Shandong New Beiyang Information Technology BTP7400 User Manual

USER’S MANUAL

Industrial Barcode printer

BTP-7400

Shandong New Beiyang Information Technology Co., Ltd

- 1 -

Declaration

Information in this document is subject to change without notice.

SHANDONG NEW BEIYANG INFORMATION TECHNOLOGY

CO., LTD. (hereinafter referred to as “SNBC”) reserves the right

to improve products as new technology, components, software,

and hardware become available. If users need further data

about these products, please feel free to contact SNBC or our

local dealer.

No part of this document may be reproduced or transmitted in

any form or by any means for any purpose without the express

written permission of SNBC.

Copyright

Copyright © 2016 by SNBC

Printed in China

Version 1.0

Trademark

Warning and caution

Warning: Items shall be strictly followed to avoid injury or

damage to body and equipment.

Caution: Items with important information and prompts for

operating the printer.

BTP-7400 User’s Manual

Our Registered trademark :

BTP-7400 User’s Manual

- 2 -

SNBC has passed the following certifications:

ISO9001 Quality Control System Certification

ISO14001 Environmental Management System Certification

OHSAS18001 Occupational Health and Safety Management

System Certification

IECQ QC 080000 Hazardous Substance Process Management

System Certification

BTP-7400 User’s Manual

- 3 -

Safety Instructions

Before installing and using the printer, please read the

following items carefully.

1 Safety warning

The print head is a thermal element and it is at a high

temperature during printing or just after operation,

therefore do not touch it or its peripherals for safety’s

sake

.

The print head is an ESD-sensitive device. To prevent

damage, do not touch either its printing parts or

connecting parts.

2 Cautions

1) Install the printer on a flat and stable surface;

2) Reserve adequate space around the printer so that

convenient operation and maintenance can be performed;

3) Keep the printer far away from water source, and do not

expose the printer to direct sunlight, strong light and heat;

4) Do not use or store the printer in a place exposed to high

temperature, high humidity or serious pollution;

5) Do not place the printer in a place exposed to vibration or

impact;

6) No condensation is allowed to the printer. In case of such

condensation, do not turn on the power until it has

completely gone away;

7) Connect the printer power to an appropriate grounding

outlet. Avoid sharing one electrical outlet with large power

BTP-7400 User’s Manual

- 4 -

motors or other devices that may cause the fluctuation of

voltage;

8)

Disconnect the power when the printer is deemed to idle

for a long time;

9)

Don’t spill water or other electric materials into the printer

(e.g. metal). In case this happens, turn off the power

immediately;

10)

Do not allow the printer to start printing when there is no

recording paper installed; otherwise the print head and

platen roller will be damaged;

11)

To ensure quality print and normal lifetime, use

recommended paper or its equivalent;

12)

Shut down the printer when connecting or disconnecting

interfaces to avoid damages to control board;

13)

Set the print darkness to a lower grade as long as the print

quality is acceptable. This will help to keep the print head

durable;

14)

Avoid turning on and off the printer frequently when using

the printer and turn on the printer at least 2 seconds after it

is turned off;

15)

Do not disassemble the printer without permission of a

technician, even for repairing purpose;

16)

Keep this manual safe and at hand for reference purpose.

BTP-7400 User’s Manual

Contents

1 Product introduction........................................................................... - 1 -

1.1 Introduction.................................................................................. - 1 -

1.2 Unpacking and checking........................................................... - 2 -

1.3 Appearance and modules..........................................................- 3 -

1.4 Introduction of main modules....................................................- 4 -

2 Printer installation...............................................................................- 5 -

2.1 Installation position..................................................................... - 5 -

2.2 Printer host connection.............................................................. - 5 -

2.3 Communication cable connection............................................ - 5 -

2.4 Paper roll installation (tear-off mode)...................................... - 6 -

2.5 Ribbon installation...................................................................... - 7 -

2.6 Starting the printer....................................................................- 10 -

2.6.1 Power-on and self-test..................................................... - 10 -

2.6.2 Print the self-test page......................................................- 11 -

2.7 Driver setup................................................................................- 11 -

3 Printer operation...............................................................................- 13 -

3.1 Print head pressure and pressure position adjustment..... - 13 -

3.2 Sensor position adjustment.....................................................- 15 -

3.3 Function of indicator light, button and LCD..........................- 17 -

3.3.1 Function of indictor light................................................... - 18 -

3.3.2 Function of Button.............................................................- 20 -

3.3.3 Function of LCD.................................................................- 23 -

3.4 Function of calibration..............................................................- 24 -

3.4.1 Manual calibration.............................................................- 24 -

3.4.2 Automatic calibration.........................................................- 25 -

3.5 Print settings..............................................................................- 26 -

3.5.1 Paper type.......................................................................... - 26 -

3.5.2 Print mode.......................................................................... - 27 -

- 5 -

BTP-7400 User’s Manual

3.5.3 Print method....................................................................... - 29 -

3.5.4 Print width........................................................................... - 29 -

3.5.5 Speed settings...................................................................- 30 -

3.5.6 Darkness settings..............................................................- 31 -

3.5.7 Action when power on / press down the print head.... - 32 -

3.5.8 Print position adjustment..................................................- 34 -

3.6 Physical distance setting.........................................................- 37 -

3.7 Serial interface settings........................................................... - 38 -

3.8 Network Settings.......................................................................- 39 -

3.9 Parallel interface settings........................................................ - 44 -

3.10 Date and time..........................................................................- 45 -

3.11 Offline printing......................................................................... - 46 -

3.12 Service......................................................................................- 47 -

3.13 Consumables library.............................................................. - 48 -

3.14 File operation...........................................................................- 50 -

3.15 Printer debugging...................................................................- 52 -

3.16 Sensor settings....................................................................... - 53 -

4 Routine maintenance...................................................................... - 55 -

4.1 Cleaning the print head........................................................... - 55 -

4.2 Cleaning the sensor................................................................. - 55 -

4.3 Cleaning the platen roller........................................................ - 57 -

5 Troubleshooting................................................................................- 59 -

5.1 Abnormity and solution............................................................ - 59 -

5.2 Print quality problems.............................................................. - 61 -

5.3 Ribbon problems.......................................................................- 62 -

5.4 Positioning and calibration problems.................................... - 62 -

Appendix............................................................................................... - 63 -

Appendix 1 Technical specification...............................................- 63 -

Appendix 1.1 Main technical specifications............................ - 63 -

Appendix 1.2 Technical specifications of ribbon.................... - 65 -

- 6 -

BTP-7400 User’s Manual

Appendix 1.3 Technical specifications of paper.....................- 66 -

Appendix 2 Self-test page..............................................................- 68 -

Appendix 3 Print and paper output position................................- 70 -

Appendix 4 Communication interface.......................................... - 71 -

Appendix 4.1 Serial interface.................................................... - 71 -

Appendix 4.2 Parallel interface................................................. - 72 -

Appendix 4.3 USB interface...................................................... - 73 -

Appendix 4.4 Ethernet interface............................................... - 74 -

Appendix 4.5 Wireless LAN interface...................................... - 75 -

Appendix 5 Guide for paper loading under peel-off mode....... - 76 -

Appendix 6 Guide for paper loading under label rewinding mode- 77 -

Appendix 7 Guide for paper loading under cutter mode...........- 78 -

Appendix 8 Menu on human-machine interface........................ - 79 -

Appendix 9 FCC statement........................................................... - 85 -

- 7 -

BTP-7400 User’s Manual

1 Product introduction

1.1 Introduction

BTP-7400 industrial barcode printer, with high performance, is the

ideal office barcode label printing equipment. It is suitable for

real-time label printing / batch product label printing / transportation

and logistics label printing /ticket printing at railways, airports and

stations / postal bag tag printing, etc.

BTP-7400 industrial barcode printer can be connected with external

devices via USB, serial or other interfaces and can provide common

drivers for operating systems such as Windows XP / 2000 /

se rver 2003 / 200 8 / Win7 / Win8 / W in1 0 and SDK based on

DLL.

The printer system adopts Linux platform with abundant resources

and it is easy for follow-up function extensions, such as the use of

standard function of off-line printing via adopting a scanner,

keyboard, SD card, U disk and other input devices, and it also can

be developed with functions like UHF tag reading and writing,

BASIC explainer, etc.

Main features:

Thermal / Thermal transfer printing;

Low noise, high speed printing;

Reliable, support continuous 7×24 hours standby operation;

Easy paper loading, convenient operation;

Intelligent and high effective, embedded Linux operating system

- 1 -

BTP-7400 User’s Manual

Adopting heat history and auto temperature adaptation control;

Adopting industrial print head with long lifetime and high printing

quality;

Supporting continuous paper, label paper, marked paper,

perforated paper, etc.

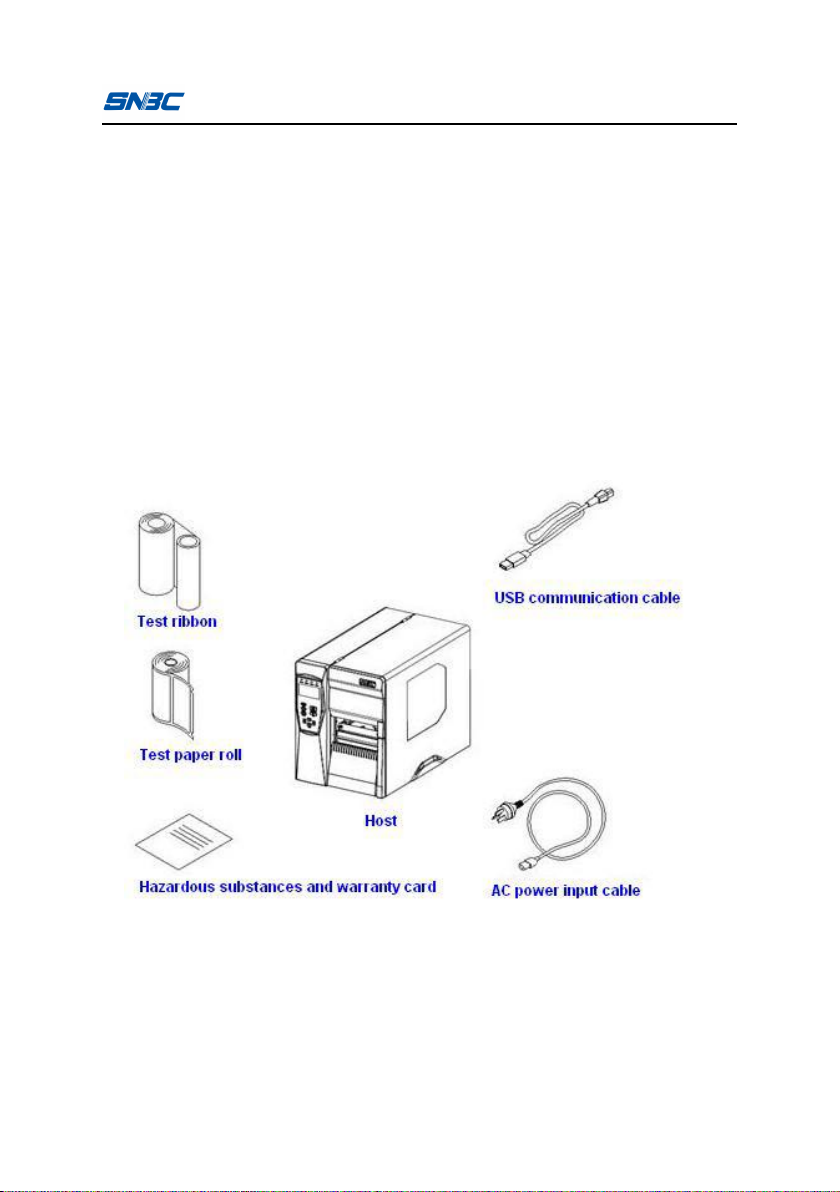

1.2 Unpacking and checking

Open the packaging and check the items according to the packing

list. Please contact your local dealer or the manufacturer if there is

any shortage or damage.

Fig. 1.2.1

- 2 -

BTP-7400 User’s Manual

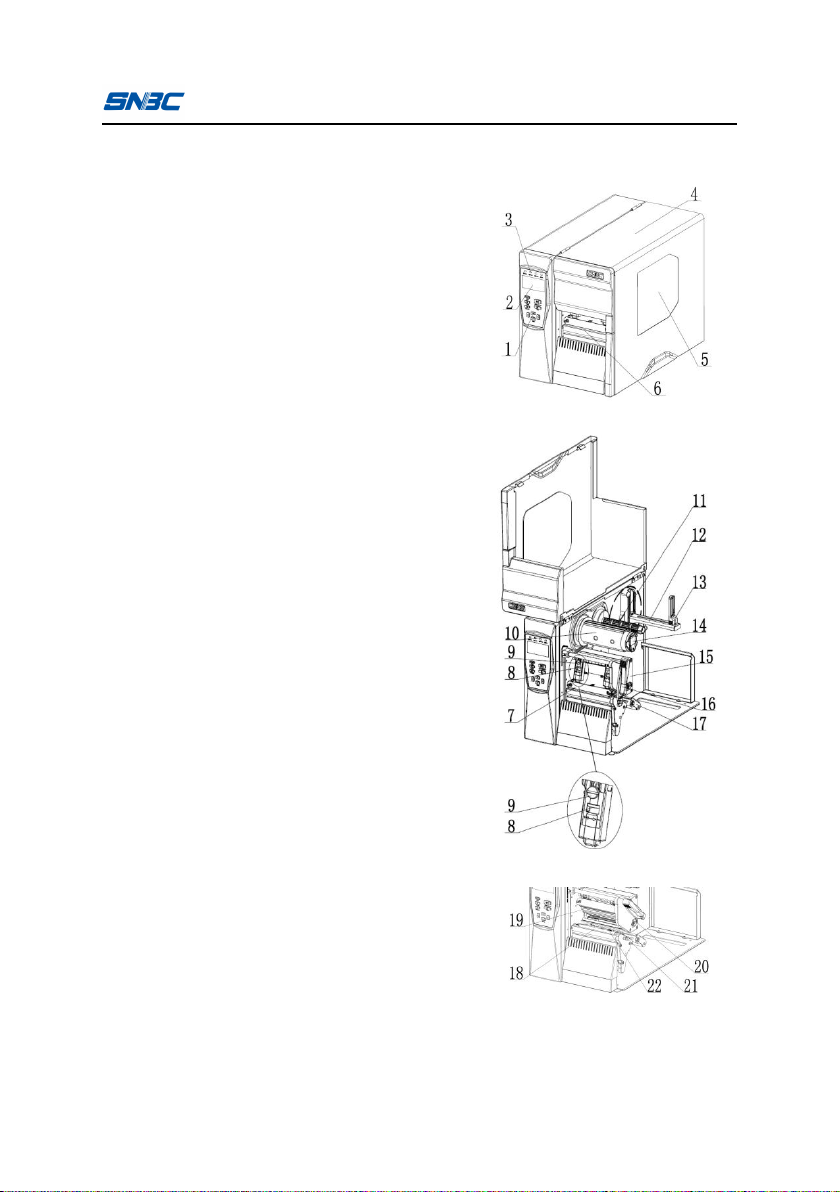

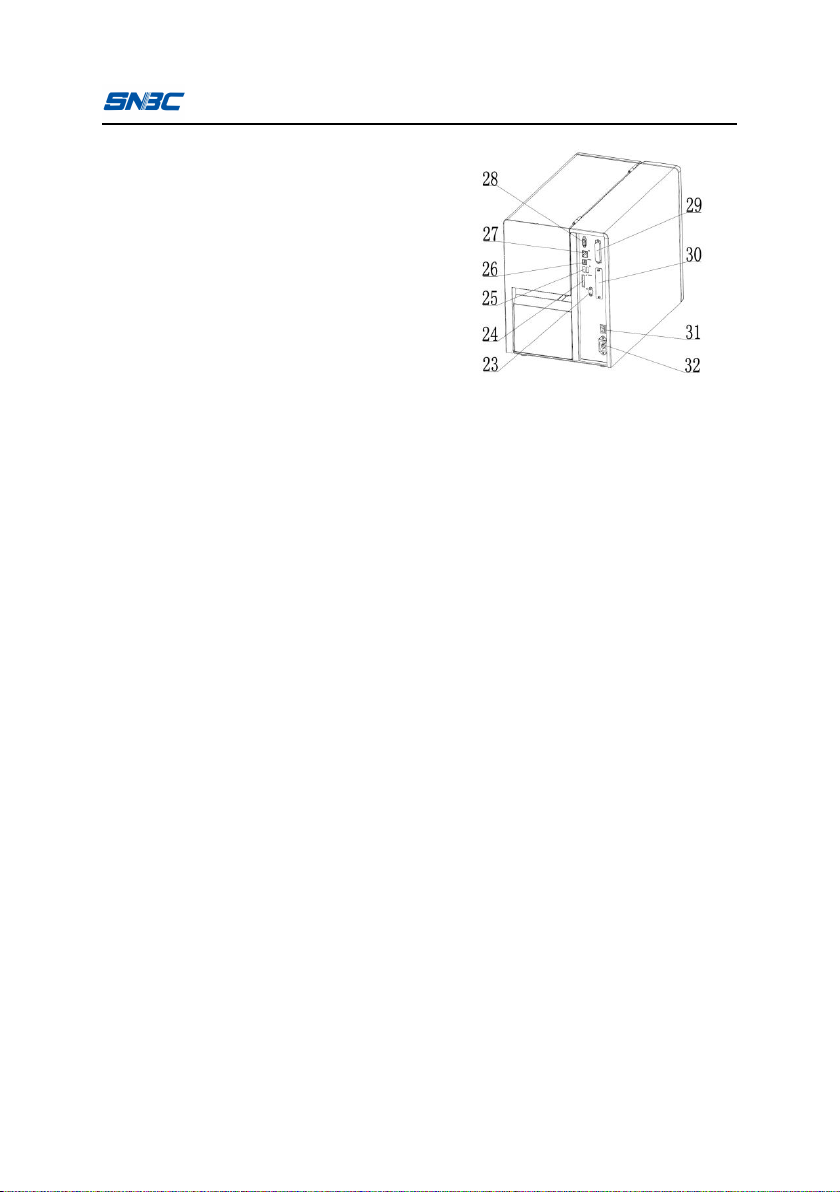

Fig.1.3.3

1.3 Appearance and modules

1—Button

2—LCD

3—Indicator light

4—right cover

5—Transparent window

6—Tear-off bar, Peel-off bar

7—Ribbon peel-off plate

8—Pressure adjustment knob

9—Pressure position lock knob

10—Ribbon retraction roller

11—Ribbon release shaft

12—Paper holder

13—Right paper guide

14—Ribbon release spanner

15—End cover of upper path

16—Print head uplifting spanner

17—Buffer module

18—Platen roller

19—Print head

20—Print head adjustment block

21—Sensor module

22—Moveable paper guide

23—Wireless interface (optional)

24—SD card interface (optional)

Fig.1.3.1

Fig.1.3.2

- 3 -

BTP-7400 User’s Manual

25—USB A interface

26—USB B interface

27—Ethernet interface

28—Serial interface

29—Parallel interface

30—Expansion interface (optional)

31—Power switch

32—Power interface

1.4 Introduction of main modules

1) Buttons, LCD and indicator light (1,2,3): indicates the printer

status, complete the print function;

2) Power switch (31): press "O" to turn off the power, press"-" to

turn off the power;

3) Paper holder (12) and right paper guide (13): supports the paper

roll, prevent the paper roll shake;

4) Moveable paper guide (22): prevent the paper moving from side

to side in the paper path;

5) Sensor module (21): calibrate, detect and position the black

mark paper, label paper and other media;

6) Print head uplifting spanner (16): control the print head status of

lifting up/ pressing down.

Fig. 1.3.4

- 4 -

BTP-7400 User’s Manual

2 Printer installation

2.1 Installation position

Flatly place the printer on the operation table, which must be

waterproof, moisture proof and dustproof. The maximal tilted angle

should not exceed 15° during installation.

2.2 Printer host connection

1) Ensure the printer is turned off;

2) Connect one end of the AC power input cable with the printer

host;

3) Connect the other end of the AC power input cable with the 220V

power socket.

Caution:

If the printer will not be used for a long time, please turn off the printer

power.

2.3 Communication cable connection

1) Ensure the printer is turned off;

2) Insert the communication cable into the suitable interface of

printer, and fix it with screw or latch spring of the plug;

3) Connect the other end of the communication cable to the host.

Caution:

Don’t connect or disconnect the communication cable when the power has

not been turned off.

- 5 -

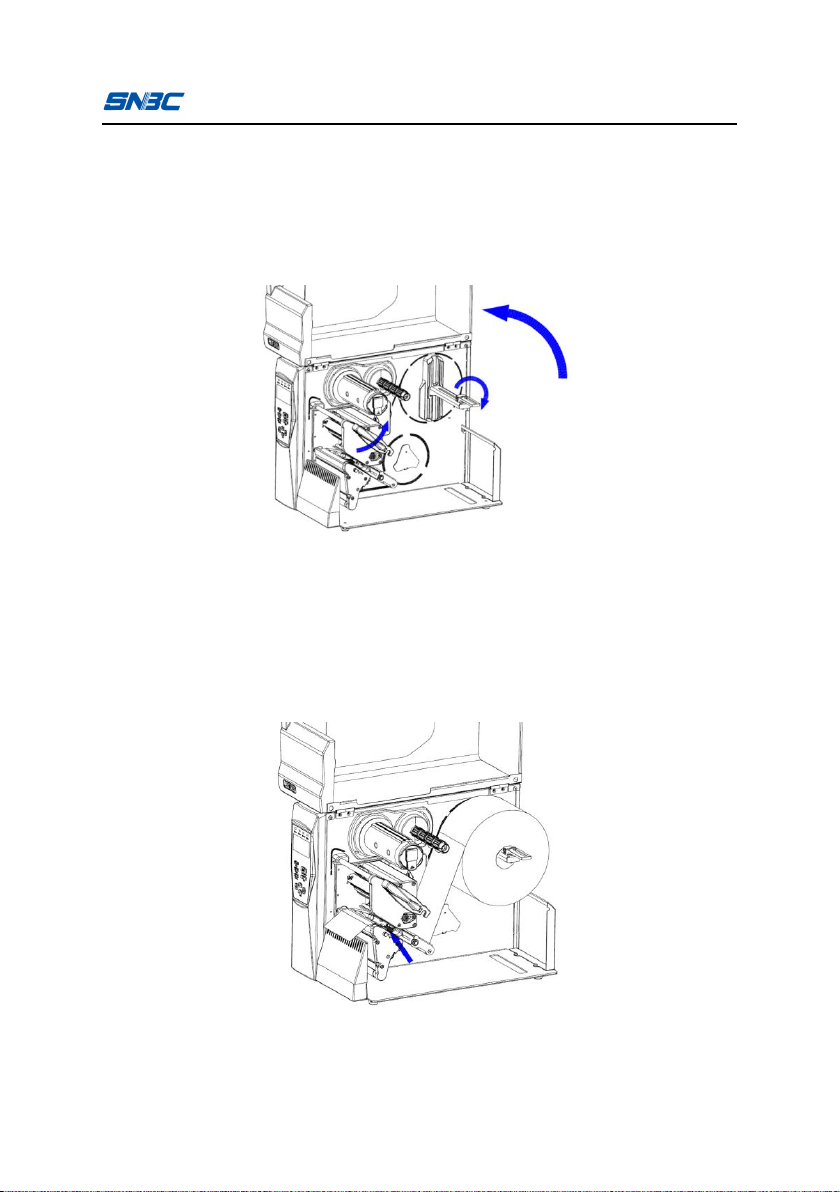

2.4 Paper roll installation (tear-off mode)

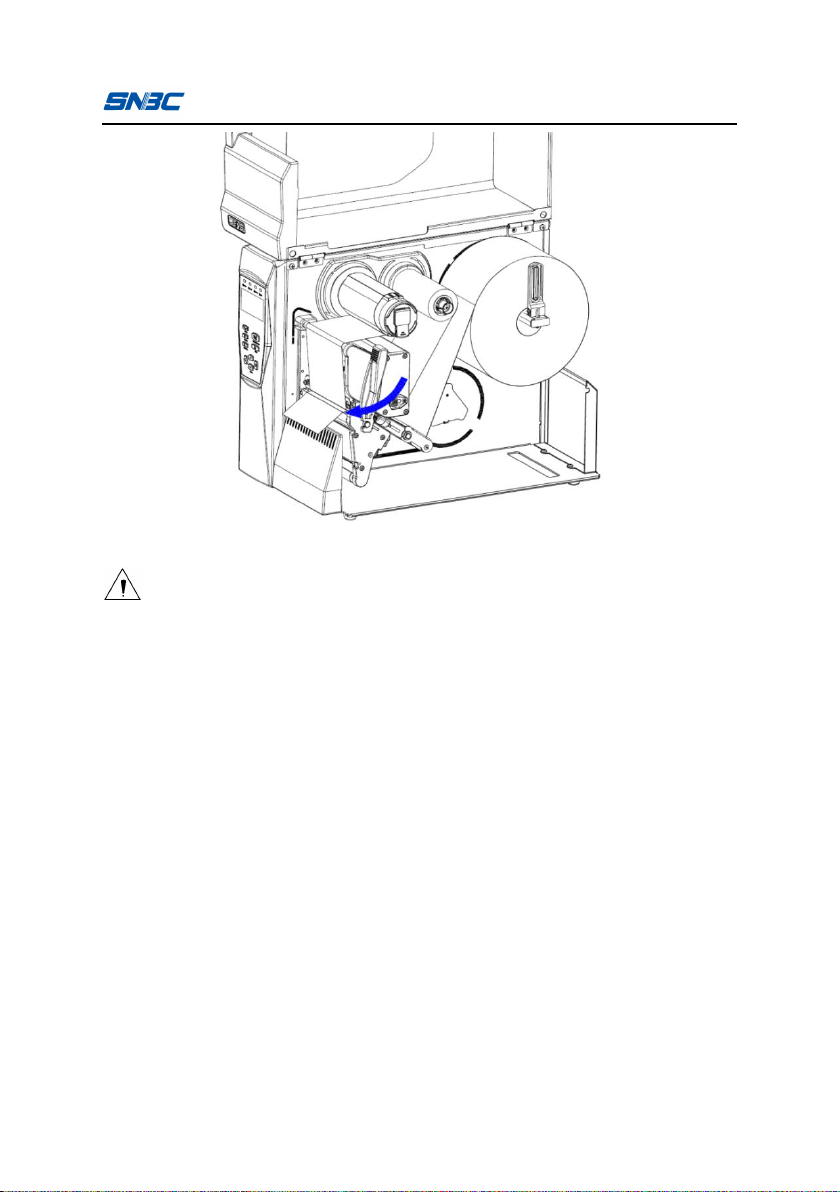

1) Open the right cover of printer, turn the print head uplifting

spanner (16) backward to the angle shown in the figure, and turn

the right paper guide (13) to horizontal position (see Fig. 2.4.1);

Fig. 2.4.1

2) Install the paper roll leftward on the paper holder, pull out and

place the paper head flatly in the paper path, align it leftward and

slightly tighten the paper with the movable paper guide (see Fig.

2.4.2);

Fig. 2.4.2

BTP-7400 User’s Manual

- 6 -

BTP-7400 User’s Manual

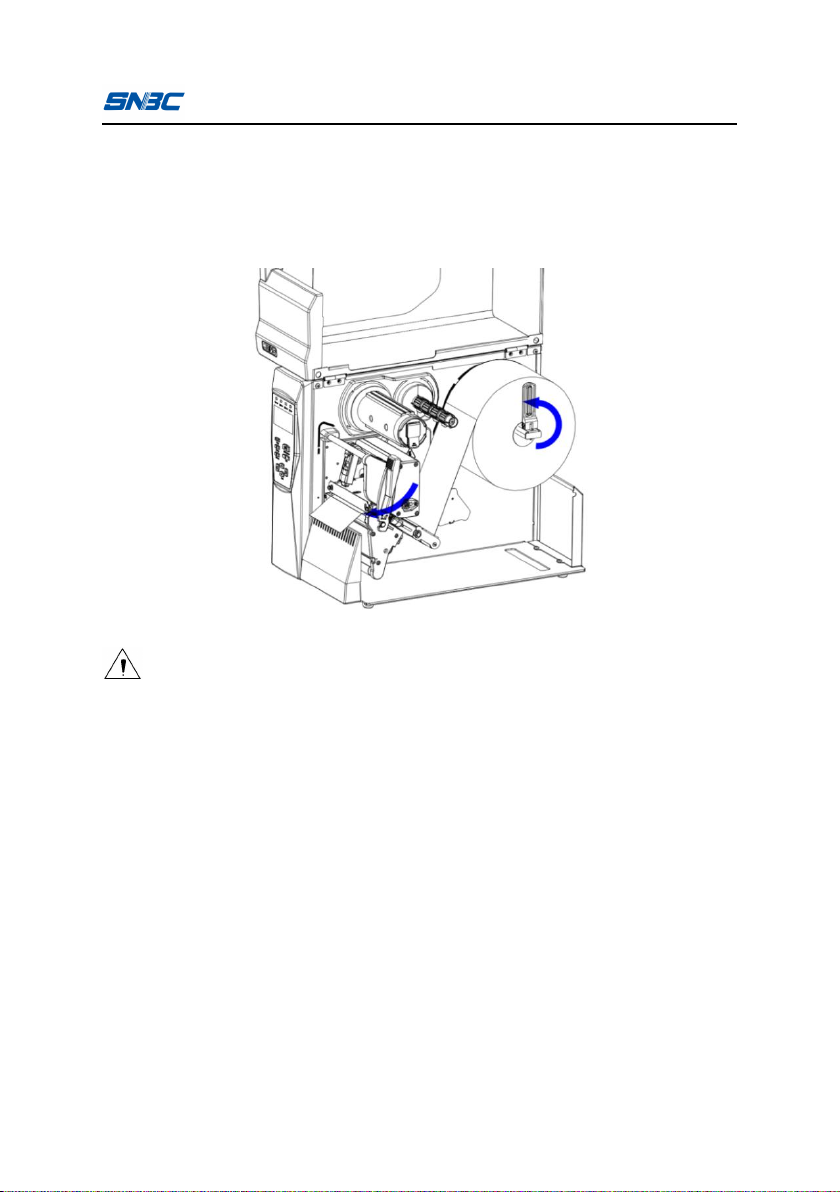

3) Turn the right paper guide (13) leftward to make it vertically and

abut the paper roll (ensure the paper roll can rotate smoothly),

and turn the print head uplifting spanner (16) forward to press

down the print head. Detail operation refers to the Fig. 2.4.3.

Fig. 2.4.3

Caution:

The print side of paper is upward. If marked paper is used, the black mark is

downward. Continuous paper with the black mark on the print side is not

supported.

2.5 Ribbon installation

1) Open the right cover of printer, turn the print head uplifting

spanner (16) backward to the angle shown in the figure (see

Fig.2.5.1);

2) Install the ribbon on the ribbon release shaft (11) in the direction

shown in the figure (pay attention to the outward/inward ribbon);

- 7 -

lead the ribbon head go under the print head module and wind

the ribbon on the ribbon rewinding roller from its underside; rotate

the roller to tighten the ribbon (see Fig. 2.5.1);

Fig. 2.5.1

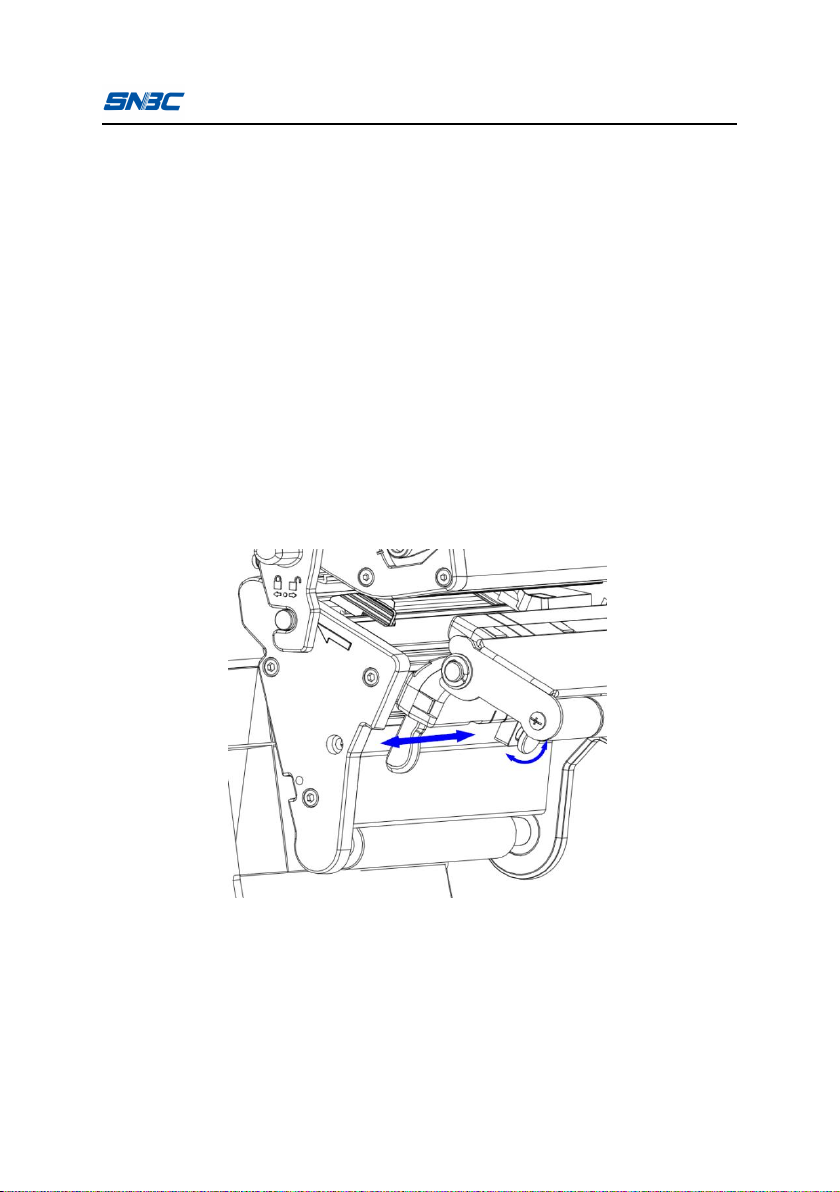

3) Turn the print head uplifting spanner forward to press down the

print head and lead it to lock status. Detail operation refers to

Fig.2.5.2;

BTP-7400 User’s Manual

- 8 -

BTP-7400 User’s Manual

Fig. 2.5.2

Caution:

Determine the print method: If thermal transfer printing is selected, the

ribbon needs to be installed; if thermal printing is selected, the ribbon does

not need to be installed.

Under normal condition, the selected ribbon should be wider than the print

media.

Keep the ribbon as flat as possible during ribbon installation in case the

ribbon is cockled or damaged during printing. If ribbon is cockled, please

adjust the pressure position of print head or ask for support from the

customer service.

- 9 -

BTP-7400 User’s Manual

2.6 Starting the printer

2.6.1 Power-on and self-test

1) Ensure the power adapter and the communication cable are

connected correctly, and turn on the printer;

2) The printer starts the self-test. After the self-test is finished, the

LCD screen displays the manufacturer LOGO and status

information or product model;

3) If power-on action is set, the printer will perform power-on action.

Note:

Power-on action refers to the actions performed automatically after the

printer being turned on, including feeding one label, starting calibration

automatically (only valid under discontinuous paper mode). The power-on

action can be set by commands or human-machine interface.

- 10 -

BTP-7400 User’s Manual

Caution

If the printer cannot be started or cannot work normally after it is started,

please contact your local dealer or the manufacturer in time.

2.6.2 Print the self-test page

1) Installed the media, turn on the power switch, click on the

'Menu / Set' button to enter the menu, select "Self-test", and

click "Menu / Set" button, then the printer will feed the paper

and print the self-test page (sample refers to Appendix 2.1)

(functions of indicator light and button refers to section 3.3.

2) The self-test page lists the current printer configuration

information.

2.7 Driver setup

1) Run “Setup.exe” in the driver package, and read the related

software license agreement carefully. If you accept the items in

the license agreement, please click “I accept the items in the

software license agreement”, and then click “Next” button;

2) Select the printer type and model to be installed. If you want to

set the printer as default printer, please check “Set As Default

Printer” and click “Next”;

3) Select the setup type, and click “Next”;

The driver supports Windows XP / 2000 / server 2003/2008 / Win7 /

Win8 / Win10 and Vista system. It is stored in one CD delivered with

the printer, and the customer can also download it from the website

www.snbc.cn.

Driver installation method:

- 11 -

BTP-7400 User’s Manual

4) Select the current system type, and click “Next”;

5) Set the printer port. “LPT1” is set as the default print port, but

users can select it according to actual needs. If it is a serial port

driver in Windows 2000 or above system, please select

“BYCOMx” (x equals to 1, 2, 3, 4, 5, 6, 7 or 8), and then click

“Install” to end the installation.

- 12 -

BTP-7400 User’s Manual

3 Printer operation

Caution

The printer parameter settings are subject to the last settings. The printer

parameters can be set via the menu of printer operation interface, user

software (including drivers and the third-party software), printer commands,

etc. For example, the printer menu and the printer drivers in computer can

be used to set the print speed. Although the print speed has been set via

the printer menu, it will be updated to the speed set by the driver in the

computer after using the printer driver in computer to print.

3.1 Print head pressure and pressure position

adjustment

The print head pressure adjustment device is equipped with two

print head pressure adjustment knobs (8), and each knob can adjust

the print head pressure steplessly. Turn the knob leftward, the print

head pressure will increase (see Fig.3.1.1). The pressure position

lock knob (9) can adjust the pressure position and lock the pressure

size.

- 13 -

Fig. 3.1.1

The pressure needs to be adjusted under the following conditions:

1) When the print head pressure cannot meet the requirement (e.g.

the ribbon cannot be rewound smoothly), turn the print head

pressure adjustment knob to increase the pressure;

2) Different pressure size and pressure position can be selected

when use label paper with different widths for printing. The two

print head modules are symmetrical with the print contents.

3) If the print quality does not meet the requirements when adopts

thicker media, the print head pressure can be increased

appropriately.

Caution

Set the print head pressure to a lower level as long as the print quality is

acceptable;

If ribbon crack occurs when print at a low temperature environment, the

operation of increasing the print head pressure is the priority measure, and

the operation of reducing the print darkness or print speed can also be

taken when meet the use requirements.

BTP-7400 User’s Manual

- 14 -

BTP-7400 User’s Manual

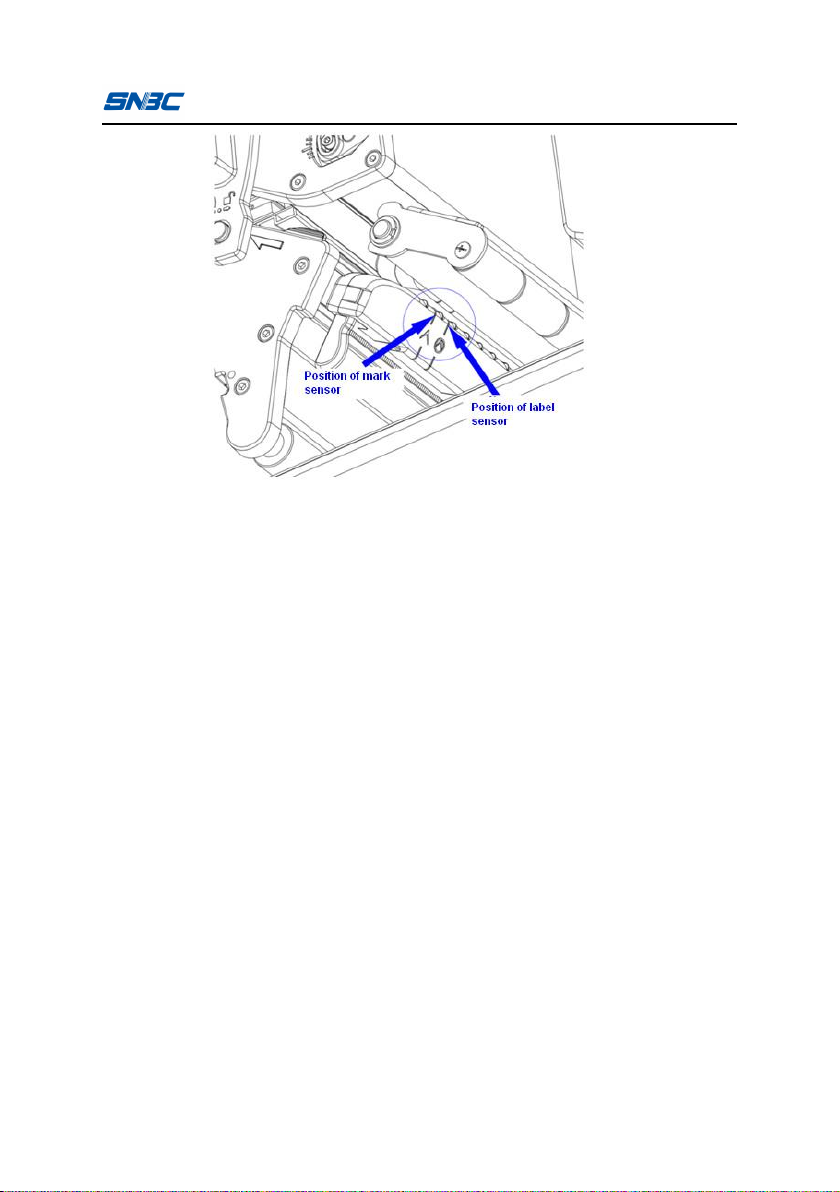

3.2 Sensor position adjustment

When the paper width is changed, the sensor position can be

adjusted according to the following steps:

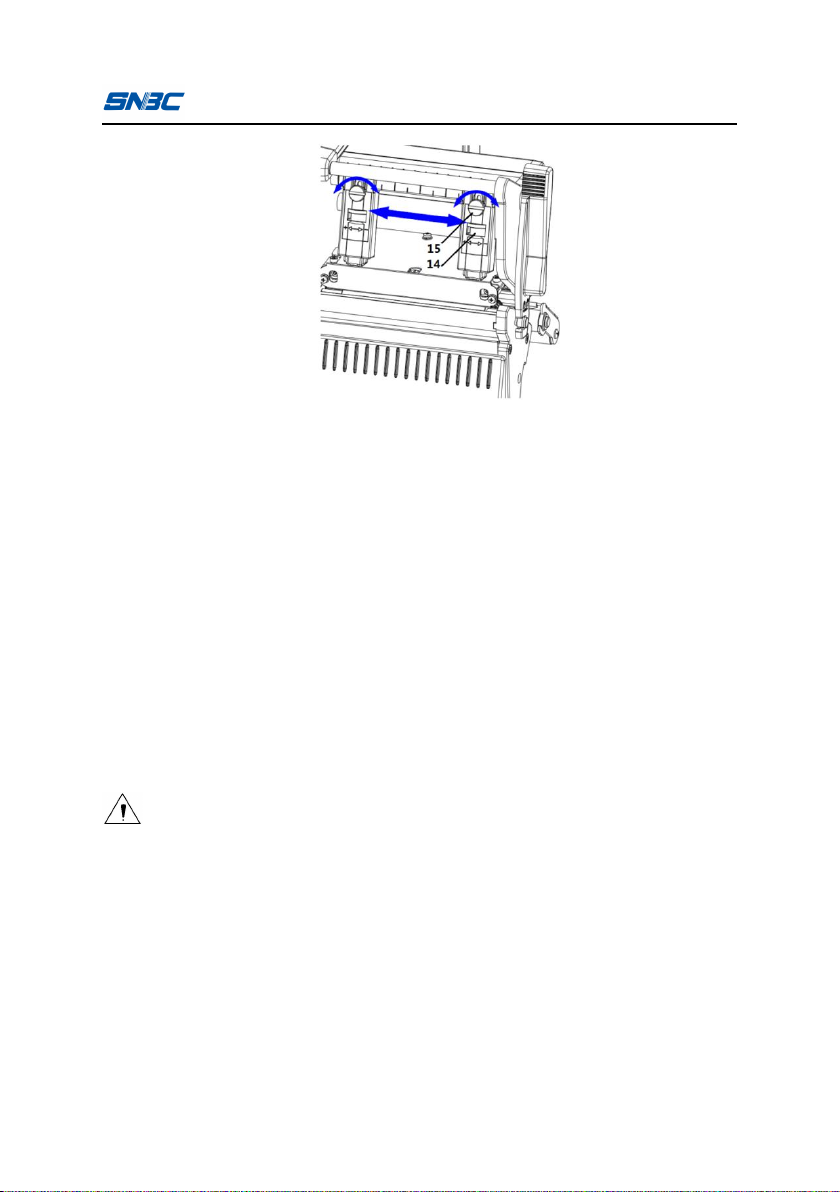

1) Counter-clockwise rotates the thumb knob to loosen the sensor

position limitation block (refer to the curved arrow in Fig. 3.2.1);

2) Observe the mark position, and move the sensor to the position

below the mark;

3) Pull the sensor spanner and move the sensor to the required

position(refer to the arrow direction in Fig. 3.2.1);

4) Clockwise rotate the thumb knob to lock the sensor position

limitation block.

Fig. 3.2.1

- 15 -

Fig. 3.2.2

BTP-7400 User’s Manual

- 16 -

BTP-7400 User’s Manual

3.3 Function of indicator light, button and LCD

- 17 -

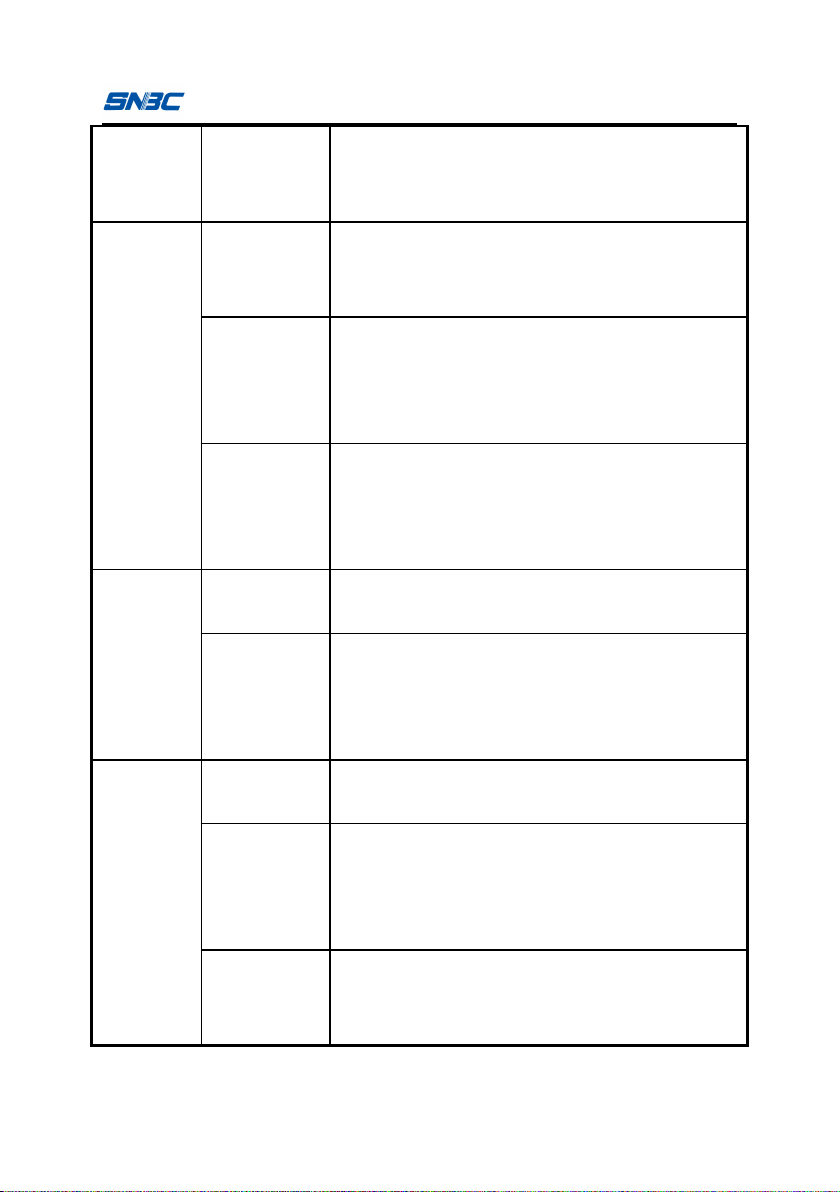

3.3.1 Function of indictor light

1) Function of indicator light

LED Name

Status

Explanation

Power LED

(Green)

Always on

Printer is already turned on.

Pause LED

(Yellow)

Always off

Printer is not in pause status.

Always on

Printer is in pause status.

Error LED

(Red)

Always off

Printer is not in error status.

Flash

Printer is in error status.

Data LED

(Yellow)

Always off

Printer is not printing.

Always on

Printer is printing.

Table 3.3.1-1

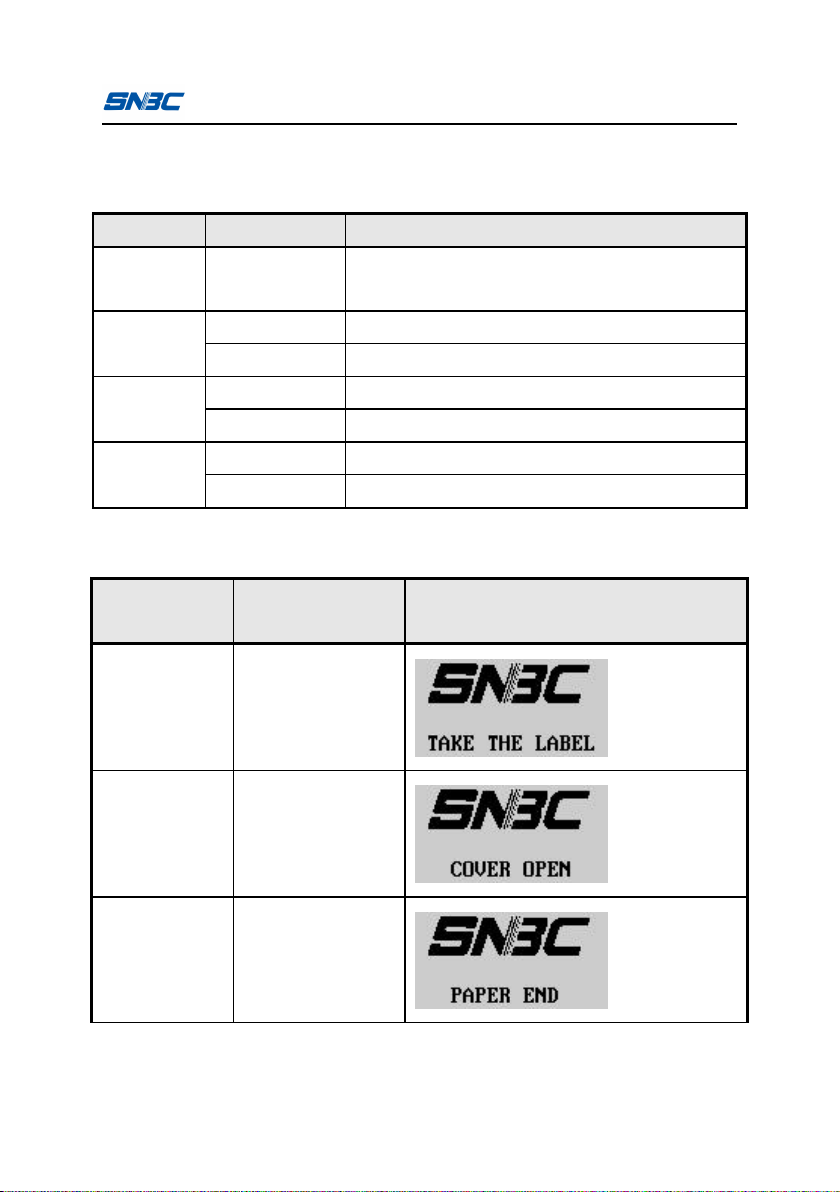

2) Error information and LED status

Error

information

Error LED

LCD

Not take away

the label

Not flash

Print head lifts

up

Circularly flashes

2 times

Printer is out of

paper

Circularly flashes

3 times

BTP-7400 User’s Manual

- 18 -

BTP-7400 User’s Manual

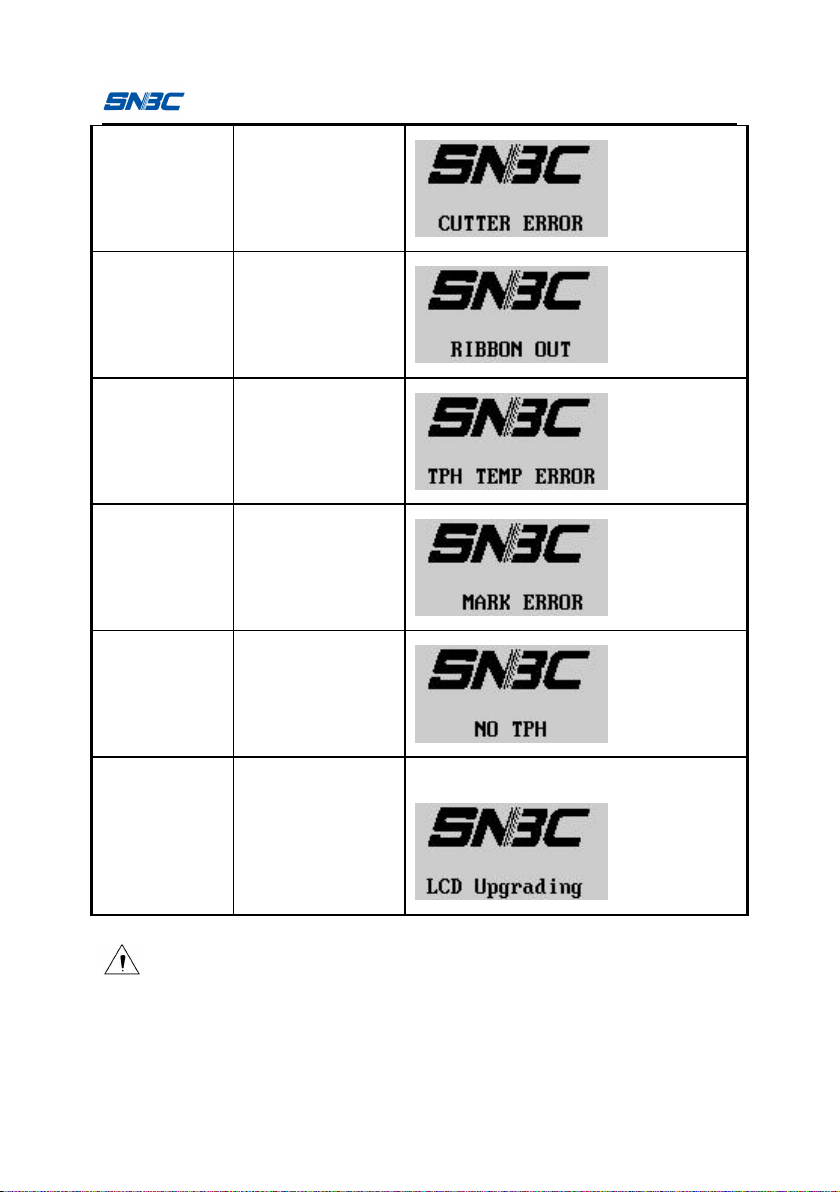

Cutter error

Circularly flashes

4 times

Out of ribbon

Circularly flashes

4 times

Print head

temperature is

abnormal

Circularly flashes

5 times

Cannot find

the mark

Circularly flashes

6 times

No print head

Circularly flashes

9 times

Updating

prompt

Always on

“xxx updating” example

Caution

Troubleshooting method refers to section 5.1 “Abnormity and solution”.

Table 3.3.1-2

- 19 -

BTP-7400 User’s Manual

3.3.2 Function of Button

Button

Printer

status

Function explanation

MENU

Standby ①

Under standby status, the user can press [Menu]

button for a short time to enter the menu display

interface.(① -⑥refer to below notes)

Menu ②

In menu display interface, the [menu] and

navigation buttons can be cooperated to perform

relevant configuration or query operation.

Text input ③

When the printer is in the status of text input, e.g.

input wireless SSID, the user can press [Menu]

button for a short time to select the current

characters, and press [Menu] button for a long

time to confirm the input at this time.

FEED

Non-printing

status

When press the [FEED] button, the printer will

feed one label if non-continuous paper is used,

while feed paper for a distance of one label length

if continuous paper is used (the label length

parameter that printer saved).

PAUSE

Non-printing

status

Under standby mode, the printer will enter pause

status by pressing the [Pause] button, and the

printer will return to standby status if press the

[Pause] button again.

Printing

status ④

The printer will stop the current print job

temporarily if press the [Pause] button during

printing, and it will continue the previous print job

if press the [Pause] button again.

- 20 -

BTP-7400 User’s Manual

CANCEL

Printing

status

Press [Pause] button to stop the current print job

temporarily, and then press the [Cancel] button to

cancel the print job.

EXIT

Menu

Press [Exit] button for a short time to exit for one

menu level, and press [Exit] button for a long time

to exit directly.

Menu

When exit to the standby interface, there will give

a prompt that save or not if the printer

configuration is changed, you can press the [Exit]

button to exit directly without saving.

Text input

Under text input status, press the [Exit] button for

a short time to delete the current characters.

Press the [Exit] button for a long time to give up

the input and return to the previous menu.

Up

navigation

Menu

When the operation interface is the menu bar, the

user can move up one menu configuration.

Digital input

⑤

When the operation interface is Leaf-menu ⑥

digital input interface, press [navigation up] button

can add 1 to the current configuration number or

switch the positive and negative number.

Down

navigation

(save

button)

Menu

When the operation interface is the menu bar, the

user can move down one menu configuration.

Digital input

When the operation interface is Leaf-menu digital

input interface, press [navigation down] button

can subtract 1 to the current configuration number

or switch the positive and negative number.

Menu

When exit to the standby interface, there will give

a prompt that save or not if the printer

configuration is changed, you can press this

- 21 -

Loading...

Loading...