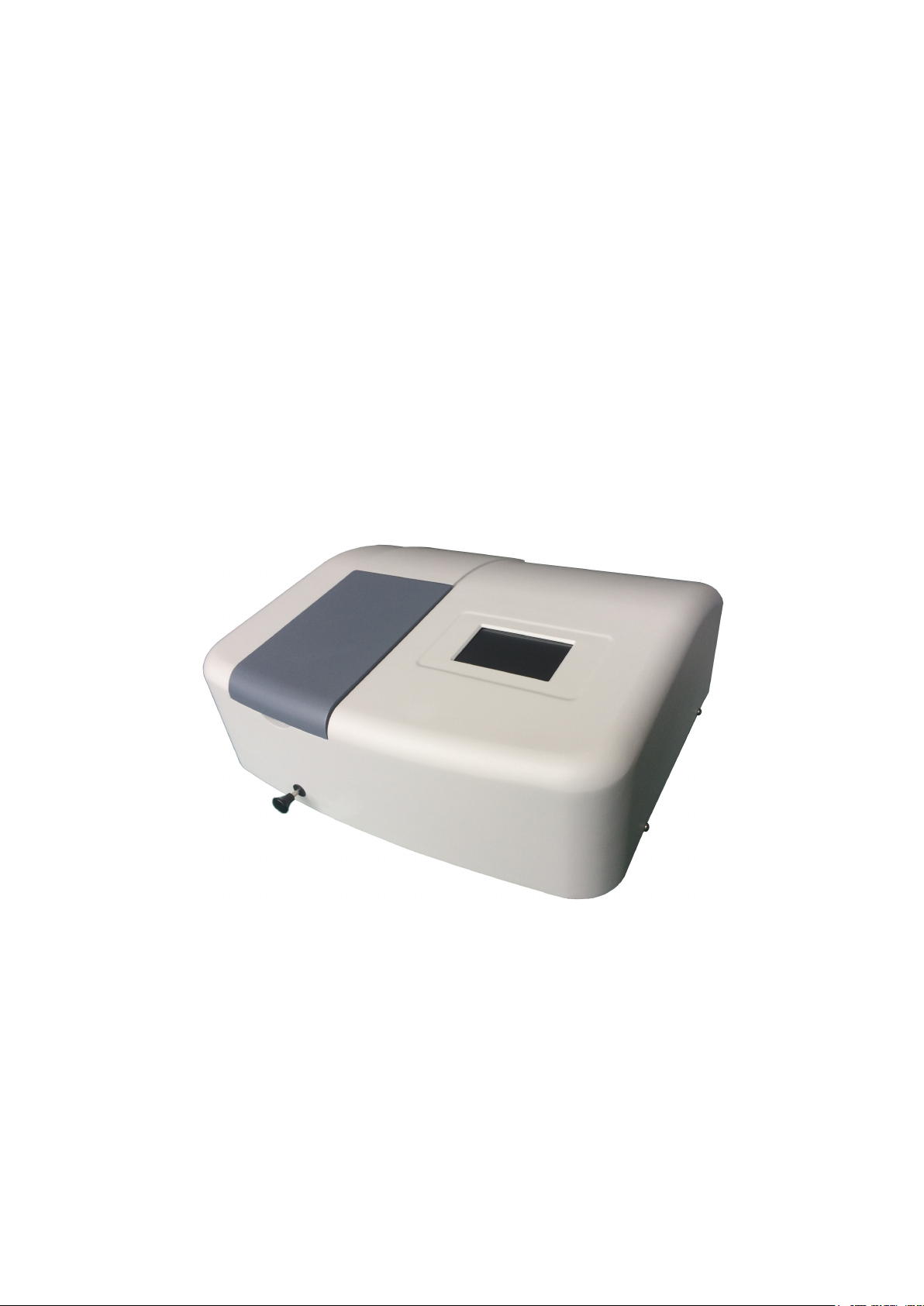

Shanghai Sunny Hengping Scientific Instrument Co., Ltd UV2000, UV2200, V2200, V2000 Instruction Manual

UV2200

V20

00

INSTRUCTION MANUAL FOR SPECTROPHOTOMETER

UV2000

V2200

Before operating the unit, please read this manual thoroughly and retain it

for future reference.

PREFACE

We are grateful for your purchase of our spectrophotometer.

This instrument is intended to be utilized for research, development,

quality control, etc. primarily in fields of optical materials,

semiconductors, new materials, electronics and so on through

qualitative and quantitative analyses of samples diverse in kind and

size.

This instrument is intended for purpose of photometric analysis. Do not

use it for any other purpose.

This instruction manual has been prepared for users of how to handle

this instrument.

This instrument is designed for use by persons having a basic

knowledge of chemical analysis. Other persons should operate the

instrument in presence of someone who has such basic knowledge.

Remember that improper use of this instrument, chemicals, or samples

would result not only in wrong analytical data but in consequences

adverse to safety.

It is requested to carefully read through this manual to enable using this

instrument properly for a long time.

For installation/maintenance of this instrument, read instruction manual

carefully to attain a full understanding of instructions. Be sure to

observe cautionary instructions. Keep this manual handy for easy

reference when necessary.

INTRODUCTION TO THIS INSTRUCTION MANUAL

This manual is made up of 5 sections: Product specifications; Outside

view and internal structure; Installation; Operation; Maintenance and

inspection.

This instruction manual describes operating instructions and

precautions for this spectrophotometer.

Before using this instrument, be sure to read through this

instruction manual. First of all, read “SAFETY SUMMARY” included

at beginning of this manual for ensuring safety in operation of

spectrophotometer mainframe.

AFTER-SALES SERVICE

After-sales service For after-sales service of the instrument, contact local sales

representative. For ordering a replacement part, its name and number

need be specified.

Before using this manual,

keep the following in mind.

2. If the instrument incurs damage due to usage contrary to one

3. This manual is neither for warranting enforcement of industrial

Caution: Contents of this instruction manual are subject to change

1. No part of this publication may be transmitted or reproduced in

any form or by any means without prior written permission of

Publisher.

instructed in this manual, manufacturer will not take any

responsibility. So customer must operate the instrument in

correct way.

property rights and other rights nor for assenting to license of

enforcement.

without prior notice for further improvement of the

product, etc.

IMPORTANT

1. PRECAUTIONS ON ELECTROMAGNETIC WAVE INTERFERENCE

1.1 Possible electromagnetic wave interference caused by this instrument

When this instrument is used a residential area or an adjacent area

thereto, it may cause interference to radio and television reception.

To prevent this, use specified system connection cables in strict

accordance with the instrument manual. The instrument is designed to

minimize possible electromagnetic wave interference caused by it if

specified cables are connected properly.

However, there is no guarantee that electromagnetic wave interference

will not be caused by the instrument. If the instrument does cause

interference to radio or television reception, which can be determined

by turning off and on the instrument, user is encouraged to try to correct

interference by one or more of following measures:

● Increase separation between the instrument and radio/TV

receiver.

● Connect the instrument to an outlet on a circuit different from that

to which radio/TV receiver is connected.

1.2 Possible electromagnetic wave interference affecting by this instrument

If this instrument is used near an intense electromagnetic source,

interference noise may be given to the instrument to incur an adverse

effect on its performance or functionality.

To prevent this, use specified system connection cables in strict

accordance with instruction manual. The instrument is designed to

minimize possible electromagnetic wave interference affecting it if

specified cables are connected properly.

However, there is no guarantee that electromagnetic wave interference

will not occur in this instrument. If the instrument does occur

electromagnetic wave interference, which can be determined by turning

on and off possible sources of electromagnetic wave interference

nearby, user is encouraged to try to correct interference by one or more

of following measures:

● Reorient the instrument.

● Increase separation between the instrument and possible

sources of electromagnetic wave interference.

● Increase separation between power cable of the instrument and

possible sources of electromagnetic wave interference.

● Connect the instrument to an outlet on a circuit different from that

to which possible sources of electromagnetic wave interference

are connected.

● Confirm that any other device connected with the instrument is

not affected by electromagnetic wave interference.

IMPORTANT –

1

2. WARRANTY ON PRODUCT

This instrument is warranted to operate according to specifications

given in instruction manual, provided it is used in accordance with

instructions described in manual.

(1) Scope of Warranty

(a) Any parts which prove to be defective in design or

workmanship during warranty period will be repaired

without charge.

(b) A substitute part may be used for repair, or replacement

with an equivalent product may be made instead of repair.

(c) Such system components as a personal computer and

printer to be updated frequently for improvement may not

be available in original versions at time of replacement.

(2) Warranty Period

One year from date of initial delivery.

Consumables such as tungsten lamp and Deuterium lamps are

excluded from warranty.

(3) Availability of Technical Support Service

Technical support service for this instrument is available within

regular working hours on workdays predetermined by us.

(4) Limitations and Exclusions on Warranty

Note that this warranty is void in the following cases, even if they

occur within warranty period.

(a) Failure due to operation at a place not meeting

installation requirements specified by us.

(b) Failure due to power supply voltage/frequency other than

specified by us or due to abnormality in power supply.

(c) Corrosion or deterioration of the tubing due to impurities

contained in reagent, gas, air or cooling water supplied by

the user.

(d) Corrosion of electric circuits or deterioration of optical

elements due to highly corrosive atmospheric gas.

(e) Failure due to use of hardware, software or spare parts

other than supplied by us.

(f) Failure due to improper handling or maintenance by user.

(g) Failure due to maintenance or repair by a service agent

not approved or authorized by us.

(h) After disposal of this instrument, or after its resale without

our approval.

(i) Consumables, and failure of parts that have reached the

end of specified useful life.

(j) Failure of parts excluded from warranty in instruction

manual or other documents.

(k) Failure due to acts of God, including fire, earthquake,

storm, lightning, social disturbance, riot, crime,

insurrection, war (declared or undeclared), radioactive

pollution, contamination with harmful substances, etc.

(l) Failure of the hardware, or damage to system software,

application software, data or hard disk due to computer

virus infection.

IMPORTANT –

2

(m) Failure of personal computer connected with instrument,

or damaged to system software, application software,

data or hard disk due to power interruption or momentary

power voltage drop caused by lightning or the like.

(n) Failure of personal computer connected with instrument,

or damage to the system software, application software,

data or hard disk due to disconnection of main power to

personal computer without taking specified normal

shutdown procedure.

(5) Disclaimer of Warranty

(a) Any express warranties other than explicit conditions

indicated in (1) are excluded from this warranty.

Any other implied warranties of merchantability and

fitness for a particular purpose are not included in this

warranty.

No liability is assumed for direct or indirect damages

arising out of explicit or implied warranties.

(b) Oral or written information or advice given by our dealers,

distributors, agents or employees without our express

permission shall not create a warranty or in any way

increase the scope of this warranty.

3. OTHER PRECAUTIONS

3.1 Handling of chemicals and samples

(1) User is responsible for following relevant legal standards and

regulations in handling, storage and discarding of chemicals and

samples used in analytical operations of this instrument.

(2) Reagents, standard solutions and accuracy – control samples

shall be handled, stored and discarded as instructed by

respective supplies.

3.2 Notice on instruction manuals

(1) Information contained in instruction manuals furnished with the

instrument is subjected to change without notice for product

improvement.

(2) This manual is copyrighted by our company with all rights

reserved.

(3) No part of this manual may be reproduced or transmitted in any

form or by any means without our express written permission.

3.3 Trademark Acknowledgements

Microsoft, Windows, Microsoft Excel, Microsoft Word and Windows XP,

Windows 7, Windows 8 and Windows 10 are registered trademarks,

trademarks or trade names of Microsoft Corporation, USA, while other

company names and product names are those of respective

companies.

IMPORTANT –

3

SAFETY SUMMARY

PRECAUTIONS ON SAFETY

GENERAL SAFETY GUIDELINES

Before using this spectrophotometer, be sure to read following safety

instructions carefully.

NOTICE:

NOTE:

● Follow all operating procedures provided in this manual.

● Maintenance of the product shall be carried out by qualified

service personnel therefore.

● Be sure to observe warnings indicated on product and in

instruction manual. Failure to do so could result in personal injury

or damage to the product.

● The hazard warnings which appear on warning labels on the

product or in manual have one of the following alert headings

consisting of an alert symbol and signal word WARNING and

CAUTION.

“NOTICE” and “Note” are heading words which do not concern

personal safety directly.

● Do not modify the product, replace parts that are not user –

serviceable, use non – specified parts, nor remove safety

devices, as it could be hazardous.

● Maintenance should be referred to our qualified service

personnel.

● Do not perform any operation or action other than described in

the instruction manual. When it doubt, please contact our sales

representative or service office nearest you.

WARNING :

CAUTION :

Used to indicate an instruction for preventing damage to

the product.

Used to indicate an instruction for ensuring correct use of

the product and accurate analysis therewith.

Indicates a potentially hazardous situation

which, if not avoided, can result in death or

serious injury.

Indicates a hazardous situation which, if not

avoided, will or can result in minor or moderate

injury, or serious damage to the product.

SAFETY –

1

SAFETY SUMMARY

GENERAL SAFETY GUIDELINES (Con’d)

● When using a chemical for analytical operation, be sure to

provide proper ventilation in the laboratory room as per local

requirements. Inadequate ventilation could endanger human

● Keep in mind that the hazard warning in manual or on the

product cannot cover every possible case, as it is impossible to

predict and evaluate circumstances beforehand.

Be alert and use your common sense.

WARNING

● Electric Shock in Contact with Dangerous High Voltage.

● Electric Shock in Contact with Dangerous High Voltage.

This instruction manual contains the following cautious instructions.

In contact with power supply voltage, you may receive an electric

shock to cause fatal or serious injury.

Before connecting power cord, make sure that the uint is turned

off.

In contact with Deuterium lamp power supply voltage (120 V),

you may receive an electric shock to cause fatal or serious injury.

Before connecting Deuterium lamp power cord, make sure that

the unit is turned off.

CAUTION

● Burn in Contact with High Temperature

Deuterium lamp and tungsten lamp reach a high temperature.

They can burn you if touched.

Before replacing or adjusting lamp, turn off the unit and wait until

it cools down sufficiently.

● Fatigue on Long Use

Watching the screen in the same posture for a long time

accumulates fatigue in your eyes or body. For long use, take a 10

to 15 minutes recess every hour for your health.

● Oxygen Deficiency due to Presence of Nitrogen

(when using Ultra Violet region measurement system)

If nitrogen purging is carried out for long hours in a narrow room

without operating an exhaust duct, oxygen concentration in room

will decrease and an oxygen deficiency could result.

Be sure to operate an exhaust duct or else open a window during

purge for ventilation purposes.

SAFETY –

2

SAFETY SUMMARY

REMARKS ON SAFETY OF SPECTROPHOTOMETER

Electricity

(1) Confirm power supply to spectrophotometer.

Fluctuation in voltage or noise on power line would not only affect spectrophotometer mainframe

adversely but also cause an accident.

(2) Be sure to provide grounding connection along with power connection.

(3) High – voltage circuits are used inside spectrophotometer. Do not open any other cover than

necessary for operation.

Fire

Avoid smoking and using a fire in the vicinity of spectrophotometer.

Data Backup

Data may become unusable in case of instrument failure or misoperation.

It is recommended to transfer data from hard disk to a flash disk periodically. Transfer of data is called

backup.

To avoid misoperation, secure a free space of 100MB or so on the hard disk as a software word area at

all times.

Computer Virus

If programs or data has suddenly been destroyed, if an unexpected operation takes place or if an

abnormal display appears on screen, your personal computer may have been infiltrated by a computer

virus. Computer virus is a rogue program that secretly invades a personal computer and operates it

willfully while destroying memorized data.

A program for eliminating the virus is called vaccine program.

There is a possibility of contamination with a program including a computer virus, or by using an

exchangeable recording medium such as a flash disk that contains a computer virus. Also, it is possible

to transmit the virus from one personal computer to another via communication or recording media. So

avoid using a program or recording medium that might include a virus.

Carry out check using a vaccine program if there is a possibility of contamination with a virus. But

depending on type of vaccine program, it may be impossible to eliminate virus.

It is therefore recommended to back up contents of hard disk beforehand.

Power Failure

A power failure or momentary voltage drop of power supply due to lighting, etc. may cause failure of

personal computer used with the instrument and also damages system software, application software

and other data. To avoid such problems, it is recommended to use an AC uninterruptible power

source.

Personal Computer (PC)

Do not t urn off PC power supply alone. If PC power supply is turned off during access to hard disk or

flash disk, PC may be damaged and data or software stored in it may be destroyed. To turn off PC

power supply, be sure to complete spectrophotometer control and data processing program before

taking shutdown procedure for system software.

SAFETY –

3

PRECAUTIONS ON HANDLING

1. CAUTION ON SAFETY

Be sure to entrust internal checks of the instrument to a serviceman for

ensuring safety.

Do not gaze at light source (Tungsten and Deuterium lamps) directly.

Particular attention must be paid to Deuterium lamp because it radiates

intense ultraviolet rays.

2. CAUTION ON USE

Optical parts are fragile. Besides, control and data processing sections

comprise high – density electronics. Therefore, precautions below must

be taken without fail.

(1) Avoid giving shock or vibration to optical parts. Do not breathe

on optical parts or touch them with bare hands.

(2) For removing dust from optical parts, blow it off by using a hand

sprayer which jets out clean dry air. Do not wipe them with a

cloth or the like.

(3) The operating temperature must be within 50C to 350C.

However, optimum condition is restricted to a range to 200C to 250C.

Hence, installation in an air – conditioned room is recommended.

(4) Operating humidity must be within 45 to 85%.

(5) Atmosphere must not be filled with acidic, alkaline or other

metal-corroding vapor.

(6) Avoid a location filled with vapor of organic solvent (particularly

benzine and thinner).

(7) Avoid direct sunlight. (Otherwise optical performance might

deteriorate. Do not locate the instrument near a window

whenever possible.)

(8) Do not allow strong vibrations nor shocks beyond a level which

can be sensed by the human body. (Otherwise delicate

adjustment mechanism might run out of order.)

(9) Protect the instrument cover from excessive heat (beyond

700C) radiated form a gas burner, heater, oven or the like.

(10) The instrument must be located away from equipment which

generates a strong electric field (such as an electric welding

machine, high-frequency electric furnace and pole transformer).

(11) Dusty environment is unallowable. (Otherwise adequate optical

performance might not be ensured.)

(12) Line voltage must not fluctuate suddenly (otherwise noise might

increase). Its fluctuation must be within ±10%.

(13) Do not turn on/off frequently power supply to a motor (stirrer,

vibrator, etc.) without a noise - preventive device in same power

line as the instrument’s.

(14) The installation plane must be level and capable of bearing a

weight of about 25Kg or more.

(15) Minimum power requirements are 90VA. But a higher power

capacity (1KVA or more) must be prepared in order to allow

another instrument to share power line.

(16) Fluctuation of power frequency must be within +0.3 to –1.0% of

rated frequency (50 or 60 Hz).

– – - 1 -

3. CAUTION ON STORAGE OF INSTRUMENT

3.1 Checks upon Completion of Measurement

(1) Turn off the unit and disconnect power from line power outlet.

(2) Contamination of the sample compartment is inevitable. There

might be a chance of an undesired trouble occurring due to

ingress of foreign material or dust. To prevent this, check sample

compartment for contamination as frequently as possible.

(3) Take off cell holder component, and clean it.

Loosen cell holder handle with anticlockwise, and pull it out.

Open sample compartment cover. Loosen 2 pcs of M4 Screws

which are used to fix cell holder component, you can take off cell

holder component.

To mount cell holder component, please set wavelength value to

546.0 nm, and there is a light beam with bright green color in

sample compartment. Be sure the green light beam must enter

into the middle aperture of cell holder, and you can mount cell

holder component with 2 pcs of M4 screws.

(4)

(5) Put dust-preventive cover or a protective sheet of a proper size

Caution: In case an organic solvent is placed in sample

3.2 Precautions for Long-Term Storage

(1) Protect the instrument from high temperature (700C or higher),

(2) Be sure to put dust-preventive cover or a sheet cover on the

(3) Protect the instrument interior from acidic, alkaline or other

(4) Avoid a location under a strong magnetic field.

(5) A dusty location is inappropriate for storage.

(6) During storage, the instrument must be free from direct sunlight.

Cleaning of lenses

For cleaning, wipe lenses with soft paper or cloth using a 1:1

mixture of alcohol and ether.

First of all, your hands must be clean.

on the instrument.

compartment, it must be taken out of compartment.

Never leave it inside.

Wash the rectangular sample cells with

petroleum-ether, dry them with gently paper and

then put them into the colorimetric box after using.

low temperature (-200C or lower), high humidity (80% or higher),

and strong vibrations throughout storage.

instrument.

harmful gases.

– – - 2 -

Table of Contents

9

10

10

11

Section Title Page

1 Product specifications······································································ 1

1.1 Technical specifications···································································· 1

1.2 Standard configurations···································································· 1

1.3 UV-Solution software (Optional) ························································· 1

2 OUTSIDE VIEW AND INTERNAL STRUCTURE······································ 2

2.1 Front – right view·············································································· 2

2.2 Rear view························································································· 2

2.3 Internal structure·············································································· 3

2.3.1 Internal structure of VIS spectrophotometer·············································· 3

2.3.2 Internal structure of UV-VIS spectrophotometer········································· 3

2.4 Optics schematic diagrams································································ 4

2.4.1 Optics schematic diagrams of VIS spectrophotometer································ 4

2.4.2

3 INSTALLATION················································································· 5

3.1 Power requirements·········································································· 5

3.1.1 Line voltage······················································································· 5

3.1.2 Frequency························································································· 5

3.1.3 Power capacity··················································································· 5

3.2 Conditions for installation·································································· 5

3.2.1 Installation area·················································································· 5

3.2.2 Installation plane················································································· 5

3.2.3 Environment at place for installation························································ 5

3.3 Check of contents············································································· 6

3.3.1 Check of packing················································································ 6

3.3.2 Check against standard configurations···················································· 6

3.4 Connection of power cord·································································· 6

3.5 Check after installation······································································ 6

3.6 Initialization····················································································· 6

3.6.1 Description of item to be tested······························································ 7

3.6.2

3.6.3

4 OPERATION····················································································· 9

4.1 Function of each key on main interface················································

4.2 Absorbance measurement mode·························································

4.2.1 Testing directly without measurement data list···········································

4.2.1.1 Setting wavelength value······································································ 10

4.2.1.2 Blanking (Adjusting 0.000Abs) ······························································ 10

4.2.1.3 Testing······························································································ 10

4.2.2 Testing with measurement data list························································· 10

4.2.2.1 Setting wavelength value······································································ 10

4.2.2.2 Blanking (Adjusting 0.000Abs) ······························································ 10

4.2.2.3 Testing······························································································ 11

4.2.2.4 Clearing all data··················································································

Optics schematic diagrams of UV-VIS spectrophotometer···························

Initializing interface·············································································

Main interface·····················································································

4

7

8

i

Table of Contents

11

18

(cont’d)

Section Title Page

4.3 Transmittance measurement mode······················································ 11

4.3.1

4.3.1.1

4.3.1.2

4.3.1.3

4.3.2

4.3.2.1

4.3.2.2

4.3.2.3

4.3.2.4

4.4 Coefficient method············································································ 13

4.4.1

4.4.1.1

4.4.1.2

4.4.1.3

4.4.1.4

4.4.2

4.4.2.1

4.4.2.2

4.4.2.3 Inputting known concentration value·······················································

4.4.2.4

4.4.3 Setting coefficient curve with known coefficient value·································

4.4.3.1

4.4.3.2 Saving coefficient curve······································································· 16

4.4.3.3

4.4.4

4.4.4.1

4.4.4.2

4.4.4.2.1

4.4.4.2.1.1

4.4.4.2.1.2

4.4.4.2.1.3

4.4.4.2.2

4.4.4.2.2.1

4.4.4.2.2.2

4.4.4.2.2.3 Blanking (Adjusting 0.000Abs) ······························································ 19

4.4.4.2.2.4

4.4.4.2.2.5 Clearing all data················································································· 19

Testing directly without measurement data list···········································

Setting wavelength value······································································

Blanking (Adjusting 100.0%T) ·······························································

Testing······························································································

Testing with measurement data list·························································

Setting wavelength value······································································

Blanking (Adjusting 100.0%T) ·······························································

Testing······························································································

Clearing all data··················································································

Reading concentration value directly·······················································

Setting wavelength value·····································································

Blanking (Adjusting 0.000A) ·································································

Inputting known concentration value·······················································

Reading unknown sample concentration value directly·······························

Testing concentration factor “K” with known concentration value···················

Setting wavelength value······································································

Blanking (Adjusting 0.000A) ·································································

Getting concentration factor “K” with known concentration value···················

Setting coefficient value·······································································

Clearing all coefficient curve·································································

Testing with coefficient curve································································

Opening coefficient curve·····································································

Testing······························································································

Testing directly without measurement data list···········································

Setting wavelength value······································································

Blanking (Adjusting 0.000A) ·································································

Testing······························································································

Testing with measurement data list·························································

Selecting concentration unit·································································

Setting wavelength value······································································

Testing·····························································································

ii

11

11

11

12

12

12

12

12

13

13

14

14

14

15

15

15

15

16

16

16

17

17

17

18

18

18

18

19

19

19

19

Table of Contents

24

28

(cont’d)

Section Title Page

4.5 Standard curve method······································································ 19

4.5.1

4.5.1.1

4.5.1.2

4.5.1.3

4.5.1.4

4.5.1.5

4.5.1.6

4.5.1.7 Displaying standard curve···································································· 23

4.5.1.8

4.5.1.9

4.5.1.10 Clearing all standard curve····································································

4.5.2

4.5.2.1

4.5.2.2 Entering measurement data list of standard curve·····································

4.5.2.3

4.5.2.4

4.5.2.5

4.5.2.6

4.5.2.7

4.6 Option····························································································· 27

4.6.1

4.6.1.1

4.6.1.2

4.6.1.3

4.6.1.4

4.6.1.5

4.6.2

4.6.2.1

4.6.2.2

4.6.2.3

4.6.2.4

4.6.2.5

4.6.2.6

5

5.1 Message during initialization······························································ 29

5.2 Troubleshooting guide······································································· 31

5.3 Replace lamp and fuse······································································ 33

5.3.1 Replacement of deuterium lamp···························································· 33

5.3.2

5.3.3 Replacement o f fuse·········································································· 35

Creating standard curve·······································································

Selecting concentration unit··································································

Setting wavelength value······································································

Inputting concentration value of standard sample·······································

Inputting standard sample name····························································

Blanking (Adjusting 0.000Abs) ······························································

Getting absorbance value of standard sample···········································

Revising standard sample information·····················································

Saving standard curve·········································································

Testing with standard curve···································································

Opening standard curve·······································································

Setting wavelength value······································································

Blanking (Adjusting 0.000A) ·································································

Testing······························································································

Inputting unknown sample name····························································

Clearing all data·················································································

Option of VIS spectrophotometer···························································

Operation version···············································································

Date and time····················································································

Initialize machine················································································

Default setting····················································································

Language··························································································

Option of UV-VIS spectrophotometer·······················································

Operation version···············································································

Date and time····················································································

Initialize machine················································································

Default setting····················································································

Language··························································································

Lamp switch wavelength······································································

MAINTENANCE AND INSPECTION······················································

Replacement of tungsten lamp······························································

21

21

21

21

22

22

22

23

23

24

24

25

25

25

25

26

26

27

27

27

27

27

27

28

28

28

28

28

28

29

34

iii

Model V2000 V2200 UV2000 UV2200

10% 60Hz 90VA

V2000 V2200 UV2000 UV2200

V2000 V

2200 UV2000 UV2200

10% 50Hz 90VA / 110V

1

10% 60Hz 75VA 220V

10% 50Hz 75VA / 110V

1. Product specifications

1.1 Technical specifications

Monochromator C-T type, 1200 L/mm grating

Detector Silicon detector

Display 4.3” color LCD, touch screen

Wavelength calibration Automatic at start

Wavelength display 0.1 nm

Light source Tungsten lamp(2000h, 20W/12V) Deuterium discharge tube(1000h), Tungsten lamp(2000h, 20W/12V)

Lamp change point / Can be set, 294 nm - 365 nm

Wavelength range 325-1100 nm 200-1100 nm

Slit width 4 nm 2 nm 4 nm 2 nm

Wavelength accuracy ±2.0 nm ±1.5 nm ±2.0 nm ±1.5 nm

Wavelength repeatability 1.0 nm 0.8 nm 1.0 nm 0.8 nm

Measurement range 0 ~ 200%T, -0.301 ~ 3.000Abs, -9999 ~ 9999C, -9999 ~ 9999F

Photometric accuracy ±0.5 %T ±0.3 %T ±0.5 %T ±0.3 %T

Photometric repeatability 0.2 %T 0.2 %T 0.2 %T 0.2 %T

Stray light 0.5 %T (at 360 nm) 0.3 %T (at 360 nm) 0.5 %T (at 220nm and 360 nm) 0.3 %T (at 220nm and 360 nm)

Baseline flatness / ≤±0.004 Abs (With UV-Solution) / ≤±0.004 Abs (With UV-Solution)

Stability ≤0.002 Abs / half hour (at 500 nm, after 2 hours energization)

Data output Digital, USB port

Power 220V

Standard sample holder 4-position sample holder

Actual dimensions 470 W X 380 D X 225 H mm, (18.6 W x 15.0 D x 8.9 H in)

Shipping dimensions 650 W X 539 D X 370 H mm, (25.6 W x 21.3 D x 14.6 H in)

Net weight 10.0 Kg (22.0 lbs) 10.0 Kg (22.0 lbs) 10.5 Kg (23.1 lbs) 10.5 Kg (23.1 lbs)

Gross weight 14.0 Kg (30.8 lbs) 14.0 Kg (30.8 lbs) 14.5 Kg (31.9 lbs) 14.5 Kg (31.9 lbs)

1.2 Standard configurations (“●” means this item is standard configurations; “/” means this item is not standard configurations)

Item Quantity

Instrument 1 ● ● ● ●

Power cord 1 ● ● ● ●

Quartz cell (10 mm path length) 2 / / ● ●

Glass cell (10 mm path length) 4 ● ● ● ●

Fuse 2 ● ● ● ●

Instruction manual for instrument 1 ● ● ● ●

1.3 UV-Solution software (Optional) (“●” means this item can be configured with this instrument; “/” means this item cannot be configured with this instrument)

Item Quantity

UV-Solution Software disk 1 / ● / ●

Instruction manual for software 1 / ● / ●

USB cable 1 / ● / ●

Watch dog 1 / ● / ●

Loading...

Loading...