OPERATOR'S MAN U AL

SMT

MODEL # ORDER #

SMT-354037E 1.103-841.0

To locate your local Shark Commercial Pressure Washer Dealer nearest you,

visit www.sharkpw.com

9.800-504.0-D10/26/16

TABLE OF CONTENTS

Important Trailer Safety Information 4-8

What to Check and How to Check 9

Important Safety Information 10-12

Component Identifi cations 13

Accessory Assembly Instructions 14

Assembly Instructions 15

Installation 16

Operating Instructions 17

Detergents & General Cleaning Techniques 18

Shut Down & Clean-up Procedures 19

Storage 19

Troubleshooting 20-21

Maintenance Charts 22

Oil Change Record 22

Preventative Maintenance 24

Maintenance & Service 25-27

2

Shark SMT • 9.800-504.0

TABLE OF CONTENTS

Notice

This trailer is equipped to meet applicable U.S. Federal safety standards. Check local and state requirements

regarding brakes and any additional equipment that may be required. Any modifi cations or additions including

load-equalizing hitches, without written factory consent: usage in an abnormal manner including overloading

voids all manufacturers’ warranties and liability.

WARNING: This Owner's Manual contains safety information and instructions for your trailer.

You must read this manual before loading or towing your trailer.

You must follow all safety precautions and instructions.

Model Number ______________________________

Serial Number ______________________________

Date of Purchase ____________________________

The model and serial numbers will be found on a decal at tached to the

pressure washer. You should record both serial number and date of purchase

and keep in a safe place for future ref er ence.

PATENT PENDING

3

Shark SMT • 9.800-504.0

IMPORTANT TRAILER SAFETY INFORMATION

Referencing the Utility Trailer in this

Manual

All references to the trailer or component parts to

either left or right are made with the assumption that

you are standing behind the trailer facing forward. Your

left hand or right hand is the equivalent on the trailer.

Tire Safety

The most common cause of trailer tire failure is underinflation. Therefore, it is important that you always

maintain the specifi ed air pressure as indicated by the tire

manufacturer on the tire's side-walls. This information can

also be found on the tire label or the air pressure molded

on the tire side-wall.

The most important things you can do to maintaining

proper tire pressure are observe all tire and trailer

maximum carrying capacities, avoid road hazards, and

inspect the tires for cuts, slashes and other irregularities.

These practices, along with other care and maintenance,

can improve handling, help protect you and others from

avoidable breakdowns and accidents, improve fuel

economy, and increase the life of your tires.

Make tire safety a regular part of your trailer maintenance

routine. The time you spend is minimal compared to the

amount of time, inconvenience, and potential safety

hazards that can occur from a fl at tire or failure.

Basic Tire Maintenance

Properly maintained tires improve the load-carrying

capability of your trailer. You can help avoid fl at tires and

tire failures by main taining proper tire pressure, observing

tire and trailer capacity limits, avoiding road hazards, and

inspecting your tires regularly.

Identifying Your Recommended Tire

Pressure and Maximum Load Carrying

Capacity for Your Trailer

Both the tire placard and the VIN label are permanently

attached on top of the frame of your trailer and have the

required information printed on them. They also list the

maximum load that can be placed on the trailer without

exceeding the load limits of the tires or the trailers other

components. These labels indicate the manufacturer’s

information including:

• Recommended tire size.

• Recommended tire infl ation pressure.

• The maximum weight the trailer is designed

to carry.

• Gross vehicle weight rating of the trailer.

• Gross axle weight rating of the trailer.

Understanding Tire Pressure and Load

Limits

Tire infl ation pressure is the level of air in the tire that

provides it with the load-carrying capacity and affects

the overall performance of the trailer. The tire infl ation

pressure is a number that indicates the amount of air

pressure that is inside the tire. It is measured in pounds

per square inch (PSI). The tire must be infl ated to the air

pressure as designated on the labels. Also listed on the

labels is the air pressure in kilo Pascals (kPa), which is a

metric measurement. Tire manufacturers determine the

air pressure to maximize the amount of weight the tires

can safely carry. The proper tire pressure for your trailer

tires is referred to as the "recommended cold infl ation

pressure." It is diffi cult to obtain the recommended tire

pressure if your tires are not cold when the reading is

taken because the air will expand when it is warmed by

towing down the road, thus increasing the air pressure

inside. If air is added to a tire that is low the air pressure

should never exceed the recommended pressure.

It is important to check your trailer’s tire pressure at least

once a month for the following reasons:

Most tires will naturally lose air over time.

Tires can lose air suddenly if driven over an object that

punctures or cuts the tire. Sometimes a sharp blow from

a pothole or curb can knock the tire loose from the rim

causing immediate defl ation.

Maintaining Proper Tire Pressure

Locate the recommended tire pressure on the trailer's tire

information placard or owner's manual.

Record the tire pressure of all tires. If the tire pressure is

too high in any of the tires, slowly release air by gently

pressing on the tire valve stem with the edge of your tire

gauge until you get the correct pressure.

If the tire pressure is too low, note the difference between

the measured tire pressure and the correct tire pressure.

These "missing" pounds of pressure are what you will

need to add.

Add the missing pounds of air pressure to each tire that

is under infl ated.

Check all tires to make sure they have the same air

pressure.

If you have been towing your trailer and think that a tire

is under infl ated, fi ll it to the recommended cold infl ation

pressure indicated on your trailer's tire label placard or the

VIN label. You can also check the sidewall of the tire for a

correct tire infl ation pressure. Your tire will have a slightly

lower air pressure because the tire is warm when you are

infl ating it, but it will be much better than to continue to

tow it with the under infl ation it may have had. Once the

trailer has been parked long enough to allow the tires to

cool down, recheck the tire pressure and add additional

air to return the tire pressure to the recommended level.

4

Shark SMT • 9.800-504.0

IMPORTANT TRAILER SAFETY INFORMATION

Tire Size

To maintain the trailer's carrying capacity and safety,

purchase only the same size tires as what were originally

supplied on the trailer.

Safety Tips

Slow down if you have to go over a pothole or other object

in road.

Do not run over curbs and try not to strike the curb when

parking.

For a free brochure visit:

www. nhtsa.dot.gov

IMPORTANT: Before towing this trailer be sure to read

the instructions and warnings supplied in this manual.

Also read the information supplied with your tow

vehicle so you know and understand it's limitations.

Never Tow the Trailer Before Checking:

• Coupler and latch assembly show no signs of

wear or damage.

• Coupler hitch and hitch ball are of the same size.

• Coupler and safety chains are safely secured

to the hitch.

• Check all fasteners for proper tightness.

• Load is securely tied down to the trailer.

• Wheel lug nuts are properly tightened to the

right torque.

• Wheel bearings are properly adjusted and

maintained.

• Load is within the maximum load carrying

capacity of trailer.

• Tires are properly infl ated and are road worthy.

• All trailer lighting is working properly.

IMPORTANT: The load must be distributed equally on

the bed of the trailer if possible. Heavy, concentrated

loads may cause damage or possible failure of the

trailer.

WARNING: Loads place on the trailer must be securely

tied to the trailer. Always use appropriate tie downs

designed to restrict loads from moving when properly

attached. Failure to do so will allow shifting of the load

causing potential trailer failure and/or loss of the load

and personal injury.

This trailer is equipped to meet all applicable federal

safety standards in effect the day of manufacture. Check

local and state requirements regarding any additional

equipment that may be required.

The addition of optional equipment to your trailer may in

crease the total weight of your trailer package to where

it now exceeds the maximum load carrying capacity of

the trailer.

Tow Vehicles

WARNING: Serious injury or property damage can

result if the total weight of your loaded trailer exceeds

the capacity of the hitch and/or your tow vehicle.

It is very important that you know and understand the

towing capabilities of your tow vehicle. This is especially

true with the braking abilities of the tow vehicle. You

should check with your authorized dealer to see what the

capabilities are for the total towing load and the maximum

allowable tongue weight for the vehicle you plan on using

for towing.

It is also important that the lighting system in the tow

vehicle has suffi cient capacity support the additional

load the trailer lighting will add to the system. A heavy

duty fl asher may be required to make your turn signals

function properly.

Trailer Ball & Couplers

WARNING: Failure to properly engage the hitch ball in

the coupler ball socket and securely lock the coupler

latch mechanism can cause the trailer to become

detached from the tow vehicle while traveling, which

may cause serious injury or property damage.

Ball diameter for which rating (GVWR) shall not exceed

the gross trailer weight marked on the trailer coupler.

The hitch balls have the rated load they are capable of

towing stamped Into the top of the ball.

Make sure the ball that you use to tow your trailer has the

same capacity rating as the coupler.

Do not use a different size ball than the size the coupler

is designed to use.

Class Coupler Ball Diameter

II 3,500# GVWR 2”

III 5,000# GVWR 2”

IV 8,000# GVWR 2”

5

Shark SMT • 9.800-504.0

IMPORTANT TRAILER SAFETY INFORMATION

Hitch Coupler Troubleshooting

If the coupler becomes damaged it must be repaired

or replaced before towing. When the coupler is placed

on the ball, the latch should close fi rmly. Keep the latch

mechanism lightly oiled and clean. Items to check for are

as follows:

1. Latch does not grasp ball securely:

• Check the ball size. Make sure the ball and

coupler are the same size.

2. Latch does not snap into full latch position:

• Check adjustment. Latch mechanism may be

too tight.

• Check to see that the coupler housing has not

been damaged, keeping the ball hitch from fi tting

completely into the housing as designed.

3. Keep the tongue blocked up when not in use so the

coupler and mechanism are not in the ground being

exposed to dirt and moisture.

4. Apply a small amount of an automotive grease to the

ball before hitching coupler to prevent wear of the two

parts during towing.

5. Make sure the latch safety pin is in position before

towing.

Safety Chains

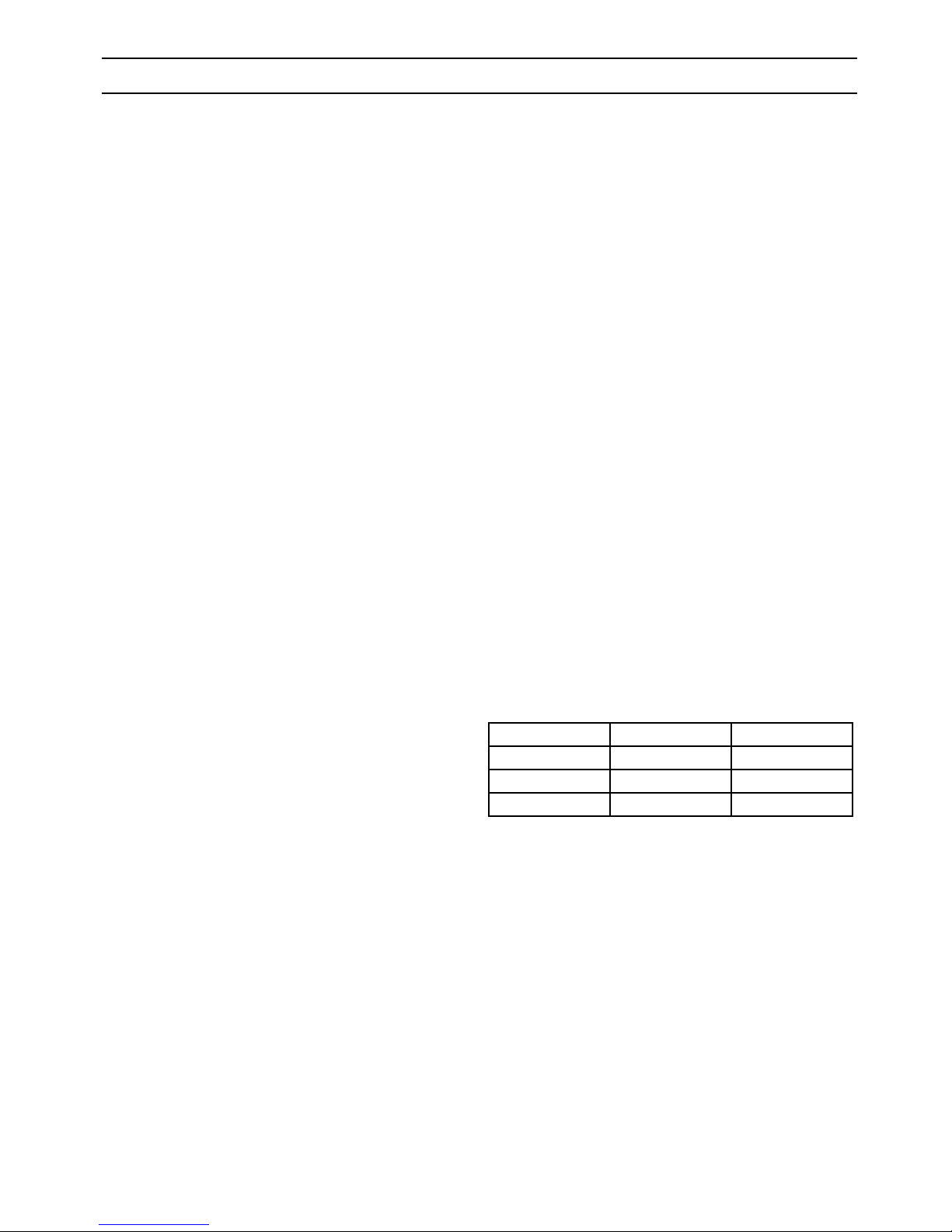

Listed in the chart below are the different class sizes

of safety chains and the rated load each chain must be

capable of withstanding.

TRAILER CLASS

TRAILER WEIGHT

GVWR IN LBS.

I to 2,000 2,000

II 2,000 to 3,500 3,500

III 3,500 to 5,000 5,000

WARNING: Failure to properly attach safety chains

between the trailer and tow vehicle can result in a

runaway trailer.

WARNING: To avoid accidents, before trailering:

• Hitch only to ball size marked on coupling.

• Ball clamp must capture ball and lever or hand

wheel is fully clamped.

• Cross safety chains under coupling.

• Allow only enough slack for turns.

MINIMUM BRAKING

STRENGTH IN LBS.

Coupler & Ball Engagement

If the coupler and towing ball resist attempts to make

engagement, do not force latch assembly. Instead, check

the ball diameter to verify that it conforms to Society of

Automotive Engineers (SAE) specifi cations. Standard

two-inch diameter ball should be within the limits of

2.000-inches to 1.970-inches. Balls larger than 2.000inches will not readily fi t the coupler. A two-piece coupler

ball is not recommended.

If the coupler becomes damaged it must be repaired

or replaced before towing. When the coupler is placed

on the ball, the latch should close fi rmly. Keep the latch

mechanism lightly oiled and clean.

Improper engagement of the coupler and ball can cause

damage if the vehicles separate in transit, thus, caution

must be exercised to insure a secure hook-up. Lower the

coupler onto the ball with the coupler latch in the vertical

position. Continue to lower the trailer tongue until the jack

clears the ground, then fl ip the coupler latch to its locked

(horizontal) position. At this point visually observe that

the ball is fully engaged in the ball hitch. An even better

check to make sure the two are fully engaged is to raise

the tongue of the trailer again using the jack. Raise until

the ball hitch connection starts to raise the rear of the

tow vehicle. If the connection was not properly made, the

ball and socket will separate as the tongue of the trailer

is raised.

Bottom View

The safety chains on your trailer are an added insurance

that it will not become detached from the tow vehicle. All

safety chains are provided with an added clasp to keep

them from becoming accidentally detached from the tow

vehicle. Your trailer hitch on the tow vehicle should

have two attaching holes or rings for attaching the safety

chains, preferably one on each side of the ball hitch.

Crisscross the chains under the tongue, the chain on the

left side of the trailer tongue attached to the right side

of the ball hitch, the chain on the right side of the trailer

tongue attached to the left side of the ball hitch.

This prevents the trailer tongue from dropping to the road

should the coupler or ball hitch fail. The chains should

be rigged as tight as possible with just enough slack to

allow tight turns to be made. This can be accomplished by

twisting the chain hook in a clockwise or counterclockwise

direction thus twisting the link spacing and making the

chain shorter. Also by keeping your chains as short as

possible you prevent them from dragging on the road

and wearing the chain links. If for any reason you fi nd

it necessary to replace a safety chain, use only original

equipment.

6

Shark SMT • 9.800-504.0

IMPORTANT TRAILER SAFETY INFORMATION

Load-Carrying Capacity

Located on the front left-hand side of the frame, (either

the inside or the outside) is the VIN (Vehicle Identifi cation

Number) tag. It will show the GVWR (Gross Vehicle Weight

Rating) which is the maximum load that can be applied

to the tires on the trailer. The GVWR and the carrying

capacity of the trailer are based on the tire size installed

on the trailer.

The GVWR is the maximum carrying capacity of the trailer

with its respective tires. It may not necessarily equal the

total GVWR of the trailer less the empty weight of the

trailer because there may be another controlling factor

such as frame strength that reduces the carrying capacity

to what is listed on the VIN tag.

The tire label will list the tire size that was installed on

the trailer as original equipment when it was sold to you,

the consumer. It also lists the maximum carrying capacity

of the trailer.

IMPORTANT: The total weight of the load must never

exceed the weight of cargo listed on the tire label and/

or the maximum load carrying capacity listed on the

VIN tag on your trailer. The GVWR (Gross Vehicle

Weight Rating) listed is the maximum total weight of

the trailer with accessories and all cargo allowable to

be carried on the tires that are installed on the trailer.

WARNING: Fishtailing caused from improper tongue

weight on the tow vehicle hitch ball can cause loss of

control of the tow vehicle and resulting serious injury

or property damage.

CAUTION: The maximum load applied to the trailer

must never exceed the carrying capacity of the trailer

as stated on the VIN label and/or the tire placard. Doing

so may cause failure of one or more component parts

of the trailer causing potential damage to the trailer

and/ or a potential accident. All concentrated loads

must be spread over as large an area as possible to

eliminate potential damage to the decking.

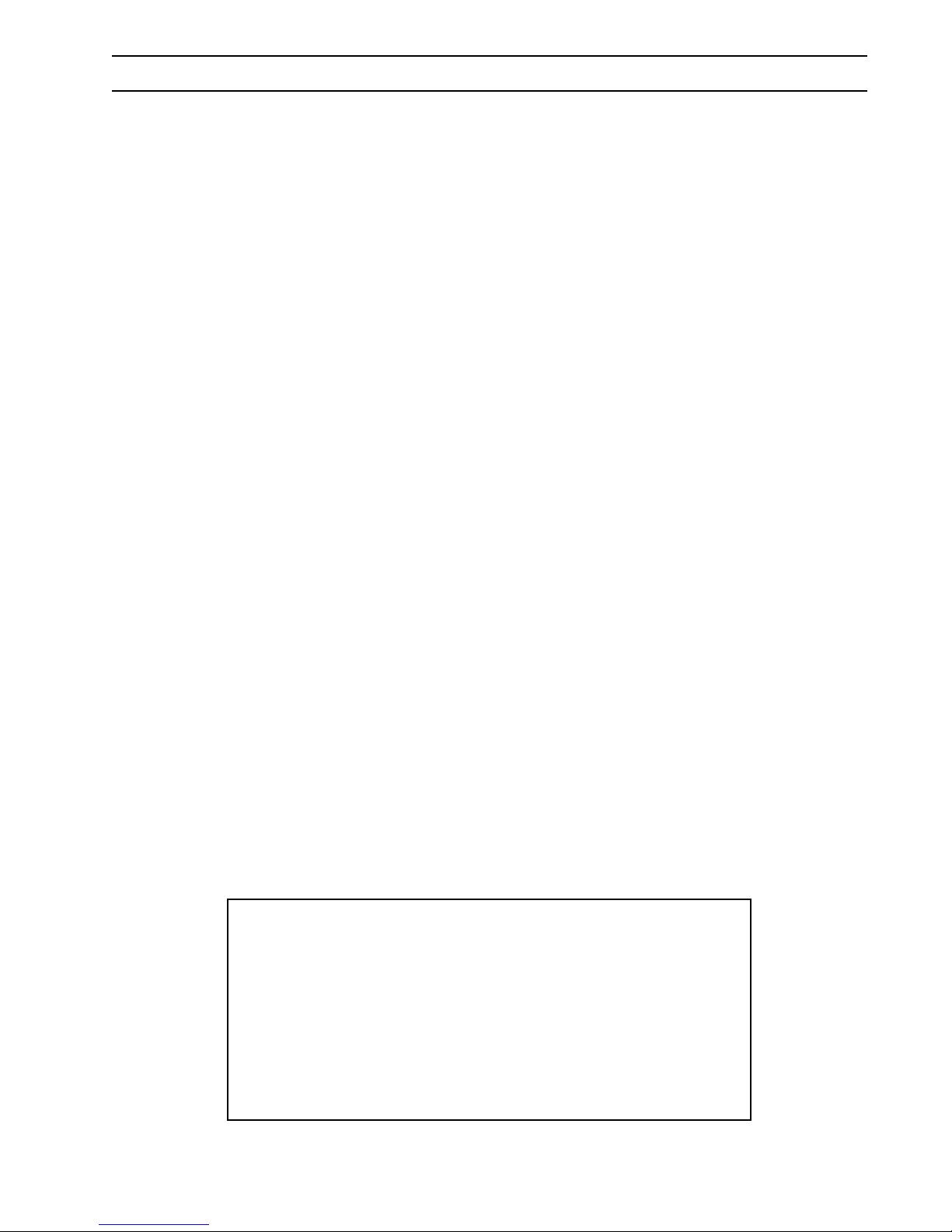

Shown below is an example of the tire label that is placed

on your trailer showing the items just discussed above.

Once you have familiarized yourself with the information

supplied on the ex ample tire label and VIN tag, check the

tire size and capacity of your trailer as shown on the VIN

tag on your trailer.

TIRE AND LOADING INFORMATION

RENSEIGNEMENTS SUR LES PNEUS ET LE CHARGEMENT

The weight of cargo should never exceed

TIRE SIZE COLD TIRE PRESS.

REAR XXXXXXX XXX KPA (XX PSI)

INTER XXXXXXXXX

FRONT XXXXX

SPARE XXXXX

MANUFACTURED BY: KARCHER NORTH AMERICA INC. DATE OF MFG.:XX/XXXX

GVWR (XXXX KG (XXXX LB)

GAWR (EACH AXLE)

XXXX KG (XXXX LB) XXXX XXXX XXX KPA (XX PSI) SINGLE

THIS VEHICLE CONFORMS TO ALL APPLICABLE U.S. FEDERAL MOTOR VEHICLE SAFETY STANDARDS

IN EFFECT ON THE DATE OF MANUFACTURE SHOWN ABOVE.

V.I.N. : TYPE : TRAILER

XXXXXXXXXXXXXXXXX

WITH TIRES RIMS AT COLD

XXXX kg or XXXX lbs

TRX-XXXX

SEE OWNER’S

MANUAL FOR

ADDITIONAL

INFORMATION

VOIR LE MANUAL

DE L’USAGER

POUR PLUS DE

RENSEIGNEMENTS

Proper Weight Distribution & Tongue

Weight

Ensuring that your trailer has the proper GVWR is very

important. Once that has been established and you

have the load on the trailer it is equally important that

you have proper weight distribution.

Tongue Weight

The tongue weight on your trailer is 10%-15% of the

total weight of the trailer and all the cargo that it is carrying. This is the amount of weight that is then transferred

to the tow vehicle through the ball hitch.

Example: The total weight of the trailer with load is 800

pounds. The tongue weight should not be less than 80

pounds (10%).

Too light of tongue weight can cause the trailer to

“fi shtail” (sway Weight Rating) as you travel down the

highway. This creates excessive strains on the tow

vehicle, hitch and on the trailer itself. It can very easily

lead to an accident.

To adjust for too light of a tongue weight the load must

be shifted for ward with respect to the axle. This will

increase the weight that is transferred to the tongue.

Adjustments should be made until the tongue weight

falls within 10% -15% recommended range. Likewise,

if you have too much tongue weight adjust the weight

backwards with respect to the axle until the tongue

weight falls in the recommended range

Tow vehicles vary on how much tongue weight they

can support for proper towing.

7

Shark SMT • 9.800-504.0

IMPORTANT TRAILER SAFETY INFORMATION

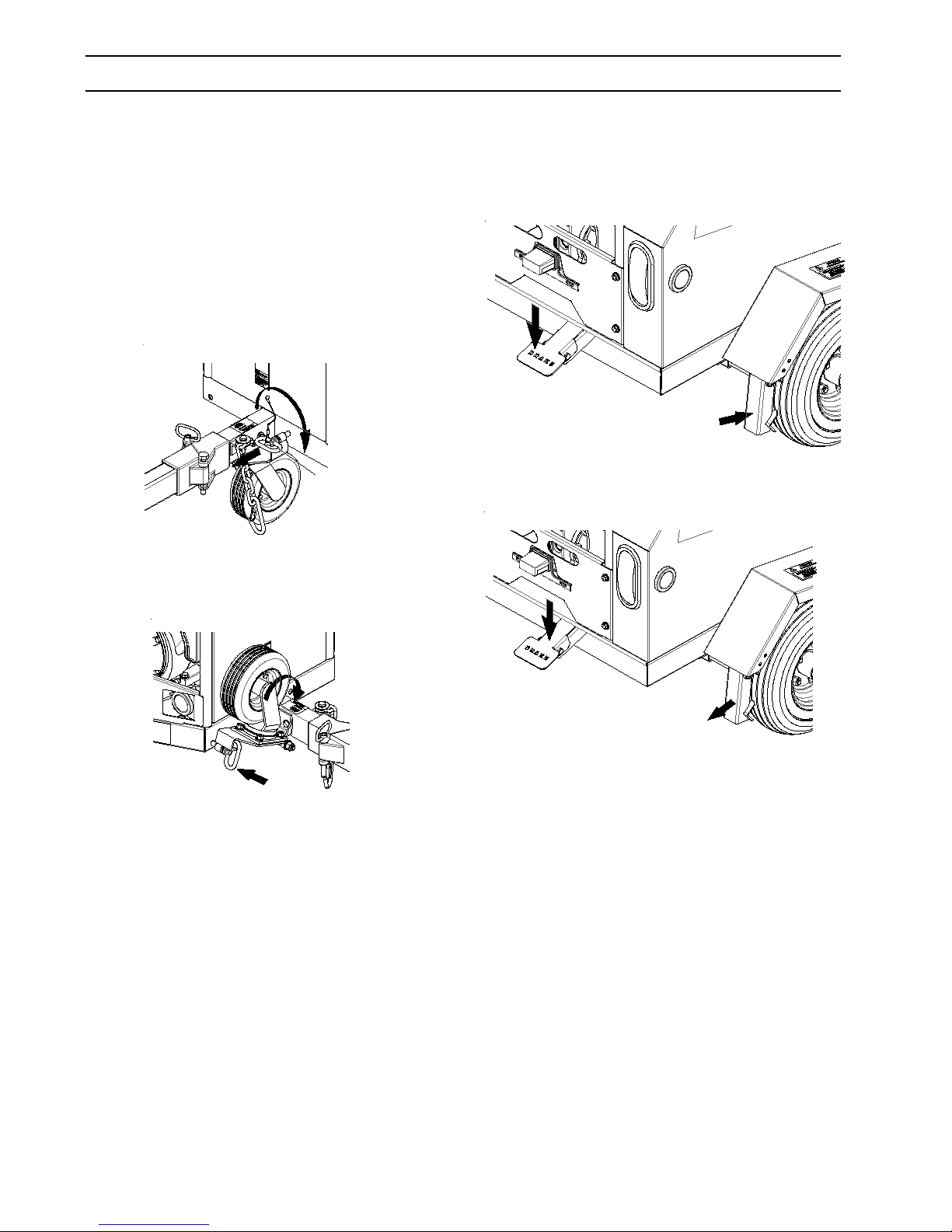

Caster Operations

This trailer has a caster for manual transporting

while using the pressure washer and to keep the

trailer tongue off the ground when not trailering.

WARNING: The caster must be in the up position

when trailering the unit.

STEP 1: Release the quick release pin by rotating

it clock wise. Pull Quick release pin from receptacle. Rotate the caster clockwise.

Trailer Brake Operations

WARNING: To avoid injury, the trailer brake must

be set when operating the pressure washer or

when not in use.

Quick release

pin

STEP 2: Insert quick release pin in receptacle.

Lock quick release pin in place by rotating pin

counter clockwise. Reverse step to lower caster.

NOTE: Before towing, diesel shut-off valve must

be in the OFF position.

To set the brake, press down on the brake pedal

until it engages on the back tires.

To release the brake, push the center of the brake to

release see that it has disengaged from the back tire.

CAUTION: This brake has a spring mechanism

that will return brake to its dis-engaged state.

Make sure foot or hand is moved out of the pinch

point area.

8

Shark SMT • 9.800-504.0

WHAT TO CHECK AND HOW TO CHECK

WHAT TO CHECK AND HOW TO CHECK

Tire Pressure

Proper air pressure for your tires is printed on the

sidewall. Check pressure while tires are cold. Do not

raise or lower pressure to meet load. Pressure other

than recommended pressure will lead to excessive tire

wear or tire failure. Balancing recommended.

Wheels

1

Check wheels for hole elongation or “out of round”. This condi-

34

tion can be caused by lug nuts

not being tight or being too tight.

Trailer wheels can be damaged

2

5

by chuck holes or curb jumping.

You may not be aware of the road shock to the wheels

without periodic checks. Replace any wheel that is

bent. Replace any wheel if you see elongation of the

bolt holes.

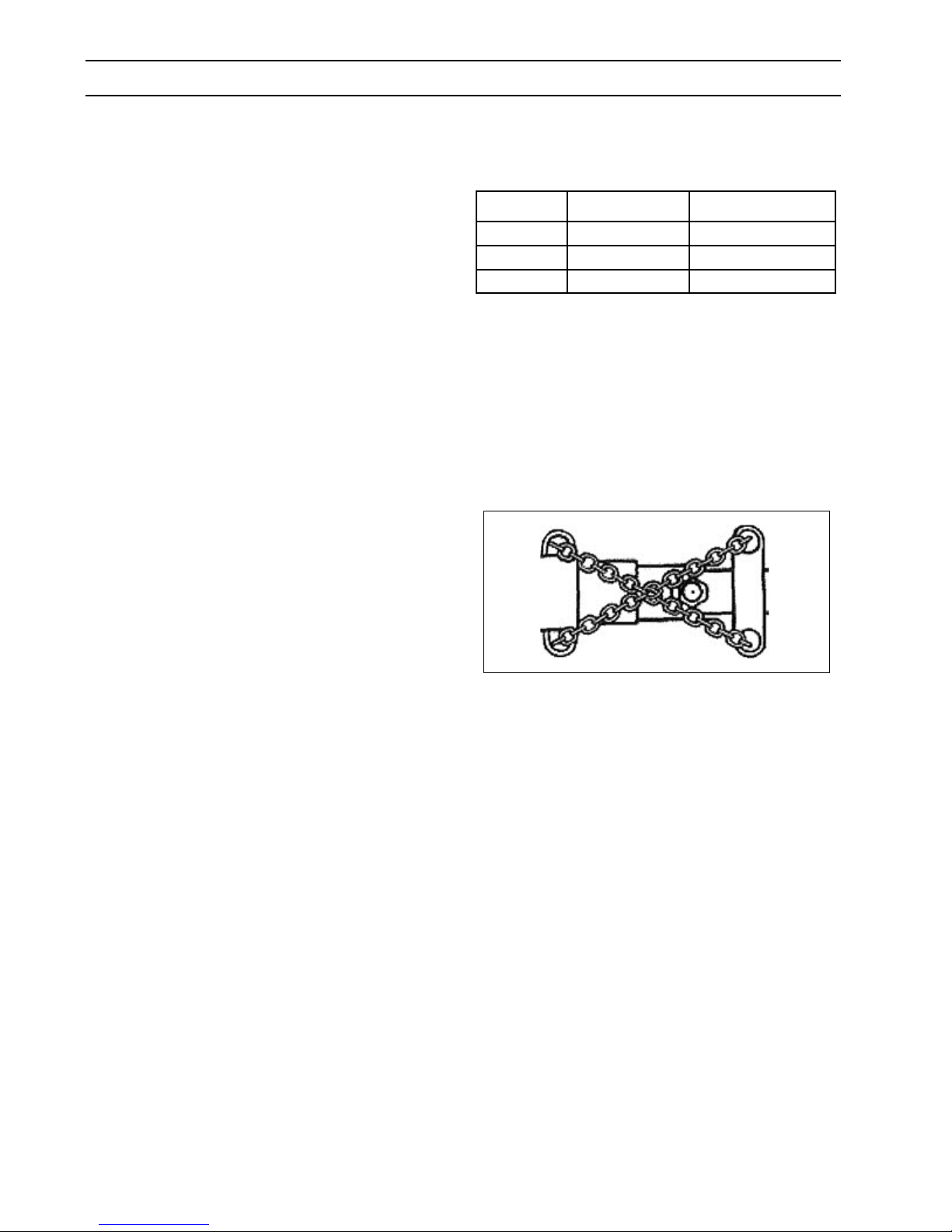

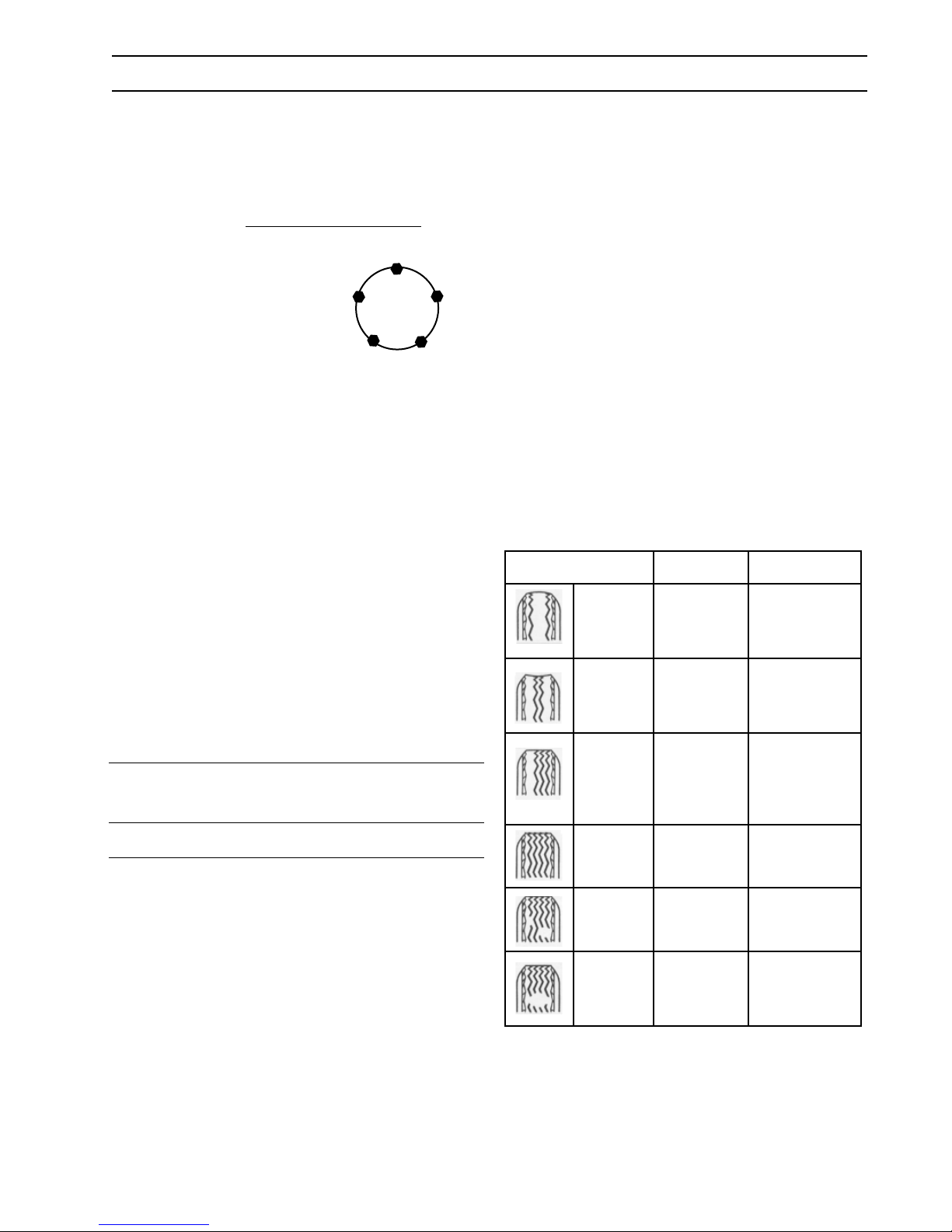

Wheel Lugs

Wheel lug nuts must be tightened with a torque wrench.

Refer to the chart below for proper torque.

1. Start all bolts or nuts by hand to prevent cross

threading.

2. Tighten bolts or nuts following sequence at right.

3. The tightening of the fasteners should be done in

stages. Following the recommended sequence,

tighten fasteners per wheel torque chart below.

4. Wheel nuts/bolts should be torqued before fi rst

road use and after each wheel removal. Check and

re-torque after the fi rst 10 miles, 25 miles and

again at 50 miles. Check periodically thereafter.

Wheel Torque Requirements

WHEEL

SIZE

1st Stage 2nd Stage 3rd Stage

TORQUE SEQUENCE

Tires

Before mounting tires onto wheels make certain that

the rim size and contour is approved for the tire as

shown in the Tire and Rim Association Yearbook or the

tire manufacturer’s catalog. Also make sure the tire will

carry the rated load. If the load is not equal on all tires

due to trailer weight distribution, use the tire rated for

the heaviest wheel position.

NOTE: The capacity rating molded into the sidewall

of the tire is not always the proper rating for the tire if

used in a trailer application. Use the following guideline:

1. LT and ST tires: use the capacity rating molded

into the tire.

2. Passenger Car Tires: Use the capacity rating

molded into the tire sidewall divided by 1.10.

Use tire mounting procedures as outlined by the Rubber

Manufacturer’s Association or the tire manufacturers.

NOTE: Tire wear should be checked frequently

because once a wear pattern becomes fi rmly

established in a tire it is diffi cult to stop, even if

the underlying cause is corrected.

WEAR PATTERN CAUSE ACTIONACTION

Adjust pressure

Center

Wear

Edge

Wear

Side Wear

Over

Infl ation

Under

Infl ation

Loss of

camber or

overloading

to particular

load per tire

catalog.

Adjust pressure

to particular

load per tire

catalog.

Make sure load

doesn't exceed

axle rating.

Align at alignment shop.

16" 20 - 25 50 - 60 80-90

Ball Coupler Hitches

Coupler assembly includes a latch lever and latch

lever safety pin or hitch pin. Be sure the latch lever is

locked and the pin properly secured before moving

your trailer. The pin can be engaged fully only if ball is

properly seated in the coupler.

Shark SMT • 9.800-504.0

Toe Wear

Cupping

Flat

Spots

Incorrect

toe-in

Out of

balance

Wheel

lockup & tire

skidding

Align at alignment shop.

Check bearing

adjustment and

balance tires.

Avoid sudden

stops when

possible and

adjust brakes.

9

Loading...

Loading...