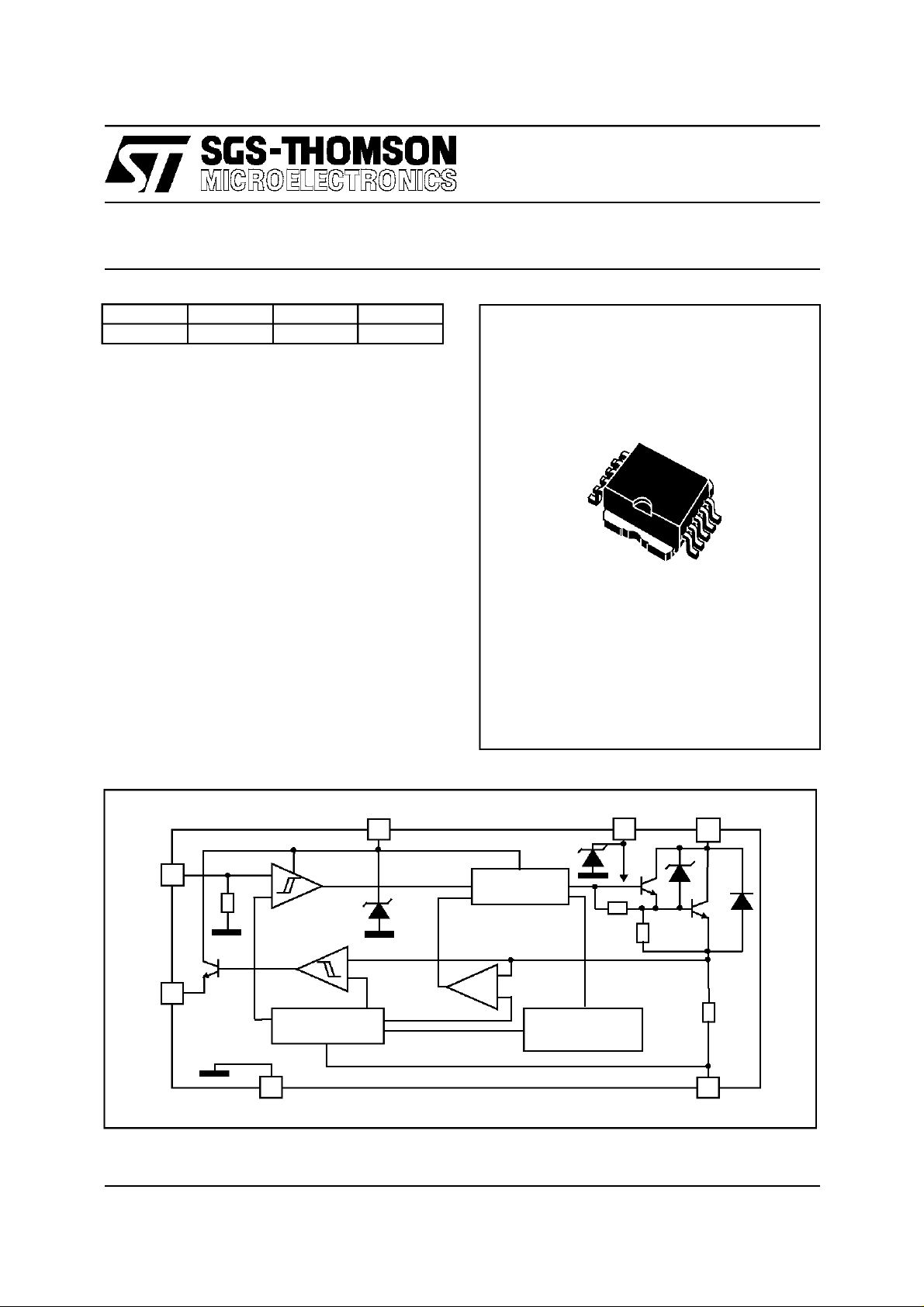

HIGH VOLTAGE IGNITION COIL DRIVER

TYPE V

VB125SP 370 V 9 A 200 mA

■ PRIMARY COILVOLTAGE INTERNALLY SET

■ COIL CURRENT LIMIT INTERNALLY SET

■ LOGIC LEVEL COMPATIBLEINPUT

■ BATTERY OPERATION

■ SINGLE FLAG-ON COIL CURRENT

■ TEMPERATURE COMPENSATED HIGH

CL

VOLTAGE CLAMP

DESCRIPTION

The VB125SP is a high voltage power integrated

circuit made using SGS-THOMSON

Microelectronics Vertical Intelligent Power

Technology, with vertical current flow power

darlington and logic level compatible driving

circuit.

The VB125SP can be directly biased by using the

12V battery voltage, thus avoiding to use a low

voltage regulator. It has built-in protection circuits

for coil current limiting and collector voltage

clamping. It issuitable as smart, high voltage, high

current interface in advanced electronic ignition

system.

I

CL

I

CC

VB125SP

POWER IC

TARGET DATA

10

1

PowerSO-10

BLOCK DIAGRAM

C

S

8

HV

TAB

C

INPUT

V

CC

6

9

DRIVER

FLAG

FLAG

(*)

September 1997 1/8

Thisispreliminary information onanew product indevelopmentorundergoing evaluation. Details are subject to change without notice.

Pins 1...5

10

VOLTAGE

REFERENCE

7

GND (Control)

THERMAL

PROTECTION

R

SENSE

*

GND (Power)

1

VB125SP

ABSOLUTE MAXIMUM RATING

Symbol Parameter Value Unit

HV

C

I

C

V

CC

I

CC

I

S

V

IN

P

TOT

V

ESD

V

ESD

T

j

T

STG

THERMAL DATA

R

thj-case

R

thj-amb

CONNECTION DIAGRAM

Collector Voltage (Internally Limited) -0.3V to V

Collector Current (Internally Limited) 10 A

Driving Stage Supply Voltage -0.2 to 40 V

Driving Circuitry Supply Current 400 mA

Logic Circuitry Supply Ccurrent 100 mA

Input Voltage -0.3 to 6 V

Power Dissipation TBD W

ESD Voltage (HVC Pin) -4 to 4 KV

ESD Voltage (Other Pin) -2 to 2 KV

Operating Junction Temperature -40 to 150 °C

Storage Temperature Range -55 to 150 °C

Thermal Resistance Junction - Case MAX 1.2 °C/W

Thermal Resistance Junction - Ambient MAX 62.5 °C/ W

CLAMP

V

V

CC

GND

Cs

INPUT

FLAG

PIN FUNCTION

No Name FUNCTION

1-5 GND Emitter Power Ground

6V

7 GND Control Ground (*)

8C

9 INPUT Logic Input Channel

10 FLAG Diagnostic Output Signal

TAB HVC Primary Coil Output Driver

(*) Pin 6 must be connected to pins 1-5externally

6

10

CC

S

HVC

5

GND

GND

GND

GND

1

Logic Supply Voltage

Logic Level Supply Voltage Filter Capacitor

GND

2/8

1

VB125SP

ELECTRICAL CHARACTERISTICS (V

to

6mH; unless otherwise specified; See Note 1)

= 6 to 24V; -40°C<Tj<125°C; R

bat

= 400 to 700m ; L

coil

Ω

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

CL

V

CE(sat)

I

CC(off)

I

CC(on)

I

CL

V

inH

V

inL

V

IN(hyst.)

I

inH

I

inL

V

diagH

V

diagL

I

diagTH

I

diag

I

diag(leak)

V

F

E

s/b

T

t

d(on)

t

d(off)

t

d(off)

j

High Voltage Clamp IC= 6.5 A; (See Note 2) 340 370 400 V

Saturation Voltage of the Power

Stage

Power Off Supply Current

Power On Supply Current

I

= 5A; Vin= 4V (See Note 3) 2 V

C

=0.4V V

V

in

=0.4V V

V

in

=4V V

V

In

=4V V

V

in

= 14V(Notes 4-5)

bat

=24V

bat

<14V (Note 4-5)

bat

=24V

bat

20

80

220

300

Coil Current Limit Vin= 4 V (See Note 6-7) 8 10 A

High Level Input Voltage 4 V

Low Level Input Voltage 0.8 V

Input Hysteresis Voltage 0.4 V

High Level Input Current Vin= 4 V 10 150

Low Level Input Current Vin= 0.8 V -100

High Level Diagnostic Output

Voltage

Low Level Diagnostic Output

Voltage

Current Threshold Level Diagnostic

R

EXT

(See Note 8)

R

EXT

(See Note 8)

T

j

High Level Flag Output Current IC>I

=22K C

Ω

Ω

=22K C

=25°C (See Note 7and fig. 5) 4.25 4.5 4.75 A

(See Note 7) 0.5 mA

DiagTH

EXT

EXT

=1nF

=1nF

3.5 5.5 V

0.5 V

Leakage Current on Flag Output Vin=LOW 10 µA

Antipallel Diode Forward Voltage IC=-1A 2 V

Single Pulse Avalanche Energy 300 mJ

Thermal Output Current Control IN = ON (See Note 9) 150 °C

Turn-on Delay Time of Output

Current

Turn-off Delay Time of Output

Current

Turn-off Delay Time of Output

Current

(See Note 10) TBD µs

(See Note 11) TBD

(See Note 11) TBD µs

coil

=2

mA

mA

mA

mA

µA

µA

µs

FIGURE 1: Temperature Compensated High

FIGURE 2: Electrical Characteristic of the Circuit

Voltage Clamp Shown in Figure 1

[mA]

I

HVC

nV

Z

R

i1

KV

R

ii

be

R

sens

PWR GND

C

40

30

20

10

100 200 300 400

slope ∝ ∑Ri

nV

Z

V

[V]

V

CL

CE

3/8

VB125SP

NOTE 1 Parametric degradation are allowed with 6V < V

< 10V and V

bat

bat

> 24V.

NOTE 2 In the high voltage clamping structure of this device a temperature compensation has been implemented. The

circuit schematic is shown in fig. 1. The KVbe cell takes care of the temperature compensation. The whole

electrical characteristic of the new circuit is shown in fig. 2. Up to V

leakage current of the power stage); for nV

compensation circuit (typical slope

≅Ω Ω

20 K ) as soon as the Vcl is reached the dinamic resistance drop to

Z<VCE<VCL

a current begins to flow across the resistances of the KVbe

=nVZno current will flow into the collector (just the

CE

~4 to

protect the device against overvoltage (See Fig. 3).

NOTE 3 The saturation voltage of the Power stage includes the drop on the sensing resistor.

NOTE 4 Considering the different ways of operation of the device (with or without spark, etc...) there are some short

periods of time in which the output terminal (HV

inductances and stray capacitances of the ignition coil.With VIPower devices, if no corrective action is taken, these

) is pulled below ground by a negative current due to leakage

C

negative currents can cause parasitic glitches on the diagnostic output. To kill this potential problem, a circuit that avoids

the possibility for the HV

implemented in the VB125SP.For this reason there are some short periods in which a current exceeding 220 mA flows

in the pin V

.

D

NOTE 5 A zener protection of 16V (typical) is placed on the supply pin (V

For this reason, when the battery voltage exceedes that value, the current flowing into V

maximum current specified at V

resistor.

to be pulled undeground, by sending the required negative current from the battery is

C

) of the chip to protect the internal circuitry.

CC

=14V (both in power on and power off condictions) : it will be limited by an internal

bat

cc pin can be greater than the

NOTE 6 The primary coil current value Icl must be measured 1 ms after desaturation of the power stage.

NOTE 7 These limits apply with regard to the minimum battery voltage and resistive drop on the coil and cables that permit

to reach the limitation or diagnostic level.

NOTE 8 No internal Pull-Down.

NOTE 9 Tj

min= 150 °C means that the behaviour of the device will not be affected for junction temperature lower than

150°C.For higher temperature, the thermal protection circuit will begin its action reducing the Icl limit according with the

power dissipation. Chip temperature is a function of the Rth of the whole system in which the device will be operating

(See Fig.4).

NOTE 10 Propagation Time measured from input voltage rising edge to 50% of output voltage falling edge.

NOTE 11 As soon as the input signal is switched low the stored charges in the base of the power transistor are removed

and the so called «Turn-off Delay Time of Coil Current» begins; after at the «Turn-off Fall Time of Coil Current» starts

and, at the same time, the HVC rises.

dLH is defined as the time between the negative edge of the input pulse to the point where the HVC reaches 100V.

t

t

fLH is defined as the delay between the 90% and the 10% of the coil current.

4/8

FIGURE 3: Vcl with load L ≅ 4mH

VB125SP

FIGURE 4: Output Current Waveform after Thermal Protection Activation.

5/8

1

VB125SP

FIGURE 5: Waveforms

INPUT

IC

HVC

FLAG

FIGURE 7: Application Circuit

4.5A

6.5A

FIGURE 6: Flag Current Versus Temperature

I

(A)

flag

5.0

4.5

4.0

3.5

-50

0

50

100

T

case

(oC)

µP

1nF 22K

C

EXT

R

EXT

INPUT

FLAG

V

CC

VB125SP

GND

HVC

PWR

GND

100nF

C

V

BAT

S

6/8

1

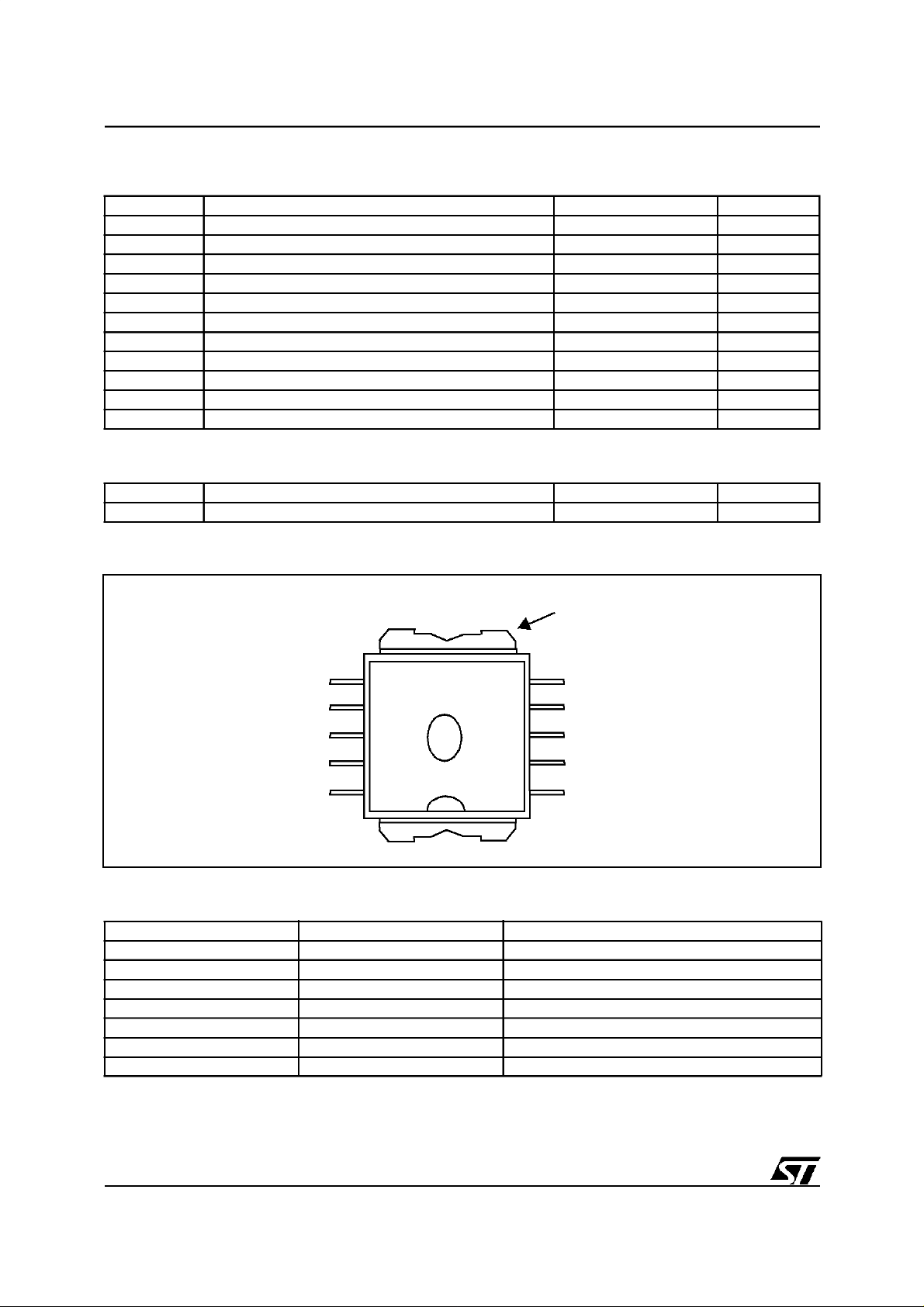

PowerSO-10 MECHANICAL DATA

VB125SP

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

mm inch

A 3.35 3.65 0.132 0.144

A1 0.00 0.10 0.000 0.004

B 0.40 0.60 0.016 0.024

c 0.35 0.55 0.013 0.022

D 9.40 9.60 0.370 0.378

D1 7.40 7.60 0.291 0.300

E 9.30 9.50 0.366 0.374

E1 7.20 7.40 0.283 0.291

E2 7.20 7.60 0.283 0.300

E3 6.10 6.35 0.240 0.250

E4 5.90 6.10 0.232 0.240

e 1.27 0.050

F 1.25 1.35 0.049 0.053

H 13.80 14.40 0.543 0.567

h 0.50 0.002

L 1.20 1.80 0.047 0.071

q 1.70 0.067

B

==

==

HE

h

A

F

A1

610

51

eB

M

0.25

D

==

D1

==

E2

==

DETAIL”A”

DETAIL”A”

Q

0.10 A

E1E3

==

SEATING

PLANE

A

C

α

B

E4

==

SEATING

PLANE

A1

L

==

0068039-C

7/8

VB125SP

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsability for

the consequences of use of such information nor for any infringement of patents or other rights of third parties which may results from its

use. No license is granted by implication or otherwise under any patent or patent rightsof SGS-THOMSON Microelectronics. Specifications

mentioned in this publication are subject to change without notice. This publication supersedes and replaces all information

previously supplied. SGS-THOMSON Microelectronics products are not authorized for use as critical components in life support devices or

systems without express written approval of SGS-THOMSON Microelectronics.

1997 SGS-THOMSON Microelectronics - Printed in Italy - All Rights Reserved.

Australia - Brazil - France - Germany - Hong Kong - Italy - Japan - Korea - Malaysia - Malta - Morocco - The Netherlands - Singapore -

SGS-THOMSON Microelectronics GROUP OF COMPANIES

Spain - Sweden - Switzerland - Taiwan- Thailand - United Kingdom - U.S.A.

8/8

Loading...

Loading...