Shark Pressure Washers DG-3022,DG-3025,DG-3030,DG-3530,DG-3535,DG-4040,DG-3033 DG-3530 Operating Instructions And Parts Manual

■

DG-3022

■

DG-3530

MODEL: DG

OPERATING INSTRUCTION

AND PARTS MANUAL

■

DG-3025

■

DG-3535

■

DG-3030

■

DG-4040

SHARK PRESSURE WASHERS

For technical assistance or the Shark Dealer nearest you, call 1-800-771-1881.

■

4275 N.W. Pacific Rim Blvd.

■

Camas, WA 98607

■

USA

2

MACHINE SPECIFICATIONS

●●

●

●●

Pump Volume At Pump Head:

DG-3022 2.7 GPM

DG-3025 2.8 GPM

DG-3030 3.0 GPM

DG-3530 3.5 GPM

DG-3535 3.5 GPM

DG-4040 4.0 GPM

● ●

●

● ●

Machine Dimensions: DG-3022 Length = 32.5" Width = 19.5" Height = 23.5"

●●

●

●●

Pump Pressure At Pump Head:

DG-3022 2200 PSI

DG-3025 2500 PSI

DG-3030 3000 PSI

DG-3530 3000 PSI

DG-3535 3500 PSI

DG-4040 4000 PSI

DG-3025 Length = 32.5" Width = 19.5" Height = 23.5"

DG-3030 Length = 32.5" Width = 19.5" Height = 23.5"

DG-3530 Length = 32.5" Width = 19.5" Height = 23.5"

DG-3535 Length = 32.5" Width = 19.5" Height = 23.5"

DG-4040 Length = 32.5" Width = 19.5" Height = 23.5"

CONTENTS

3

Introduction............................................................. 4

Important Safety Information ............................... 4-5

Pre-Operation Check .............................................. 5

Set-Up Procedures ................................................. 5

Component Identification ........................................ 6

Operating Instructions ............................................ 7

Shut Down Procedures........................................... 7

General Washing Techniques ................................. 7

How To Use the Detergent Injector ......................... 8

Exploded View ........................................................ 9

Exploded View, Parts List ................................. 10-11

Hose & Spray Gun Assembly & Parts List .............12

Troubleshooting ................................................. 13-14

Preventative Maintenance ......................................15

Oil Change Record ................................................. 15

Storage ..................................................................16

Warranty

SERIAL NUMBER:

DATE PURCHASED:

FOR SALES AND SERVICE, PLEASE CONTACT:

Shark DG Manual • Form #97-6124 • Revised 1/03

4

DG SERIES PRESSURE WASHER

OPERATOR’S MANUAL

INTRODUCTION

Thank you for purchasing a Shark Pressure Washer.

This manual covers the operation and maintenance of the

DG-302231, DG-302531, DG-303031, DG-353031,

DG-353531, DG-404021, DG-302237, DG-302537,

DG-303037, DG-353037, DG-353537, and DG-404027

washers. All information in this manual is based on the

latest product information available at the time of printing.

Shark reserves the right to make changes at any time

without incurring any obligation.

The DG Series was designed for maximum

use of 4 hours per day, 5 days per week.

Owner/User Responsibility:

The owner and/or user must have an understanding of

the manufacturer’s operating instructions and warnings

before using this Shark pressure washer. Warning information should be emphasized and understood. If the operator is not fluent in English, the manufacturer’s instructions and warnings shall be read to and discussed with

the operator in the operator’s native language by the purchaser/owner, making sure that the operator comprehends

its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’ instructions.

This manual should be considered a permanent

part of the machine and should remain with it if

machine is resold.

When ordering parts, please specify model and

serial number.

IMPORTANT

SAFETY INFORMATION

CAUTION

READ OPERATOR’S

MANUAL THOROUGHLY

PRIOR TO USE.

2. All installations must comply with local codes. Contact your electrician, plumber, utility company or the

selling distributor for specific details.

CAUTION: To reduce the risk of injury, read operating instructions

carefully before using.

1. Read the owner's manual thoroughly. Failure to follow instructions could cause malfunction

of the machine and result in

death, serious bodily injury and/

or property damage.

WARNING

WARNING: Risk of asphyxiation —

Use this product only in a well ventilated area.

3. Avoid installing machines in

small areas or near exhaust

RISK OF

ASPHYXIATION.

USE ONLY IN A WELL

VENTILATED AREA.

fans. Exhaust contains poisonous carbon monoxide gas; exposure may cause loss of consciousness and may lead to

death. It also contains detergents known, in certain

quantities, to cause cancer, birth defects, or other

reproductive harm.

WARNING

WARNING: Flammable liquids can

create fumes which can ignite

causing property damage or

severe injury.

WARNING: Risk of fire — Do not

RISK OF FIRE.

DO NOT ADD FUEL

WHEN OPERATING

MACHINE.

add fuel when the product is

operating.

WARNING: Risk of explosion — Do

not spray flammable liquids.

4. Do not place machine near flammable objects as the

engine is hot.

5. Allow engine to cool for 2 minutes before refueling. If

any fuel is spilled, make sure the area is dry before

testing the spark plug or starting the engine. (Fire

and/or explosion may occur if this is not done.)

Gasoline engines on mobile or portable equipment

shall be refuelled:

(a) outdoors;

(b) with the engine on the equipment stopped;

(c) with no source of ignition within 10 feet of

the dispensing point; and

(d) with an allowance made for expansion of

the fuel should the equipment be exposed

to a higher ambient temperature.

In an overfilling situation, additional precautions are

necessary to ensure that the situation is handled in

a safe manner.

WARNING

WARNING: High pressure stream

of water that this equipment can

produce can pierce skin and its

underlying tissues, leading to serious injury and possible amputation.

HIGH PRESSURE

SPRAY CAN PIERCE

SKIN AND TISSUES.

Shark DG • Rev. 1/03

DG SERIES PRESSURE WASHER

OPERATOR’S MANUAL

5

WARNING

WARNING: High pressure spray

can cause paint chips or other particles to become airborne and fly

at high speeds.

6. Eye safety devices and foot pro-

PROTECTIVE

EYEWEAR AND

CLOTHING MUST

BE WORN.

tection must be worn when using this equipment.

7. High pressure developed

by these machines will cause

personal injury or equipment damage. Use caution

when operating. Do not direct discharge stream at

people or severe injury or death will result.

8. Never make adjustments on machine while it is in

operation.

9. Do not operate with spray gun in the off position for

extensive periods of time as this may cause damage to the pump.

10. The best insurance against an accident is precaution and knowledge of the machine.

11. Shark will not be liable for any changes made to our

standard machines, or any components not purchased

from Shark.

12. Read engine safety instructions provided.

WARNING

WARNING: Keep water spray away

from electrical wiring or fatal electric shock may result.

13. Never run pump dry or leave

spray gun closed longer than 2

minutes.

KEEP WATER SPRAY

AWAY FROM

ELECTRICAL WIRING.

14. Do not allow children to operate

the pressure washer at any

time.

15. Inlet water supply must be cold and clean fresh

water.

PRE-OPERATION CHECK

Pump oil (SAE 30W non-detergent oil)

❑

Cold, clean, fresh water supply

❑

(6 GPM • 5/8" • 20 PSI)

Hose, wand, nozzle (nozzle size per serial plate)

❑

Water filter (intact, non-restrictive)

❑

Fuel (unleaded 86 or higher octane)

❑

Engine oil (SAE 10W40)

❑

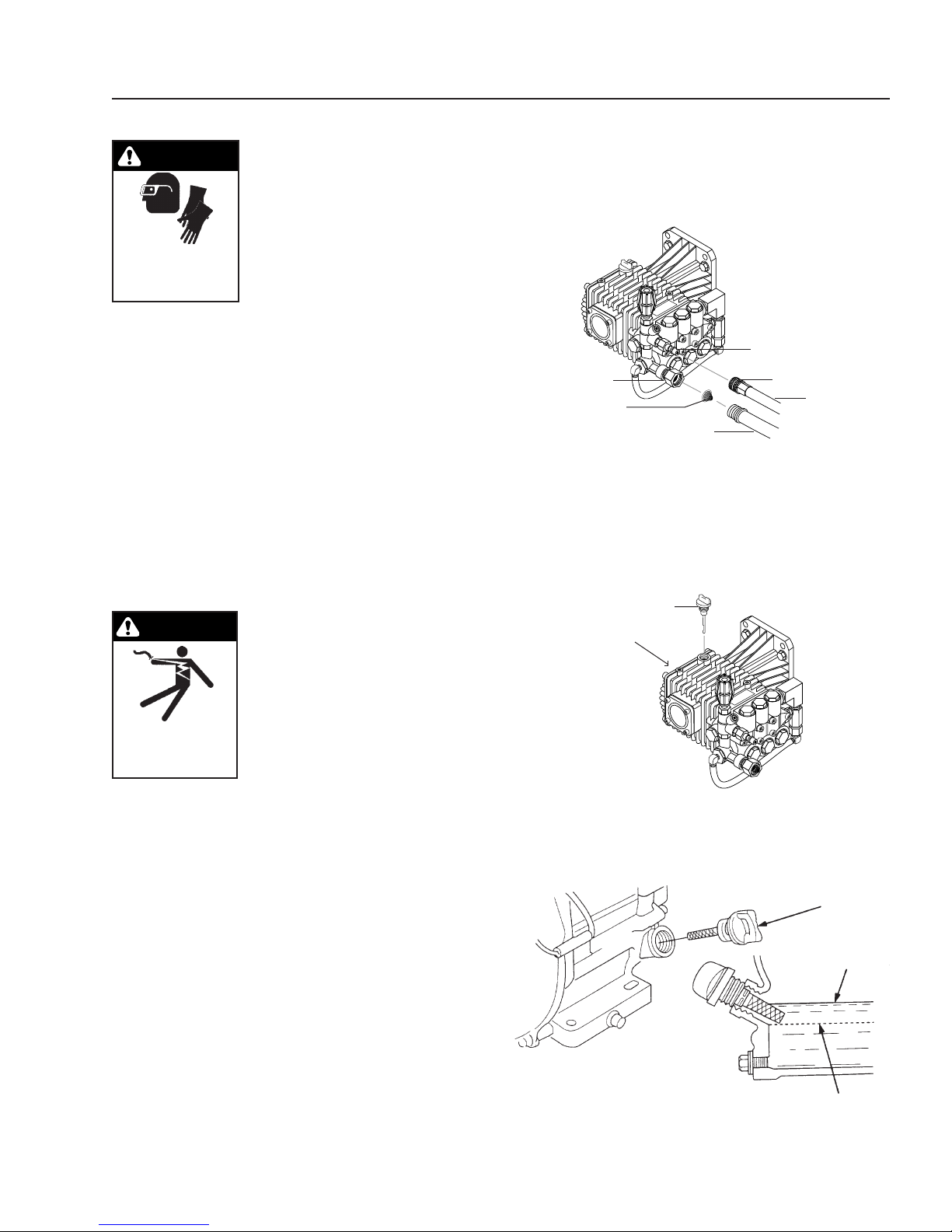

2. Attach high pressure hose to discharge nipple using

quick coupler. Lock coupler securely into place by

pulling back coupler collar and inserting it onto discharge nipple, then pushing collar forward to lock in

place.

Discharge

Inlet

Connector

Filter

Garden Hose

Nipple

Collar

Pressure

Hose

3. Attach wand to spray gun using teflon tape on threads

to prevent leakage.

4. Attach swivel connector on discharge hose to spray

gun using teflon tape on threads.

5. Remove oil plug on top of pressure washer pump

and replace with dipstick supplied on vented cap on

Comet pumps.

Dipstick

Sightglass

6. Check oil level on sight glass on side of pump. Oil

should be visible one half way up sight glass (30W

non-detergent).

7. Fill gasoline tank and check engine oil.

Dipstick

Upper Limit

SET-UP PROCEDURES

1. Attach a 5/8" garden hose to inlet connector. Minimum flow should be 6 GPM.

Shark DG • Rev. 1/03

Lower Limit

Notice: Running the engine with a low oil level can

cause engine damage.

6

DG SERIES PRESSURE WASHER

COMPONENT IDENTIFICATION

ALL MODELS

Unloader

Pump

High Pressure

Nozzles

OPERATOR’S MANUAL

Starter

Grip

▲▲

▲

▲▲

Pump

Protector

Soap Nozzle

Detergent

Bucket

(not included)

Pressure

Nozzle

Detergent Injector

Detergent

Pick-Up Tube

Wand

Wand Grip

Inlet Strainer

Garden Hose

(not included)

High Pressure

Hose

Trigger

Spray Gun

Pump — Develops high pressure.

Starter Grip — Used for starting the engine manually.

Spray Gun — Controls the application of water and

detergent onto cleaning surface with trigger device.

Includes safety latch.

Detergent Injector — Allows you to siphon and mix

detergents.

Straight Through Wand w/Grip — Must be connected

to the spray gun.

Shark DG • Rev. 1/03

High Pressure Hose — Connect one end to water pump

discharge nipple and the other end to spray gun.

Pump Protector — Cycles fresh cool water through

pump when recirculating water reaches 140°F.

NOTE: If trigger on spray gun is released for more

than 2 minutes, water will leak from valve. Warm water will discharge from pump protector onto floor.

This system prevents internal pump damage.

Loading...

Loading...