SHAN DONG HUA YUAN LAI DONG ENGNE CO..LTD KM385BT Series Operation Manual

KM385BT ㌫ࡇḤ⋩ᵪ䈤᰾Җ

DIESEL ENGINE MODEL KM385BT SERIES

OPERATION MANUAL

ኡьⓀ㧡ࣘ⟳ᵪᴹ䲀ޜ

SHAN DONG HUA YUAN LAI DONG ENGNE CO..LTD

PREFACE

Please read the manual of operation carefully before opefrate the engine ,and the operator

should maintain it strictly as required.

The engine is improved from time to time ,so the manual of operation may be different from

the engine ,please draw attentions to it .The engine NO.is engraved in the central position of

cylinder-block upper end by the side of the fly wheel.

PRECAUTIONS

To ensure the availability and a long service-life, the engine should be operated and

maintained strictly as required .

Never let the engine run in overload ,or the engine will be damaged .To avoid premature

wearing of the engine parts ,do not allow to run the engine with high speed in the period of

commissioning.

If not necessary ,don’t run the engine with high speed . While running with low ger ,the

engine should keep running in low speed .Cooling water should be soft-water.

Do not allow to frequently work in the condition of boiling or in high temperature water

(over 95ć).

Please choose the real parts supplied by our works or appointed one by our works.

Wellkeep the manual of operation and transfer it with the engine.

CONTENTS

CHAPTER I engine ntroduction……………………………………………….. 1

1. Main specifications

2. Main accessories specifications

3. Fitting clearances and wearing limits of the main moving parts

4. Main bolts tightening torque

CHAPTER Ċ engine operation and precautions…………………………….5

1. Engine operation

2. Precautions when operating

3. Assembling air filter

CHAPTER ċ

engine maintenance…… …………………………………. . . 7

1. Daily m aintenance

2. Maintenance after 1 0 0 hours

3. Maintenance after 5 0 0 hours

4. Engine preservation storage

CHAPTER IV the structure of engine…… ……… ……… … ……… ……1 0

1. Cyli nde r b loc k a ssem bly

2. Cyli nde r h ead as s em b ly

3. Cra nksh aft an d f lywhe el ass e mb l y

4. Pist on - con n ec tin g ro d a s sem bl y

5. Dri vin g me cha nis m

6. val a e s yste m

7. Fuel sup pl y sys tem

8. Lubrication system

9. Cooling system

10. Electric systsem

CHAPTER V engine trouble and remedy……………………………………17

A. Engine can not be started

B. Engine power declines

C. Engine stops suddenly

D. Enigine running with knocking sound

E. Oil pressure too low

F. Engine over heat

G. Encine exhausts abnormal smoke

H. Troubles and remedies of the fuel injection pump

I. Starter is out of order

J. Alternator is out of order

CHAPTER I ENGINE INTRODUCTION

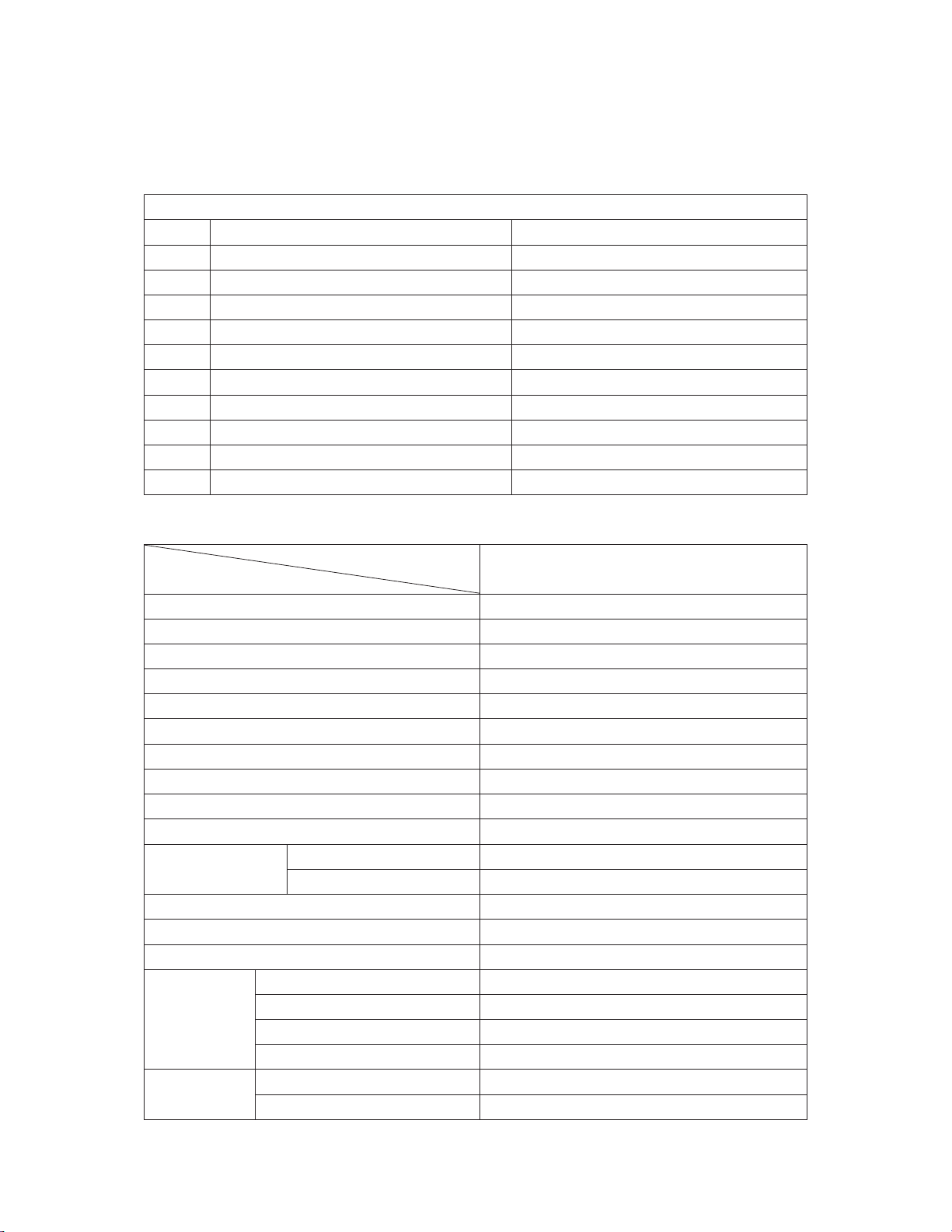

1. MAIN SPECIFICATIONS

Dynamic Norm of the Engine(the power of each type is show on the nameplate)

KM385BT Diesel Engine

order

Rated Power/Speed(KW/rpm)

Max Torque/Speed(Ngm/rpm)

1

18.4/2350

86 /İ1762

2

17.8/2400

81.5/İ1800

3

17.6/2350

82.3/İ1762

4

18.3/2350

85.5/İ1762

5

18.4/2400

84.2/İ1800

6

17.4/2350

81.3/İ1762

Main Paraments of the Diesel Engine

MODEL

SPECIFICATION

KM385BT

Type

In---Line,water—cooling, direct injection

No.of Cylinder

3

Cylinder bore(mm)

85

Piston stroke(mm)

90

Compression ratio

18:1

Displacement(L)

1.532

Cylinder working sequence

1ü3ü2

Lowest steady speed without load(rpm)

İ

850

Lowest fuel consumption at full load(g/KW.h)

İ

248

Oil consumption at full load(g/kw.h)

İ

0.8%

Oil pressure

At idle speed(kpa)

ı

50

At rated speed(kpa)

200~400

Crankshaft rotating direction

counterclockwise

Injection advance angle(T.D.C)

18~22

Fuel injection pressure(kpa)

20000f500

Valve timing

phase

Intake valve open

14.5ebefore T.D.C

Intake valve close

37.5eafter B.D.C

Exhaust valve open

56ebefore B.D.C

Exhaust valve close

12eafter T.D.C

Valve

clearance

Intake valve(mm)

0.20~0.30

Exhaust valve(mm)

0.25~0.35

Valve sinkage

Intake valve(mm)

0.7~0.9

Exhaust valve(mm)

0.7~0.9

Steady speed adjusting ratio at rated conditon

İ

8%

Oil sump capacity(L)

5

Temperature(ć)

Water outlet

75~85

Oil

85~95

Exhaust pipe

İ

600

Starting method

Electric starting

Lubricating method

Pressure & splash

Cooling method

Water cooling

Overall dimension (L×W×H) (mm)

569×525×604

Net weight (kg)

234

Applications

Tractor, engineering

machine

2. MAIN ACCESSORIES SPECIFICATIONS

Model KM385BT

Injection

pump

Model

IW or BQ

Type

Plunger˄3I344˅

Plunger diameter (mm)

Ï

7

Nozzle tip model

ZCK154S425

or ZCK154S423

Starter

QDJ1332A or QDJ1309J1

(12V, 2.5kW or 3kW)

Alternator

2JF200

(14V

ǃ

350W)

Water pump

Centrifugal

Oil pump

Rotary type

Fuel filter

Model

CX0706

Type

Rotary

Oil filter

Model

WB178

Type

Rotary

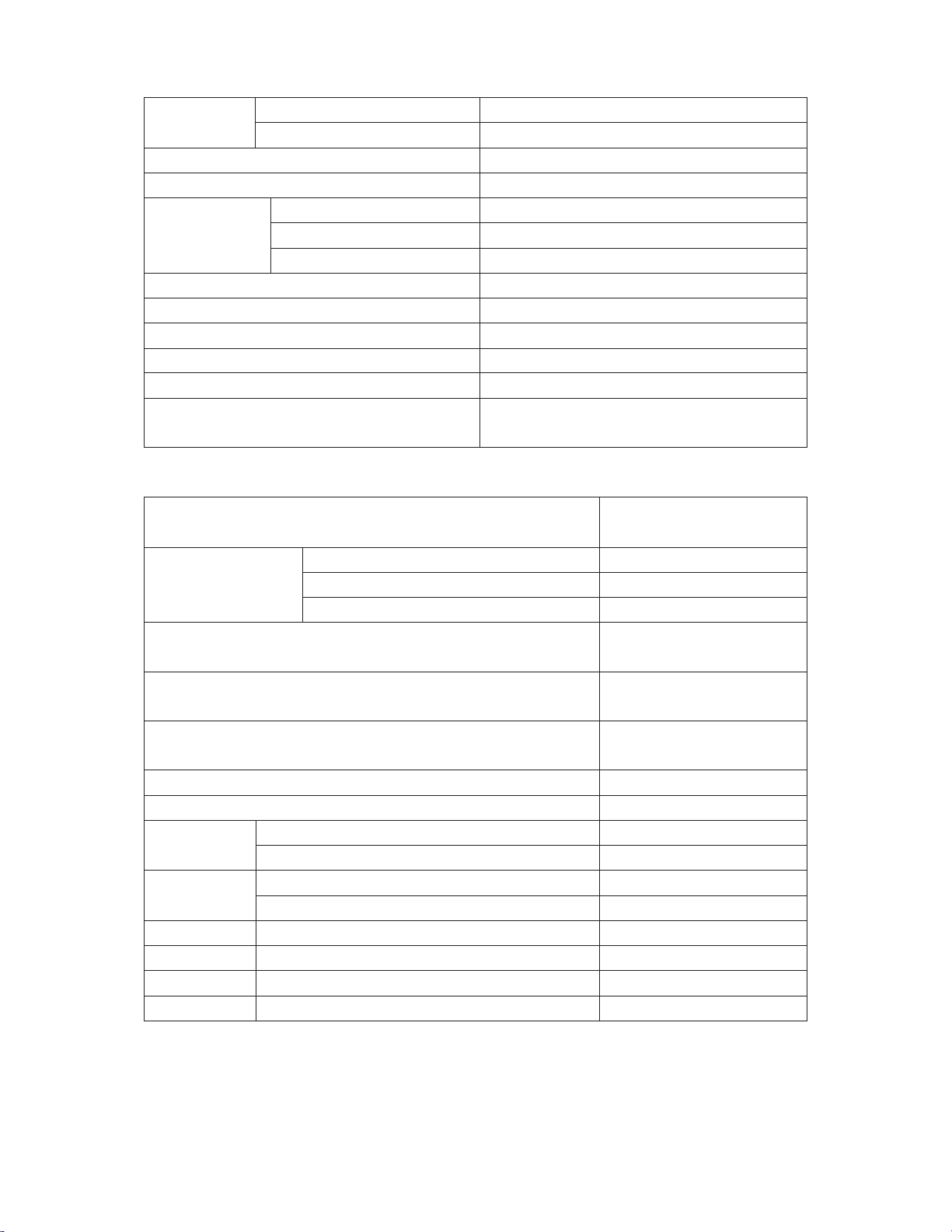

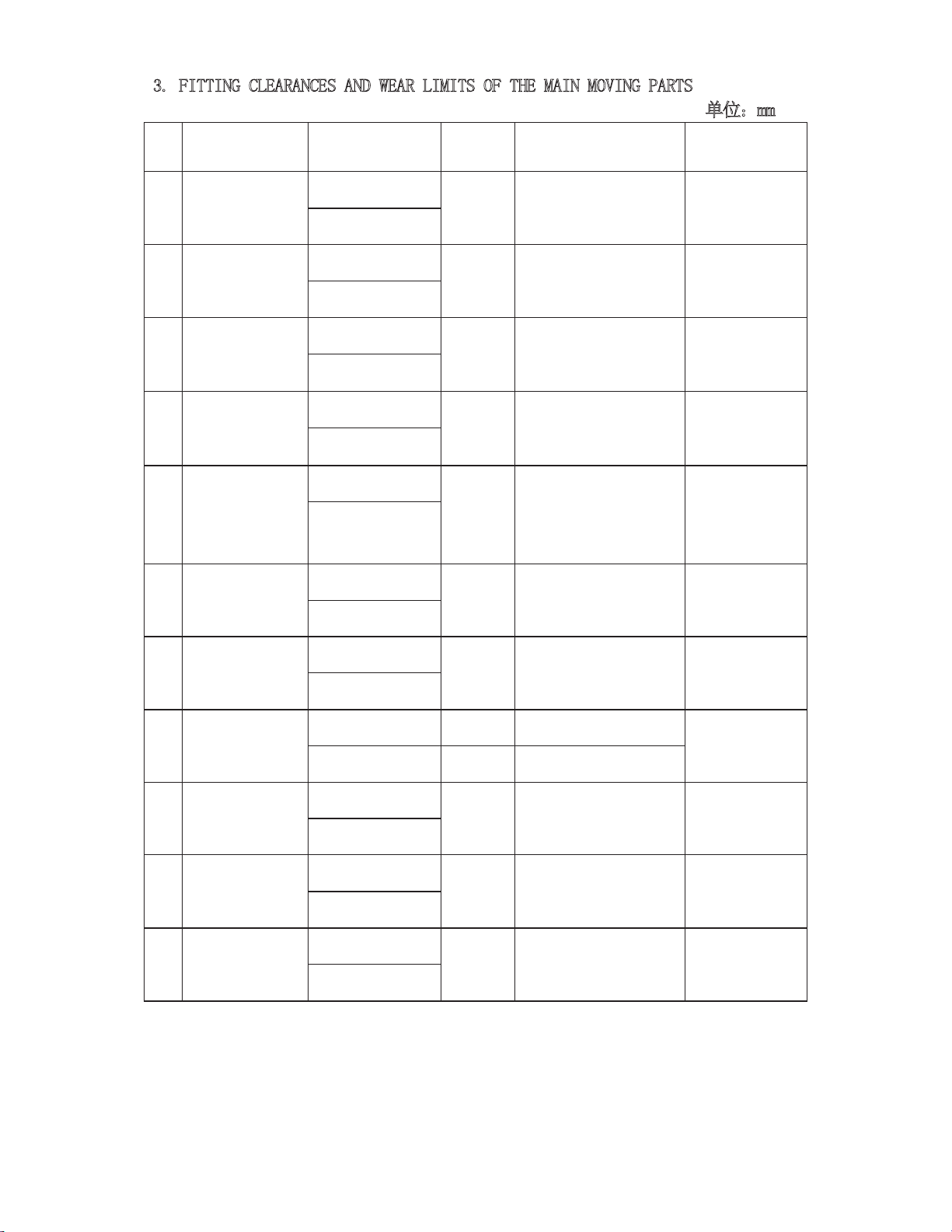

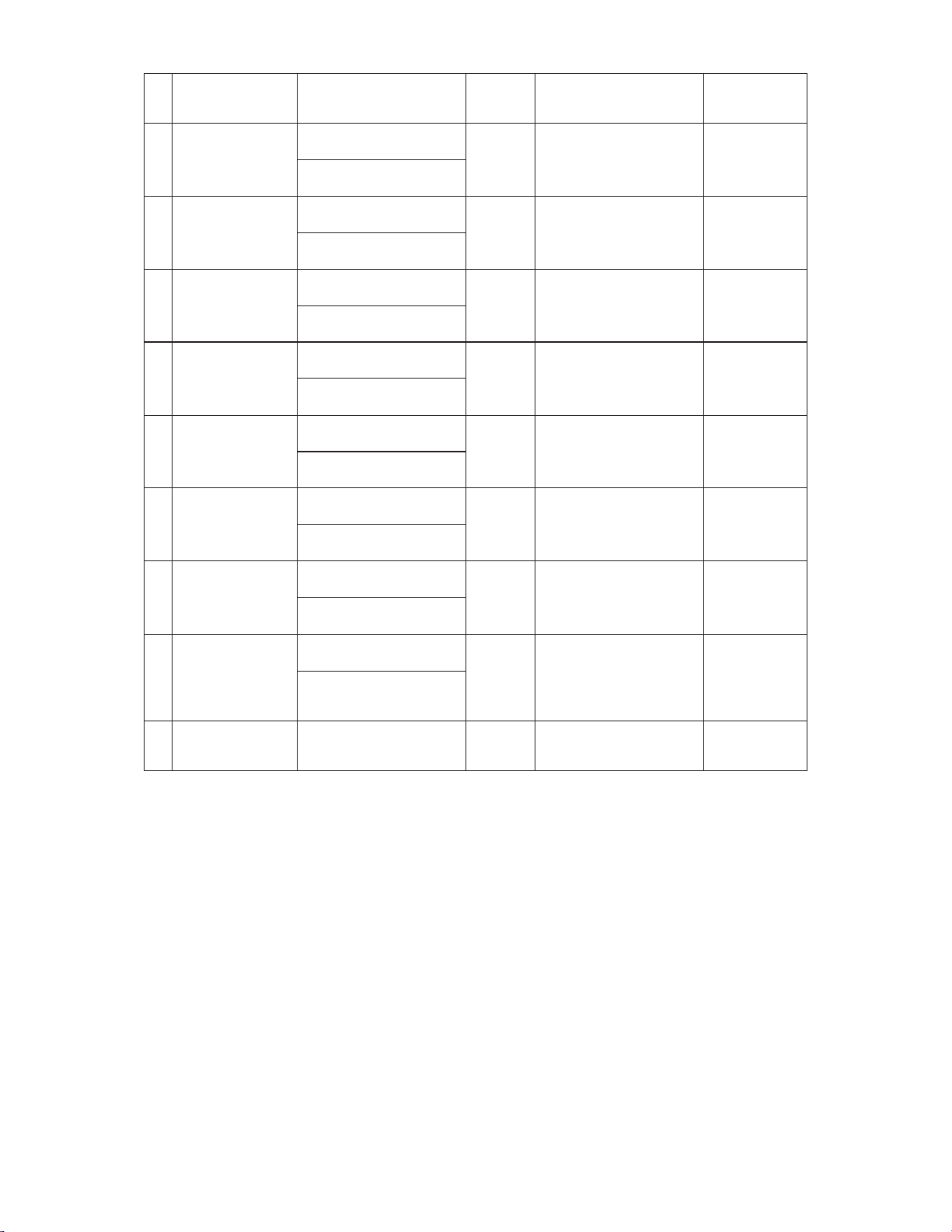

),77,1*&/($5$1&(6$1':($5/,0,762)7+(0$,1029,1*3$576

অս˖PP

No.

NAME

STANDARD

SIZE

FITTING

NEW ENGINE

FITTING CLEARANCE

L1MIT

ALLOWANCE

1

Main journal and

main bearing hole

Shaft

¶58h6

0

–0.01 9

Clearance

fit

0.07~0. 138 0.25

Hole

¶58

+0.11 9

+0.07

2

Axial clearance of

crankshaft

29

-0.075

-0.165

Clearance

fit

0.075~0. 265 0.50

29

+0.10

0

3

Crankshaft journal

and connecting rod

bearing hole

Shaft

¶50h6

0

–0.01

6

Clearance

fit

0.04~0.102 0. 20

Hole

¶50

+0.086

+0.04

4

Connecting rod big

end facing

clearance

31b11

-0.115

-0.22

Clearance

fit

0.115~0.32

31

+0.10

0

5

Piston pin &

connecting rod

small end bushing

hole

Shaft

¶26h4

0

–0.00 6

Clearance

fit

0.025~0.044 0.10

Hole

¶26

+0.03 8

+0.025

6

Piston pin & piston

pin seat hole

Shaft

¶26(

0

–0.006

)

Interim fit

-0 0045~+0. 0105

Hole

¶26JS5

+0.004 5

–0.00 45

7

Piston skirt &

cylinder liner

Skirt

¶80

-0.106

-0.13

Clearance

fit

0.106~0. 160 0.4

Hole

¶80h7

+0.030

0

8

Piston ring opening

clearance

First ring

0.30-0.50

2.2

Third ring & oil ring

0.25-0.45

9

First ring and its

slot

Ring 2.5

0

-0.012

Clearance

fit

0.06~0.092 0.20

Slot 2.5

+0.080

+0.060

10

Second & third ring

and its slot

Ring 2.5

0

-0.012

Clearance

fit

0.04-0. 072 0.18

Slot 2.5

+0.06

+0.04

11

Oil scraper ring and

its slot

Ring 4

0

-0.012

Clearance

fits

0.03~0.067 0.18

Slot 4

+0.055

+0.03

No

NAME

STANDARD

SIZE

FITTING

NEW ENGINE

FITTING CLEARANCE

LIMIT

ALLOWANCE

12

Camshaft journal

and its bushing

Shaft

¶44c7(

-0.05 0

–0.07 5

)

Clearance

fit

0.08~0.130 0.20

Hole

¶44

+0.05 5

+0.03

13

Camshaft axial

clearance

¶

5C11

-0.070

-0.145

Clearance

fit

0.07~0.245 0.60

¶

5

+0.10

0

14

Valve tappet

and its hole

Shaft

¶13f6(

-0.01 6

–0.02 7

)

Clearance

[it

0.016~0.045 0.25

Hole

¶13H7

+0.01 8

0

15

Rocker arm shaft

and shaft hole

Shaft

¶16f7(

-0.01 6

–0.03 4

)

Clearance

fit

0.016~0.052 0.20

Hole

¶16H7

+0.01 8

0

16

Intake valve and

valve guide hole

Shaft

¶7e8(

-0.025

–0.04 7

)

Clearance

fit

0.025~0.069 0.15

Hole

¶7H8

+0.02 2

0

17

Exhaust valve and

valve guide hole

Shaft

¶7d7(

-0.040

–0.05 5

)

Clearance

fit

0.040~0.077 0.15

Hole

¶7H8

+0.02 2

0

18

Idle gear shaft

journal and

bushing hole

Shaft

¶44f7(

-0.02 5

–0.05 0

)

Clearance

fit

0.025~0.075 0.20

Hole

¶44H7

+0.02 5

0

19

Idle gear end facing

clearance

17c9

-0.09 5

-0.138

Clearance

fit

0.19~0.276

17C9

+0.138

+0.095

20

Gears engaging

side clearance

Clearance

fit

0.11~0.18 0.30

4. MAIN BOLT TIGHTENING TORQUE

Cylinder head bolt 135~150 N.m

Main bearing cover bolt 115-130 N.m

Connecting rod bolt 50~60 N.m

Fly wheel bolt 50~60 N.m

CHAPTER Ċ

ENGINE OPERATION AND PRECAUTIONS

1. ENGINE OPERATION

Fuel, oil and cooling water

1) Fuel and oil:

Fuel and oil selected subject to local ambient temprature.

2) Cooling water:

Water of rain or clear river water is always preferably selected as cooling water. You are

always suggested to fill some anti-frozen liquid in cooling system in cold winter. Heat the cooling

water up to 80ć before filling it into the water tank, if the engine is hard to start, when the

ambient temperature is below 0ć.

Inspection and preparation before starting:

1) Check each connection for tightness, check operation levers such as fuel supply lever, engine

stop lever whether they are running freely.

2) Running the crankshaft several turns, check each part for running smoothly.

3) Check the oil level in oil sump and injection pump to ensure that the oil level is at the upper

side of the oil dipstick mark.

4) Check water tank for full of cooling water and whether there is any leakage on water pipe

connections.

5) Check fuel tank for full of fuel and fuel pipes for smooth flowing and its leakage.

6) Check each attached parts for correct connection as injection pump, fuel filter, oil filter, water

pump, fan, generator and its bracket, fan belt, starter and water tank etc.

7) Check each connector of electrical system for correctness, tightness.

Check alternator for sufficient voltage.

Check alternator for negative electrode bonding and the accumulator for negative electrode

bonding.

Engine starting

1) Set speed adjusting level at middle position.

2) Loosen the air exhaust screw on fuel filter, continuously press the hand – operated fuel delivery

pump to discharge the air inside fuel system, especially for new engine or engines stocked for long

time.

3) To start the engine first turn the switch to “pre-heat” position to heat the engine for 25-30

seconds.. Then turn to “pre-heat” position to start the engine. Repeat as above procedures in 2

minutes, if you failed to start the engine.

4) After startingˈimmediately adjust fuel supply to make the engine running at idle speedˊ

Care should be taken to ensure that the oil pressure is up to50kPaˈthen gradually increase speed to

warm up the engine without 1oadˊ

Loading...

Loading...