Page 1

MODEL 925A/925SS

OPERATING INSTRUCTIONS

Shark

Read instructions carefully before attempting to assemble, install, operate or service this pressure

washer. Failure to comply with instructions could result in personal injury and/or property damage!

R

SPECIFICATIONS

● Pump Volume At Pump Head: 3.0 GPM/180 GPH

● Pump Pressure At Pump Head: 3000 PSI

● Burner Type: Fuel Oil Fired, 239,000 BTU/Hr.

● Burner Fuel Pressure: 130 PSI

● Machine Power: 9.0 HP Gasoline Engine, Manual Start

● Machine Weight: 385 Lbs.

● Shipping Weight: 415 Lbs.

● Burner Exhaust Vent: 8"

● Machine Dimensions: Length = 47", Width = 31", Height = 45"

AND PARTS MANUAL

Output specifications are based on engine power curves at 100

meters above sea level and 25

dance with SAE J1349.

o

C ambient temperature in accor-

SHARK PRESSURE WASHERS

SERIAL NUMBER: 21 INVERNESS WAY EAST

ENGLEWOOD, CO 80112

1-800-771-1881

DATE PURCHASED:

FOR SALES AND SERVICE, PLEASE CONTACT:

Page 2

WARNING

Read and observe to prevent severe personal injury or property damage.

● Check hoses, fittings, wand, trigger gun and

fuel connections daily for signs of wear,

cracks and looseness, and replace as

required.

● Keep all electrical components on

machine dry.

● Do not point wand or trigger gun at your-

self or at any person. Bodily injury may

result from water under high pressure.

● Do not block or tie trigger gun in open

position.

● Wear eye, ear, hand, foot, and skin protec-

tion at all times while operating pressure

washer.

● Do not place hands or feet on non-insu-

lated areas of the pressure washer when

starting gasoline engine.

● Do not fill engine fuel tank while engine is

running or hot. Let engine cool before

refueling or spontaneous fire may result.

Fuel spillage or vapors could ignite if

engine is hot.

● Disconnect spark plug and battery prior to

performing any maintenance.

● Do not store flammable liquids (gasoline,

diesel fuel, solvents, etc.) near pressure

washer or in non-ventilated areas.

● Use extreme caution when moving pres-

sure washer over rough or uneven surfaces.

● For permanent installation consult local

building codes for installation requirements. Licensed contractor may be

required.

● Troubleshoot machine prior to using

reset buttons or replacing blown fuses.

See Troubleshooting Guide.

● Pressure washers produce a kickback. To

prevent personal injuries due to falls use

auxiliary safety equipment.

● When applying detergents follow the

safety rules on the detergent label.

● Use detergent from a covered D.O.T.

approved container.

● Cleaning area should be provided with

adequate slopes and drainage. This will

reduce the possibility of a fall due to slippery surface.

● Avoid contact with non-insulated areas of

pressure washer to prevent the possibility

of severe burns.

● Do not allow machine to run unattended.

● Unauthorized machine modification or use

of non-approved replacement parts may

cause personal injury and/or property

damage and will void the manufacturer

warranty.

● Do not run machine indoors or in an

enclosed area, as exhaust fumes may be

hazardous to your health.

● This machine has been provided with

Warning and Instruction decals for the

safety of the operator. If these decals are

● Do not operate machine in areas where

flammable vapors, (gasoline, solvents, etc.)

may be present, as this machine may

removed or become damaged they should

be replaced. Contact your dealer for

replacement decals.

ignite the vapors.

Page 2 Shark 925A/925SS

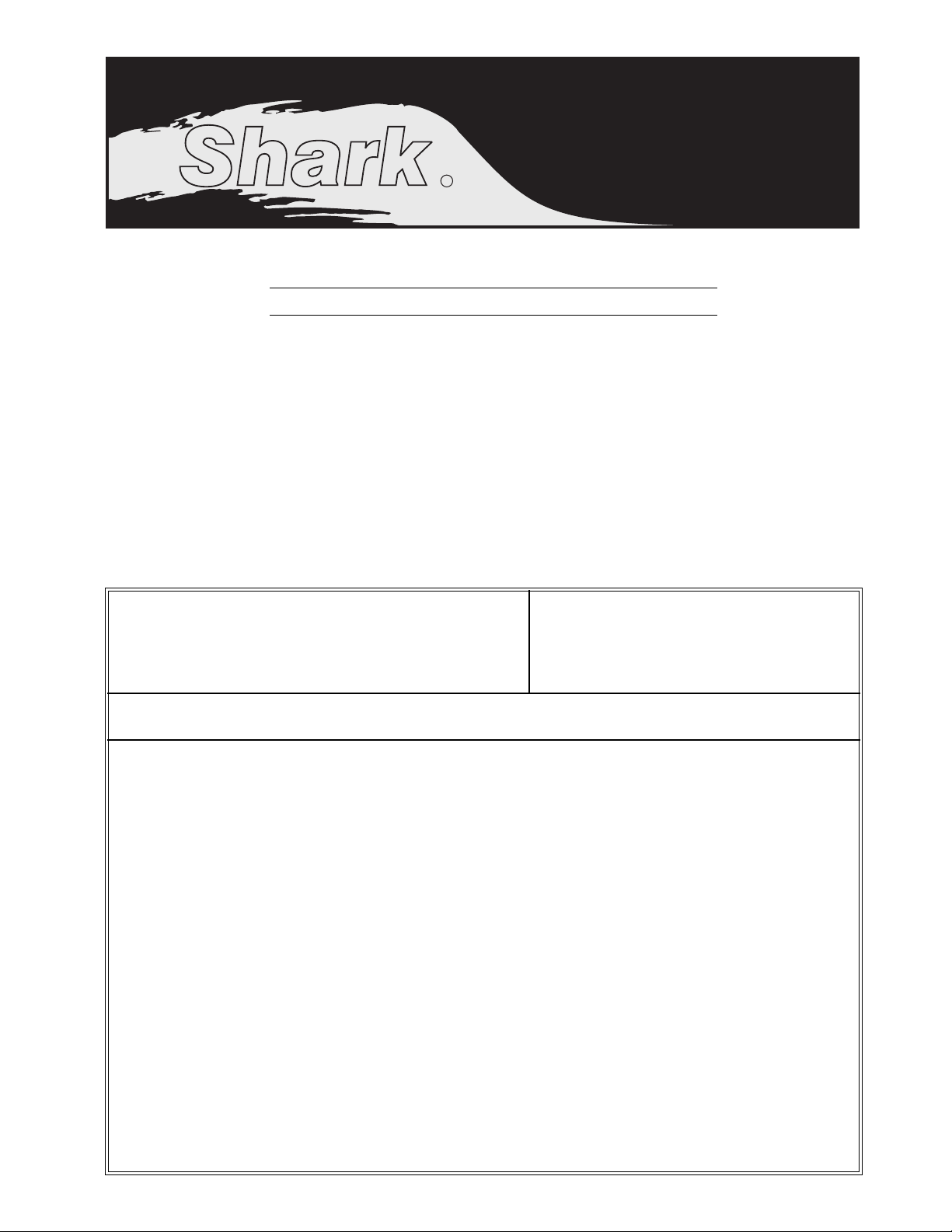

Page 3

DETERGENT

NOZZLE

DUAL LANCE WAND

TRIGGER GUN

PRESSURE

NOZZLE

PRESSURE HOSE

RELIEF VALVE BURNER EXHAUST VENT

NOZZLE HOLDERS

ENGINE

DETERGENT

INJECTOR

COIL DRAIN PLUG

OIL BURNER

BATTERY BOX

BURNER SWITCH

THERMOSTAT

CONTROL BOX

GARDEN HOSE

CONNECTOR

OIL BURNER

FUEL TANK

PUMP

DETERGENT INLET LINE

Figure 1 - Machine Component Layout

Page 3Shark 925A/925SS

Page 4

ASSEMBLY

+

-

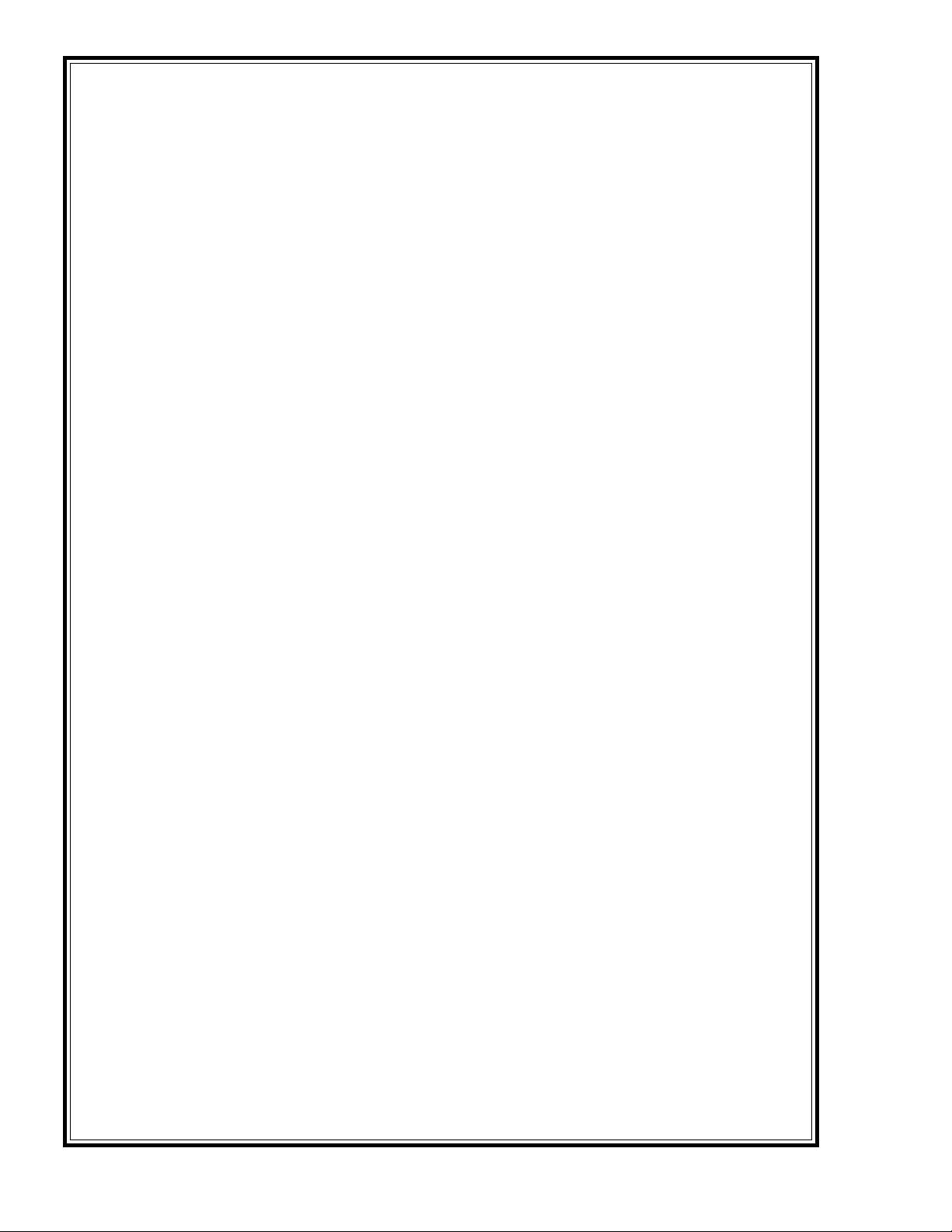

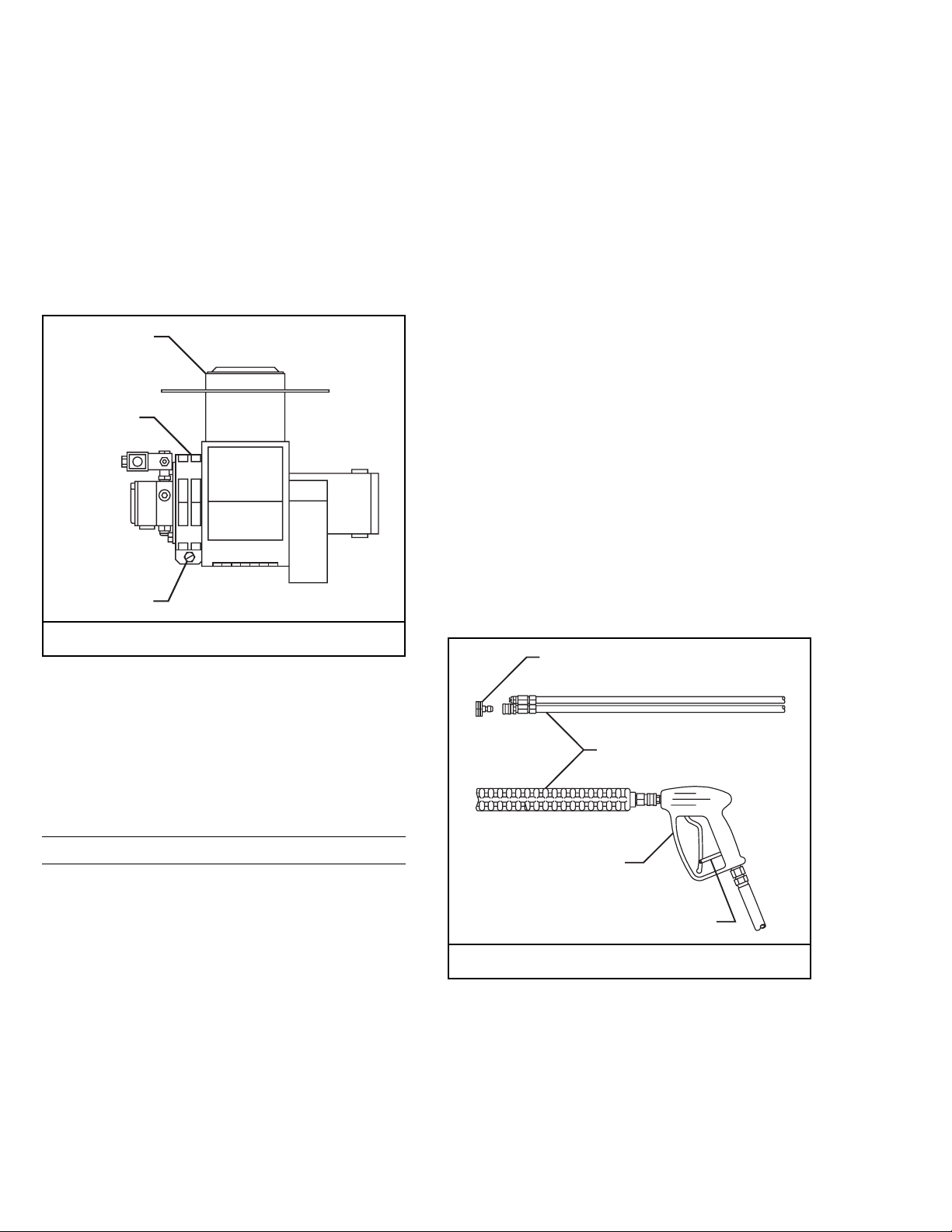

2. Assemble wand components as shown in Figure 3.

Unpacking

Unpack carefully. Wear safety glasses or goggles while

unpacking, assembling, or operating pressure washer. If

there are missing components or hidden damage,

immediately contact carrier concerning discrepancies.

1. Cut strapping band from pressure washer and pallet.

2. Remove pressure washer from pallet.

Parts Included

• Pressure Washer

• Pressure Hose

• Trigger Gun

• Dual Lance Wand

• Pressure Nozzle (3 ea.)

• Battery Terminal (2 ea.)

• Operating Instructions/Parts Manual

• Gasoline Engine Manual

Tools Required

• 1/2" Open End Wrench

• Flat Blade Screwdriver

DUAL LANCE WAND

TRIGGER GUN

Figure 3 - Trigger Gun/Dual Lance Wand

3. Make sure all plumbing connections are tight.

Battery

WARNING: Wear eye, hand and skin protection when

handling or connecting battery.

WARNING: Batteries generate explosive gases during normal battery operation. Do not expose the battery to flame or sparks as these gases may ignite.

Pressure Hose, Trigger Gun and Wand

1. Install the pressure hose on the pressure washer as

shown in Figure 2.

RELIEF VALVE

PRESSURE HOSE

WARNING: Battery fluid is highly acidic. If battery fluid

contacts skin or clothing, wash immediately with soap

and water. If battery fluid enters eye, immediately flood

eye with running cold water for at least 15 minutes

and get immediate medical attention.

1. Place battery in battery box (battery not included).

Use a standard 12 volt automotive battery. Select a

battery similar to the one in Figure 4 for proper fit

and installation.

8-3/4”

MAX

10-1/2”

MAX

6-3/4”

MAX

Figure 4 - Battery Dimensions

Figure 2 - Pressure Hose Installation

Page 4 Shark 925A/925SS

Page 5

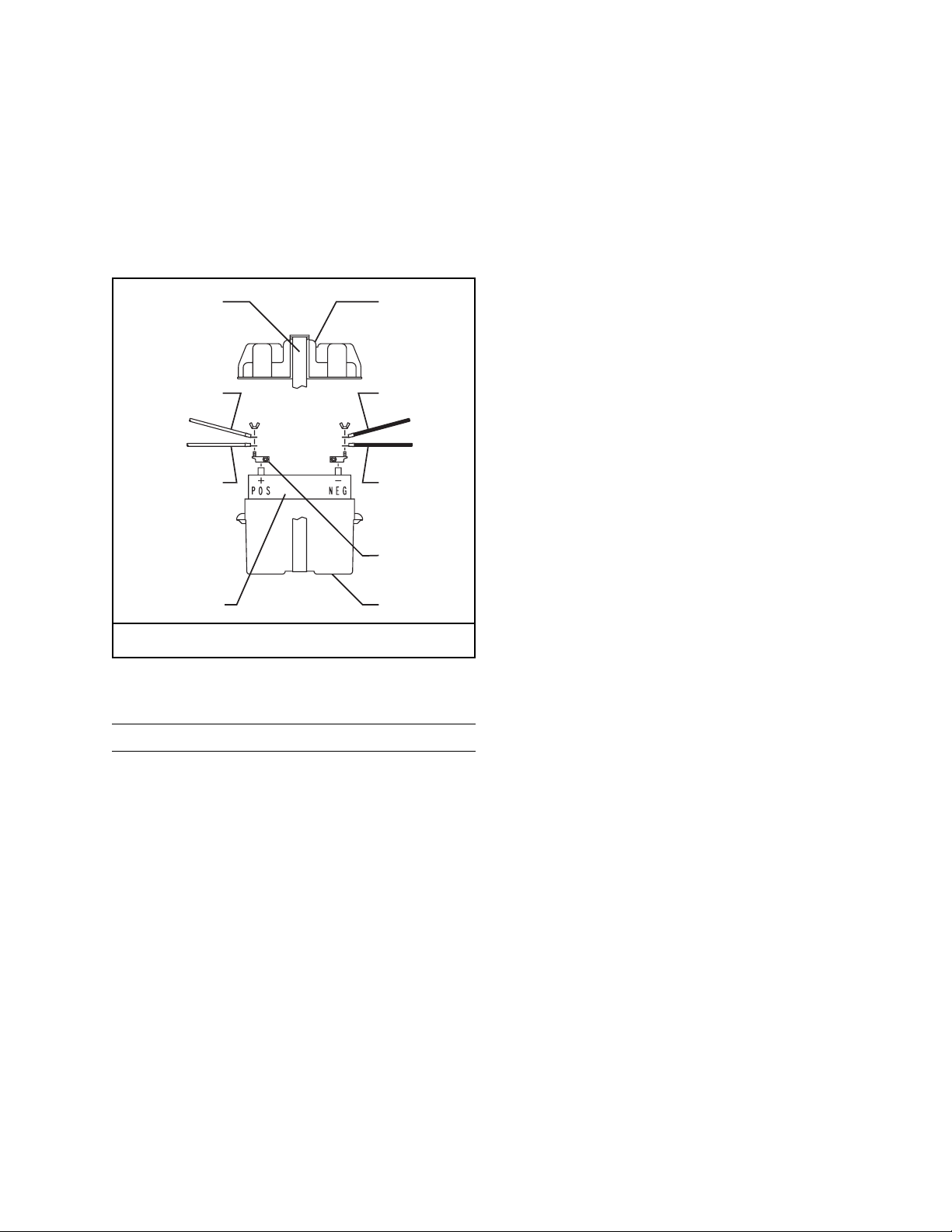

2. Install the provided battery terminals as shown in

Figure 5.

3. To reduce the possibility of sparking attach the wires

to the battery in the following order. Refer to Figure 5.

First attach the red wire from the voltage regulator

and the red wire from the control box to the positive

“+” terminal of battery. Next, attach the black wire from

the control box and the black wire from the voltage

regulator to the negative “-” terminal of the battery. To

disconnect the battery remove the wires in the opposite order as installed. Install battery box cover and

fasten in place.

be made between the wash area and the pressure washer

to prevent direct spray from the wand from coming in

contact with the pressure washer. Moisture reaching the

equipment will reduce the pressure washer’s service life.

All installations must comply with the local codes covering

such installations.

Venting

DANGER: Do not run machine indoors or in an

enclosed area, as exhaust fumes may be hazardous

to your health.

BOX STRAP

RED WIRE FROM

CONTROL BOX

RED WIRE

FROM VOLTAGE

REGULATOR

12 VOLT BATTERY

BATTERY BOX

BLACK WIRE

FROM VOLTAGE

REGULATOR

BLACK WIRE

FROM

CONTROL BOX

BATTERY

TERMAINAL

BATERY BOX

Figure 5 - Battery Connections

INSTALLATION

Getting Started

IMPORTANT: Proper initial installation of equipment

will assure more satisfactory performance, longer service life, and lower maintenance cost.

IMPORTANT: The use of a backflow preventer on the

water supply hose is recommended and may be

required by local code.

The pressure washer should be run on a level surface

and in a protected area where it is not readily influenced

by outside forces such as strong winds, freezing

temperatures, rain, etc. The pressure washer should be

located to assure easy access for filling of fluids,

adjustments and maintenance. Normal precautions should

be taken by the operator to prevent moisture from reaching

the pressure washer. It is recommended that a partition

DANGER: Do not operate machine in areas where

flammable vapors (gasoline, solvents, etc.) may be

present, as this machine may ignite the vapors.

CAUTION: All venting must be in accordance with

applicable federal and state laws, and local ordinances. Consult local heating contractors.

If the pressure washer is to be used in an enclosed area,

a flue must be installed to vent burner and engine exhaust

to the outside atmosphere. Be sure the flue is the same

size as the burner exhaust vent on the pressure washer.

See Figure 1 for location. Poor draft will cause the

pressure washer to soot and not operate properly. When

selecting the location for installation, beware of poorly

ventilated locations or areas where exhaust fans may

cause an insufficient supply of oxygen. Proper combustion

can only be obtained when there is a sufficient supply of

oxygen available for the amount of fuel being burned. If it

is necessary to install the machine in a poorly ventilated

area, outside fresh air may have to be piped to the burner

and a fan installed to bring sufficient air into the machine.

Locate the pressure washer so that the flue will be as

straight as possible and protrude through the roof at a

proper height and location to provide adequate draft. This

oil fired pressure washer must have a draft regulator

installed in the flue (available from most heating

contractors). A draft regulator will permit proper upward

flow of exhaust flue gases.

In addition, the pressure washer should never be operated

in an enclosed area where high ambient temperatures

exist. High ambient temperatures (above 100

cause engine oil failure and will greatly reduce the engine’s

performance.

o

F) can

Gasoline Engine

This gasoline engine is preset for operation at altitudes

below 3000 feet above sea level. If operated at higher

altitudes, it may be necessary to install a high altitude

main jet in the carburetor. Contact an authorized engine

sales and service center for details.

Page 5Shark 925A/925SS

Page 6

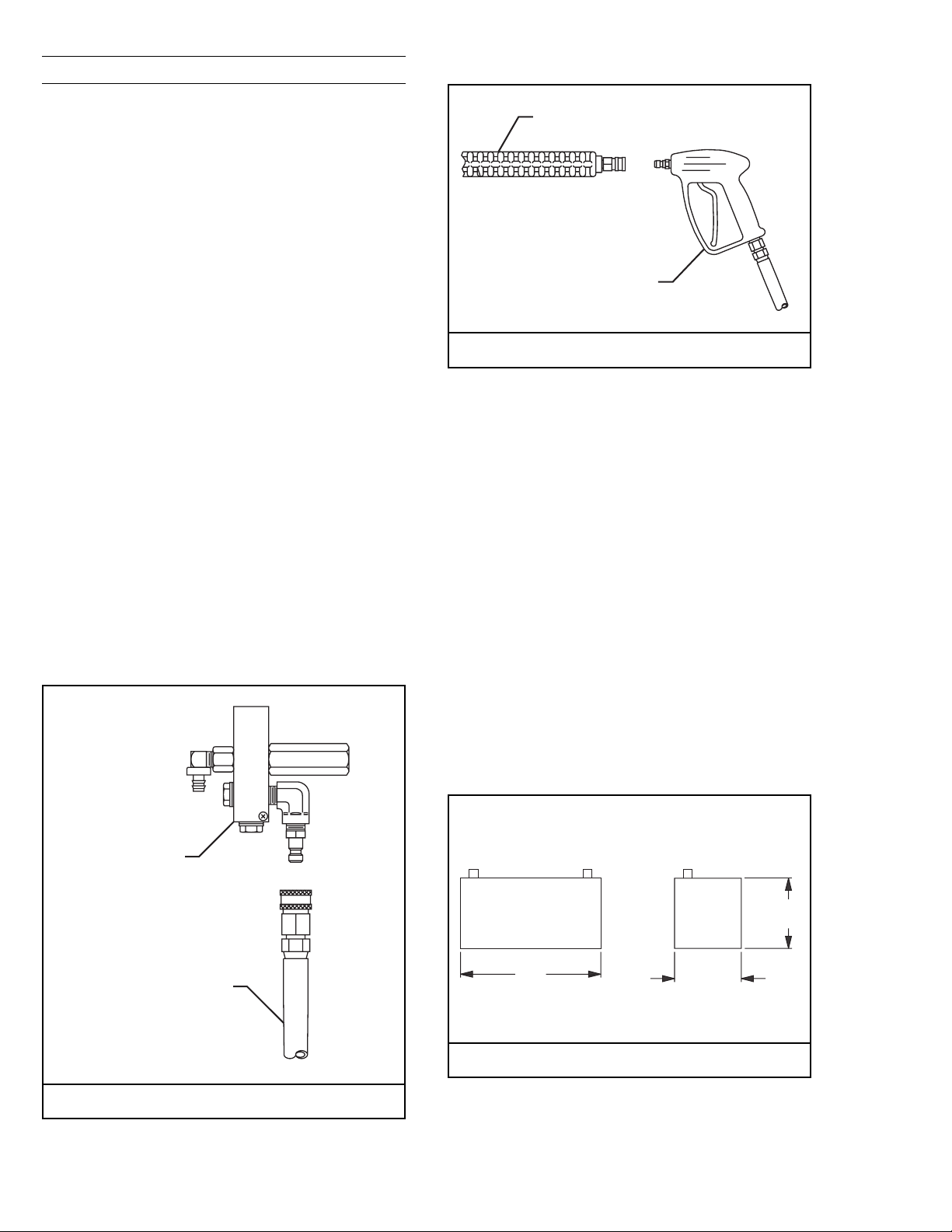

Oil Burner

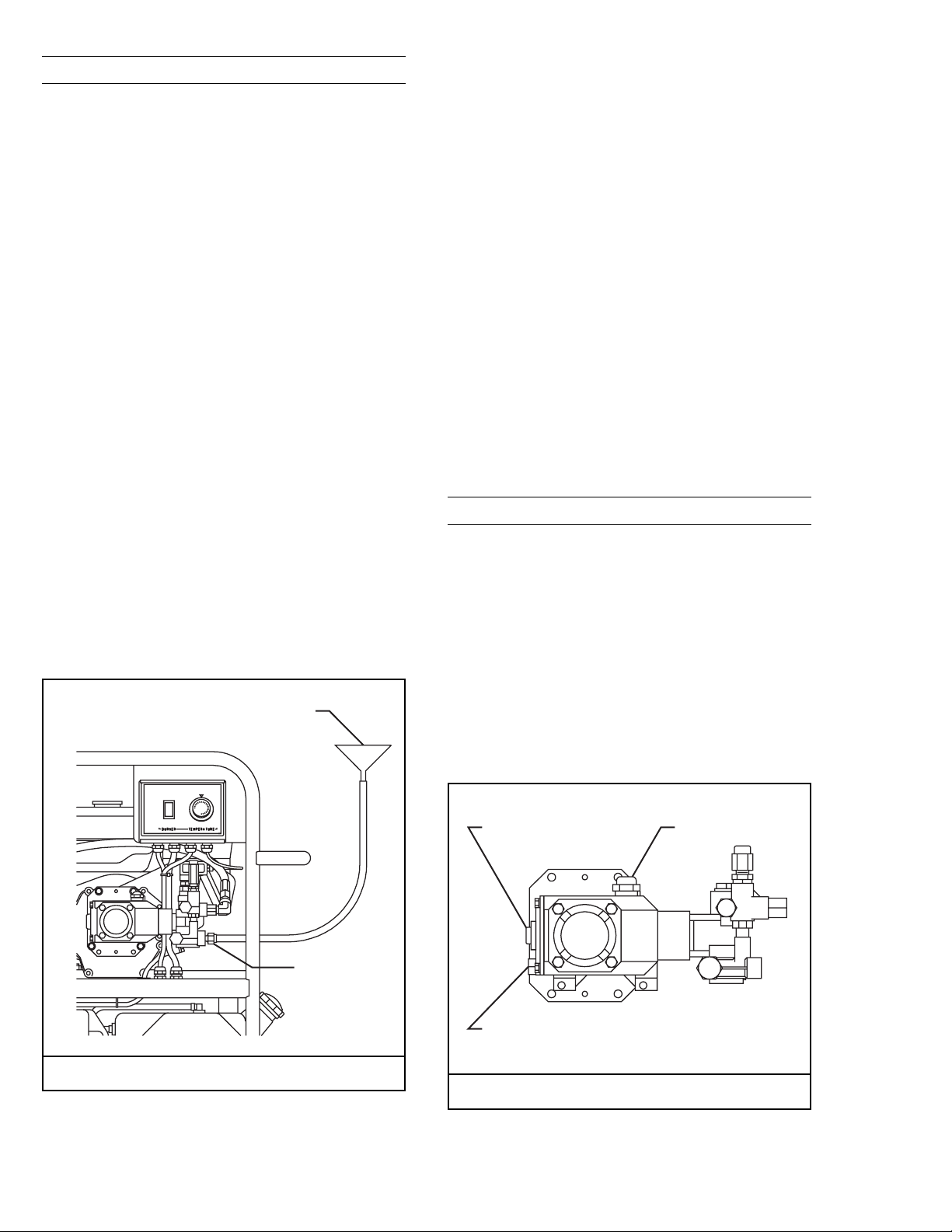

Burner Air Adjustment: The oil burner on this

machine is preset for operation at altitudes below 3000

feet. If operated at higher altitudes, it may be necessary

to adjust the air band setting. Adjust the air band for a #1

or #2 smoke spot on the Bacharach scale.

To adjust, start machine and turn burner ON (refer to

Operation for details). Loosen locking screw (refer to

Figure 6) and close air band until black smoke appears

from burner exhaust vent. Note air band position. Next,

slowly open the air band until white smoke just starts to

appear. Turn air band halfway back to the black smoke

position previously noted. Tighten locking screw.

OIL BURNER

AIR BAND

LOCKING SCREW

Figure 6 - Burner Adjustment

CAUTION: If white smoke appears from burner

exhaust vent during start-up or operation, discontinue

use and readjust air bands.

3. Fill oil burner fuel tank. Use kerosene, #1 grade home

heating oil, #1 or #2 diesel fuel. DO NOT USE GASO-

LINE, CRANKCASE OIL DRAININGS, OR WASTE

OIL.

WARNING: Do not fill engine fuel tank while engine

is running or hot. Let engine cool before refueling or

spontaneous fire may result. Fuel spillage or vapors

could ignite if engine is hot.

4. Fill the engine fuel tank. Do not overfill, fill to the bot-

tom of filler neck only. Use lead free gasoline minimum 86 octane, or lead free gasoline containing no

more than 15% MTBE. DO NOT use gasoline con-

taining more than 5% methanol or more than 10%

ethanol. Refer to the provided gasoline engine

manual for additional details.

5. Check pump and engine oil levels.

6. If detergents are to be used, only use detergents

intended for pressure washers. Follow instructions on

the detergent container.

IMPORTANT: Before installing pressure nozzle on

initial start-up, turn on the water supply and allow

water to run from the end of the wand until clear to

prevent the nozzle from clogging.

IMPORTANT: If the pressure washer has not been

used for an extended period of time, remove the pressure nozzle from the end of the wand and turn on

water supply. Allow water to run from the end of the

wand until clear.

7. Install the proper pressure nozzle for your cleaning

needs on end of wand, refer to Figure 7.

PRESSURE NOZZLE

NOTE: If a flue is installed, have a professional serviceman adjust your burner for a #1 or #2 smoke spot

DUAL LANCE WAND

on the Bacharach scale.

OPERATION

TRIGGER GUN

Before Starting

1. Read all manuals provided with this pressure washer.

Become familiar with location and function of all

operating and safety controls.

Figure 7 - Nozzle Installation/Trigger Lock

WARNING: Check hoses, fittings, wand, trigger gun

and fuel connections daily for signs of wear, cracks

and looseness, and replace as required.

2. Connect water supply hose to the garden hose connector located on pump. The water faucet and supply

hose must be capable of providing a minimum of 3.0

gallons per minute (GPM).

IMPORTANT: The trigger gun provided with this pressure washer is equipped with a manual trigger lock

to prevent accidental operation of the trigger gun,

refer to Figure 7. The trigger lock should be used

whenever the trigger gun is not in use.

Page 6 Shark 925A/925SS

TRIGGER LOCK

Page 7

To Start

DANGER: Do not point wand or trigger gun at yourself or at any person. Bodily injury may result from

water under high pressure.

WARNING: Wear eye, ear, hand, foot and skin protection at all times while operating pressure washer.

IMPORTANT: The water must be turned on before

starting. Running the pump dry will cause damage

and void warranty.

IMPORTANT: Do not allow the machine to run with

trigger of the trigger gun released for more than

10 minutes at any one time or damage to pump may

occur.

1. Turn ON water supply.

2. Hold wand firmly, release trigger of trigger gun.

3. Turn engine ON/OFF switch to ON position.

4. Turn fuel shut-off valve to ON position (if so equipped).

Move choke lever to FULL CHOKE position, (choke

may not be needed on warm engine). Move throttle

lever to HALF THROTTLE position.

5. Pull the rope starter slowly until resistance is felt, then

pull briskly. Do not allow the rope starter to snap back

against the engine. Return it gently to prevent damage to the starter.

6. When the engine starts, move choke lever until

engine runs smoothly. Move throttle lever to FULL

THROTTLE position. When engine warms, move

choke lever to NO CHOKE position.

IMPORTANT: To allow for proper battery cha rging the

throttle control must be kept in the full throttle position during operation.

NOTE: If engine fails to start, refer to Troubleshooting Guide in this manual.

7. Squeeze trigger of trigger gun and allow air to purge

from system.

8. If HOT water is desired, adjust the thermostat to the

proper temperature and turn burner switch ON. The

burner will light immediately with a small puff of smoke.

You may need to initially adjust your burner for peak

performance. See Oil Burner section under Installation. If smoke continues, contact Customer Service

at 1-800-771-1881. When the trigger of the trigger

gun is released or when the thermostat temperature

setting is reached, the burner will automatically turn

off.

To Clean

DANGER: Do not place hands or fingers in front of

high pressure spray. Bodily injury may result.

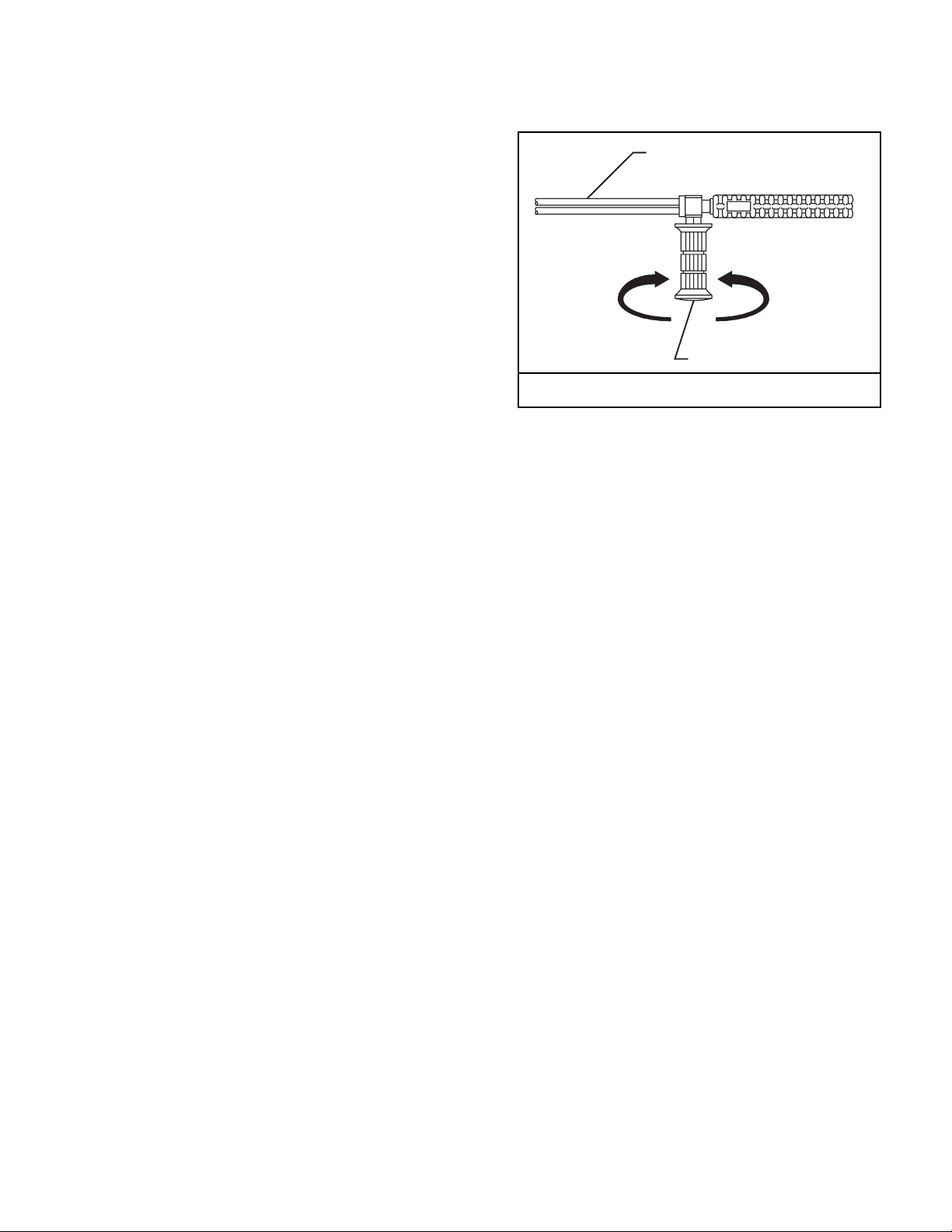

1. Insert detergent inlet line into container of mixed

detergent. Squeeze the trigger of the trigger gun.

Open detergent control handle on the dual lance wand,

refer to Figure 8. The output pressure is automatically reduced for detergent application. Allow

detergent to reach end of wand before proceeding to

step 2.

DUAL LANCE WAND

OPEN CLOSE

DETERGENT CONTROL HANDLE

Figure 8 - Dual Lance Wand Operation

2. Wash from the bottom to the top, using side to side

motions. This washes away heavy dirt and allows the

detergent to soak as you work toward the top.

3. Do not wash at a 90

This will allow water to splash back at you and

reduces your cleaning power. Wash at a 30

angle to the work. This will allow the water to splash

away from you and the water will wash the dirt away

faster and easier.

4. Use the full width of the spray pattern to wash in

a wide path. Overlap spray paths for complete

coverage. Wash from side to side, using slow, steady

motions.

5. The nozzle should be 12" to 24" from work, closer for

tough areas. Be careful on painted or delicate surfaces, the pressure may damage surface if nozzle is

too close.

6. Small parts should be washed in a basket so the pressure does not push them away. Larger, lightweight

parts should be clamped down so the pressure does

not push them away.

7. Close the detergent control handle on the dual lance

wand to permit high pressure rinse, refer to Figure 8.

Rinse from top to bottom to prevent detergent from

dripping onto rinsed area.

o

angle to work (straight at it).

o

to 60

To Stop

1. If detergents were used, draw clear water through the

detergent inlet line to purge detergent. Failure to do

so may clog detergent injector valve.

2. If burner was used, turn OFF burner switch and

allow pump to run cold water through coil for several

minutes.

3. Move throttle lever to idle position.

4 Turn engine ON/OFF switch to the OFF position.

5. Close fuel shut-off valve.

6. Turn water supply OFF.

7. Squeeze trigger of trigger gun to relieve system

pressure.

o

Page 7Shark 925A/925SS

Page 8

STORAGE

DANGER: Do not store flammable liquids (gasoline,

diesel fuel, solvents, etc.) near pressure washer, or

in non-ventilated areas.

Protect from freezing by storing in a heated area, or by

flushing the system with antifreeze (use an automotive

engine antifreeze or windshield washer solvent to

antifreeze). To flush the system with antifreeze, the

following steps are to be followed:

1. Open detergent control handle on dual lance wand,

refer to Figure 8.

2. Connect the water supply hose to the garden hose

connector located on the pump. Turn on water supply.

3. Place the detergent inlet line into a container of antifreeze.

4. Hold wand firmly, release trigger of trigger gun.

5. Start engine. Place throttle lever in FULL THROTTLE

position.

6. Squeeze trigger of trigger gun and allow water to flow

from the end of the wand. Watch for antifreeze to be

drawn through the detergent inlet line. Allow the antifreeze to be drawn into the system for 5 to 10 seconds.

7. Release the trigger of the trigger gun and stop

engine.

8. Turn off water supply and disconnect water supply

hose from the pump.

9. Attach a short length of hose (approximately 3 feet

long) to the garden hose connector located on the

pump. Install a funnel in the other end of the hose as

shown in Figure 9.

FUNNEL

10. Hold wand firmly, release the trigger of the trigger

gun.

11. Start engine. Place throttle lever in the idle position.

12. Squeeze trigger on trigger gun.

13. Slowly pour antifreeze into the funnel. Continue to add

antifreeze until antifreeze flows from the end of the

wand.

14. Squeeze and release the trigger of the trigger gun

several times to antifreeze the unloader system.

15. Release the trigger of the trigger gun. Stop engine.

16. Squeeze the trigger of the trigger gun to relieve system pressure.

For added protection, after antifreezing, disconnect the

pressure hose from the machine and remove the coil drain

plug (refer to Figure 1 for location.) After coil has drained,

replace pressure hose and coil drain plug. If the pressure

washer is not to be used for an extended length of time, it

is recommended that the system be flushed with

antifreeze for rust protection. Refer to the Gasoline

Engine Manual for engine storage information.

MAINTENANCE

WARNING: Unauthorized machine modification or

use of non-approved replacement parts may cause

personal injury and/or property damage and will void

the manufacturer warranty.

Pump

Lubrication: To lubricate pump, use 10W30 non-

detergent oil for pump crankcase. Crankcase must be filled

to red dot on oil gauge found on the rear of the pump,

refer to Figure 10. During the break-in-period, make sure

the oil is changed after the first 50 hours of operation.

After that, replace oil every 3 months or 500 hours of

operation, whichever comes first.

OIL GAUGE

GARDEN HOSE

CONNECTOR

OIL DRAIN

OIL FILL / DIPSTICK

Figure 9 - Winterizing

Figure 10 - Pump Lubrication

Page 8 Shark 925A/925SS

Page 9

Proper Pump Care:

• Do not pump acids.

• Do not allow pump to run dry.

• Winterize if storing in freezing temperatures, refer

to Storage for details.

• Use a water softener on the water system if known

to be high in mineral content.

• Use only high quality detergents and follow manufacturer’s mix recommendations.

• Flush the system with clear water immediately

after using detergent solutions.

• Clean filter screen on detergent inlet line periodically.

• Flush the pressure washer system with antifreeze

if storing for an extended period of time, refer to

Storage for details.

Gasoline Engine

Refer to the provided gasoline engine manual for

recommended maintenance.

Oil Burner

Blower Motor: Inspect the motor brushes for wear

every 250 hours of operation and replace when 1/8" to

1/4" brush material remains. DO NOT allow the brushes

to wear out completely or motor damage will occur. Refer

to Figure 22. The motor bearings are permanently

lubricated and will not require any additional lubrication.

Relief Valve

Unloader Valve

WARNING: The unloader valve on this pressure

washer has been factory set and sealed and is a field

non-adjustable part. Tampering with the factory

setting may cause personal injury and/or property

damage, and will void the manufacturer warranty. For

replacement refer to Figure 18.

Burner Fuel Filter

Drain any water which has accumulated in fuel filter and

clean or replace filter element as needed. Refer to

Figure 21.

Heating Coil

Coil Descaling: In hard water areas, scale buildup within

the heating coil will occur. Scale deposits will decrease

the water temperature rise and may eventually clog the

heating coil. Contact your local service center when

descaling is needed.

Coil Desooting: Poor grades of fuel oil or inadequate

combustion air will cause heavy soot buildup on the

outside surface of the heating coil. These deposits will

insulate the coil. This will restrict the air flow through the

coil, further aggravating the soot buildup. Contact your

local service center when desooting is needed.

Hour Meter

An optional hour meter (P/N 783865) is available for use

on the Model 925A/925SS. This hour meter will monitor

the total hours of operation of the pressure washer to

signal when routine maintenance is required.

WARNING: The relief valve on this pressure washer

has been factory set and sealed and is a field nonadjustable part. Tampering with the factory setting

may cause personal injury and/or property damage,

and will void the manufacturer warranty. For replacement parts refer to Figure 15.

Battery

Refer to battery manufacturer’s literature for recom-

mended maintenance.

Page 9Shark 925A/925SS

Page 10

TROUBLESHOOTING GUIDE

G

SYMPTOM POSSIBLE CAUSES CORRECTIVE ACTION

as engine will not run. Out of gas. Replenish supply. Use only recom-

mended fuels. Refer to

Starting

Fuel valve closed (if so equipped). Open valve.

Loose spark plug wire. Reconnect.

under

Operation

Before

.

Pressure washer runs

but won't spray.

Low spray pressure

at nozzle.

Choke or throttle set incorrectly. Refer to

Engine ON/OFF switch in OFF

position.

Low engine oil level. Replenish supply. Engine will not start

Refer to provided gasoline engine manual for additional troubleshooting.

Trigger of trigger gun released. Squeeze trigger.

Water supply not turned on. Open water supply valve.

Clogged pressure nozzle. Clean pressure nozzle opening.

Inadequate water supply. Fully open faucet. Check for kinked or

Partially clogged or damaged

pressure nozzle.

Air being drawn through detergent

inlet line.

Place engine ON/OFF switch in ON

position.

or run if oil is low (on engines equipped with low oil protection).

damaged hose. Use 5/8 inch minimum hose. Check for debris clogging

inlet screen.

Clean or replace.

Refill detergent container. Ensure

that pick-up screen is fully immersed.

To Sta r t

under

Operation

.

Dual lance wand set for detergent

application.

Uneven spray pattern. Partially clogged or damaged

pressure nozzle.

Pressure washer will

not produce hot water.

Burner switch in OFF position. Place switch in ON position.

Inadequate fuel supply. Refill fuel tank. Use only recom-

Engine not running. Engine must be running before

Inadequate water supply. Fully open faucet. Check for kinked

Set dual lance wand for rinse. Refer

to

will not create high pressure when

set for detergent application.

Clean or replace.

mended fuels. Refer to

Starting

burner will light.

or damaged hose. Use 5/8 inch minimum hose. Check for debris clogging

inlet screen.

Step 7

under

under

To Clean

Before

Operation

. Washer

.

Page 10 Shark 925A/925SS

Page 11

TROUBLESHOOTING GUIDE

SYMPTOM POSSIBLE CAUSES CORRECTIVE ACTION

Pressure washer will

not produce hot water.

...continued

Poor or no detergent

flow.

Trigger of trigger gun released. Squeeze trigger. Water must be

spraying for burner to light.

Thermostat is set too low. Adjust thermostat to desired tempera-

ture.

Blown fuse. Replace. Fuse is located in Control

Box. Refer to

Engine is running too slow. Move throttle lever to full throttle posi-

tion.

Battery charge is low. Charge battery or replace if neces-

sary.

Inadequate detergent supply. Refill detergent container. Ensure

that pick-up screen is fully immersed.

Detergent screen or hose clogged. Clean. Always start with a clean

detergent container.

Dual lance wand set for high

pressure.

Clogged detergent injector check

val ve.

Set dual lance wand for detergent

application. Refer to

.

Clean

Clean check valve at detergent

injector inlet.

Figure 14

for location.

under

Step 1

To

Poor cleaning. Improper detergent concentration or

mixing.

Wrong detergent for the application. Select appropriate detergent.

Rinsing with hot water. A final rinse with cold water will

IMPORTANT

If the pressure washer demonstrates other symptoms or the corrective

actions listed do not correct the problem, contact the local authorized Shark

Pressure Washer Service Center. The Shark Pressure Washer Service

Center can be identified by contacting:

Customer Service Department

Shark Pressure Washers

21 Inverness Way East • Englewood, Colorado 80112

1-800-771-1881

Mix detergent per manufacturer's

instructions. Ensure that powdered

detergents are fully dissolved.

reduce water spotting.

Page 11Shark 925A/925SS

Page 12

When ordering from your dealer, please provide the following:

Model Number: 925A/925SS

Machine Serial Number: ________________________________

Component Part Number: _______________________________

Description: __________________________________________

FOR HELP OR ADDITIONAL INFORMATION, CONTACT:

Customer Service Department

Shark Pressure Washers

21 Inverness Way East

Englewood, CO 80112

1-800-771-1881

Page 12 Shark 925A/925SS

Page 13

5,6

4

3

2

7,8,9 10 11 12,13 14

15,16

17,18,19,20

1

20,21,22,23,24

Figure 11 - Machine Assembly, Left Side View

Ref. No. Part No. Description Qty.

1 375448 Chassis 1

2 646089 Decal Warnings 1

3 444469 Decal Shark Detergent 1

4 Fig. 16 Coil Inlet Assembly 1

5 829980 Shark Logo Plate 2

6 926598 Rivet 8

7 213044 Burner Exhaust Vent 1

8 268004 Insulation 1

9 860102 Retaining Ring 1

10 824115 Vent Clip 4

11 Fig. 17 Pump Assembly 1

12

13

■

■

Bolt 3/8” - 16 x 1-3/8” 4

Lock Washer 3/8” 4

Ref. No. Part No. Description Qty.

14 Fig. 14 Control Box Assembly 1

15 826167 Strain Relief 2

16 703127 Strain Relief Nut 2

17 Fig. 19 Fuel Tank Assembly 1

18 834153 Decal Fuel Type 1

19

20

■

■

Bolt 1/4” - 20 x 1/2” 2

Flat Washer 1/4” 6

21 220119 Battery Box 1

22 890904 Battery Terminal 2

23 375292 Mounting Plate 1

24

■

Locknut 1/4” - 20 4

■ Standard hardware item available locally.

Page 13Shark 925A/925SS

Page 14

5

123 4

6

7

8

15,26

Figure 12 - Machine Assembly, Right Side View

Ref. No. Part No. Description Qty.

1 661254 Engine 9 HP 1

2 961532 Tubing 3/8” ]

3 823987 Hose Clamp 1

4 Fig. 15 Coil Outlet Assembly 1

5 Fig. 20 Trigger Gun/Dual Lance Wand 1

6 707226 Pressure Hose 1

7 826176 Quick Disconnect 1

8 268006 Insulation 1

9 375444 Coil Tank (925A) 1

375449 Coil Tank (925SS) 1

10

11

■

■

Fender Washer 5/16” 4

Flange Nut 5/16” - 18 4

12 646047 Decal Troubleshooting 1

13 213191 Insulation 1

14 Fig. 21 Burner Assembly 1

9,10,11

12

13

14,15,16

17,18,19,202122,23,24,25

Ref. No. Part No. Description Qty.

15

■

Flat Washer 5/16” 7

16 799362 Crownlock Nut 5/16” - 18 3

17 817322 Hubcap 4

18 848616 Push Nut 4

19

■

Flat Washer 5/8” 8

20 983013 Wheel 4

21 815329 Snap Bushing 1

22 860232 Voltage Regulator 1

23 218189 Regulator Harness 1

24

25

26

✽

■

■

■

■

Locknut 1/4” - 20 2

Flat Washer 1/4” 2

Locknut 5/16” - 18 4

Order amount needed in feet.

Standard hardware item available locally.

Page 14 Shark 925A/925SS

Page 15

42321

5

6

10 9 8 7 2

Figure 13 - Machine Assembly, Top View

Ref. No. Part No. Description Qty.

1 646088 Decal Operating Instruction 1

2 815329 Snap Bushing 3

3 834154 Decal Winterize 1

4 226222 Coil 1

5 859815 Grommet (Nozzle Holder) 3

6 859806 Grommet 1

Ref. No. Part No. Description Qty.

7 890783 Tag Gasoline Engine 1

8 444462 Decal Caution Gasoline 1

9 232025 Decal Important Battery 1

10 646026 Decal Carbon Monoxide 1

11 646115 Decal Hot Surface 1

Page 15Shark 925A/925SS

Page 16

1 2 3 4 5 6 7 8 9 10 12 13 14,15

16

17

18

11

Figure 14 - Control Box Assembly

Ref. No. Part No. Description Qty.

1 875465 Burner Switch 1

2 645932 Decal Control Box 1

3 835150 Thermostat Dial 1

4 915390 Thermostat Mounting Plate 1

5

■

Screw (4 mm x 6 mm) 2

6 615413 Control Box Front 1

7 630649 Channel 2

8 615414 Control Box Back 1

9

10

■

■

Locknut 1/4” - 20 4

Bolt 1/4” - 20 x 3/4” 4

11 955940 Thermostat 1

12 860140 Isolation Relay 1

Ref. No. Part No. Description Qty.

13 645990 Bridge Rectifier 1

14 676638 Fuse 30A 1

15 707146 Fuse Holder 1

16 826184 Strain Relief 4

17 847750 Wire Cover ]

18

✪

875651 Pressure Switch 1

■

Standard hardware item available locally.

✽

Order amount needed in feet

Replacement Parts

✪

753134 O-Ring Kit 1

✪

875653 Switch 1

Page 16 Shark 925A/925SS

Page 17

10

12 3 4

5

8,9

Figure 15 - Coil Outlet Assembly

Ref. No. Part No. Description Qty.

1 799501 Elbow 1/4” x 3/8” Hose 1

2 875555 Relief Valve Seat 1

3 783845 Relief Valve Manifold 1

4 630720 Relief Valve Cartridge 1

5 644802 Street Elbow 3/8” 1

6 844806 Quick Disconnect Plug 1

7

6

Ref. No. Part No. Description Qty.

7

■

Screw (4 mm x 6 mm) 1

8 780565 Copper Washer 2

9 915630 Plug 3/8” 2

10 698247 Hex Nipple 1/2” x 2” 1

■

Standard hardware item available locally.

Page 17Shark 925A/925SS

Page 18

3

7

2

1

Figure 16 - Coil Inlet Assembly

Ref. No. Part No. Description Qty.

1 935159 Filter Screen 1

2 961534 Tubing 1/4”

✽

3 823989 Hose Clamp 1

4 715744 Coil Drain Plug 1

6

5

4

Ref. No. Part No. Description Qty.

5 754711 Tee 3/8” 1

6 801102 Hex Nipple 3/8” x 1-1/2” 1

7 873594 Detergent Injector 1

✽

Order amount needed in feet.

Page 18 Shark 925A/925SS

Page 19

12

3

4

Figure 17 - Pump Assembly

Ref. No. Part No. Description Qty.

1 829938 Pump Fig. 18 1

2 890769 Tag Unloader 1

3 707179 Hose 3/8” x 30” 1

4 644802 Street Elbow 3/8” 2

5 875575 Garden Hose Connector Spring 1

4

9

8

5,6,7

Ref. No. Part No. Description Qty.

6 801139 Garden Hose Connector 1

7 856035 Garden Hose Connector Gasket 1

8 844758 Street Elbow 1/2” 1

9 915567 Plug Pipe 1/2” 1

Page 19Shark 925A/925SS

Page 20

8

9

1

23

7

4

2

1

Figure 18 - Pump, Exploded View

Ref. No. Part No. Description Qty.

1 835225 Valve Plug 6

2 753164 Check Valve Kit 6

3 753165 Plunger Seal Kit 3

4

✪

755250 Unloader Assembly 1

5 885426 Crankcase Oil Seal 3

6 885425 Crankshaft Oil Seal 1

5

6

Ref. No. Part No. Description Qty.

7 755256 Pump Mounting Kit 1

8 646327 Oil Fill/Dipstick 1

9 814285 Gasket 1

Replacement Parts Qty/Pump

✪

755255 Unloader O-Ring Kit 1

Page 20 Shark 925A/925SS

Page 21

12 3 4

8

Figure 19 - Fuel Tank Assembly

Ref. No. Part No. Description Qty.

1 817312 Fuel Tank Cap 1

2 661277 Elbow 1/4” Hose x Stand Pipe 1

3 823988 Hose Clamp 4

4 707116 Hose 1/4” Green

✽

5 815230 Bushing 2

56

7

Ref. No. Part No. Description Qty.

6 309294 Nipple 3/8” Hose x 1/4” Hose 1

7 867368 Hose 1/4” Black

✽

8 890890 Fuel Tank 1

✽

Order amount needed in feet.

Page 21Shark 925A/925SS

Page 22

56 789

1,2,3

4

Figure 20 - Trigger Gun/Dual Lance Wand Assembly

Ref. No. Part No. Description Qty.

1 799177 Pressure Nozzle (Red) 1

2 799178 Pressure Nozzle (Yellow) 1

3 799179 Pressure Nozzle (White) 1

4 826170 Quick Disconnect 1

5 900958 Detergent Nozzle 1

6

✪

936686 Dual Lance Wand 1

Ref. No. Part No. Description Qty.

7 826169 Quick Disconnect 1

8 915786 Quick Disconnect Plug 1

9

✹

691867 Trigger Gun 1

Replacement Parts

✪

859762 Insulator Grip Assembly 1

✹

753179 Trigger Gun Repair Kit 1

Page 22 Shark 925A/925SS

Page 23

1/8”

AIR CONENOZZLE

1

1/8”

23456

5/16”

ELECTRODE

ELECTRODE SETTINGS

3/16”

NOZZLE

Figure 21 - Burner Assembly

Ref. No. Part No. Description Qty.

1 615850 Burner Fig. 22 1

2 698023 Nipple 3/8” x 1/4” Hose 1

3

✪

851080 Fuel Filter 1

4 615279 Reducer Bushing 3/8” x 1/4” 1

5 698200 Pipe Nipple 1/4” x 2-1/2” 1

6 661257 Street Elbow 1/4” 1

7 698020 Nipple 1/4” x 1/4” Hose 1

7 8,9 10,11

Ref. No. Part No. Description Qty.

8 826167 Strain Relief 1

9 703127 Strain Relief Nut 1

10

11

■

Standard hardware item available locally.

■

■

Screw #6 - 32 x 1” 1

Locknut #6 - 32 1

Replacement Parts

✪

875490 Filter Element 1

Page 23Shark 925A/925SS

Page 24

12345 6

7

910 711

8

Figure 22 - Burner Parts Breakdown

Ref. No. Part No. Description Qty.

1 919791 Fuel Pump 1

2 944422 Solenoid Valve 1

3 890906 Ignitor 1

4 901230 Solenoid Metering Bolt 1

5 900650 Nozzle 1

6 661302 Electrode (Pair) 1

7 753167 Brush Kit 2

8 784353 Motor 1

Ref. No. Part No. Description Qty.

9 825924 Coupling 1

10 676865 Blower Fan 1

11 880806 Fuel Line 1

NS 875312 Relay 1

NS 895312 Timer 1

NS 890916 Terminal Block 1

NS 877667 Tune Up Repair Kit 1

NS = Not Shown

Page 24 Shark 925A/925SS

Page 25

Figure 23 - Wiring Diagram

Page 25Shark 925A/925SS

Page 26

WARRANTY

Shark

R

SHARK ONE-YEAR LIMITED WARRANTY:

Shark products are warranted by Shark Pressure Washers (Shark), to be free of defects in material and

workmanship under normal use, for a period of ONE YEAR from the date of the original purchase. Items

that fail due to normal wear such as pump seals, pump valves, unloader valves, detergent valves, water

nozzles, quick couplings, hoses, gunjets, o-rings, etc. are not covered under this warranty. Damage resulting from neglect, abuse, tampering, modification or misuse is not covered under this warranty. Shark will at

its option repair or replace any part covered by this warranty which is defective under normal use for one

year at no charge for parts or labor. All defects must be verified by an authorized Shark Pressure Washers

service location.

EXCEPTIONS TO THE ONE YEAR WARRANTY FOR PARTS ONLY ARE:

Hawk Pumps: SEVEN YEAR Warranty (LIFETIME Brass Manifold Warranty-Even

Against Freezing)

Heating Coils: FOUR YEAR Warranty

Chassis Assembly and Pulleys: THREE YEAR Warranty

Plumbing and Belts: TWO YEAR Warranty (This additional warranty will be in effect as

applicable.)

LIMITATION OF LIABILITY:

To the extent allowable under applicable law, Shark liability for consequential and incidental damages is

expressly disclaimed. Shark liability in all events is limited to, and shall not exceed, the purchase price paid

for the equipment. Shark liability excludes field labor charges, loss of use of the unit, loss of time or rental,

inconvenience, or commercial loss and is limited to repair or replacement of defective parts only, at the

option of Shark Pressure Washers.

WARRANTY DISCLAIMER:

Shark has made a diligent effort to illustrate and describe the product in this literature accurately; however,

such illustrations and descriptions are for the sole purpose of identification, and do not express or imply a

warranty that the product is merchantable, or fits a particular purpose, or that the product will necessarily

conform to the illustrations or descriptions.

PRODUCT SUITABILITY:

Many states and localities have codes and regulations governing sales, construction, installation, and/or

use of products for certain purposes, which may vary from those in neighboring areas. While attempts to

assure that its products comply with such codes, it cannot guarantee compliance, and cannot be responsible for how the product is installed or used. Before purchase and use of a product, please review the

product application, and national and local codes and regulations, and be sure that the product, installation,

and use will comply with them.

PROMPT DISPOSITION:

Shark will make a good faith effort for prompt correction or other adjustments with respect to any product

which proves to be defective within limited warranty. For any product believed to be defective within limited

warranty, contact Shark Pressure Washers at 1-800-771-1881.

SHARK PRESSURE WASHERS

21 Inverness Way East

Englewood, Colorado 80112

1-800-771-1881

785925-10-99

Loading...

Loading...