Page 1

Motor for sliding gates SHARK 500/800

Manual for installation and operation

Page 2

2

Contents

1.1 SHARK 500/800 products and accessories .................................................. 4

1.2 Dim ension ...................................................................................................... 5

1.3 Gate variations ............................................................................................... 5

2.1 General notes ................................................................................................. 6

2.2 Checks ............................................................................................................ 6

2.3 Gate and foundation layout ............................................................................ 8

2.4 Cabling layout ................................................................................................ 9

3.1 Installing the m otor unit ............................................................................... 10

3.2 Mounting the toothed rack ........................................................................... 12

3.2.1 General ................................................................................................ 12

3.2.2 Determ ining the installation height .................................................... 12

3.2.3 Determ ining the length and installation position of the toothed rack

...................................................................................................................... 13

3.2.4 Adjust the length of the toothed rack ............................................... 14

3.2.5 Mounting the toothed rack ............................................................... 15

3.2.6 Adjust the m otor unit ....................................................................... 16

3.3 A djusting the height of the m otor unit ......................................................... 17

3.4 Mounting the reference point m agnet .......................................................... 17

3.5 Release ......................................................................................................... 19

3.6 Locking ....... ………… ……… … ………… ……… … ………… ……… ….19

3.7 Restore the lim it setting after power restoration ....................................... 20

Page 3

3

4.1 Connection of Mains cable .......................................................................... 21

4.2 Connection of control elements ................................................................... 22

4.2.1Wireless closing edge safety device connection .................................. 22

4.2.2 Infrared beam connection ................................................................... 23

4.2.3 Opening edge and closing edge safety device connection ................. 23

4.2.4 "O/S/C" button connection ................................................................. 24

4.2.5 Caution light connection ..................................................................... 24

4.2.6 Battery backup connection ................................................................. 24

4.2.7 Pedestrian mode .................................................................................. 24

4.3 Setting the function ...................................................................................... 25

4.4 Hand transmitter coding............................................................................... 26

5.1 Technical feature of sliding gate operator .................................................... 27

6.1 FAQ .............................................................................................................. 28

Page 4

4

1.SHARK 500/800

products and accessories

Standard products and accessories

1-1-1

1. SHARK 500/800 motor unit

2. Keys

3. M8 wall plugs

1-1-2

4. Block of magnet housing

5. Reference point magnet

6. Cover of magnet housing

7. Magnet housing

1-1-3

8. Hand transmitter

9. Wall mounting bracket

10. Set screw of bracket

11. Plastic expansion

In addition to the components in the

standard package,the following is

required for the installation:

— Toothed rack

Toothed rack

1-1-4

The toothed rack and accessories

includes:

12. Toothed rack

13. Set screw for toothed rack

14. Washer

15. Fixing nuts for toothed rack

The quantities of the individual

components are dependent on the gate

length.

Page 5

5

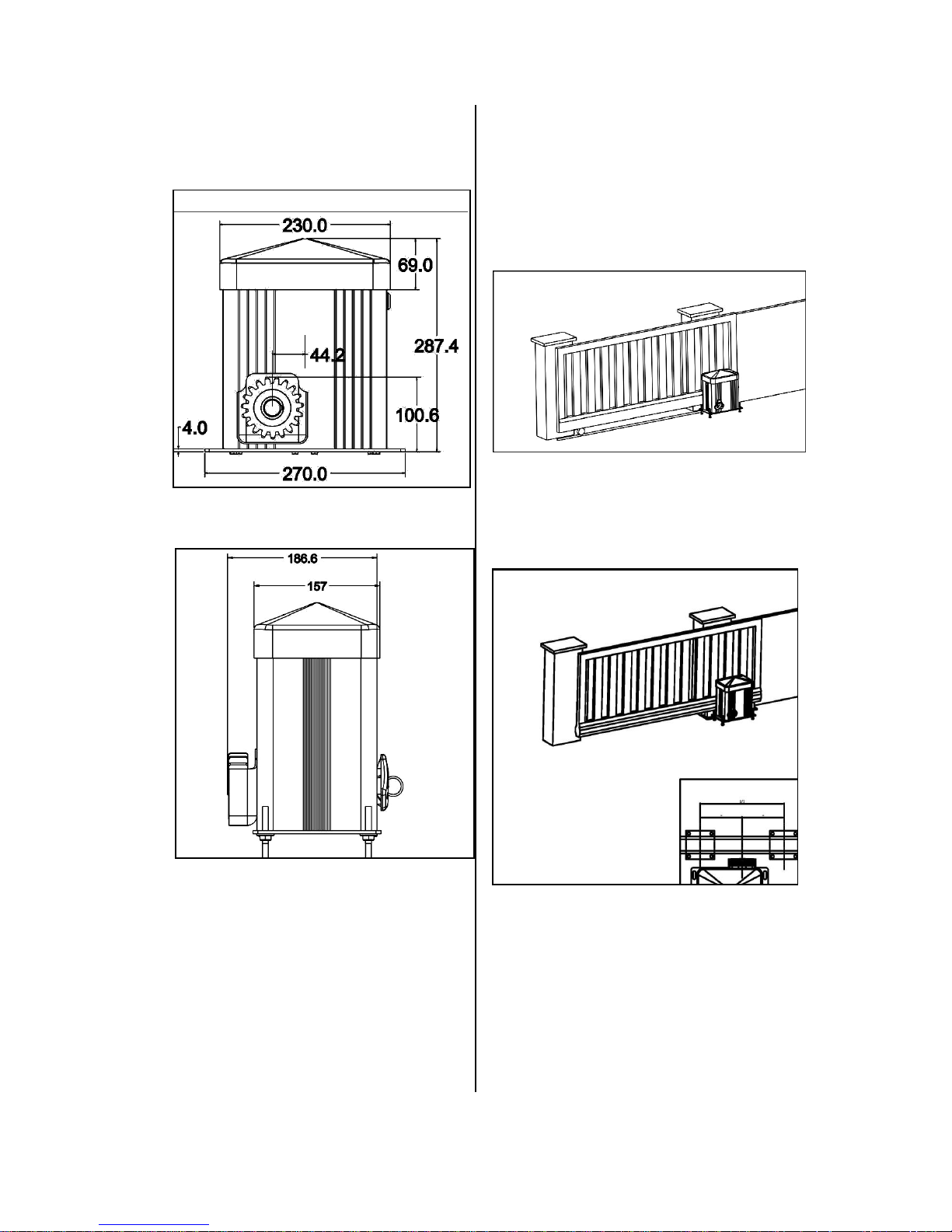

1.2 Dimension

1-2-1

1-2-2

1.3 Gate variations

The standard supply package is suitable

for the following types of gates.

Gate system on rails

1-3-1

Cantilevered gate system

1-3-2

Page 6

6

2.1 General notes

The picture in these instruction are not

true-to-scale.

All the dimensions are shown in

millimeters(mm)!

The motor can be mounted on the right

or left hand side of the gate depending

on the direction of opening.

These instructions show the motor being

installed on the right hand side.

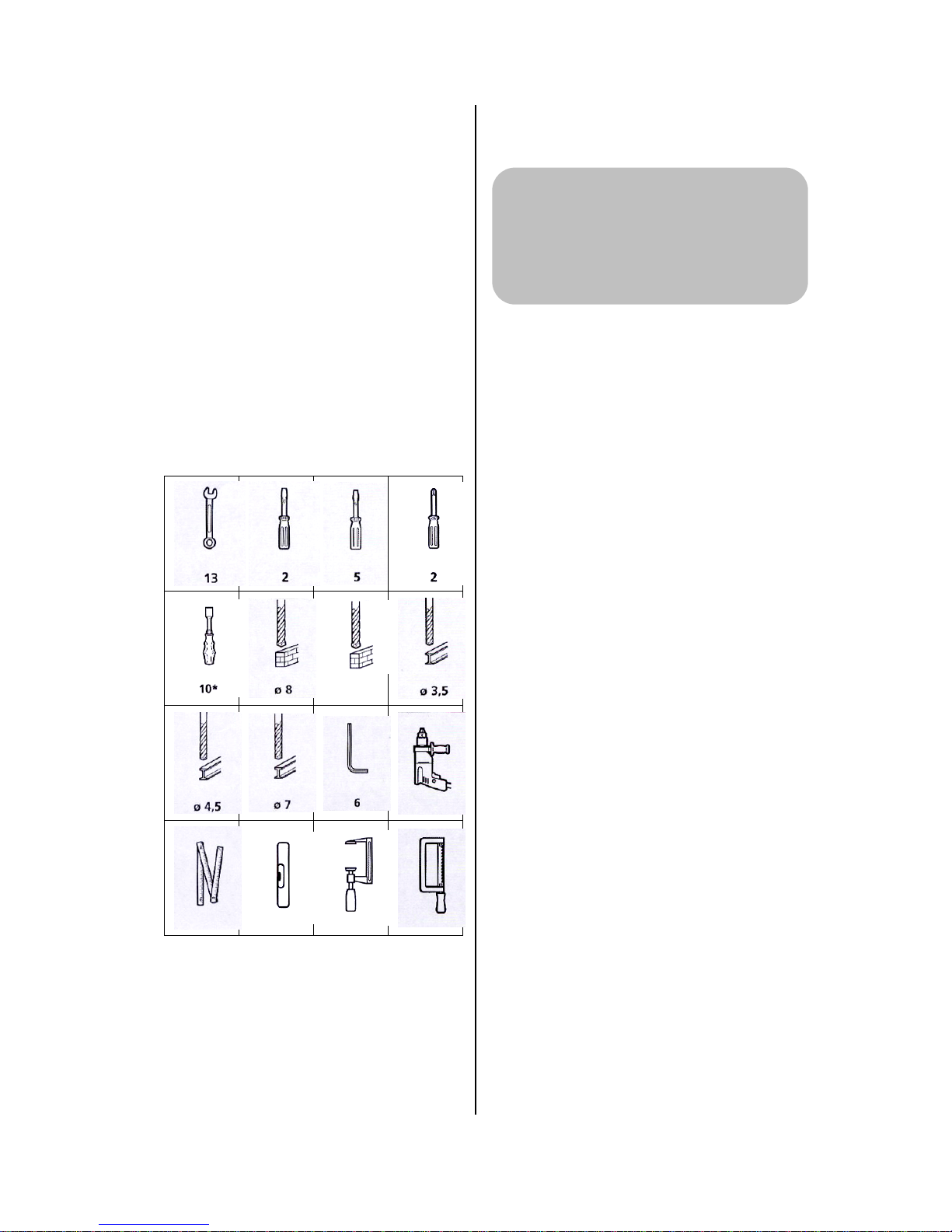

For correct mounting you will need the

following tools:

2-1-1

* Minimum shaft length is 160mm.

2.2 Checks

Supply contents :

Check the package to ensure that all

the parts are included.

Check that you have all the

additional components that are

necessary for your particular

installation requirements.

Foundations

Check the proposed installation

location for the operator system:

— The motor unit and the toothed

rack must be installed on the

inside of the gate with the gate

closed.

— The motor unit should not be

installed within the clear width!

— For cantilevered gates, the motor

unit must be mounted at the mid

point between the carrier roller

assemblies.

— The foundations must be suitable

for heavy duty wall plugs.

Check whether the existing

foundations are suitable.

Check the supply cable.

Pay particular attention to the cable

exit point where the motor unit is to

be installed.

Attention!

In order to guarantee correct

mounting,carry out the following

checks before installation.

Φ12

Page 7

7

Gate system

Ensure that your gate system has an

appropriate electricity supply

connection and a facility for

disconnecting the mains. The

minimum cross-sectional area of the

earth cable is 3×1.5mm2

Ensure that all cables are suitable

for outdoor use(cold resistant and

UV resistant).

Check that the gate to be operated

fulfils the following conditions:

— The travel path of the gate must

be horizontal.

— When closed, the gate should

exceed at least 400mm further

than the height on the same

installation side.

— The gate must have a mechanical

gate stop for both direction.

— The closing edges must be fitted

with a flexible gate seal.

— The gate itself must be straight,

so that the distance between

motor unit and the gate never

changes.

Page 8

8

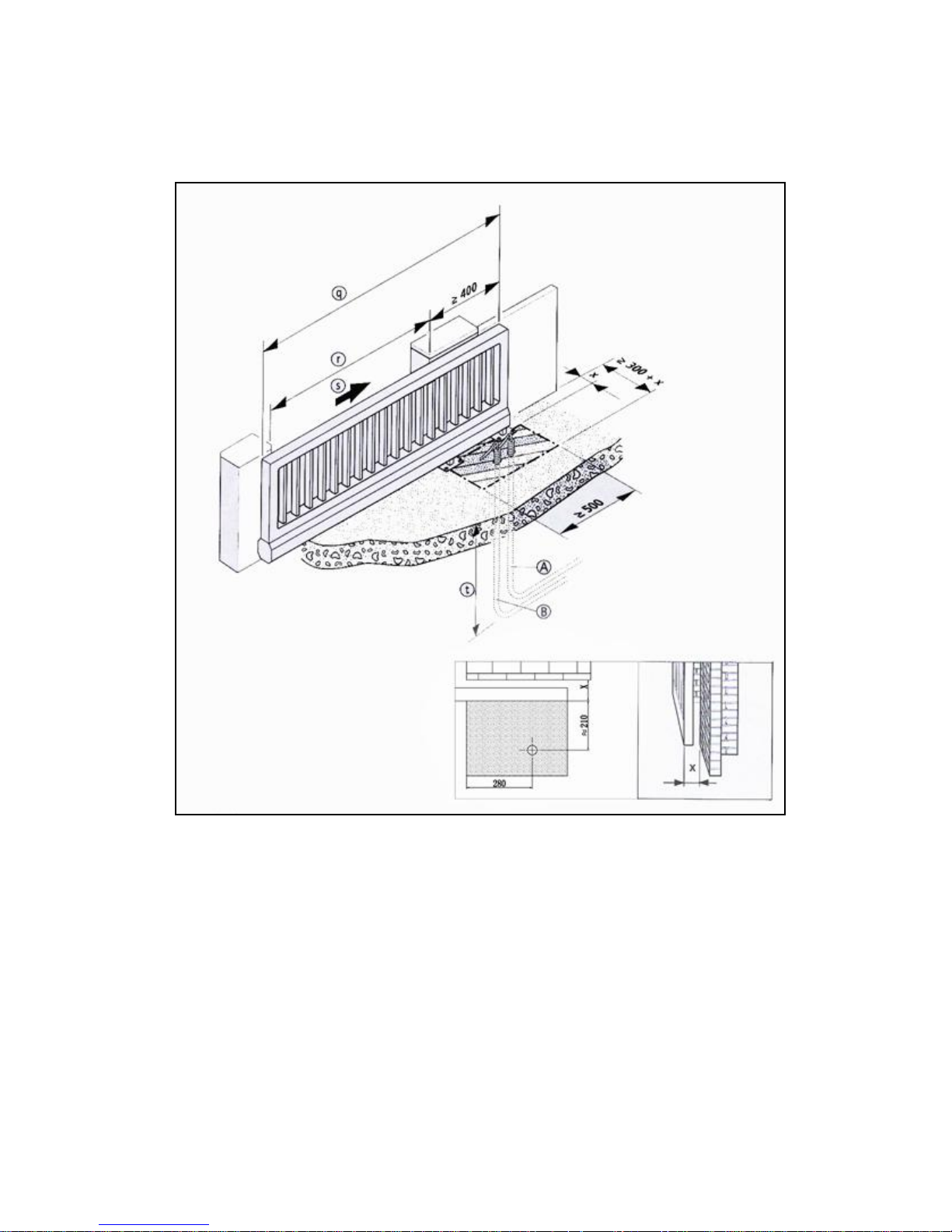

2.3 Gate and foundation layout

2-3-1

A Empty conduit for control cable

B Empty conduit for electricity supply cable

q Gate width

r Clear width

s Opening direction

t Below depth of frost penetration

x Gate thickness+ distance from structure

Page 9

9

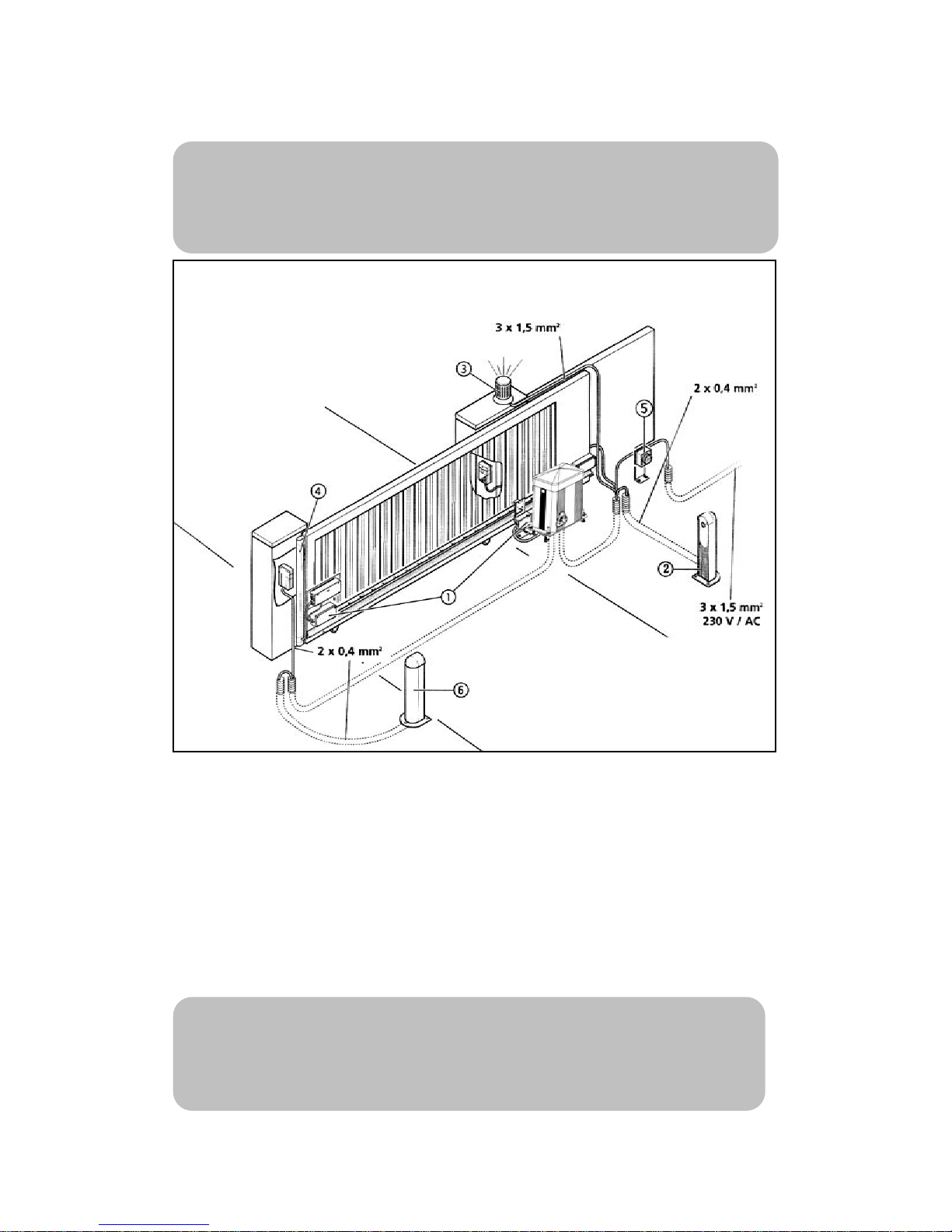

2.4 Cabling layout

2-4-1

1、Signal transmission system

2、Infrared beam

3、Caution light

4 、 Closing edge safety device

(SKS)

5 、 Mains isolater switch(mains

disconnection facility)

Reference:

For the installation and cabling of the gate sensors, control elements and

safety equipment ,the relevant installation instructions must be observed.

Advice:

This is just an example of a cabling layout,the layout can vary according to the

type of gate and the associated equipment.

Page 10

10

3.1 Installing the motor unit

3-1-1

3-1-2

Open the motor unit cover.

3-1-3

A Wall

B Gate

C Mounting surface for the

toothed rack

D Output shaft of the motor unit

E Front edge of the toothed rack

F Floor console

G Clear width

H Cable entry for power

supply/control cable

I Foundation

Attention!

To install the motor unit correctly,

it must be mounted at the mid

point between the carrier roller

assemblies if the gates are

cantilevered.

Attention!

To install the motor unit

correctly,the following points

must be assured:

—The spur gear must accurately

mesh with the toothed rack.

— The wall plugs for the floor

console must be at least 80mm

from the edge of the foundation.

Page 11

11

Before installing the motor unit,

check whether the possible height

adjustment of the motor unit is

sufficient for the situation on site,or

if the motor unit needs to be raised

on a backplate.

Align the floor console ,with the

motor unit parallel to the gate.

Drill the holes for the wall plugs as

shown in the drilling diagram.

3-1-4

Push in the wall plugs

Feed the control cable and the

power supply cable through the

floor console.

Adjust the motor unit

Screw the floor console into place

Caution!

Danger of electric shock:

Before commencing cabling

works it is very important to

disconnect the operator system

from the electricity supply.

Ensure that the electricity

supply remains disconnected for

the duration of the cabling works.

Reference:

The height adjustment of the

motor unit is described in section

3.3.

Notes:

When using an existing toothed

rack, the correct dimension is

27mm from the first screw to the

front edge of the toothed rack.

Reference:

When determining the mounting

surface for the toothed rack, the

information given in section 3.2.2

must be observed.

Page 12

12

3.2 Mounting the toothed

rack

3.2.1 General

Toothed rack are available in several

standard lengths and some fixing rack

accessories.

The toothed rack is made up of several

toothed rack segments.

Minimum length of toothed rack

Minimum length of toothed rack is equal

to the movement stroke of the gate

between the gate OPEN and CLOSED

positions+180mm

Maximum length of toothed rack

Maximum length of toothed rack is

equal to the width of gate.

3.2.2 Determining the

installation height

3-2-1

Determine the installation height of

the toothed rack on the gate

Adjust the height of the spur gear

accordingly.

Notes:

The toothed rack can be adapted to

fit the gate by means of backplate(D).

Reference:

Section 3.3 describes the height

adjustment for the motor unit.

Attention!

gate,the following points must be assured:

operation of the gate.(e.g. by extending into

the path of the gate rollers(B).)

the gate.

low to avoid mesh apart with the rack.

point that meshed)

Reference:

— For gates with an existing

toothed rack,please skip to

Section 3.3.

— Section3.5 describes how to

release the motor unit.

Attention!

To install the rack

correctly,the following

must be ensured:

— The motor unit has been

mounted.

— The motor unit is released.

Page 13

13

3.2.3 Determining the length

and installation position of

the toothed rack

Maximum length of toothed rack

If a toothed rack is to be installed across

the entire width of the gate ,then the

installation position does not have to be

determined.

The length and installation position of

the toothed rack correspond to the gate

width.

Minimum length of toothed rack

The minimum length of toothed rack

must be determined at the gate.

3-2-2

Move the gate to the CLOSED

position.

Make a mark on the gate:

90mm from the centre of the spur

gear in the direction of opening.

3-2-3

Move the gate to the OPEN

position.

Make a mark on the gate:

90mm from the centre of the spur

gear in the direction of closing.

3-2-4

Attention!

To ensure trouble-free operation,

the toothed rack must at least extend

across the area(E) between the

markings.

Page 14

14

3.2.4 Adjust the length of

the toothed rack

Measure the required length of the

toothed rack at the gate.

Change the standard length to required

length of the toothed rack:

The toothed rack need not to be

adjusted.

When the standard rack length is

longer than the required length:

3-2-5

When the standard rack length is

shorter than the required length.

3-2-6

Place the required number of the

toothed rack end to end.

Cut off any excess length from the

last toothed rack using a metal

saw.

Cut off the excess length of the toothed

rack using a metal saw.

Attention!

To avoid damaging the

toothed rack segments , there

should be no toothed rack

segments in the rack housing at

the point where the cut is to be

made.

Page 15

15

3.2.5 Mounting the toothed

rack

Fixing nuts need to be welded on

different position of the gate before

installing the toothed rack.

3-2-7

3-2-8

Hold the toothed rack in place

according to the fixing rack nuts

welded on the gate on the spur

gear side.

Place the toothed rack onto the

spur gear so that the toothed rack

engages the spur gear.

Adjust the toothed rack

horizontally.

Using a spanner to hold the

toothed rack in position of the

fixing rack nuts.

3-2-9

According to the above-mentioned

process, place other racks with the

bolts to the fixing rack nuts.

Attention!

To ensure correct operation, the

toothed rack must always be pushed

onto the spur gear as the gate is

moved.

Reference:

The reference point magnet

must be installed before the rack is

mounted. Section 3.4 describes

how to install the reference point

magnet.

Attention!

To ensure the gate can move

smoothly, the countersunk screw

must be tightened and adjusted

accordingly.When welding the

fixing rack nuts, make sure to

weld the smaller end to the gate

barrier, and the bigger end face to

the toothed rack. All the surface

of bigger ends must flush with

each other.

Page 16

16

3-2-10

Push the gate one cycle in the

direction of closing by hand, and

adjust the clearance between the

rack and spur gear.

Tighten all the nuts after adjusting

the height.

3.2.6 Adjust the motor unit

3-2-11

The height of the motor unit must be

re-adjusted now.

Lower the spur gear by 1 to 2mm

Check:

To check that the spur gear

engages the toothed rack along its

entire length,the gate must be

pushed once to the OPEN position

and back to the CLOSED position.

Reference:

Section 3.3 describes how to adjust

the height of the motor unit.

Attention!

To ensure the gate runs smoothly,

it is important that a vertical gap of 1

to 2mm is maintained between the

toothed rack and the spur gear.

Page 17

17

3.3 Adjusting the height of

the motor unit

3-3-1

3-3-2

According to the Fig.3-1-4,tighten

the bottom screw A after fixing the

wall plug.

Adjust the Nut(B) in the middle of

the wall plug until the motor is in

suitable position.

Tighten screw(C) at the top after

fixing the flat washer and spring

washer.

3.4 Mounting the reference

point magnet

The operator system determines the

gate positions and the extent of travel

electronically. So it requires a

reference point on the gate or on the

toothed rack.

Using a special reference point magnet

as the reference point.

3-4-1

Drive the door to the CLOSED

position

Attention!

To ensure correct operation, any

existing magnets must be

removed.(e.g.in the case of retrofit

measures with an existing toothed

rack).

Caution!

To avoid injury ,the gate must have

a mechanical end stop in both

directions; otherwise it could spring

out of line.

Page 18

18

Determin the position for the

reference point magnet.

3-4-2

The mounting of the reference point

magnet is dependent on the type of

toothed rack that is used.

3

3-4-4

3-4-5

Mount the reference point magnet

in the magnet housing.

Mount the cover onto the magnet

housing.

Mount the magnet housing at the

previously determined position on

the toothed rack.

Check the position of the reference

point magnet.

Check the distance between the

reference point magnet and the

motor unit.

Check the distance between the

centre of the reference point

magnet and the internal hall height

of the motor unit.

Attention!

To avoid faults occuring, the

following dimensions must be

adhered to without fail:

— The distance between the

reference point magnet(A) and the

motor unit(B) must be 2 to 8mm.

—The distance between the centre of

the magnet(A) and the centre of the

spur gear(C) must be 70mm.

Page 19

19

3.5 Release

3-5-1

Place the release key into the

keyhole at the bottom of the motor unit.

3-5-2

Hold the triangle plastic part

outside the lock, turn clockwise by

180·until it stops.

Move the door shortly by hand in

the OPEN and CLOSE direction.

The transmission is now mechanically

disengaged from the drive shaft. The

gate can only be moved manually. The

electric circuit in the controls is

interrupted and the controls are out of

operation.

3.6 Locking

3-5-3

Hold the triangle plastic part outside

the lock, turn anti-clockwise by

180·until it stops. Push the door

front and back by hand

to ensure the gear is engaged.

3-5-4

Pull the key out of the keyhole at

the bottom of the motor unit.

The transmission and drive shaft are

now mechanically engaged. The gate

can be driven via the motor. The

electric circuit in the controls are in

operation.

Page 20

20

3.7 Restore the limit setting after power restoration

When the power restoration, Please use the transmitter or wall switch to open and

close the door for one cycle, then the initial set travel limit will be recovered

automatically. If not, the door opening/closing position will be error.

Attention!

Do not rotate the key !

When re-engage after releasing,

limit movement may happen. Please

use the transmitter or wall switch to

open and close the door for one cycle,

then the initial set travel limit will be

recovered automatically.

Page 21

21

4.1 Connection of Mains

cable

4-1-1

Open the cover of the motor unit,

loosen the two fixing screws on the

junction box at the wall side of the

motor,and open the cover.

4-1-2

Put the mains cable with protector

jacket through the hole at the bottom of

the motor unit.

Loosen the screws on the terminal

block, then connect the two peeled

end(L、 N) to the terminals on the

terminal block, tightened the screws.

Connect the ground wire to the earth

terminal of the motor, make sure it is

tight.

Fix the mains cable together with

the motor wire using cable ties.

Close the cover of the junction box,

and then tighten the screws.

4-1-3

Fix the cable plugged into the

motor to the hole like the drawing.

Attention:

The sliding gate operator

should use:

---AC220V (or

AC240V/AC110V) power

supply.

---To be installed by

professional technicians, and to

use the cables fit safety standard

3 × 0.75mm ².

Page 22

22

4.2 Connection of control elements

4-2-1

4.2.1Wireless closing edge safety device connection

The connection is suitable for the wireless safety device with DC24V and NC

type. Section 4-2-1 describes how to connect the wireless safety device .

Attention!

Please shorten the two terminals “COM” and “SAFE” by wire conductor if this

function is not required, or the motor will not be able to close the gate.

Opening edge safety

device(opening direction)

Wireless

protector

receiver

Infrared beam

O/S/C button

Caution light

Battery backup

Closing edge safety

device(closing

Page 23

23

4.2.2 Infrared beam connection

Section 4-2-1 describes the

connection of “Infrared beam”

Activate the infrared beam(H1 or

H2) by the setting interface

“P4”.Press „SET‟ button and hold

on until the LED displays figure

„P4‟,then press ”SET” once to

confirm, the LED will

displays”H1or H2”,then the

function is available.

When the self-checking function of

infrared beam(H2) is activated, the

motor will not work if the protector

is failure, the LED will display “r”.

If the connection is OK, the lamp

“PE” will normally on during

closing cycle,will off when it is

obstructed.

4.2.3 Opening edge and closing

edge safety device connection

This is suitable for pressing to

short-connected safety device.

Connect an 8.2 kΩ resistor to the far end

of the closing edge safety device.

Section 4-2-1 describes the

connection of “closing edge safety

device-closing direction” and

“closing edge safety device-opening

direction”

Attention:

When the safety device is not used,

an 8.2 kΩ resistor is required to be

installed at the relevant terminals.

When the resistance of the safety

device is far below 8.2 kΩ,(corresponds

to the shor-connecting of the safety

device),or the resistance is much higher

than 8.2 kΩ,(equals to the open circuit

of safety device), the relevant CEP light

will normally on, and the motor will not

work.

Attention:

If the infrared beam is not used,

please disable the function, as the

same setting “P4→ HO”, or the

gate can not be closed by the

motor.(Please according to section

4.3)

Attention!

To correctly operation, we

strongly advise to use infrared

beam with three-wire,on-off

controlled, DC24V, the control

contact points is NC style.

Page 24

24

4.2.4 "O/S/C" button

connection

Section 4-2-1 describes the

connection of “O/S/C button”.

4.2.5 Caution light

connection

Section 4-2-1 described the

connection of caution light.

The caution light will go on during

opening and closing,will go out when

stopped.

The output voltage is DC24V, and

the maximum current is :800mA.

Please choose the caution light

DC24V , ≤ 20W, and use the 2 ×

0.5mm

2

wire to connect

4.2.6 Battery backup

connection

The section 4-2-1 described the

connection of the battery backup.

Use the battery 24V, ≥ 3.6AH,the

wire cross-sectional area ≥

0.75mm2 × 2.

Please note“+, -” polarity, and fix by

the professional electrician.

4.2.7 Pedestrian mode

Set according to section4.3, when

the LED displays”0”,this function is

invalid. When the LED displays “1”, the

door will be opened to the 30cm position.

When it displays”2”,the door will be

opened to the 60cm position, and so

forth. When the LED displays ”9”,the

door will be approximately opened to

the 270cm position.

Attention:

Please choose the one-touch

switch.

Use the 2 × 0.4mm

2

plastic-covered cable to connect.

Page 25

25

4.3 Setting the function

Page 26

26

4.4 Hand transmitter coding

Press and hold „CODE‟ button over than 8 seconds, the LED dot lights up. And

then press “O/S/C” button on the transmitter, the LED goes out. Press “O/S/C” button

once again ,the LED fast flashed 8 times. The transmitter coding finished.

Auto reverse:

The gate will stop when obstacle during the opening.

The gate will reverse when obstacle during the closing.

Attention:

Press and hold “CODE”button until the LED dot lights up,all the transmitters

codes held in the memory will be erased.

This operator can learn at least 20 transmitters.

Page 27

27

5.1 Technical feature of sliding gate operator

Model

500KG

800KG

Model

500KG

800KG

Input

voltage

AC220~240V

AC220~240V

Caution light

connector

one group

one group

Working

voltage

DC24V

DC24V

Opening

edge safety

device

connector

one group

one group

Rated

Power

150W

180W

Closing edge

safety device

connector

one group

one group

Rated pull

force

210N

260N

Wireless

security

switch

connector

one group

one group

Rated

torque

7NM

10NM

Infrared

beam

connector

one group

one group

Max travel

speed

10M/MIN

10M/MIN

O/S/C

connector

one group

one group

Max

Opening

width

10M

10M

Auto reverse

YES

YES

Automatic

closing time

120S

120S

Soft start

YES

YES

Transmitter

frequency

433.92Hz

433.92 Hz

Soft stop

YES

YES

Page 28

28

6.1 FAQ

Error

Possible causes

Advised solution

No reaction on the operator.

1、 Power failure.

2、 Connecting wire loosen

between transformer

and main board.

※ 1 、 Check plug and power

supply.

※2、Loosen the four screws of

the control box on the

cover, re-fit the referent

plug.

Motor does not work, there is

“da da” sound inside the

motor, as well as the LED

displays“— —”.

The clutch is in the

disengaging state.

Engage the clutch.

Motor does not work, there is

no sound inside the motor, and

the LED displays“— —”.

Opening and closing limit

has not been set.

Reset the travel limit according to

the instruction.

Only opening allowed,and the

LED shows “— —”or ”r”.

The infrared beam function

is activated, but has not been

connected.

Enter the setting interface (P4→

HO), and close the function.(we

suggest to use the infrared beam)

Only opening allowed, and the

CDP light is off.

Has not connected the

wireless protector, and the

relevant terminal has not

been short circuited,or short

wires is loosen.

Installed the wireless protector or

shorten the two terminals “COM”

and “SAFE”.And now the CDP

light will be on.

Can not opened or closed,the

CEP or the OEP light is on .

1、 Did not connect the 8.2

kΩ reference resistor

when fixing the safety

device.

2、 The 8.2 kΩ reference

resistor loosen when the

safety device not

connected.

3、 Faulty wiring in safety

device.

1、 As required, connect an 8.2

kΩ reference resistor to the

far end of the safety device.

2、 Re-connect the 8.2 kΩ

reference resistor.

3、 Get rid of any open or shorted

faults of the safety device.

After setting the travel limit, in

the process of auto-learn ,the

motor stopped automatically,

as well as the LED shows “E”.

Has not installed the

reference point magnet or

the installation position is

out of place.

Re-install the reference point

magnet as required and ensure

that when the motor passed

through the reference point

magnet, the signal light will be

on.

Page 29

29

The motor exceed the travel

limit and not stop.

Reference point magnet

come off or dislocated.

Re-install the reference point

magnet as required and re-set the

travel limit.

Opening and closing turn

upside down.

The setting of the right hand

or left hand installation is

wrong.

Press the “SET” button until the

LED shows “P6”. And then

change the right hand and left

hand installation. Right hand

installation is “Lt”, right hand

installation is “rt” .

The gate can not be fully

closed but reversed 20cm.

Some obstacle in the gate.

1、 Remove the obstacle and try

again.

2、 Re-set the travel limit.

3、 Increase the auto-reverse

force.

Automatically stop during

opening.

Some obstacle in the gate

and the motor auto stop.

1、 Remove the obstacle and try

again.

2、 Re-set the travel limit.

3、 Increase the auto-reverse

force.

The motor stops automatically

after running few centimeters

in both opening and closing

cycle, the LED shows “H”.

1、 Hall sensor wires

loosen.

2、 Hall sensor damaged.

3、 Failure on circuit board.

※1、Re-plug Hall sensor wires.

※2、Check or replace Hall sensor

wires.

※ 3 、 Replace control circuit

board .

The hand transmitter is out of

use or has short remote control

distance.

1、 Battery has run out.

2、 Aerial goes off or has

not been stretched properly.

3、 Any radio interference

nearby.

1、 Replace battery.

2、 Check and stretch aerial.

3、 Eliminate source of

disturbance.

Hand transmitter can‟t be

learnt.

1、 Full memory in the

transmitter(The motor

can be learnt by 20

transmitters).

2、 The transmitter which

you used is not the one

supplied with the motor.

1、 Erase all memories and

re-coding ( Press “CODE”

button until the LED shows

“dL”).

2、 Use the transmitter we

supplied.

When re-engage after

releasing, limit movement

happened.

After re-engaging ,the

beginning of travel is not

synchronous.

Use the transmitter or wall

switch to open and close the

door for one cycle,then the

initial set travel limit will be

recovered automatically.

Page 30

30

The power restoration after

power failure , the limit

movement happened.

when power restoration,

the motor can not

distinguish the current

position.

Plesae make sure the clutch

is engaged . then use the

transmitter or wall switch to

open and close the door for

one cycle,then the initial set

travel limit will be recovered

automatically.

Note:

The Asterisk(※)solution should be finished by professional technician.

Loading...

Loading...