 1FF

Below is the contents of these data

Adjustment Mode Items

01 RF-AGC 0…63 UOC-TV 23 23

02 V-SLOPE 0…63 UOC-TV 31 31

03 S-COR 0…63 UOC-TV 16 16

04 DRI-RS 0…63 UOC-TV 32 32

05 DRI-GS 0…63 UOC-TV 32 32

06 DRI-BS 0…63 UOC-TV 32 32

07 CUT-RS 0…63 UOC-TV 16 16

08 CUT-GS 0…63 UOC-TV 16 16

09 CUT-BS 0…63 UOC-TV 16 16

10 SUB-BRI 0…63 UOC-TV 32 32

11 SUB-CON 0…63 UOC-TV 25

12 SUB-COL 0…63 UOC-TV 10 10

13 SUB-TINT 0…63 UOC-TV 36 36

14 SUB-SHARP 0…63 UOC-TV 32 32

15 DRI-RW 0…63 UOC-TV 38 38

16 DRI-GW 0…63 UOC-TV 32 32

17 DRI-BW 0…63 UOC-TV 19 19

18 DRI-RLW 0…63 UOC-TV 33 33

19 DRI-GLW 0…63 UOC-TV 32 32

20 DRI-BLW 0…63 UOC-TV 25 25

21 DRI-RC 0…63 UOC-TV 32 32

22 DRI-GC 0…63 UOC-TV 32 32

23 DRI-BC 0…63 UOC-TV 37 37

24 DRI-RLC 0…63 UOC-TV 32 32

25 DRI-GLC 0…63 UOC-TV 32 32

26 DRI-BLC 0…63 UOC-TV 34 34

27 V-SHI-60 0…63 UOC-TV 32 32

28 V-AMP-60 0…63 UOC-TV 32 32

29 H-SHI-60 0…63 UOC-TV 45 45

30 VSD 0/1 UOC-TV 0 0

31 CUT OFF 0…63 UOC-TV 27 27

32 DCXO 0…4 UOC-TV 2 1

33 ISP MODE 0/1 UOC-TV 0 0

34 BLOC 0…15 UOC-TV 6 6

35 SUB-VOL 0…60 UOC-TV 60 60

14T1-L

45 (BUS SETUP)

5 – 2

Page 3

14T1-L

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

CONTROL

PRE-ADJUST

REQUIREMENT

CONTENT

INPUT

CONDITION

OUTPUT

ADJUSTMENT

PROCEDURE

MAX - 0.1V dc

SYMBOL

RF INPUT

FIELD STRENGTH

56dBµV

(FIX)

TUNER AGC TERMINAL (JA352) OR CRT DISPLAY CONFIRMATION

(AT SELF ADJUSTMENT MODE)

1.GO TO SERVICE MODE

2.GO TO SERVICE DATA "RF-AGC" ITEM IN THE ADJUSTMENT, PRESS R/C TO OPERATE AUTOAGC KEY AND CONFIRM THE OK DISPLAY ON THE SCREEN .

3.BLUE DISPLAY WITH OK SIGN INDICATES THE ADJUSTMENT IS WORKING PROPERLY.

(AT MANUAL ADJUSTMENT MODE)

[CHECKING CONFIRMATION ]

14T1-L

I2C CONTROL

BUS SET UP

US10CH HALF COLOR BAR

RF-AGC

01

STEP RANGE

0-63

HISTORY

OF REVISION

REVISED CONTENT .

MODEL NAME

1. SELECT "RF-AGC" ITEM IN THE ADJUSTMENT MODE. ADJUST THE "RF-AGC" BUS

DATA TO OBTAIN THE TUNER OUTPUT PIN DROP 0.1V~1.0V BELOW MAXIMUM

VOLTAGE.

2. CHANGE THE ANTENNA INPUT SIGNAL TO 63~67 dBuV, AND MAKE SURE THERE IS NO

NOISE

3. CHANGE THE ANTENNA INPUT SIGNAL TO 90~95 dBuV TO BE SURE THAT THERE IS NO

CROSS MODULATION BEAT.

5 – 3

Page 4

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

CONTROL

PRE-ADJUST

REQUIREMENT

CONTENT

INPUT

CONDITION

AC 220 V, RF INPUT, ZERO MAGNETIC FIELD

CRT DISPLAY CONFIRMATION

ADJUST THE V-SLOPE BUS DATA UNTILL THE OVERSCAN BECOME AS SPECIFIED BELOW.

CAUTION:- PLEASE AGING TV MORE THAN 10 MINUTES BEFORE ADJUSTMENT.

[CHECKING CONFIRMATION ]

14T1-L

I2CCONTROL

BUS SET UP,CRT PURITY

US 4 CH LION HEAD

V-SLOPE

02

STEP RANGE

0~63

HISTORY

OF REVISION

REVISED CONTENT .

MODEL NAME

A = Outofspec

B=OK

C = Out of spec

OUTPUT

14T1-L

ADJUSTMENT

PROCEDURE

SYMBOL

5 – 4

Page 5

14T1-L

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

CONTOROL

PRE-ADJUST

REQUIREMENT

INPUT

CONDITION

AC 220 V, RF INPUT, ZERO MAGNETIC FIELD

CRT DISPLAY CONFIRMATION

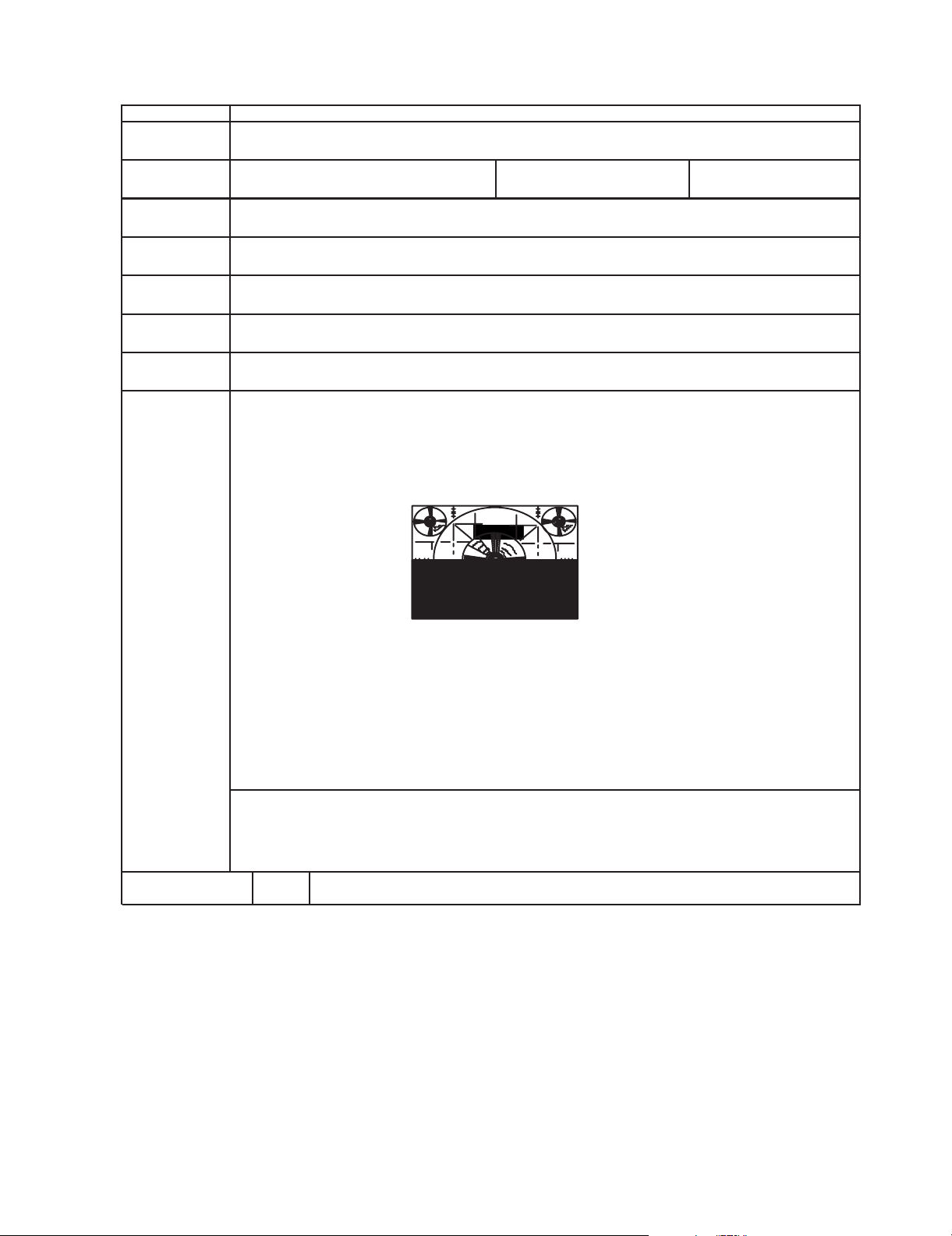

ADJUST V-SHIFT BUS DATA TO HAVE A MOST ACCEPTABLE VERTICAL POSITION.

THE MONOSCOPE PATTERN SHOULD BE BALANCE IN VERTICAL POSITION

[CHECKING CONFIRMATION ]

14T1-L

I2C CONTROL

BUS SET UP, CRT PURITY, V-SLOPE

US4CHLIONHEAD(MONOSCOPEPATTERN)

V-SHIFT-60

27

STEP RANGE

0-63

HISTORY

OFREVISION

REVISED CONTENT .

MODEL NAME

CONTENT

OUTPUT

ADJUSTMENT

PROCEDURE

SYMBOL

5 – 5

Page 6

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

CONTROL

PRE-ADJUST

REQUIREMENT

CONTENT

INPUT

CONDITION

ADJUST THE V-AMP-60 BUS DATA UNTILL THE OVERSCAN BECOME AS SPECIFIED BELOW.

[CHECKING CONFIRMATION ]

OVERSCAN 10 ± 2.5%

HISTORY

OF REVISION

REVISED CONTENT .

BUS SET UP,CRT PURITY, V-SLOPE, V-SHIFT 60

US 4 CH LION HEAD (MONOSCOPE PATTERN)

AC 220 V, RF INPUT, ZERO MAGNETIC FIELD

CRT DISPLAY CONFIRMATION

28

STEP RANGE

0~63

I2C CONTROL

MODEL NAME

14T1-L

V-AMP-60

OUTPUT

14T1-L

ADJUSTMENT

PROCEDURE

SYMBOL

5 – 6

Page 7

14T1-L

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

CONTROL

PRE-ADJUST

REQUIREMENT

INPUT

CONDITION

I2C BUS CONTROL

BUS SET UP,CRT-PURITY

MODEL NAME

H-SHIFT-60

STEP RANGE

29

0-63

14T1-L

AC 220 V, RF INPUT, ZERO MAGNETIC FIELD

1.ADJUST THE

H-SHIFT

BUS DATA TO HAVE A BALANCE POSITION TO SPEC OF

A=B

[CHECKING CONFIRMATION ]

CONFIRMATION BY CRT SCREEN

HISTORY

OFREVISION

REVISED CONTENT .

US4CHLIONHEAD(MONOSCOPE)

B

A

CONTENT

OUTPUT

ADJUSTMENT

PROCEDURE

LEFT AND RIGHT SYMMETRICAL

SYMBOL

5 – 7

Page 8

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

CONTROL

PRE-ADJUST

REQUIREMENT

CONTENT

INPUT

CONDITION

MODEL NAME

CRT CUT OFF ADJUSTMENT

30 (VSD)

STEP RANGE

14T1-L

I2C CONTROL

BUS SET UP

AV MODE (WITHOUT SIGNAL) WITH BLUEBACK OFF

AC 220 V, AV INPUT

CONFIRMATION ON CRT DISPLAY.

[CHECKING CONFIRMATION ]

1) IN SERVICE MODE, SET CUT OFF TO 27, SUB-CON TO 45, SUB-BRI TO 32 AND DRI-RS, DRI-RS&

DRI-BS TO 32; CUT-RS, CUT-GS & CUT-BS TO 16 , SWITCH TV TO VIDEO MODE, BLUE BACK OFF,

WITHOUT SIGNAL.

2) GO TO ADJUSTMENT MODE ITEM VSD AND PRESS VOLUME UP AT R/C. ADJUST THE SCREEN

VR OF FBT SO THAT CUT-OFF LINE APPEAR IN LOW BRIGHT, THEN JUDGE THAT WHETHER THE

CUT-OFF LINE APPEAR IN RED OR GREEN OR BLUE COLOR. FIX THE CUT OFF DATA OF THE

COLOR APPEAR IN CUT-OFF LINE AND USE R/C TO ADJUST THE OTHER TWO AMONG CUT-RS,

CUT-GS & CUT-BS UNTIL COLOUR BECOME W HITE.

3)TURN THE SCREEN VR OF FBT SO THAT CUT-OFF LINE JUST DISAPPEAR.

HISTORY

OFREVISION

REVISED CONTENT .

OUTPUT

14T1-L

ADJUSTMENT

PROCEDURE

SYMBOL

5 – 8

Page 9

14T1-L

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

CONTROL

PRE-ADJUST

REQUIREMENT

INPUT

CONDITION

MODEL NAME

WHITE BALANCE

4,5,6,7,8,9

STEP RANGE

0~63

14T1-L

I2C BUS CONTROL

BUS SET UP,CRT PURITY, SCREEN

AV; W/B PATTERN 1 (PATTERN GENERATOR SX- 1006)

AC 220 V, AV INPUT

CONFIRMATION ON CRT DISPLAY.

1)

WHITE

(HIGH BEAM)

FIRST LET THE GUN POINT AT

WHITE

POSITION (AS DRAWING ATTACH), ADJ

THE

PATTERN GENERATOR UPPER VR

UNTILYBECOME

150 cd/m

2

.

AFTER THAT, LET THE

GUN POINT AT W HITE POSITION AGAIN AND ADJUST THE BUS DATA OF DRI-RS AND

DRI-BS UNTLL THE AXIS OF COLOUR TEMPERATURE BECOME

X=0.273,Y=0.280

.

2)

DARK

(LOW BEAM)

LET THE GUN POINT AT DARK POSITION (AS DRAWING ATTACH),ADJUST THE

PATTERN GENERATOR LOWER VR UNTIL Y BECOME 5 cd/m2. ADJUST THE

TWO

SERVICE DATA

(AMONG CUT-RS, CUT-GS AND CUT-BS) WHICH HAVE CHOSEN AT CUT

OFF ADJUSTMENT SO THAT TO OBTAIN THE SIMILAR AXIS OF COLOUR TEMPERATURE

AS ABOVE.

*FOR ADJUSTMENT IN 1 & 2, MUST ALWAYS MAINTAIN THE Y AT 150cd/m2 (WHITE) AND

AT 5cd/m2 (DARK) WITH ADJUSTING THE UPPER AND LOWER VR OF PATTERN

GENERATOR.

**REPEAT STEP 1),2) TO GET A REGULATED LEVEL.

[CHECKING CONFIRMATION ]

X=0.273,Y=0.280 (11,600° K+1 MPCD)

HISTORY

OF REVISION

REVISED CONTENT .

WHITE

DARK

CONTENT

OUTPUT

ADJUSTMENT

PROCEDURE

SYMBOL

5 – 9

Page 10

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

CONTROL

PRE-ADJUST

REQUIREMENT

CONTENT

INPUT

CONDITION

REVISED CONTENT .

HISTORY

OF REVISION

[CHECKING CONFIRMATION ]

I2C CONT ROL

BUS SET UP, CUT OFF, W HITE BALANCE

AV; WINDOW PATTERN (PATTERN GENERATOR SX- 1006)

AC 220 V, AV INPUT

MODEL NAME

BLOC

34

STEP RANGE

0~15

14T1-L

CONFIRMATION ON CRT DISPLAY.

1)LET THE GUN POINT AT BLACK POSITION(AS ATTACH DRAW ING), ADJUST

BLOC

BUS DATA

UNTIL LUMINANCE Y = 0.43cd/m

2

+ 0.1

BLACK

OUTPUT

14T1-L

ADJUSTMENT

PROCEDURE

SYMBOL

5 – 10

Page 11

14T1-L

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

CONTROL

PRE-ADJUST

REQUIREMENT

INPUT

CONDITION

MODEL NAME

SUB COLOUR

12

STEP RANGE

0~63

14T1-L

I2C BUS CONTROL

BUS SET UP, RF-AGC, CUT OFF, WHITE BALANCE

US 10 CH HALF COLOR BAR PATTERN

AC 220 V, RF INPUT

R-AMPTRBASE(JA801ORTP851)

CONFIRM WITH OSCILLOSCOPE

1)CONNECT THE OSCILLOSCOPE TO TP 851 RED TO OBTAIN WAVEFORM AS BELOW.

2)ADJUST THE 100% WHITE & RED PORTIONS OF COLOR BAR UNTIL THE SAME LEVEL

[CHECKING CONFIRMATION ]

HISTORY

OFREVISION

REVISED CONTENT .

W

Y

Cy

G

100% WHITE

MgRB

CONTENT

OUTPUT

ADJUSTMENT

PROCEDURE

SYMBOL

5 – 11

Page 12

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

CONTROL

PRE-ADJUST

REQUIREMENT

CONTENT

INPUT

CONDITION

MODEL NAME

SUB-TINT

13

STEP RANGE

0~63

14T1-L

I2C CONTROL

BUS SET UP, RF-AGC, CUT OFF, WHITE BALANCE, SUB-COLOUR

US 10 CH HALF COLOR BAR PATTERN

AC 220 V, RF INPUT

B-AMP TR BASE (JA810 OR TP853)

CONFIRRM WITH OSCILLOSCOPE

1)RECEIVE THE US 10 CH HALF COLOR BAR PATTERN.

2)CONNECT THE OSCILLOSCOPE TO TP 853 BLUE OUT.

[CHECKING CONFIRMATION ]

HISTORY

OFREVISION

REVISED CONTENT .

Range : 100mV/ Div USE PROBE 10:1

SWEEP TIME : 10 usec/Div

3) SELECT THE "SUB-TINT" ITEM IN THE ADJUSTMENT MODE. ADJUST THE "SUB-TINT" DATA

TO OBTAIN THE WAVEFORM AS SHOWN AS BELOW (W & MG SAME LEVEL)

G

G

Mg

R

B

Y

Cy

W

OUTPUT

14T1-L

ADJUSTMENT

PROCEDURE

SYMBOL

5 – 12

Page 13

14T1-L

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

CONTROL

PRE-ADJUST

REQUIREMENT

INPUT

CONDITION

MODEL NAME

X-RAY PROTECTION OPERATING CONFIRMATION

ˉ

STEP RANGE

ˉ

14T1-L

AC 220V, RF INPUT

CONFIRMATION BY THE CRT

[CHECKING CONFIRMATION ]

[VOLTAGE CONFIRMATION]

CHECK THE VOLTAGE OF C602 +VE TERMINAL AS SPECIFIED BELOW.

[OPERATION CONFIRMATION]

SUPPLY THE DC VOLTAGE (27V AS BELOW) TO C602 +VE TERMINAL AND MAKE SURE THE

PROTECTOR IS FUNCTIONED , HORIZONTAL OSCILATION STOP AND PICTURE DISAPPEAR.

[RECOVER INFORMATION]

PULL OUT THE AC CORD .

[CAUTION]

FROM THE RECOVER CONFIRMATION MENTIONED ABOVE,THE AC CODE MUST BE PULLED

OUT AT LEAST 5 SECONDS BEFORE PLUGGING IN AGAIN. (IN ORDER TO MAKE SURE THE CON HAS BEEN RESET.)

27V

HISTORY

OF REVISION

REVISED CONTENT .

TP VOLTAGE

20.6 ± 1.1V DC

PROTECTOR OPERATION VOLTAGE

ˉ

AFTER ALL ADJUSTMENT FINISHED.

US 4 CH LION HEAD (MONOSCOPE PATTERN)

CONTENT

OUTPUT

ADJUSTMENT

PROCEDURE

MODEL

14T1-L

SYMBOL

5 – 13

Page 14

ADJUSTMENT

ITEM

ADJUSTMENT

POSITION

CONTROL

PRE-ADJUST

REQUIREMENT

CONTENT

INPUT

CONDITION

MODEL

HISTORY

OF REVISION

REVISED CONTENT .

[CHECKING CONFIRMATION ]

CRT ANODE VOLTAGE

CONFIRM THE VOLTAGE OF CRT ANODE BY HIGH VOLTAGE METER AND MAKE SURE THE

READINGISASBELOW.

HIGH VOLTAGE

BELOW 25.5kV

ˉ

AFTER ALL ADJUSTMENT FINISHED.

US 4 CH LION HEAD (MONOSCOPE PATTERN)

AC 220V, RF INPUT

MODEL NAME

14T1-L

HIGH VOLTAGE

ˉ

STEP RANGE

ˉ

OUTPUT

14T1-L

ADJUSTMENT

PROCEDURE

14T1-L

SYMBOL

5 – 14

Loading...

Loading...