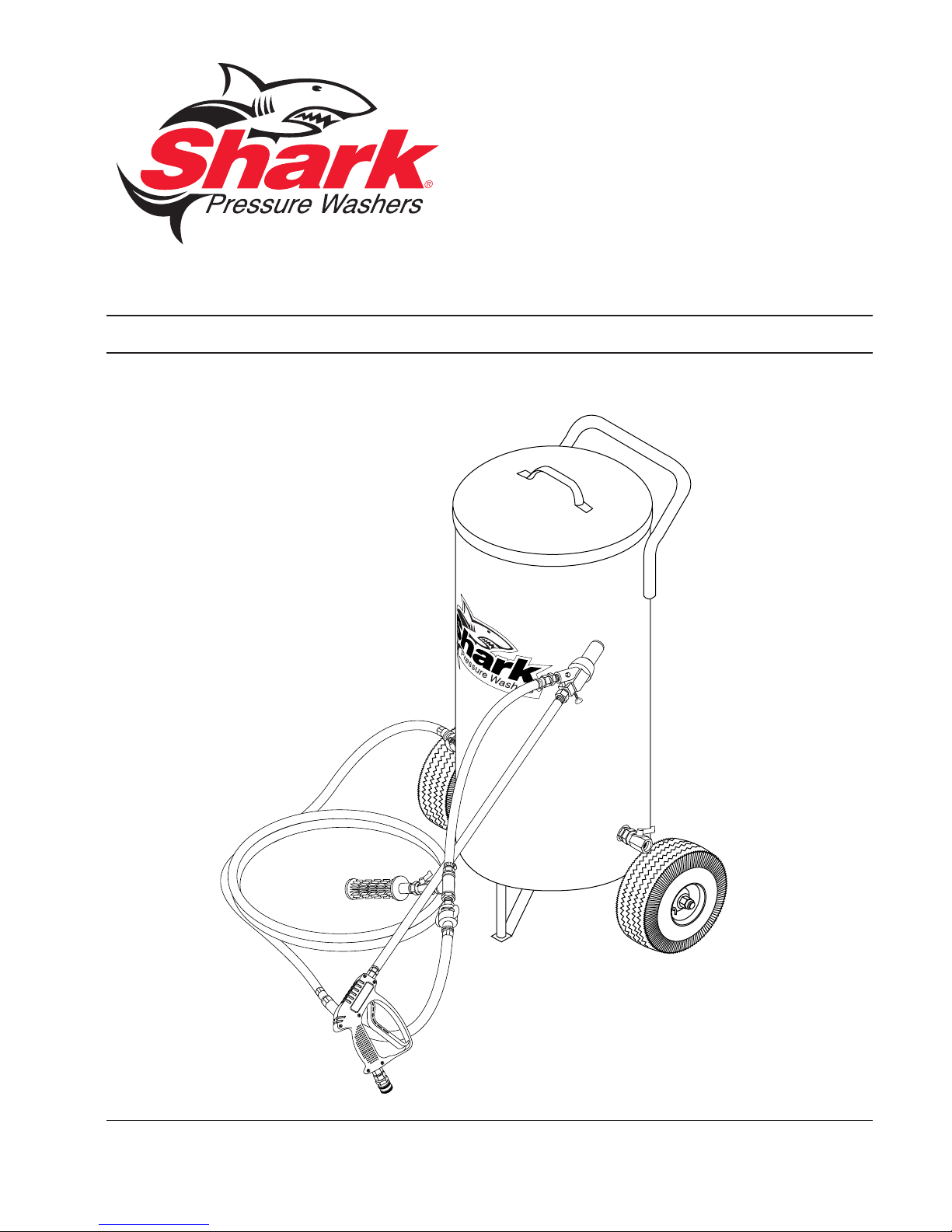

Page 1

SANDBLAST

SYSTEM

OPERATOR’S MANUAL

■■

■

4-011201S WITH POT - 2000/3500 PSI

■■

■ ■

■ 4-011211S WITH PROBE - 2000/3500 PSI

■ ■

For technical assistance or the SHARK dealer nearest you, call 1-800-771-1881

or visit our website at www.shark-pw.com

Page 2

2

CONTENTS

Introduction ................................................................................................................................... 3

Important Safety Information ......................................................................................................... 3

Operating Instructions ................................................................................................................... 3

General Operating Techniques...................................................................................................... 4

Sandblasting Material ................................................................................................................... 4

Component Identification .............................................................................................................. 5

Sandblaster, Exploded View, #4-011201, #4-011217 .................................................................... 6

Sandblaster, Exploded View, #4-011211, #4-011216 .................................................................... 7

Sandblaster Exploded View #4-011201, #4-011211, #4-011216, #4-011217, Parts List ............... 8

Troubleshooting ............................................................................................................................ 9

Warranty .....................................................................................................................................10

Model Number ______________________________

Serial Number ______________________________

Date of Purchase ____________________________

The model and serial numbers will be found on a decal attached to

the sandblast system. You should record both serial number and

date of purchase and keep in a safe place for future reference.

Sandblast System Manual • Form #97-612 • Revised 3/06

Page 3

SANDBLAST SYSTEM

WARNING

OPERATOR’S MANUAL

3

INTRODUCTION

Thank you for purchasing a Shark Sandblast System.

This manual covers the operation and maintenance of

the 4-011201S and 4-011211S systems. All information

in this manual is based on the latest product information

available at the time of printing.

Shark, Inc. reserves the right to make changes at any

time without incurring any obligation.

The Shark Sandblast System is designed to inject sand

into a stream of water created by a high pressure washer.

The pressure washer, in conjunction with the Sandblast

System, acts as a vacuum to draw the sand into a mixing chamber and propel it at a velocity sufficient to become abrasive to the surface being cleaned. Many types

of abrasive material can be used with a Shark

Sandblaster — sand, glass beads, walnut chips, lead

shot and more —making your sandblaster a versatile

unit for cleaning and etching most types of surfaces.

The Shark Water Sandblaster has benefits over other

methods of surface preparation. First, using water instead

of air, allows for more effective removal of rust from surfaces with cavities. Air impacts dust particles in the cavities, while water flushes all foreign material away. Water

does not create the dust and noise pollution generally

associated with air driven sandblasters.

Another advantage is the ability to use the pressure

washer to coat the surface being sandblasted with rust

inhibitors, leaving a rust free surface ready for painting.

Owner/User Responsibility:

The owner and/or user must have an understanding of

the manufacturer’s operating instructions and warnings

before using this Shark pressure washer. Warning information should be emphasized and understood. If the operator is not fluent in English, the manufacturer’s instructions and warnings shall be read to and discussed with

the operator in the operator’s native language by the purchaser/owner, making sure that the operator comprehends its contents.

Owner and/or user must study and maintain for future

reference the manufacturers’ instructions.

This manual should be considered a permanent

part of the machine and should remain with it if

machine is resold.

When ordering parts, please specify model and

serial number.

IMPORTANT SAFETY

INFORMATION

CAUTION

READ OPERATOR’S

MANUAL THOROUGHLY

PRIOR TO USE.

WARNING

USE PROTECTIVE

CLOTHING WHEN

OPERATING.

CAUTION: To reduce the risk of

injury, read operating instructions carefully before using.

1. Read the owner's manual thoroughly. Failure to follow instructions could cause malfunction

of the machine and result in

death, serious bodily injury and/

or property damage.

2. Eye safety devices must be

worn when using this equipment.

3. Never point sandblaster at any

part of your body.

4. Check your machine nozzle

size before using. The sandblast wand assembly comes

equipped with a 0° #6 nozzle.

OPERATING INSTRUCTIONS

1. Attach sand hose assembly to sand pot, or sand

probe (whichever is applicable) by pushing together,

then twisting air hose coupling. Attach other end of

sand hose to sand wand assembly.

2. Attach sand wand and spray gun to the pressure

washer hose using teflon tape on threads to prevent

leakage.

3. Fill sand pot or insert sand probe into abrasive material.

4. Turn on water supply and start pressure washer.

5. Open spray gun and spray water out of nozzle to

create a siphon to draw sand into mixing chamber.

Note: Valve on sand wand and sand pot must be

closed to draw sand.

6. The ball valve on the sand wand or ball valve on the

sand pot are for regulating the flow of air and sand.

Should flow of sand be erratic, open valve on pot or

wand to smooth the flow. When rinsing is needed,

open valve on sand wand to stop the flow of sand.

7. To control the flow amount of sand, adjust the ball

valve on the pot or the ball valve on the sand wand.

NOTE: During normal operation, the ball valve on

the sand wand should be closed and the sandpot air

ball valve should be slightly opened.

Shark Sandblast System • 97-612 • Rev. 3/06

Page 4

4

SANDBLAST SYSTEM

OPERATOR’S MANUAL

GENERAL OPERATING

TECHNIQUES

Use the correct size pressure washer with the

Sandblast System. The 4-011201S and 4-011211S

Sandblast System should be used with a pressure

washer rated at 4-6 gpm @ 2000-3500 psi. If the pressure washer being used requires a nozzle other than a

#6, replace it with a 0° 1/4" nozzle of the proper size.

Keep sand, sand hose, probe and pot dry. Wet sand will

not draw properly, causing clogs to form.

Proper size and type of abrasive is important. Silica sand

is the most universal type of abrasive. It is normally available in grits of 16 to 60 (30 being the most common).

Remember, the coarser the grit the quicker the job, however a coarse grit (such as #16) also leaves the most

pitted surface. For best results experiment with different

grits.

Any kind of sandblasting opens metal up to corrosion

and flash rusting. A rust inhibitor prevents or delays corrosion and should be applied shortly after using a hand

sprayer.

Begin blasting with the nozzle 12 to 18 inches away from

the work surface. For best results, adjust the distance

as required.

To conserve the amount of sand being used, you may

reduce the sand flow by opening the valve on either the

sand wand or the sand pot.

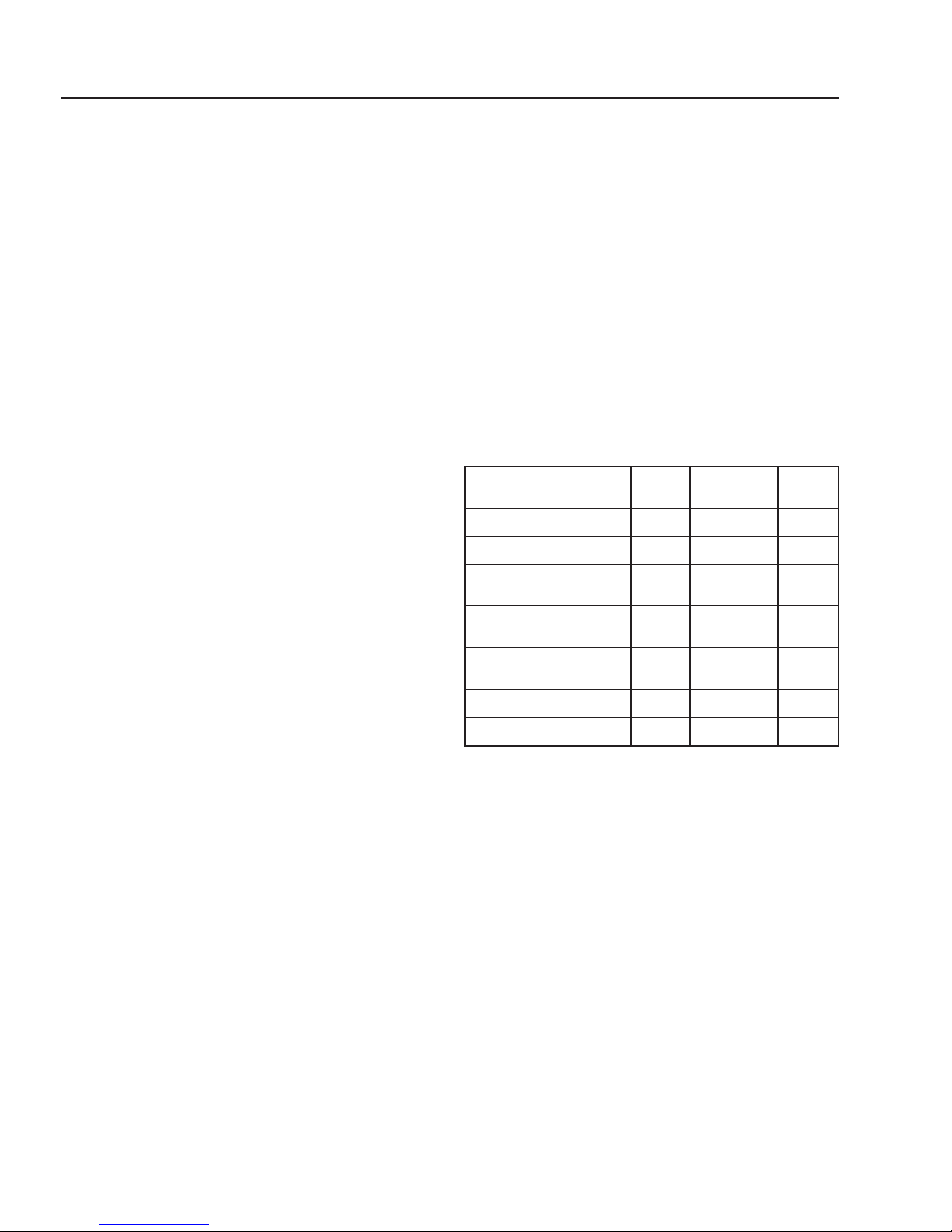

SANDBLASTING MATERIAL

Round Sand

A grain of sand with rounded edges. River sand is a good

example of sand worn to a rounded shape by water.

Angular Sand

Sand with angular shaped edges. Crushed rock or

crushed sand is usually of this type.

Blasting Angle and Distance

The blasting angle can affect the nozzle distance. For

best sandblasting performance, always maintain the recommended blasting angle and proper distance from your

work surface.

dnaS

:folavomeR

latemmorftniaP04/02aciliSdnuoR03-0

yrnosammorftniaP04/02aciliSdnuoR02-0

morftniapesabrebbuR

yrnosam

esraoc(doowmorftniaP

)tceffetuc-hguor

htooms(doowmorftniaP

)tceffedoowtfird

elacSlateM04/02dnuoR51-0

tsuR05/61ralugnA52-0

hseM

53/01ralugnA51-0

06/04dnuoR01-0

04/02dnuoR01-0

epyTdnaS

gnitsalB

elgnA

o

o

o

o

o

o

o

Sand Mesh

Sand mesh refers to the size of sieve through which a

particular grade of sand will pass. A 16/50 mesh means

that normally most of these particles will pass through a

#16 sieve and a very small percentage will pass through

a #50 sieve.

Note: A #16 sieve is a mesh that has sixteen

0.046 sq. in. (1.19mm) openings per inch.

Shark Sandblast System • 97-612 • Rev. 3/06

Page 5

SANDBLAST SYSTEM

COMPONENT IDENTIFICATION

SANDBLASTER WITH ACCESSORIES

Sand Hose Assembly

Sand

Pot Lid

OPERATOR’S MANUAL

Air Hose Coupling

5

Pressure

Washer

(not included)

Ball Valve

Sand Pot

Assembly

Mixing

Head

Sand Wand

Assembly

Sand Probe

Assembly

Carbide Sand

Nozzle

Mixing

Cone

Ball Valve

Bag of Sand

(not included)

Sand Hose

Assembly

High Pressure

Trigger Spray Gun

Shark Sandblast System • 97-612 • Rev. 3/06

High Pressure Hose

(not included)

Head Gear &

Face Shield

Page 6

6

SANDBLAST SYSTEM

SANDBLASTER #4-011201

EXPLODED VIEW

OPERATOR’S MANUAL

38

24

28

35

36

32

25

23

33

10

5

37

11

2

1

9

36

10

5

3

8

14

31

20

34

4

12

29

16

29

25

7

24

28

39

26

17

21

13

15

30

22

8

27

27

27

27

15

27

6

27

9

30

15

15

13

Shark Sandblast System • 97-612 • Rev. 3/06

Page 7

SANDBLAST SYSTEM

SANDBLASTER #4-011211

EXPLODED VIEW

OPERATOR’S MANUAL

7

38

10

11

2

1

9

8

36

10

14

5

3

5

37

31

32

36

34

4

16

21

17

33

35

20

12

8

18

39

26

Shark Sandblast System • 97-612 • Rev. 3/06

19

Page 8

8

SANDBLAST SYSTEM

OPERATOR’S MANUAL

SANDBLASTER #4-011201, #4-011211

EXPLODED VIEW PARTS LIST

ITEM PART NO. DESCRIPTION QTY

1 2-0016 Nipple, 3/4" x 5" 1

2 2-01101 Grip, Handle (Waffle) 1" 1

3 2-00681 Bushing, 1/2" x 3/8" Steel 1

4 2-0069 Adapter, 1/4" x 3/8" Steel 2

5 2-0088 Hose Barb, Steel, 3/4" x 1/2"

MPT 2

6 95-07161010 Sand Pot, Less Fittings 1

7 95-07161011 Lid, Complete, Sand Pot 1

8 2-21 Coupling, Air Hose, 3/8" Male

w/String Clip 4

9 2-3003 Valve, Ball, SMC, Brass, 3/4" 1

10 2-9004 Clamp, Screw, #12 2

11 4-02190000 Hose, Sand, Spiralite, 3/4" /in. 20

12 4-2002 Nozzle, Sand, Carbide,

Tungsten 1

13 90-2004 Nut, 5/8" Jam, ESNA, NF 2

14 95-07161125 Wand, Sand, Less Fittings 1

15 90-4005 Washer, 5/8" Flat, SAE 4

16 4-2015 Nozzle w/Brass Diffuser, 1/4" #6 1

4-01406000 Nozzle Only, 1/4" MEG-0006 1

95-07161130 Diffuser, Only, Brass 1

17 4-02199925 Hose, Sand, Spiralite 115, 25 ft.1

18 95-07161126 Probe, Sand, Less Fittings 1

ITEM PART NO. DESCRIPTION QTY

19 95-07161127 Cone, Sand Probe, Steel 1

20 2-9010 K-Head Gear 1

21 2-9011 K-Face Shield 1

22 11-0131 Label, Shark Logo 1

23 2-0027 Elbow 3/8" Female, Pipe 1

24 2-00575 Elbow, 3/8" STL, Street, 45° 2

25 2-0089 Push-on 3/8", Male, Pipe, Steel 2

26 2-2006 Nipple, 3/8" x 3/8" NPT Fem 1

27 2-11039 Connector, 3/8", Anchor 2

28 2-1108 Push-on, 3/8", Male, Pipe 2

29 4-02110000 Hose, 1/2" /ft. Push-on 2

30 4-0303 Wheel & Tire Assy 4" w/Tube 2

31 2-0124 Gasket, Rubber 1

32 89-8103131200 Sandblaster Head Assy.,

(includes items # 33, 34, 35, 36)1

33 89-8103190400 Mixing Head Only 1

34 89-8103190500 Tip Adaptor 1

35 89-8103190800 Thumb Screw 1

36 2-1009 Nipple, Hex, 3/4" 1

37 2-1081 Bushing, 3/4" x 1/2" 1

38 4-01212 Gun, Spray 1

39 2-2003 Coupler, 3/8" Male, Brass 1

Shark Sandblast System • 97-612 • Rev. 3/06

Page 9

SANDBLAST SYSTEM

OPERATOR’S MANUAL

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSES SOLUTION

9

NO SAND BEING

DRAWN INTO SYSTEM

LOW SAND FLOW

Plugged sand pot, probe or hose Remove obstruction.

Wet sand Use only dry sand.

Plugged spray nozzle Remove nozzle with 9/16" socket and clean.

Air leaks at hose connection Keep connections tight and in good repair.

Valve on wand open Close valve.

Cone or probe closed Turn cone to open position.

Sand probe not imbedded in sand Keep probe in sand.

Low water pressure Check pump and nozzle for improper operation.

Collapsed hose Replace hose or remove obstruction.

Clogged hose or probe Clear obstruction.

Air leaks at hose connections Keep connection tight.

Shark Sandblast System • 97-612 • Rev. 3/06

Page 10

SANDBLAST SYSTEM

OPERATOR’S MANUAL

10

ACCESSORIES AND PARTS WARRANTY

LIMITED MINIMUM 90 DAY WARRANTY

We warrant to the original consumer that each new part and accessory sold by SHARK will be free from manufacturing defects in

materials or workmanship in normal service for the duration specified by the original component manufacturer with a 90 day minimum from date of purchase, provided it is installed properly and the equipment is maintained in accordance with SHARK’S instructions and manuals.

Our obligation under this warranty is expressly limited as to the replacement or repair, at our option, at SHARK Inc., Camas,

Washington 98607, or at a service facility designated by us, for such part or parts as inspection shall disclose to have been

defective.

EXCLUSIONS:

This warranty does not apply to defects caused by casualty or unreasonable use, including faulty repairs by others and

failure to provide reasonable and necessary maintenance.

THE FOLLOWING ITEMS ARE NOT COVERED BY THIS WARRANTY:

1. Normal wear items, such as sand nozzles, quick disconnect, o-rings.

2. Damage or malfunction resulting from accidents, abuse, modification, alteration, misapplication, incorrect installation,

improper servicing, failure to follow manufacturer's instructions.

3. Freeze damage, chemical damage, rust, corrosion.

4. Transportation. Components must be delivered, freight prepaid, to Shark or to an authorized service center.

5. Field and direct labor charges

6. Freight damage.

WE SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OF ANY KIND,

including but not limited to labor costs or transportation charges in connection with the replacement or repair of defective parts.

ANY IMPLIED OR STATUTORY WARRANTIES, INCLUDING WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, ARE EXPRESSLY LIMITED TO THE DURATION OF THIS WRITTEN WARRANTY. We make no

other express warranty, nor is anyone authorized to make any on our behalf.

Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of incidental or

consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

TO OBTAIN WARRANTY SERVICE:

You must return product to an Authorized Dealership, freight prepaid, with proof of purchase, and be within the applicable

warranty period.

SHARK PRESSURE WASHERS

1-360-833-9100 • 1-800-771-1881 • www.shark-pw.com

Shark Sandblast System • 97-612 • Rev. 3/06

Page 11

Page 12

Form #97-612 • Revised 3/06 • Printed in U.S.A.

Loading...

Loading...