Page 1

SSD

98011940-1

L

I

S

T

E

D

®

OPERATOR’S MANUAL

SSD-603567E 1.110-586.0

SSD-603567E/G

To locate your local Shark Commercial Pressure Washer Dealer nearest you,

MODEL # ORDER #

1.110-587.0

visit www.sharkpw.com

9.801-194.0

Page 2

Page 3

Introduction & Important Safety Information 4-6

Component Identification 7

Assembly Instruction 8

Operating Instructions 9

Detergents & Cleaning Tips 10

Shut Down & Clean-Up 11

Storage 11

Maintenance 12-14

Troubleshooting 15-18

Preventative Maintenance & Oil Change Chart 19

Exploded View 20-21

Exploded View, Parts List 22-24

Hose and Spray Gun Assembly & Parts List 25

Platform, Isolator, Exploded View & Parts List 26-27

CONTENTS

Pump Assemblies, Exploded View 28

Pump Assemblies, Parts List 29

Control Box, Exploded View & Parts List 30

Float Tank Assembly, Exploded View & Parts List 31

Specifications 32

VRT 3 Unloader Exploded View & Parts List 33

KT.1 Series Pump Exploded View & Parts List 34-35

Clear Flame Burner "S" Replacement & Parts List 36-37

Clear Flame Burner "M/L" Replacement & Parts List 38-39

Warranty

Model Number ______________________________

Serial Number ______________________________

Date of Purchase ____________________________

The model and serial numbers will be found on a decal attached

to the pressure washer. You should record both serial number and

date of purchase and keep in a safe place for future reference.

3

SSD • 9.801-194.0 • Rev. 12/13

Page 4

INTRODUCTION & IMPORTANT SAFETY INFORMATION

MANUAL THOROUGHLY

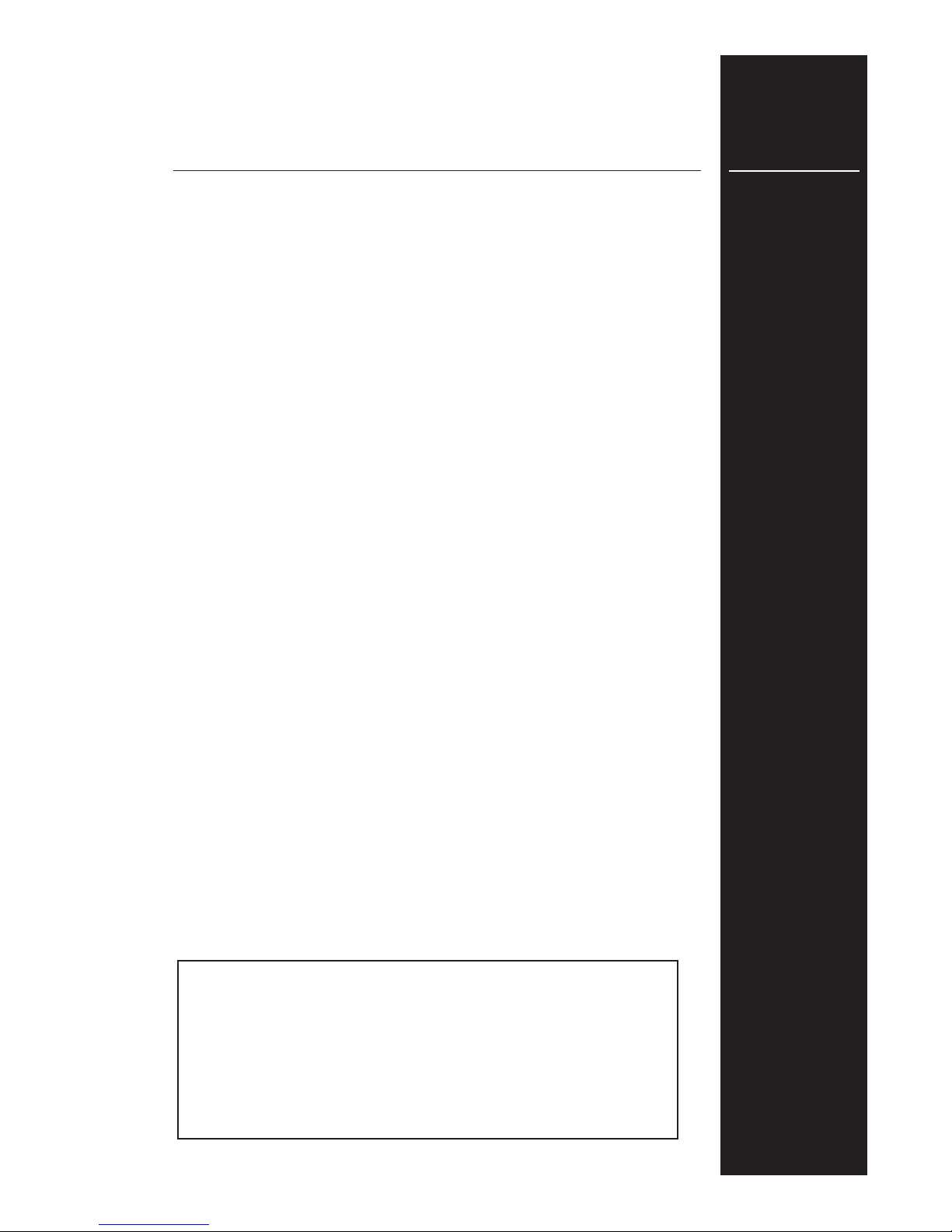

WARNING

WARNING

WARNING

WARNING

WARNING

Thank you for purchasing a Shark Pressure Washer. We

reserve the right to make changes at any time without

incurring any obligation.

Owner/User Responsibility:

The owner and/or user must have an understanding of

the manufacturer’s operating instructions and warnings

before using this pressure washer. Warning information

PRESSURE WASHER

should be emphasized and understood. If the operator

is not fluent in English, the manufacturer’s instructions

and warnings shall be read to and discussed with

the operator in the operator’s native language by the

purchaser/owner, making sure that the operator comprehends its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’ instructions.

OPERATOR’S MANUAL

The operator must know how to stop the machine

quickly and understand the operation of all controls.

Never permit anyone to operate the engine without

proper instructions.

SAVE THESE INSTRUCTIONS

This manual should be considered a permanent

part of the machine and should remain with it if

machine is resold.

When ordering parts, please specify model and serial number. Use only identical replacement parts.

This machine is to be used only by trained

operators.

WARNING: This machine exceeds

85 db appropriate ear protection

must be worn.

EAR PROTECTION

MUST BE WORN

WARNING: High pressure spray

can cause paint chips or other

particles to become airborne

and fly at high speeds. To avoid

personal injury, eye, hand and

USE PROTECTIVE

EYE WEAR

AND CLOTHING

WHEN OPERATING

THIS EQUIPMENT.

foot safety devices must be

worn.

5. Eye, hand, and foot protection

must be worn when using this

equipment.

6. Keep operating area clear of all persons.

WARNING: Flammable liquids

can create fumes which can ignite, causing property damage

or severe injury.

RISK OF EXPLOSION:

OPERATE ONLY

WHERE OPEN FLAME

OR TORCH IS

PERMITTED

WARNING: Risk of explosion —

Operate only where open flame

or torch is permitted.

IMPORTANT SAFETY

INFORMATION

WARNING: To reduce the risk of

injury, read operating instructions carefully before using.

1. Read the owner's manual

thoroughly. Failure to follow

instructions could cause mal-

READ OPERATOR’S

PRIOR TO USE.

2. Know how to stop the machine and bleed pressure

quickly. Be thoroughly familiar with the controls.

3. Stay alert — watch what you are doing.

KEEP WATER

SPRAY AWAY FROM

ELECTRICAL WIRING.

4

function of the machine and

result in death, serious bodily

injury and/or property damage.

WARNING: Keep wand, hose, and

water spray away from electric

wiring or fatal electric shock may

result.

4. All installations must comply with

local codes. Contact your electrician, plumber, utility company or

the selling distributor for specific

details.

RISK OF FIRE.

DO NOT ADD FUEL

WHEN OPERATING

MACHINE.

Spray flammable liquids.

7. Allow engine to cool for 1-2 minutes before refueling. If any fuel is spilled, make sure the area is dry

before testing the spark plug or starting the engine.

(Fire and/or explosion may occur if this is not done.)

Gasoline engines on mobile or portable equipment

shall be refueled:

a. outdoors;

b. with the engine on the equipment stopped;

c. with no source of ignition within 10 feet of

the dispensing point; and

d. with an allowance made for expansion of the

fuel should the equipment be exposed to a

higher ambient temperature.

SSD • 9.801-194.0 • Rev. 12/13

WARNING: Risk of fire — Do not

add fuel when the product is

operating or still hot.

WARNING: Do not use gasoline

crankcase draining or oil containing gasoline, solvents or

alcohol. Doing so will result in

fire and/or explosion.

WARNING: Risk of fire — Do not

Page 5

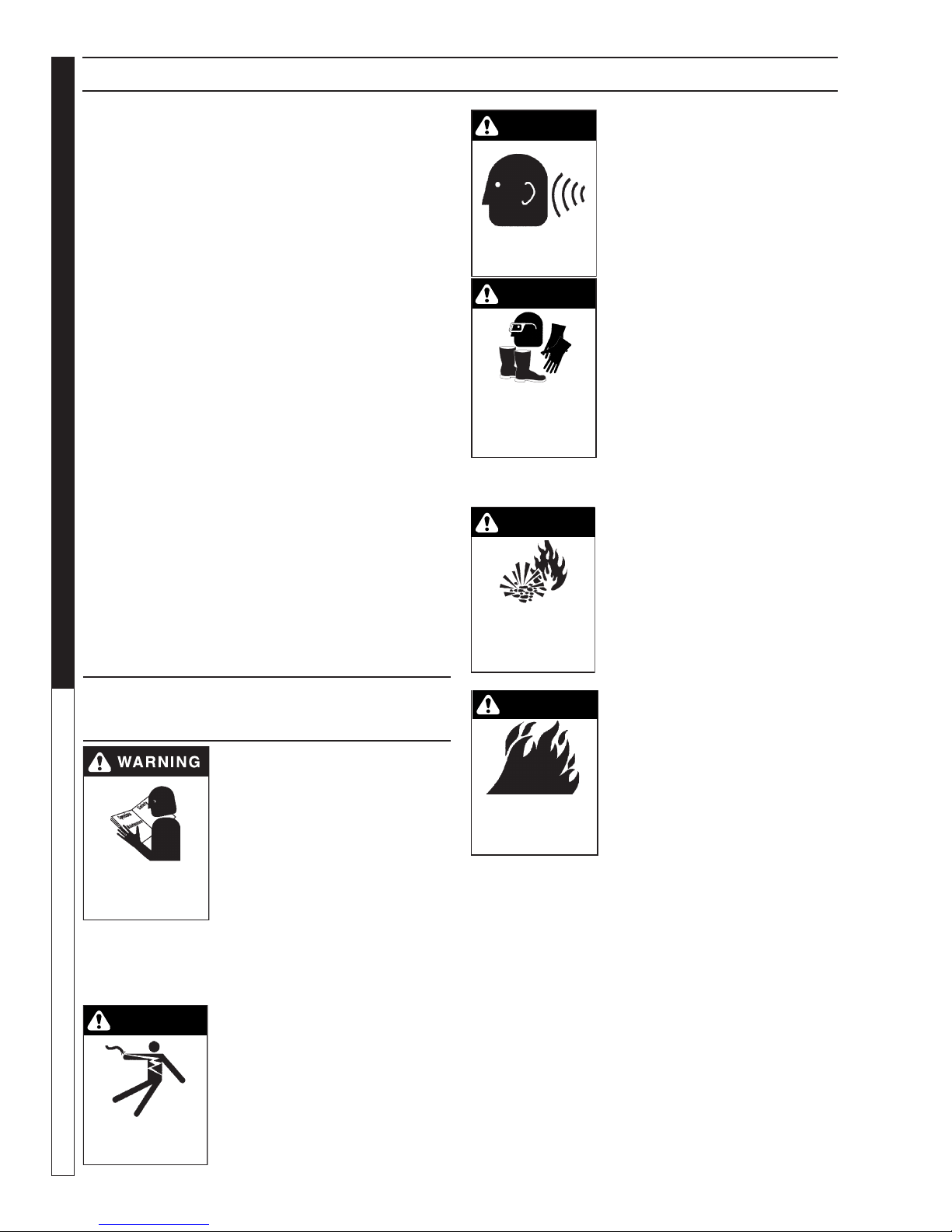

WARNING

WARNING

WARNING

WARNING

IMPORTANT SAFETY INFORMATION

WARNING

WARNING

PRESSURE WASHER

In an overfilling situation, additional precautions are

necessary to ensure that the situation is handled

in a safe manner.

WARNING: Risk of injury. Disconnect battery

ground terminal before servicing.

8. When in use , do not place machine near flammable

objects as the engine is hot.

9. Oil burning appliances shall be installed only in

locations where combustible dusts and flammable

gases or vapors are not present. Do not store or

use gasoline near this machine.

10. Use No. 1 or No. 2 heating oil (ASTM D306) only.

NEVER use gasoline in your fuel oil tank. Gasoline

is more combustible than fuel oil and could result

in a serious explosion. NEVER use crankcase or

waste oil in your burner. Fuel unit malfunction could

result from contamination.

11. Do not confuse gasoline and fuel oil tanks. Keep

proper fuel in proper tank.

WARNING: Risk of injury. Hot

surfaces can cause burns. Use

only designated gripping areas

of spray gun and wand. Do not

place hands or feet on non-insulated areas of the pressure

RISK OF INJURY.

HOT SURFACES

CAN CAUSE BURNS

washer.

12. Transport/repair with fuel tank EMPTY or with fuel

shut-off valve OFF.

CAUTION: Hot discharge fluid.

Do not touch or direct discharge

stream at persons.

WARNING: This machine produces hot water and must have

HOT DISCHARGE

FLUID: DO NOT

TOUCH OR DIRECT

DISCHARGE STREAM

AT PERSONS.

insulated components attached

to protect the operator.

13. To reduce the risk of injury, close supervision is

necessary when a machine is used near children.

Do not allow children to operate the pressure

washer. This machine must be attended during

operation.

WARNING: Grip cleaning wand

securely with both hands before

starting. Failure to do this could

result in injury from a whipping

wand.

14. Never make adjustments on

TRIGGER GUN KICKS

BACK - HOLD WITH

BOTH HANDS

machine while in operation.

SSD • 9.801-194.0 • Rev. 12/13

15. Be certain all quick coupler fittings are secured

before using pressure washer.

WARNING: High pressure devel-

oped by these machines will

cause personal injury or equipment damage. Keep clear of

nozzle. Use caution when operating. Do not direct discharge

RISK OF INJECTION

OR SEVERE INJURY

TO PERSONS. KEEP

CLEAR OF NOZZLE.

stream at people, or severe injury or death will result.

WARNING: Protect machine from

freezing.

16. To keep machine in best

operating conditions, it is

important you protect machine

from freezing. Failure to protect

PROTECT FROM

FREEZING

machine from freezing

could cause malfunction of the

machine and result in death,

serious bodily injury, and/or property damage. Follow storage instructions specified in this manual.

17. Inlet water must be clean fresh water and no hotter

then 90°F.

WARNING: Risk of asphyxiation.

Use this product only in a well

ventilated area.

18. Avoid installing machines in

small areas or near exhaust

RISK OF

ASPHYXIATION: USE

THIS PRODUCT ONLY

IN A WELL

VENTILATED AREA.

fans. Adequate oxygen is

needed for combustion or

dangerous carbon monoxide

will result.

19. Manufacturer will not be liable for any changes

made to our standard machines or any components

not purchased from us.

20. The best insurance against an accident is precaution and knowledge of the machine.

WARNING: Be extremely careful

when using a ladder, scaffolding

or any other relatively unstable

location. The cleaning area

should have adequate slopes

and drainage to reduce the pos-

RISK OF INJURY

FROM FALLS WHEN

USING LADDER.

sibility of a fall due to slippery

surfaces.

21. Do not allow acids, caustic or abrasive fluids to pass

through the pump.

22. Never run pump dry or leave spray gun closed

longer than 1-2 minutes.

OPERATOR’S MANUAL

5

Page 6

IMPORTANT SAFETY INFORMATION

23. Machines with shut-off spray gun should not be

operated with the spray gun in the off position for

extensive periods of time as this may cause damage to the pump.

24. Protect discharge hose from vehicle traffic and

sharp objects. Inspect condition of high pressure

hose before using or bodily injury may result.

PRESSURE WASHER

25. Before disconnecting discharge hose from water

outlet, turn burner off and open spray gun to allow water to cool below 100° before stopping the

machine. Then open the spray gun to relieve pressure. Failure to properly cool down or maintain the

heating coil may result in a steam explosion.

26. Do not overreach or stand on unstable support.

Keep good footing and balance at all times.

OPERATOR’S MANUAL

27. Do not operate this machine when fatigued or under

the influence of alcohol, prescription medications,

or drugs.

28. In oil burning models, use only kerosene, No. 1

home heating fuel, or diesel. If diesel is used, add

a soot remover to every tankful.

Follow the maintenance instructions

specified in the manual.

6

SSD • 9.801-194.0 • Rev. 12/13

Page 7

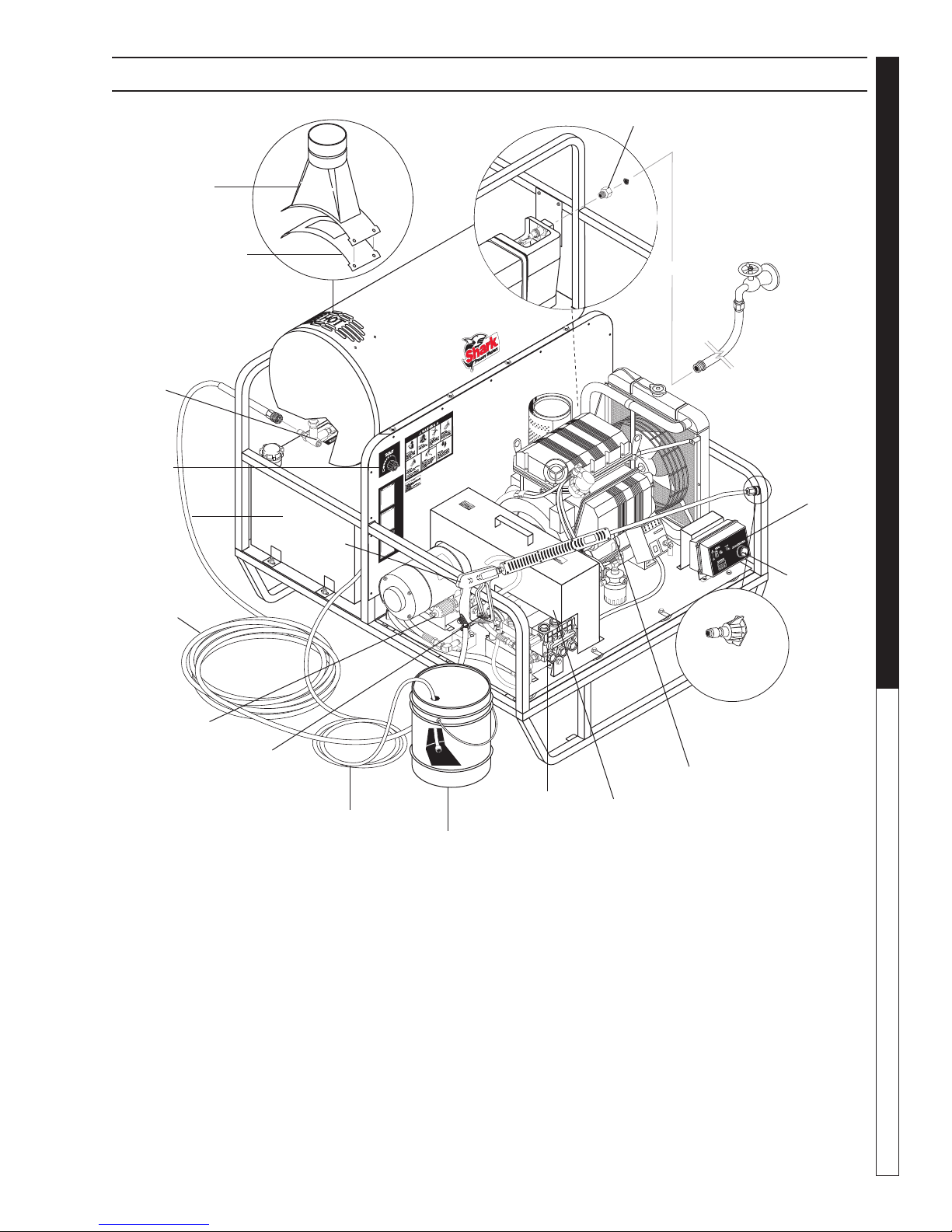

98011940-2

Flue Adapter

Optional 7-10049

Insulation Gasket

Optional 7-01471

NOTE: Burner air adjustment

must be tested after installation.

Rupture

Disk

Detergent

Metering

Valve

Diesel

Fuel Tank

PRESSURE WASHER

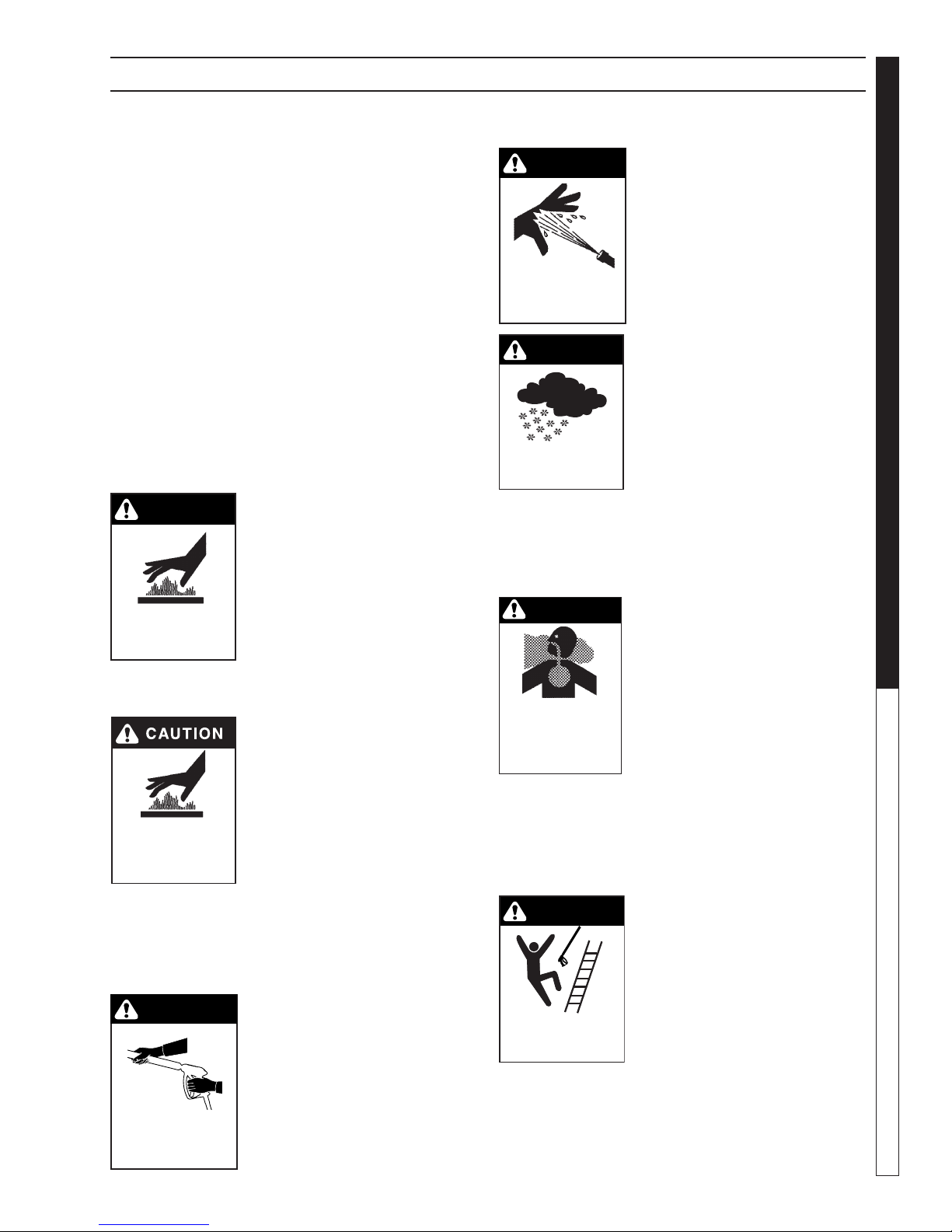

COMPONENT IDENTIFICATION

Inlet Connection

Water

Supply Hose

(not included)

OPERATOR’S MANUAL

Burner

Switch

Spray

Gun

High

Pressure

Hose

Unloader

Valve

Trigger/Safety

Latch

Pick-up Hose

Pump — Develops high pressure by pumping water

volume through nozzle.

Spray Gun — Controls the application of water and

detergent onto cleaning surface with trigger device.

Includes safety latch.

Detergent Metering Valve — Controls detergent

mixture.

Wand — Must be connected to the spray gun.

Rupture Disk — Will burst when extreme pressure

limits are reached.

Pressure Switch — Activates fuel solenoid to turn off

burner when trigger on spray gun is released.

Detergent

Pump

Detergent Bucket

(not included)

Unloader Valve — Safety control which releases

pressure when spray gun trigger is released.

High Pressure Hose — Connect one end to water

pump discharge nipple and the other end to spray

gun.

Pressure Nozzle — Inserted into wand quick coupler

to develop pressure

Adjustable Thermostat — Prevents water temperature from exceeding high temperatures. Is not used to

maintain constant temperature setting.

SSD • 9.801-194.0 • Rev. 12/13

Adjustable

Thermostat

Pressure

Nozzle

Wand

Pressure

Switch

7

Page 8

98011940-10

98011940-15

98011940-13

98011940-12

98011940-11

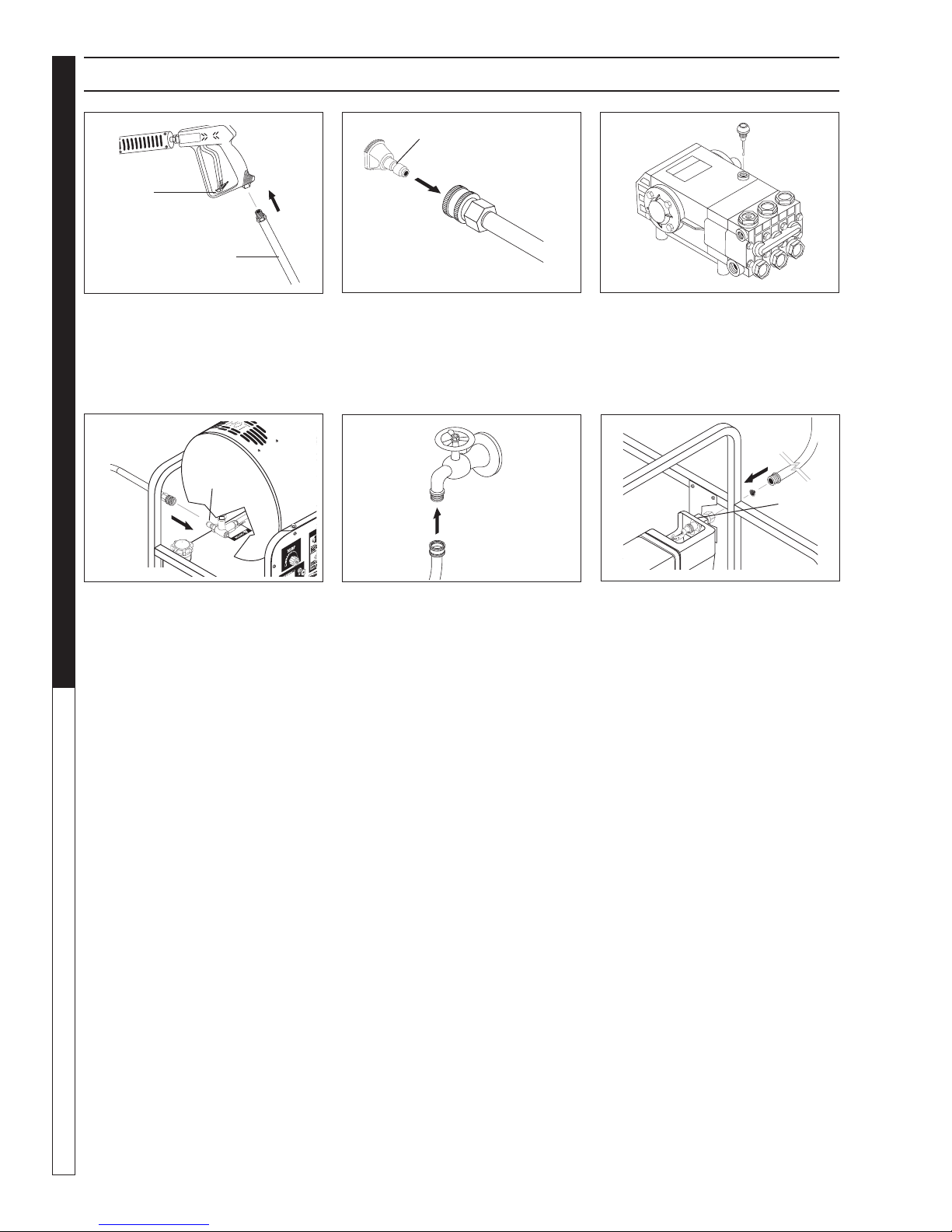

ASSEMBLY INSTRUCTIONS

98011940-14

Spray

Gun

Safety

Latch

High

PRESSURE WASHER

Pressure

Hose

STEP 1: Attach the high pressure

hose to the spray gun using teflon

tape on hose threads.

OPERATOR’S MANUAL

Pump

Discharge

Fitting

Pressure

Nozzle

Wand

STEP 2: Pull the spring-loaded

collar of the wand coupler back to insert your choice of pressure nozzle.

Dipstick

STEP 3: Remove shipping cap and

install oil dipstick. Check pump oil

level by using dipstick or observe

oil level in oil window (if equipped).

Use 30 wt. non detergent oil.

Garden

Hose

Water

Inlet

STEP 4: Connect the high pressure

hose to the pump discharge fitting.

Push coupler collar forward until

secure.

STEP 5: Connect garden hose to

cold water source and turn water on

completely. Never use hot water.

STEP 6: Connect the garden hose

to pump water inlet. Inspect inlets.

CAUTION: Do not run the pump

without water or pump damage

will result.

8

SSD • 9.801-194.0 • Rev. 12/13

Page 9

98011940-17

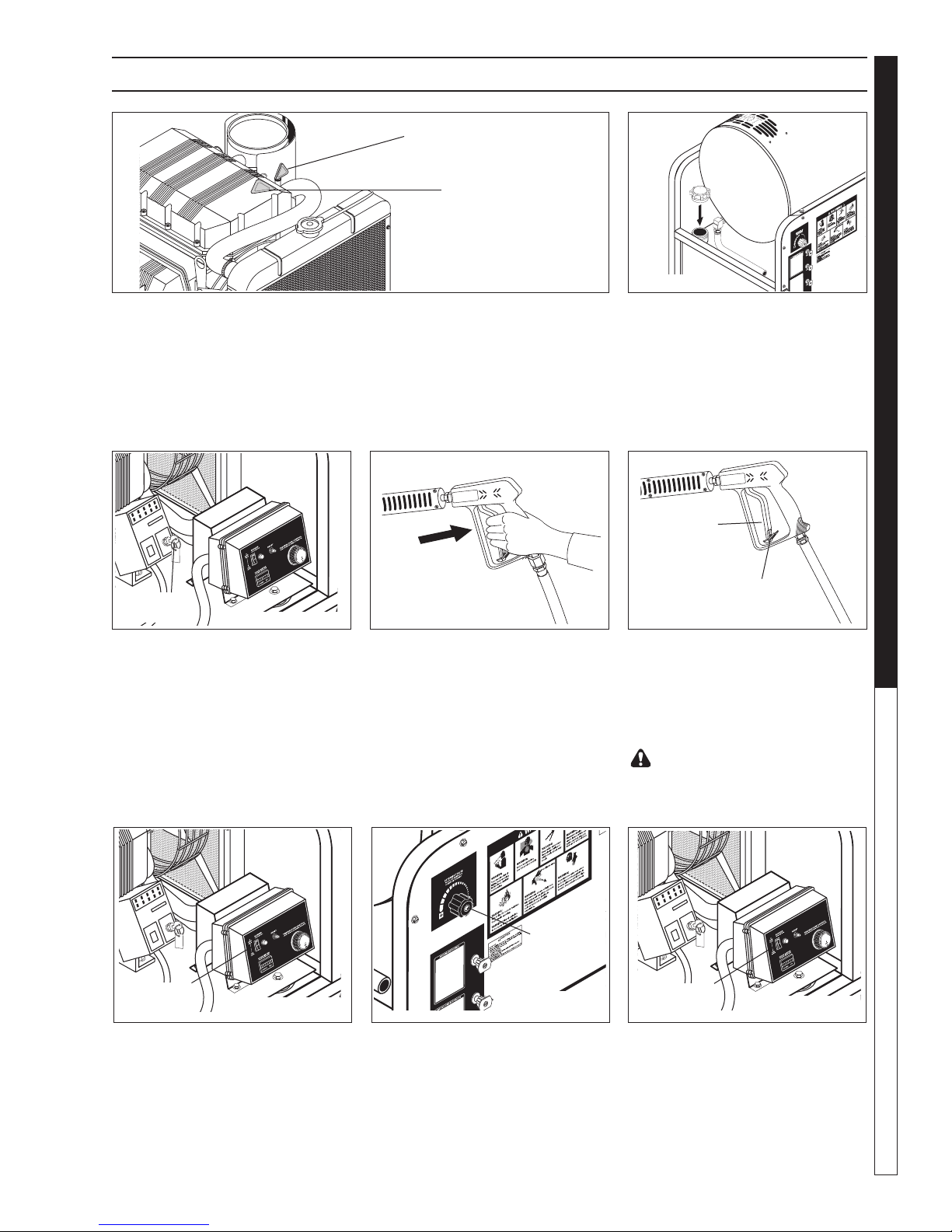

OPERATING INSTRUCTIONS

98011940-16

98011940-19

98011940-21

PRESSURE WASHER

Oil Dipstick

Oil Cap Filter

STEP 1: Read operator's manual before operating machine. Check engine

oil level. Oil level should be level with the bottom of the oil filler neck. (Refer

to the engine’s operating manual included with machine.) We recommend

that the oil be changed after the first 50 hours of use, then once every

250 hours. NOTE: Improper oil levels will cause low oil sensor to shut off

engine. IMPORTANT! Do not run engine with high or low oil levels

as this will cause engine damage.

Fuel

Tank

OPERATOR’S MANUAL

STEP 2: Fill engine fuel tank with

No. 2 diesel fuel. Check engine and

pump oil levels. Check engine radiator fluid level. Install battery and

connect red cable to the + terminal

and black to the - terminal.

Trigger

Key

Switch

98011940-18

STEP 3: Read engine manual. The

keyed ignition is located on the engine control panel. Turn key to first

position. The glow plug light will illuminate. When the light goes out, turn

key to start (second) position. Do not

hold key in start position longer than

five (5) seconds or starter motor will

be damaged.

Burner

Switch

98011940-18

STEP 4: Before installing pressure nozzle, trigger spray gun to

eliminate trapped pressure. Then

run machine allowing water to flush

through the system until clear.

Detergent

Valve

Safety

98011940-20

Latch

STEP 5: With spray gun and wand

pointed away from you or anybody

else, insert pressure nozzle into

quick coupler on end of wand.

Press trigger on spray gun to obtain

pressurized cold water spray.

WARNING! Never replace nozzles without engaging the safety

latch on the spray gun trigger.

Burner

Switch

98011940-18

STEP 6: For hot water, turn the

burner switch to ON when a steady

stream of water flows out of the

spray gun. Burner will light automatically.

NOTE: Do not start machine with

burner switch on.

STEP 7: To apply detergent, place

detergent pick-up tube into a container of detergent and turn the

detergent valve counterclockwise.

SSD • 9.801-194.0 • Rev. 12/13

STEP 8: To stop, reverse steps

and set all controls to their original

settings.

Turn burner switch OFF and open

trigger on spray gun, allowing water

to cool.

9

Page 10

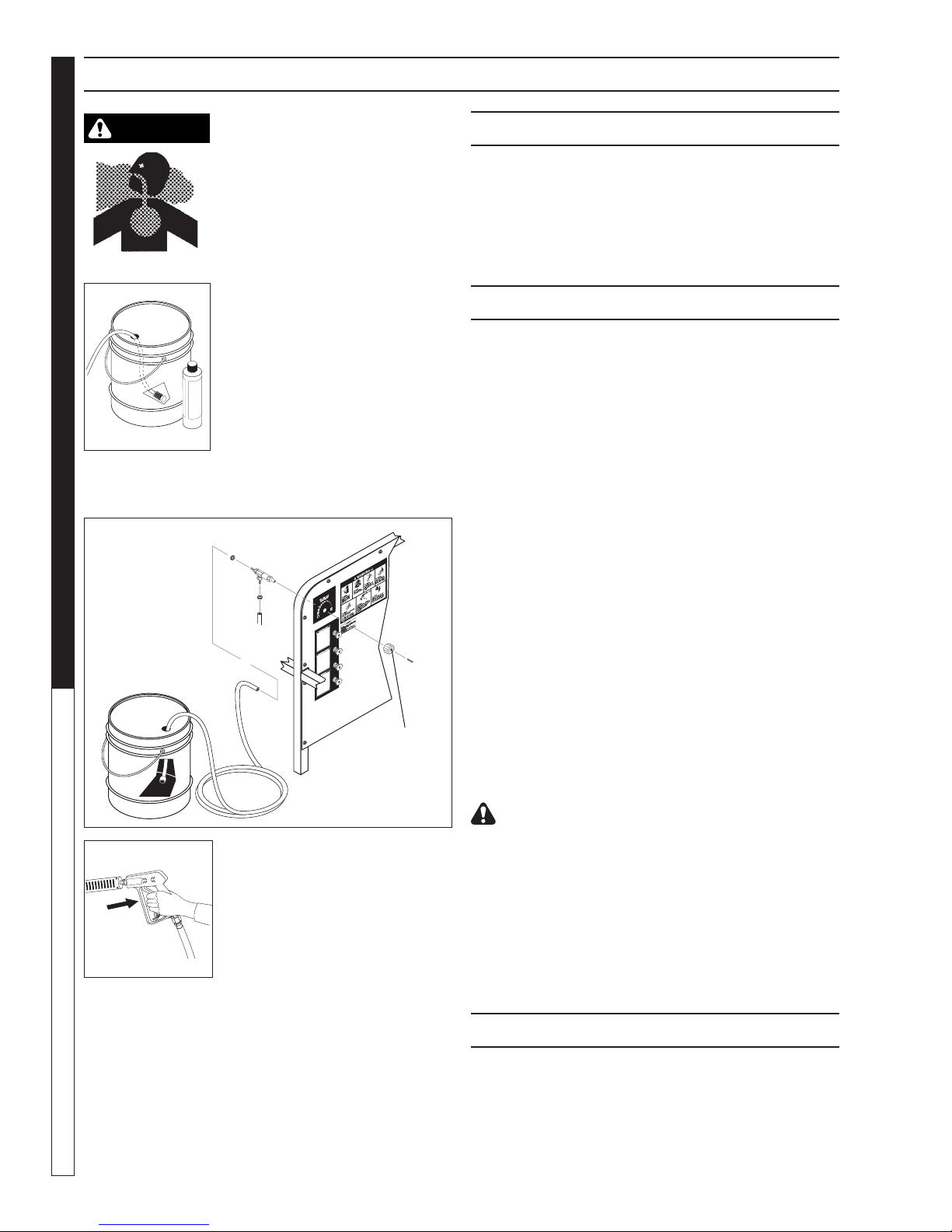

WARNING

98011940-23

98011940-19

DETERGENTS & GENERAL CLEANING TECHNIQUES

WARNING: Some detergents

may be harmful if inhaled or ingested, causing severe nausea,

fainting or poisoning. The harmful elements may cause property

damage or severe injury.

PRESSURE WASHER

STEP 1: Use detergent designed

specifically for pressure washers.

Household detergents could damage the pump. Prepare detergent

solution as required by the manufacturer. Fill a container with pressure washer detergent. Place the

OPERATOR’S MANUAL

STEP 2: Open detergent valve to desired mixture

ratio.

filter end of detergent suction tube

into the detergent container.

THERMAL PUMP PROTECTION

If you run the engine on your pressure washer for 3-5

minutes without pressing the trigger on the spray gun,

circulating water in the pump can reach high temperatures. When the water reaches this temperature,

the pump protector engages and cools the pump by

discharging the warm water onto the ground. This

thermal device prevents internal damage to the pump.

CLEANING TIPS

Pre-rinse cleaning surface with fresh water. Place

detergent suction tube directly into cleaning solution

and apply to surface (for best results, limit your work

area to sections approximately 6 feet square and always

apply detergent from bottom to top). Allow detergent

to remain on surface 1-3 minutes. Do not allow detergent to dry on surface. If surface appears to be drying,

simply wet down surface with fresh water. If needed,

use brush to remove stubborn dirt. Rinse from top to

bottom in an even sweeping motion keeping the spray

nozzle approximately 1 foot from cleaning surface. Use

overlapping strokes as you clean and rinse any surface.

For best surface cleaning action spray at a slight angle.

Detergent

Valve

STEP 3: With the engine running,

pull trigger to operate machine.

Liquid detergent is drawn into the

machine and mixed with water.

Apply detergent to work area.

Do not allow detergent to dry on

surface.

IMPORTANT: You must flush

the detergent line after each use by placing the

suction tube into a bucket of clean water, then run the

pressure washer for 1-2 minutes.

Recommendations:

• Before cleaning any surface, an inconspicuous

area should be cleaned to test spray pattern and

distance for maximum cleaning results.

• Ifpaintedsurfacesarepeelingorchipping,use

extreme caution as pressure washer may remove

the loose paint from the surface.

• Keepthespraynozzleasafedistancefromthe

surface you plan to clean. High pressure wash a

small area, then check the surface for damage.

If no damage is found, continue to pressure

washing.

CAUTION - Never use:

• Bleach, chlorine products and other corrosive

chemicals

• Liquids containing solvents (i.e., paint thinner,

gasoline, oils

• Tri-sodiumphosphateproducts

• Ammoniaproducts

• Acid-basedproducts

These chemicals will harm the machine and will damage the surface being cleaned.

RINSING

It will take a few seconds for the detergent to clear.

Apply safety latch to spray gun. Open detergent valve.

Select and install the desired high pressure nozzle.

NOTE: You can also stop detergent from flowing by

simply removing detergent siphon tube from bottle.

10

SSD • 9.801-194.0 • Rev. 12/13

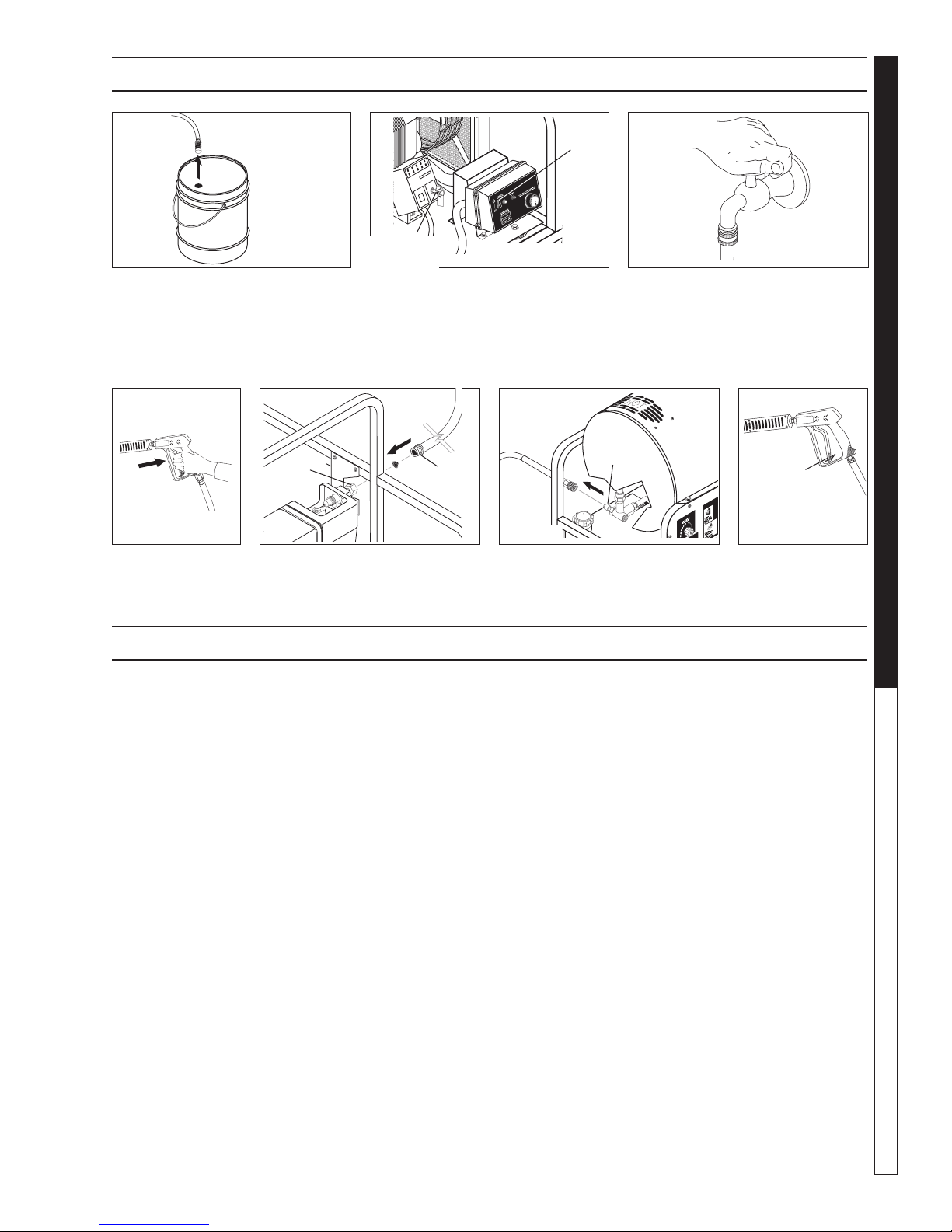

Page 11

98011940-18

98011940-20

98011940-24

SHUTTING DOWN AND CLEAN-UP

98011940-25

98011940-19

98011940-26

STEP 1: Remove detergent suction

tube from container and insert into

one gallon of fresh water. Open

detergent mixing valve. Pull trigger

on spray gun and siphon water for

one minute.

Water

Inlet

Burner

Switch

On-Off

Key Switch

STEP 2: Turn burner switch off and

continue spraying, allowing water to

cool below 100°F.

To stop engine, turn key to off

position.

Pressure

Outlet

Garden

Inlet

STEP 3: Turn off water supply.

High

Safety

Latch

PRESSURE WASHER

OPERATOR’S MANUAL

STEP 4: Press trigger to release water pressure.

STEP 5: Disconnect the garden

hose from the water inlet on the

machine.

Measures should be taken to protect your FOCS series

engine if the engine is not operated for a period of 30

days or more. Proper storage will protect the engine

from corrosion and prevent costly repairs due to storage

induced problems.

Storage - 1 to 6 months

1. Start and idle the engine at a no-load condition for

15 minutes.

2. Stop the engine, allow the engine to cool enough

to safely drain the oil as shown Re-install the oil

drain plug, then fill the crankcase with MIL-L-644P9 protectant oil. Fill the fuel tank with a high grade

fuel preservative (add mix) such as STA-BIL per the

manufacturer recommendations.

3. Start and operate the engine at 3/4 speed for 5-10

minutes.

4. Stop the engine, allow to cool enough to safely

drain the engine oil as shown. Re-install the oil

drain plug.

5. Refill the engine with standard recommended lubricating oil.

6. Drain the fuel tank. Remove the fuel filter. Install a

new fuel filter.

7. Carefully clean all debris from the radiator fins.

98011940-15

STEP 6: Disconnect the high

pressure hose from high

pressure outlet. Protect from

freezing.

STORAGE

8. Remove the intake manifold. Rotate the engine

until the intake valve opens at each cylinder. Using

suitable means, pour approximately 1 tsp. of engine

oil into each cylinder. Rotate the engine several

revolutions. Spray the inside of the intake manifold

with SAE 10 W oil. Replace the intake manifold

using a new gasket.

9. Spray the inside of the exhaust manifold with SAE

10W oil.

10. Cover all openings with tape and apply grease to

any and all unpainted surfaces.

11. Loosen the fan belt before wrapping the engine in

plastic film and storing in a dry place away from

high voltage sources and off the ground.

Storage - In excess of 6 months

Perform the storage preparation procedures approximately as detailed, except with the following changes.

1. Replace the oil in step 2 above with MIL-L-21260,

grade 2, SAE 30W rustproof oil.

2. Delete steps 5 and 11 above.

3. Coat any and all unpainted surfaces with MIL-C

16173D, grade 3 anti-rust grease.

4. Replace anti-freeze every 2 years.

SSD • 9.801-194.0 • Rev. 12/13

STEP 7: Engage

the spray gun

safety lock.

11

Page 12

MAINTENANCE

PREVENTATIVE MAINTENANCE

1. Check to see that water pump is properly

lubricated.

2. Follow winterizing instructions to prevent freeze

damage to pump and coils.

3. Always neutralize and flush detergent from system

after use.

PRESSURE WASHER

4. If water is known to have high mineral content, use

a water softener in your water system, or de-scale

as needed.

5. Do not allow acidic, caustic or abrasive fluids to be

pumped through system.

6. Always use high grade quality cleaning products.

7. Never run pump dry for extended periods of time.

OPERATOR’S MANUAL

8. Use clean No. 2 diesel fuel. Clean or replace fuel

filter every 250 hours of operation. Avoid water

contaminated fuel as it will damage the fuel pump.

9. If machine is operated with smoky or eye burning

exhaust, coils will soot up. Adjust air bands and fuel

pressure for proper emission.

10. Never allow water to be sprayed on or near

the engine or burner assembly or any electrical

component.

11. Periodically delime coils as per instructions.

12. Check to see that engine is properly lubricated. Use

SAE 10W40 grade oil.

It is advisable, periodically, to visually inspect the

burner. Check air inlet to make sure it is not clogged

or blocked. Wipe off any oil spills and keep equipment

clean and dry.

The flow of combustion and ventilating air to the burner

must not be blocked or obstructed in any manner.

The area around the washer should be kept clean

and free of combustible materials, gasoline and other

flammable vapors and liquids.

Winterizing Procedure:

Damage due to freezing is not covered by warranty.

Adhere to the following cold weather procedures whenever the washer must be stored or operated outdoors

under freezing conditions.

During winter months, when temperatures drop below

32°F, protecting your machine against freezing is necessary. Store the machine in a heated room. If this is not

possible then mix a 50/50 solution of anti-freeze and

water in the float tank. Turn the engine on to siphon the

anti-freeze mixture through the machine. If compressed

air is available, an air fitting can be screwed into the

float tank by removing the float tank strainer and fitting.

Then inject the compressed air. Water will be blown

out of the machine when the trigger on the spray gun

is opened.

High Limit Hot Water Thermostat:

For safety, each machine is equipped with a temperature sensitive high limit control switch. In the event that

the water should exceed its operating temperature,

the high limit control will turn the burner off until the

water cools, then it will automatically reset itself. The

thermostat sensor is located on the discharge side of

the heating coil. The thermostat control dial is located

on the control panel.

Pumps:

Use only SAE 10/40 weight non-detergent oil. Change

oil after first 50 hours of use. Thereafter, change oil

every three months or at 500 hour intervals. Oil level

should be checked through use of dipstick found on top

of pump, or the red dot visible through the oil gauge

window. Oil should be maintained at that level.

MAINTENANCE AND SERVICE

Unloader Valves:

Unloader valves are preset and tested at the factory

before shipping. Occasional adjustment of the unloader

may be necessary to maintain correct pressure.

Adjusting Unloader Valves:

Tampering with the factory setting may cause

personal injury and/or property damage and will void

the manufacturer's warranty.

12

SSD • 9.801-194.0 • Rev. 12/13

Page 13

MAINTENANCE AND SERVICE

98011930-28

PRESSURE WASHER

Deliming Coils:

Periodic flushing of coils or optional float tank is

recommended.

Step 1 Fill a container with 4 gallons of water, then .

add 1 lb. of deliming powder. Mix thoroughly.

Pour mixture into float tank.

Step 2 Remove wand assembly from spray gun and

put spray gun into float tank. Secure the trig ger on the spray gun into the open position.

Step 3 Turn engine on, allowing solution to be

pumped through coils back into the float tank.

The solution should be allowed to circulate 2- 4

hours or until the color changes.

Step 4 After circulating solution, flush the entire

system with fresh water. Clean out float tank

and then reinstall wand assembly to spray gun.

Removal of Soot from Heating Coil:

In the heating process, fuel residue in the form of soot

deposits may develop between the heating coil pipe,

and block air flow which will affect burner combustion.

When soot has been detected on visual observation,

the soot on the coil must be washed off after following

the coil removal steps (See Coil Removal section).

Fuel:

Use clean fuel oil that is not contaminated with water

and debris. Replace fuel filter and drain tank every 100

hours of operation.

Use No.1 or No 2 Heating Oil (ASTM D306) only.

NEVER use gasoline in your burner fuel tank. Gasoline

is more combustible than fuel oil and could result in a

serious explosion. NEVER use crankcase or waste oil

in your burner. Fuel unit malfunction could result from

contamination.

Fuel Control System:

This machine utilizes a fuel solenoid valve located on

the fuel pump to control the flow of fuel to the combustion chamber. The solenoid, which is normally closed,

is activated by a flow switch when water flows through

it. When the operator releases the trigger on the spray

gun, the flow of water through the flow switch stops,

turning off the electrical current to the fuel solenoid.

The solenoid then closes, shutting off the supply of

fuel to the combustion chamber. Controlling the flow

of fuel in this way gives an instantaneous burn-or-noburn situation, thereby eliminating high and low water

temperatures and the combustion smoke normally

associated with machines incorporating a spray gun.

Periodic inspection, to insure that the fuel solenoid

valve functions properly, is recommended. This can

be done by operating the machine and checking to

see that the burner is not firing when the spray gun is

in the OFF position.

Fuel Pressure Adjustment:

To control water temperature, adjust fuel pressure

by turning the regulating pressure adjusting screw

clockwise to increase, counterclockwise to decrease.

NOTE: When changing fuel pump, a bypass plug must

be installed in return port or fuel pump will not prime.

Burner Nozzle:

Keep the tip free of surface deposits by wiping it with

a clean, solvent saturated cloth, being careful not to

plug or enlarge the nozzle. For maximum efficiency,

replace the nozzle each season.

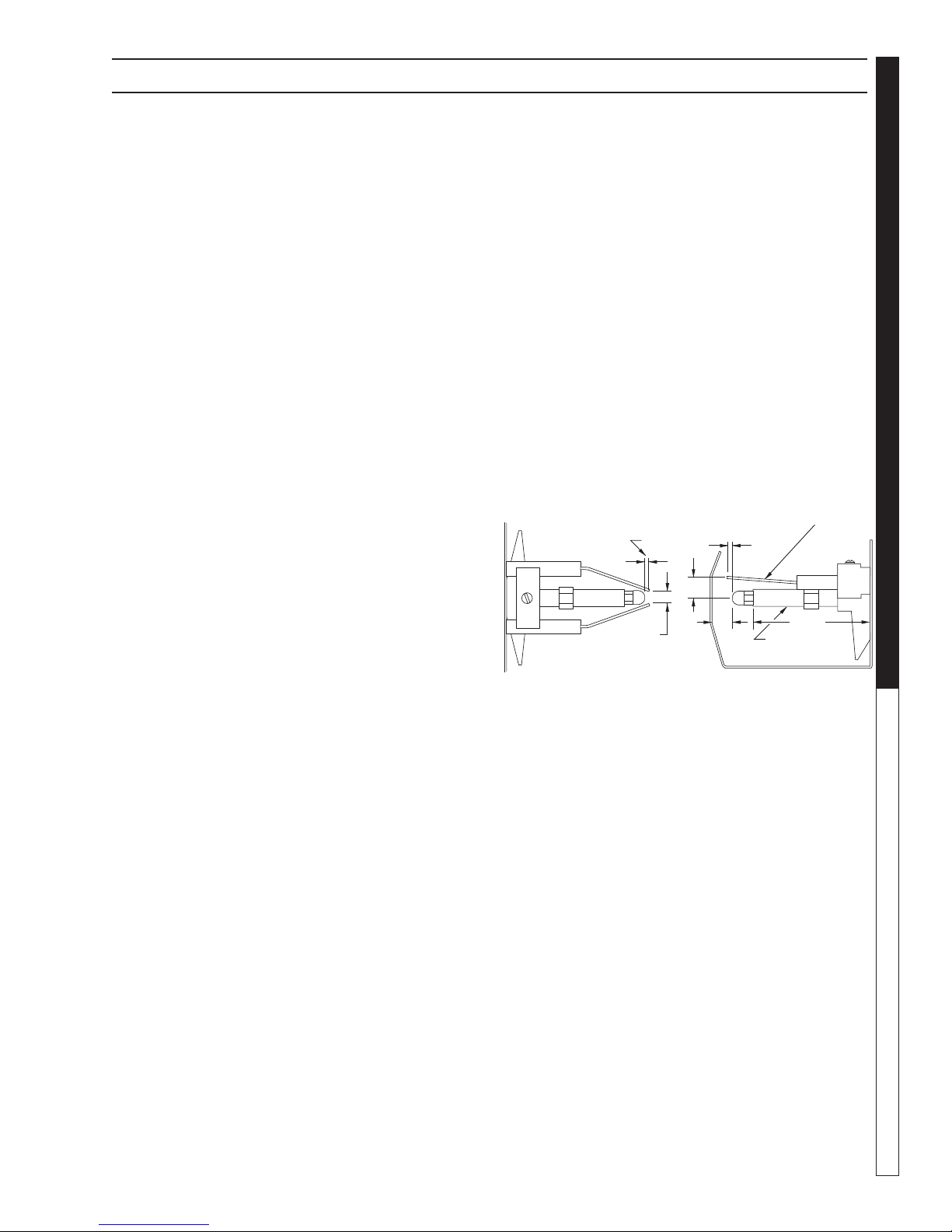

Electrode Setting:

Electrodes

Gap

1/8"

3/8"

3/16"

Top View Side View

Periodically Check Wiring Connections. If Necessary

To Adjust Electrodes, Use Diagram.

1/2"

1/8"

2-7/8"

Nozzle

Adapter

Beckett Burner Air Adjustment:

The oil burner on this machine is preset for operation

at altitudes below 1000 feet. If operated at higher

altitudes, it may be necessary to adjust the air band

setting. Adjust air band for a #1 or #2 smoke spot

on the Bacharach scale. If a smoky or eye-burning

exhaust is being emitted from the stack, two things

should be checked. First, check the fuel to be certain

that kerosene or No.1 home heating fuel is being used.

Next, check the air adjustment on the burner. An oily,

smoky fire indicates a lack of air and the air band

should be moved to allow the air to flow through the

burner. Sharp eye-burning fumes indicate too much

air flowing through the combustion chamber. The air

band should be readjusted to allow less air to flow

through the burner.

OPERATOR’S MANUAL

13

SSD • 9.801-194.0 • Rev. 12/13

Page 14

MAINTENANCE AND SERVICE

Air Shutter

Locking Screw

Air Shutter

Air Band

PRESSURE WASHER

Air Shutter

Locking Screw

OPERATOR’S MANUAL

To adjust, start the machine and turn burner ON.

Loosen two locking screws found in the air shutter

openings (see illustration) and close air shutter until

black smoke appears from burner exhaust vent. Note

air band position. Next, slowly open the air shutter until

white smoke just starts to appear. Turn air shutter halfway back to the black smoke position previously noted.

Tighten locking screws.

If the desired position cannot be obtained using only

the air shutter, lock the air shutter in as close a position

as can be obtained, then repeat the above procedure

on the air band setting.

Air Band Locking

Screw

Clear Flame Burner Air Adjustment

Reference Numbers

Air Band

Air Band Locking Screws

CAUTION: If white smoke appears from burner ex-

haust vent during start-up or operation, discontinue

use and readjust air bands.

NOTE: If a flue is installed, have a professional serviceman adjust your burner for a #1 or #2 smoke spot on

the Bacharach scale.

Shark Clear Flame Oil Burner

Burner Air Adjustment: The oil burner on this machine

is preset for operation at altitudes below 1000 feet. If

operated at higher altitudes, it may be necessary to

adjust the air band for a #1 or #2 smoke spot on the

Bacharach scale.

To adjust, start machine and turn burner ON. Loosen

two locking screws found on the air band and close air

band until black smoke appears from burner exhaust

vent. Note air band position. Next, slowly open the air

band until white smoke just starts to appear. Turn air

band halfway back to the previously noted position.

Tighten locking screws.

14

SSD • 9.801-194.0 • Rev. 12/13

Page 15

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

PRESSURE WASHER Troubleshooting Guide

LOW

OPERATING

PRESSURE

Faulty pressure gauge Install new gauge.

Insufficient water supply Use larger supply hose; clean filter at water

inlet.

Old, worn or incorrect spray nozzle Match nozzle number to machine and/or

replace with new nozzle.

Belt slippage Tighten or replace; use correct belt.

Plumbing or hose leak Check plumbing system for leaks.

Retape leaks with teflon tape.

Faulty or misadjusted unloader

valve

Worn packing in pump Install new packing kit.

Fouled or dirty inlet or discharge

valves in pump

Worn inlet or discharge valves Replace with valve kit.

Obstruction in spray nozzle Remove obstruction.

Leaking pressure control valve Rebuild or replace as needed.

Slow engine RPM Set engine speed at proper specifications.

Adjust unloader for proper pressure. Install

repair kit when needed.

Clean inlet and discharge valves.

BURNER

WILL NOT

LIGHT

(continued on next

page)

Pump sucking air Check water supply and possibility of air

seepage.

Valves sticking Check and clean or replace if necessary.

Unloader valve seat faulty Check and replace if necessary.

Little or no fuel Fill tank with fuel.

Improper fuel or water in fuel Drain fuel tank and fill with proper fuel.

Clogged fuel line Clean or replace.

Plugged fuel filter Replace as needed.

Misadjusted burner air bands Readjust air bands for clean burn.

Little or no fuel pressure from fuel

pump

Faulty burner transformer Test transformer for proper arc between

Disconnected or short in electrical

wiring

Increase fuel pressure to specification and/or

replace fuel pump. Test with pressure gauge.

contacts. Replace as needed.

All wire contacts should be clean and tight.

No breaks in wire.

15

SSD • 9.801-194.0 • Rev. 12/13

Page 16

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

BURNER WILL

NOT LIGHT

(continued from

previous page)

PRESSURE WASHER Troubleshooting Guide

FLUCTUATING

PRESSURE

Flex coupling slipping on fuel

pump shaft or burner motor shaft

On-Off switch defective Check for electrical current reaching burner

Heavy sooting on coil and burner

can cause interruption of air flow

and shorting of electrodes

Improper electrode setting Check and reset according to diagram in

Fuel not reaching combustion

chamber

Clogged burner nozzle Clean as required.

Thermostat faulty or slow engine

speed

Flow switch malfunction Remove, test for continuity and replace as needed.

Flow solenoid malfunction Replace if needed.

Valves worn Check and replace if necessary.

Blockage in valve Check and replace if necessary.

Replace if needed.

assembly with burner switch on.

Clean as required.

Operator’s Manual.

Check fuel pump for proper flow. Check

solenoid flow switch on machines with spray

gun control, for proper on-off fuel flow control.

Increase engine RPM to increase voltage.

MACHINE

SMOKES

Pump sucking air Check water supply and air seepage at joints in

suction line.

Worn piston packing Check and replace if necessary.

Gasoline engine altitude The gasoline engine is preset for operation

at altitudes below 1000 feet above sea level.

If operated at higher altitudes, it may be necessary

to install a high altitude main jet in the carburetor.

Contact your local authorized engine sales

and service center for details.

Improper fuel or water in fuel Drain tank and replace contaminated fuel.

Improper air adjustment Readjust air bands on burner assembly.

Low fuel pressure Adjust fuel pump pressure to specifications.

Plugged or dirty burner nozzle Replace nozzle.

Faulty burner nozzle spray

pattern

Heavy accumulation of soot on

coils and burner assembly

Misaligned electrode setting Realign electrodes to specifications.

Obstruction in smoke stack Check for insulation blockage or other foreign

Replace nozzle.

Remove coils and burner assembly, clean

thoroughly.

objects.

Low engine RPM Increase RPM.

16

SSD • 9.801-194.0 • Rev. 12/13

Page 17

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

PRESSURE WASHER Troubleshooting Guide

LOW WATER

TEMPERATURE

WATER

TEMPERATURE

TOO HOT

Improper fuel or water in fuel Replace with clean and proper fuel.

Low fuel pressure Increase fuel pressure.

Weak fuel pump Check fuel pump pressure. Replace pump if

needed.

Fuel filter partially clogged Replace as needed.

Soot build-up on coils not allowing

heat transfer

Improper burner nozzle Call Dealer.

Incoming water to machine warm

or hot

Fuel pump pressure too high See specifications for proper fuel pressure.

Fuel pump defective Replace fuel pump.

Detergent line sucking air Tighten all clamps. Check detergent lines for

Defective temperature switch Replace.

Incorrect fuel nozzle size Call Dealer.

Insufficient water supplied Check water G.P.M. to machine.

Clean coils.

Lower incoming water temperature.

holes.

PUMP NOISY

PRESENCE OF

WATER IN OIL

WATER DRIPPING

FROM UNDER

PUMP

Restricted water flow Check nozzle for obstruction, proper size.

Air in suction line Check water supply and connections on

suction line.

Broken or weak inlet or discharge

valve springs

Excessive matter in valves Check and clean if necessary.

Worn bearings Check and replace if necessary.

Oil seal worn Check and replace if necessary.

High humidity in air Check and change oil twice as often.

Piston packing worn Check and replace if necessary.

O-Ring plunger retainer worn Check and replace if necessary.

Cracked piston Check and replace if necessary.

Pump protector Lower water supply pressure. Do not run

Check and replace if necessary.

with spray gun closed longer than 2 minutes.

17

SSD • 9.801-194.0 • Rev. 12/13

Page 18

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

OIL DRIPPING

EXCESSIVE

VIBRATION IN

DELIVERY LINE

DETERGENT

NOT DRAWING

PRESSURE WASHER Troubleshooting Guide

PUMP RUNNING

NORMALLY BUT

PRESSURE LOW

ON INSTALLATION

Oil seal worn Check and replace if necessary.

Irregular functioning of the valves Check and replace if necessary.

Air leak Tighten all clamps. Check detergent lines for

holes.

Restrictor in float tank is missing Replace restrictor. Check for proper orifice in

restrictor.

Filter screen on detergent suction

hose plugged

Dried up detergent plugging metering

valve

High viscosity of detergent Dilute detergent to specifications.

Hole in detergent line(s) Repair hole.

Low detergent level Add detergent, if needed.

Pump sucking air Check water supply and possibility of air

Valves sticking Check and clean or replace if necessary.

Nozzle incorrectly sized Check and replace if necessary

Clean or replace.

Disassemble and clean thoroughly.

seepage.

(See serial plate for proper size).

BURNER

MOTOR WILL

NOT RUN

RELIEF VALVE

LEAKS WATER

Unloader valve seat faulty Check and replace if necessary.

Worn piston packing Check and replace if necessary.

Fuel pump seized Replace fuel pump.

Burner fan loose or misaligned Position correctly, tighten set screw.

Defective control switch Replace switch.

Loose wire Check and replace or tighten wiring.

Defective burner motor Replace motor.

Relief valve defective Replace or repair.

18

SSD • 9.801-194.0 • Rev. 12/13

Page 19

PREVENTATIVE MAINTENANCE

This pressure washer was produced with the best available materials and quality craftsmanship. However, you

as the owner have certain responsibilities for the correct care of the equipment. Attention to regular preventative

maintenance procedures will assist in preserving the performance of your equipment. Contact your dealer for

maintenance. Regular preventative maintenance will add many hours to the life of your pressure washer. Perform

maintenance more often under severe conditions.

Check pump oil level before first use of your new pressure washer. Change pump oil after first 50 hours and

every 3 months or 500 hours thereafter. Use SAE 30 weight oil, non-detergent.

PRESSURE WASHER

Date Oil Changed

Month/Day/Year

No. of Operating Hours

Since Last Oil Change

Brand Name and

OPERATOR’S MANUAL

Type of Oil (see above)

MAINTENANCE

Maintenance Operation

Pump

Check Oil

Engine

Pump

Change Oil

Engine

Air Cleaner Check Clean

Spark Plug

Check Valve Clearance

Fuel Tank Filter

Water Filter/Clean Check

Every 8 Hrs

or Daily

X

SSD • 9.801-194.0 • Rev. 12/13

25 Hrs

or Weekly

X

50 Hrs

or Monthly

X

100 Hrs

or Yearly

X

X

Yearly

X

X

X

19

Page 20

98011940-3

EXPLODED VIEW

B04

PRESSURE WASHER

OPERATOR’S MANUAL

G00

L04

L00

L02

L01

L03

L08

G03

G02

G30,

G31

X05

X01

X00

X04

E05

G32

E04

X03

P32

L06

L05

R070

P31

P30

L06

R071

B03

L05

B05

B01

B02

B00

(Reversed

View Of

Label)

R101

R103

R100

R105

F00

H050

X03

X02

H051

H052

For

Detail See

Float Tank

Illus.

R104

R106

R107

For

Detail See

Platform

Isolator

Illus.

LEGEND

G = Generator

R = Controls

20

E = Engine

N = Final Assembly

L = Fuel Tank

F = Frame

X = Battery Box

T = Float Tank

B = Beltguard

H = Hose

SSD • 9.801-194.0 • Rev. 12/13

W= Power Platform

U = Unloader

P = Pump

C = Coil

Page 21

HOUR METER

BURNER

RESET

OFF

ON

TEMPERATURE CONTROL

O

I

APAGAR

QUEMADOR/BRULEUR

HOROMETRO / CHRONOMETRE

CONTROL DE TEMERATURA / CONTROLE DE TEMPERATURE

PRENDER

OFF

F°

10-02033

200

165

130

95

235

270

300

98011940-4

EXPLODED VIEW

PRESSURE WASHER

E28

H023,H024,

H025

E00

H010,H011,

H020,H021,H022

Fuel Lines To

Fuel Tank

E14

G25,G26,G27

E002

E26

E03

E02

G10,G11,

G12,G13

U022

C17

C21

C22

C16

C15

E20,E21,

E22 E23,

E24,E25

E251,E252

W00

P091,

P092,P093

C09

C-39

E09,E10,E11,

E12, E13

E17

E16

E18

P25, P26,

C08

C04

P082

P27

C07

C23

C-41

P081

E19

C-38

C19

C11

C-37

R030

R018

R017

R102

C20

H060

H070

C00

C19

C36

Detail See

Control

R016

R017

To Float

Tank

C-10

C05

For

Box

Illus.

U021

H071

C20

C-35

C301

C30

C31

C01

H040,

H041

C02

C32

C18

H100,H101

H030

H081

OPERATOR’S MANUAL

C33

C34

C40

C31

Fuel Lines

To Burner

H110,H111

For

Detail

See Pump

Assy.

llus.

H090

H080

U023

E02

E01

SSD • 9.801-194.0 • Rev. 12/13

H071

21

Page 22

EXPLODED VIEW PARTS LIST

ITEM PART NO. DESCRIPTION QTY

B00 9.803-023.0 Belt Guard, Diesel, Black

(587) 1

9.803-024.0 Belt Guard, 12VDC Diesel

(586) 1

B01 9.802-779.0 Nut, 3/8" ESNA, NC 3

B02 9.802-807.0 Washer, 3/8", SAE, Flat 3

PRESSURE WASHER

B03 9.802-067.0 Bumper Pad, Engine 2

B04 9.800-006.0 Label, Hot/Caliente

w/Arrows Warning 1

B05 9.800-007.0 Label, Warning-Exposed

Pulleys 1

C00 9.803-014.0 Coil, Rodless 1

C01 9.802-013.0 Nipple, 1/2" x 2-1/2",

Galvanized SCH 80 1

OPERATOR’S MANUAL

C02 8.752-113.0 Adapter, 1/4" 1

C04 8.706-141.0 Coupling, 1/2" 1

C05 9.802-039.0 Elbow, 1/2" JIC x 3/8" MPT 1

C07 9.149-003.0 Discharge, Manifold 1

C08 9.802-014.0 Nipple, 1/2" x 3" Sch80 1

C09 9.802-171.0 Nipple, 3/8" x 3/8" NPT, Male 1

C10 8.933-006.0 Switch, MV60 1

C11 8.706-944.0 Hose Barb, 3/8" Barb, ML Pipe 1

C15 9.803-006.0 Weldment, Bottom Wrap 1

C16 9.802-896.0 Insulation, Blanket, No Foil 1

C17 9.802-883.0 Insulation, Front Head,

No Hole 1

C18 9.802-894.0 Insulation, Burner Head,

w/Hole 1

C19 9.802-899.0 Gasket, Burner Plate 2

C20 9.803-132.0 Insulation Retainer 2

C201 9.802-797.0 ▲ Screw, SS #10 HH Tek 8

C21 9.803-005.0 Top Wrap, SS 1

C211 9.802-808.0 ▲ Washer, 3/8", SAE, SS 4

C22 9.802-902.0 Insulation/Blanket, Die-Cut 28 1

C23 9.802-766.0 Screw, 3/8" x 1" HX Wash Head 8

C30 Burner Assembly, See Spec's Pages

C301 9.802-519.0 Strain Relief, 1/2" Metal,

Two Screw 1

C31 6.390-126.0 Clamp, Hose, .46 -, .54 ST 4

C32 8.706-941.0 Hose Barb, 1/4" Barb x 1/4"

MPT Brass 1

C33 8.706-958.0 Hose Barb, 1/4" Barb x 1/4"

Pipe, 90° 1

C34 8.725-306.0 Filter, Fuel/H2O/Oil Separator 1

C35 9.802-024.0 Elbow, Street 1/2"x 3/8" 1

C36 8.706-207.0 Elbow, 3/8" Street 1

ITEM PART NO. DESCRIPTION QTY

C37 9.184-030.0 Spacer, Rupture Disk 1

C38 8.706-248.0 Plug, 3/8" 1

C39 9.196-012.0 Screw, 10-24 x 1/4" 1

C40 8.752-114.0 Nipple, 1/4" 1

C41 8.725-944.0 Rupture Disk 8000 1

R030 8.750-094.0 Thermostat, Adjustable 302°F 1

E00 9.802-327.0 Engine, Kohler Diesel, 27 HP 1

9.802-658.0 ▲ Kit, Pressure Switch,

Oil Dual Port 1

E002 9.802-691.0 Exhaust Deflector 1

E01 9.802-725.0

GRD

E02 9.802-807.0 Washer, 3/8", SAE, Flat 9

E03 9.802-779.0 Nut, 3/8" ESNA, NC 4

E04 Pulley, See Parts Specifications Pages

E05 Bushing, See Parts Specifications Pages

E051 9.802-710.0 ▲ Bolt, 5/16" x 1", NC HH 3

E09 9.802-155.0 Adapter, M18-1.5 x 3/8" FNPT 1

E10 9.802-036.0 Nipple, 1/2" JIC, 3/8" FNPT 1

E11 9.802-253.0 Hose, 1/2" Push-On 24"

E12 9.802-151.0 Swivel, 1/2" Female,

Push-On 2

E13 9.802-126.0 Plug, 1/2" JIC, Flare,

639F-8 1

E14 9.802-660.0 Shaft, Lombardini

LDW602/903 1

E16 9.802-203.0 Clamp, 1/2" Ro-Clip,

Kleinhuis 1

E17 9.802-762.0 Screw, 10/32" x 1-1/4" RH,

SL, Black 1

E18 9.802-695.0 Nut, 10/32" Keps 1

E19 9.802-802.0 Washer, 1/4", Flat, SAE 1

E20 9.802-444.0 Wire, THWN, 6 Gauge,

Red 80"

E21 9.802-444.0 Wire, THWN, 6 Gauge,

Black 70"

E22 9.802-487.0 Terminal, Ring Tongue 2

E23 9.802-487.0 Terminal, Ring Tongue 2

E24 9.802-501.0 Connector, Battery Post 2

E25 9.802-587.0 Insulation,

Fiber Sleeving, 1/2" 42"

E251 9.802-207.0 Clamp, Round, 0.56 ID 3

E252 9.802-799.0 Screw, #14 x 1", TEK,

Black,Zinc 3

E26 9.800-011.0 Label, RPM Factory Set 1

F00 9.803-021.0 Frame Assy, 27 HP,

Diesel, Black 1

Bolt, 3/8" x 1-1/2", HH NC

8, Zinc 4

LEGEND

G = Generator

R = Controls

22

E = Engine

N = Final Assembly

L = Fuel Tank

F = Frame

X = Battery Box

T = Float Tank

SSD • 9.801-194.0 • Rev. 12/13

B = Beltguard

H = Hose

W= Power Platform

U = Unloader

P = Pump

C = Coil

Page 23

EXPLODED VIEW PARTS LIST

PRESSURE WASHER

ITEM PART NO. DESCRIPTION QTY

G00 9.802-527.0 Generator, 2FSM2PC-1/A,

WINC (587) 1

G01 9.802-720.0 ▲ Bolt, 3/8" x 1", NC HH (587) 4

G02 9.802-807.0 Washer, 3/8", SAE, Flat (587) 8

G03 9.802-779.0 Nut, 3/8", ESNA, NC (587) 4

G10 9.803-004.0 Weldment, Pump/Gen. Rail

(587) 1

G11 9.802-779.0 Nut, 3/8", ESNA 3

G12 9.802-099.0 ▲ Washer, Snubbing (587) 3

G13 9.802-814.0 ▲ Washer, 3/8", Lock,

Split Ring (587) 3

G25 9.802-733.0 Bolt, 3/8" x 3-1/2", TAP

(587) 1

G26 9.802-807.0 Washer, 3/8", SAE, Flat

(587) 4

G27 9.802-789.0 Nut, 3/8", Hex, NC (587) 2

G30 Pulley, See Parts Specifications Pages

G31 ▲ Bushing, See Parts

Specifications Pages

G32 Belt, See Parts Specifications Pages

G33 8.752-150.0 ▲ Cord, Moulded 1

E28 9.804-532.0 ▲ Dipstick Extended Kit 1

H010 9.802-255.0 Hose, 3/16", Push-On, Fuel

Line 48"

H011 9.802-200.0 Clamp, Screw, #4 2

H020 9.802-254.0 Hose, 1/4", Push-On,

Fuel Line 40"

H021 9.802-200.0 Clamp, Screw, #4 2

H022 9.802-587.0 Insulation,

Fiber Sleeving, 1/2" 30"

H023 9.802-207.0 Clamp, Round, 0.56 ID 1

H024 9.802-741.0 Bolt, 8mm x 16mm

Hex Head 1

H025 9.802-813.0 Washer, 5/16", Lock,

Split Ring 1

H030 8.918-429.0 Hose, 3/8" X 62",

2 Wire, Pressure 1

H040 9.802-252.0 Hose, 1/4" x 1/2",

Braided Vinyl 48"

H041 6.390-126.0 Clamp, Hose, .46 -, .54 ST 2

H050 9.802-251.0 Tube, 1/4" x 1/2", Clear Vinyl 72"

H051 9.802-200.0 Clamp, Screw, #4 1

H052 9.802-161.0 Strainer, 1/4", Brass w/Check 1

H060 8.711-785.0 Hose, 3/8", Push-on 2 ft

H070 9.802-261.0 Hose, 3/4", Push-On 48"

H071 9.802-152.0 Swivel, 3/4" SAE Female,

Push-On 2

H080 9.802-259.0 Hose, 1/2" Push-On 15"

SSD • 9.801-194.0 • Rev. 12/13

ITEM PART NO. DESCRIPTION QTY

H081 9.802-151.0 Swivel, 1/2" FJIC, Push-On 2

H090 8.918-421.0 Hose, Pressure, 3/8" x 16" 1

H100 9.802-254.0 Hose, 1/4", Push-On,

Fuel Line 19"

H101 9.802-200.0 Clamp, Screw #4 2

H110 9.802-254.0 Hose, 1/4”, Push-On,

Fuel Line 25"

H111 9.802-200.0 Clamp, Screw, #4 2

L00 9.803-025.0 Fuel Tank Assembly,

20 Gallon MS 1

L01 9.802-804.0 Washer, 5/16", Flat, SAE 4

L02 9.802-776.0 Nut, 5/16", ESNA, NC 4

L03 9.802-067.0 Bumper Pad, Engine 4

L04 9.802-082.0 Cap, Fuel Tank, Plastic 1

L05 9.802-142.0 Hose Barb, 1/4" Barb x 1/8"

ML Pipe, 90° 3

L06 8.706-962.0 Hose Barb, 3/16" Barb x 1/8"

MPT, 90° 2

L07 9.802-124.0 ▲ Plug, 1/4" Countersunk 1

L08 8.932-960.0 Label, Diesel Fuel 1

P081 9.802-587.0 Insulation, Fiber Sleeving, 22" 1

P082 9.802-207.0 Clamp, Round, 0.56 ID 2

P091 9.802-779.0 Bolt, 3/8", ESNA 3

P092 9.802-099.0 ▲ Washer, Snubbing 3

P093 9.802-814.0 ▲ Washer, 3/8" Lock, Split

Ring 3

P25 9.802-733.0 Bolt, 3/8" x 3-1/2", Tap 1

P26 9.802-807.0 Washer, 3/8", SAE, Flat 4

P27 9.802-789.0 ▲ Nut, 3/8", Hex, NC 2

P30 Pulley, See Parts Specifications Pages

P31 Bushing, See Parts Specifications Pages

P32 Belt, See Parts Specifications Pages

R016 9.802-710.0 Bolt, 5/16" x 1", NC HH 4

R017 9.802-776.0 Nut, 5/16", ESNA, NC 4

R018 9.802-804.0 Washer, 5/16", Flat, SAE 8

R070 9.802-188.0 Valve, Metering, 1/4" Hose 1

R071 9.800-039.0 Label, Detergent Valve 1

R100 9.803-020.0 Control Panel, Black 1

R101 9.802-799.0 Screw, #14 x 1", Tek,

Black, Zinc 13

R102 8.900-870.0 Label, Shark 1

R103 9.800-041.0 Label, Warning, Text 1

R104 9.800-042.0 Label, Control Panel 1

R105 9.800-049.0 Label, Manufacturer’s

Cleaning Solution 1

R106 9.802-064.0 Grommet, Rubber, Nozzle 4

R107 Nozzle, Please See Hose &

Spray Gun Assembly

OPERATOR’S MANUAL

23

Page 24

EXPLODED VIEW PARTS LIST

ITEM PART NO. DESCRIPTION QTY

U021 9.802-730.0 Bolt, 3/8" x 2-1/2",

Grade 5, Zinc 2

U022 9.802-807.0 Washer, 3/8", SAE, Flat 2

U023 9.802-779.0 Nut, 3/8", ESNA, NC 2

W00 9.803-022.0 Assy, Power

Platform, Diesel 1

PRESSURE WASHER

X00 9.802-075.0 Box, Battery, M100 1

X01 9.802-701.0 Bolt, 1/4" x 1",

Hex Head 4

X02 9.802-773.0 Nut, 1/4", ESNA, NC 4

X03 9.802-802.0 Washer, 1/4", Flat, SAE 8

X04 9.802-067.0 Bumper Pad, Engine 4

X05 9.802-076.0 Plate, Battery Box,

Large, PO 1

OPERATOR’S MANUAL

▲ Not Shown

LEGEND

G = Generator

R = Controls

E = Engine

N = Final Assembly

L = Fuel Tank

F = Frame

24

X = Battery Box

T = Float Tank

SSD • 9.801-194.0 • Rev. 12/13

B = Beltguard

H = Hose

W= Power Platform

U = Unloader

P = Pump

C = Coil

Page 25

98011940-9

HOSE & SPRAY GUN ASSEMBLY

3

2

1

PRESSURE WASHER

4

OPERATOR’S MANUAL

HOSE & SPRAY GUN PARTS LIST

ITEM PART NO. DESCRIPTION QTY

1 8.739-203.0 Hose, 3/8" x 50',

2 Wire, Tuff-Flex 1

2 8.710-384.0 Gun, ST-1500, 5000

10.4 GPM 1

3 9.803-805.0 Wand 1

4 9.802-307.0 Nozzle, 0006, Red 1

9.802-308.0 Nozzle, 1506, Yellow 1

9.802-309.0 Nozzle, 2506, Green 1

9.802-310.0 Nozzle, 4006, White 1

LEGEND

G = Generator

R = Controls

E = Engine

N = Final Assembly

L = Fuel Tank

F = Frame

X = Battery Box

T = Float Tank

SSD • 9.801-194.0 • Rev. 12/13

B = Beltguard

H = Hose

W= Power Platform

U = Unloader

P = Pump

C = Coil

25

Page 26

PRESSURE WASHER

98011940-8

OPERATOR’S MANUAL

PLATFORM ISOLATOR EXPLODED VIEW

W11

W06

W08

W10

W12

W13

W05

W06

W06

W14

W05

W08

W13

W09

W07

W06

W05

W06

W01

W09

W09

W06

W07

W11

LEGEND

G = Generator

R = Controls

26

E = Engine

N = Final Assembly

L = Fuel Tank

F = Frame

X = Battery Box

T = Float Tank

B = Beltguard

H = Hose

SSD • 9.801-194.0 • Rev. 12/13

W= Power Platform

U = Unloader

P = Pump

C = Coil

Page 27

PLATFORM ISOLATOR PARTS LIST

ITEM PART NO. DESCRIPTION QTY

W01 9.802-057.0 Isolator, Vibration Mount,

100L 12

W05 9.802-710.0 Bolt, 5/16" x 1", NC HH 24

W06 9.802-804.0 Washer, 5/16", Flat,

SAE 48

W07 9.802-776.0 Nut, 5/16", ESNA, NC 24

W08 9.802-730.0 Bolt, 3/8" x 2-1/2"

Grade 5 Zinc 10

W09 9.802-099.0 Washer, Snubbing 12

W10 9.802-807.0 Washer, 3/8", SAE, Flat 10

W11 9.802-779.0 Nut, 3/8", ESNA, NC 10

W12 9.802-717.0 Bolt, 5/16" x 2-1/2", NC HH 2

W13 9.802-804.0 Washer, 5/16", Flat, SAE 4

W14 9.802-776.0 Nut, 5/16", ESNA, NC 2

PRESSURE WASHER

OPERATOR’S MANUAL

LEGEND

G = Generator

R = Controls

E = Engine

N = Final Assembly

L = Fuel Tank

F = Frame

X = Battery Box

T = Float Tank

SSD • 9.801-194.0 • Rev. 12/13

B = Beltguard

H = Hose

W= Power Platform

U = Unloader

P = Pump

C = Coil

27

Page 28

PRESSURE WASHER

98011940-5

PUMP ASSEMBLY EXPLODED VIEW

H090

U051

U05

U09

U01

U07

H081

H080

U08

P04

P03

U04

U021

P12

P16

P13

P013

OPERATOR’S MANUAL

U03

H030

U031

P11

P05

P10

U02

H081

P01

P14

P09

P012

P011

LEGEND

G = Generator

R = Controls

28

E = Engine N = Final Assembly

L = Fuel Tank

F = Frame

X = Battery Box

SSD • 9.801-194.0 • Rev. 12/13

T = Float Tank

B = Beltguard

H = Hose

W= Power Platform

U = Unloader

P = Pump

C = Coil

Page 29

PUMP ASSEMBLIES PARTS LIST

ITEM PART NO. DESCRIPTION QTY

H030 8.918-429.0 Hose, 3/8" Pressure 60"

H080 9.802-254.0 Hose, 1/2" Push-On 19"

H081 9.802-151.0 Swivel, 1/2" JIC Fem,

Push-On 2

H090 8.711-653.0 Hose, 3/8" Pressure 16"

P01 9.802-346.0 Pump, KT 6035 1

P011 9.803-042.0 Screw, Pump 4

P012 9.803-042.0 Washer, Lock, Pump 4

P013 9.802-132.0 Elbow, 3/4" JIC x 1/2" 90° 1

P03 9.803-050.0 Tee, 1/2" with 1/8" Hole,

Street 1

P04 9.802-131.0 Elbow, 1/2" JIC, 1/2", 90° 1

P05 8.706-955.0 Hose Barb, 1/4" Barb x 1/8"

ML Pipe, 90° 2

P09 9.803-013.0 Weldment, Pump Rail,

Wide 1

P10 6.390-126.0 Clamp, Hose 1

P11 8.706-958.0 Hose Barb, 1/4" Barb x 1/4"

ML Pipe, 90° 1

P12 9.802-187.0 Valve, Steam 1

P13 9.802-039.0 Elbow, 1/2" JIC x 3/8"

MPT Street 1

P14 8.706-234.0 Tee, 3/8" Street 1

P16 8.706-120.0 Nipple, 3/8" x 1/4",

Hex Steel 1

U01 8.750-299.0 Unloader, VRT 3, 8 GPM

@ 4500 PSI 1

U02 9.802-869.0 Block Unloader,

1/2" x 1/2", Brass 1

U021 9.802-731.0 Bolt, 3/8" x 3" 2

U03 9.802-013.0 Nipple, 1/2" x 2-1/2",

Galv. SCH 80 1

U031 9.802-043.0 Elbow, 1/2" FNPT x 1/2"

MJIC 1

U04 9.802-038.0 Nipple, 1/2" JIC, 1/2" Pipe 1

U05 9.802-041.0 Elbow, 3/8", Street, 45° 1

U051 9.802-036.0 Nipple, 1/2" MJIC x 3/8"

NPT 1

U07 9.802-048.0 Swivel, 1/2" JIC Female,

3/8" Male 1

U08 9.802-133.0 Elbow, 1/2" JIC x 3/8", 45° 1

U09 8.707-254.0 Pump Protector, 3/8" PTP 1

PRESSURE WASHER

OPERATOR’S MANUAL

LEGEND

G = Generator

R = Controls

E = Engine

N = Final Assembly

L = Fuel Tank

F = Frame

X = Battery Box

T = Float Tank

SSD • 9.801-194.0 • Rev. 12/13

B = Beltguard

H = Hose

W= Power Platform

U = Unloader

P = Pump

C = Coil

29

Page 30

89001000-7

98011940-6

CONTROL BOX EXPLODED VIEW

R012

PRESSURE WASHER

OPERATOR’S MANUAL

R015

R010

R011

R023

R097

NOTE:

"586.0 Only"

R080

R013

R050

CONTROL BOX PARTS LIST

R030

R020

R021

R095

R096

R094

R060

R040

ITEM PART NO. DESCRIPTION QTY

R010 9.803-693.0 Box, Plastic, Back 1

R011 9.802-700.0 Bolt, 1/4" x 3/4", NC HH 4

R012 9.802-775.0 Nut, 1/4", Flange, ZN 4

R013 9.803.249.0 Screw, M4 x 10 4

R015 8.912-806.0 Bracket, Electrical Box,

Black 1

R020 9.802-482.0 Box, Plastic Front,

Fabricated 1

R021 9.800-043.0 Label, Electrical Box,

w/o Reset (587.0) 1

9.800-044.0 Label, Electrical Box,

w/Reset (586.0) 1

R022 9.800-040.0 ▲ Label, Ground 1

R023 9.803-250.0 Nut (Electrical Bin) 4

R030 8.750-094.0 Thermostat, Adjustable,

302°F 1

R031 9.802-447.0 ▲ Conduit, Corrugated,

Tubing 36"

R040 9.802-453.0 Switch, Curvette 1

R050 9.802-283.0 Hour Meter 1

ITEM PART NO. DESCRIPTION QTY

R060 9.802-455.0 Light Indicator,

Green 115V (587.0) 1

9.802-456.0 Light Indicator,

Green 12V (586.0) 1

R080 9.802-485.0 Breaker (586.0) 1

R090 9.802-470.0 ▲ Relay, P&B,

12V/40A (586.0) 1

R091 9.802-771.0 ▲ Screw, 10/32" x 3/4"

BH SOC CS 1

R092 9.802-762.0 ▲ Screw, 10/32" x 1-1/4",

Ground 1

R093 9.802-695.0 ▲ Nut, 10/32" 8

R094 8.750-096.0 Knob, Thermostat 1

R095 8.712-190.0 Bezel, Thermostat 1

R096 8.718-779.0 Screw, 4mm x 6mm 2

R097 9.802-104.0 Grommet 1

▲ Not Shown

LEGEND

G = Generator

R = Controls

30

E = Engine

N = Final Assembly

L = Fuel Tank

F = Frame

X = Battery Box

B = Beltguard

SSD • 9.801-194.0 • Rev. 12/13

H = Hose

W= Power Platform

U = Unloader

P = Pump

C = Coil

Page 31

98011940-7

FLOAT TANK ASSEMBLY

T01

PRESSURE WASHER

T12

T09

T02

T03

T00

T07

OPERATOR’S MANUAL

T10

T08

T11

T06

T04

T05

To Pump

FLOAT TANK PARTS LIST

ITEM PART NO. DESCRIPTION QTY

T00 9.804-042.0 Tank, Float, 2-1/2

Gallon, Blank 1

T01 8.749-328.0 Valve, Float, PVC 1

T02 9.802-162.0 Strainer, 1/2" Basket 1

T03 9.802-128.0 Nipple, 1/2" JIC x 1/2" MPT 1

T04 8.750-743.0 Bulkhead, 1/2” Polypro 1

T05 9.802-132.0 Elbow, 3/4" JIC x 1/2", 90° 1

T06 9.803-007.0 Support Plate, Float Tank 1

T07 9.802-799.0 Screw, #14 x 1", TEK,

Black, Zinc 2

T08 9.802-146.0 Swivel, 1/2" MP x 3/4"

GHF w/Strainer 1

ITEM PART NO. DESCRIPTION QTY

T09 9.803-671.0 Stem, 5" Float 1

T10 9.802-512.0 Cable, TY, 48" 1

T11 9.802-150.0 Anchor,

Connector, 1/2" 1

T12 9.802-061.0 Ball, Float,

Black Plastic 1

LEGEND

G = Generator

R = Controls

E = Engine

N = Final Assembly

L = Fuel Tank

F = Frame

SSD • 9.801-194.0 • Rev. 12/13

X = Battery

Box

B = Beltguard

H = Hose

W= Power Platform

U = Unloader

P = Pump

C = Coil

31

Page 32

SPECIFICATIONS

BECKETT BURNER SPECIFICATIONS

Burner Burner Fuel Pump/ Fuel

Model No. Assy No. Fuel Nozzle Igniter Motor Solenoid/Cord Solenoid Coil Electrode

1.110-586.0 9.802-559.0 9.802-577.0 9.802-663.0 9.802-638.0 9.802-562.0 9.802-634.0 9.802-668.0

1.110-587.0 9.802-556.0 8.717-366.0 9.803-060.0 9.803-056.0 9.802-645.0 9.802-640.0 9.802-669.0

PRESSURE WASHER

CLEAR FLAME BURNER SPECIFICATIONS

Burner Burner Fuel Pump/ Fuel

Model No. Assy No. Fuel Nozzle Igniter Motor Solenoid/Cord Solenoid Coil Electrode

1.110-586.0 8.918-919.0 8.717-273.0 8.919-116.0 8.751-074.0 8.700-758.0 9.802-639.0 8.751-342.0

1.110-587.0 8.920-645.0 8.717-366.0 8.919-114.0 8.752-930.0 8.700-759.0 9.802-640.0 8.750-778.0

OPERATOR’S MANUAL

PART SPECIFICATIONS

PUMP

Machine

Model

1.110-586.0 KT6035 9.802-346.0 9.802-366.0 2BK80H 9.802-389.0 25MM 9.802-403.0 27 HP 9.802-327.0 3TB40 9.802-394.0

1.110 - 587. 0 KT6035 9.802-346.0 9.802-366.0 2BK80H 9.802-389.0 25MM 9.802-403.0 27 HP 9.802-327.0 3TB40 9.802-394.0

Model

(Con’t) Bushing Part # Size Part # Pulley Part# Belts Par t # Bushing Part#

1.110-586.0 P2 x 1-1/2 9.802-406.0 BX 32 9.802-413.0 NA NA NA NA NA NA

1.110 - 587. 0 P2 x 1-1/2 9.802-406.0 BX 32 9.802-413.0 BK36 9.802-379.0 BX22 9.802-412.0 5/8 9.802-397.0

Pump Pulley Bushing Engine Engine Engine Pulley

Model Par t # Unloader Pulley Part # Bushing Part # Size Par t# Pulley Part#

ENGINE (CON’T)

Bushing Belt Belt Pulley Belt Bushing

GENERATOR

ENGINE

32

SSD • 9.801-194.0 • Rev. 12/13

Page 33

VRT3 UNLOADER EXPLODED VIEW AND PARTS LIST

8.750-297.0, 8 GPM, 2320 PSI

8.750-298.0, 8 GPM, 3630 PSI

8.750-299.0, 8 GPM, 4500 PSI

20

19

18

14

8

10

PRESSURE WASHER

ITEM PART NO. DESCRIPTION QTY

25 8.750-713.0 Outlet Fitting 1

18 8.750-712.0 Knob, Unloader 1

8.750-709.0 Repair Kit, VRT3, 2320/3630 PSI

8.750-710.0 Repair Kit, VRT3, 4500 PSI

(Kit Items: 3, 4, 6, 9-12, 21, 24)

9

9

OPERATOR’S MANUAL

17

13

16

12

11

26

3

15

15

6

4

5

6

1

22

23

24

21

25

7

2

Unloader Adjustment Procedures

1. Remove lock nut (Item 19).

2. Remove adjustment knob (Item 18).

3. Loosen the two (2) nuts (Item 15), move them upward on stem (Item 8) until you see 4 or more threads below the nut.

4. Re-attach adjusting knob (Item 18).

5. Start machine. Open the trigger of the spray gun. Increase pressure by turning adjustment knob (Item 18) clockwise until

pressure is at the desired operating pressure.

6. Remove the adjustment knob (Item 18), tighten the lower nut (Item 15) tightly against the upper nut (Item 15).

Re-attach adjustment knob (Item 18) and screw down until contact is made with the nuts (Items 15). Screw down lock nut

(Item 19) onto the stem (Item 8) until the threads cut into the nylon insert of the lock nut (Item 19).

*If adjustment knob (Item 18) DOES NOT make contact with upper nut (Items 15), remove adjusting knob (Item 18), re-adjust

(raise) nuts (Items 15) on stem (Item 8) and re-attach adjustment knob (Item 18), then repeat step #6.

**If adjustment knob (Item 18) DOES make contact with upper nut; release the trigger of the spray gun and watch the

pressure gauge for the pressure increase (“spike”). This “spike” SHOULD NOT exceed 500 psi above the operating pressure.

If “spike” pressure exceeds the 500 psi limit, remove the adjusting knob (Item 18) and re-adjust (lower) the nuts (Items 15)

on the stem (Item 8). Re-attach the adjusting knob (Item 18), then repeat step #6.

33

SSD • 9.801-194.0 • Rev. 12/13

Page 34

9.802-345.0 KT4035.1 Right

9.803-410.0 KT4035.1 Left

9.803-411.0 KT4040.1 Right

9.803-412.0 KT4040.1 Left

9.803-413.0 KT5030.1 Right

9.803-414.0 KT5030.1 Left

9.802-346.0 KT6035.1 Right

9.803-416.0 KT6035.1 Left

PRESSURE WASHER

OPERATOR’S MANUAL

KT.1 SERIES PUMP EXPLODED VIEW

TORQUE SPECS

Item # Ft.-Lbs.

17 75

18 45

27 18

37 10

48 30

53 7.6

KT.1 SERIES PUMP EXPLODED VIEW & PARTS LIST

ITEM PART NO. DESCRIPTION QTY

1 9.804-604.0 Crankcase 1

2 9.803-195.0 Plunger Guide 3

3* See Kit

4* See Kit O-Ring Ø1.78 x 31. 47 3

5* See Kit Pressure Ring, Brass 3

6* See Kit "U" Seal Low Pressure 3

7* See Kit Intermediate Ring, Brass 3

8* See Kit

9* See Kit

10* See Kit Support Ring 3

11 9.802-926.0 Brass Plug, 1/2" 1

12 9.803-199.0 Copper Washer 1/2" 1

13 9.802-933.0 Manifold Head 1

14* See Kit O-Ring Ø2.62 x 17.13 6

15* See Kit Valve Assembly 6

16 See Kit O-Ring Ø2.62 x 20.29 6

17 9.802-928.0 Valve Plug 6

18 9.802-943.0 Manifold Stud Bolt 8

34

Plunger Oil Seal 3

Support Ring, Teflon Bronze 3

"U" Seal High Pressure

3

SSD • 9.801-194.0 • Rev. 12/13

ITEM PART NO. DESCRIPTION QTY

19 9.802-890.0 Washer 8

20 9.803-198.0 Copper Washer 3/8" 1

21 9.802-925.0 Brass Plug 3/8"

26 9.802-884.0 Washer 8

27 9.802-944.0 Hexagonal Screw

28 9.803-182.0 Closed Bearing Housing

29 9.803-186.0 O-Ring Ø2.62 x 71.12 2

30 9.803-160.0 Roller Bearing, Tapered 2

31 9.803-148.0 Crankshaft (GT4040.1,

5030.1, 6035.1) 1

9.803-149.0 Crankshaft (GT 4035.1) 1

32 9.803-167.0 Crankshaft Key 1

33 9.802-923.0 Oil Dip Stick 1

34 9.803-139.0 Crankshaft Seal 1

35 9.803-177.0 Shim 2

36 9.803-181.0 Bearing Housing 1

37* See Kit Plunger Bolt 3

38* See Kit Copper Spacer 3

1

8

1

Page 35

KT.1 SERIES PUMP EXPLODED VIEW & PARTS LIST

ITEM PART NO. DESCRIPTION QTY

39* See Kit O-Ring Ø1.78 x10.82 3

40* See Kit Teflon Ring 3

41* See Kit Plunger 3

42* See Kit Copper Spacer 3

43 9.803-143.0 Plunger Rod 3

44 9.803-157.0 Connecting Rod 3

45 9.802-912.0 Snap Ring 6

46 9.802-915.0 Connecting Rod Pin 3

47 9.802-889.0 Spring Washer 6

48 9.802-937.0 Connecting Rod Screw 6

49 9.803-194.0 O-Ring Ø2.62 x 152.07 1

50 9.803-166.0 Crankcase Cover 1

51 9.803-197.0 Gasket, G3/8 1

52 9.803-202.0 Sight Glass G3/4 1

53 9.802-939.0 Cover Screw 5

* Part available in kit (See below)

PRESSURE WASHER

OPERATOR’S MANUAL

REPAIR KIT

NUMBER

KIT

DESCRIPTION

ITEM NO.S

INCLUDED

NUMBER OF

CYLINDERS KIT

WILL SERVICE

8.916-488.0 8.916-487.0 8.916-322.0 8.916-323.0 9.802-607.0 9.802-611.0 9.802-603.0 9.802-606.0

Plunger

"U" Seal

20mm

4040.1

6035.1

4035.1

4, 6, 8, 9,

10

3 3 1 1 1 1 6 3

Plunger

"U" Seal

22mm

5030.1

4, 6, 8,

9, 10

"U" Seal

Packing

Assy 20mm

4040.1

6035.1

4035.1

4, 5, 6, 7, 8,

9, 10,

"U" Seal

Packing Assy

22mm

5030.1

4, 5, 6, 7, 8,

9, 10,

Plunger

20mm

4040.1

6035.1

4035.1

37, 38, 39,

40, 41, 42

Plunger

22mm

5030.1

37, 38, 39,

40, 41, 42

Complete

Valve

(all pumps)

14, 15, 16 3

Plunger Oil

Seals

(all pumps)

35

SSD • 9.801-194.0 • Rev. 12/13

Page 36

CLEAR FLAME BURNER "S" REPLACEMENT PARTS

For best performance specify genuine KNA replacement parts

8.918-919.0

PRESSURE WASHER

OPERATOR’S MANUAL

36

SSD • 9.801-194.0 • Rev. 12/13

Page 37

CLEAR FLAME BURNER "S" REPLACEMENT PARTS

For best performance specify genuine KNA replacement parts

PRESSURE WASHER

OPERATOR’S MANUAL

1 8.919-050.0 BURNER HOUSING ASSEMBLY 1 25 8.750-830.0 PLUG, HOLE 0.285 PLASTIC 1

2 8.751-160.0 AIR GUIDE 26 8.751-134.0 PLUG, 1/8" NPT x HEX SHOULDER 1

3 8.700-758.0 FUEL PUMP, SUNTEC A2VA-3106 12-24V SOL 1 27 8.918-454.0 GASKET, JUNCTION BOX 1

3 8.700-759.0 FUEL PUMP, SUNTEC A2VA-3106 120V SOL 1 28 8.750-542.0 COVER, JUNCTION BOX 1

3 8.700-760.0 FUEL PUMP, SUNTEC A2VA-3106 230V SOL 1 29 8.750-116.0 BLOCK, TERMINAL, 5 POLE 1

3 8.753-000.0 FUEL PUMP, DANFOSS 071N1298 1 30 8.750-817.0 LIGHT, INDICATOR, GREEN 14V 2

4 8.750-762.0 COIL, SOLENOID DANFOSS 230V 1 30 8.750-818.0 LIGHT, INDICATOR, GREEN 28V 1

4 8.750-763.0 COIL, SOLENOID DANFOSS 115V 1 30 8.750-819.0 LIGHT, INDICATOR, GREEN 125V 1

Item # Part # Description Qty Item # Part # Description Qty

4 8.750-764.0 COIL, SOLENOID DANFOSS 12-24V 1 30 8.750-820.0 LIGHT, INDICATOR, GREEN 250V 1

5 8.750-765.0 CABLE, SOLENOID COIL, DANFOSS 1 31 8.750-784.0 SITE GLASS 1

6 8.750-541.0 AIR BAND 1 33 8.733-001.0 SCREW, 8 x 1/4" HI LOW THREAD CUT, PPH 2

7 8.750-517.0 MOTOR, 1/6 HP 115V 60Hz 1 34 8.718-762.0 SCREW, 8-32 X 1/2", M PH RDH PL 2

7 8.750-518.0 MOTOR, 1/6 HP 230V 60Hz 1 35 8.752-137.0 WASHER, COPPER 1

7 8.751-074.0 MOTOR, 1/7 HP 12VDC AMETEK 1 36 8.718-810.0 SCREW, 10/32 x 1/2", WHIZ LOC FLANGE 6

8 8.750-543.0 COUPLING, FLEX, 1/2" x 5/16" 1 37 8.750-770.0 SCREW, 10/32 x 5/8", WHIZ LOC FLANGE 3

8 8.751-073.0 COUPLING, FLEX, 5/16" x 5/16" 1 38 8.750-816.0 SCREW, 10/32 X 1/4" GROUNDING 1

9 8.750-520.0 FAN, 4.53" X 2.42", 1/2" BORE, F115-62S 1 39 8.750-768.0 SCREW, 1/4-20 x 1", WHIZ LOC FLANGE 4

5a 8.750-783.0 MOUNTING KIT, FLANGE/HUB, DANFOSS 1 32 8.750-785.0 RING, PUSH ON INTERNAL, 1305-112 1

9 8.751-072.0 FAN, 4.53" x 2.42" x .313 BORE, F115-625 1 40 8.750-771.0 SCREW, 1/4-20 X 1/2", PHIL FHMS 4

11 8.750-547.0 CONNECTOR, 37 DEG FLARE X 1/8" NPT, LONG 1 42 — LABEL, BRAND NAME 1

12 8.750-545.0 CONNECTOR, 37 DEG FLARE X 1/8" NPT 1 43 9.801-268.0 LABEL, DISCONNECT POWER SUPPLY 1

13 8.749-000.0 FUEL LINE ASSEMBLY 1 44 — LABEL, SERIAL PLATE 1

14 8.752-034.0 FLANGE, KNA BURNER, 1" TUBE 1 46 9.807-339.0 LABEL, WIRING DIAGRAM, BURNER 115V-115V 1

15 8.752-035.0 FLANGE, KNA BURNER, 3" TUBE 1 46 9.807-340.0 LABEL, WIRING DIAGRAM, BURNER 230V-230V 4

16 8.750-539.0 GASKET, FLANGE 1 46 9.807-341.0 LABEL, WIRING DIAGRAM, BURNER 230V-115V 1

18 8.750-526.0 GUN, ELECTRODE / NOZZLE, 3" 1 46 9.807-342.0 LABEL, WIRING DIAGRAM, BURNER 115V-24V 1

19 8.750-525.0 GUN, ELECTRODE / NOZZLE, 1" 1 46 9.807-343.0 LABEL, WIRING DIAGRAM, BURNER 230V-24V 1

20 Varies NOZZLE, FUEL 1 46 9.807-344.0 LABEL, WIRING DIAGRAM, BURNER 12VDC 1

21 8.750-778.0 ELECTRODE, IGNITION, AC 1 48 9.801-274.0 LABEL, BURNER LIGHTS 1

21 8.751-342.0 ELECTRODE, IGNITION, DC 1 49 8.919-105.0 PLATE, TERMINAL BLOCK NUMBERS 1

22 8.750-779.0 CONE, AIR F4 1 50 8.716-451.0 TERMINAL, JUMPER SPADE 1

22 8.750-782.0 CONE, AIR F6 1 51 9.802-510.0 CABLE, TIE, 4" BLACK 2

22 8.750-780.0 CONE, AIR F12 1 52 9.807-348.0 LABEL, CLEAR MYLAR 1

22 8.750-781.0 CONE, AIR F22 1 53 9.807-345.0 LABEL, IGNITER 120V 1

23 8.919-114.0 IGNITOR, BURNER 120V 1 53 9.807-346.0 LABEL, IGNITER 230V 1

23 8.919-115.0 IGNITOR, BURNER 230V 1 53 9.807-347.0 LABEL, IGNITOR 12VDC 1

23 8.919-116.0 IGNITOR, BURNER 12VDC 1 54 8.751-354.0 GASKET, BURNER TUBE 1

24 8.751-165.0 PLUG, HOLE 0.875 PLASTIC 1

37

SSD • 9.801-194.0 • Rev. 12/13

Page 38

CLEAR FLAME BURNER "M/L" REPLACEMENT PARTS

For best performance specify genuine KNA replacement parts

8.920-645.0

PRESSURE WASHER

OPERATOR’S MANUAL

38

SSD • 9.801-194.0 • Rev. 12/13

Page 39

CLEAR FLAME BURNER "M/L" REPLACEMENT PARTS

For best performance specify genuine KNA replacement parts

PRESSURE WASHER

OPERATOR’S MANUAL

Item # Part # Description Qty Item # Part # Description Qty

1 8.752-865.0 BURNER HOUSING ASSEMBLY-M/L 1 30 8.750-818.0 LIGHT, INDICATOR, GREEN 28V 1

3 8.700-758.0 FUEL PUMP, SUNTEC A2VA-3106 12-24V SOL 1 30 8.750-819.0 LIGHT, INDICATOR, GREEN 125V 1

3 8.700-759.0 FUEL PUMP, SUNTEC A2VA-3106 120V SOL 1 30 8.750-820.0 LIGHT, INDICATOR, GREEN 250V 1

3 8.700-760.0 FUEL PUMP, SUNTEC A2VA-3106 230V SOL 1 31 8.750-784.0 SITE GLASS 1

3 8.752-923.0 FUEL PUMP, SUNTEC A2YA-7916 1 32 8.750-785.0 RING, PUSH ON INTERNAL 1

4 8.752-924.0 SOLENOID VALVE, SUNTEC R642NL, 115V 1 33 8.733-001.0 SCREW, 8 x 1/4" HI LOW THREAD CUT 2