Shark Pressure Washers STP-231007D, STP-201507D, STP-352007A Operator's Manual

M

STP-231007D 1.109-101.0

STP-201507D 1.109-102.0

STP-352007A 1.109-103.0

STP-231007D 1.109-133.0

STP-352007A 1.109-134.0

o locate your local Shark Commercial Pressure Washer Dealer nearest you,

T

ORDER #

visit www.shark-pw.com

9.801-191.0

CONTENTS

Introduction and Safety Information 3-5

Component Identifi cation 6

Operating Instructions 7-8

Preventative Maintenance and Service 9-11

Exploded Views 12-13

Exploded Views Parts List 14-15

Control Panel Exploded View and Parts List 16

Hose & Spray Gun Assembly and Parts List 17

Downstream Injector Assembly and Parts List 18

UU1 Unloader Exploded View and Parts List 19

Pump Exploded View and Parts List 20-21

Burner Clear Flame Exploded View and Parts List 22-23

Troubleshooting 24

Maintenance Schedule 25

Model Number ______________________________

Serial Number ______________________________

Date of Purchase ____________________________

The model and serial numbers will be found on a decal at tached

to the pressure washer. You should record both serial number and

date of purchase and keep in a safe place for future ref er ence.

2

99

v. 02/14B

INTRODUCTION & IMPORTANT SAFETY INFORMATION

PRESSURE W ASHER

ou for purchasing this Pressure Washer.

We reserve the right to make changes at any time

without incurring any obligation.

Owner/User Responsibility:

The owner and/or user must hav e an understanding of

the manufacturer’ s operating instructions and warnings

before using this pressure washer . W arning information

should be emphasized and understood. If the operator

is not fluent in English, the manufacturer’ s instructions

and warnings shall be read to and discussed with

the operator in the operator’s native language by the

purchaser/owner, making sure that the oper ator comprehends its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’ instructions.

The operator must know how to stop the machine

quickly and understand the operation of all controls.

Never permit anyone to operate the engine without

proper instructions.

SA VE THESE INSTRUCTIONS

This manual should be considered a permanent

part of the machine and should remain with it if

machine is resold.

When ordering parts, please specify model and

serial number . Use onl y identical replacement parts.

This machine is to be used only by trained operators.

IMPORTANT SAFETY

INFORMATION

WARNING: To reduce the risk of

injury, read operating instructions carefully before using.

1. Read the owner's manual

thoroughly. Failure to follow instructions could cause

R R

MANUAL THOROUGHL Y

PRIOR TO USE.

TOR’S

2. Know how to stop the machine and bleed pressure

quickly. Be thoroughly familiar with the controls.

3. Stay alert — watch what you are doing.

4. All installations must comply with local codes.

Contact your electrician, plumber, utility compan y

or the selling distributor for specifi c details. If your

machine is rated 250 volts or less, single phase will

be provided with a ground fault circuit interrupter

(GFCI). If r ated more than 250 volts , or more than

single phase this product should only be connected

to a power supply receptacle protected by a GFCI.

malfunction of the machine

and result in death, serious

bodily injury and/or proper ty

damage.

DANGER: Improper connection of the equipmentgrounding conductor can result in a risk of electrocution. Check with a qualified electrician or

service personnel if you are in doubt as to whether

the outlet is properly grounded. Do not modify the

plug provided with the product - if it will not fi t the

outlet, have a proper outlet installed by a qualifi ed

electrician. Do not use any type of adaptor with

this product

ARNING: Keep wand, hose, and

WARNING

W

water spray away from electric

wiring or fatal electric shock may

result.

5. To protect the operator from

electrical shock, the machine

ATER

K

SPRAY AWAY FROM

ELECTRICAL WIRING.

must be electrically grounded.

It is the responsibility of the

owner to connect this machine

to a UL grounded receptacle of proper voltage and

amperage ratings. Do not spray water on or near

electrical components. Do not touch machine with

wet hands or while standing in water. Always disconnect power before servicing.

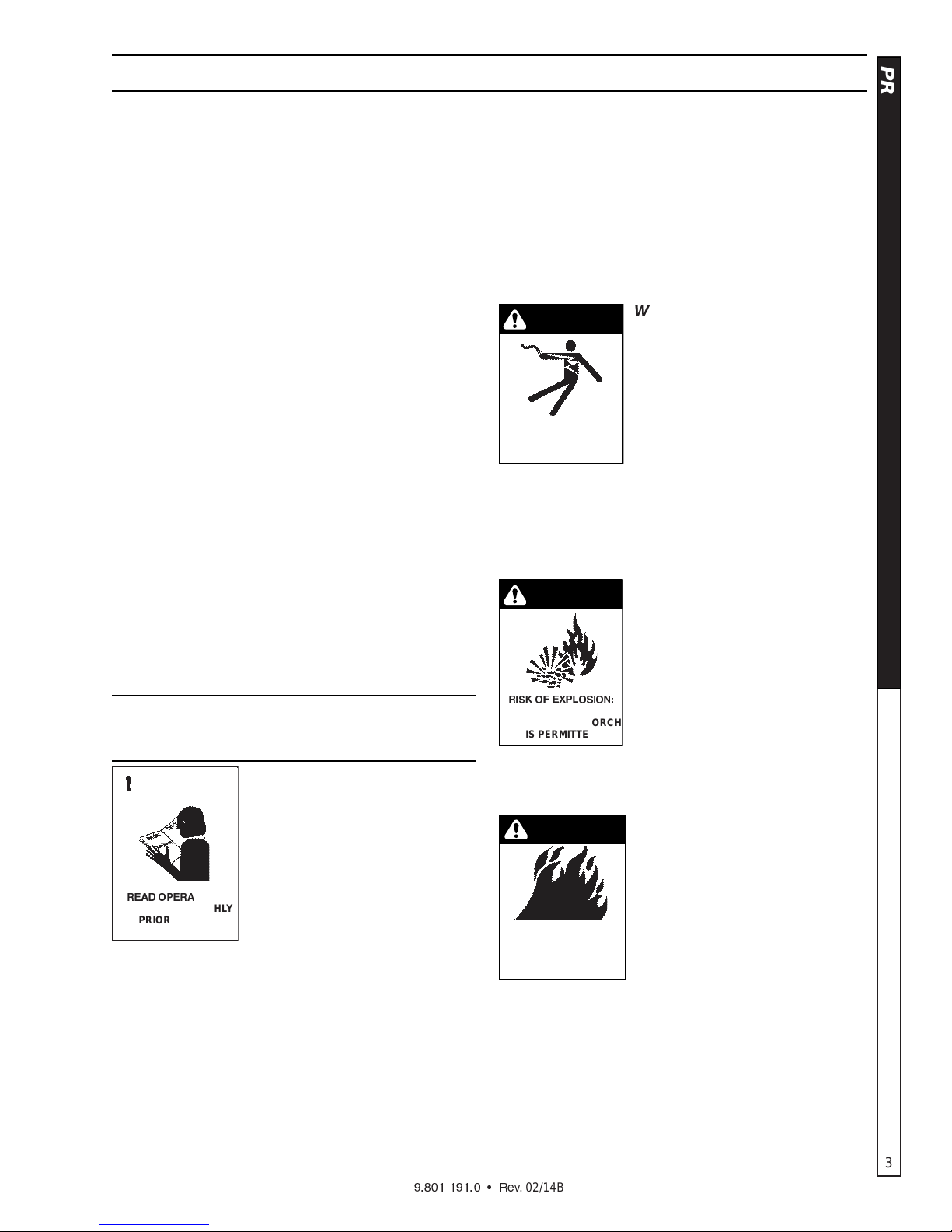

ARNING: Flammable liquids

WARNING

W

can create fumes which can ig-

nite, causing property damage

or severe injury.

WARNING: Risk of explosion

Operate only where open fl ame

!"K#$%"!&'

R

OPERATE ONLY WHERE

OPEN FLAME OR TORCH

IS PERMITTED

or torch is permitted.

6. In oil burning models, use only kerosene, No. 1

home heating fuel, or diesel. If diesel is used, add

a soot remover to every tankful.

ARNING: Risk of fi re — Do not

WARNING

W

add fuel when the product is

operating or still hot.

WARNING: Do not use gasoline

crankcase draining or oil con-

RISK OF FIRE.

DO NOT ADD FUEL

WHEN OPERATING

MACHINE.

taining gasoline, solvents or

alcohol. Doing so will result in

fi re and/or explosion.

7. Oil burning appliances shall be installed only in

locations where combustible dusts and fl ammable

gases or vapors are not present. Do not store or

use gasoline near this machine.

8. Do not allow acids, caustic or abrasive fl uids to pass

through the pump.

9. Never run pump dry or leave spray gun closed

longer than 1-2 minutes.

v. 02/14B

OPERATOR’S MAN U AL

3

IMPORTANT SAFETY INFORMATION

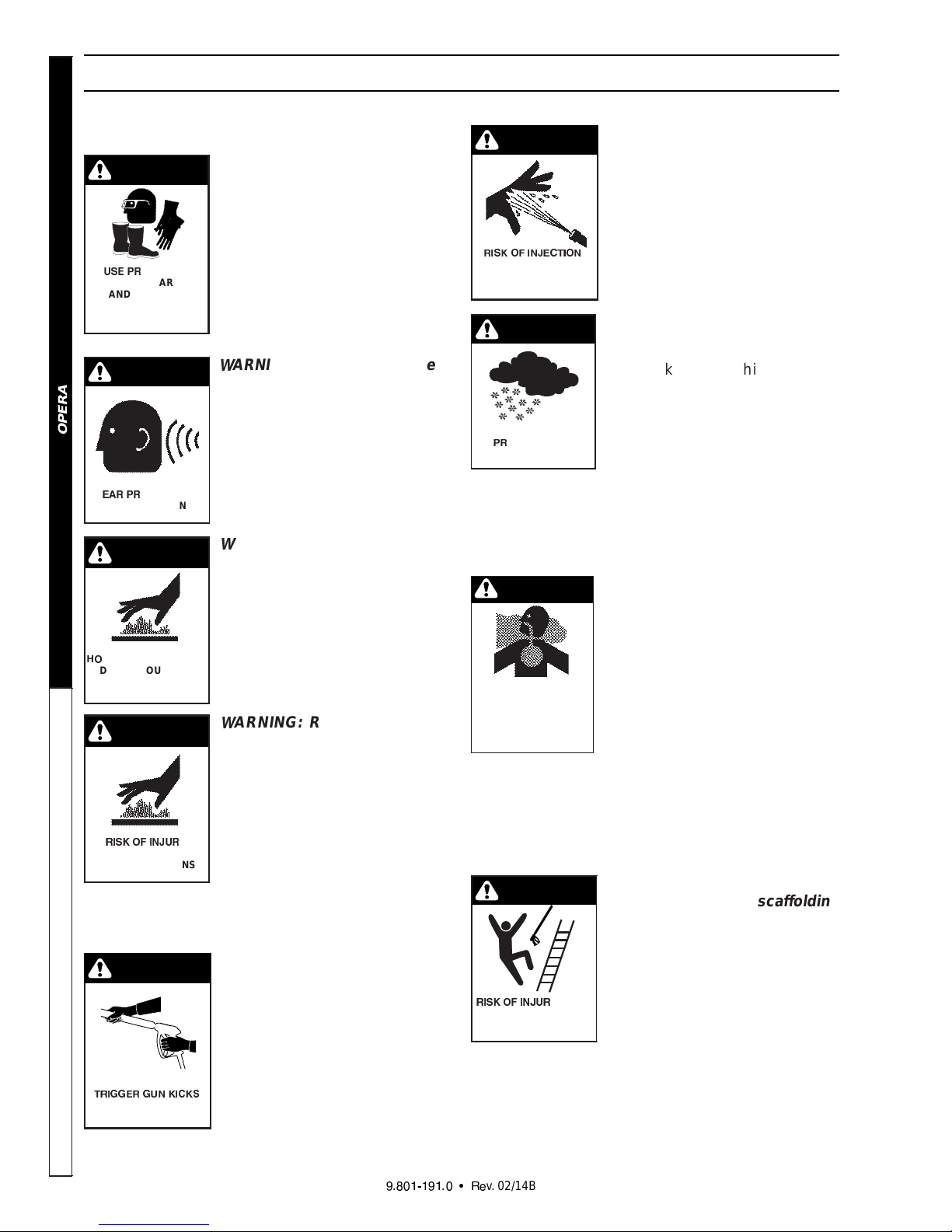

10. Keep operating area clear of all persons.

WARNING

WARNING: High pressure spray

can cause paint chips or other

particles to become airborne

and fl y at high speeds. To avoid

personal injury, eye, hand and

PRESSURE W ASHER

U13 56

AND CLOTHING

WHEN OPERATING

THIS EQUIPMENT.

OTECTIVE

EYE WEAR

foot safety devices must be

worn.

11. Ey e, hand, and foot protection

must be worn when using this

equipment.

ARNING: This machine exceeds

WARNING

7

85 db appropriate ear protection

must be worn.

OPERATOR’S MANUAL

OTECTION

3E6 56

MUST BE WORN

WARNING

ARNING: Hot discharge fl uid.

7

Do not touch or direct discharge

stream at persons.

WARNING: This machine produces hot water and must have

T DISCHARGE FLUID:

H8

DO NOT TOUCH OR

DIRECT DISCHARGE

STREAM AT PERSONS.

WARNING

insulated components attached

to protect the operator.

ARNING: Risk of injury. Hot

7

surfaces can cause burns. Use

only designated gripping areas

of spray gun and wand. Do not

place hands or feet on non-insulated areas of the pressure

washer.

6:1;8< :=>U6

HOT SURFACES

CAN CAUSE BURNS

Y:

12. To reduce the risk of injury,

close supervision is necessary

when a machine is used near children. Do not allow children to operate the pressure washer. This

machine must be attended during operation.

WARNING

ARNING: Grip cleaning wand

7

securely with both hands before

starting. Failure to do this could

result in injury from a whipping

wand.

13. Never make adjustments on

?6:@@36@

BACK - HOLD WITH

U= ;:A;1

BOTH HANDS

machine while in operation.

14. Be certain all quick coupler fi ttings are secured before using

4

pressure washer.

16. Inlet water must be clean fresh water and no hotter

18. Manufacturer will not be liable for any changes

19. The best insurance against an accident is precau-

20. Do not overreach or stand on unstable support.

21. Do not operate this machine when fatigued or under

()*+,-,(,)+ . /0

ARNING: High pressure devel-

WARNING

7

oped by these machines will

cause personal injury or equipment damage. Keep clear of

nozzle. Use caution when operating. Do not direct discharge

6:1;8< :=>3A?:8=

OR SEVERE INJURY

TO PERSONS. KEEP

CLEAR OF NOZZLE.

WARNING

stream at people, or severe injury or death will result.

WARNING: Protect machine fr om

freezing.

15. To keep machine in best

operating conditions, it is

important you protect machine

from freezing. F ailure to protect

OTECT FROM

56

FREEZING

machine from freezing

could cause malfunction of the

machine and result in death,

serious bodily injury, and/or property damage. F ollow storage instructions specifi ed in this manual.

then 90°F.

WARNING

WARNING: Risk of asph yxiation.

Use this product only in a well

ventilated area.

17. Avoid installing machines in

small areas or near exhaust

6:1;8<

ASPHYXIATION: USE

THIS PRODUCT ONLY

IN A WELL

VENTILATED AREA.

fans. Adequate oxygen is

needed for combustion or

dangerous carbon monoxide

will result.

made to our standard machines or any components

not purchased from us.

tion and knowledge of the machine.

WARNING

WARNING: Be extremel y careful

when using a ladder , scaffolding

or any other relatively unstable

location. The cleaning area

should have adequate slopes

and drainage to reduce the pos-

6:1;8< :=>U6

FALLS WHEN USING

Y FROM

LADDER.

sibility of a fall due to slippery

surfaces.

Keep good footing and balance at all times.

the infl uence of alcohol, prescription medications,

or drugs.

v. 02/14B

IMPORTANT SAFETY INFORMATION

PRESSURE W ASHER

w the maintenance instructions

OPQ QP

specifi ed in the manual.

SVXY

ALLATION

Place machine in a convenient location providing ample

support, draining and room for maintenance.

This machine is intended for indoor use. Machine

must be stored indoors when not in use.

Location:

The location should protect the machine from damaging environmental conditions, such as wind, rain, and

freezing.

1. This machine should be run on a level surface

where it is not readily influenced by outside

sources such as strong winds, freezing temperature, rain, etc. It should be located to allow

accessibility for refi lling of fuel, adjustments, and

maintenance. Normal precautions should be

taken by the operator of the machine to prevent

moisture from reaching the electrical controls.

2. It is recommended that a partition be made

between the wash area and the machine to prevent water spra y from coming in contact with the

machine. Excess moisture reaching any electric

components or electrical controls will reduce

machine life and may cause electrical shorts.

3. During installation of the machine, beware of

poorly ventilated locations or areas where exhaust fans may cause an insuffi cient supply of

oxygen. Suffi cient combustion can only be obtained when there is a suffi cient supply of oxygen

available for the amount of fuel being burned. If

it is necessary to install a machine in a poorly

ventilated area, outside fresh air may ha v e to be

piped to the burner and a fan installed to bring

air into the machine.

Avoid small locations or areas near exhaust fans.

OPERATOR’S MAN U AL

BCDFGIGBGCF J LN

5

v. 02/14B

PRESSURE W ASHER

OPERATOR’S MANUAL

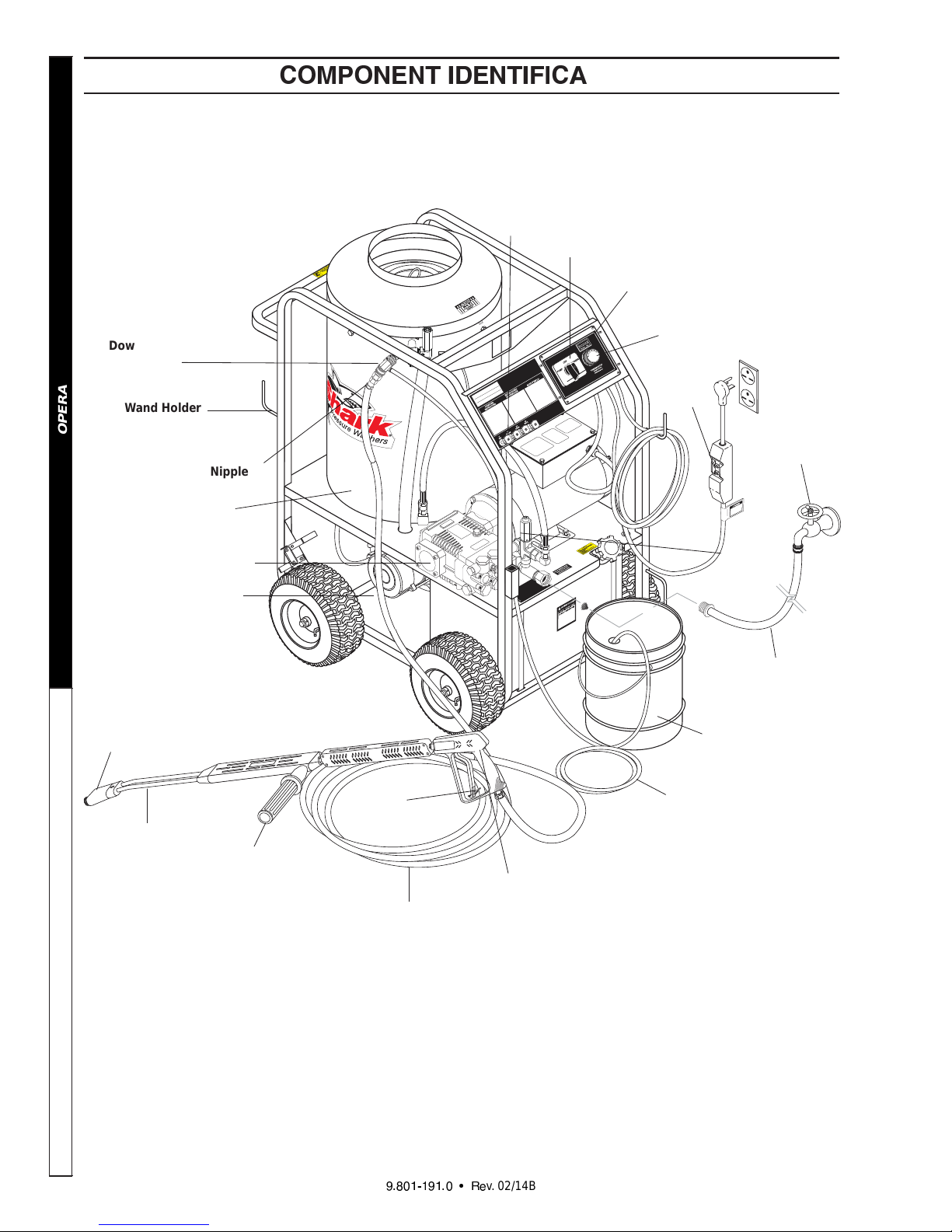

Downstream

Detergent

Injector

Wand Holder

Discharge

Nipple

Burner

Chamber

defgehihj klihjkmkdn

Nozzle

ON - OFF

Switch

TION

CAUTION HOT WATER:

Must use insulated spray gun

and wand.

Hour Meter

Adjustable

Thermostat

GFCI

Fresh Water

Faucet

(not included)

Burner Motor

Nozzle

Coupler

Variable Pressure

Insulated Wand

Pump

Control

Handle

Trigger

High Pressure

Outlet Hose

Unloader

Garden Hose

(not included)

Detergent Bucket

(not included)

Detergent

Suction Hose

Insulated

Spray Gun

c

Z[\]^_^Z^[] ` ab

v. 02/14B

xyz{|

TING INSTRUCTIONS

PRESSURE W ASHER

Electrical:

This machine, when installed, must be electrically

grounded in accordance to local codes. Check for

proper power supply using a volt meter.

Placement:

Do not locate near any combustible material. Keep all

flammable material at least 20 feet away.

Allow enough space for servicing the machine.

Local code will require certain distances from floor and

walls. (Two feet away from walls should be adequate.)

Water Source:

The water source for the pressure washer should be

supplied by a minimum 5/8" I.D. garden hose with a

city water pressure of not less than 30 PSI. If the water

supply is inadequate, or if the garden hose is kinked,

the attached pressure washer will run very rough and

the burner will not fire.

Connection:

Connect the wand, nozzle, hose and spra y gun (where

applicable). On pipe thread connections, use teflon tape

to avoid water leaks. (See Component Identification).

Venting:

Adding exhaust vent pipe to your oil fired burner is

not recommended because restricted air flow causes

carbon buildup, which affects the operation, and increases maintenance on the coil. If a stack must be

used, refrain form using 90° bends. If the pipe can not

go straight up then use only 45° bends and go to the

next size pipe. The o verall pipe length must not e xceed

6 feet in length.

5. Insert quick coupler onto discharge nipple and

secure by pushing quick coupler collar forward.

6. Securely attach the desired high pressure nozzle

into wand coupler as described in steps 4 and 5.

7. Connect the power cord into the proper electrical

outlet, then push in the GFCI reset button (Refer

to serial plate for information.)

8. Grip spray gun handle securely and pull trigger.

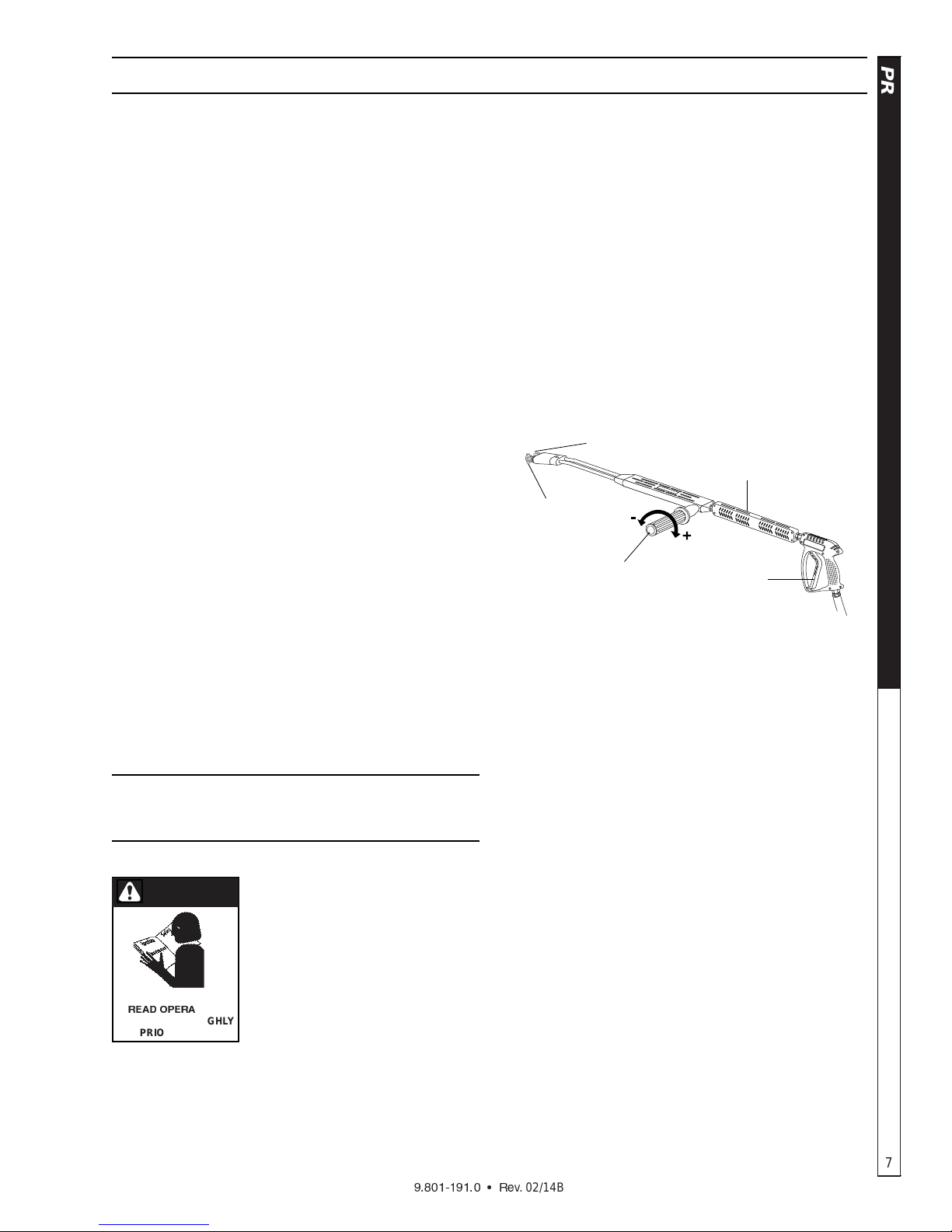

Then turn variable pressure control handle counterclockwise.

9. Turn switch to pump position. When a steady

stream of water fl ows from the spray gun and wand,

the machine is ready for cold water cleaning by turning the variable pressure control handle clockwise

to raise the pressure.

Brass Soap

Nozzle

High

Pressure

Nozzle

Variable Pressure

Control Handle

Variable Pressure

Wand (VP)

Trigger

Selection of high or low pressure is accompanied by

turning the handle. Note: High pressure nozzle must

be inserted at end of wand to obtain high pressure. To

apply soap read operator's manual.

10. For hot water washing, turn the switch to the burner

position. (The burner will light automatically when

the trigger on the spray gun is pulled.)

OPERATOR’S MAN U AL

STARTING AND OPERATING

INSTRUCTIONS

To Start:

CAUTION

CAUTION

}~ ~}

MANUAL THOROUGHL Y

PRIOR TO USE.

TOR’S

4. Connect high pressure hose to discharge nipple by

sliding quick coupler collar back. (If detergent is to

be applied, insert a detergent injector as shown in

Component Identifi cation).

1. STOP! Read operator's man-

ual before operating. Failure

to read operation and warning instructions may result in

personal injury or property

damage.

2. Connect water supply hose

and turn on water.

3. Check fuel tank and pump oil

levels.

To Stop:

1. If using the detergent injector, place the suction

2. T urn burner switch off and continue spra ying water ,

3. After water has cooled to less than 100°F, turn the

4. Turn garden hose water off. Open the spray gun to

5. Protect from freezing.

opqrstsospr u vw

line in a bucket of water allowing detergent to be

fl ushed from system.

allowing the water to cool.

attached pressure washer off.

relieve remaining pressure.

7

v. 02/14B

OPERATING INSTRUCTIONS

WARNING

CHAUD!

HOW TO USE THE

DETERGENT INJECTOR

WARNING: Some detergents

may be harmful if inhaled or ingested causing severe nausea,

PRESSURE W ASHER

SOME DETERGENTS

MAY BE HARMFUL

IF INHALED OR

INGESTED.

1. Pull injector quick coupler collar back and secure on

discharge nipple. Injector valv e body arrow should

point in direction of fl ow.

OPERATOR’S MANUAL

2. Connect high pressure hose to injector nipple securing quick coupler.

3. Start machine as outlined in Operating Instructions.

fainting or poisoning. The harmful elements may cause property

damage or severe injury.

The machine can siphon and

mix detergents with the use of

Shark's detergent injector kit.

4. Place detergent pick-up tube into container of

detergent solution.

5. T urn pressure control handle counterclockwise on

the variable pressure wand. This lowers the pressure by directing the water fl ow through the soap

nozzle and allows the detergent injector to siphon

soap.

6. Open trigger spray gun. Water detergent ratio is

approximately 15 to 1.

7. When you fi nish washing, rinse by simply turning

the variable pressure wand control handle clockwise to increase pressure.

NOTE: The detergent injector will not siphon with

water fl owing through the high pressure nozzle at

the end of the wand.

8. For clean up, place detergent pick-up tube into

container of clear water and follow steps 5 and 8

to prevent detergent deposits from damaging the

injector.

Nozzle Quick

Coupler

Brass Soap

Nozzle

Variable Pressure

Wand (VP)

Relief Valve

harge Nipple

Detergent Injector

Collar

Detergent

Pickup T ube

Trigger

Quick Coupler

Spray Gun

High Pressure

Hose

Variable Pressure

Control Handle

v. 02/14B

Loading...

Loading...