Page 1

MODEL: BT

OPERATING INSTRUCTION

AND PARTS MANUAL

■ BT-3530 ■ BT-4020 ■ BT-5030

For technical assistance or the SHARK dealer nearest you, call 1-800-771-1881

or visit our website at www.shark-pw .com

#97-727

Page 2

Page 3

Introduction............................................................................................. 4

Important Safety Information................................................................4-5

Component Identification ........................................................................ 6

Assembly Instructions.............................................................................7

Operating Instructions............................................................................. 8

Detergents and General Operating T echniques ......................................9

Shut Down and Clean-Up ..................................................................... 10

Storage ................................................................................................. 10

Troubleshooting ...............................................................................11-12

Preventativ e Maintenance..................................................................... 13

Oil Change Record ............................................................................... 13

Exploded View .................................................................................14-15

Exploded View Parts List .................................................................16-18

Hose & Spray Gun................................................................................19

Downstream Injector.............................................................................19

Specifications ..................................................................................20-21

Warranty

CONTENTS

Model Number ______________________________

Serial Number ______________________________

Date of Purchase ___________________________

The model and serial numbers will be found on a decal attached to

the pressure washer. You should record both serial number and

date of purchase and keep in a safe place f or future reference.

97-711, 97-727, 96-721 • REV. 2/04

3

Page 4

INTRODUCTION

Thank you for purchasing this Pressure Washer.

All information in this manual is based on the latest prod-

uct information availab le at the time of printing.

We reserve the right to make changes at any time with-

out incurring any obligation.

This model was designed for a maximum

PRESSURE W ASHER

use of 8 hours per day, 5 days per week.

Owner/User Responsibility:

The owner and/or user must have an understanding of

the manufacturer’s operating instructions and warnings

before using this pressure washer. Warning information

should be emphasized and understood. If the oper ator is

not fluent in English, the manufacturer’ s instructions and

warnings shall be read to and discussed with the operator in the operator’s native language by the purchaser/

OPERATOR’S MANUAL

owner, making sure that the operator comprehends its

contents.

Owner and/or user must study and maintain for future

reference the manufacturers’ instructions.

This manual should be considered a permanent

part of the machine and should remain with it if

machine is resold.

When ordering parts, please specify model and

serial number .

IMPORTANT SAFETY

INSTRUCTIONS

WARNING: When using this machine basic precautions should always be followed, including the

following:

WARNING

CAUTION

READ OPERATOR’S

MANUAL

THOROUGHLY

PRIOR TO USE.

2. Know how to stop the machine and bleed pressures

quickly. Be thoroughly familiar with the controls .

3. Stay alert — watch what you are doing.

4. All installations must comply with local codes. Contact your electrician, plumber, utility company or the

selling distributor for specific details.

CAUTION: To reduce the risk of

injury, read operating instructions carefully before using.

1. Read the owner's manual thoroughly. Failure to follow instructions could cause malfunction of the machine and

result in death, serious bodily

injury and/or property damage.

T o comply with the National Electrical Code (NFPA

70) and provide additional protection from risk of

electric shock, these pressure washer are equipped

with a UL approved ground fault circuit interrupter

(GFCI) power cord (120V and 230V 1 Ph). All other

models must be connected to a GFCI circuit

breaker.

WARNING: Flammable liquids

WARNING

can create fumes which can ignite causing property damage or

severe injury .

WARNING: Risk of explosion —

do not spray flammable liquids.

RISK OF EXPLOSION:

DO NOT USE WITH

FLAMMABLE LIQUIDS.

WARNING

5. Risk of explosion - do not spray

flammable liquids or operate in

an explosive location.

WARNING: Keep water spray

away from electric wiring or fatal electric shock may result.

6. To protect the operator from

electrical shock, the machine

must be electrically grounded.

KEEP WATER SPRAY

AWAY FROM

ELECTRICAL WIRING.

It is the responsibility of the

owner to connect this machine

to a UL grounded receptacle

of proper voltage and amperage ratings. Do not

spray water on or near electrical components. Do

not touch machine with wet hands or while standing in water. Always disconnect power before servicing.

7. Gr ip cleaning wand securely with both hands before starting the cleaner. Failure to do this could

result in injury from a whipping wand.

WARNING

WARNING: The high pressure

stream of fluid that this equipment can produce can pierce

skin and its underlying tissues,

leading to serious injury and

possible amputation.

RISK OF INJECTION

OR SEVERE INJURY

TO PERSONS. KEEP

CLEAR OF NOZZLE.

8. High pressure developed by

these machines will cause personal injury or equipment dam

age. Use caution when oper-

ating. Do not direct discharge stream at people , or

severe injury or death will result.

9. Never make adjustments on machine while in

operation.

4

97-711, 97-727, 96-721 • REV. 2/04

Page 5

PRESSURE WASHER

WARNING

WARNING: High pressure spray

can cause paint chips or other

particles to become airborne and

fly at high speeds.

10. Eye safety devices and foot

protection must be worn when

USE PROTECTIVE

EYEWEAR WHEN

OPERATING.

using this equipment.

11. Machines with spray gun

should not be operated with

the trigger in the off position for extensive periods

of time as this may cause damage to the pump.

12. Protect from freezing.

13. Be certain all quick coupler fittings are secured before using pressure washer .

14. Do not allow acids, caustic or abrasive fluids to pass

through the pump.

15. Inlet water must be cold and clean fresh water .

16. To reduce the risk of injury , close supervision is necessary when a machine is used near children. Do

not allow children to operate the pressure washer .

This machine must be attended during operation.

17. The best insurance against an accident is precaution and knowledge of the machine.

18. Manufacturer will not be liable f or any changes made

to our standard machines or any components not

purchased from us.

OPERATOR’S MANUAL

97-711, 97-727, 96-721 • REV. 2/04

5

Page 6

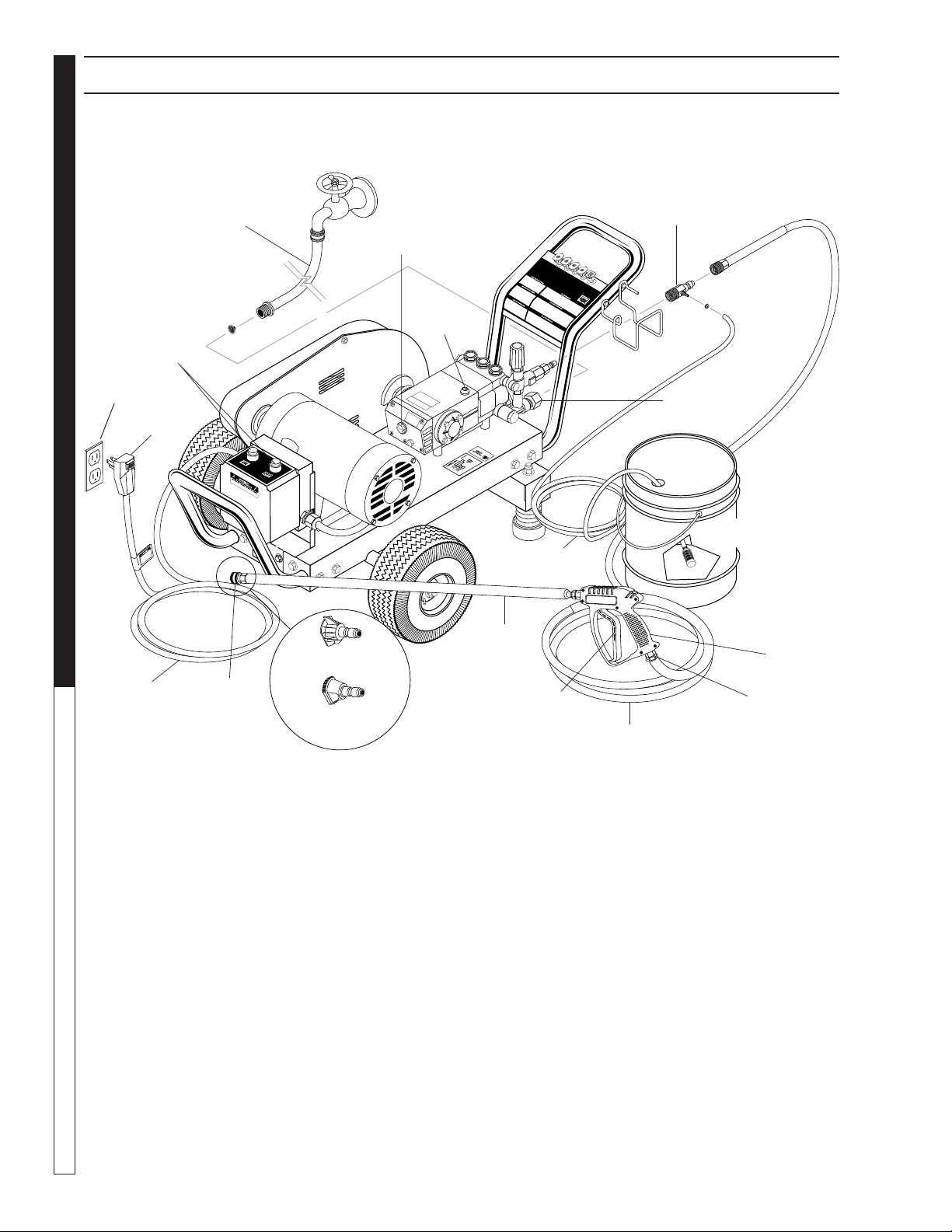

COMPONENT IDENTIFICATION

PRESSURE W ASHER

Start/Stop

Switches

Power

Supply

OPERATOR’S MANUAL

Power

Cord

Water Supply Hose

(not included)

GFCI

Nozzle

Quick

Coupler

Sight Glass

Pressure Nozzle

Soap

Nozzle

Oil Level

Oil

Dipstick

Detergent

Tube

Wand

Trigger

High Pressure Hose

Detergent

Injector

Inlet

Connector

Detergent Bucket

(not included)

Spray

Gun

Swivel

Connector

Detergent Injector - Allows you to siphon and mix de-

tergents.

High Pressure Hose - Connect one end to water pump

discharge nipple and the other end to spray gun.

Nozzle Quick Coupler - To easily connect the high pres-

sure hose and soap nozzle to wand.

Oil Level Sight Glass - A quick visual ref erence to the

oil level in the pump .

Pump - Develops high pressure.

Pump Protector - Cycles fresh cool water through pump

when recirculating water reaches 140°F.

6

97-711, 97-727, 96-721 • REV. 2/04

Spray Gun - Must be connected to the high pressure

hose and wand.

Swivel Connector - Connects to the spray gun and

wand. Minimizes hassle of hose coiling.

Wand - Must be connected to the spra y gun.

Note: If trigger on spray gun is released for more

than 2 minutes, water will leak from valve. Warm

water will discharge from pump protector onto floor .

This system prevents internal pump damage.

Page 7

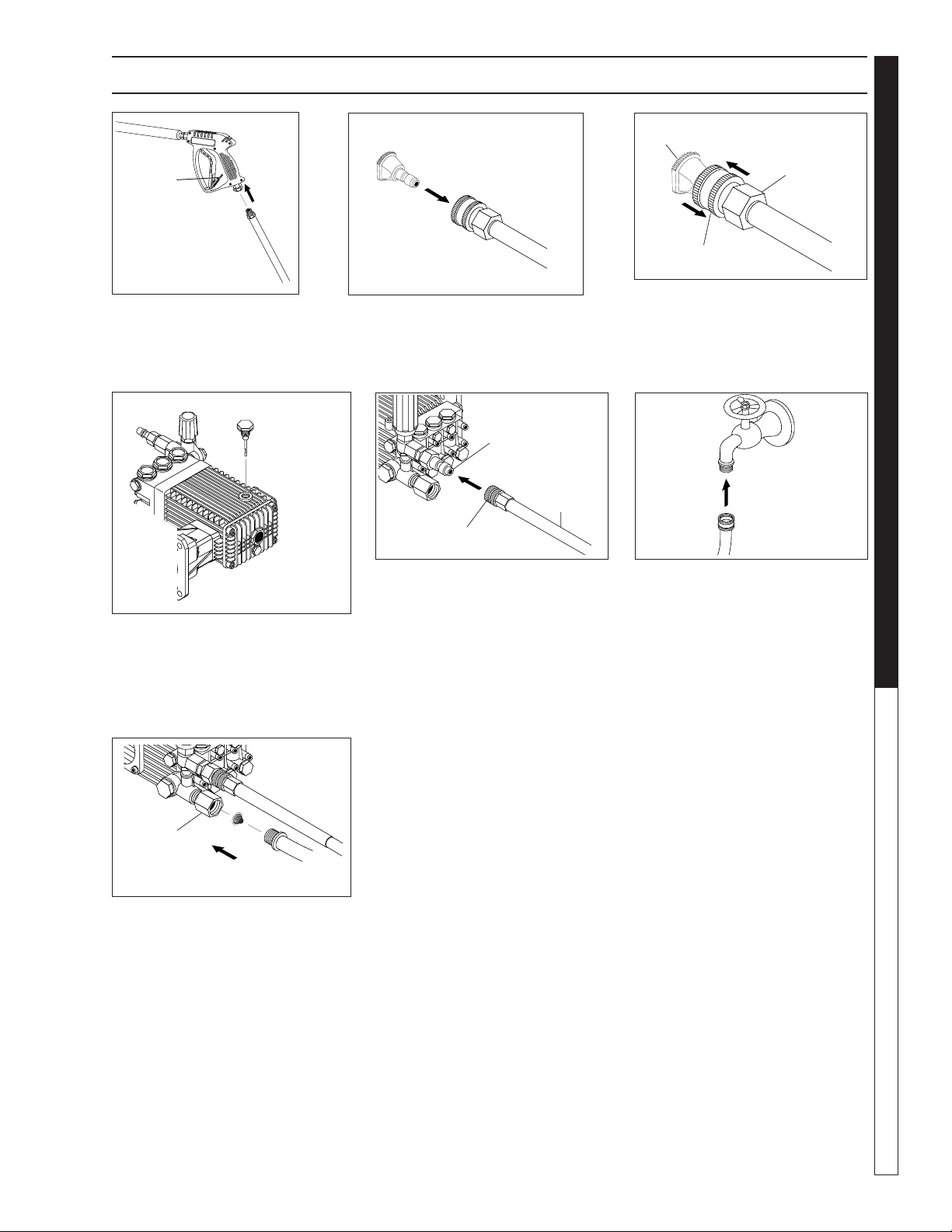

ASSEMBLY INSTRUCTIONS

PRESSURE WASHER

Spray

Gun

Safety

Latch

High Pressure

Hose

STEP 1: Attach the high

pressure hose to the spray

gun using teflon tape on

hose threads.

DipStick

Pressure

Nozzle

Wand

Coupler

STEP 2: Pull the spring-loaded col-

lar of the wand coupler back to insert your choice of pressure nozzle.

Pump

Discharge

Fitting

High

Pressure

Hose

Coupler Collar

Pressure

Nozzle

Wand

Coupler

Wand

Collar

STEP 3: Release the coupler col-

lar and push the nozzle until the

collar clicks. Pull the nozzle to

make sure it is seated properly.

Cold

Water

Source

Garden

Hose

OPERATOR’S MANUAL

STEP 4: Remove shipping cap and

install oil dipstick. Check pump oil

level b y using dipstick or observe oil

level in oil windo w (if equipped). Use

30 wt. non detergent oil.

Pump

Water Inlet

Garden

Hose

STEP7: Connect the garden hose

to pump water inlet. Inspect inlets.

CAUTION: Do not run the pump

without water or pump damage

will result.

STEP 5: Connect the high pressure

hose to the pump discharge fitting.

Push coupler collar forward until

secure.

STEP 6: Connect garden hose to

the cold water source.

97-711, 97-727, 96-721 • REV. 2/04

7

Page 8

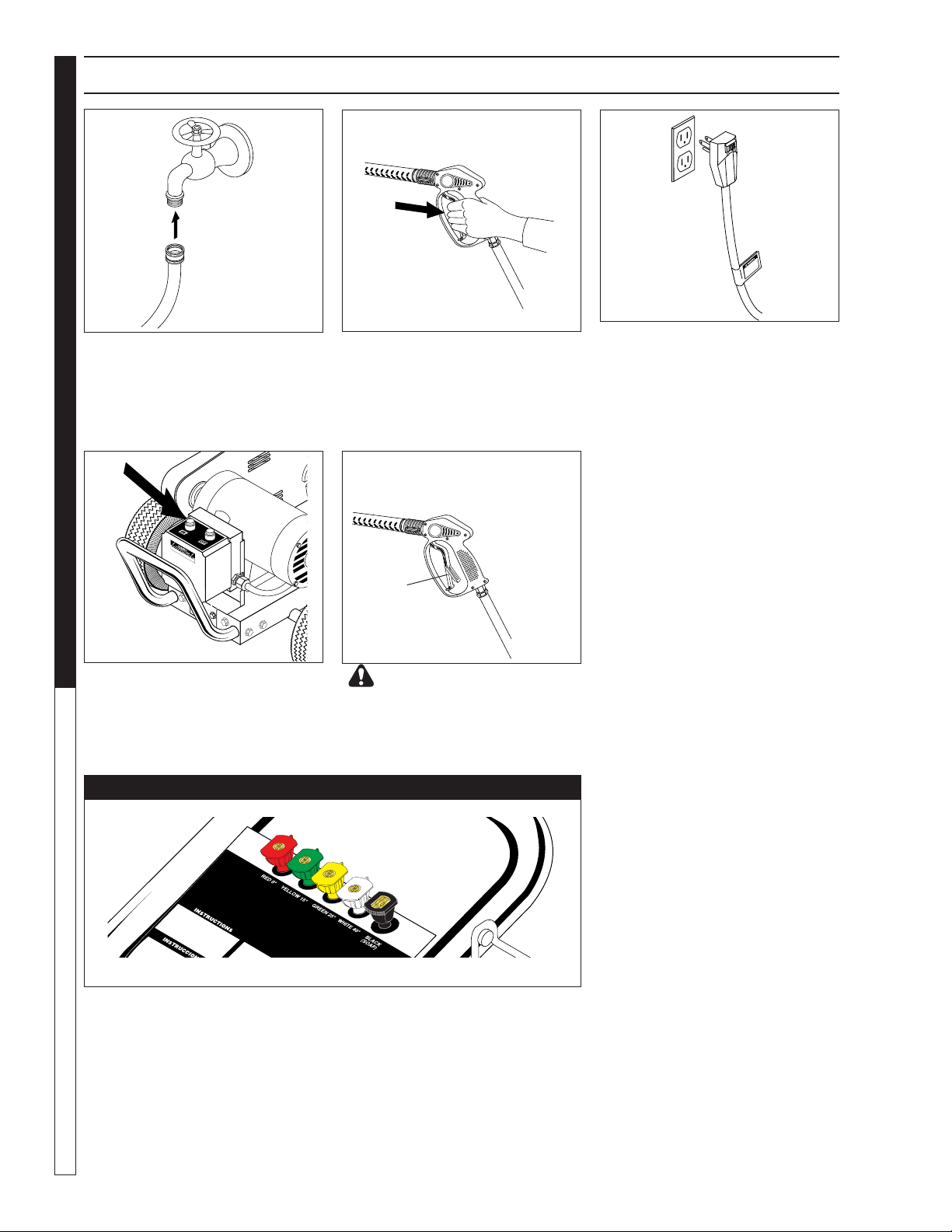

Cold

Water

Source

PRESSURE W ASHER

Garden

STEP 1: Connect garden hose to the

cold water source and turn water on

completely. Never use hot w ater.

OPERATOR’S MANUAL

Hose

OPERATING INSTRUCTIONS

STEP 2: Trigger the spray gun to

eliminate trapped air then wait f or

a steady flow of water to emerge

from the spray nozzle.

STEP 3: Connect machine to adequate power source. Push reset

button on GFCI.

Safety

Latch

STEP 4: Turn machine on.

WARNING! Never replace

nozzles without engaging the

safety latch on the spray gun trigger.

NOZZLES

The five color-coded quick connect nozzles provide a wide arr ay of spray

widths from 0° to 45° and are easily accessible when placed in the convenient rubber nozzle holder, which is provided on the front of the machine .

NOTE: F or a more gentle rinse, select the white 40° or green 25° nozzle.

T o scour the surf ace, select the yellow 15° or red 0° nozzle . To apply detergent select the black nozzle.

8

97-711, 97-727, 96-721 • REV. 2/04

Page 9

DETERGENTS AND GENERAL OPERATING TECHNIQUES

PRESSURE WASHER

WARNING

STEP 2: Apply safety latch to spra y gun trigger. Secure

black detergent nozzle into quick coupler. NOTE: Detergent cannot be applied using Red, Yellow, Green or

White nozzles.

IMPORT ANT : You m ust flush the detergent injection

system after each use by placing the suction tube

into a bucket of clean water, then run the pressure

washer in low pressure for 1-2 minutes.

WARNING: Some detergents

may be harmful if inhaled or ingested, causing severe nausea,

fainting or poisoning. The harmful elements may cause property

damage or severe injury .

STEP 1: Use detergent designed

specifically for pressure washers.

Household detergents could damage the pump. Prepare detergent

solution as required by the manufacturer . Fill a container with pressure washer detergent. Place the

filter end of detergent suction tube

into the detergent container.

STEP 3: With the engine running, pull trigger to operate machine. Liquid detergent is

drawn into the machine and

mixed with water . Apply detergent to work area. Do not allow detergent to dry on surface.

pump protector engages and cools the pump by discharging the warm water onto the ground. This thermal

device prev ents internal damage to the pump .

CLEANING TIPS

Pre-rinse cleaning surface with fresh water . Place detergent

suction tube directly into cleaning solution and apply to surface at low pressure (for best results , limit your work area to

sections approximately 6 feet square and alw a ys apply detergent from bottom to top). Allow detergent to remain on

surface 1-3 minutes. Do not allow detergent to dry on surface. If surface appears to be drying, simply wet down surface with fresh water . If needed, use brush to remove stubborn dir t. Rinse at high pressure from top to bottom in an

even sweeping motion keeping the spray nozzle approximately 1 foot from cleaning surface . Use overlapping strok es

as you clean and rinse any surface. For best surf ace cleaning action spray at a slight angle.

Recommendations:

• Before cleaning any surf ace, an inconspicuous area

should be cleaned to test spray pattern and distance for maximum cleaning results.

• If painted surfaces are peeling or chipping, use e xtreme caution as pressure washer may remo ve the

loose paint from the surface.

• Keep the spra y nozzle a saf e distance from the surface you plan to clean. High pressure wash a small

area, then check the surface f or damage. If no damage is found, continue to pressure washing.

CAUTION - Never use:

• Bleach, chlorine products and other corrosive

chemicals

• Liquids containing solvents (i.e., paint thinners,

gasoline, oils)

• Tri-sodium phosphate products

• Ammonia products

• Acid-based products

These chemicals will harm the machine and will damage the surface being cleaned.

RINSING

• It will take a fe w seconds f or the detergent to clear .

Apply safety latch to spray gun. Remov e black soap

nozzle from the quick coupler . Select and install the

desired high pressure nozzle. NOTE: Y ou can also

stop detergent from flowing by simply removing detergent siphon tube from bottle.

OPERATOR’S MANUAL

THERMAL PUMP PROTECTION

If you run the engine on your pressure washer for 3-5

minutes without pressing the trigger on the spray gun,

circulating water in the pump can reach high temperatures. When the water reaches this temperature, the

97-711, 97-727, 96-721 • REV. 2/04

9

Page 10

SHUTTING DO WN AND CLEAN-UP

STEP 1: Remove detergent suction

PRESSURE W ASHER

tube from container and insert into

one gallon of fresh water. Slide

nozzle forward for low pressure or

to connect black detergent nozzle.

Pull trigger on spray gun and siphon

water for one minute .

OPERATOR’S MANUAL

Pump

Water

Inlet

STEP 4: Press trig-

ger to release water pressure.

STEP 5: Disconnect the garden

hose from the water inlet on the

machine.

STEP 2: Turn off machine.

STEP 6: Disconnect the high

pressure hose from high pressure outlet.

STORAGE

STEP 3: Turn off water

supply.

High

Pressure

Outlet

Safety

Latch

STEP 7: Engage

the spray gun

safety lock.

Pump Storage

CAUTION: Always store your pressure washer in a location where the

temperature will not fall below 32° F

(0° C). The pump in this machine is

CAUTION

If you must store your pressure washer in a location

where the temperature is below 32° F, you can minimize the chance of damage to your machine by draining your machine as follo ws:

1. Stop the pressure washer and detach supply hose

and high pressure hose. Squeez e the trigger of the

spray gun to drain all water from the wand and

hose.

2. Restart pressure washer and let it run briefly (about

5 seconds) until water no longer discharges from

the high pressure outlet.

10

susceptible to permanent damage if

frozen.

FREEZE DAMA GE IS NOT CO VERED

BY WARRANTY .

97-711, 97-727, 96-721 • REV. 2/04

Page 11

TROUBLESHOOTING

MELBORPESUACELBISSOPNOITULOS

GNINNURPMUP

TUBYLLAMRON

NOWOLERUSSERP

NOITALLATSNI

riagnikcuspmuP .egapeesriafoytilibissopdnaylppusretawkcehC

gnikcitssevlavkcehC.yrassecenfiecalperronaelcdnakcehC

ytluaftaesevlavredaolnU.yrassecenfiecalperdnakcehC

dezisyltcerrocnielzzoN.yrassecenfiecalperdnakcehC

gnikcapnotsipnroW.yrassecenfiecalperdnakcehC

PRESSURE WASHER Troubleshooting Guide

GNITAUTCULF

ERUSSERP

WOLERUSSERP

FODOIREPRETFA

ESULAMRON

YSIONPMUP

RETAWFOECNESERP

LIOPMUPNI

nrowsevlaV.yrassecenfiecalperdnakcehC

evlavniegakcolB.yrassecenfituonaelcdnakcehC

riagnikcuspmuP.snoitcennocylppusretawkcehC

gnikcapnotsipnroW.yrassecenfiecalperdnakcehC

retawtneiciffusnI.egakaerbrofesohdnaretlifkcehC

nrowelzzoN.yrassecenfiecalperdnakcehC

sevlavyreviledronoitcuS

dekcolb

nrowtaesevlavredaolnU.yrassecenfiecalperdnakcehC

egakcapnotsipnroW.yrassecenfiecalperdnakcehC

enilnoitcusniriA .enilnoitcusnosnoitcennocdnaylppusretawkcehC

ronoitcuskaewronekorB

gnirpsevlavyreviled

sevlavnirettamngieroF.yrassecenfinaelcdnakcehC

sgniraebnroW.yrassecenfiecalperdnakcehC

nrowlaesliO.yrassecenfiecalperdnakcehC

rianiytidimuhhgiH.netfosaeciwtlioegnahcdnakcehC

nrowsevlavyreviledronoitcuS.yrassecenfiecalperdnakcehC

retawfoerutarepmetevissecxE041wolebotecudeR

.yrassecenfinaelcdnakcehC

.yrassecenfiecalperdnakcehC

o

.F

nrowgnikcapnotsiP.yrassecenfiecalperdnakcehC

GNIPPIRDRETAW

PMUPREDNUMORF

GNIPPIRDRETAW

PMUPMORF

ROTCETORP

GNIPPIRDLIO

NOITARBIVEVISSECXE

ERUSSERP-HGIHNI

ESOH

nrowgnikcapnotsiP.yrassecenfiecalperdnakcehC

nrowreniaterregnulpgniR-O.yrassecenfiecalperdnakcehC

hgihooterusserpylppusretaW

)isp09revo(

noitisopffoehtnisinugyarpS

setunim5revorof

nrowlaesliO.yrassecenfiecalperdnakcehC

ehtfogninoitcnufralugerrI

sevlavpmup

97-711, 97-727, 96-721 • REV. 2/04

.rotalugeragnisuerusserpylppusretawrewoL

.setunim5revorofesunitonfiffoenihcamnruT

.yrassecenfiecalperdnakcehC

11

Page 12

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

MOTOR WILL NOT

START

MOTOR OVERHEATING

PRESSURE WASHER Troubleshooting Guide

Usually caused by line trouble, such

as single phasing at the starter

Overload. Compare actual amps

(measured) with nameplate rating

Single phasing Check current at all phases (should be

Improper ventilation Check external cooling fan to be sure air is

Unbalanced voltage Check voltage at all phases (should be

Over voltage or under voltage Check input voltage at each phase to motor.

Open stator winding Check stator resistance at all three phases for

Improper connections Inspect all electrical connections for proper

Check source of power. Check overloads,

fuses, cont r ol s, et c.

Locate and remove source of excessive

friction in motor or load.

Reduce load or replace with motor of greater

capacity.

approximately equal) to isolate and correct

problem.

moving properly across cooling fins.

Excessive dirt build-up on motor. Clean motor.

approximately equal) to isolate and correct the

problem.

balance.

termination, clearance, mechanical strength

and electrical continuity. Refer to wiring

diagrams.

BEARING

OVERHEATING

GROWLING OR

WHINING

Misalignment Check and align motor and driven equipment.

Excessive belt tension Reduce belt tension to proper point for load.

Excessive grease in bearing Remove gr ease until cavity is approximately

3/4 filled.

Insufficient grease in bearing Add grease until cavity is approximately 3/4

filled.

Dirt in beari ng Clean bearing cavity and bearing. Repack with

correct grease until cavity is approximately 3/4

filled.

Bad bearing Replace bearing. Clean all grease from cavity

and new bearing. Repack with correct grease

until cavity is approximately 3/4 filled.

12

97-711, 97-727, 96-721 • REV. 2/04

Page 13

PREVENTATIVE MAINTENANCE

This pressure washer was produced with the best av ailable materials and quality craftsmanship. Howe ver , you as

the owner have certain responsibilities for the correct care of the equipment. Attention to regular preventative

maintenance procedures will assist in preserving the performance of your equipment. Contact your dealer for

maintenance. Regular preventativ e maintenance will add many hours to the life of y our pressure washer . P erform

maintenance more often under severe conditions .

PRESSURE WASHER

Pump Oil

Inspect Daily inspect the oil level

Change After first 50 hours, then every 500 hours or annually

Replace High Pressure Nozzle Every 6 months

Replace Quick Connects Anually

Clean Water Screen/Filter Weekly

Replace HP Hose Anually if there is any sign of wear

Grease Motor Every 10,000 hours or annually

General Inspection Inspect the motor at regular intervals, approximately every 500 hours of operation,

or every 3 months, whichever occurs first. K eep the motor clean and the ventilation

openings clear. The following steps should be perf ormed at each inspection:

WARNING: Do not touch electrical connections before you first ensure that power

has been disconnected. Electrical shock can cause serious or f atal injury . Only qualified personnel should attempt the installation, operation and maintenance of this

equipment.

1. Chec k that the motor is clean. Check that the interior and exterior of the motor

is free of dirt, oil, grease, water, etc. Oily vapor , paper pulp , te xtile lint, etc. can

accumulate and block motor v entilation. If the motor is not properly ventilated

overheating can occur and cause early motor failure .

2. Check all electrical connectors to be sure that they are tight.

Lubrication & Bearings Bearing grease will lose its lubricating ability over time, not suddenly. The lubricating

ability of a grease (over time) depends primarily on the type of grease, the size of the

bearing, the speed at which the bearing operates and the severity of the operating

conditions. Good results can be obtained if the following recommendations are used in

your maintenance program.

Type of Grease A high grade ball or roller bearing grease should be used. Recommended greases

standard service conditions are: Shell Dolium R (Factory installed) or Chevron SRI

OPERATOR’S MANUAL

Date Oil Chang ed

Month/Day/Year

OIL CHANGE RECORD

Estimated Operating

Hours Since La st

Oil Change

97-711, 97-727, 96-721 • REV. 2/04

Date Oil Chang ed

Month/Day/Year

Estimated Operating

Hours Since La st

Oil Change

13

Page 14

EXPLODED VIEW

71

Model PE3-1100

35

47

53

PRESSURE W ASHER

OPERATOR’S MANUAL

37

66

64

65

46

68

58

27

36

24

29

45

21

59

44

70

29

61

57

60

74

62

25

75

42

73

28

23

45

52

51

25

45

44

69

63

1

67

5

2

48

4

7

5

5

5

6

7

75

3

2

6

5

76

5

76

23

48

5

9

8

91

43

5

18

90

89

2

48

91

43

9

75

5

5

48

3

2

1

14

97-711, 97-727, 96-721 • REV. 2/04

Page 15

EXPLODED VIEW

PRESSURE WASHER

41

41

40

40

83

26

88

86

82

80

85

84

26

22

72

87

78

34

80

79

22

33

34

81

41

Models PE4-2000,

5

72

PE4-3000

55

6

5

26

31

78

22

34

40

19

33

32

OPERATOR’S MANUAL

94

30

20

93

56

Model PE5-3000

5

6

6

17

14

11

12a

12b

5

15

16

13

6

5

6

10

97-711, 97-727, 96-721 • REV. 2/04

15

Page 16

EXPLODED VIEW PARTS LIST

ITEM PART NO. DESCRIPTION QTY

1 90-2004 Nut, Jam, ESNA, NC, 5/8" 2

2 90-4005 Washer, Flat, SAE, 5/8" 4

3 4-0307 Tire & Wheel Cmpl, Steel 6"

(5-3000, 4-2000, 4-3000) 2

4-0303 Wheel & Tire Assembly, 4" Tube,

(3-1100) 2

4 95-07101145 Handle, Bumper, 1-1/4",

PRESSURE W ASHER

5 90-4002 Washer, Flat, SAE, 3/8" 32

6 90-2002 Nut, ESNA, NC, 3/8" 16

7 90-10220 Bolt, 3/8" x 3-1/2", Tap 2

8 95-07101135 Bracket, Belt Tension 1

9 90-2020 Nut, Cage, 3/8", 12 Gauge 2

10 95-07101219 Bracket, Foot, Black (PE) 1

95-07101219R Bracket, Foot, Red (BB, BT)1

11 92-102 Foot Assembly

OPERATOR’S MANUAL

12a 90-1023 Bolt, 3/8" x 5", NC 2

12b 90-40125 Washer, 3/8" x 1", Steel 2

13 2-01041 Pad, Soft Rubber 2

14 90-4015 Washer, 2-1/2" x 7/16",

15 95-07161114A Tube, Foot, Bolt PC 2

16 90-5009 Spring, Foot, Compression 2

17 2-0107 Bellows, Leg (Boot) 2

18 95-07101216 Frame, Black, Welded

95-07101222 Frame, Large, Black,

95-07101222R Frame, Large, Red (BB, BT)1

19 11-0364 Label, BT 1

11-0331 Label, BB 1

10-99060 Label, PE 1

20 95-07101132 Handle, 1-1/4", Chrome 1

21 6-05172 Locknut, 3/4" 2

22 2-2007 Nipple, 3/4" x 3/8" Male 1

23 95-07101021 Bracket, Electrical Box 1

95-07101022 Bracket, Electr ical Box

24 10-08018 Label, Warning Service

25 2-0106 Cushion, Pump 2

26 5-3208 Unloader, AL 607, 7.8 GPM @

5-3029 Unloader PA 8@3650 PSI VB55

Chrome Plated 1

(items 11-17) 2

Flat Washer 2

(PE3-1100) 1

Welded (PE Models) 1

(4-3000A) 1

Cord 1

4200PSI (PE) 1

(BB, BT) 1

ITEM PART NO. DESCRIPTION QTY

27 6-01060 Cord, w/GFCI, 120V/20 Amp,

36' (3-1100) 1

6-0105 Cord, Service 12/4 (4-2000B,C;

4-3000C,N;5-3000C) 15 ft.

6-01059 Cord w/GFCI, 240V/30Amp

36' (4-2000A) 1

6-0109 Cord, Service,10/4

(4-3000B) 15 ft.

6-010690 GFCI, 240V, 40A, 1 PH, 37' Cord

(4-3000A) 1

6-01021 Cord, Service, 8/4

(5-3000B) 15 ft.

28 6-0108 Cord, Service, SEO, 10/3

(4-2000A) 2.75 ft.

6-0104 Cord Service SEO, 12/3

(3-1100) 2 ft.

6-0105 Cord, Service, SEO, 12/4

(4-2000B,C; 4-3000C,N,

5-3000C) 2.75 ft.

6-0109 Cord, Service, SEO, 10/4

(4-3000B) 2.75 ft.

6-0102 Cord, Service SEO 8/3

(4-3000A) 4 ft.

6-01021 Cord, Service SEO, 8/4

(5-3000B) 2.75 ft.

29 6-051595 Fitting, STRT, LQ Tite, Plastic

(4-2000A,B,C;4-3000B,C,N;

5-3000C) 2

6-0517 Strain Relief, 3/4"(4-3000A) 1

6-05170 Strain Relief, W ater Tight

(4-300A) 1

(5-3000B) 2

30 2-0103 Grommet, Rubber, 1/8" 5

31 4-12804000 Nozzle, SAQC MEG 0004

Red (4-3000) 1

4-12804015 Nozzle, SAQC MEG 1504

Yellow (4-3000) 1

4-12804025 Nozzle, SAQC MEG 2504

Green (4-3000) 1

4-12804040 Nozzle, SAQC MEG 4004

White (4-3000) 1

4-12805500 Nozzle SAQC MEG 0005.5 Red

(3-1100, 5-3000) 1

4-12805515 Nozzle, SAQC MEG 15055

Yellow (3-1100, 5-3000) 1

4-12805525 Nozzle, SAQC MEG 25055

Green (3-1100, 5-3000) 1

4-12805540 Nozzle, SAQC MEG 4055 White

(3-1100, 5-3000) 1

4-12806000 Nozzle, SAQC MEG 0506 Red

(4-2000) 1

4-12806015 Nozzle, SAQC MEG 1506

Yellow (4-2000) 1

4-12806025 Nozzle, SAQC, Meg 2506

Green (4-2000) 1

4-12806040 Nozzle, SAQC MEG 4006

White (4-2000) 1

16

97-711, 97-727, 96-721 • REV. 2/04

Page 17

EXPLODED VIEW PARTS LIST

PRESSURE WASHER

ITEM PART NO. DESCRIPTION QTY

32 4-16540 Nozzle, Brass, Soap 1

33 2-1902 Strainer, Inlet Garden Hose 1

34 2-10942 Swivel, 1/2" MP x 3/4" GHF 1

35 6-05154 Strain Relief, Plastic, LQ Tite

(3-1100) 1

36 See Overload Specifications, Pages 20-21

37 See Contactor Specifications, Pages 20-21

38 90-1991 ▲ Screw, 10/32" x 1/2" 7

39 90-017 ▲ Nut, 10/32" Keps 7

40 2-30082 Pump Protector, 1/2", PTP 1

41 See Pump Specifications, Pages 20-21

42 See Motor Specifications, Pages 20-21

43 90-1007 Bolt, 5/16" x 1", NC HH

(3-1100) 4

90-1017 Bolt, 3/8" x 1-1/4", NC HH

(4-2000, 4-3000, 5-3000) 4

44 90-4001 Washer, 5/16" Flat (3-1100)4

90-4002 Washer, 3/8" Flat 4

45 90-2001 Nut, 5/16" ESNA (3-1100) 4

90-2002 Nut, 3/8" ESNA 4

46 90-4001 Washer, 5/16" Flat 6

47 90-2001 Nut, 5/16" ESNA, NC 3

48 90-1020 Bolt, 3/8" x 2", NC HH 8

49 90-4000 ▲ Washer, 1/4" Flat, SAE 4

50 90-2000 ▲ Nut, 1/4" ESNA, NC 2

51 90-1006 Bolt, 5/16" x 3/4", NC HH 1

52 95-07101211 Back Plate, Belt Guard,

Large 1

95-07101213 Back Plate, Belt Guard, Small

(3-1100) 1

90-5004 ▲ Belt Guard, Pull Spring 1

90-1028 ▲ Eyebolt, 1/4" x 1" 2

53 2-01171 Belt Guard, Small (3-1100) 1

2-01172 Belt Guard, Large (PE) 1

2-0117201 Belt Guard, Large (BB, BT) 1

10-99055 ▲ Label (PE) 1

11-32291 ▲ Label (BT) 1

11-0330 ▲ Label (BB) 1

54 90-1007 Bolt, 5/16" x 1" NC, HH 2

55 10-020PE Label, PE 1

56 10-2031100 Label, 3-1100 1

10-2042000 Label, 4-2000 1

10-2043000 Label, 4-3000 1

10-2053000 Label, 5-3000 1

57 See Pump Bushing Specifications, Pages 20-21

58 See Motor Bushing Specifications, Pages 20-21

59 See Motor Pulley Specifications, Pages 20-21

60 See Pump Pulley Specifications, Pages 20-21

97-711, 97-727, 96-721 • REV. 2/04

ITEM PART NO. DESCRIPTION QTY

61 See Belt Specifications, Pages 20-21

62 6-03911 Lid, Plastic, Carlon (3-1100)1

63 6-03904 Enclosure, Fiberglass, Nema 4X

(except 3-1100, 4-3000A) 1

6-03909 Box, Plastic 10" x 8" x 6"

(4-3000A) 1

95-07290068 Standoff, Electrical Box

(4-3000A) 1

64 10-08015A Label, OFF/ON for Push

Button (except 3-1100) 1

65 10-08021 Label, Disconnect

Power Supply 1

66 6-2021 Switch, Green Push Button, CH

E22PB3 (All Models Except 3-

1100) 1

67 6-2001 Block, Contact, N/O, CH E22B2

(All Models Except 3-1100) 1

68 6-2022 Switch, Red Push Button, CH

E22EB2(All Models Except 3-

1100) 1

69 6-2000 Block, Contact, N/C, CH E22B1

(All Models Except 3-1100) 1

70 6-021595 Din Rail (All Models Except

(3-1100, 4-2000A,

4-3000A) 4"

90-1991 ▲ Screw, 10/32" x 1/2" 1

90-1994 ▲ Screw, 10/32"x1-1/4",

Ground 1

90-017 ▲ Nut, 10/32" Keps 2

71 6-03910 Box, Electric (3-1100 only) 1

72 2-1044 Plug, Brass 1/8"(General

Pump) 1

73 6-051595 Strain Relief, STRT, LQ Tite

Large, 3/4" (3-1100) 1

74 6-020204 Switch, 2 Pos., 1-3 PH

(3-1100) 1

75 90-1016 Bolt, 3/8" x 1", NC 4

76 90-2007 Nut, 3/8" Hex NC 2

77 11-1042 ▲ Label, Ground 1

78 2-1042 ■ Tee, 1/2" 1

79 2-02110000 ■ Hose, 1/2" Push-On 1.3 ft.

80 2-1105 ■ Swivel, 1/2" JIC Fem,

Push-On 2

81 2-1062 ■ Elbow, 1/2" JIC x 1/2",

90° 1

82 4-02047720 ■ Hose, 3/8" x 20", 2 Wire,

Pressure Loop 1

83 2-0053 ■ Elbow, 1/2" JIC x 3/8",

90° 1

84 2-0051 ■ Nipple, 1/2" JIC x 3/8",

Pipe 1

85 2-0006 ■ Nipple, 3/8", Hex 1

OPERATOR’S MANUAL

17

Page 18

EXPLODED VIEW PARTS LIST

ITEM PART NO. DESCRIPTION QTY

86 95-07101216/B ■ Block, Unloader, 3/8" x 3/8",

Brass 1

87 2-1060 ■ Elbow, 1/2" x 3/8", 90° 1

88 90-1020 ■ Bolt, 3/8" x 2", NC HH 2

89 90-10343 ■ Bolt, 10mm x 20mm, HH 4

90 90-400910 ■ Washer, 7/16" Lock, Split 4

91 90-4007 Washer, 3/8" x 1-1/2",

PRESSURE W ASHER

Fender 6

92 2-1042 Tee, 1/2" (3-1100) 1

93 95-07102382 Hanger, Hose & Wand 1

94 90-20012 Nut, 5/16" Whiz Loc, Flange2

95 6-05195 ▲ Strain Relief, Watertite (3-11D;

4-2A,B,C; 4-3B,C) 1

6-05171 ▲ Strain Relief, 1" Metal (4-3A,

N; 5-3B, C) 1

96 6-05181 Lock Nut, 3/4" (3-11D, 4-2A,B,C;

OPERATOR’S MANUAL

4-B,C) 1

▲ Not Shown

■ PE Models Only (Except

3-11021D)

18

97-711, 97-727, 96-721 • REV. 2/04

Page 19

HOSE & SPRAY GUN ASSEMBLY

1

PRESSURE WASHER

8

11

3

2

HOSE & SPRAY GUN ASSEMBLY PARTS LIST

ITEM PART NO. DESCRIPTION QTY

1 2-2002 Coupler, 3/8" Female 1

2-0121 ▲ Quick Coupler O-Ring

Large 1

2 4-02043450C Hose 50' x 3/8" w/Coupler

(PE Models) 1

4-020650C BB Models 1

4-02093450BC BT Models 1

3 4-01212 Spray Gun, Shut-off (PE

Models) 1

4-01246 BB &BT Models 1

4 4-0110410 Wand, Straight (PE Models)1

4-0110322 Wand w/side Grip ( BB & BT

Models) 1

5 4-011231 Cover, Wand (PE Models) 1

10

7

12

4,5

6

9

ITEM PART NO. DESCRIPTION QTY

6 4-16540 Brass Soap Nozzle 1

7 Nozzle, See Page 16, Item #31

8 4-011183 Detergent Injector (3-1100) 1

4-011184 Detergent Injector (All Other

Models) 1

9 2-2000 Coupler, 1/4" Female 1

2-0119 ▲ Quick Coupler O-Ring

Small 1

10 4-02080000 Tube, 1/4” x 1/2” Clear Vinyl 6 ft.

11 2-9040 Clamp, Hose 2

12 2-1904 Strainer, 1/4” Hose Barb

▲ Not Shown

OPERATOR’S MANUAL

97-711, 97-727, 96-721 • REV. 2/04

19

Page 20

SPECIFICATIONS

PARTS SPECIFICATIONS

MOTORPUMP

Pump Unloader Pump Pump Pulley Pump Bushing Motor Motor

Model Pump Part No. Par t No. Pulley Part No. Bushing Part No. Size Voltage/ph Hz

3-11021D T991 5-2302 5-3025 2AK84H 5-40208401 24MM 5-512024 2HP 120V/1PH 60

4-20024A LT5030 5-1728 5-3208 2AK84H 5-40208401 25MM 5-512025 6.2HP 230V/1PH 60

4-20024B LT5030 5-1728 5-3208 2AK84H 5-40208401 25MM 5-512025 6.2HP 230V/3PH 60

4-20024C LT5030 5-1728 5-3208 2AK84H 5-40208401 25MM 5-512025 6.2HP 460V/3PH 60

4-30024A LT5030 5-1728 5-3208 2BK90H 5-40509001 25MM 5-512025 7.5HP 230V/1PH 60

4-30024B LT5030 5-1728 5-3208 2BK90H 5-40509001 25MM 5-512025 7.5HP 230V/3PH 60

4-30024C LT5030 5-1728 5-3208 2BK90H 5-40509001 25MM 5-512025 7.5HP 460V/3PH 60

4-30024N LT5030 5-1728 5-3208 2BK70H 5-40507001 25MM 5-512025 7.5HP 380V/3PH 50

PRESSURE WASHER Specifications

5-30024B LT5030 5-1728 5-3208 2BK65H 5-40506501 25MM 5-512025 1HP 230V/3PH 60

5-30024C LT5030 5-1728 5-3208 2BK65H 5-40506501 25MM 5-512025 1HP 460V/3PH 60

402007A GM4030 5-1910 5-3029 2AK74H 5-40207401 24MM 5-512024 6.2HP 230V/1PH 60

402007B GM4030 5-1910 5-3029 2AK74H 5-40207401 24MM 5-512024 6.2HP 230V/3PH 60

402007C GM4030 5-1910 5-3029 2AK74H 5-40207401 24MM 5-512024 6.2HP 460V/3PH 60

353007A GM4030 5-1910 5-3029 2BK70H 5-40507001 24MM 5-512024 8.2HP 230V/1PH 60

353007B GM4030 5-1910 5-3029 2BK70H 5-40507001 24MM 5-512024 8.2HP 230V/3PH 60

353007C GM4030 5-1910 5-3029 2BK70H 5-40507001 24MM 5-512024 8.2HP 460V/3PH 60

503007B GM5030 5-1915 5-3029 2BK52H 5-40505201 24MM 5-512024 10HP 230V/3PH 60

503007C GM5030 5-1915 5-3029 2BK52H 5-40505201 24MM 5-512024 10HP 460V/3PH 60

20

97-711, 97-727, 96-721 • REV. 2/04

Page 21

SPECIFICATIONS

MOTOR (CON'T)

Motor Motor Pulley Motor Bushing Belt Belt Contactor Overload

Model Pulley Par t No. Bushing Part No. Size Part No. Part No. Part No.

5-1047 AK28x5/8 5-40202858 n/a n/a AX37 (1) 5-602037 n/a n/a

5-10401 2AK46H 5-40204601 HX1-1/8" 5-511113 AX42 (2) 5-602042 6-4019 n/a

5-1011 2AK46H 5-40204601 HX1-1/8" 5-511113 AX42 (2) 5-602042 6-4011 6-5011

5-1011 2AK46H 5-40204601 HX1-1/8" 5-511113 AX42 (2) 5-602042 6-4009 6-5009

5-1013 2BK40H 5-40504001 HX1-3/8" 5-511138 BX42 (2) 5-604042 6-4019 6-5015

5-10145 2BK40H 5-40504001 HX1-3/8" 5-511138 BX42 (2) 5-604042 6-4011 6-5012

5-10145 2BK40H 5-40504001 HX1-3/8" 5-511138 BX42 (2) 5-604042 4-4009 6-5010

5-1063 2BK34H 5-40503401 HX1-3/8" 5-511138 BX39 (2) 5-604039 6-4011 5-5010

5-1018 2BK36H 5-40503601 HX1-3/8" 5-511138 BX38 (2) 5-604038 6-4014 6-5013

5-1018 2BK36H 5-40503601 HX1-3/8" 5-511138 BX38 (2) 5-604038 6-4009 6-5010

PRESSURE WASHER Specifications

5-10401 2AK46H 5-40204601 HX1-1/8" 5-511113 AX40 (2) 5-602040 6-4019 n/a

5-1011 2AK46H 5-40204601 HX1-1/8" 5-511113 AX40 (2) 5-602040 6-4011 6-5011

5-1011 2AK46H 5-40204601 HX1-1/8" 5-511113 AX40 (2) 5-602040 6-4009 6-5009

5-1082 2BK36H 5-40503601 HX1-3/8" 5-511138 BX37 (2) 5-604037 6-4019 6-5015

5-1083 2BK36H 5-40503601 HX1-3/8" 5-511138 BX37 (2) 5-604037 6-4011 6-5012

5-1083 2BK36H 5-40503601 HX1-3/8" 5-511138 BX37 (2) 5-604037 4-4009 6-5010

5-1018 2BK45H 5-40504501 HX1-3/8" 5-511138 BX36 (2) 5-604036 6-4014 6-5013

5-1018 2BK45H 5-40504501 HX1-3/8" 5-511138 BX36 (2) 5-604036 6-4009 6-5010

97-711, 97-727, 96-721 • REV. 2/04

21

Page 22

Page 23

BT SERIES PRESSURE WASHER

WARRANTY

SHARK LIMITED NEW PRODUCT WARRANTY

PRESSURE WASHERS

WHA T THIS W ARRANTY COVERS

All SHARK PRESSURE WASHERS are warranted by SHARK to the original purchaser to be free from defects in materials and

workmanship under normal use, for the periods specified below . This Limited W arranty is subject to the e xclusions sho wn below ,

is calculated from the date of the original purchase, and applies to the original components only. Any parts replaced under this

warranty will assume the remainder of the part’s warranty period. This warranty applies to the original purchaser and is not

transferable.

LIMITED LIFETIME PARTS WARRANTY:

Components manufactured by SHARK, such as frames, handles, coil wraps, float tanks, and belt guards. Forged brass pump

manifold. All heating coils will have a three year warranty. Internal components on the oil-end of all pressure washer pumps will

have a seven year warranty.

ONE YEAR PARTS WARRANTY:

All other components, excluding normal wear items as described below, will be warranted for one year on parts. Warranty on

these parts will be for one year regardless of the duration of the original component manufacturer’s part warranty.

WARRANTY PROVIDED BY OTHER MANUFACTURERS:

Motors, generators, and engines, which are warranted by their respective manufacturers, are serviced through these manufacturers’ local authorized service centers. SHARK cannot provide warranty on these items.

WHAT THIS WARRANTY DOES NOT COVER

This warranty does not cover the following items:

1. Normal wear items, such as nozzles, guns, discharge hoses, wands, quick couplers, seals, filters, gaskets, O-rings,

packings, pistons, pump valve assemblies, strainers, belts, brushes, rupture disks, fuses, pump protectors.

2. Damage or malfunctions resulting from accidents, abuse, modifications, alterations, incorrect installation, improper

servicing, failure to follow manufacturer’s maintenance instructions, or use of the equipment beyond its stated usage

specifications as contained in the operator’s manual.

3. Damage due to freezing, chemical deterioration, scale buildup, rust, corrosion, or thermal expansion.

4. Damage to components from fluctuations in electrical or water supply.

5. Normal maintenance service, including adjustments, fuel system cleaning, and clearing of obstructions.

6. Transportation to service center, shop labor charges, field labor charges, or freight damage.

WHAT YOU MUST DO TO OBTAIN WARRANTY SERVICE

While not required for warranty service, we request that you register your SHARK pressure washer by returning the completed

registration card. In order to obtain warranty service on items, you must return the product to an Authorized SHARK Dealer,

freight prepaid, with proof of purchase, within the applicable warranty period. If the product is permanently installed, you must

notify your Authorized SHARK Dealer of the defect. The Authorized Dealer will file a claim, which must subsequently verify the

defect. In most cases, the part must be returned to SHARK freight prepaid with the claim. For warranty service on components

warranted by other manufacturers, the Authorized Dealer can help you obtain warranty ser vice through these manufacturers’

local authorized service centers.

LIMIT A TION OF LIABILITY

SHARK’S liability for special, incidental, or consequential damages is expressly disclaimed. In no event shall SHARK’S liability

exceed the purchase price of the product in question. SHARK makes every effort to ensure that all illustrations and specifications are correct, however, these do not imply a warranty that the product is merchantable or fit for a particular purpose, or that

the product will actually conform to the illustrations and specifications. THE WARRANTY CONTAINED HEREIN IS IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE. SHARK does not authorize any other party , including authorized Dealers, to mak e any representation or

promise on behalf of SHARK, or to modify the terms, conditions, or limitations in any way. It is the buyer’s responsibility to ensure

that the installation and use of SHARK products conforms to local codes. While SHARK attempts to assure that its products

meet national codes, it cannot be responsible for how the customer chooses to use or install the product.

PRESSURE WASHER WARRANTY

SHARK PRESSURE WASHERS

1-360-833-9100 • 1-800-771-1881 • www.shark-pw.com

SHARK BT • 97-727 • REV. 2/04

Page 24

Form #97-727 • Revised 2/04 • Printed in U .S.A.

Loading...

Loading...