1/13

■ CURRENT MEASUREMENT ON OUTPUT

POSITIVE LI NE

■ CONSTANT VOLTAGE MODE CONTROL

■ CONSTANT CURRENT MODE CONTROL

■ PRECISION VOLTAGE AND CURRENT

CONTROL LOOPS

■ ADJUSTABLE SWITCHING FREQUENCY

■ ADJUSTABLE OVER VOLTAGE LOCKOUT

■ ADJUSTABLE UNDER VOLTAGE LOCKOUT

■ STANDBY MO D E (L OW QUIESCE NT

CURRENT)

■ SUSTAINS 60V

■ MINIMAL EXTERNAL COMPONENTS

COUNT

■ DRIVING ABILITY FOR EITHER P-MOSFET

OR PNP TRANSISTORS

DESCRIPTION

TSM108 is a P-channel MOSFET controller which

ensures constant voltage and constant current in

Switching Mode Power Supply (step down) like in

automotive battery charging applications.

TSM108 can easily be configured for very wide

voltage and current needs.

TSM108 is built in rugged BCD technology and

includes a PWM generator, Voltage and Current

control loops, a precision Voltage Reference, and

a P-Mosfet Gate Drive output. TSM108 can

sustain 60V on Vcc, and therefore meet the

standard Load Dump requirements in the

Autom o tive field.

TSM108 includes security functions which lock the

PMosfet in OFF state: OVLO (Over Voltage

Lockout) and UVLO (Under Voltage Lockout). The

P-Mosfet Gate is also protected from over voltage

drive thanks to a 12V clamping protection circuit.

TSM108 includes a standby feat ure which allows

very low quiescent current when activated, as well

as safe P-Mosfet Off state .

TSM108 is suitable for car environment

accessories, as well as numerous other DC/DC

step down regulation.

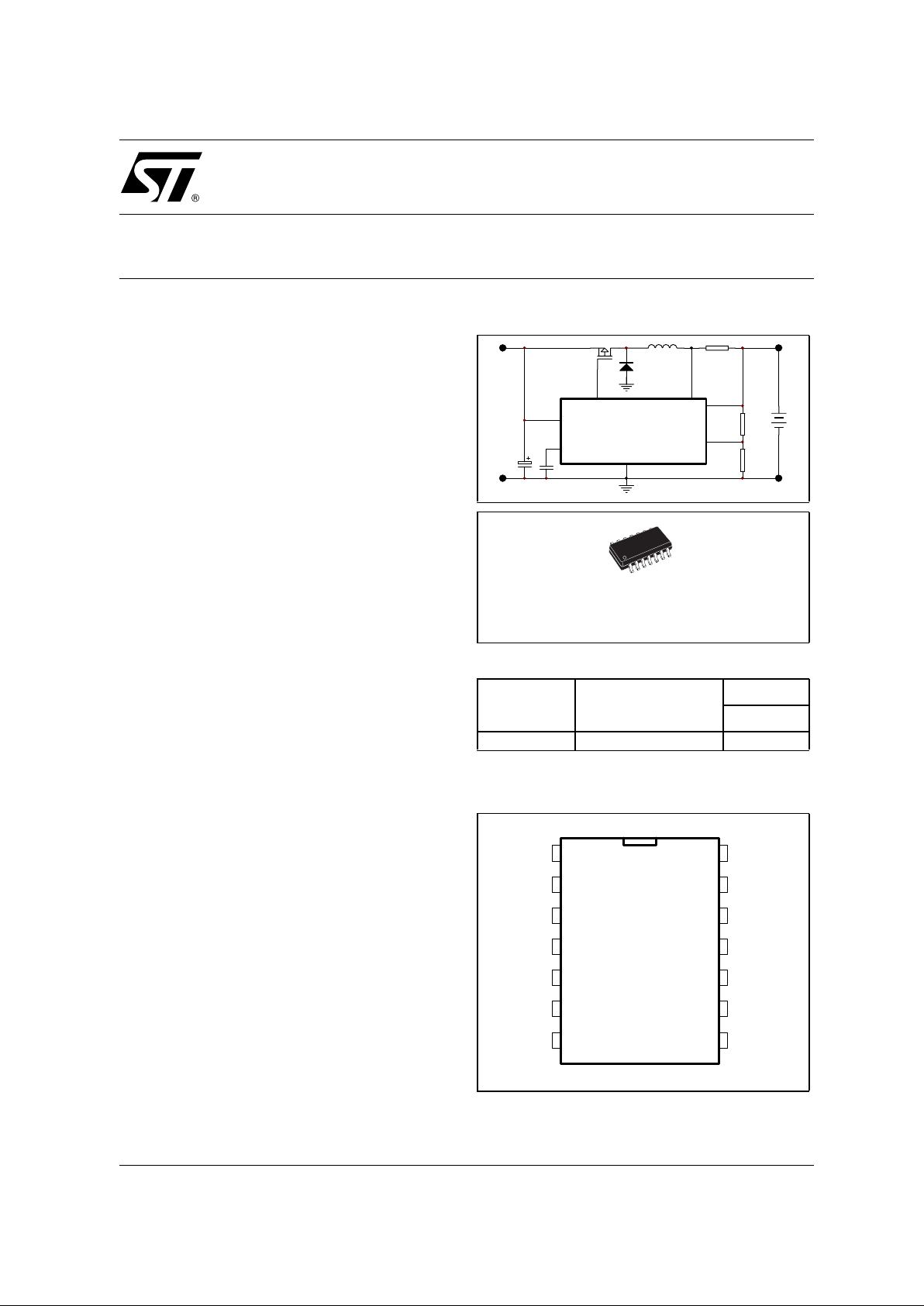

APPLICATION DIAGRAM

ORDER CODE

D = Small Outline Package (SO) - also available in Tape & Reel (DT)

PIN CONNECTIONS (top view)

Part Number Temperature Range

Package

D

TSM108I -40°, +125°C

•

MOSFET P

BATTERY

TSM108

DC INPUT

or PNP

D

SO14

(Plastic Micropacka ge)

VCC

G

OV

UV

ICTRL

OSC

GND

VCOM

P

VCTRL

ICOMP

VREF

VS

7

6

5

4

3

2

1

8

9

10

11

12

13

14 GD

!STBY

TSM108

AUTOMOTIVE SWITCH MODE

VOLTAGE AND CURRENT CONTROLLER

November 2001

TSM108

2/13

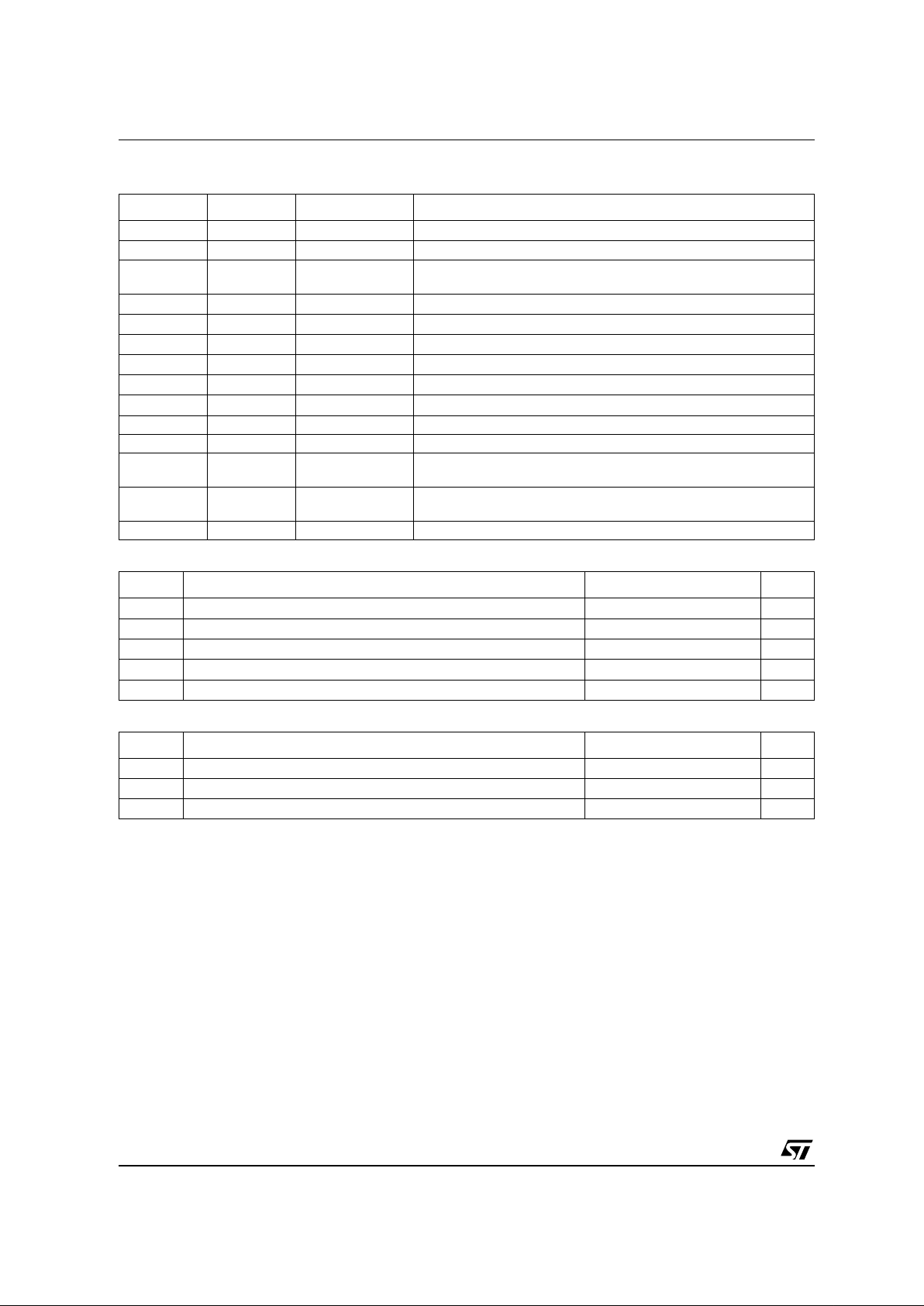

PIN DESCRIPTION

ABSOLUTE MAXIMUM RATINGS

OPERATING CONDITIONS

Name Pin Type Description

VCC 1 Power Supply Power Supply Line of the Device - Source of the P-MOSFET

GND 3 Power Ground 0V Reference for all Voltages

GD 14 Gate Drive Gate Drive Pin of the P-MOSFET - Middle Point of the MOSFET

Push Pull Output Stage

VREF 10 Output Voltage Reference Output

VS 13 HZ Input Voltage Sense Resistor Input

ICTRL 12 HZ Input Current Regulation Input

VCTRL 11 HZ Input Voltage Regulation Input

VCOMP 8 Output Compensation pin - Output of Voltage Control Op-Amp

ICOMP 9 Output Compensation pin - Output of Current Control Op-Amp

OSC 7 Input Oscillator Frequency Set Capacitor

!STBY 2 Input Standby Command (Command = 0V ===> Device Standby)

UV 4 I/O Programmable Under Voltage Lockout. The middle point of the

integrated resistor bridge is accessible. Preset value is 8V min.

OV 5 I/O Programmable Over Voltage Lockout. The middle point of the

integrated resistor bridge is accessible. Preset value is 33V max.

G 6 Test Pin Internally Connected to Ground

Symbol Parameter Value Unit

V

CC

Supply Voltage 60 V

T

j

Maximum Junction Temperature 150 °C

R

thja

Thermal Resistance Junction to Ambient (SO package) 130 °C/W

T

amb

Ambient Temperature -55 to +125 °C

V

max

Out Terminal Voltage (ICTRL, VS) 10 V

Symbol Parameter Value Unit

V

CC

Supply Voltage UVLO to OVLO V

V

ter1

Out Terminal Voltage (ICTRL, VS) 0 to 9 V

V

ter2

Out Terminal Voltage (UV, OV, OSC) 0 to 6 V

TSM108

3/13

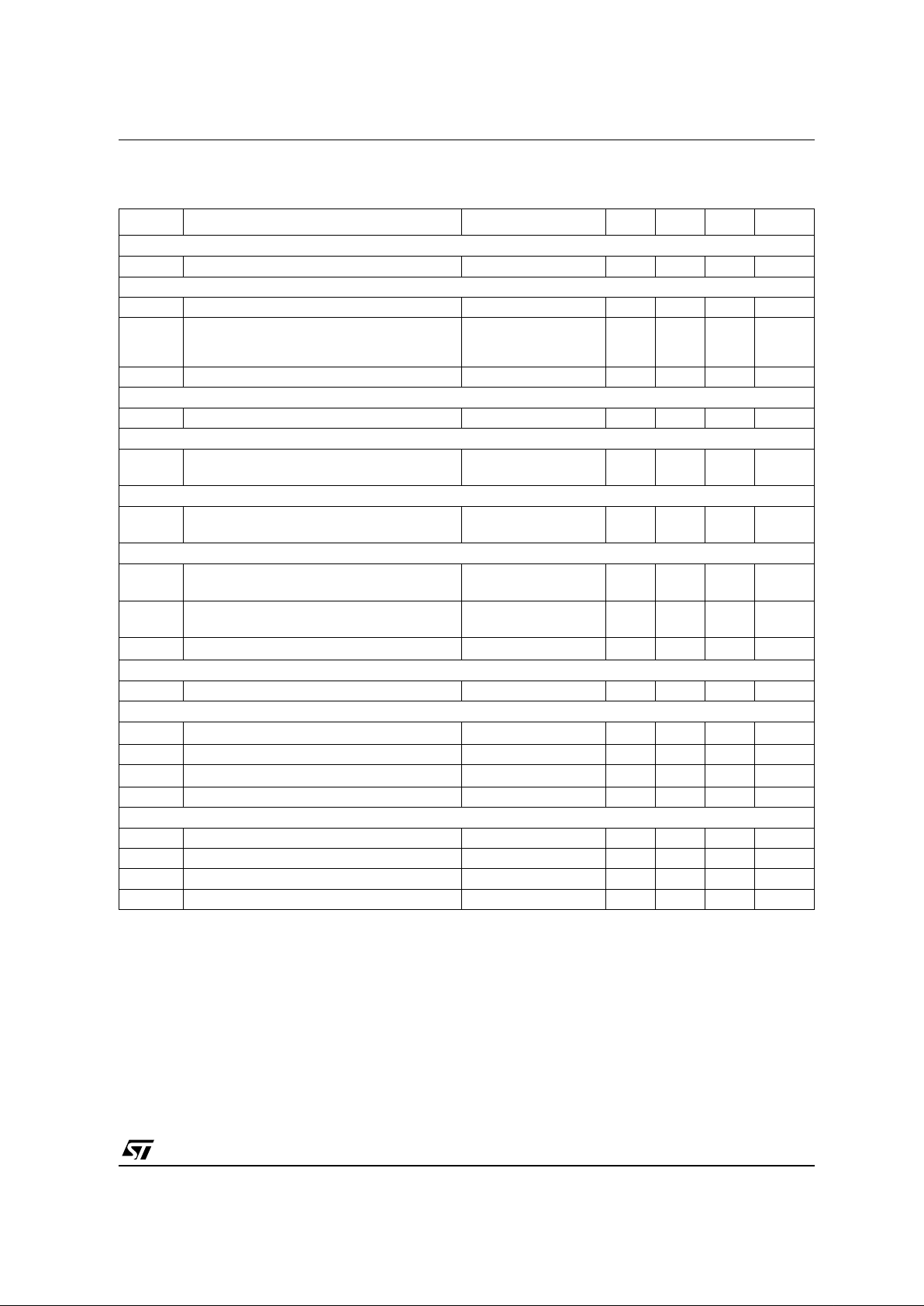

ELECTRICAL CHARACTERISTICS

T

amb

= 25°C, VCC = 12V (unless otherwise specified)

Symbol Parameter Test Condition Min. Typ. Max. Unit

CURRENT CONSUMPTION

I

CC

Current Consumption 4 7 mA

STANDBY

I

stby

Current Consumption in Standby Mode 150

µ

A

V

sh

Input Standby Voltage High Impedance Internal Pull up resistor.

Stby pin should be left

open

2V

V

sl

Input Standby Voltage Low 0.8 V

OSCILLATOR

F

OSC

Frequency of the Oscillator C

OSC

= 220pF 70 100 130 kHz

VOLTAGE CONTROL 1)

2)

1. V

ref

paramete r i ndi cates glob al precision of the voltage control loop.

2. Control Gain : A

v

= 95dB ; Input R esistance : Rin = infinite ; Output Resistance : R

out

= 700MΩ ; Output Source/Sink Current :

I

so

, Isi = 150µA ; Recommended val ues for the com pensation network are : 22nF & 22kΩ in series bet ween outpu t and ground.

V

ref

Voltage Control Reference T

amb

= 25°C

-25°C < T

amb

< 85°C

2.450

2.520

2.590

V

CURRENT CONTROL 3) 4)

5)

3. V

sense

paramete r i ndi cated global precis i on of the current contro l lo op.

4. Control Gain : A

v

= 105dB ; Input Resistance : Rin =380kΩ ; Output Resistance : R

out

= 105MΩ ; Output Source/Sink Current :

I

so

, Isi = 150µA ; Recommended val ues for the com pensation network are : 22nF & 22kΩ in series bet ween outpu t and ground.

5. A current foldb ack function i s implemented thanks to a systema tic -6mV negat i ve offset on the current amplifier i nputs which

protects the battery fr om over charging current under low battery volt age conditi ons, or output short circui t conditions.

V

sense

Current Control Reference Voltage T

amb

= 25°C

-25°C < T

amb

< 85°C

196

191

206 216

221

mV

GATE DRIVE - P CHANNEL MOSFET DRIVE

I

sink

Sink Current - Switch ON T

amb

= 25°C

-25°C < T

amb

< 85°C

15

40 mA

I

source

Source Current - Switch OFF T

amb

= 25°C

-25°C < T

amb

< 85°C

30

80 mA

C

load

Input Capacitance of the PMOSFET

6)

6. The Gate Drive output stag e has been optim i zed for PMo sf ets with input capacitance equal to Cload. A bigger Mosfet (with input

capacitance higher than Cload) can be used with TSM108, but the gate drive performances will be reduced (in particular when

reaching the Dmax. PW M mode).

11.5nF

PWM

∆

max.

Maximum Duty Cycle of the PWM function 95 100 %

UVLO

UV

Under Voltage Lock Out

7)

7. The given limits comprise the hysteresis (UV

hyst

).

-25°C < T

amb

< 85°C 8 9 V

UV

hyst

UVLO Voltage Hysteresis - low to high 200 mV

R

uvu

Upper Resistor of UVLO bridge

8)

8. It is possible to m odify the UVLO and OVLO l i m i ts by adding a resi stor (to ground or to VCC) on the pins UV and OV.

The internal values of the resistor should be taken into account

T

amb

= 25°C 184 k

Ω

R

uvl

Lower Resistor of UVLO bridge (see note 8) T

amb

= 25°C 76.5 k

Ω

OVLO

OV Over Voltage Lock Out (see note 7) -25°C < T

amb

< 85°C 32 35 V

OV

hyst

OVLO Voltage Hysteresis - low to high 400 mV

R

ovu

Upper Resistor of OVLO bridge (see note 8) T

amb

= 25°C 275 k

Ω

R

ovl

Lower Resistor of OVLO bridge (see note 8) T

amb

= 25°C 23.2 k

Ω

TSM108

4/13

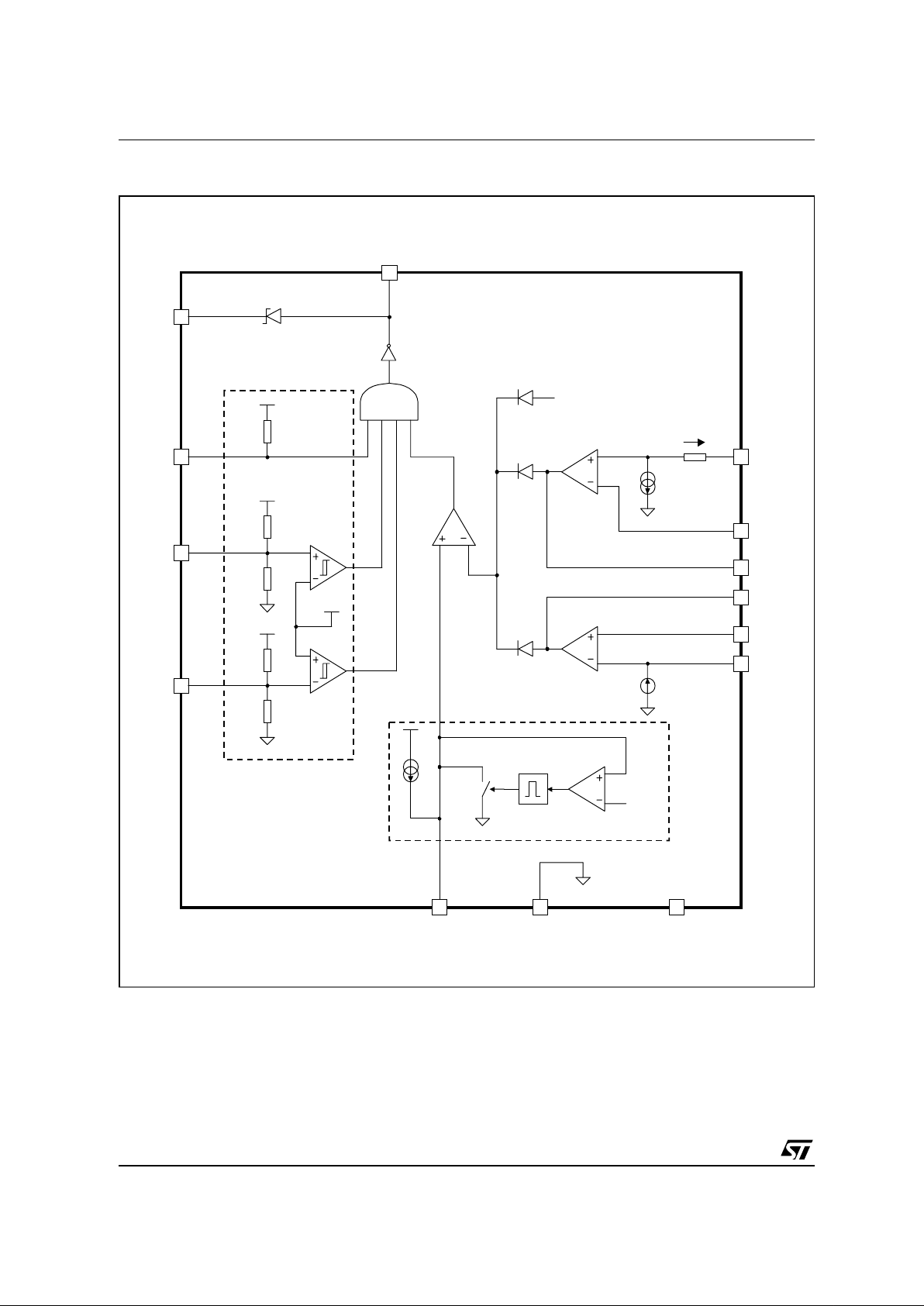

DETAILED INTERNAL SCHEMATIC

13

12

9

11

10

8

14

7

2

4

5

1

3

VS

ICTR

L

ICOMP

VCOMP

VREF

VCTR

L

Vsense

200mV

VREF

2,52V

GND

6

VCC

!STBY

UV

OV

OSC

GD

TSM108

10k

Ω

20µA

VCC

Ruvu

184k

Ω

Ruvl

76,5k

Ω

VREF

VCC

Rovu

275k

Ω

Rovl

23,2k

Ω

G

4,5V

15V

Oscillator block

Protection block

maximum duty cycle = 95%

TSM108

5/13

OSCILLATOR FREQUENCY VERSUS TIMING CAPACITOR

TSM108 AS A STAND ALONE DC/DC CONVERTER FOR CIGARETTE LIGHTER ACCESSORIES

0

50

100

150

200

250

300

350

10 100 1000

Oscilla tor freque ncy (kHz)

Cosc Timing Capacitor (pF)

Q1

MOSFET P

L1

Rsense

Csupply

load

L2

1

DC INPUT

1

Cf

Rf

R1

R2

1

DC OUTPUT

1

CompDComp

+

-

-

+

+-

Vcc

Gnd

!Stby

UV

OV

Vs

Vs

Ictrl

Icomp

Vcomp

Vref

Vctrl

G

Oscillator

Uv/Ov/Stby

Cosc

Osc

6/13

Description of a DC/DC step down battery

charging application

1. Voltage and Current Controller

TSM108 is designed to drive a P-Channel

MOSFET transistor in Switch Mode Step Down

Converter applications. Its two integrated

operational amplifiers ensure accurate Voltage

and Current Regulation.

The Voltage Control dedicated operational

amplifier acts as an error amplifier and compares

a part of the output voltage (external resistor

bridge) to an integrated highly precise voltage

reference (V

ref

).

The Current Control dedicated operational

amplifier acts as an error amplifier and compares

the drop voltage through the s ense resistor to an

integrated low value voltage reference (V

s

).

These two amplified errors are ORed through

diodes, and the resulting signal (“max of”) is a

reference for the PWM generator to set the

switching duty cycle of the P-Channel MOSFET

transistor.

The PWM generator comprises an oscillator (saw

tooth) and a comparator which gives a variable

duty cycle from 0 to 95%. This PWM signal is the

direct command o f the output Push Pull stage to

drive the Gate of the P-Channel MOSFET.

Thanks to this architecture, the TSM108 is ideal to

be used from a DC power supply to control the

charging Voltage and Current of a battery in

applications such as Automotive accessories for

Portable Phone charging and power supplies.

2. Voltage Control

The Voltage Control loop is to be set thank s to an

external resistor bridge connected between the

output positive line and the Ground reference. The

middle point is to be connected to the V

ctrl

pin of

TSM108, and, if R1 is the upper resistor, and R2,

the lower resistor of the bridge, the values of R1

and R2 should follow:

❑ eq1: Vref = Vout x R2 / (R1 + R2)

When under Constant Voltage Control mode, the

output voltage is fixed thanks to the R1/R2 resistor

bridge.

The total value of R1 + R2 resistor bridge will

determine the necessary bleeding current to keep

the Voltage Control loop effective, even under “no

load” conditions.

The voltage compensation loop is directly

accessible from the pins Vcomp and Vref

(negative input of the Voltage Control dedicated

operational amplifier). The c ompens ation net work

is highly dependant of the conditions of use of the

TSM108 (switching frequency, external

components (R, L, C), MOSFET, output

capacitor...).

3. Current Control

The Current control loop is to be set thanks to the

Sense resistor which is to be placed in series on

the output positive line. The output side of the

Sense resistor should be connected to the Ictrl pin

of TSM108, and the common point between

Rsense and the filtering self L should be

connected to the Vs pin of TSM108. If Ilim is the

value of the charging current limit The value of

Rsense should verify:

❑ eq2: V

s

= R

sense

x Il

im

When under Constant Current Control mode, the

output current is fixed thanks to the Rsense

resistor (under output short circuit conditions,

please refer to this corresponding section).

The wattage calibration (W) of the sense resistor

should be chosen according to:

❑ eq2a: W > R

sense

x Il

im

2

The current compensation loop is directly

accessible from the pins Icomp and Ictrl (negative

input of the Current Control ded icated operat iona l

amplifier.

The compensation network is highly dependant of

the conditions of use of the TSM108 (switching

frequency, external components (R, L, C),

MOSFET, output capacitor...).

4. PWM frequency

The internal oscillator of T SM108 is a saw tooth

waveform that can be frequency adjusted.

In automotive accessory battery charging

applications, it is recommended to set the

switching frequency at a typical 100kHz in order to

PRINCIPLE OF OPERATION AND APPLICATION HINTS

TSM108

TSM108

7/13

obtain the best compromise between electrical

noise, and size of the filtering self.

An external capa citor is t o be connected betwe en

ground and the Osc pin of TSM108 to set the

switching frequency.

The maximum duty cycle of the PWM function is

limited to 95% in order to ensure safe driving of

the MOSFET.

5. Gate Drive

The Gate Drive stage is directly commanded from

the PWM output signal. The Gate Drive stage is a

Push Pull Mosfet s tage which bears different On

resistances in order to ensure a slower turn ON

than turn OFF of the P-Channel MOSFET. The

values of the output Gate Drive currents are given

by Isink (switch ON) and Isource (switch OFF).

The Gate Drive stage bears an i nteg rated vo ltage

clamp which will prevent the P-Channel MOSFET

gate to be driven with voltages higher than 15V

(acting like a zener diode between Vcc and GD

(Gate Drive) pin.

6. Under Voltage Lock-Out, Over Voltage

Lock-Out

The UVLO and OVLO security functions aim at the

global application security.

When the Power supply decreases, there is the

inherent risk to drive the P-Channel MOSFET with

insufficient Gate voltage, and therefore to lead the

MOSFET to linear operation, and to its

destruction.

The UVLO is an input power supply voltage

detection which imposes a complete switch OFF

of the P-Channel MOSFET as soon as the Power

Supply decreases below UV. To avoid un wanted

oscillation of the MOSFET, a fixed hysteresis

margin is integrated (UVhyst).

UVLO is internally programmed to ensure 8V min

and 9V max, but the middle point of the integrated

resistor bridge is accessible and the value of t he

UVLO is therefore adjustable by adding an

external resistor to modify the bridge ratio. The

resistor typical values of the bridge are given

(Ruvh, Ruvl).

When the Power supply increases, there is the

inherent risk to dissipate too much conduction

energy through the P-Channel MOSFET, and

therefore to lead to its destruction.

The OVLO is an input power supply voltage

detection which imposes a complete switch OFF

of the P-Channel MOSFET as soon as the Power

Supply increases above O V. To avoid unwanted

oscillation of the MOSFET, a fixed hysteresis

margin is integrated (OV

hyst

).

OVLO is internally programmed to ensure 32V

min. and 33V max., but the middle point of the

integrated resistor bridge is accessible and the

value of the OVLO is therefore adjustable by

adding an external resistor to modify the bridge

ratio.

The resistor typical values of the bridge are given

(R

ovh

, R

ovl

).

Examples:

Let’s suppose that the internally set value of the

UVLO and / or OVLO level should be modified in a

specific application, or under specific

requirements.

6.1. UVLO decrease:

If the UVLO level needs to be lowered (UV 1), an

additional resistor (Ruvh1) must be connected

between UV and Vcc following the equation:

❑ UV = Vref (Ruvh/Ruvl +1)

❑ UV1 = Vref ((Ruvh//Ruvh1)/Ruvl +1) (i)

where Ruvh//Ruvh1 means that Ruvh1 is in

parallel to Ruvh

Solving i. we obtain:

❑ Ruvh1 = Ruvl x Ruvh (UV1 - Vref) / (Vref x

Ruvh - Ruvl (UV1 - Vref))

As an example, if UV1 needs to be set to 6V,

Ruvh1 = 256kΩ

6.2. UVLO increase:

If the UVLO level needs to be increased (UV2), an

additional resistor (Ruvl2) must be connected

between UV and Gnd following the equation.

❑ UV = Vref (Ruvh/Ruvl +1)

❑ UV1 = Vref (Ruvh/(Ruvl//Ruvl2) +1) (ii)

where Ruvl//Ruvl2 means that R uvl2 is in parallel

to Ruvl

Solving ii. we obtain:

❑ Ruvl2 = Vref x Ruvh Ruvl / (UV2 x Ruvl -

Vref x (Ruvh + Ruvl))

As an example, if UV2 needs to be set to 12V,

Ruvl2 = 132kΩ

6.3. OVLO decrease:

If the OVLO level needs to be lowered (OV1), an

additional resistor (Rovh1) must be connected

between OV and Vcc following the equation:

❑ OV = Vref (Rovh/Rovl +1)

❑ OV1 = Vref ((Rovh//Rovh1)/Rovl +1) (iii)

where Rovh//Rovh1 means that Rovh1 is in

parallel to Rovh

Solving iii. we obtain:

❑ Rovh1 = Rovl x Rovh (OV1 - Vref) / (Vref x

Rovh - Rovl (OV1 - Vref))

As an example, if OV1 needs to be set to 25V,

Rovh1 = 867kΩ

TSM108

8/13

6.4. OVLO increase:

If the OVLO level needs to be increased (OV2), an

additional resistor (Rovl2) must be connected

between OV and Gnd following the equation.

❑ OV = Vref (Rovh/Rovl +1)

❑ OV2 = Vref (Rovh/(Rovl//Rovl2) +1) (iv)

where Rovl//Rovl2 means that R ovl2 is in parallel

to Rovl

Solving iv. we obtain:

❑ Rovl2 = Vref x Rovh Rovl / (OV2 x Rovl -

Vref x (Rovh + Rovl))

As an example, if OV2 needs to be set to 40V,

Rovl2 = 87kΩ

7. Standb y Mode

In order to reduce to a minimum the current

consumption of the TSM108 when in inactive

phase, the Standby mode (!STBY pin of TSM108)

imposes a complete OFF state of the P-Channel

MOSFET, as well as a complete shut off of the

main functions of the TSM108 (operational

amplifier, PWM generator and oscillator, UVLO

and OVLO) and therefore reduces the

consumption of the TSM108 to the Istby value.

This !STBY command is TTL compatible, which

means that it can be directly commanded from

whatever logic signal.

8.Power Transistor: P-MOSFET or PNP

Transistor?

The TSM108 can drive, with minor external

components change, either a P-channel

MOSFET, or a PNP transistor. The choice of the

transistor is completely to the user’s responsibility,

nevertheless, here follows a few elements which

will help to decide which is the most adapted

transistor to drive depending on the application

characteristics in terms of power and

performances.

The following figures shows two different

schematics where both driving abilities of TSM108

are shown. The third schematic shows how to

improve the switch off commutation when using a

bipolar PNP transistor.

P- MOSFET? PNP Transistor?

The most immediate way to choose from a

P-channel MOSFET or a PNP transistor is to

consider the ratio between the output power of the

application and the expected components price:

the lower the power, the more suitable the PNP

transistor is; the higher the power, the more

suitable the P-channel MOSFET is. As an

example, for a DC/DC adaptor built for 12V/6V,

the recommended limit to choos e from one to the

other is situated around 200mA.

Below 200mA, the price/ performance ratio of the

PNP transistor is very attractive, whereas above

200mA, the P-channel Mosfet takes the

advantage.

9. Calculation of the Passive Elements

Let’s consider the following characteristics for a

Cigarette Lighter Cellular Phone Battery Charger:

Vin = 12V - input voltage of the converter

Vout = 6V - output voltage of the converter

F = 100kHz - switching frequency of the converter

adjustable with an external capacitor

Iout = 625mA - output current limitation

9.1. Inductor

The minimum inductor value to choose should

apply to

Lmin = (1 - D) R / 2F

where R = Vout / Iout = 9.6Ω

and where D = Vout / Vin = 0.5

Therefore, Lmin = 24µH.

L1

GD

D1

TSM108

Q1

MOSFET P

Q1 L1

GD

D1

TSM108

Q1 L1

GD

D1

TSM108

TSM108

9/13

This component value is valid if the above

described characteristics are fixed... but in the

automotive field, the input voltage of the converter

is dependant of the car bat tery conditions. Also,

the frequency may vary depending on the

temperature, due to the fact that the frequency is

fixed by an external capacitor. Therefore, we must

calculate the inductor v al ue considering the worst

case condition in order to av oid the saturation of

the inductor, which is when the batt ery voltage is

at it’s highest, and the switching frequency at it’s

lowest. Thanks to the OVLO function integrated in

TSM108, the operation of the DC/DC converter

will be stopped as soo n as the voltage exceeds

the OVLO level. Let’s suppose the O VLO pin has

been left open, therefore, the maximum input

voltag e of the D C / D C converter will b e V in max. =

32V. Frequency min stands in the range of 75kHz

In this case, D = 6 / 32 = 0.1875, therefore Lmin =

52µH.

If we allow a 25% security margin

Lmin = 68µH

9.2. Capacitor

The capacitor choice will depend mainly on the

accepted voltage ripple on the output

Ripple = DVout / Vout = (1-D) / 8LCF²

Therefore, C = (1-D) / 8LRippleF². If C = 22µF,

then Ripple = 0.4% which should be far

acceptable.

Here again, the worst co nditions for t he ripple are

set when the input voltage is a t the highest (32V )

and the frequency at it's lowest (75kHz).

with C = 22µF, Ripple = 1.2%

9.3. Ratings for the Inductor, Capacitor,

Transistor and Diode

The inductor wire must be rated at the rms c urrent,

and the core should not saturate for peak inductor

current. The capacitor must be selected to limit the

output ripple to the design specifications, to

withstand peak output voltage, and to carry the

required rms current.

The transistor and the diode should be rated for

the maximum input voltage (up to 60V in

automotive applications). The diode recovery time

must be in accordance with the time period a nd

the maximum authorized switching time of the

power transistor.

A compromise between the switching and

conducting performances of the transistor must be

found, because choosing a very low ohmic Mosfet

aiming at the benefit of low conduction losses may

bring much higher switching losses than the

expected benefit.

Losses in the switch are:

Pswitch = Prise + Pfall + Pon

where Prise + Pfall represent the switching losses

and where Pon represents the conduction losses.

Prise + Pfall = Iout x Vin x (Trise + Tfall) x F / 2

Pon = Ron x Iout² x d

where Trise is the switching on time, and Tfall is

the switching off time, and where d is the duty

cycle of the switching profile, which can be

approximated to 1 under full load conditions.

With the two last equations, we can see easily that

what we may gain by choosing a performing low

Rdson P-channel M OSF ET (for example) may be

jeopardized by the long on and off switching times

required when using a large input gate

capacitance.

10. Electromagnetic Compatibility

The small schematic hereafter shows how to

reduce the EMC noise when used in an EMC

sensitive environment:

EMC Improvement

The RC components should realize a time

constant corresponding to one tenth of the

switching time constant of the TS M10 8 (i.e. in our

example, the oscillator frequency is set to 10µs

corresponding to 100kHz, therefore, the RC

couple should realise a time constant close to

1µs).

Choosing the componen ts must privilege a rather

small resistivity (between 10 to 100W). A guess

couple of values for RC in our example would be:

R= 22W, C= 47nF

11. Efficiency Calculations (rough estimation)

The following gives a rough estimation of the

efficiency of a car phone charger, knowing that the

exact calculations depend on a lot of paramete rs,

as well as on a wide choice of external

components.

Let’s consider the following characteristics of a

classical car phone charger application:

L1

GD

D1

TSM108

Q1

MOSFET P

TSM108

10/13

❑ Vin = Vcc = 12V, Iout = 625mA, Vout = 6V

❑ Mosfet: Pchannel Mosfet: Rdson = 100mΩ,

Ciss = 1nF.

❑ Driver: TSM108

❑ PWM frequency: 100kHz

❑ Free wheel diode: Vf = 0.7V

❑ Shunt: Rsense = 330mΩ

The efficiency (η) of a regulator is defined as t he

ratio of the charging power (Pout) to the total

power from the supply (Pin).

❑ Eq3: η = Pout/Pin

The output power is:

Pout=Iout x Vout where Iout is the charging

current (Vsense/Rsense = 625mA at full load) and

Vout is the regulated voltage (Vref(1+R1/R2) =

6V).

Pout = 3.75W

The input power can be found by adding the

output power (Pout) to the total power loss in the

circuit (Plosses) i.e.

❑ Pin = Pout + Plosses

The power is lost partly on the chip and partly on

the external components which are mainly the

diode, the switch and the shunt. Plosses = Pchip +

Pswitch + Pdiode + Pshunt.

In Plosses, we neglect the losses in the inductor

(because the current through the inductor is

smoothened making the serial resistor of the

inductor very low), and the losses in the Gate

(charge and discharge).

a. The power lost in the chip is Pchip = Vcc x Icc.

(Vcc = 12V, Icc = 6mA) Pchip = 72mΩ

b. The power lost in the switch depends on the ON

resistance of the switch and the c urrent passing

through it. Also there is power loss in the switch

during switching time (commutation losses) and

that depends on the switching freq uency and the

rise and fall time of the switching signal.

Rise time (Pchannel goes off) depends on the

output source current of the TSM108 and the input

gate capacitance of the Mosfet.

Trise = Ciss x Vgate / Isource

Fall time (Pchannel goes on) depends on the

output sink current of the TSM 108 and the input

gate capacitance of the Mosfet .

Tfall = Ciss x Vgate / Isink

Trise = 150ns and Tfall = 300ns (Vgate is approx

12V).

❑ Pswitch = Prise + Pfall + Pon

where:

Prise = Iout x (Vcc+Vf) x Trise x PWMfreq / 2

Prise = 625mA x 12.7 x 150ns x 100kHz / 2.

Prise = 59.5mW

where:

Pfall = Iout x (Vcc+Vf) x Tfall x PWMfreq / 2

Pfall = 625mA x 12.7 x 300ns x 100kHz / 2.

Pfall = 119.1mW

where:

Pon = Rdson x Iout² x D (where D is the duty cycle

- at full charge, D can be approximated to 1)

Pon = 100mΩ x 625mA². Pon = 39.1mW

❑ Pswitch = 217.7mW

c. The power lost in the fly back diode is Pdiode =

Vf x Iout(1-D) where D = Vout/Vcc = 6/12. D = 0.5

❑ Pdiode=219mW

d. the power lost in the sense resistor (shunt

resistor) is Pshunt = Rsense x Iout²

❑ Pshunt = 129mW

Therefore,

Plosses = Pchip+Pswit ch+P diode +P shunt

= 72mW + 217.7mW + 219mW + 129m W

❑ Plosses = 638mW

The yield (efficiency) is

❑ Pout / Pin = 3.75 / (3.75 + 0.638) = 85.5%

η

= 85.5%

The following table gives a tentative efficiency

improvement view following the choice of some

external components. Be aware that some of the

following choices have non negl igible cost effects

on the total application.

Improved efficiency - by changing the external comp on ents value one by on e

Rsense 330m

Ω

220m

Ω

---Iout 625mA 936mA - - - Vout (R1/R2) 6V - 7.5V - - Rdson 100m

Ω

- - 140m

Ω

-Ciss 0nF - - 0.85nF - PWM Freq 100kHz - - - 50kHz Free Wheel 0.7V - - - - 0.3V

Yield 85.5% 85.6% 88.9% 85.7% 87.3% 88.1%

Cost influence - ==<>>>

TSM108

11/13

12. Measured Performances

The few following curves show the measured

performances of TSM108 used in DC/DC step

down converter, either with a Pchannel MOSFET

or with a PNP bipolar transistor.

12.1. Voltage and Current Control, Efficiency Performances using a Pchann el MOSFET :

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

Iout (A)

0

1

2

3

4

5

6

7

Vout (V)

0%

10%

20%

30%

40%

50%

60%

70%

duty cycle on (%)

CV & CC Regulation - Switching duty cycle vs Iout

Vin = 12V, Vout = 6V, Iout = 600mA

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

Iout (A)

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

Efficiency (%)

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

duty cycle on (%)

Converter efficiency & Switching duty cycle vs Iout

Vin = 12V, Vout = 6V, Iout = 600mA

5 1015202530 35

Vin (V)

5.992

5.993

5.994

5.995

5.996

5.997

5.998

5.999

6

6.001

Vout (V)

77%

78%

79%

80%

81%

82%

83%

84%

85%

86%

Efficiency (%)

Vout & Ef ficiency versus Vin

Vout = 6V, Iout = 600mA

TSM108

12/13

12.2. Voltage and Current Control, Efficiency Performances using a PNP bipolar transistor

0 0.05 0.1 0.15 0.2 0.25

Iout (A)

0

1

2

3

4

5

6

7

Vout (V)

0%

10%

20%

30%

40%

50%

60%

70%

duty cycle on (%)

PNP transistor Rbase = 220 L=150µH

Vout & duty cycle ver sus Iout

Vin=12V, Vout=6V , Iout=200m A

0 0.05 0.1 0.15 0.2 0.25

Iout (A)

0%

10%

20%

30%

40%

50%

60%

70%

80%

Efficiency (%)

0%

10%

20%

30%

40%

50%

60%

70%

80%

duty cycle on (%)

PNP transistor Rbase = 220 L=150µH

Efficiency & duty cycle versus Iout

Vin=12V, Vout=6V, Iout=200mA

5 101520253035

Vin (V)

6.025

6.03

6.035

6.04

6.045

6.05

Vout (V)

60%

65%

70%

75%

80%

85%

Efficicency (%)

PNP transistor Rbase =220 L=150µH

Vout & Efficiency versus Vin

Vout = 6V, Iout = 200mA

TSM108

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of su ch i n for mat i on n or f or a ny in fr ing em ent o f pa te nts or ot her r igh ts of th ir d pa r tie s w hic h may res ul t f rom i ts us e. No license is granted

by impl i cation or ot herwise under any patent or patent r i ghts of STM i croelectronics. Specificat i ons mentio ned in this publicat ion are subject

to change without notic e. T hi s publicati on supersedes and replaces all informat i on previou sly supplied . S T M i croelectronics produc ts are not

authori zed for use as critical com ponents in l i fe support devices or systems without express written ap proval of STM i croelectr o nics.

© The ST logo is a registered trademark of STMicroelectronics

© 2001 STMicroelectronics - Printed in Italy - All Rights Reserved

STMicr oelectronics GROUP OF COMPANIES

Australi a - Brazil - Chi na - Finlan d - F rance - Germ any - Hong Kong - India - It al y - Japan - Ma l aysia - Malta - Morocco

Singapo re - Spain - Sweden - Switzerland - United Ki ngdom

© http://www.st.com

13/13

PACKAGE MECHANICAL DATA

14 PINS - PLASTIC MICROPACKAGE (SO)

Dim.

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

A 1.75 0.069

a1 0.1 0.2 0 .004 0.008

a2 1.6 0.063

b 0.35 0.46 0.014 0.018

b1 0.19 0.25 0.007 0.010

C 0.5 0.020

c1 45° (typ.)

D (1) 8.55 8.75 0.336 0.344

E 5.8 6.2 0.228 0.244

e 1.27 0.050

e3 7.62 0.300

F (1) 3.8 4.0 0.150 0.157

G 4.6 5.3 0.181 0.208

L 0.5 1.27 0.020 0.050

M 0.68 0.027

S 8° (max.)

Note : (1) D and F do not include mold flash or protrusions - Mold flash or protrusions shall not exceed 0.15mm (.066 inc) ONLY FOR DATA BOOK.

Loading...

Loading...