Page 1

USER’S MANUAL

Label Printer

BTP-3200E

Shandong New Beiyang Information

Technology Co., Ltd

Page 2

BTP-3200E User’s Manual

- 1 -

Declaration

Information in this document is subject to change without notice.

SHANDONG NEW BEIYANG INFORMATION TECHNOLOGY CO.,

LTD. (hereinafter referred to as “SNBC”) reserves the right to

improve products as new technology, components, software, and

hardware become available. If users need further data about these

products, please feel free to contact SNBC or our local dealer.

No part of this document may be reproduced or transmitted in any

form or by any means for any purpose without the express written

permission of SNBC.

Copyright

Copyright © 2013 by SNBC

Printed in China

Version 1.0

Trademark

Our Registered trademark:

Warning and caution

Warning:

Items shall be strictly followed to avoid injury or

damage to body and equipment.

Caution:

Items with important information and prompts for

operating the printer.

Page 3

BTP-3200E User’s Manual

- 2 -

SNBC has passed the following certifications:

ISO9001 Quality Control System Certification

ISO14001 Environmental Management System Certification

OHSAS18001 Occupational Health and Safety Management

System Certification

IECQ QC 080000 Hazardous Substance Process Management

System Certification

Page 4

BTP-3200E User’s Manual

- 3 -

Safety Instructions

Before installing and using the printer, please read the following

items carefully.

1 Safety warning

The print head is a thermal element and it is at a high

temperature during printing or just after operation, therefore do

not touch it or its peripherals for safety’s sake

.

The print head is an ESD-sensitive device. To prevent damage,

do not touch either its printing parts or connecting parts.

2 Cautions

1) Install the printer on a flat and stable surface;

2) Reserve adequate space around the printer so that convenient

operation and maintenance can be performed;

3) Keep the printer far away from water source, and do not expose

the printer to direct sunlight, strong light and heat;

4) Do not use or store the printer in a place exposed to high

temperature, high humidity or serious pollution;

5) Do not place the printer in a place exposed to vibration or

impact;

6) No condensation is allowed to the printer. In case of such

condensation, do not turn on the power until it has completely

gone away;

7) Connect the printer power to an appropriate grounding outlet.

Avoid sharing one electrical outlet with large power motors or

other devices that may cause the fluctuation of voltage;

Page 5

BTP-3200E User’s Manual

- 4 -

8) Disconnect the power when the printer is deemed to idle for a

long time;

9) Don’t spill water or other electric materials into the printer (e.g.

metal). In case this happens, turn off the power immediately;

10) Do not allow the printer to start printing when there is no

recording paper installed; otherwise the print head and platen

roller will be damaged;

11) To ensure quality print and normal lifetime, use recommended

paper or its equivalent;

12) Shut down the printer when connecting or disconnecting

interfaces to avoid damages to control board;

13) Set the print darkness to a lower grade as long as the print

quality is acceptable. This will help to keep the print head

durable;

14) Avoid turning on and off the printer frequently when using the

printer and turn on the printer at least 2 seconds after it is

turned off;

15) Do not disassemble the printer without permission of a

technician, even for repairing purpose;

16) Keep this manual safe and at hand for reference purpose.

Page 6

BTP-3200E User’s Manual

- 5 -

Contents

1 Product introduction ................................................................ - 1 -

1.1 Introduction .......................................................................... - 1 -

1.2 Unpacking and checking ...................................................... - 1 -

1.3 Appearance and modules .................................................... - 2 -

1.4 Introduction of main modules .............................................. - 4 -

2 Printer installation .................................................................... - 5 -

2.1 Installation position .............................................................. - 5 -

2.2 Installing paper roll ............................................................... - 5 -

2.3 Installing ribbon .................................................................... - 8 -

2.4 Power adapter connection ................................................. - 10 -

2.5 Communication cable connection...................................... - 11 -

2.6 Starting the printer ............................................................. - 11 -

2.6.1 Power-on and self-test ................................................ - 11 -

2.6.2 Printing self-test page ................................................. - 12 -

2.7 Driver setup ........................................................................ - 12 -

3 Printer operation ..................................................................... - 15 -

3.1 LED, buzzer, feed button and LCDLED functions ............. - 15 -

3.1.1 Button functions .......................................................... - 15 -

3.1.2 Buzzer functions .......................................................... - 16 -

Page 7

BTP-3200E User’s Manual

- 6 -

3.1.3 LCD functions .............................................................. - 16 -

3.2 Printer status and operation .............................................. - 17 -

3.2.1 Printer status ............................................................... - 17 -

3.2.2 Daily operations .......................................................... - 17 -

3.3 Printer parameter settings ................................................. - 19 -

3.3.1 Button menu settings .................................................. - 19 -

3.3.2 Detailed parameter setting range ................................ - 21 -

3.4 Print head pressure adjustment ......................................... - 22 -

3.5 Sensor position adjustment ............................................... - 24 -

3.6 Print position adjustment ................................................... - 25 -

4 Routine maintenance ............................................................. - 28 -

4.1 Cleaning print head ............................................................ - 28 -

4.2 Cleaning the sensor ........................................................... - 28 -

4.3 Cleaning platen roller ......................................................... - 29 -

5 Troubleshooting ..................................................................... - 31 -

5.1 Troubleshooting ................................................................. - 31 -

5.2 Print quality problems ........................................................ - 33 -

Appendix .................................................................................... - 34 -

Appendix 1 Technical specification ......................................... - 34 -

Appendix 1.1 Main technical specifications ......................... - 34 -

Page 8

BTP-3200E User’s Manual

- 7 -

Appendix 1.2 Technical specifications of paper ................... - 37 -

Appendix 2 Self-test page ........................................................ - 39 -

Appendix 3 Print and paper out position ................................. - 41 -

Appendix 4 Communication interface ...................................... - 41 -

Appendix 4.1 Serial interface ............................................... - 41 -

Appendix 4.2 Parallel interface ............................................ - 42 -

Appendix 4.3 USB interface ................................................. - 43 -

Appendix 4.4 Ethernet interface ........................................... - 43 -

Appendix 5 Operation guide for paper loading under peel-off

mode (optional) ........................................................................ - 44 -

Page 9

BTP-3200E User’s Manual

- 1 -

1 Product introduction

1.1 Introduction

BTP-3200E label printer is an ideal thermal transfer desktop label

printing device, with delicate appearance and excellent performance.

It can be used for label printing in many fields, such as retailing,

medical, clothing, electronic manufacturing, logistics, etc..

BTP-3200E label printer can be connected with external devices via

USB or other interfaces and can provide common drivers for

operating systems such as Windows 2000/ Windows XP/ vista/

Windows 7/ Windows 8/ Windows server 2008/ Windows server2003

and SDK based on DLL.

Main features:

Ø Thermal transfer printing;

Ø Low noise, high speed printing;

Ø Easy paper loading, convenient operation;

Ø With 32 bit high speed microprocessor;

Ø Adopting heat history and auto temperature adaptation control;

Ø Adopting a new type of print head with long lifetime, high printing

quality;

Ø Supporting continuous paper, label paper, marked paper, etc.

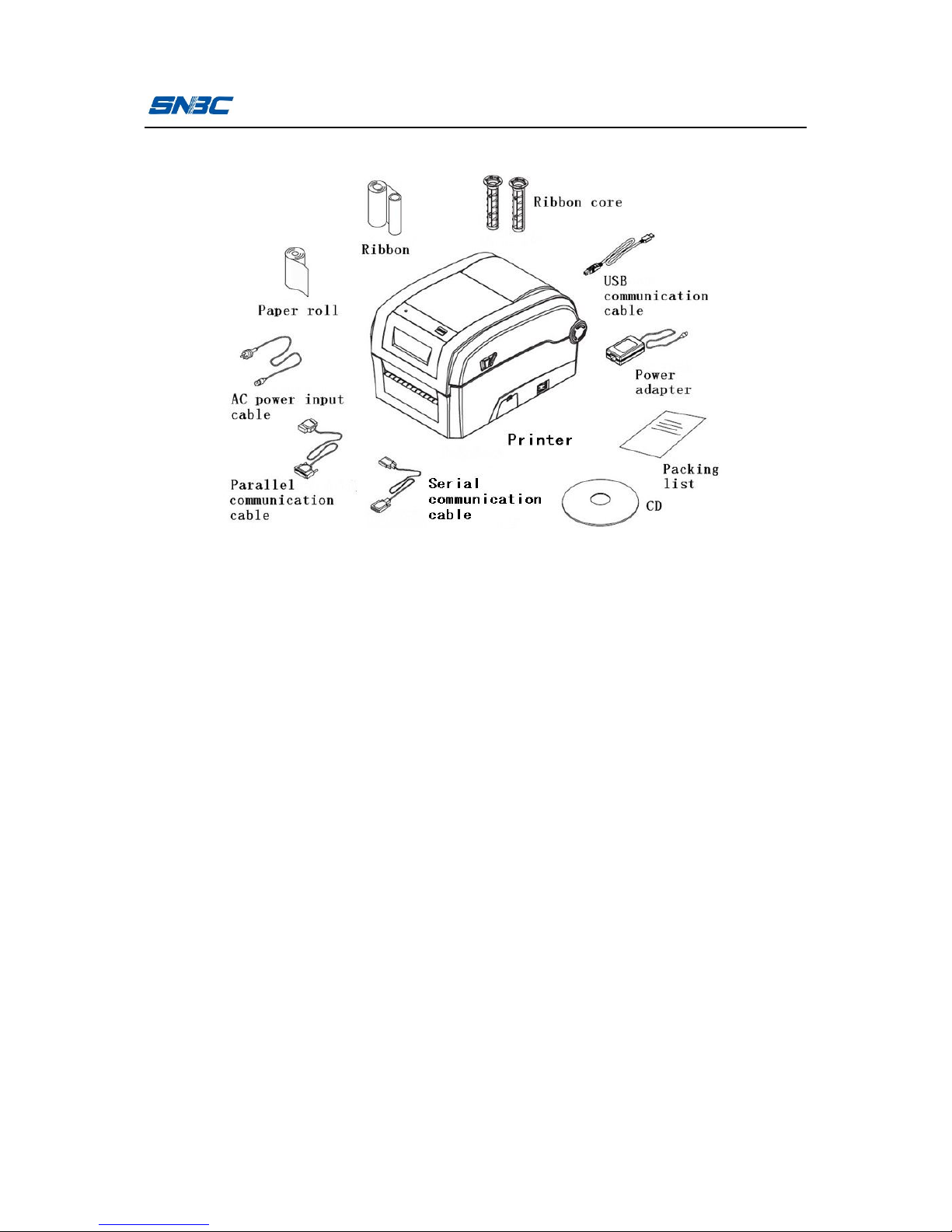

1.2 Unpacking and checking

Open the packaging and check the items according to the packing

list. Please contact SNBC or your local dealer if there is shortage or

damage (communication cables are optional depending on the

Page 10

BTP-3200E User’s Manual

- 2 -

printer interface type).

Figure 1.2.1

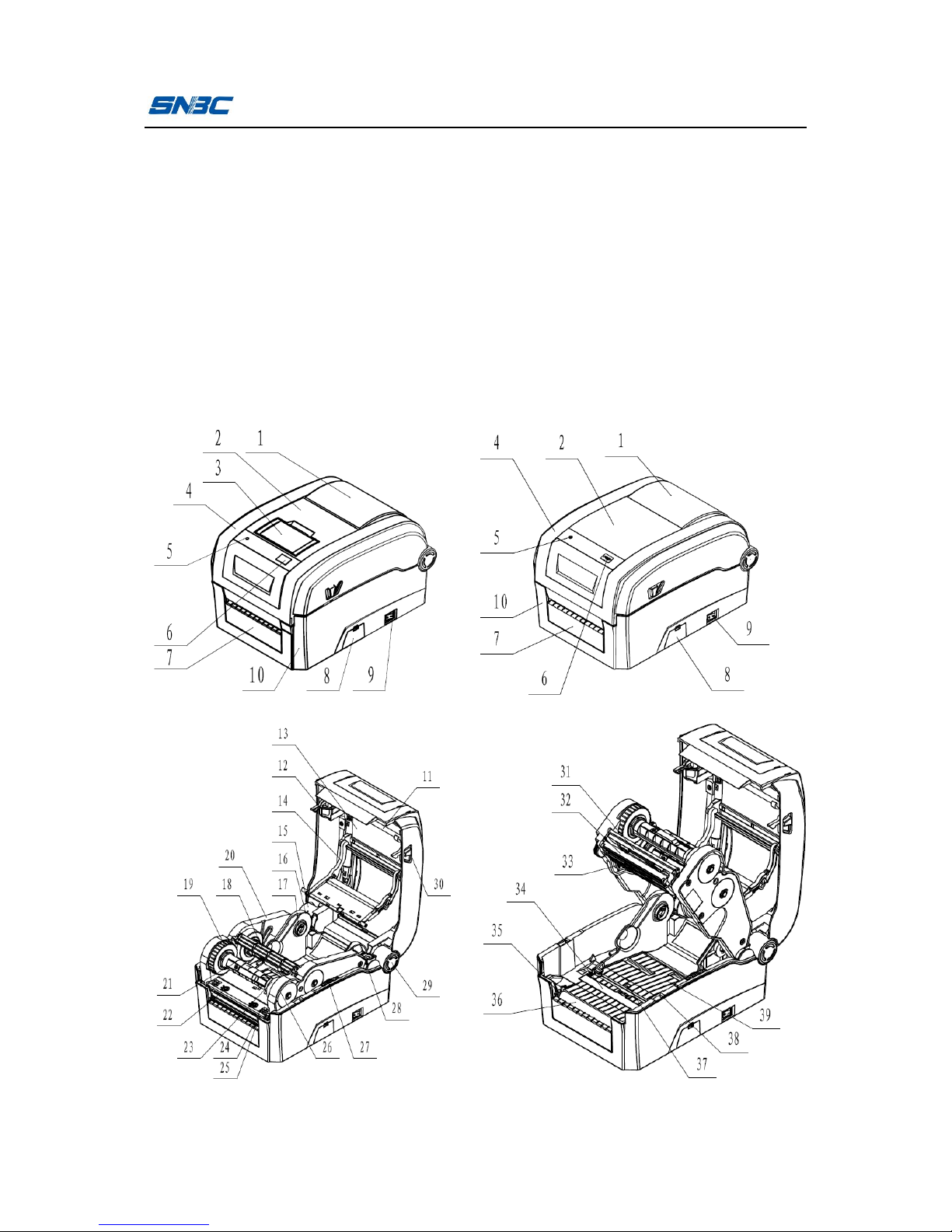

1.3 Appearance and modules

1—window 2—top plate

3—LCD (optional) 4—top cover

5—LED 6—【FEED】button

7—front cover 8—SD card cover

9—power switch 10—bottom cover

11—latch axis 12—left latch

13—linkage cover 14—baffle

15—left shaft cover 16—left paper guide

17—paper holder baffle 18—ribbon sending wheel

19—ribbon rewind wheel 20—left holder

21—ribbon core 22—print head pressure adjusting knob

23—ribbon baffle 24—ribbon adjusting axis

25—peel-off bar 26—right holder

27—paper guide thumb wheel 28—right paper guide

Page 11

BTP-3200E User’s Manual

- 3 -

29—right shaft cover 30—right latch

31—holder underbeam 32—print head fixing plate

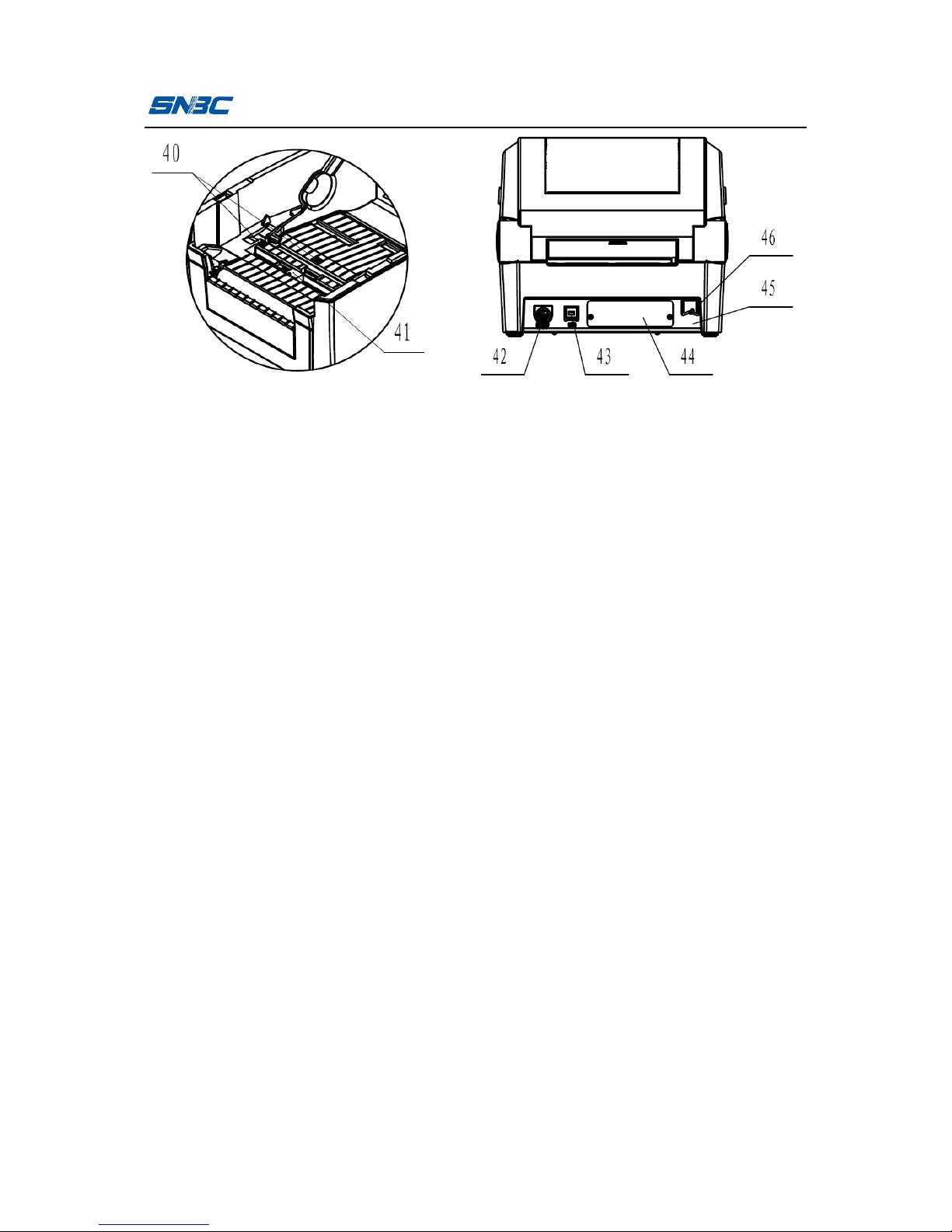

33—print head 34—sensor cover board

35—platen roller shaft sleeve 36—print platen roller

37—Photointerrupter dustproof cover 38—micro switch

39—middle cover 40—transmissive sensor

41—sensor fixing seat 42—power adapter interface

43—USB interface 44—communication interface

45—main board fixing plate 46—cable hook

Page 12

BTP-3200E User’s Manual

- 4 -

1.4 Introduction of main modules

1) Button and LED (6, 5): indicate the printer status and complete

printing function;

2) Power switch (9): press “O” to power off and “-” to power on;

3) Transmissive sensor (40): used for calibration, detection and

location of media like label paper;

4) Paper holder baffle (17), left paper guide (16), right paper guide

(28): support paper holder and prevent paper roll from shaking;

5) Micro switch (38): used to detect whether the print head is

uplifted or pressed down.

Page 13

BTP-3200E User’s Manual

- 5 -

2 Printer installation

2.1 Installation position

Flatly place the printer on the operation table, which must be

waterproof, moistureproof and dustproof. The maximal tilted angle

should not exceed 15° during installation.

2.2 Installing paper roll

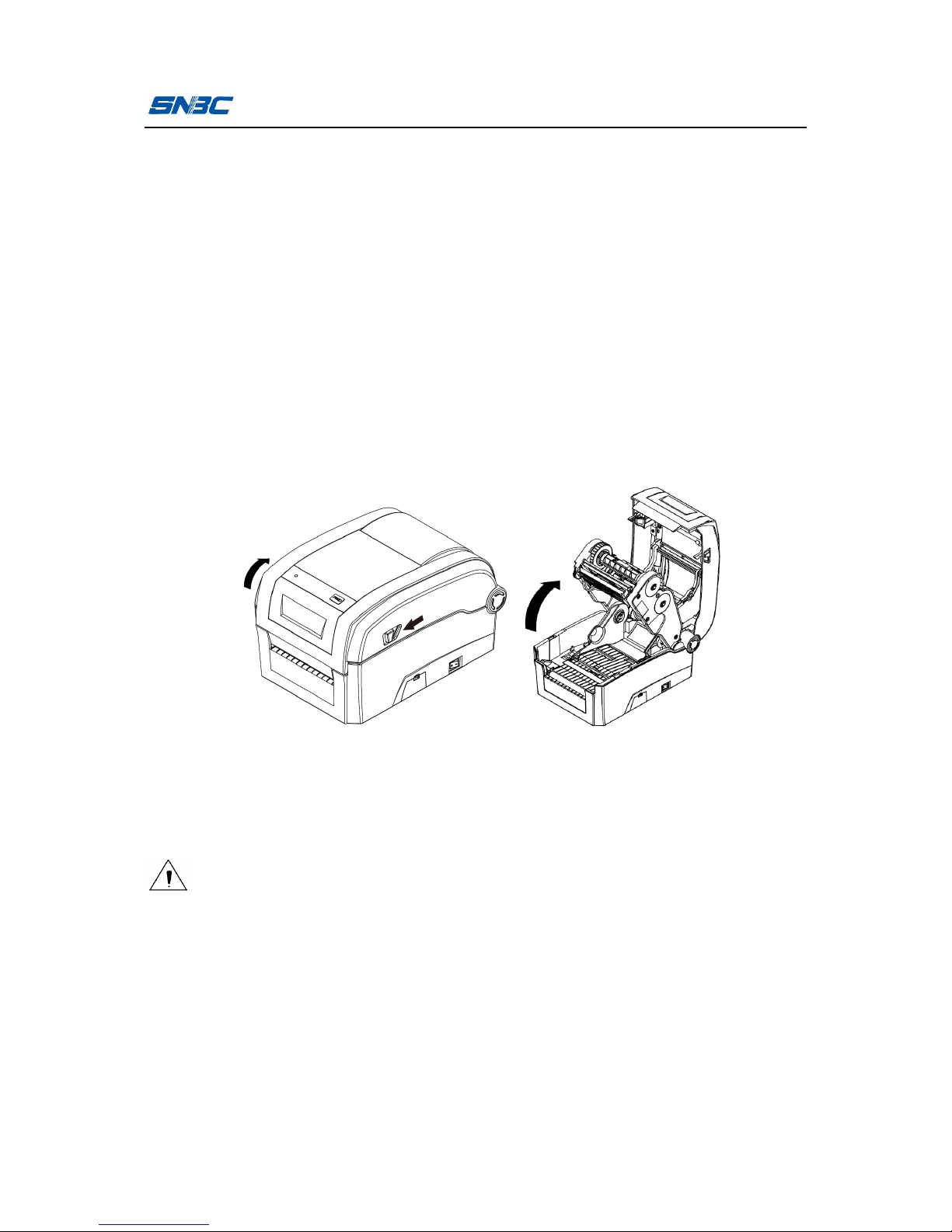

1) Press the cover open lever with both hands and turn the top

cover upward to open it (see figure 2.2.1);

Figure 2.2.1

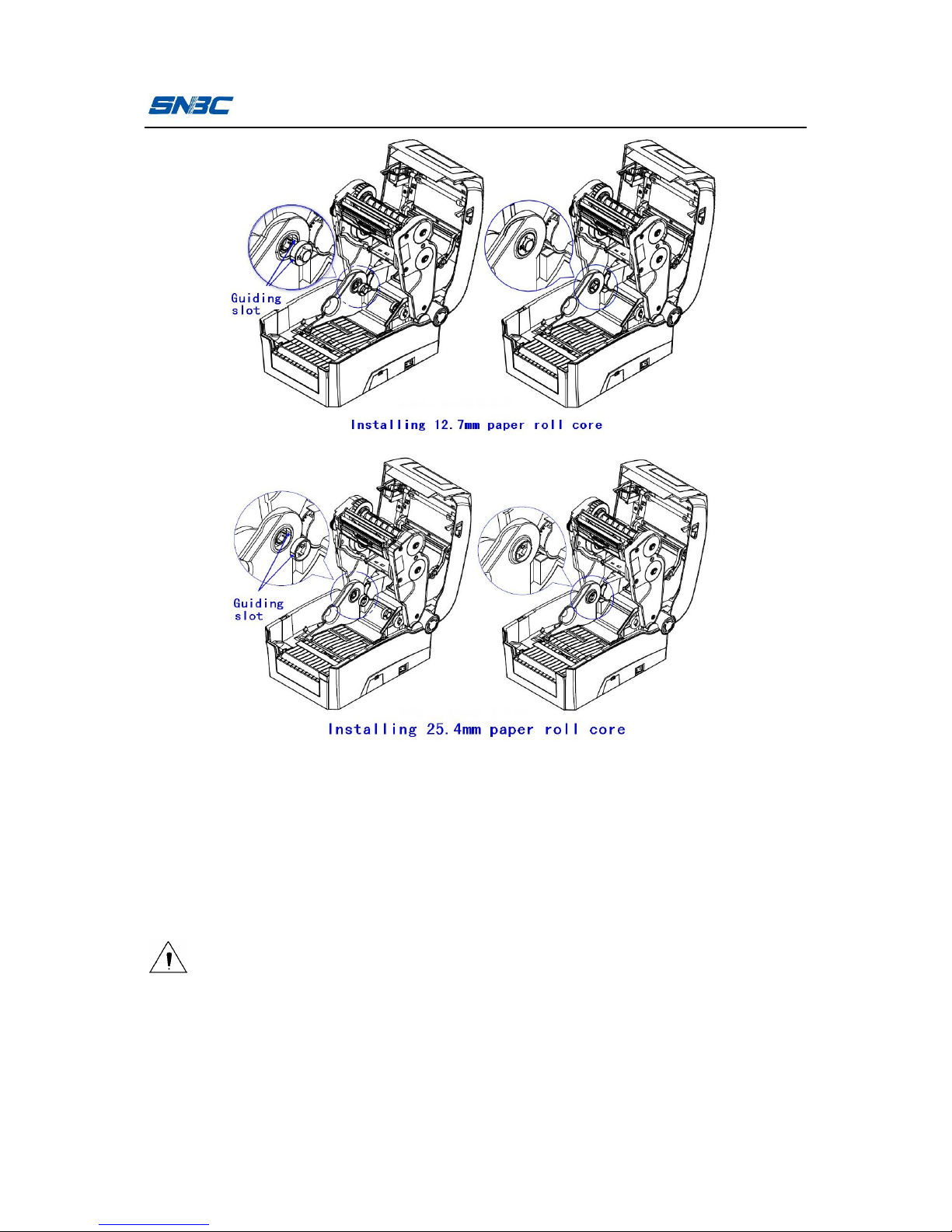

2) Insert the two paper holder baffles into the center holes of the left

and right paper guides along the guiding slot;

Caution:

n There are two kinds of paper roll ID: 12.7mm (1/2 inch) and

25.4mm (1 inch). The insertion method of paper holder baffle

depends on paper roll ID. The detailed operation methods are

shown in the figure (please pay attention to the installation

direction in 2.42.2):

Page 14

BTP-3200E User’s Manual

- 6 -

Figure 2.2.2

3) Pull the left and right paper guides apart and load the paper roll,

insert the left and right baffles into paper roll core, and then lead

the front of paper roll through paper guide block to spread it in

the print path.

Caution:

n The print surface of paper should face up (if it is marked paper,

the black mark should face down).

Page 15

BTP-3200E User’s Manual

- 7 -

Figure 2.2.3

4) Turn the thumb wheel according to the indication on the middle

cover to make the paper holder a little wider than the paper roll

width in case the paper roll bears any force (see figure 2.2.4).

Figure 2.2.4

Page 16

BTP-3200E User’s Manual

- 8 -

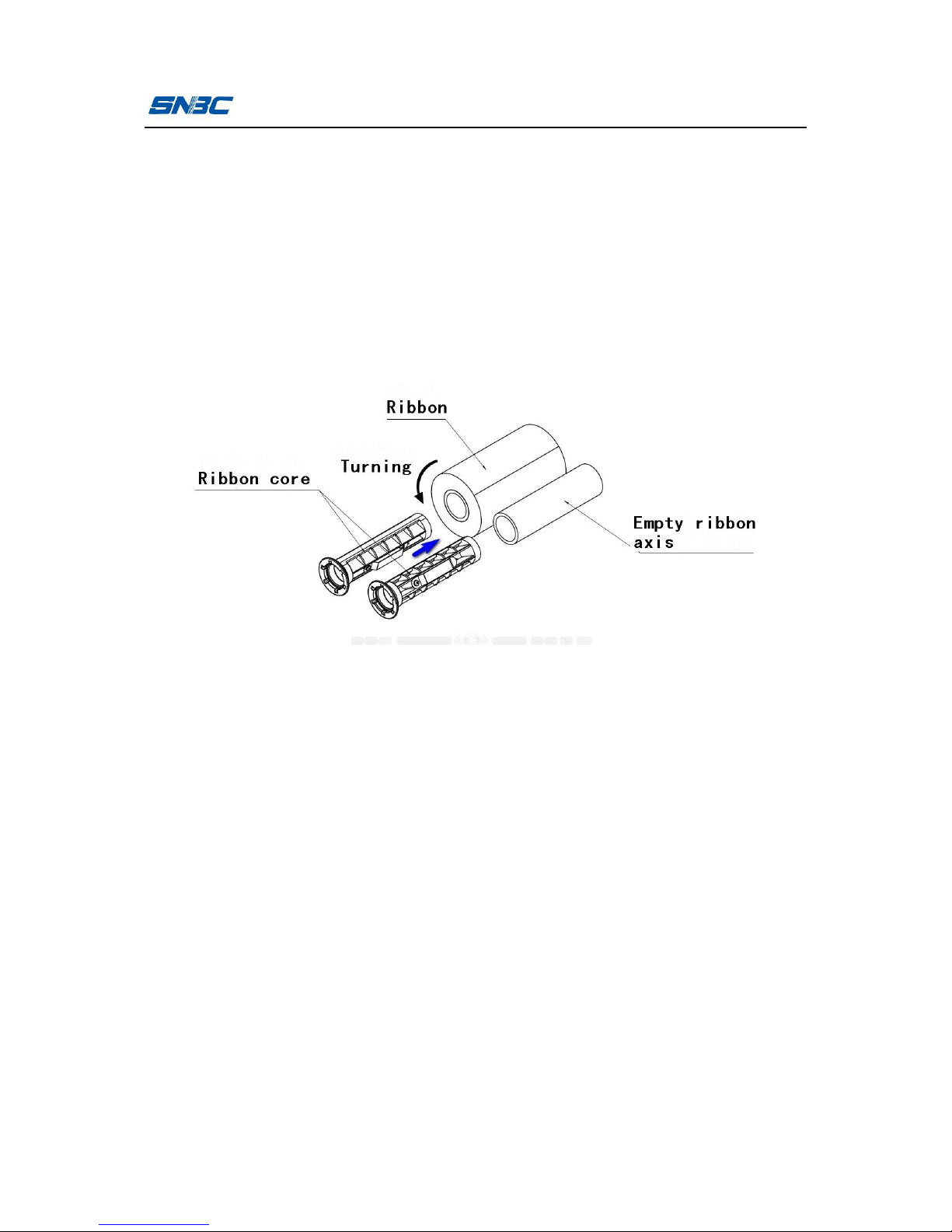

2.3 Installing ribbon

1) Push the ribbon core slightly in the direction of ribbon baffle to

take off the ribbon core, and insert the two ribbon cores into the

ribbon and empty ribbon axis respectively in the direction

indicated in the figure. Pay attention to the winding direction of

ribbon (see figure 2.3.1);

Figure 2.3.1

2) Push one end of the installed ribbon module into ribbon baffle

and the other end into the ribbon sending wheel, rotate the

sending wheel cover, and install the bulge of sending wheel

cover into the slot of ribbon core to end the installation of ribbon

module (see figure 2.3.2); install the empty ribbon axis module to

ribbon rewind wheel module according to the same method (see

figure 2.3.3);

Page 17

BTP-3200E User’s Manual

- 9 -

Figure 2.3.2

Figure 2.3.3

3) Lead the ribbon from beneath the print head module, stick the

front of ribbon onto the empty ribbon axis, and turn the ribbon

rewind wheel to tighten the ribbon (for the paper roll and ribbon

that have been installed, see figure 2.3.4);

Page 18

BTP-3200E User’s Manual

- 10 -

Figure 2.3.4

4) Close the printer top cover module to locking status.

Caution:

n Determine print method: If thermal transfer printing is selected,

the ribbon needs to be installed; if thermal printing is selected,

the ribbon does not need to be installed.

n Under normal condition, the selected ribbon should be wider

than the print media.

n Keep the ribbon as flat as possible during ribbon installation in

case the ribbon is cockled or damaged during printing.

2.4 Power adapter connection

1) Ensure the printer is turned off;

2) Connect one end of the AC power input cable to power adapter,

and then insert the other end of the power adapter into the power

adapter interface on the back of printer;

3) Insert the other end of AC power input cable into the 220V power

socket.

Page 19

BTP-3200E User’s Manual

- 11 -

Caution:

n If leaving the printer idle for a long time, please disconnect the

power of printer.

2.5 Communication cable connection

1) Ensure the printer is turned off;

2) Insert the communication cable into the suitable interface, and fix

it with screw or latch spring of the plug;

3) Connect the other end of the communication cable to the host.

Caution:

n Don’t connect or disconnect the serial/parallel communication

cable when the power has not been turned off.

2.6 Starting the printer

2.6.1 Power-on and self-test

1) Ensure the power adapter and the communication cable are

connected correctly, and turn on the printer;

2) The printer starts the self-test. The buzzer beeps once for a short

time after the self-test is finished, and then the LCD displays

manufacturer LOGO and status information or product model;

3) If power-on action is set, the printer will perform power-on action.

Note: Power-on action refers to the actions performed automatically after

the printer is turned on, including feeding one label, starting

calibration automatically (only valid under discontinuous paper

mode). The power-on action can be set by commands or

configuration tools.

Page 20

BTP-3200E User’s Manual

- 12 -

Caution

n If the printer can not be started or can not work normally after it

is started, please contact SNBC or local dealer in time.

2.6.2 Printing self-test page

1) Install the media, and turn on the printer. The printer will feed

paper and print self-test page (see Appendix 2) through button

operations (for the detailed operation methods, please refer to

3.3.1 Button menu settings);

2) The self-test page lists the current configuration information of

the printer.

2.7 Driver setup

The installation program of the driver is included in the CD packed

with the printer, which can also be downloaded from the website

www.newbeiyang.com.

Ø The 32-bit operating systems supported by the driver are as

follows:

Windows 2000/Windows XP/Windows server 2003/Windows

Vista/Windows server 2008/Windows 7/Windows 8.

Ø The 64-bit operating systems supported by the driver are as

follows:

Windows XP/Windows server 2003/Windows Vista/Windows

server 2008/Windows 7/Windows 8.

1) Run “Setup.exe” in the driver package, and read the related

software license agreement carefully. If you accept the items in

the license agreement, please click “I accept the items in the

Page 21

BTP-3200E User’s Manual

- 13 -

software license agreement”, and then click “Next” button;

2) Select printer type and model to be installed. If you want to set

the printer as default printer, please check “Set As Default

Printer” and click “Next”;

3) Select setup type, and click “Next”;

4) The driver will select the current OS type automatically, and

click “Next”;

5) Set printer port. “LPT1” is set as the default print port, but users

Page 22

BTP-3200E User’s Manual

- 14 -

can select it according to actual needs. If it is a serial port driver,

please select “BYCOMx” (x equals to 1, 2, 3, 4, 5, 6, 7 or 8); if it

is Ethernet port, please select “NET”; if it is USB port, please

select “USB_BTP-3200E_x” (if USB port printer is connected

correctly to the computer under power-on status, the driver

setup program will set USB port as default port automatically).

Then click “Install” to end the installation.

Page 23

BTP-3200E User’s Manual

- 15 -

3 Printer operation

3.1 LED, buzzer, feed button and LCDLED functions

LED name Status Explanation

Work LED

(green)

Always on Printer is idle or working.

Flash twice

Prompt that the menu or parameter selection

becomes effective. See 3.2.2 Daily operations

for details.

Pause LED

(orange)

Always on Printer is in pause status.

Error LED

(red)

Flash

An error occurs. See 5.1 Troubleshooting for

details.

3.1.1 Button functions

Button

Function

Explanation

Short

press

Feed paper

In standby status, press the button for a short time

to feed paper.

Pause

During the printing, press the button for a short

time to enter pause status.

Continue

After the printer enters pause status, press the

button for a short time to resume the printing.

Menu switching

After entering the menu, press the button for a

short time to switch the menu.

Parameter

selection

After entering the submenu, press the button for a

short time to select the parameter.

Long

press

Enter the menu

When the printer is idle, press the button for a long

time to enter the menu.

Menu selection

After entering the menu, press the button for a

long time to select the current menu.

Page 24

BTP-3200E User’s Manual

- 16 -

Parameter

confirmation

When setting the parameter, press the button for a

long time to validate the current parameter.

Note: Short press means the duration from pressing down the button to

the time when the button uplifts is less than 0.5s.

Long press means the duration of pressing down the button is

more than 1s.

3.1.2 Buzzer functions

1) The buzzer beeps for a short time when the printer is turned on

or reset;

2) The buzzer beeps many times when an exception occurs. For

the details, please refer to 5.1 Troubleshooting.

3.1.3 LCD functions

LCD is used to display the printer status and menu and configure

the printer parameters by cooperating with the button.

Page 25

BTP-3200E User’s Manual

- 17 -

3.2 Printer status and operation

3.2.1 Printer status

The printer has five status: idle status, working status, pause status,

configuration status, and abnormal status.

Printer status

LED LCD

Idle status Green LED is always on.

Display LOGO and printer

model information.

Working

status

Green LED is always on. Display LOGO and RINTING....

Pause status Orange LED is always on. Display LOGO and pausing.

Configuration

status

Green LED is always on. Display configuration menu.

Abnormal

status

Refer to 5.1 Troubleshooting.

Note: The work LED flashes twice when pressing the button for a long

time under any of the status listed above.

3.2.2 Daily operations

Ø Operations under idle status

It refers to the ready status when the printer is normal and

waiting for an operation or a task. The printer enters idle status

by default after turned on normally or returns to idle status after

finishing performing a task. Under idle status, if pressing the

button for a short time, the printer will feed paper; if pressing the

button a long time and releasing the button after the green LED

flashes twice, the printer will enter the menu.

Page 26

BTP-3200E User’s Manual

- 18 -

Ø Operations under working status

It refers to the status when the printer has a print task. The

printer will enter pause status if releasing the button after

pressing it down at this time.

Ø Operations under pause status

The printer is under the status of stopping the print task

temporarily. The printer will enter pause status under the

following situations:

1) Select “PAUSE” through the menu;

2) Press down the button during the printing;

3) After an exception is removed.

When the printer is in pause status, press the button for a short

time to resume the print task or press the button for a long time

to enter the menu to realize the selection of more functions, such

as canceling the print task, configuring the printer parameters,

etc.

Ø Operations under configuration status

It refers to the status of setting the printer parameters. Select

“SETUP” to enter the configuration menu through the menu. At

this time, press the button for a short time to switch the menu or

adjust the parameter or press the button for a long time to select

the menu or validate the current parameter.

Ø Operations under abnormal status

It refers to the status when an exception occurs. The printer

failure is prompted by LED, buzzer or LCD. For the details of

failure prompt and removing, refer to 5.1 Troubleshooting.

Page 27

BTP-3200E User’s Manual

- 19 -

3.3 Printer parameter settings

3.3.1 Button menu settings

When the printer is idle, enter the configuration status through long

press of the button. The common parameters of printer can be set

and saved under configuration status. Parameters can be

configured by the cooperation of LCD and button.

The following describes the setting and saving of printer parameters

by taking the serial port configuration for example:

1) Keep pressing the button until the green LED flashes under idle

status. Then the LCD will display the menu as shown in figure

3.3.1.1.

1 .S E T U P

2 .S E L F TE S T

3 .P A U S E

4 .C AN C E L

1 .S E T U P

Figure 3.3.1.1 menu

Note: After entering the menu, the printer will exit the menu automatically

if the menu is not operated in two minutes.

2) Press the button for a short time to switch to “SETUP” option.

Then press the button for a long time and release it after the

green LED flashes to select the option and enter configuration

menu. Press the button for a short time to switch the menu to

“SERIAL COM” option as shown in figure 3.3.1.2 and then press

the button for a long time to enter the submenu.

Page 28

BTP-3200E User’s Manual

- 20 -

Figure 3.3.1.2 configuration menu

3) Press the button for a short time to switch the submenu to

“BAUDRATE” option as shown in figure 3.3.1.3.

1.BAUDRATE

2.DATA BIT

3.STOP BIT

4.PARITY

1.BAUDRATE

Figure 3.3.1.3 serial configuration menu

Press the button for a long time to enter baud rate configuration

option as shown in figure 3.3.1.4. At this time, what is displayed

on the LCD is the parameter being used now. If you do not want

to change the parameter, press the button for a long time to exit

the option; if you want to change the parameter, press the button

for a short time to modify it.

Figure 3.3.1.4 submenu of serial baud rate

4) Repeat step 1-3 to change other parameters of the serial port.

5) Save the modified parameters. Switch the menu to “SAVE ALL”

option and press the button for a long time to save the modified

Page 29

BTP-3200E User’s Manual

- 21 -

parameters. The printer will restart automatically after the saving

to validate the parameter changes. (Remarks: if “SAVE ALL”

option is not executed, the printer will not save the setting and

will execute the previous configuration parameters when

powered on next time).

6) If you want to discard your changes, choose “EXIT” directly to

exit.

Configuring other parameters is similar to the process described

above, which can be operated according to the menu prompts.

3.3.2 Detailed parameter setting range

Adjustment object Setting range Remarks

Paper type

CONTINOUS

MARK

WEB

CONTINOUS: continuous

paper

MARK: marked paper

WEB: label paper, please see

Appendix 1.2 Technical

specifications of paper for

details.

Paper out mode

REWIND

TEAR OFF

PEEL OFF

CUTTER

The peel off module and cutter

are optional.

Print darkness 00—30

Set the print darkness as low

as possible on condition that

the print effect is acceptable so

as to ensure the lifetime of

print head.

Print speed (unit: IPS) 3-6

Page 30

BTP-3200E User’s Manual

- 22 -

3.4 Print head pressure adjustment

The print head pressure adjusting device is configured with two print

Vertical position

adjustment (unit: dots)

-120-+120

For adjustment effect, please

refer to 3.6 Print position

adjustments.

Horizontal position

adjustment (unit: dots)

-9999-+9999

Tear-off position

adjustment (unit: dots)

-120-+120

Time

00-23

Supported display format:

MM/DD/YY 24HR

MM/DD/YY 12HR

DD/MM/YY 24HR

DD/MM/YY 12HR

00-59

Date

00-99

01-12

01-31

Paper calibration None

The printer feeds paper and at

the same time rectifies the

sensor parameters in order to

adapt to the paper.

Serial port configuration

Baud rate

110, 300, 600,

1200, 2400, 4800,

9600, 19200,

38400, 57600,

115200

Data bit (unit: bit)

7 bit, 8 bit

Stop bit (unit: bit)

1 bit, 2 bit

Parity NONE, ODD, EVEN

Handshake signal

Hardware

handshake,

software handshake

Page 31

BTP-3200E User’s Manual

- 23 -

head pressure adjusting knob, and every knob has 3 levels,

indicating different print head pressure. When turning the knob

clockwise, both the number of level and the pressure of print head

increase (see figure 3.4.1). The default pressure level is generally at

level 3, which does not need to be changed during normal printing.

Figure 3.4.1

The pressure level needs to be changed under the following

conditions:

1) When the print head pressure cannot meet the requirement (the

ribbon cannot be rewound smoothly, for example), turn the print

head pressure adjusting knob to increase the pressure;

2) Different levels can be selected when using label paper of

different widths for printing (just for reference, see the table

below).

Label paper width Levels on the left Levels on the right

25mm 1 1

Page 32

BTP-3200E User’s Manual

- 24 -

Caution:

Set the print head pressure to a lower level as long as the print

quality is acceptable.

3.5 Sensor position adjustment

When marked paper is used or marked paper width is changed, the

sensor position can be adjusted according to the following steps:

1) Measure the required sensor position in advance based on the

mark position of media;

2) Push the spanner in the direction indicated by the arrow on the

sensor cover board, and then turn to take off the sensor cover

board (see figure 3.5.1);

3) Pull or push the sensor to the required position (as shown in the

figure);

4) Press down the top cover board spanner and install the top

cover board.

Figure 3.5.1

51mm 2 2

110mm 3 3

Page 33

BTP-3200E User’s Manual

- 25 -

3.6 Print position adjustment

1) Adjust vertical print position

When the situation like figure A or B occurs, adjust the vertical

print position to figure C. (For the detailed adjustment method,

please refer to 3.3.1 Button menu settings).

Figure 3.6.1

Caution:

n Figure A indicates that the print position is upper than the

correct position. Adjust it in the negative direction (The data

symbol in the option “Vertical position adjustment” is “+”);

n Figure B indicates that the print position is lower than the

correct position. Adjust it in the positive direction. (The data

symbol in the option “Vertical position adjustment” is “-”).

2) Adjust horizontal print position

When the situation like figure D or E occurs, adjust the

horizontal print position to figure F (For the detailed adjustment

method, please refer to 3.3.2 Detailed parameter setting range).

Page 34

BTP-3200E User’s Manual

- 26 -

Figure 3.6.2

Caution:

n Figure D indicates that the print position is on the left of the

correct position. Adjust it in the positive direction (The data

symbol in the option “Horizontal position adjustment” is “+”);

n Figure E indicates that the print position is on the right of the

correct position. Adjust it in the negative direction. (The data

symbol in the option “Horizontal position adjustment” is “-”).

3) Adjust tear-off position

When the situation like figure G or H occurs, adjust the tear-off

position to figure J. (For the detailed adjustment method, please

refer to 3.3.2 Detailed parameter setting range).

Page 35

BTP-3200E User’s Manual

- 27 -

Figure 3.6.3

Caution:

n Figure G indicates that the tear-off position is upper than the

correct position. Adjust it in negative direction; (The data

symbol in the option “Tear-off position adjustment” is “-”);

n Figure H indicates that the tear-off position is lower than the

correct position. Adjust it in positive direction. (The data symbol

in the option “Tear-off position adjustment” is “+”).

Page 36

BTP-3200E User’s Manual

- 28 -

4 Routine maintenance

Clean the print head, platen roller and sensor every month

according to the following steps. If the printer works in a tough

environment, the maintenance times can be properly increased.

4.1 Cleaning print head

When any of the following cases occurs, the print head should be

cleaned:

Ø Printout is not clear;

Ø Feed or retract paper with big noise;

Ø Something else sticks onto the print head.

Follow the steps below to clean the print head:

1) Turn off the printer and open the top cover;

2) Lift up the top cover and find the print head. Wait for print head to

cool down completely if it has just finished the printing;

3) Wipe off the dust and stains on the surface of the print head with

alcohol cotton ball (it should be wrung out);

4) Wait for 5 to 10 minutes until the alcohol evaporates completely,

press down print head module, and close the top cover.

4.2 Cleaning the sensor

When any of the following cases occurs, the mark sensor should be

cleaned:

Ø During printing, the printer sometimes misinforms paper end;

Ø The printer does not alarm when paper end;

Ø The printer cannot identify marks effectively.

Page 37

BTP-3200E User’s Manual

- 29 -

Follow the steps below to clean the mark sensor:

A. Transmissive sensor

1) Turn off the printer and open the top cover;

2) Wipe off the dust and stains on the surface of the

transmissive sensor with alcohol cotton ball (it should be

wrung out);

3) Wait for 5 to 10 minutes until the alcohol evaporates

completely, and close top cover.

B. Reflective sensor

1) Turn off the printer and open the top cover;

2) Find the reflective sensor and take off the top cover board of

it;

3) Wipe off dust and stains on the surface of sensor with alcohol

cotton ball (it should be wrung out);

4) Wait for 5 to 10 minutes until the alcohol evaporates

completely, close the top cover board of the sensor, and

close the top cover.

4.3 Cleaning platen roller

When any of the following cases occurs, the platen roller should be

cleaned:

Ø Printout is not clear;

Ø Feed and retract paper with big noise;

Ø Something else sticks onto the platen roller.

Follow the steps below to clean the platen roller:

1) Turn off the printer and open the top cover;

2) Uplift the top cover and find the platen roller. Wait for the platen

Page 38

BTP-3200E User’s Manual

- 30 -

roller to cool down completely if it has just finished printing;

3) Wipe off the dust and stains on the surface of the platen roller

with alcohol cotton ball (it should be wrung out) while turning the

platen roller;

4) Wait for 5 to 10 minutes until the alcohol evaporates completely,

and close the top cover.

Caution

n Before starting routine maintenance of printer, make sure the

printer is turned off;

n Do not touch the surface of print head with hands or metal. Do

not use forceps in case it scratches the surface of the print

head, platen roller and sensor;

n Do not use organic solvent like gasoline, acetone etc. to clean

the print head or platen roller;

n Do paper calibration again after cleaning the paper end sensor;

n Please wait for alcohol to evaporate completely before starting

printing.

Page 39

BTP-3200E User’s Manual

- 31 -

5 Troubleshooting

When the printer has a malfunction, please handle it with reference

to this charter. If it still can not be cleared, please contact SNBC or

your local dealer.

5.1 Troubleshooting

The error LED flashes and the buzzer beeps when an error or

exceptional status occurs. At this time, the printer stops the printing.

Please handle it with reference to the following method:

Error indication mode:

Error message

Buzzer Error LED LCD

Print head up 2 beeps Flash 2 times circularly

Display LOGO and

“COVER OPEN”

Paper end 3 beeps Flash 3 times circularly

Display LOGO and

“PAPER END”

Ribbon out 4 beeps Flash 4 times circularly

Display LOGO and

“RIBBON OUT”

Abnormal

temperature of

print head

No beep Flash 5 times circularly

Display LOGO and

“PRINT HEAD TOO

COLD OR HOT”

Mark location

failure

No beep Flash 6 times circularly

Display LOGO and

“MARK ERROR”

Mark calibration

error

No beep Flash 7 times circularly

Display LOGO and

“CALIBRA

TION FAILED”

Page 40

BTP-3200E User’s Manual

- 32 -

Troubleshooting methods:

Error LED

status

Reason analysis Solutions

Print head up

Print head is lifted up.

Please press down the print

head.

The micro switch has a

failure.

Contact the maintainer.

Paper end

Paper roll is used up or no

paper roll is installed.

Install a paper roll.

Paper jam Clear the paper jam.

Paper roll surface is dirty or

damaged.

Please skip the dirty or

damaged part.

Paper roll breaks away

from the mark sensor.

Install a paper roll again.

The surface of mark sensor

is dirty.

Clean mark sensor surface.

The position of reflective

sensor is not correct.

Adjust the sensor position

according to the description in

3.5.

Paper roll type does not

match with mark sensor

type.

Set the paper type in printer

driver to make it consistent with

actual paper type.

Lack of ribbon

Ribbon is used up Install ribbon

Ribbon is jammed Clear up the ribbon

Ribbon sensor has failures Replace the ribbon sensor

Print head

temperature

abnormal

Operating environment

temperature is too high,

causing overheating print

head.

Please improve ventilation

condition. The printer can return

to normal with the fall of

temperature.

Page 41

BTP-3200E User’s Manual

- 33 -

Print darkness is too high.

Lower the print darkness

properly.

Paper is jammed in the

path, causing heat

accumulation and

overheating print head.

Clear paper jam. Check if the

print head test pattern is normal

or not after the temperature of

print head drops. If normal, the

printer can continue to work;

otherwise please replace the

print head.

Mark location

failure or mark

calibration

failure

Paper type does not match

with sensor type.

Set the paper type in printer

driver to make it consistent with

actual paper type.

Something wrong with

marked paper (for example:

no mark or unclear mark)

Use the required media.

Mark height is less than the

required height.

Table 5.1.1

5.2 Print quality problems

Malfunction Reason Solution

Printout is unclear

or has stains.

Print head or platen

roller is dirty.

Clean the print head or platen

roller.

Paper does not meet

the requirement.

Use recommended paper.

Print darkness is too

low.

Increase print darkness.

Paper is not installed

correctly.

Install paper roll correctly.

Table 5.2.1

Page 42

BTP-3200E User’s Manual

- 34 -

Appendix

Appendix 1 Technical specification

Appendix 1.1 Main technical specifications

Item

BTP-3200E

parameter

BTP-3300E

parameter

Printing

Resolution 203DPI 300DPI

Print method Thermal/Thermal transfer

Print width

(Max.)

104mm 106mm

Print speed

(Max.)

152mm/s 102mm/s

CPU 32bit RISC microprocessor

Memory

FLASH: 4MB

SDRAM: 64MB

Extended FLASH: it can be extended to

8MB.

Print head

temperature

detection

Thermal resistor

Print head

position

detection

Micro switch

Paper mark

detection

Photoelectric sensor

Paper

existence

detection

Photoelectric sensor

Page 43

BTP-3200E User’s Manual

- 35 -

Communication

interface

USB interface or USB interface +

optional interface;

Optional interface: serial interface,

CENTRONICS parallel interface,

Ethernet interface and WLAN interface.

Media

Paper type

Continuous paper, label paper, marked

paper, etc.

Paper roll OD

(Max.)

127mm (5 inches)

Paper roll width

(Max.)

120mm

Paper roll ID 12.5mm (0.5 inch)/25mm (1 inch)

Paper out mode Tear-off, peel-off, cutter, etc.

Character

Barcode

Graphics

Character

enlargement/rot

ation

Support four types of rotation printing (0°,

90°, 180°, 270°)

Bitmap fonts can be enlarged up to 10

times.

Vector fonts can be zoomed without

scale.

Character set

7 bitmap fonts and 1 vector font are

built-in.

User-defined bitmap and vector fonts can

be downloaded into the printer.

Graphics

Plain bitmaps in binary system, HEX,

PCX, BMP and IMG files can be

downloaded to FLASH or RAM.

Page 44

BTP-3200E User’s Manual

- 36 -

Barcode

1D barcode:

Code39, Code93, Codabar,

Code128(Subsets A, B, and C), EAN-13,

EAN-8, UPC-A, UPC-E, UPC/EAN

Extensions, Planet Code, Standard 2 of

5, Industrial 2 of 5, Interleaved 2 of 5,

LOGMARS, GS1 DataBar (RSS)

2D barcode:

PDF 417, MicroPDF417, QR Code,

DataMatrix, MaxiCode, GS1 Composite

Operation

interface

Button, LED,

LCD

1 button, 1 LED,1 LCD

Power adapter

Input

AC 110~240V, 50/60Hz

Output DC 24V, 2.5A

Environmental

requirements

Operating

environment

+5℃~45℃, 20%~90%(40℃)

Storage

environment

-40℃~60℃, 20%~93%(40℃)

Physical

features

Overall size 216(W)x 306(D)x185mm(H)

Weight About 3.45Kg

Table appendix 1.1.1

Page 45

BTP-3200E User’s Manual

- 37 -

Appendix 1.2 Technical specifications of paper

1) Specifications of continuous paper (unit: mm)

Type Illustration Index

Continuous paper

without adhesive

Print paper

width: 18≤a≤120

Continuous paper

with adhesive

Base paper

width: 18≤a≤120

Print paper

width: 18≤b≤118

Paper margin

width: c ≤1

Table appendix 1.2.1

2) Discontinuous paper specifications (unit: mm)

Type Illustration Index

Discontinuous label

paper with adhesive

Base paper width:

18≤a≤120

Paper margin width:

b≤1

Label width:

18≤c≤118

Label height:: d≥10

Gap width: e≥2

Page 46

BTP-3200E User’s Manual

- 38 -

Discontinuous

punched paper

without adhesive

Punched paper width:

18≤a≤120

Punched paper

height: b≥10

Detection hole

position: c≤a/2

Detection hole width:

d≥5

Detection hole height:

e≥2

Discontinuous

marked paper

without adhesive

Marked paper width:

18≤a≤120

Marked paper height:

b≥10

Mark position: c≤a/2

Mark width: d≥10

Mark height: e≥4

Table appendix 1.2.2

Page 47

BTP-3200E User’s Manual

- 39 -

Appendix 2 Self-test page

Self-test page includes printer configuration information, printer

internal fonts and print head test information. The printer

configuration information and printer internal fonts reflect the current

internal configuration of the printer, and the print head test

information reflects the status of the print head.

Printer configuration information

Printer configuration information (BPLZ II) (this information is related

to the configuration of the printer.)

PRINTER CONFIGURATION

BTP-3200E……………………..……….. MODEL

FV2.000…………………………………. MAIN FIRMWARE

7…………………………………………. DARKNESS

+0……………………………………….. TEAR OFF

TEAR OFF……………………………… PRINT MODE

CONTINUOUS…………………..……... MEDIA TYPE

MEDIA…………………………………. SENSOR TYPE

MANUAL………………………………. SENSOR SELECT

DIRECT-THERMAL…………………… PRINT METHOD

56……………………………………….. PRINT WIDTH

640.…………………………………… LABEL LENGTH

11IN 300MM…………………………… MAXIMUM LENGTH

CONNECTED………………………….. USB COMM

NONE…………………………………… PARALLEL COMM

115200…………………………………... BAUD

Page 48

BTP-3200E User’s Manual

- 40 -

8 BITS…………………………………… DATA BITS

NONE…………………………………… PARITY

HARD…………………………………… HOST HANDSHAKE

NONE…………………………………… PROTOCOL

<~> 7EH…………………………… CONTROL CHAR

<^> 5EH………………………….... COMMAND CHAR

<,> 2CH…………………………… DELIM. CHAR

NO MOTION……………………………. MEDIA POWER UP

NO MOTION……………………………. HEAD CLOSE

DEFAULT……………………………….. BACKFEED

+0………………………………………… LABEL TOP

+0………………………………………… LEFT POSITION

152mm/s…………………………………. PRINT SPEED

152mm/s…………………………………. FEED SPEED

152mm/s…………………………………. BACKFEED SPEED

203DPI…………………………………... RESOLUTION

16360K………………………………….R: RAM

1472K…………………………………...E: ONBOARD FLASH

NONE…………………………………….. FORMAT CONVERT

0123456789………………………………. SERIAL NUMBER

Page 49

BTP-3200E User’s Manual

- 41 -

Appendix 3 Print and paper out position

Figure appendix 3.1

Caution

n To take marked paper for example, the figure above explains

the print and paper out position;

n Discontinuous paper locates by the front edge of the mark;

n Refer to Section 3.6 to adjust the print and paper out position.

Appendix 4 Communication interface

Appendix 4.1 Serial interface

1) Interface signal

Pin Signal name Signal direction

Function

1 None

2 RXD Input Data input

3 TXD Output Data output

4 DTR Output Data terminal ready

5 SG - Signal ground

6 DSR Input Data device ready

7 RTS Output Request transmission

8 CTS Input Allow transmission

9 FG - Frame ground

Table appendix 4.1.1 printer signal and status

Page 50

BTP-3200E User’s Manual

- 42 -

2) Wiring diagram

PC Printer

TXD---------------RXD

RXD---------------TXD

CTS----------------RTS

RTS----------------CTS

SG -----------------SG

Caution

n The following connection method can be used, which only

needs 3 wires. This method applies to small data amount or

XON/XOFF flow control:

PC Printer

TXD---------------RXD

RXD---------------TXD

SG ----------------SG

Appendix 4.2 Parallel interface

Parallel interface works under IEEE1284 compatible mode.

Pin Definition Description

Pin Definition

Description

1 Input /STROBE 13 Output SELECT

2 Input Data0 14 Input /AutoFd

3 Input Data1 15 Not defined

NC

4 Input Data2 16 -

Logic Ground

5 Input Data3 17 - Chassis Ground

6 Input Data4 18 - Vcc

7 Input Data5 19 ~ 30

- Signal Ground

8 Input Data6 31 Input /Init

9 Input Data7 32 Output /Fault

10

Output /ACK 33 - Ground

Page 51

BTP-3200E User’s Manual

- 43 -

11

Output BUSY 34 ~ 35 Not defined

/NC

12

Output PError 36 Input /SelectIn

Table appendix 4.2.1 parallel signal list

Caution

n In the process of data transmission, the host computer should

not ignore the Busy signal; otherwise the print data may be lost;

n Parallel interface signal adopts TTL level. Ensure the rise and

fall time of host computer is not longer than 0.5ms when it is

used.

Appendix 4.3 USB interface

USB interface meets USB1.1 protocol standard and is optional.

USB interface transmits signal and power via a four–wire cable, as

shown in the following figure:

Figure appendix 4.3.1 USB cable

Wire D+ and D- in figure appendix 4.3.1 are used for signal

transmission, and the VBUS is +5V.

Appendix 4.4 Ethernet interface

Ethernet interface meets the standard communication protocol of

10/100M BASE-T in IEEE802.3 and is optional.

PIN Signal name Signal direction

Function

P1 TX+ Output + Difference data signal output+

P2 TX- Output - Difference data signal output-

Page 52

BTP-3200E User’s Manual

- 44 -

P3 RX+ Input + Difference data signal input+

P4 Reserve —— ——

P5 Reserve —— ——

P6 RX- Input - Difference data signal inputP7 Reserve —— ——

P8 Reserve —— ——

G+ VCC power SPEED_LED power

G- SPEED_LED output SPEED LED signal

Y- LINK_LED output LINK LED signal

Y+ VCC power LINK_LED power

Table appendix 4.4.1 Ethernet signal list

Appendix 5 Operation guide for paper loading under

peel-off mode (optional)

When using label paper with adhesive, the user can refer to “2.4

Installing paper roll” for installation, and the paper out mode can be

set to peel-off mode. When peel-off mode is selected, follow the

steps below to load paper:

1) Remove several labels on the front of label paper, ensure the

front of base paper is flush, and pull the peel-off turning board

outward (see figure appendix 5.1);

Page 53

BTP-3200E User’s Manual

- 45 -

Figure appendix 5.1

2) Pass the base paper through the peel-off module according to

the path shown in the figure (see figure appendix 5.2);

Figure appendix 5.2

3) Push the peel-off turning board back into place and keep the

base paper in tension state to end paper loading.

4) When the printer is working, it peels labels off the base paper

and sends each label out one by one. After the user takes the

label away from the printer, the printer will continue to execute

the next command.

Loading...

Loading...