Shark BR-442537, BR-373537, BR-353237, BR-404027, BR-455037E Operating Instructions And Parts Manual

...

MODEL: BR

OPERATING INSTRUCTION

AND PARTS MANUAL

■ BR-442537 ■ BR-353237 ■ BR-373537

■ BR-404027 ■ BR-455037E ■ BR-343087E

For technical assistance or the SHARK dealer nearest you, call 1-800-771-1881

or visit our website at www.shark-pw.com

97-723

Important Safety Information ................................................................4-5

Component Identifi cation Small...............................................................6

Component Identifi cation Large...............................................................7

Assembly Instructions..............................................................................8

Operating Instructions ........................................................................9-10

Applying Detergent and General Operating Techniques........................11

Shut Down and Clean-Up......................................................................12

Storage..................................................................................................12

Troubleshooting................................................................................13-14

Preventative Maintenance .....................................................................15

Oil Change Record................................................................................15

Exploded View - Large...........................................................................16

Exploded View Parts List..................................................................17-19

Exploded View - Small...........................................................................20

Exploded View Parts List..................................................................21-22

Hose and Spray Gun Assembly.............................................................23

Specifi cations....................................................................................24-25

Warranty

CONTENTS

Model Number _________________________________

Serial Number _________________________________

Date of Purchase _______________________________

The model and serial numbers will be found on a decal at tached

to the pressure washer. You should record both serial number and

date of purchase and keep in a safe place for future ref er ence.

3

96-718, 97-721, 97-723 • REV. 8/05a

INTRODUCTION & IMPORTANT SAFETY INFORMATION

Thank you for purchasing a this pressure washer.

All in for ma tion in this man u al is based on the lat est

prod uct in for ma tion avail able at the time of print ing.

Manufacturer reserves the right to make changes at

any time with out incurring any obligation.

Owner/User Responsibility:

The owner and/or user must hav e an un der stand ing of

PRESSURE W ASHER

the manufacturer’ s operating instructions and warnings

be fore us ing this pressure washer. W arning in for ma tion

should be emphasized and understood. If the op er a tor

is not fl uent in En glish, the manufacturer’s in struc tions

and warnings shall be read to and dis cussed with

the op er a tor in the operator’s native lan guage by the

pur chas er/owner, making sure that the operator com pre hends its contents.

Owner and/or user must study and maintain for fu ture

ref er ence the man u fac tur ers’ instructions.

OPERATOR’S MANUAL

The operator must know how to stop the machine

quick ly and un der stand the operation of all controls.

Never per mit any one to op er ate the engine without

proper in struc tions.

This manual should be considered a permanent

part of the machine and should remain with it if

ma chine is resold.

When ordering parts, please specify model and

serial number.

MPORTANT SAFETY

I

INFORMATION

CAUTION

READ OPERATOR’S

MANUAL THOR OUGH LY

PRI OR TO USE.

2.All installations must com ply with local codes. Con tact your elec tri cian, plumb er, utility com pa ny or the

sell ing dis trib u tor for spe cifi c details.

3. This machine has been pro vid ed with Warn ing and

In struc tion decals for the safety of the operator. If

these decals are removed or be come damaged

they should be re placed. Contact your dealer for

re place ment de cals.

CAUTION: To reduce the risk of

in ju ry, read op er at ing in struc tions care ful ly be fore us ing.

1. Read the own er's man u al

thor ough ly. Fail ure to fol low

in struc tions could cause mal func tion of machine and re sult

in death, se ri ous bodily injury

and/or prop er ty dam age.

CAUTION

CAUTION: Risk of as phyx i a tion

— Use this product only in a well

ven ti lat ed area.

4. Avoid installing ma chines in

small areas or near ex haust

RISK OF

ASPHYXIATION.

USE ONLY IN A WELL

VENTILATED AREA.

fans. Ex haust con tains poi son ous car bon mon ox ide gas;

ex po sure may cause loss of

con scious ness and may lead to

death. It also con tains chemicals known, in cer tain

quan ti ties, to cause can cer, birth de fects or oth er

re pro duc tive harm.

WARNING

WARNING: Flammable liquids

can create fumes which can

ig nite caus ing prop er ty damage

or se vere in ju ry.

WARNING: Risk of fi re — Do not

add fuel when the prod uct is

RISK OF FIRE.

DO NOT ADD FUEL

WHEN OPERATING

MACHINE.

operating.

WARNING: Risk of explosion —

Do not spray fl am ma ble liq uids.

5.Do not place ma chine near fl ammable ob jects as

the en gine is hot.

6. Allow engine to cool for 2 minutes before re fu el ing. If

any fuel is spilled, make sure the area is dry be fore

test ing the spar k plug or start ing the en gine. (Fire

and/or ex plo sion may oc cur if this is not done.)

When refueling gasoline engines on mo bile or

por ta ble equipment, make sure to refuel:

a. outdoors;

b. with the engine on the equip ment stopped;

c. with no source of ig ni tion within 10 feet of the

dis pens ing point; and

d. with an allowance made for ex pan sion of the

fuel should the equip ment be exposed to a

high er am bi ent tem per a ture.

In an overfi lling or spillage situation, additional pre-

cau tions are nec es sary to en sure that the sit u a tion

is han dled in a safe man ner.

WARNING

WARNING: High pressure stream

of water that this equip ment can

pro duce can pierce skin and its

un der ly ing tis sues, lead ing to

se ri ous in ju ry and pos si ble

am pu ta tion.

HIGH PRESSURE

SPRAY CAN PIERCE

SKIN AND TIS SUES.

4

96-718, 97-721, 97-723 • REV. 8/05a

INTRODUCTION & IMPORTANT SAFETY INFORMATION

PRESSURE WASHER

WARNING

WARNING: High pressure spray

can cause paint chips or other

par ti cles to become air borne and

fl y at high speeds. To avoid per son al in ju ry, eye safe ty de vic es

must be worn.

PROTECTIVE

EYEWEAR AND

CLOTH ING MUST

BE WORN.

7. Protective cloth ing and foot

protection must be worn when

using this equipment.

8. High pres sure de vel oped by these machines will

cause per son al in ju r y or equip ment dam age. Use

cau tion when op er at ing. Do not di rect dis charge

stream at peo ple, or se vere in ju ry or death will

re sult.

9. Never make ad just ments on ma chine while in

operation.

10. Do not block or tie spray gun in open position.

11. Do not place hands or feet on non-insulated areas

of the pres sure washer when starting gas o line

engine.

12. When applying detergents, fol low the safety rules

on the de ter gent label.

13. Use detergent from a covered D.O.T. approved

con tain er.

14. Cleaning area should be provided with adequate

slopes and drainage. This will reduce the pos si bil i ty

of a fall due to slippery surface.

15. The best in sur ance against an accident is pre cau tion and knowl edge of the ma chine.

16. Manufacturer will not be liable for any changes

made to our stan dard ma chines, or any com po nents not pur chased from the manufacturer.

17. Read engine safety in struc tions provided.

WARNING

WARNING: Keep water spray

away from electrical wir ing or

fa tal elec tric shock may re sult.

18. Never run pump dry or leave

spray gun closed long er than

5 min utes.

KEEP WA TER SPRAY

AWAY FROM

ELECTRICAL WIRING.

19. Do not allow children to op er ate the pressure wash er at

any time.

20. Do not allow machine to run un at tend ed.

21. Inlet water sup ply must be cold and clean fresh

water.

CAU TION: Spray gun kicks back – Hold with both

hands.

CAU TION: Risk of injury – Dis con nect battery

ground ter mi nal be fore servicing.

OPERATOR’S MAN U AL

5

96-718, 97-721, 97-723 • REV. 8/05a

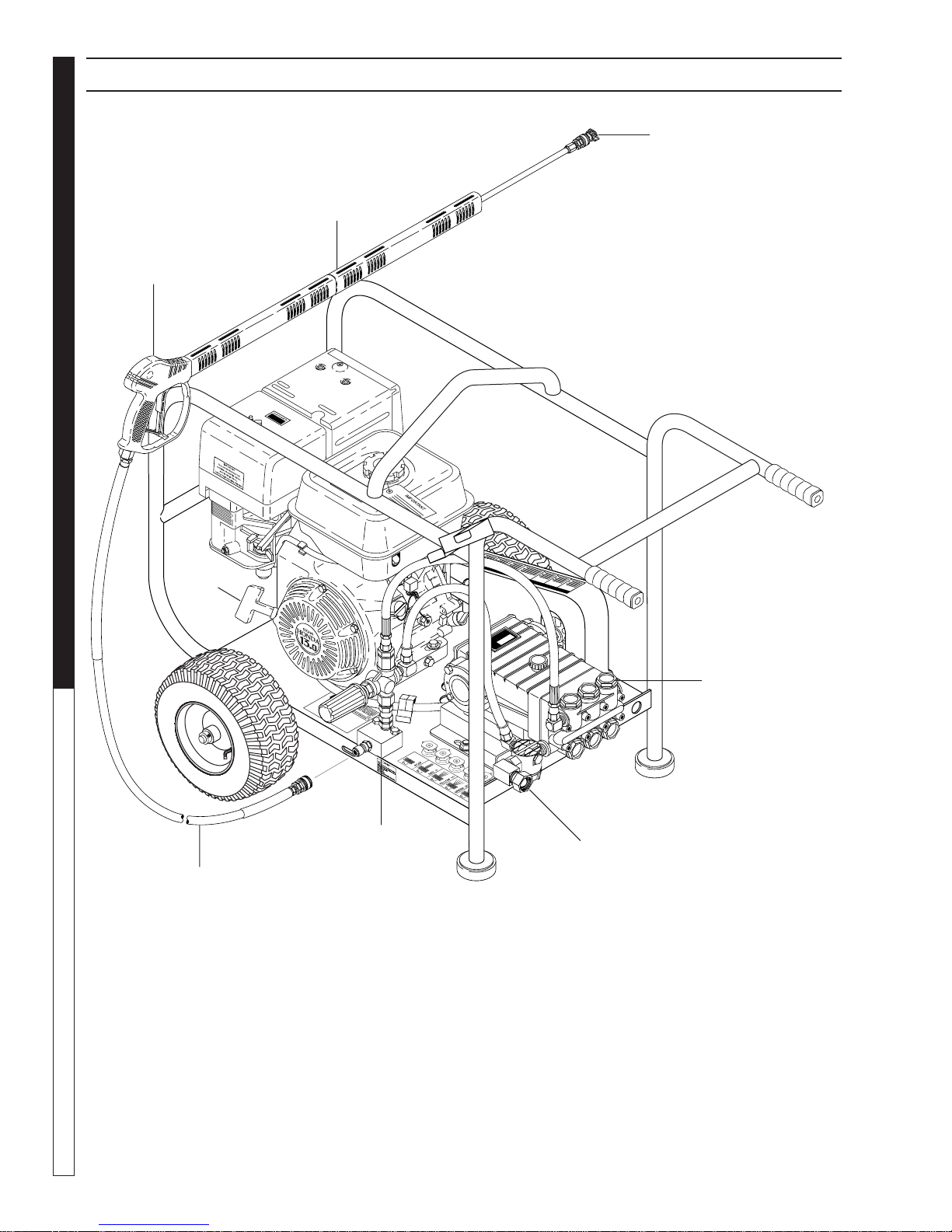

COMPONENT IDENTIFICATION — SMALL MODELS

Nozzle

Wand

PRESSURE W ASHER

OPERATOR’S MANUAL

Spray Gun

Starter

Grip

Pump

High Pressure

Hose

Pump — Develops high pressure.

Starter Grip— Used for starting the engine man u al ly.

Spray Gun — Controls the application of water and

de ter gent onto cleaning surface with trigger device.

In cludes safe ty latch.

Detergent Injector — Allows you to siphon and mix

detergents (not shown).

6

High Pressure

Discharge

Wand — Must be connected to the spray gun.

High Pressure Hose — Connect one end to water

pump dis charge nipple and the other end to spray

gun.

Note: If trigger on spray gun is released for more

than 2 minutes, water will leak from valve. Warm

water will dis charge from pump protector onto fl oor.

This sys tem pre vents internal pump dam age.

96-718, 97-721, 97-723 • REV. 8/05a

Water Inlet

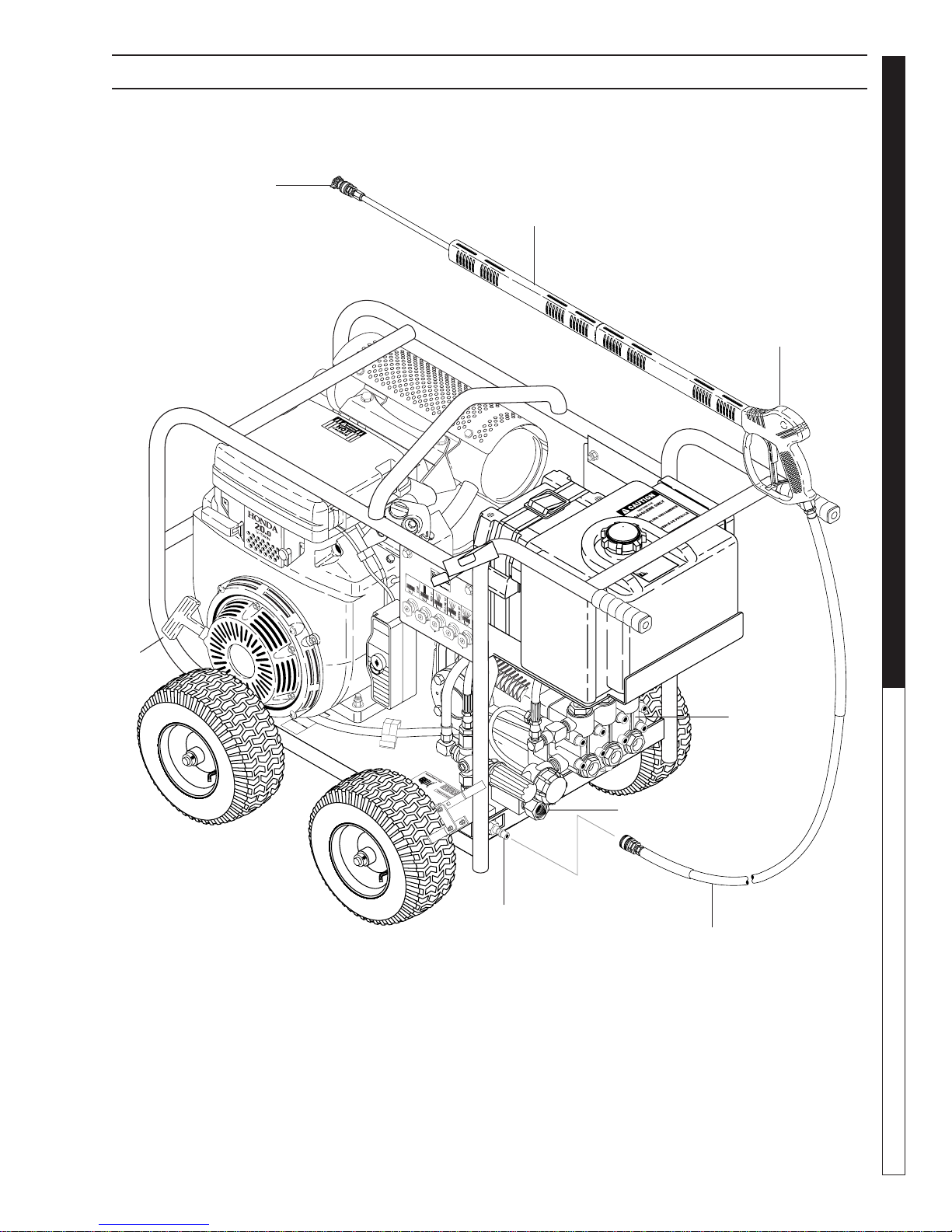

COMPONENT IDENTIFICATION — LARGE MODELS

Nozzle

Wand

Spray Gun

PRESSURE WASHER

OPERATOR’S MAN U AL

Starter

Grip

High Pressure

Discharge

Pump

Water Inlet

High Pressure

Hose

7

96-718, 97-721, 97-723 • REV. 8/05a

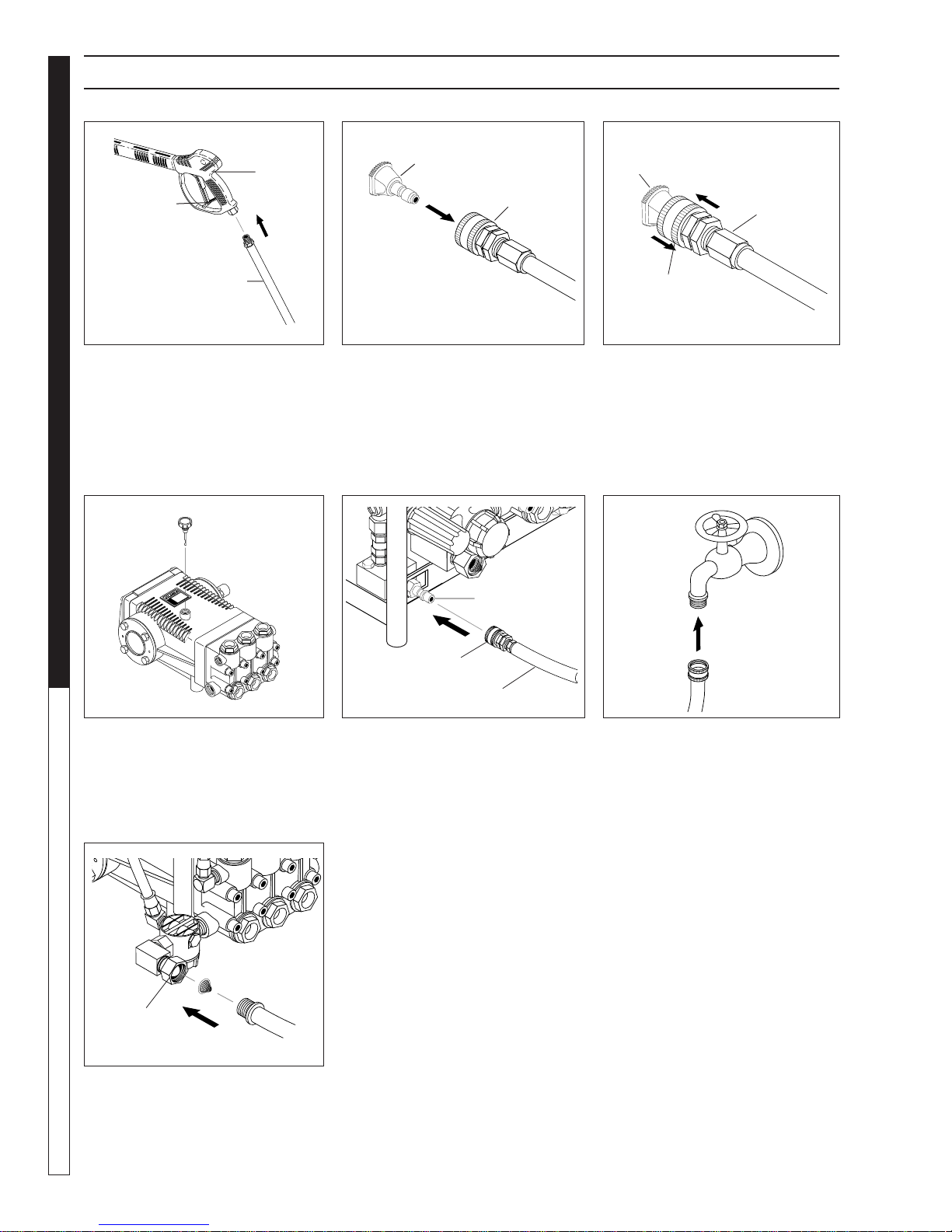

ASSEMBLY INSTRUCTIONS

Spray

Gun

Safety

Latch

PRESSURE W ASHER

High Pressure

Hose

STEP 1: Attach the high pres sure

hose to the spray gun using tefl on

tape on hose threads.

OPERATOR’S MANUAL

Dipstick

Pressure

Nozzle

Wand

Coupler

STEP 2: Pull the spring-load ed col-

lar of the wand coupler back to in sert

your choice of pres sure noz zle.

Discharge

Nipple

Pressure

Nozzle

Wand

Coupler

Wand

Collar

STEP 3: Release the coupler col lar

and push the nozzle until the collar

clicks. Pull the nozzle to make sure

it is seat ed properly.

Cold

Water

Source

STEP 4: Remove shipping cap and

install oil dipstick. Check pump oil

level by using dipstick or observe

oil level in oil window (if equipped).

Use 30 wt. non detergent oil.

Pump

Water Inlet

STEP 7: Check inlet fi lters, remove

debris, then connect garden hose

to pump wa ter in let. CAU TION: Do

not run the pump with out wa ter or

pump dam age will result.

8

Garden

Hose

Coupler Collar

High Pressure Hose

STEP 5: Connect the high pres sure

hose to the pump discharge nipple.

Push coupler collar forward until

se cure.

96-718, 97-721, 97-723 • REV. 8/05a

Garden

Hose

STEP 6: Connect garden hose to

the cold water source.

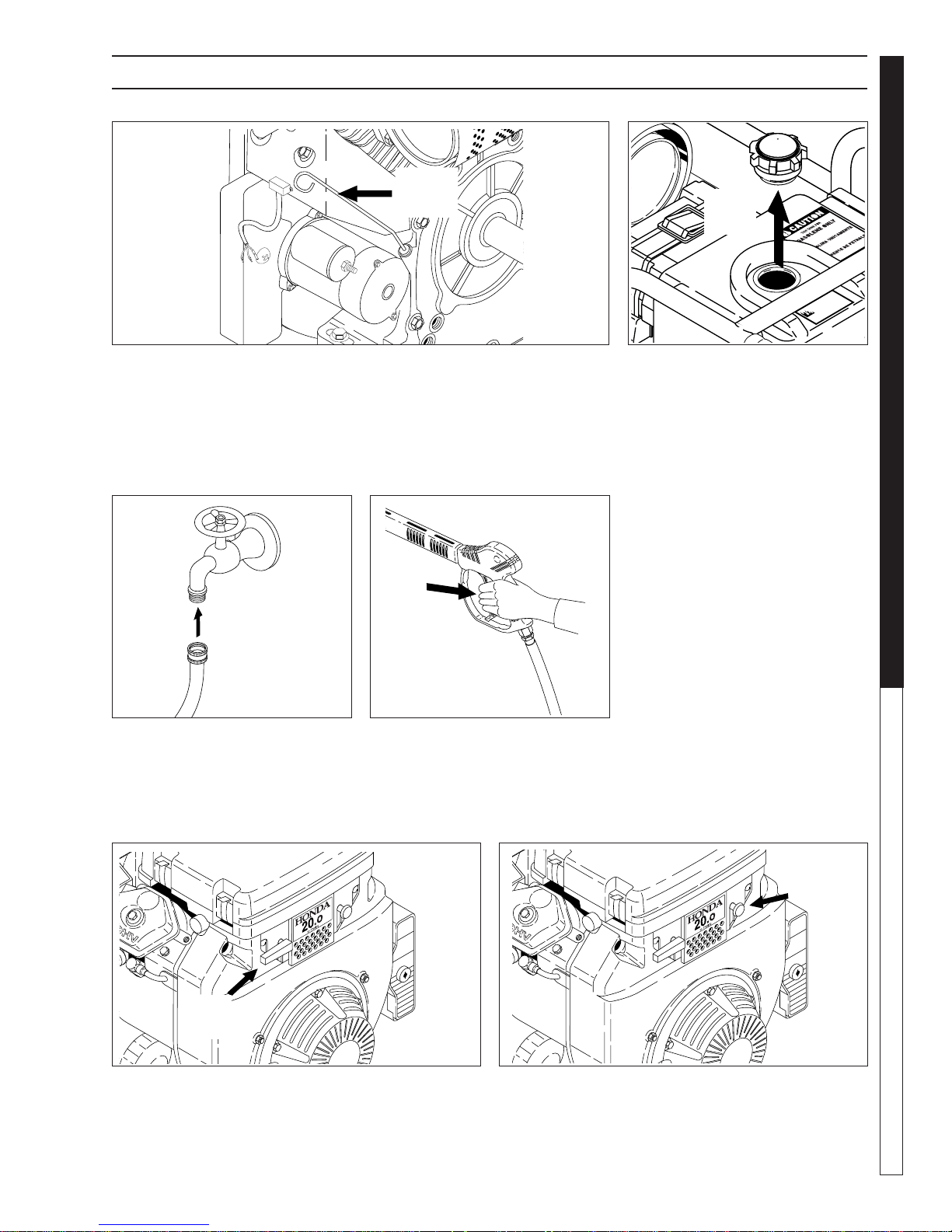

OPERATING INSTRUCTIONS

Engine

Oil

Dipstick

PRESSURE WASHER

Gas

Tank

OPERATOR’S MAN U AL

STEP 1: Check engine oil level. Oil level should be level with the bottom

of the oil fi ller neck. Be sure the ma chine is level when checking the oil

level. (Refer to the en gine's op er at ing manual included with machine.) W e

rec om mend that the oil be changed after the fi rst 5 hours of use, then once

every 50 hours. Note: Im prop er oil levels will cause low oil sensor to shut

off engine. IMPORTANT! Do not run engine with high or low oil le vels

as this will cause engine damage.

Cold

Water

Source

Garden

Hose

STEP 3: Connect garden hose

to the cold water source and turn

wa ter on completely. Never use

hot wa ter.

STEP 4: Tr igger the spray gun to

elim i nate trapped air then wait for a

steady fl ow of water to emerge from

the spray noz zle.

STEP 2: Fill gas tank with un lead ed gasoline. Do not use leaded

gas o line.

Fuel

Valve

STEP 5: Rotate the fuel shut-off valve to the "On" po-

si tion. Slide the fuel valve lever to the "ON" position.

When the engine is not in use, leave the fuel valve in

the "OFF" position.

STEP 6: Pull the choke knob out to the "Chok e" po si tion

(on a warm engine, when in the run po si tion, leave the

choke knob in). Push the choke knob to the "Closed"

po si tion. T o restart a warm engine, leave the chok e knob

in the "Open" position.

96-718, 97-721, 97-723 • REV. 8/05a

Choke

Knob

9

Loading...

Loading...