Shandong New Beiyang Information Technology Co., ltd. BT-T080 Plus Service Manual

SERVICE MANUAL

Embedded Printer

BT-T080 Plus

Shandong New Beiyang Information Technology Co., ltd.

BT-T080 Plus Service Manual

- 1 -

Revision History

Date Version Description Author

2017-6-20 V1.0 Initial version.

Li Lingang

Wang Xinping

Wang Junxian

Chen Yi

BT-T080 Plus Service Manual

- 2 -

Declaration

This manual is special for embedded printer BT-T080 plus and it is not allowed to be modified without

permission. Shandong New Beiyang Information Technology Co., Ltd. (hereinafter referred to as “SNBC”)

reserves the right to improve products as new technology, components, software, and firmware available. If

users need the further data about these products, please feel free to contact SNBC or our distributors.

No part of this document may be reproduced or transmitted in any form or by any means, electronic or

mechanical, for any purpose without the express written permission of SNBC.

Copyright

Copyright © 2017 by SNBC.

Printed in China.

Version 1.0.

Trademark

Our registered trademark:

SNBC has been approved by following certifications:

ISO9001 Quality Control System Certification

ISO14001 Environmental Management System Certification

OHSAS18001 Occupational Health and Safety Management System Certification

IECQ QC 080000 Hazardous Substance Process Management System Certification

Contact us:

Address: No.169 huoju road, high-tech zone, Weihai, China

Hot line: 400-618-1368 800-860-1368

Fax: +86-631-5656098

PC: 264209

Website: www.snbc.cn

BT-T080 Plus Service Manual

- 3 -

Notes

1) Follow the steps in this manual hereafter during maintenance.

2) Make sure that the printer and the computer are turned off before plugging the communication cable,

changing print head or doing maintenance to the printer.

3) Take anti- static measures, when replace print head or other electronic components.

4) Time between turning on and turning off the printer is no less than 20 seconds.

5) Do not allow the printer to print when there is no paper loading, otherwise the print head and platen

roller will be damaged.

6) Set the printing darkness in a lower grade as long as the print quality is acceptable. This will help to

keep the print head durable.

BT-T080 Plus Service Manual

- 4 -

Content

1 Printer characteristics .......................................................................................................................... - 1 -

1.1 Function .............................................................................................................................................- 1 -

1.2 Appearance and components .............................................................................................................-

1 -

1.3 Performance index .............................................................................................................................-

2 -

1.3.1 Print specification ...................................................................................................................... - 2 -

1.3.2 Cut mode .................................................................................................................................. - 2 -

1.3.3 Status detection ........................................................................................................................ - 2 -

1.3.4 Sensor position ......................................................................................................................... - 2 -

1.3.5 Paper specification ................................................................................................................... - 3 -

1.3.6 Lable paper specification .......................................................................................................... - 4 -

1.3.7 Print area .................................................................................................................................. - 5 -

1.3.8 Print and cut position ................................................................................................................ - 5 -

1.3.9 Power supply voltage ................................................................................................................ - 5 -

1.3.10 Reliability .................................................................................................................................. - 6 -

2 Whole printer and components ............................................................................................................ - 7 -

2.1 Printer overview ..................................................................................................................................-

7 -

2.2 Main control board module connecting diagram .................................................................................-

7 -

3 Disassembly and assembly .................................................................................................................. - 8 -

3.1 Disassemble the printer ......................................................................................................................- 8 -

3.1.1 Disassemble the print unit ......................................................................................................... - 8 -

3.1.2 Disassemble the print head .................................................................................................... - 13 -

3.1.3 Disassemble the paper feeding path module .......................................................................... - 14 -

3.2 Assemble the print unit ..................................................................................................................... -

15 -

4 Replacement and maintenance of key parts ..................................................................................... - 16 -

4.1 Print head maintenance and replacement ........................................................................................ - 16 -

4.1.1 Print head maintenance .......................................................................................................... - 16 -

4.1.2 Print head replacement ........................................................................................................... - 16 -

BT-T080 Plus Service Manual

- 5 -

4.1.3 Caution ................................................................................................................................... - 16 -

4.2 Platen roller maintenance and replacement ..................................................................................... -

16 -

4.2.1 Platen roller maintenance ....................................................................................................... - 16 -

4.2.2 Platen roller replacement ........................................................................................................ - 16 -

4.2.3 Caution ................................................................................................................................... - 17 -

4.3 Micro switch replacement ................................................................................................................. -

17 -

4.3.1 Micro switch replacement ....................................................................................................... - 17 -

4.3.2 Caution ................................................................................................................................... - 17 -

4.4 Sensor replacement ......................................................................................................................... -

17 -

4.4.1 Mark sensor replacement ....................................................................................................... - 17 -

4.4.2 Caution ................................................................................................................................... - 17 -

4.5 Cutter replacement ........................................................................................................................... -

17 -

4.5.1 Cutter replacement ................................................................................................................. - 17 -

4.5.2 Caution ................................................................................................................................... - 17 -

4.6 Print motor replacement ................................................................................................................... -

18 -

5 Printer Adjustment .............................................................................................................................. - 19 -

5.1 Paper near end sensor position adjustment ..................................................................................... - 19 -

5.2 Mark sensor position adjustment ...................................................................................................... -

20 -

6 Troubleshooting .................................................................................................................................. - 21 -

Appendix .................................................................................................................................................. - 23 -

Appendix 1 Product naming rule ............................................................................................................ -

23 -

Appendix 2 EEPROM setting table ......................................................................................................... -

23 -

Appendix 3 Command set ...................................................................................................................... -

24 -

Appendix 4 Easily damaged parts list ..................................................................................................... -

26 -

Appendix 5 Printer exploded view .......................................................................................................... -

28 -

Appendix 6 Parts list ............................................................................................................................... -

31 -

Appendix 7 Overall dimension ................................................................................................................ -

32 -

BT-T080 Plus Service Manual

- 1 -

1 Printer characteristics

1.1 Function

High speed printing

The print speed is 150mm/s;

High reliability

The lifetime of cutter is not less than 1 million times (60g recommended paper, the paper type is OJI

PD15/PD150R, room temperature 25°C);

The lifetime of printhead is not less than 100km (12.5% duty ratio, 60g recommended paper, paper

type is OJI FD210, room temperature 25°C);

MCBF 37,000,000 lines.

Single paper feeding path

This product is configured with one straight paper feeding path.

Adapt to single-type width paper

This product can adapt to paper with a width of 79.5±0.5 mm;

Semi-automatic paper feeding

This product has semi-automatic paper feeding function

Easy to maintain

The product adopts unique patented technology—platen roller slips away from the print head and it is

easy to clean the print head and clear the errors. If the cutter can’t reset, the user still can open the

platen and stationary blade at the same time without damaging the movable blade.

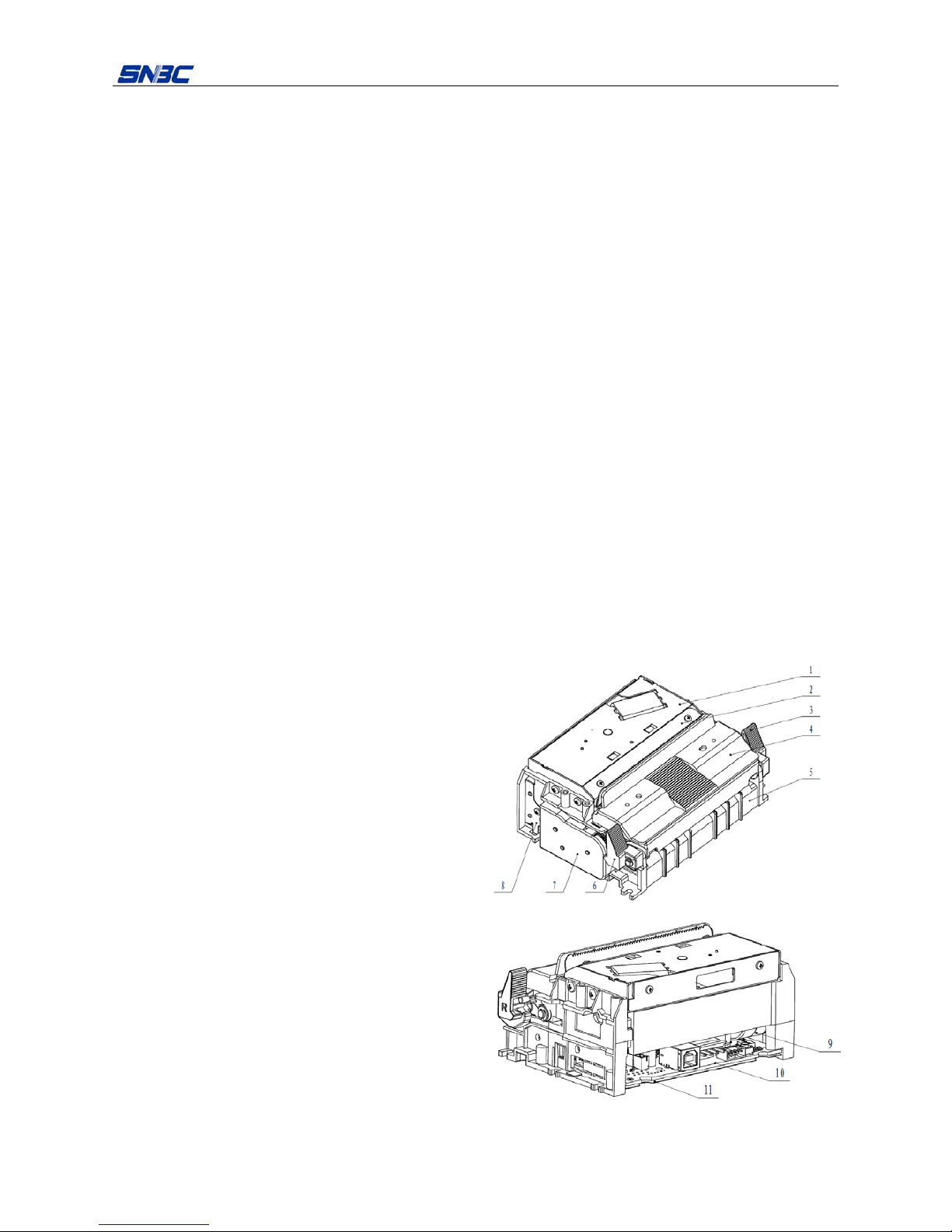

1.2 Appearance and components

The appearance is in the nature color of parts.

1—cutter

2—tear-off knife

3—right spanner

4—external path

5—mechanism holder

6—spanner

7—gear cover

8—grounding part

9—stepper motor

10—main control board

11—main control board protective film

Fig. 1.2-1 BT-T080 Plus embedded printer

BT-T080 Plus Service Manual

- 2 -

1.3 Performance index

1.3.1 Print specification

Model

Item

BT-T080 Plus

Print method Direct thermal line

Print direction Consistent with the paper feeding direction

Dot density 203dpi x 203dpi

Print width

Max.80mm

Max.640 dots

Print speed 150mm/s

Table 1.3.1 Print specification

Note: Dpi: printed dots per inch (1 inch ≈ 25.4 mm);

1.3.2 Cut mode

Full cut

Half cut

1.3.3 Status detection

No. Detection contents Sensor type

1 Mark/out of paper Photoelectric sensor

2 Print head position Micro switch

3 Print head temperature Thermistor

4 Paper near end Photoelectric sensor

5 Anti-pull Photoelectric sensor

6 Anti-jam Photoelectric sensor

Table 1.3.2

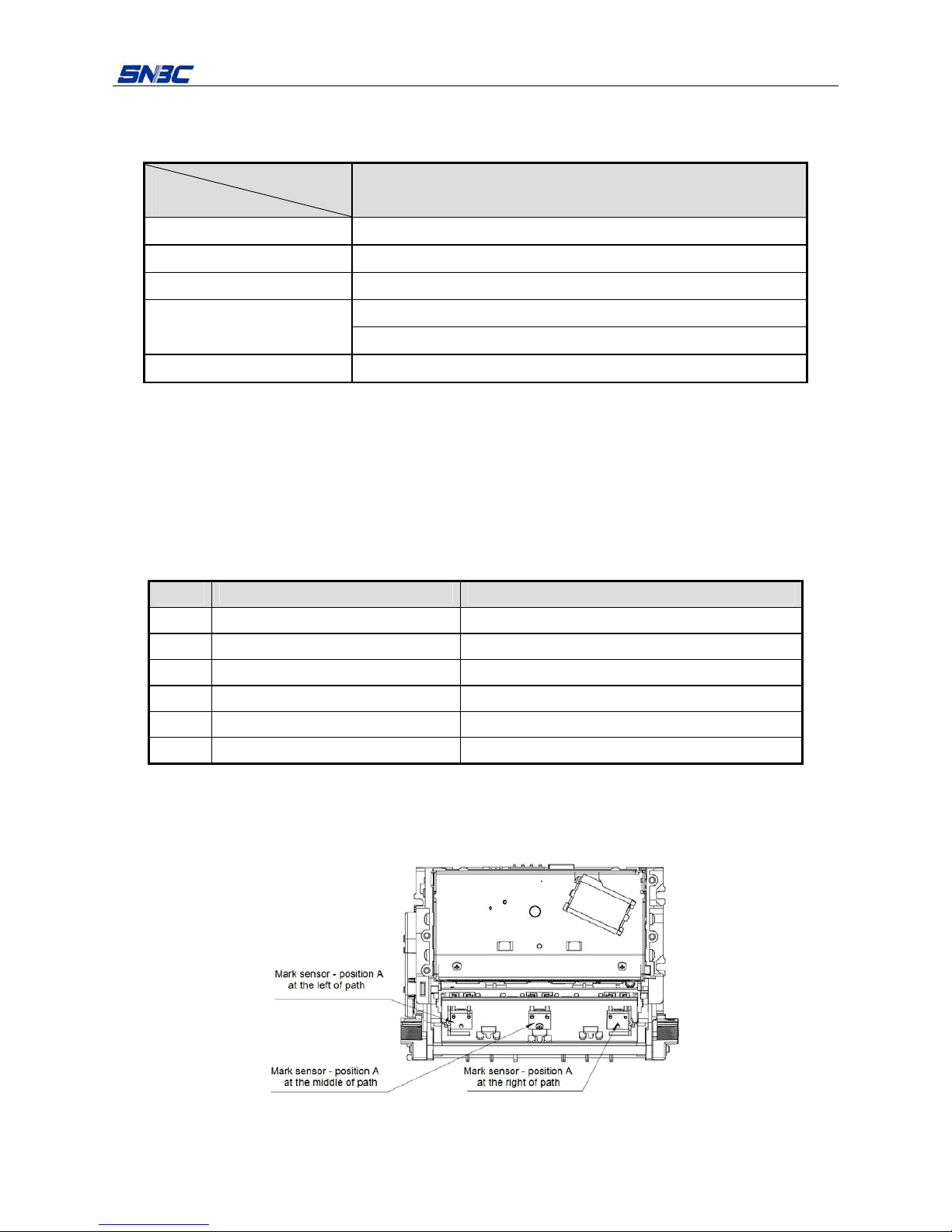

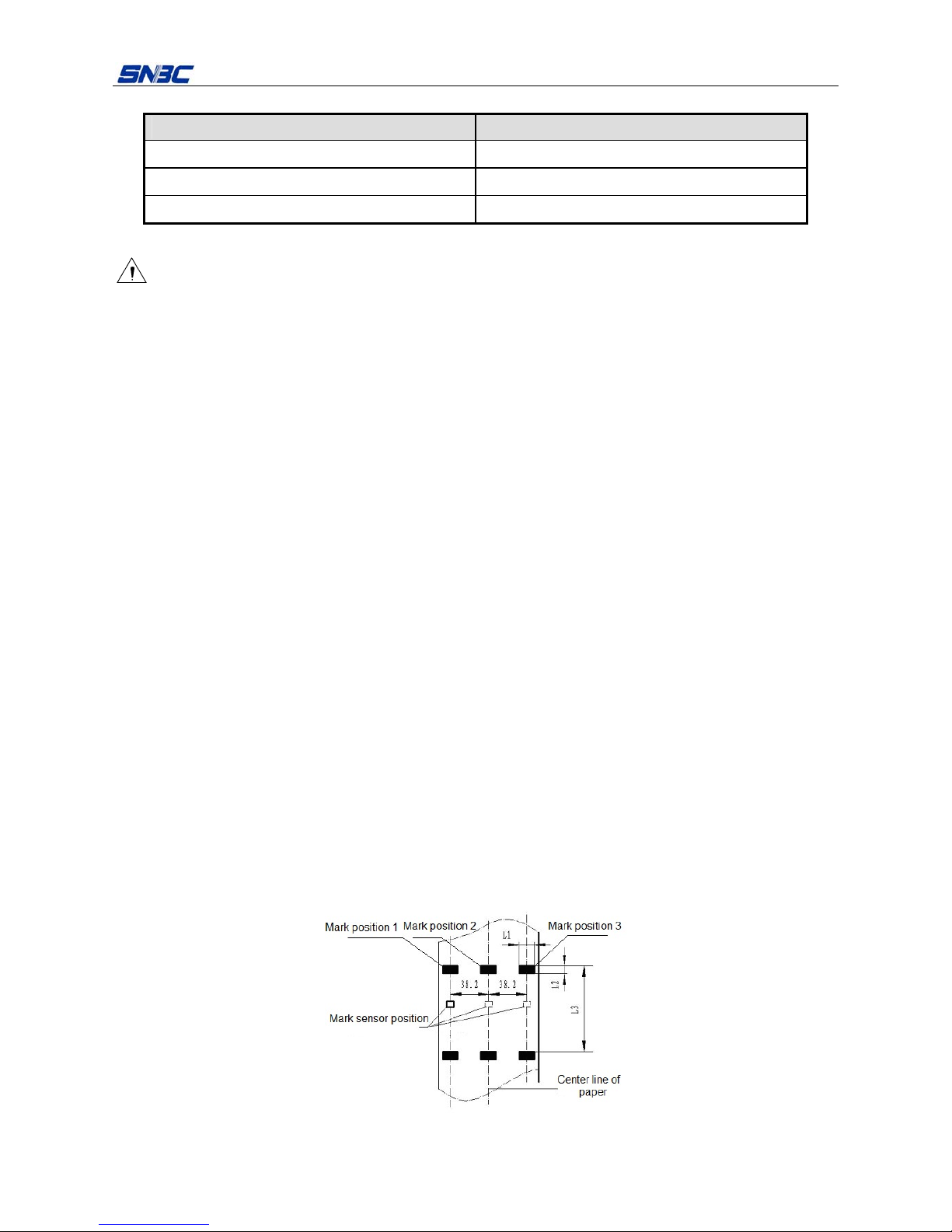

1.3.4 Sensor position

Fig.1.3.4.1 Sensor position 1

BT-T080 Plus Service Manual

- 3 -

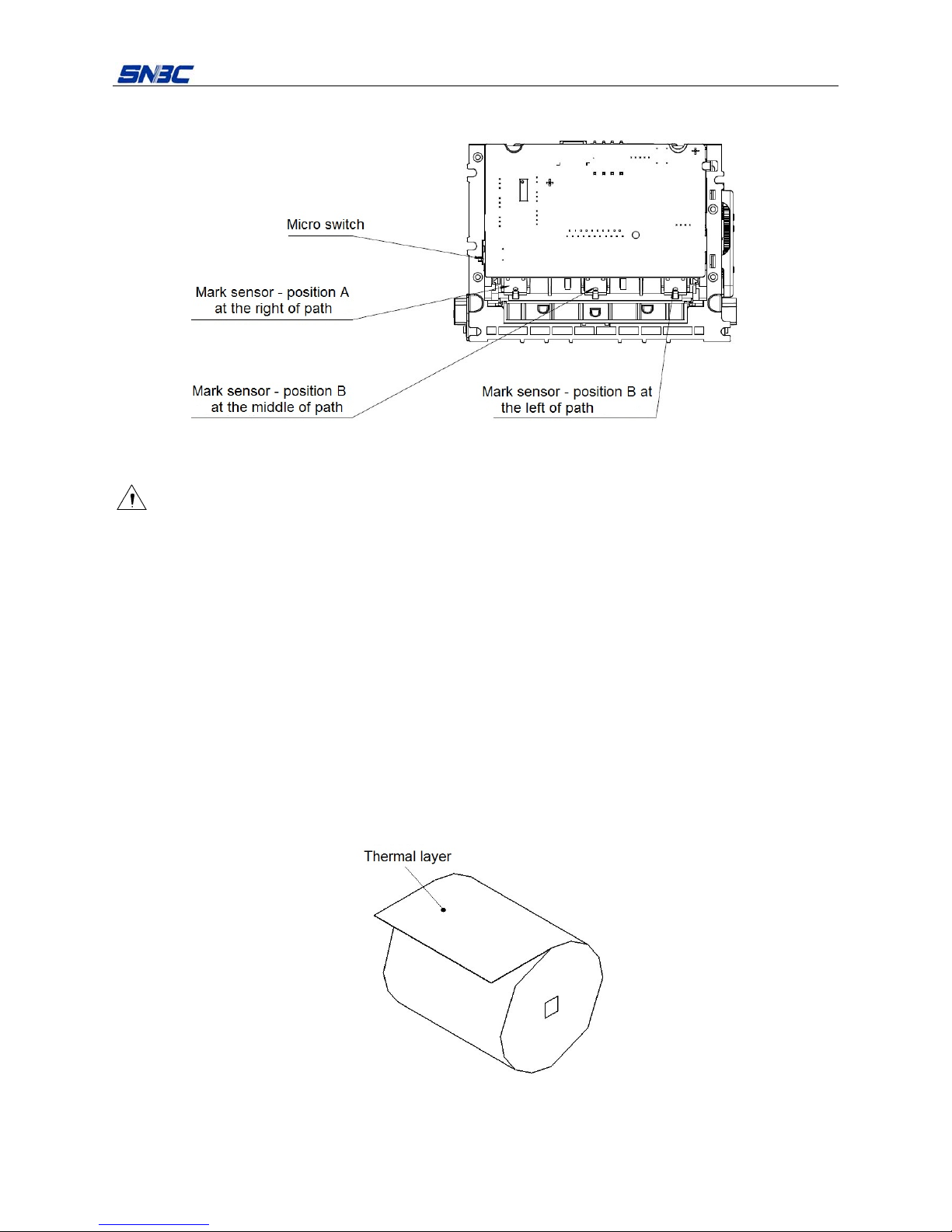

Fig. 1.3.4.2 Sensor position 2

Caution:

When the mark sensor is at position A, the marks are in the non-thermal layer;

When the mark sensor is at position B, the marks are in the thermal layer.

1.3.5 Paper specification

1) Paper type: thermal paper

2) Paper supply: continuous paper

3) The paper width is selected according to the selected configuration model:

Model: BT-T080 Plus 79.5±0.5mm

4) Paper roll specification:

Paper roll outer diameter (Max.): ф150 mm

Paper roll inner diameter (Min.): ф12.5mm, ф25.4mm

5) Thermal layer: outward

Fig. 1.3.5 Thermal layer diagram

6) Paper thickness: 60~100 μm

BT-T080 Plus Service Manual

- 4 -

7) Recommended paper:

Paper type Manufacturer

FD210 OJI Paper CO., LTD.

PD150 OJI Paper CO., LTD.

PD150R OJI Paper CO., LTD.

Table 1.3.5 Recommended paper

Caution:

Please use the recommended paper or its equivalents. Using the paper of low quality might affect the

print quality and shorten the lifetime of print head;

Do not stick paper onto the paper roll core shaft;

If the paper is contaminated by chemical or oil, it may discolor at the polluted spot or have poor printing

effect;

Do not rub the thermal side of paper with hard objects, otherwise the printing contents may be not

clear.

When the environment temperature goes up to 70℃, paper will discolor. Thus don’t use or store paper

under high temperature, high humidity and strong light conditions, etc.;

1.3.6 Lable paper specification

Except for the requirements of standard paper, the mark paper should aslo meet the following

requirements:

1) Mark position

The mark with the paper width is more than 79mm can be selected to be at the left, middle and right

positions of the thermal / non-thermal layer, as shown in Fig.1.2.6. Make sure that the marks on both sides

are completely covered by the mark sensor (distance from the mark sensors at both sides to the center line

of paper is 38.2mm).

2) When select the mark, the following parameters are recommended:

L1 makr height: 8mm≤L1≤Paper width

L2 makr height: 4mm≤L2≤8mm

3) The mark’s reflectivity should be less than 10%, and the reflectivity of the other parts along the paper

feeding direction within the width of the mark should be more than 75%.

Fig. 1.3.6 Mark position diagram

BT-T080 Plus Service Manual

- 5 -

Caution:

Due to the jitter during paper feeding and the difference in paper parameters, the positioning of mark

may have an error of ±1 mm;

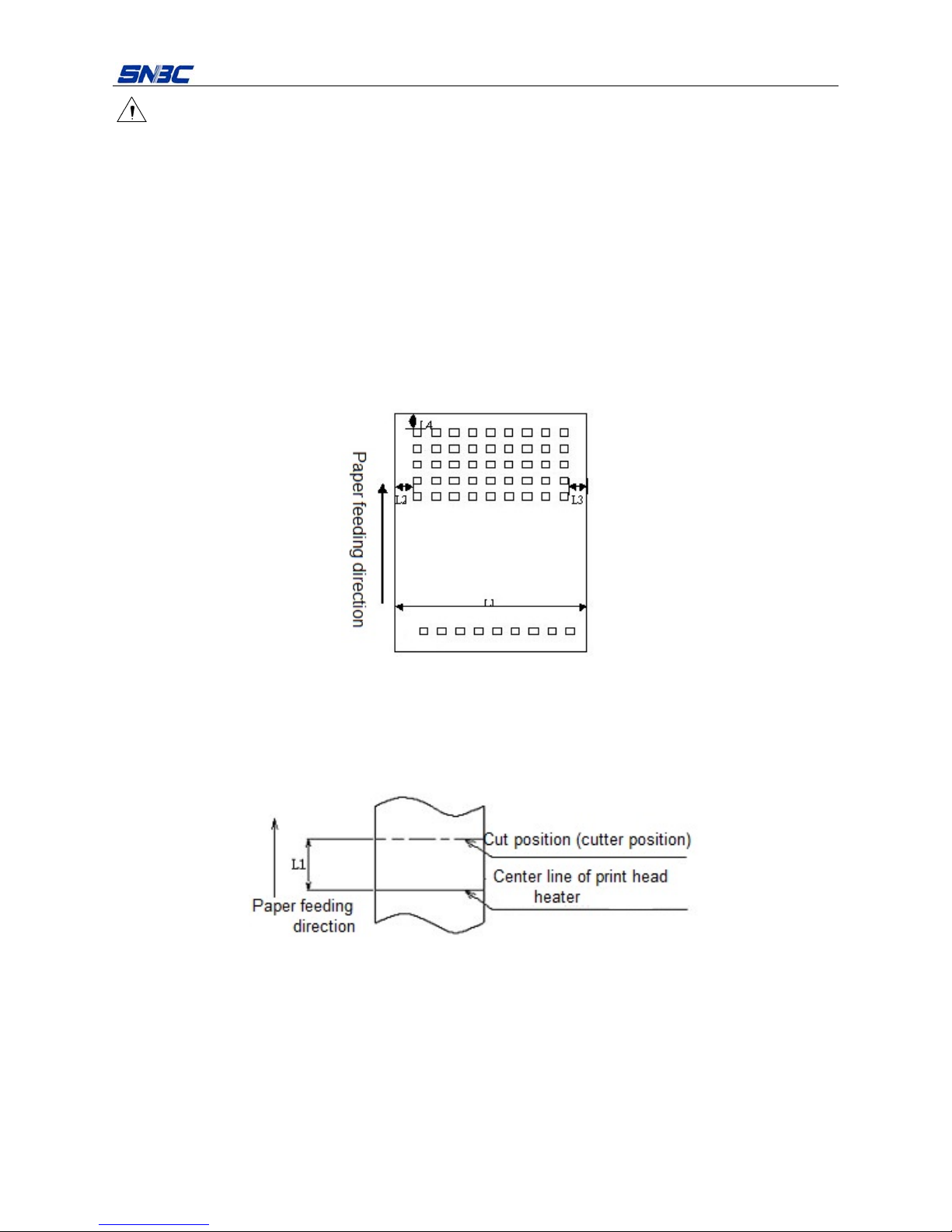

1.3.7 Print area

The path of the BT-T080 Plus embedded printing unit is suitable for paper with 80mm width, and the

specific paper width refers to the section 1.3.5 paper specification.

L1: Maximum printable width 80mm

L2: Left print margin adjustable

L3: Right print margin adjustable

L4: Top margin recommended: ≥5mm

Fig. 1.3.7 Print width diagram

1.3.8 Print and cut position

L1: 14.5mm

Fig. 1.3.8 Relationship between print and cut positions

1.3.9 Power supply voltage

1) Drive voltage: 24VDC±10%

Note: used to drive the print head and the motor.

2) Detection voltage: 3.3VDC±5%

Note: Used to detect the status of print head control, mark sensor, paper sensor, micro switch, etc.

BT-T080 Plus Service Manual

- 6 -

1.3.10 Reliability

Print device

MCBF: 37,000,000 lines (paper feeding)

Print head

Lifetime: 100km (12.5% duty ratio, 60g recommended paper, paper type is OJI FD210, room

temperature 25℃)

Cutter

Lifetime: 1 million times (60g recommended paper, paper type OJI PD15/PD150R, room temperature

25℃)

Loading...

Loading...