TS4972

1.2W AUDIO POW ER AMPL IFIER

WITH STANDBY MODE ACTIVE HIGH

■OPERATING FROM V

= 2.5V to 5.5V

CC

■RAIL TO RAIL OUTPUT

■1.2W OUTPUT POWER @ Vcc=5V, THD=1%,

F=1kHz, with 8Ω Load

■ULTRA LOW CONSUMPTION IN STANDBY

MODE (10nA)

■75dB PSRR @ 217Hz from 2.5 to 5V

■ LOW POP & CLICK

■ULTRA LOW DISTORTION (0.05%)

■UNITY GAIN STABLE

■FLIP CHIP PACKAGE 8 x 300µm bumps

DESCRIPTION

The TS497 2 i s an Audio Pow er Amplifier capable

of delivering 1.6W of continuous RMS ouput power into a 4

This Audio Am plifier is exhibiting 0.1% distortion

level (THD) from a 5V supply for a Pout = 250mW

RMS. An external standby mode cont rol reduces

the supply current to less than 10n A. An internal

shutdown protection is provided.

Ω load @ 5V.

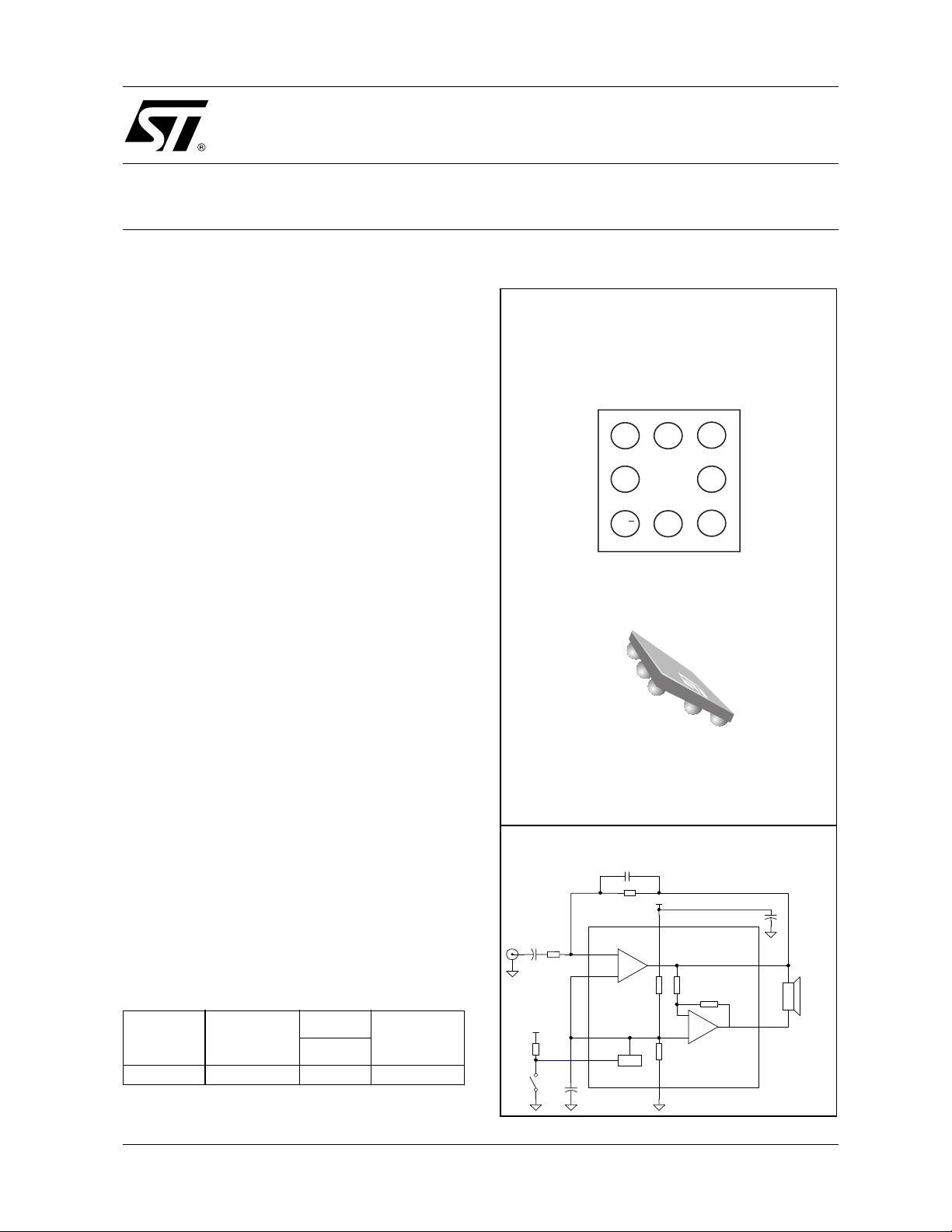

PIN CONNECTIONS (Top View)

TS4972JT - FLIP CHIP

76

Vin

8

Vout1

Vin

12

+

Vcc

Gnd

5

Stdby

Vout2

Bypass

3

4

The TS4972 has been designed for high quality

audio applications such as m obile phones and t o

minimize the number of external components.

The unity-gain stable amplifier can be configured

by external gain setting resistors.

APPLICATIONS

■Mobile Phones (Cellular / Cordless)

■PDAs

■Laptop/Notebook computers

■Portable Audio Devices

ORDER CODE

Part

Number

Temperature

Range

TS4972IJT -40, +85°C

J = Flip Chip Package - only available in Tape & Reel (JT))

January 2003

Package

J

•

Marking

4972

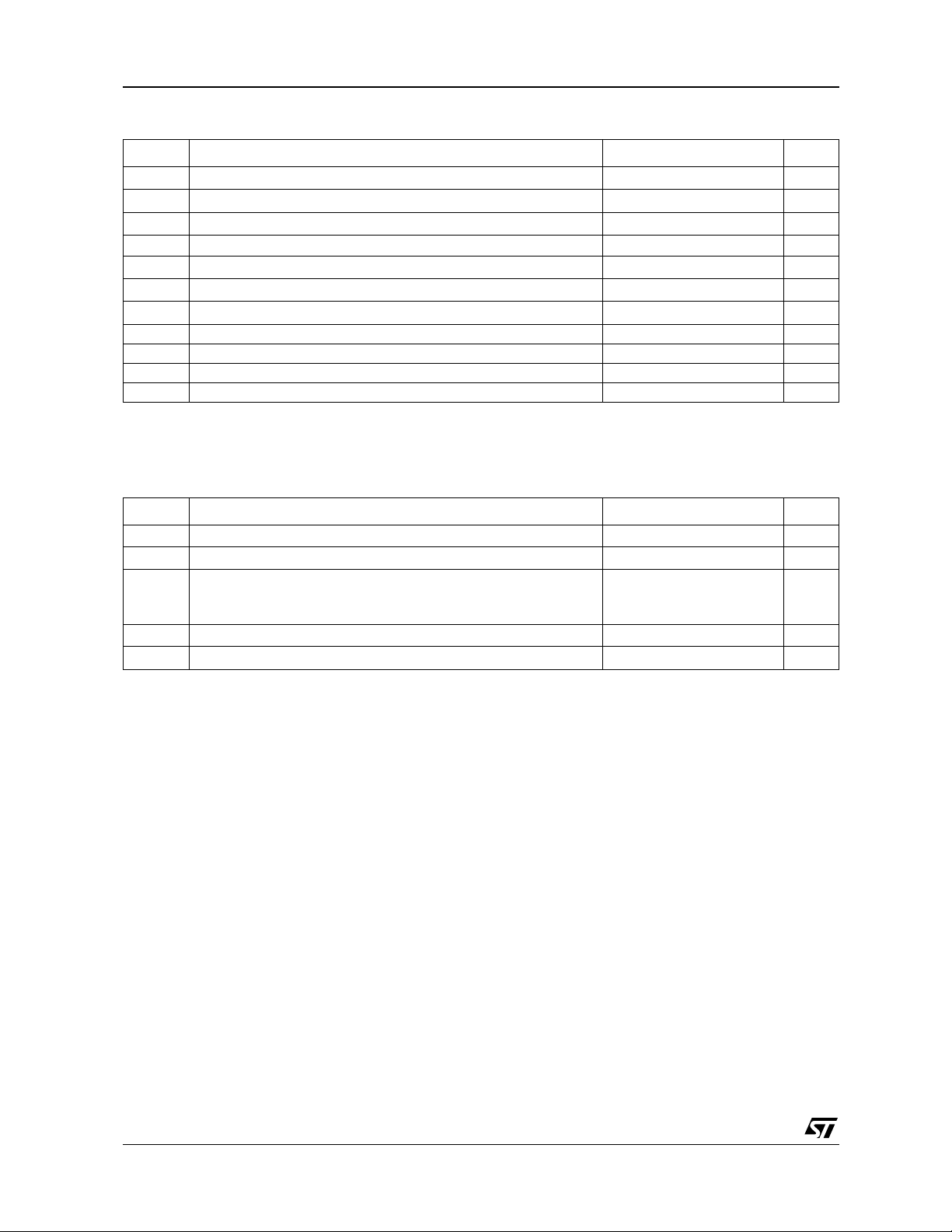

TYPICAL APPLICATION SCHEMATIC

Audio

Input

Rin

Vin-

1

Cin

VCC

Rstb

Vin+

7

Bypass

3

Standby

5

Cb

Cfeed

Rfeed

VCC

6

VCC

-

+

Bias

GND

2

AV = -1

+

Vout 1

Vout 2

8

4

TS4972

Cs

RL

8 Ohms

1/28

TS4972

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

T

T

R

Supply voltage

CC

V

Input Voltage

i

Operating Free Air Temperature Range -40 to + 85 °C

oper

Storage Temperature -65 to +150 °C

stg

T

Maximum Junction Temperature 150 °C

j

Thermal Resistance Junction to Ambient

thja

Pd Power Dissipation

ESD Human Body Model 2 kV

ESD Machine Model 200 V

Latch-up Latch-up Immunity Class A

Lead Temperature (soldering, 10sec ) 250 °C

1. All voltages values are measured with respect to the ground pin.

2. The magnitude of input signal must never exceed V

3. Device is protected in case of over temperature by a thermal shutdown active @ 150°C.

4. Exceeding the power derating curves during a long period, involves abnormal operating condition.

OPERATING CONDITIONS

Symbol Parameter Value Unit

V

V

V

R

1. With Heat Sink Surface = 125mm2

Supply Voltage 2.5 to 5.5 V

CC

Common Mode Input Voltage Range

ICM

Standby Voltage Input :

STB

Device ON

Device OFF

R

Load Resistor 4 - 32

L

Thermal Resistance Junction to Ambient

thja

1)

2)

3)

Internally Limited

+ 0.3V / GND - 0.3V

CC

G

G

V

- 0.5V ≤ V

CC

1)

6V

GND to V

CC

200 °C/W

4)

to VCC - 1.2V

ND

≤ V

STB

≤ 0.5V

≤ V

STB

CC

ND

90 °C/W

V

V

V

Ω

2/28

TS4972

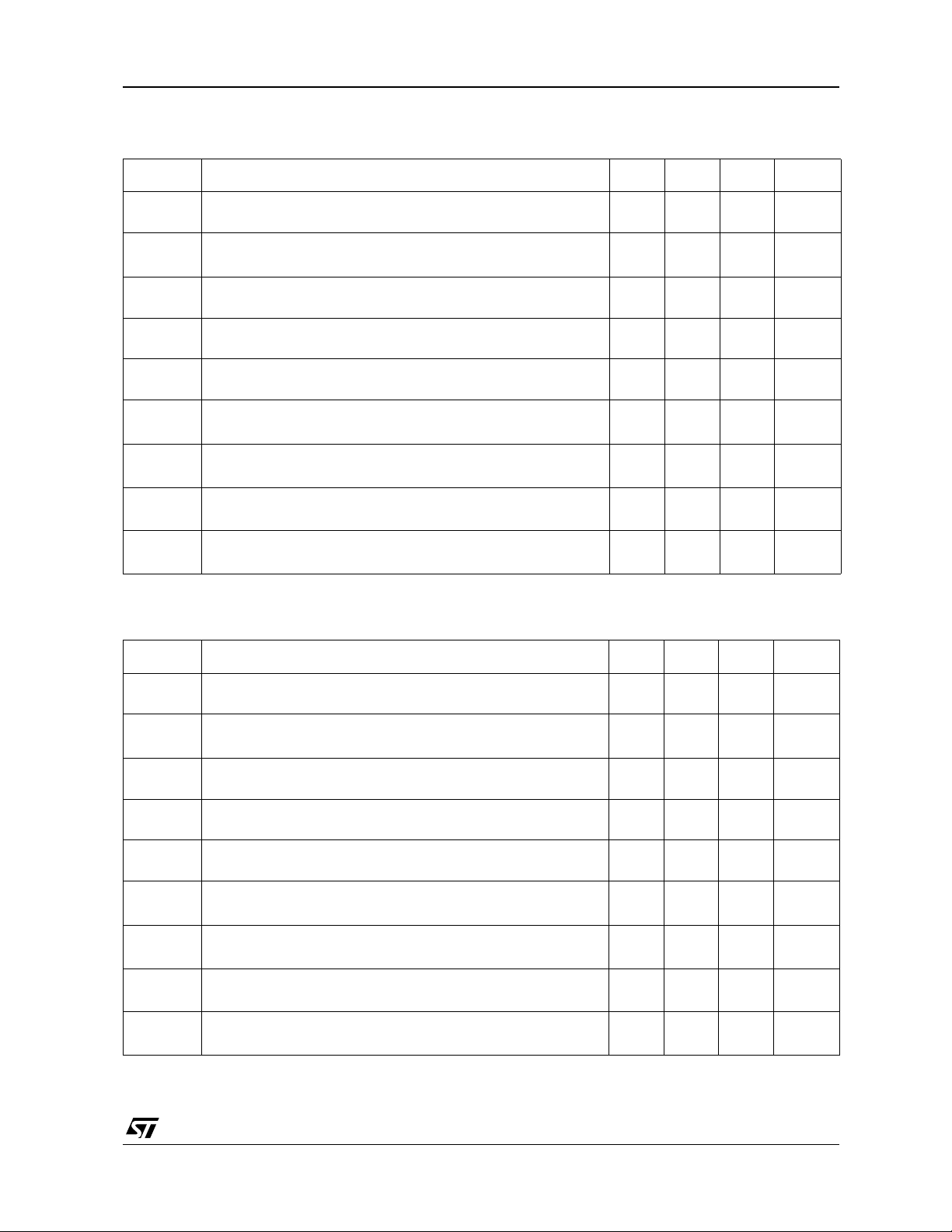

ELECTRICAL CHARACTERISTICS

V

= +5V, GND = 0V , T

CC

Symbol Parameter Min. Typ. Max. Unit

= 25°C (unless otherwise specified)

amb

I

CC

I

STANDBY

Voo

Po

THD + N

PSRR

Φ

GM

GBP

1. Standby mode i s actived when Vstdby is tied to Vcc

2. Dynamic mea surements - 20*log(rms(Vout )/ rms(Vri ppl e)). Vripple is an added sinus signal to Vcc @ f = 217Hz

V

= +3.3V, GND = 0V, T

CC

Supply Current

No input signal, no load

Standby Current

1)

No input signal, Vstdby = Vcc, RL = 8

Output Offset Voltage

No input signal, RL = 8

Output Power

THD = 1% Max, f = 1kHz, RL = 8

Total Harmonic Distortion + Noise

Po = 250mW rms, Gv = 2, 20Hz < f < 20kHz, RL = 8

Power Supply Rejection Ratio

f = 217Hz, RL = 8

Phase Margin at Unity Gain

M

R

= 8Ω, CL = 500pF

L

Gain Margin

R

= 8Ω, CL = 500pF

L

Gain Bandwidth Product

R

= 8

Ω

L

amb

Ω

Ω

Ω

Ω

2)

RFeed = 22K

Ω,

Vripple = 200mV rms

Ω,

= 25°C (unless otherwise specified)3)

68mA

10 1000 nA

520mV

1.2 W

0.1 %

75 dB

70 Degrees

20 dB

2MHz

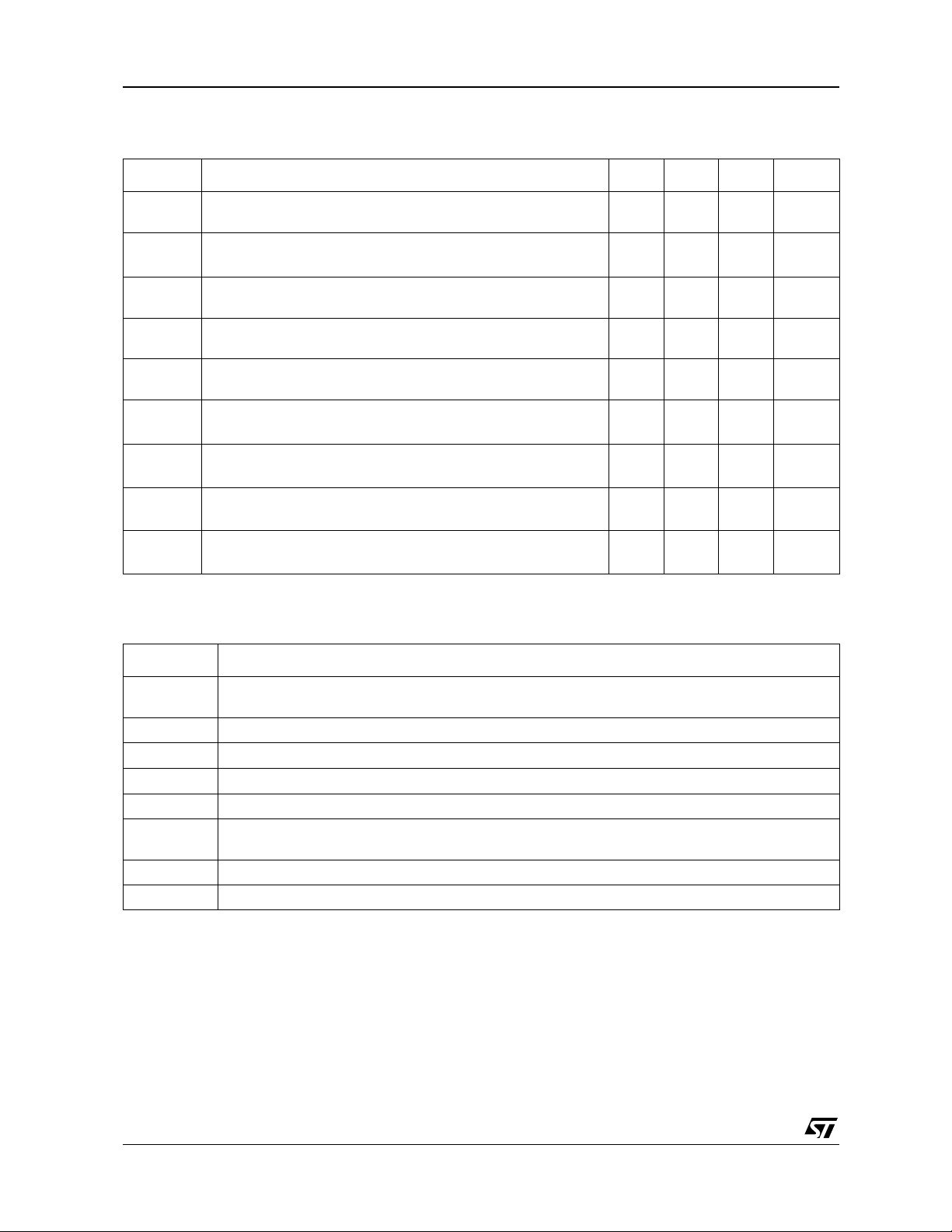

Symbol Parameter Min. Typ. Max. Unit

I

CC

I

STANDBY

Voo

Po

THD + N

PSRR

Φ

GM

GBP

1. Standby mode i s actived when Vstdby is tied to Vcc

2. Dynamic mea surements - 20*log(rms(Vout )/ rms(Vri ppl e)). Vripple is an added sinus signal to Vcc @ f = 217Hz

3. All electrical values are made by correlation between 2.6V and 5V measurements

Supply Current

No input signal, no load

Standby Current

1)

No input signal, Vstdby = Vcc, RL = 8

Output Offset Voltage

No input signal, RL = 8

Output Power

THD = 1% Max, f = 1kHz, RL = 8

Total Harmonic Distortion + Noise

Po = 250mW rms, Gv = 2, 20Hz < f < 20kHz, RL = 8

Power Supply Rejection Ratio

f = 217Hz, RL = 8

Phase Margin at Unity Gain

M

R

= 8Ω, CL = 500pF

L

Gain Margin

R

= 8Ω, CL = 500pF

L

Gain Bandwidth Product

R

= 8

Ω

L

Ω

2)

RFeed = 22K

Ω,

Ω

Ω

Vripple = 200mV rms

Ω,

5.5 8 mA

10 1000 nA

520mV

500 mW

Ω

0.1 %

75 dB

70 Degrees

20 dB

2MHz

3/28

TS4972

ELECTRICAL CHARACTERISTICS

V

= 2.6V, GND = 0V, T

CC

Symbol Parameter Min. Typ. Max. Unit

= 25°C (unless otherwise specified)

amb

I

CC

I

STANDBY

Voo

Po

THD + N

PSRR

Φ

GM

GBP

1. Standby mode i s actived when Vstdby is tied to Vcc

2. Dynamic mea surements - 20*log(rms(Vout )/ rms(Vri ppl e)). Vripple is an added sinus signal to Vcc @ f = 217Hz

Supply Current

No input signal, no load

Standby Current

1)

No input signal, Vstdby = Vcc, RL = 8

Output Offset Voltage

No input signal, RL = 8

Output Power

THD = 1% Max, f = 1kHz, RL = 8

Total Harmonic Distortion + Noise

Po = 200mW rms, Gv = 2, 20Hz < f < 20kHz, RL = 8

Power Supply Rejection Ratio

f = 217Hz, RL = 8

Phase Margin at Unity Gain

M

R

= 8Ω, CL = 500pF

L

Gain Margin

R

= 8Ω, CL = 500pF

L

Gain Bandwidth Product

R

= 8

Ω

L

Ω

2)

RFeed = 22K

Ω,

Ω

Ω

Vripple = 200mV rms

Ω,

5.5 8 mA

10 1000 nA

520mV

300 mW

Ω

0.1 %

75 dB

70 Degrees

20 dB

2MHz

Components Functional Description

Rin

Inverting input resistor which sets the closed loop gain in conjunction with Rfeed. This resistor also

forms a high pass filter with Cin (fc = 1 / (2 x Pi x Rin x Cin))

Cin Input coupling capacitor which blocks the DC voltage at the amplifier input terminal

Rfeed Feed back resistor which sets the closed loop gain in conjunction with Rin

Cs Supply Bypass capacitor which provides power supply filtering

Cb Bypass pin capacitor which provides half supply filtering

Cfeed

Low pass filter capacitor allowing to cut the high frequency

(low pass filter cut-off frequency 1 / (2 x Pi x Rfeed x Cfeed))

Rstb Pull-up resistor which fixes the right supply level on the standby pin

Gv Closed loop gain in BTL configuration = 2 x (Rfeed / Rin)

REMARKS

1. All measurements, except PSRR measurements, are made with a supply bypass capacitor Cs = 100µF.

2. External resistors are not needed for having better stability when supply @ Vcc down to 3V. By the way,

the quiescent current remains the same.

3. The standby response time is about 1µs.

4/28

TS4972

0.3 1 10 100 1000 10000

-40

-20

0

20

40

60

-220

-200

-180

-160

-140

-120

-100

-80

-60

-40

-20

0

Gain (dB)

Frequency (kHz)

Vcc = 5V

ZL = 8Ω + 560pF

Tamb = 25°C

Gain

Phase

Phase (Deg)

Fig. 1 : Open Loop Frequency Response

0

60

Gain

40

Vcc = 5V

RL = 8

Ω

Tamb = 25°C

Phase

20

Gain (dB)

0

-20

-40

-60

-80

-100

-120

-140

-160

-20

-180

-200

-40

0.3 1 10 100 1000 10000

Frequency (kHz)

-220

Fig. 3 : Open Loop Frequency Response

80

60

40

Phase

20

Gain (dB)

0

-20

-40

0.3 1 10 100 1000 10000

Gain

Frequency (kHz)

Vcc = 33V

RL = 8

Ω

Tamb = 25°C

0

-20

-40

-60

-80

-100

-120

-140

-160

-180

-200

-220

-240

Phase (Deg)

Phase (Deg)

Fig. 2 : Open Loop Frequency Response

Fig. 4 : Open Loop Frequency Response

80

Vcc = 3.3V

ZL = 8Ω + 560pF

Tamb = 25°C

60

40

20

Gain (dB)

0

-20

-40

0.3 1 10 100 1000 10000

Gain

Phase

Frequency (kHz)

0

-20

-40

-60

-80

-100

-120

-140

-160

-180

-200

-220

-240

Phase (Deg)

Fig. 5 : Open Loop Frequency Response

80

60

40

Phase

20

Gain (dB)

0

-20

-40

0.3 1 10 100 1000 10000

Gain

Frequency (kHz)

Vcc = 2.6V

RL = 8

Tamb = 25°C

Fig. 6 : Open Loop Frequency Response

0

-20

-40

Ω

-60

-80

-100

-120

-140

-160

Phase (Deg)

-180

-200

-220

-240

80

Vcc = 2.6V

ZL = 8Ω + 560pF

Tamb = 25°C

60

40

20

Gain (dB)

0

-20

-40

0.3 1 10 100 1000 10000

Gain

Phase

Frequency (kHz)

0

-20

-40

-60

-80

-100

-120

-140

-160

-180

-200

-220

-240

Phase (Deg)

5/28

TS4972

0.3 1 10 100 1000 10000

-40

-20

0

20

40

60

80

100

-240

-220

-200

-180

-160

-140

-120

-100

-80

Gain (dB)

Frequency (kHz)

Vcc = 3.3V

CL = 560pF

Tamb = 25°C

Gain

Phase

Phase (Deg)

Fig. 7 : Open Loop Frequency Response

100

80

60

Gain

40

20

Gain (dB)

0

Vcc = 5V

CL = 560pF

-20

Tamb = 25°C

-40

0.3 1 10 100 1000 10000

Phase

Frequency (kHz)

-80

-100

-120

-140

-160

-180

-200

-220

Fig. 9 : Open Loop Frequency Response

100

80

60

Gain

40

20

Gain (dB)

0

Vcc = 2.6V

-20

CL = 560pF

Tamb = 25°C

-40

0.3 1 10 100 1000 10000

Phase

Frequency (kHz)

-80

-100

-120

-140

-160

-180

-200

-220

-240

Fig. 8 : Open Loop Frequency Response

Phase (Deg)

Phase (Deg)

6/28

TS4972

10 100 1000 10000 100000

-80

-70

-60

-50

-40

-30

-20

-10

Cfeed=680pF

Cfeed=330pF

Cfeed=150pF

Cfeed=0

Vcc = 5, 3.3 & 2.6V

Cb = 1µF & 0.1µF

Rfeed = 22kΩ

Vripple = 200mVrms

Input = floating

RL = 8Ω

Tamb = 25°C

PSRR (dB)

Frequency (Hz)

Fig. 10 : Power Supply Rejection Ratio (PSRR)

vs Power supply

-30

Vripple = 200mVrms

Rfeed = 22Ω

-40

Input = floating

RL = 8Ω

Tamb = 25°C

-50

PSRR (dB)

-60

-70

-80

Vcc = 5V, 3.3V & 2.6V

Cb = 1µF & 0.1µF

10 100 1000 10000 100000

Frequency (Hz)

Fig. 12 : Power Supply Rejection Ratio (PSRR)

vs Bypass Capacitor

-10

-20

-30

-40

-50

PSRR (dB)

-60

-70

Cb=100µF

-80

10 100 1000 10000 100000

Cb=1µF

Cb=10µF

Vcc = 5, 3.3 & 2.6V

Rfeed = 22k

Rin = 22k, Cin = 1µF

Rg = 100Ω, RL = 8

Tamb = 25°C

Cb=47µF

Frequency (Hz)

Ω

Fig. 11 : Power Supply Rejection Ratio (PSRR)

vs Feedback Capacitor

Fig. 13 : Power Supply Rejectio n Ratio (PSRR)

vs Input Capacitor

-10

Cin=1µF

-20

-30

-40

PSRR (dB)

-50

-60

Cin=330nF

Cin=220nF

Cin=100nF

Cin=22nF

10 100 1000 10000 100000

Vcc = 5, 3.3 & 2.6V

Rfeed = 22kΩ, Rin = 22k

Cb = 1µF

Rg = 100Ω, RL = 8

Tamb = 25°C

Frequency (Hz)

Ω

Fig. 14 : Power Supply Rejection Ratio (PSRR)

vs Feedback Resistor

-10

Vcc = 5, 3.3 & 2.6V

-20

Cb = 1µF & 0.1µF

Vripple = 200mVrms

-30

Input = floating

RL = 8Ω

-40

Tamb = 25°C

-50

PSRR (dB)

-60

-70

-80

10 100 1000 10000 100000

Rfeed=110kΩ

Rfeed=47kΩ

Rfeed=22kΩ

Rfeed=10kΩ

Frequency (Hz)

7/28

TS4972

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

0.0

0.1

0.2

0.3

0.4

0.5

0.6

RL=4

Ω

RL=8

Ω

Vcc=3.3V

F=1kHz

THD+N<1%

RL=16

Ω

Power Dissipation (W)

Output Power (W)

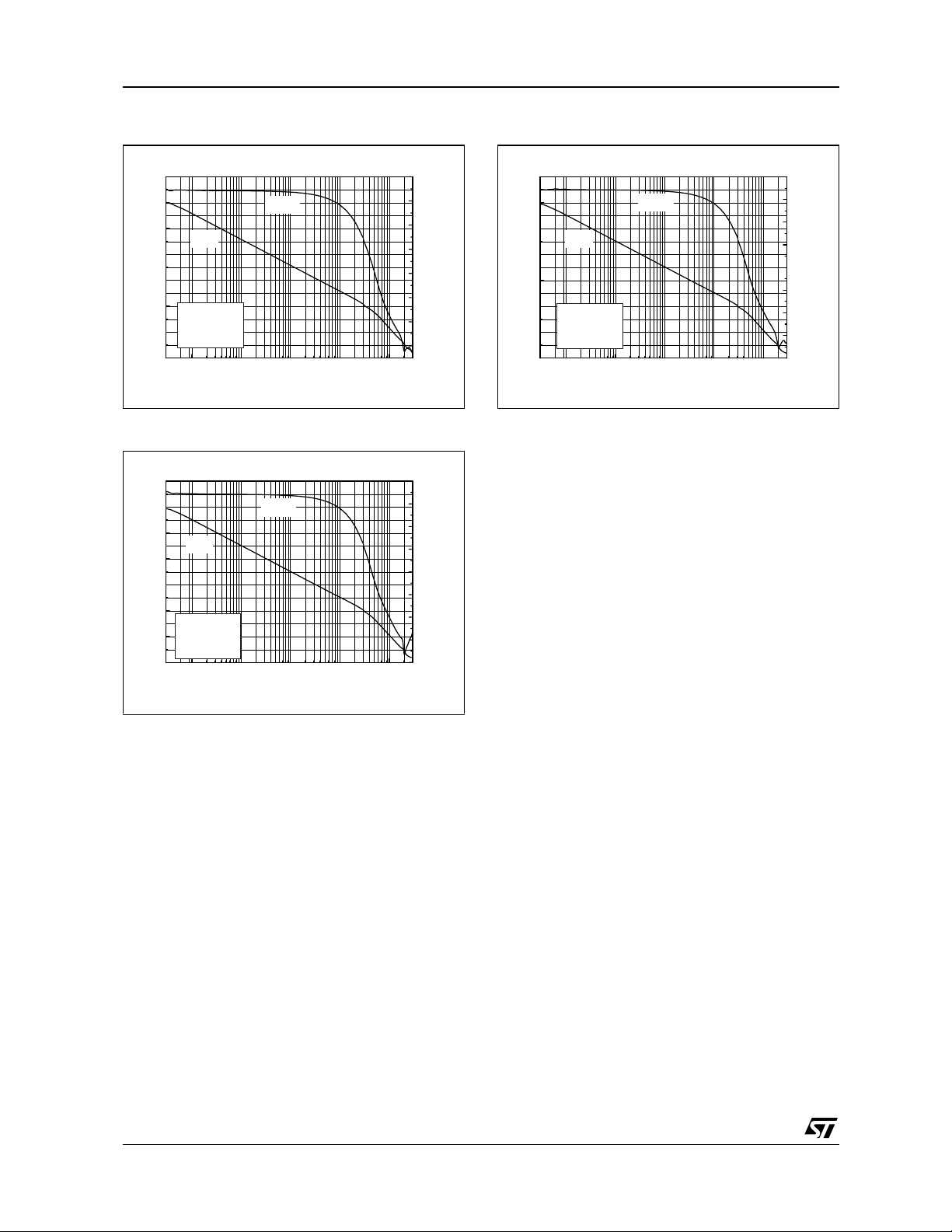

Fig. 15 : Pout @ THD + N = 1% vs Supply

Voltage vs RL

1.6

Gv = 2 & 10

1.4

Cb = 1µF

F = 1kHz

1.2

BW < 125kHz

Tamb = 25°C

1.0

0.8

0.6

0.4

0.2

Output power @ 1% THD + N (W)

0.0

2.5 3.0 3.5 4.0 4.5 5.0

4

Ω

Power Supply (V)

8

Ω

6

Ω

16

Ω

32

Ω

Fig. 17 : Power Dissipation vs Pout

1.4

Vcc=5V

F=1kHz

1.2

THD+N<1%

1.0

0.8

0.6

0.4

Power Dissipation (W)

0.2

0.0

0.0 0.2 0. 4 0.6 0.8 1.0 1.2 1.4 1.6

RL=16

Ω

Output Power (W)

RL=4

RL=8

Ω

Ω

Fig. 16 : Pout @ THD + N = 10% vs Supply

Voltage vs RL

2.0

Gv = 2 & 10

1.8

Cb = 1µF

F = 1kHz

1.6

BW < 125kHz

1.4

Tamb = 25°C

1.2

1.0

0.8

0.6

0.4

Output power @ 10% THD + N (W)

0.2

0.0

2.5 3.0 3.5 4.0 4.5 5.0

4

Ω

Power Supply (V)

8

Ω

6

Ω

16

Ω

32

Ω

Fig. 18 : Power Dissipation vs Pout

Fig. 19 : Power Dissipation vs Pout

0.40

Vcc=2.6V

0.35

F=1kHz

THD+N<1%

0.30

0.25

0.20

0.15

0.10

Power Dissipation (W)

0.05

0.00

8/28

0.0 0.1 0.2 0.3 0. 4

RL=16

RL=8

Ω

Output Power (W)

Fig. 20 : Power Derating Curves

1.4

Heat sink surface = 125mm

(See demoboard)

RL=4

1.2

Ω

1.0

0.8

0.6

Ω

0.4

0.2

Flip-Chip Package Power Dissipation (W)

0.0

No Heat sink

0 25 50 75 100 125 150

Ambiant Temperature ( C)

2

TS4972

1E-3 0.01 0.1 1

0.01

0.1

1

10

RL = 4Ω, Vcc = 5V

Gv = 10

Cb = Cin = 1µF

BW < 125kHz, Tamb = 25°C

20kHz

20Hz

1kHz

THD + N (%)

Output Power (W)

1E-3 0.01 0.1

0.01

0.1

1

10

RL = 4Ω, Vcc = 2.6V

Gv = 10

Cb = Cin = 1µF

BW < 125kHz

Tamb = 25°C

20kHz

20Hz

1kHz

THD + N (%)

Output Power (W)

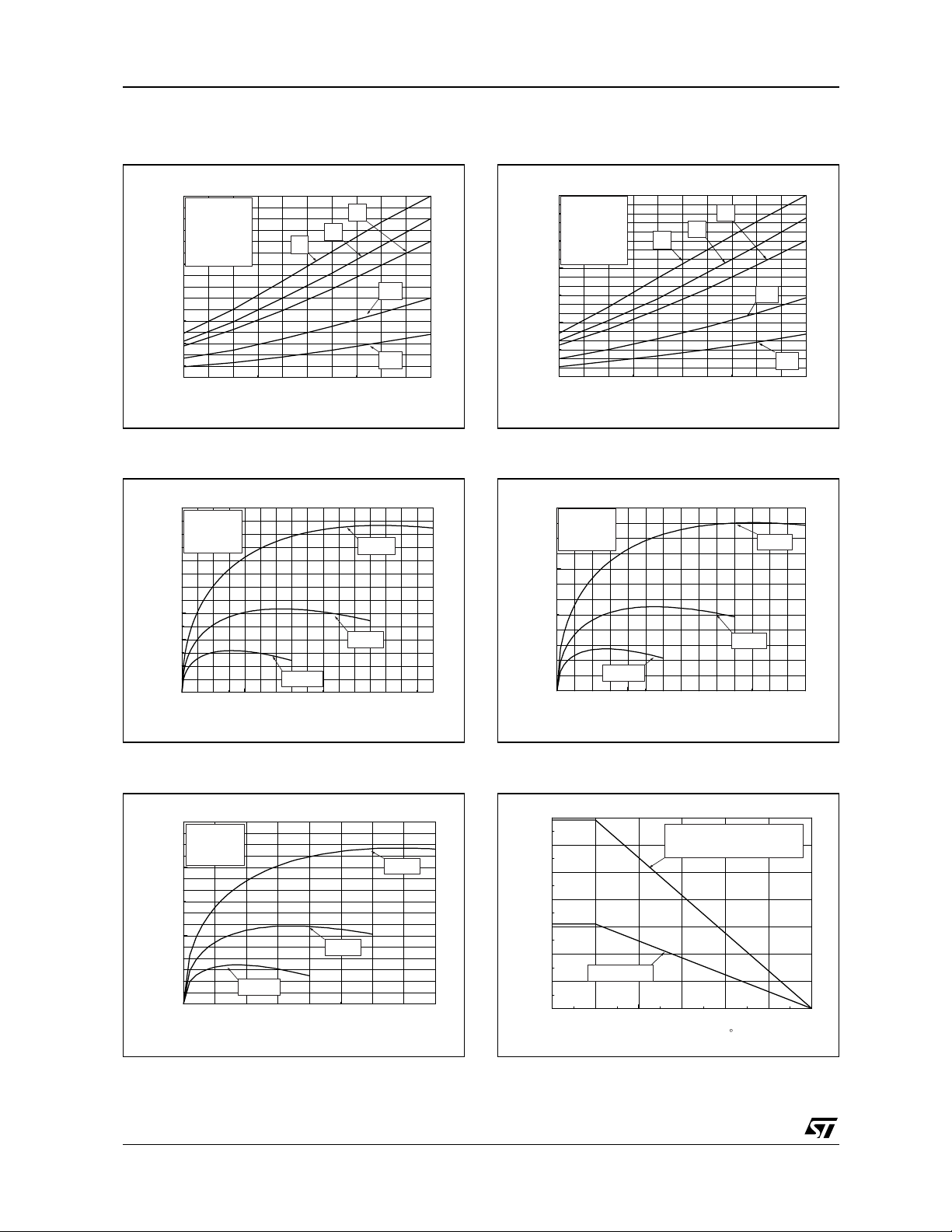

Fig. 21 : THD + N vs Output Power

10

RL = 4

Ω

Vcc = 5V

Gv = 2

Cb = Cin = 1µF

1

BW < 125kHz

Tamb = 25°C

THD + N (%)

0.1

0.01

1E-3 0.01 0.1 1

20kHz

20Hz

Output Power (W)

1kHz

Fig. 23 : THD + N vs Output Power

10

RL = 4Ω, Vcc = 3.3V

Gv = 2

Cb = Cin = 1µF

BW < 125kHz

1

Tamb = 25°C

Fig. 22 : THD + N vs Output Power

Fig. 24 : THD + N vs Output Power

10

RL = 4Ω, Vcc = 3.3V

Gv = 10

Cb = Cin = 1µF

BW < 125kHz

1

Tamb = 25°C

20kHz

20kHz

THD + N (%)

0.1

20Hz

0.01

1E-3 0.01 0.1 1

Output Power (W)

1kHz

Fig. 25 : THD + N vs Output Power

10

RL = 4Ω, Vcc = 2.6V

Gv = 2

Cb = Cin = 1µF

BW < 125kHz

1

Tamb = 25°C

THD + N (%)

0.1

0.01

1E-3 0.01 0.1

20kHz

20Hz

1kHz

Output Power (W)

THD + N (%)

0.1

0.01

1E-3 0.01 0.1 1

Output Power (W)

20Hz

1kHz

Fig. 26 : THD + N vs Output Power

9/28

TS4972

1E-3 0.01 0.1 1

0.01

0.1

1

10

RL = 8

Ω

Vcc = 5V

Gv = 10

Cb = Cin = 1µF

BW < 125kHz

Tamb = 25°C

20kHz

20Hz

1kHz

THD + N (%)

Output Power (W)

1E-3 0.01 0.1

0.01

0.1

1

10

RL = 8Ω, Vcc = 2.6V

Gv = 10

Cb = Cin = 1µF

BW < 125kHz

Tamb = 25°C

20kHz

20Hz

1kHz

THD + N (%)

Output Power (W)

Fig. 27 : THD + N vs Output Power

10

RL = 8

Ω

Vcc = 5V

Gv = 2

Cb = Cin = 1µF

1

BW < 125kHz

Tamb = 25°C

THD + N (%)

0.1

0.01

1E-3 0.01 0.1 1

20Hz

20kHz

1kHz

Output Power (W)

Fig. 29 : THD + N vs Output Power

10

RL = 8Ω, Vcc = 3.3V

Gv = 2

Cb = Cin = 1µF

BW < 125kHz

1

Tamb = 25°C

Fig. 28 : THD + N vs Output Power

Fig. 30 : THD + N vs Output Power

10

RL = 8Ω, Vcc = 3.3V

Gv = 10

Cb = Cin = 1µF

BW < 125kHz

1

Tamb = 25°C

THD + N (%)

0.1

0.01

1E-3 0.01 0.1 1

20Hz

1kHz

20kHz

Output Power (W)

Fig. 31 : THD + N vs Output Power

10

RL = 8Ω, Vcc = 2.6V

Gv = 2

Cb = Cin = 1µF

BW < 125kHz

1

Tamb = 25°C

THD + N (%)

0.1

0.01

1E-3 0.01 0.1

1kHz

20Hz

20kHz

Output Power (W)

20Hz

THD + N (%)

0.1

1kHz

0.01

1E-3 0.01 0.1 1

20kHz

Output Power (W)

Fig. 32 : THD + N vs Output Power

10/28

TS4972

1E-3 0.01 0.1 1

0.01

0.1

1

10

RL = 8Ω, Vcc = 5V, Gv = 10

Cb = 0.1µF, Cin = 1µF

BW < 125kHz, Tamb = 25°C

20kHz

20Hz

1kHz

THD + N (%)

Output Power (W)

1E-3 0.01 0.1

0.01

0.1

1

10

RL = 8Ω, Vcc = 2.6V, Gv = 10

Cb = 0.1µF, Cin = 1µF

BW < 125kHz, Tamb = 25°C

20kHz

20Hz

1kHz

THD + N (%)

Output Power (W)

Fig. 33 : THD + N vs Output Power

10

RL = 8

Ω

Vcc = 5V

Gv = 2

Cb = 0.1µF, Cin = 1µF

1

BW < 125kHz

Tamb = 25°C

THD + N (%)

0.1

0.01

1E-3 0.01 0.1 1

20kHz

Output Power (W)

20Hz

1kHz

Fig. 35 : THD + N vs Output Power

10

RL = 8Ω, Vcc = 3.3V

Gv = 2

Cb = 0.1µF, Cin = 1µF

BW < 125kHz

1

Tamb = 25°C

THD + N (%)

0.1

20Hz

20kHz

Fig. 34 : THD + N vs Output Power

Fig. 36 : THD + N vs Output Power

10

RL = 8Ω, Vcc = 3.3V, Gv = 10

Cb = 0.1µF, Cin = 1µF

BW < 125kHz, Tamb = 25°C

1

20Hz

20kHz

THD + N (%)

0.1

0.01

1E-3 0.01 0.1 1

1kHz

Output Power (W)

Fig. 37 : THD + N vs Output Power

10

RL = 8Ω, Vcc = 2.6V

Gv = 2

Cb = 0.1µF, Cin = 1µF

BW < 125kHz

1

Tamb = 25°C

THD + N (%)

0.1

0.01

1E-3 0.01 0.1

1kHz

20Hz

Output Power (W)

20kHz

1kHz

0.01

1E-3 0.01 0.1 1

Output Power (W)

Fig. 38 : THD + N vs Output Power

11/28

TS4972

1E-3 0.01 0.1 1

0.01

0.1

1

10

RL = 16Ω, Vcc = 5V

Gv = 10

Cb = Cin = 1µF

BW < 125kHz

Tamb = 25°C

20kHz

20Hz

1kHz

THD + N (%)

Output Power (W)

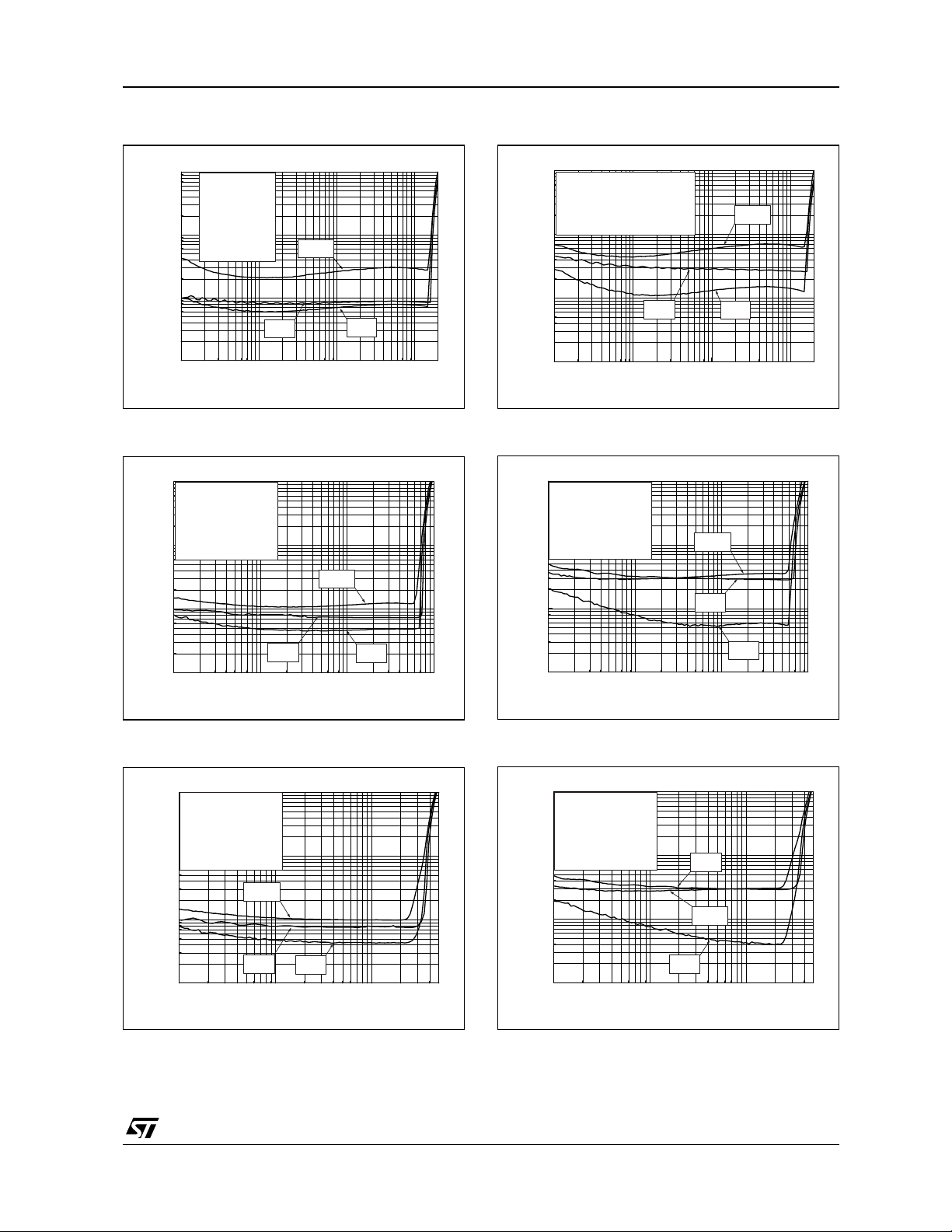

Fig. 39 : THD + N vs Output Power

10

RL = 16Ω, Vcc = 5V

Gv = 2

Cb = Cin = 1µF

BW < 125kHz

1

Tamb = 25°C

0.1

THD + N (%)

0.01

1kHz

1E-3 0.01 0.1 1

20Hz

Output Power (W)

20kHz

Fig. 41 : THD + N vs Output Power

10

RL = 16Ω, Vcc = 3.3V

Gv = 2

Cb = Cin = 1µF

BW < 125kHz

1

Tamb = 25°C

0.1

THD + N (%)

1kHz

0.01

1E-3 0.01 0.1

20Hz

Output Power (W)

20kHz

Fig. 40 : THD + N vs Output Power

Fig. 42 : THD + N vs Output Power

10

RL = 16

Ω

Vcc = 3.3V

Gv = 10

Cb = Cin = 1µF

1

BW < 125kHz

Tamb = 25°C

20Hz

THD + N (%)

0.1

20kHz

1kHz

0.01

1E-3 0.01 0.1

Output Power (W)

Fig. 43 : THD + N vs Output Power

10

RL = 16

Ω

Vcc = 2.6V

Gv = 2

Cb = Cin = 1µF

1

BW < 125kHz

Tamb = 25°C

0.1

THD + N (%)

0.01

1E-3 0.01 0.1

12/28

20Hz

1kHz

Output Power (W)

20kHz

Fig. 44 : THD + N vs Output Power

10

RL = 16

Ω

Vcc = 2.6V

Gv = 10

Cb = Cin = 1µF

1

BW < 125kHz

Tamb = 25°C

THD + N (%)

0.1

20kHz

0.01

1E-3 0.01 0.1

1kHz

20Hz

Output Power (W)

TS4972

20 100 1000 10000

0.01

0.1

1

RL = 4Ω, Vcc = 5V

Gv = 10

Cb = 1µF

BW < 125kHz

Tamb = 25°C

Pout = 650mW

Pout = 1.3W

THD + N (%)

Frequency (Hz)

20 100 1000 10000

0.01

0.1

1

RL = 4Ω, Vcc = 3.3V

Gv = 10

Cb = 1µF

BW < 125kHz

Tamb = 25°C

Pout = 280mW

Pout = 560mW

THD + N (%)

Frequency (Hz)

20 100 1000 10000

0.01

0.1

1

RL = 4Ω, Vcc = 2.6V

Gv = 10

Cb = 1µF

BW < 125kHz

Tamb = 25°C

Pout = 240 & 120mW

THD + N (%)

Frequency (Hz)

Fig. 45 : THD + N vs Frequency

RL = 4Ω, Vcc = 5V

1

Gv = 2

Cb = 1µF

BW < 125kHz

Tamb = 25°C

0.1

THD + N (%)

0.01

20 100 1000 10000

Frequency (Hz)

Pout = 1.3W

Fig. 47 : THD + N vs Frequency

RL = 4Ω, Vcc = 3.3V

1

Gv = 2

Cb = 1µF

BW < 125kHz

Tamb = 25°C

Pout = 560mW

0.1

THD + N (%)

Fig. 46 : THD + N vs Frequency

Pout = 650mW

Fig. 48 : THD + N vs Frequency

0.01

20 100 1000 10000

Fig. 49 : THD + N vs Frequency

RL = 4Ω, Vcc = 2.6V

1

Gv = 2

Cb = 1µF

BW < 125kHz

Tamb = 25°C

Pout = 240 & 120mW

0.1

THD + N (%)

0.01

20 100 1000 10000

Pout = 280mW

Frequency (Hz)

Fig. 50 : THD + N vs Frequency

Frequency (Hz)

13/28

TS4972

20 100 1000 10000

0.01

0.1

1

Cb = 1µF

Cb = 0.1µF

RL = 8Ω

Vcc = 5V

Gv = 2

Pout = 460mW

BW < 125kHz

Tamb = 25°C

THD + N (%)

Frequency (Hz)

20 100 1000 10000

0.01

0.1

1

Cb = 1µF

Cb = 0.1µF

RL = 8Ω, Vcc = 5V

Gv = 10

Pout = 460mW

BW < 125kHz

Tamb = 25°C

THD + N (%)

Frequency (Hz)

20 100 1000 10000

0.01

0.1

1

Cb = 1µF

Cb = 0.1µF

RL = 8Ω, Vcc = 3.3V

Gv = 2

Pout = 210mW

BW < 125kHz

Tamb = 25°C

THD + N (%)

Frequency (Hz)

Fig. 51 : THD + N vs Frequency

1

Cb = 0.1µF

0.1

THD + N (%)

Cb = 1µF

0.01

20 100 1000 10000

Frequency (Hz)

Fig. 53 : THD + N vs Frequency

1

Cb = 0.1µF

RL = 8Ω, Vcc = 5V

Gv = 10

Pout = 920mW

BW < 125kHz

Tamb = 25°C

Fig. 52 : THD + N vs Frequency

RL = 8Ω

Vcc = 5V

Gv = 2

Pout = 920mW

BW < 125kHz

Tamb = 25°C

Fig. 54 : THD + N vs Frequency

0.1

THD + N (%)

Cb = 1µF

0.01

20 100 1000 10000

Fig. 55 : THD + N vs Frequency

1

0.1

THD + N (%)

Cb = 1µF

0.01

14/28

20 100 1000 10000

Frequency (Hz)

Cb = 0.1µF

Frequency (Hz)

Fig. 56 : THD + N vs Frequency

RL = 8Ω, Vcc = 3.3V

Gv = 2

Pout = 420mW

BW < 125kHz

Tamb = 25°C

TS4972

20 100 1000 10000

0.01

0.1

1

Cb = 1µF

Cb = 0.1µF

RL = 8Ω, Vcc = 3.3V

Gv = 10

Pout = 210mW

BW < 125kHz

Tamb = 25°C

THD + N (%)

Frequency (Hz)

20 100 1000 10000

0.01

0.1

1

Cb = 1µF

Cb = 0.1µF

RL = 8Ω, Vcc = 2.6V

Gv = 10

Pout = 110mW

BW < 125kHz

Tamb = 25°C

THD + N (%)

Frequency (Hz)

Fig. 57 : THD + N vs Frequency

1

0.1

THD + N (%)

Cb = 1µF

0.01

20 100 1000 10000

Cb = 0.1µF

Frequency (Hz)

RL = 8Ω, Vcc = 3.3V

Gv = 10

Pout = 420mW

BW < 125kHz

Tamb = 25°C

Fig. 59 : THD + N vs Frequency

1

RL = 8Ω, Vcc = 2.6V

Gv = 2

Pout = 220mW

Cb = 0.1µF

0.1

BW < 125kHz

Tamb = 25°C

Fig. 58 : THD + N vs Frequency

Fig. 60 : THD + N vs Frequency

THD + N (%)

Cb = 1µF

0.01

20 100 1000 10000

Fig. 61 : THD + N vs Frequency

1

0.1

THD + N (%)

Cb = 1µF

0.01

20 100 1000 10000

Frequency (Hz)

Cb = 0.1µF

Frequency (Hz)

RL = 8Ω, Vcc = 2.6V

Gv = 10

Pout = 220mW

BW < 125kHz

Tamb = 25°C

Fig. 62 : THD + N vs Frequency

1

0.1

THD + N (%)

Cb = 1µF

0.01

20 100 1000 10000

Cb = 0.1µF

Frequency (Hz)

RL = 8Ω, Vcc = 2.6V

Gv = 10

Pout = 110mW

BW < 125kHz

Tamb = 25°C

15/28

TS4972

20 100 1000 10000

0.01

0.1

RL = 16Ω, Vcc = 5V

Gv = 10, Cb = 1µF

BW < 125kHz

Tamb = 25°C

Pout = 315mW

Pout = 630mW

THD + N (%)

Frequency (Hz)

20 100 1000 10000

0.01

0.1

1

RL = 16Ω, Vcc = 3.3V

Gv = 10, Cb = 1µF

BW < 125kHz

Tamb = 25°C

Pout = 140mW

Pout = 280mW

THD + N (%)

Frequency (Hz)

20 100 1000 10000

0.01

0.1

1

RL = 16Ω, Vcc = 2.6V

Gv = 10, Cb = 1µF

BW < 125kHz

Tamb = 25°C

Pout = 80mW

Pout = 160mW

THD + N (%)

Frequency (Hz)

Fig. 63 : THD + N vs Frequency

0.1

Pout = 315mW

0.01

THD + N (%)

1E-3

Pout = 630mW

20 100 1000 10000

Frequency (Hz)

RL = 16Ω, Vcc = 5V

Gv = 2, Cb = 1µF

BW < 125kHz

Tamb = 25°C

Fig. 65 : THD + N vs Frequency

0.1

Pout = 140mW

0.01

Fig. 64 : THD + N vs Frequency

Fig. 66 : THD + N vs Frequency

THD + N (%)

Pout = 280mW

1E-3

20 100 1000 10000

Frequency (Hz)

RL = 16Ω, Vcc = 3.3V

Gv = 2, Cb = 1µF

BW < 125kHz

Tamb = 25°C

Fig. 67 : THD + N vs Frequency

0.1

Pout = 80mW

0.01

THD + N (%)

1E-3

16/28

Pout = 160mW

20 100 1000 10000

Frequency (Hz)

RL = 16Ω, Vcc = 2.6V

Gv = 2, Cb = 1µF

BW < 125kHz

Tamb = 25°C

Fig. 68 : THD + N vs Frequency

TS4972

2.5 3.0 3.5 4.0 4.5 5.0

50

60

70

80

90

RL=16

Ω

RL=4

Ω

RL=8

Ω

Gv = 10

Cb = Cin = 1µF

THD+N < 0.7%

Tamb = 25°C

SNR (dB)

Vcc (V)

2.5 3.0 3.5 4.0 4.5 5.0

60

70

80

90

100

RL=16Ω

RL=4Ω

RL=8Ω

Gv = 10

Cb = Cin = 1µF

THD+N < 0.7%

Tamb = 25°C

SNR (dB)

Vcc (V)

012345

0

1

2

3

4

5

6

7

Vstandby = 0V

Tamb = 25°C

Icc (mA)

Vcc (V)

Fig. 69 : Signal to Noise Ratio vs Power Supply

with Unweighted Filter (20Hz to 20kHz)

100

90

RL=4

RL=8

RL=16

80

70

SNR (dB)

60

50

2.5 3.0 3.5 4.0 4.5 5.0

Ω

Ω

Vcc (V)

Ω

Gv = 2

Cb = Cin = 1µF

THD+N < 0.4%

Tamb = 25°C

Fig. 71 : Signal to Noise Ratio vs Power Supply

with Weighte d Fi lte r Type A

110

100

RL=4

RL=8

RL=16

90

Ω

Ω

Ω

Fig. 70 : Signal to Noise Ratio vs Power Supply

with Unweighted Filter (20Hz to 20kHz)

Fig. 72 : Signal to Noise Ratio vs Power Supply

with Weighte d Fi lte r Type A

80

SNR (dB)

70

60

2.5 3.0 3.5 4.0 4.5 5.0

Vcc (V)

Fig. 73 : Frequency Response Gain vs Cin, &

Cfeed

10

5

0

-5

-10

Gain (dB)

-15

-20

-25

10 100 1000 10000

Cin = 82nF

Cin = 470nF

Cin = 22nF

Frequency (Hz)

Gv = 2

Cb = Cin = 1µF

THD+N < 0.4%

Tamb = 25°C

Fig. 74 : Current Consum ption vs Power

Supply Voltage

Cfeed = 330pF

Cfeed = 680pF

Cfeed = 2.2nF

Rin = Rfeed = 22kΩ

Tamb = 25°C

17/28

TS4972

0.0 0.5 1.0 1.5 2.0 2.5 3.0

0

1

2

3

4

5

6

Vcc = 3.3V

Tamb = 25°C

Icc (mA)

Vstandby (V)

Fig. 75 : C urrent Consumption vs Standby

Voltage @ Vcc = 5V

7

6

5

4

3

Icc (mA)

2

1

0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Vstandby (V)

Vcc = 5V

Tamb = 25°C

Fig. 77 : C urrent Consumption vs Standby

Voltage @ Vcc = 2.6V

6

5

4

3

Icc (mA)

2

Vcc = 2.6V

Tamb = 25°C

Fig. 76 : C urrent Consumption vs Standby

Voltage @ Vcc = 3.3V

Fig. 78 : Clipping Voltage vs Power Supply

Voltage and Load Resistor

0.6

Tamb = 25°C

0.5

0.4

0.3

Vout1 & Vout2

0.2

RL = 4Ω

RL = 8Ω

1

0

0.0 0.5 1.0 1.5 2.0 2.5

Vstandby (V)

Fig. 79 : Clipping Voltage vs Power Supply

Voltage and Load Resistor

0.7

RL = 4

RL = 8

Ω

Ω

RL = 16

Ω

18/28

Tamb = 25°C

0.6

0.5

0.4

0.3

Vout1 & Vout2

0.2

0.1

Clipping Voltage Low side (V)

0.0

2.5 3.0 3.5 4.0 4.5 5.0

Power supply Voltage (V)

0.1

Clipping Voltage High side (V)

0.0

2.5 3.0 3.5 4.0 4.5 5.0

Power supply Voltage (V)

RL = 16Ω

APPLICA TI ON INFORMATION

Fig. 80 : Demoboard Schematic

S1

P1

Neg. Input

P2

Pos. Inp ut

Vcc

S2

GND

VCC

R3

R8

1k

C3

R4

C4

S5

Positive Input mode

VCC

R7

100k

S8

Standby

R5

C11

+

VCC

GND

TS4972

C1

R2

R1

C5

1

7

R6

3

5

C12

+

C8

1u

100n

Vin-

Vin+

Bypass

Standby

C2

VCC

+

C6

C7

100µ

100n

Vout 1

Vout 2

U1

8

4

TS4972

+

+

C9

470µ

C10

470µ

S6

OUT1

S3

GND

S4

GND

S7

OUT2

6

VC

C

-

+

-

AV = -1

+

Bias

G

ND

2

Fig. 81 : Flip-Chip 300µm Demoboard Components Side

19/28

TS4972

Fig. 82 : Flip-Chip 300µm Demoboard Top

Solder Layer

Fig. 83 : Flip-Chip 300µm

Solder Layer

Demoboard Bottom

The output power is:

2

)Vout2(

Pout

=

RMS

R

L

)W(

For the same power supply voltage, the output

power in BTL configuration is four times higher

than the output power in single ended

configuration.

■Gain In Typical Application Schematic

(cf. page 1)

In flat region (no effect of Cin), the output voltage

of the first stage i s:

Vout1 = Vin –

For the second stage : Vout2 = -Vout1 (V)

The differential output voltage is:

Vout2

V o ut 1 = 2Vin –

Rfeed

------------------- - (V)

Rin

Rfeed

------------------- - (V)

Rin

■BTL Configuration Principle

The TS4972 is a monolithic power amplifier with a

BTL output type. BTL (Bridge Tied Load) means

that each end of the load is connected to two

single ended output amplifiers. Thus, we have :

Single ended output 1 = Vout1 = Vout (V)

Single ended output 2 = Vout2 = -Vo ut (V)

And Vout1 - Vout2 = 2Vout (V)

The differential gain named gain (Gv) for more

convenient usage is:

Vout2 Vout1–

Gv =

--------------------------------------- = 2

Vin

Rfeed

------------------- Rin

Remark : Vout2 is in phase with Vin and Vout1 is

180 phased with Vin. It means that the positive

terminal of the l oudspeaker should be connected

to Vout2 and the negative to Vout1.

■Low and high frequency response

In low frequency region, the effect of Cin starts.

Cin with Rin forms a high pass filter with a -3dB cut

off frequency.

CL =

F

In high frequency region, you can limit the

bandwidth by adding a capacitor (Cfeed) in

parallel on Rfeed. Its form a l ow pass filter with a

-3dB cut off frequency .

F

CH =

---------------------------------------------- - Hz()

2π Rf eed Cfeed

1

------------------------------- - Hz()

2π Rin Cin

1

20/28

TS4972

)W(

R

Vcc2

maxPdiss

L

2

2

π

=

■Power dissipation and efficiency

Hypothesis :

• Voltage and current in the load are sinusoidal

(Vout and Iout)

• Supply voltage is a pure DC source (Vcc)

Regarding the load we have:

V

OUT = V

and

OUT =

I

and

P

OUT =

Then, the average current delivered by the supply

voltage is:

CC

AVG

= 2

I

The power delivered by the supply voltage is

Psupply = Vcc Icc

AVG

(W)

Then, the po wer dissip ated by the amplifier is

Pdiss = Psupply - Pout (W)

P

22Vcc

diss =

---------------------- P OUT POUT (W)–

πR

L

sinωt (V)

PEAK

V

OUT

---------------- - (A)

L

R

2

PEAK

V

---------------------- (W )

L

2R

PEAK

V

-------------------- (A)

L

πR

The maximum theoret ical value is reached when

Vpeak = Vcc, so

π

----- = 78.5%

4

■Decoupl i ng of the ci rc u it

Two capacitors are needed to bypass properly the

TS4972, a power supply bypass capacitor Cs and

a bias voltage bypass capacitor Cb.

Cs has especially an influence on the THD+N in

high frequency (above 7kHz) and indirectly on the

power supply disturbances.

With 100µF, you can expect similar THD+N

performances like shown in the datasheet.

If Cs is lower than 100µF, in high frequency

increases, THD+N and disturbances on the power

supply rail are less filtered.

To the contrary, if Cs is higher t han 100µF, those

disturbances on the power supply rail are more

filtered.

Cb has an influence on THD+N in lower frequency,

but its function is critical on the final result of PSRR

with input grounded in lower frequency.

If Cb is lower than 1µF, T HD+N increase in lower

frequency (see THD+N vs frequency curves) and

the PSRR worsens up

If Cb is higher than 1µF, the benefit on THD+N in

lower frequency is small but the ben efit on PSRR

is substantial (see PSRR vs. Cb curve : fig.12).

and the maximum value is obtained when:

∂Pdiss

--------------------- - = 0

OUT

∂P

and its value is:

Note that Cin has a non-negligible effect on PSRR

in lower frequency. Lower is its value, higher is the

PSRR (see fig. 13).

■Pop and Click perfo r m ance

Pop and Click performance is intimately linked

with the size of the input capacitor Cin and the bias

voltage bypass capacitor Cb.

Remark : This maximum valu e is only depending

on power supply voltage and load values.

The efficiency is the ratio between the output

power and the power supply

OUT

P

----------------------- - =

η =

Psupply

πV

PEAK

----------------------4VCC

Size of Cin is du e to the lower cut-off frequency

and PSRR value requested. Size of Cb is due to

THD+N and PSRR requested always in lower

frequency.

Moreover, Cb determines the speed that the

amplifier turns ON. The slower th e speed is, the

softer the turn ON noise is.

21/28

TS4972

The charge time of Cb is directly proportional to

the internal generator resistance 50kΩ.

Then, the charge time constant for Cb is

τb = 50kΩxCb (s)

As Cb is directly connected to the non-inverting

input (pin 2 & 3) and if we want to minimize, i n

amplitude and duration, the output spike on Vout1

(pin 5), Cin must be charged faster than Cb. T he

charge time constant of Cin is

τin = (Rin+Rfeed)xCin (s)

Thus we have the relation

τin << τb (s)

The respect of this relation permits to minimize the

pop and click noise.

Remark

: Minimize Cin and Cb has a benefit on

pop and click phenomena but also on cost and

size of the application.

Example

: your target for the -3dB cut off

frequency is 100 Hz. With Rin=Rfeed=22 kΩ,

Cin=72nF (in fact 82nF or 100nF).

With Cb=1µF, if you choose the one of the latest

two values of Cin, the pop and click phenomena at

power supply ON or standby function ON/OFF will

be very small

50 kΩx1µF >> 44kΩx100nF (50ms >> 4.4ms).

Increasing Cin value increas es the pop and click

phenomena to an unpleasant sound at power

supply ON and standby function ON/OFF .

t

DischCs =

5Cs

------------- - = 83 ms

Icc

Now, we must consider the discharge time of Cb.

At power OFF or standby ON, Cb is discharged by

a 100kΩ resistor. So the discharge time i s about

τb

≈ 3xCbx100kΩ (s).

Disch

In the majority of application, Cb=1µF, then

τb

≈300ms >> t

Disch

dischCs

.

■Power amplifier design examples

Given :

• Load impedance : 8Ω

• Output power @ 1% THD+N : 0.5W

• Input impedance : 10kΩ min.

• Input voltage peak to peak : 1Vpp

• Bandwidth frequency : 20Hz to 20kHz (0, -3dB)

• Ambient temperature max = 50°C

• SO8 package

First of all, we must cal culate t he m inimum p ower

supply voltage to obtain 0.5W into 8Ω. With curves

in fig. 15, we can read 3.5V. Thus, the power

supply voltage value min. will be 3.5V.

Following the maximum power dissipation

equation

2

Vcc2

=

maxPdiss

2

π

R

)W(

L

Why Cs is not important in pop and click

consideration ?

Hypothesis :

• Cs = 100µF

• Supply voltage = 5V

• Supply voltage internal resistor = 0.1Ω

• Supply current of the amplifier Icc = 6mA

At power ON of the supply, the supply capacitor is

charged through the internal power supply

resistor. So, to reach 5V you need about five to ten

times the charging time constant of Cs (τs =

0.1xCs (s)).

Then, this time equal 50µs to 100µs << τb in the

majority of application.

At power OFF of the supply, Cs is discharged by a

constant current Icc. The di scharge time from 5V

to 0V of Cs is:

22/28

with 3.5V we have Pdissmax=0.31W.

Refer to power derating curves (fig. 20), with

0.31W the maxim um ambien t temperature will be

100°C. This last value could be higher if you follow

the example layout shown on the demoboard

(better dissipation).

The gain of the amplifier in flat region will be:

GV =

OUTPP

V

--------------------- =

VINPP

L POUT

22R

----------------------------------- - = 5.65

VINPP

We have Rin > 10kΩ. Let's take Rin = 10kΩ, then

Rfeed = 28.25kΩ. We could use for Rfeed = 30kΩ

in normalized value and th e gain will be Gv = 6.

TS4972

In lower frequency we want 20 Hz (-3dB cut off

frequency). Then:

CIN =

1

------------------------------ = 795nF

2π

RinFCL

So, we could use for Cin a 1µF capacitor val ue

which gives 16Hz.

In Higher frequency we want 20k Hz (-3dB cut off

frequency). The Gain Bandwidth Product of the

TS4972 is 2MHz typical and doesn't change when

the amplifier delivers power into the load.

The first amplifier has a gain of:

Rfeed

----------------- = 3

Rin

and the theoretical value of the -3dB cut-off higher

frequency is 2MHz/3 = 660kHz.

We can keep this value or limit the bandwidth by

adding a capacitor Cfeed, in parallel on Rfeed.

Then:

C

FEED =

1

-------------------------------------- - = 265pF

FEEDFCH

2π R

So, we could use for Cfeed a 220pF capacitor

value that gives 24kHz.

Now, we can calculate the value of Cb with the

formula τb = 50kΩxCb >> τin = (Rin+Rfee d)xCin

which permits to redu ce t he po p and click effects.

Then Cb >> 0.8µF.

We can choose for Cb a normalized value of 2.2µF

that gives good results in THD+N and PSRR.

In the following tables, you could find three

another examples with values required for the

demoboard.

Application n°1 : 20Hz to 20kHz bandwidth and

6dB gain BTL power amplifier.

Designator Part Type

R8 Short Circuit

C5 470nF

C6 100µF

C7 100nF

C9 Short Circuit

C10 Short Circuit

C12 1µF

S1, S2, S6, S7

S8

P1 SMB Plug

2mm insulated Plug

10.16mm pitch

3 pts connector 2.54mm

pitch

Application n°2 : 20Hz to 20kHz bandwidth and

20dB gai n BTL power am pl i fie r.

Components :

Designator Part Type

R1 110k / 0.125W

R4 22k / 0.125W

R6 Short Cicuit

R7 100k / 0.125W

R8 Short Cicuit

C5 470nF

C6 100µF

C7 100nF

C9 Short Circuit

C10 Short Circuit

Components :

Designator Part Type

R1 22k / 0.125W

R4 22k / 0.125W

R6 Short Cicuit

R7 100k / 0.125W

C12 1µF

S1, S2, S6, S7

S8

P1 SMB Plug

2mm insulated Plug

10.16mm pitch

3 pts connector 2.54mm

pitch

23/28

TS4972

2.5 3.0 3.5 4.0 4.5 5.0 5.5

10

15

20

25

30

35

40

Differential Gain min. (dB)

Power Supply Voltage (V)

Application n°3 : 50Hz to 10kHz bandwidth and

10dB gai n BTL power am pl i fie r.

Components :

Designator Part Type

R1 33k / 0.125W

R2 Short Circuit

R4 22k / 0.125W

R6 Short Cicuit

R7 100k / 0.125W

R8 Short Cicuit

C2 470pF

C5 150nF

C6 100µF

C7 100nF

C9 Short Circuit

C10 Short Circuit

C12 1µF

S1, S2, S6, S7

2mm insulated Plug

10.16mm pitch

Fig. 8 4 :

Voltage

Minimum Differential Gain vs Power Supply

For Vcc=5V, a 20Hz to 20kHz bandwidth and 20dB

gain BTL power amplifier you could follow the bill

of material be low.

Components :

Designator Part Type

R1 110k / 0.125W

R4 22k / 0.125W

S8

P1 SMB Plug

3 pts connector 2.54mm

pitch

Application n°4 : Differential inputs BTL power

amplifier.

In this configuration, we need to place these

R5 22k / 0.125W

R6 110k / 0.125W

R7 100k / 0.125W

R8 Short circuit

C4 470nF

C5 470nF

components : R1, R4, R5, R6, R7, C4, C5, C12.

C6 100µF

We have also : R4 = R5, R1 = R 6, C4 = C5.

The differential gain of the amplifier is:

GVDIFF = 2

Note : Due to the VICM range (see Operating

R1

------- R4

Condition), GVDIFF must have a minim um value

shown in figure 84.

24/28

C7 100nF

C9 Short Circuit

C10 Short Circuit

C12 1µF

S1, S2, S6, S7 2mm insulat e d Plu g

10.16mm pitch

S8

P1, P2 SMB Plug

3 pts connector 2.54mm

pitch

TS4972

■Note on how to use the PSRR curves

(page 7)

We have finished a design and we have ch osen

the components values :

• Rin=Rfeed=22kΩ

• Cin=100nF

• Cb=1µF

Now, on fig. 13, we can see the PSRR (input

grounded) vs frequency curves. At 217Hz we have

a PSRR value of -36dB.

In reality we want a value about -70dB. So, we

need a gain of 34dB !

Now, on fig. 12 we can see the effect of Cb on the

PSRR (input grounded) vs. frequency. With

Cb=100µF, we can reach the -70dB value.

The process to obtain the final curve (Cb=100µF,

Cin=100nF, Rin=Rfeed=22kΩ) is a simple transfer

point by point on each frequency of the curve on

fig. 13 to the curve on fig. 12.

The measurement result is shown on the next

figure.

Fig. 85 : PSRR changes with Cb

How we measure the PSRR

?

Fig. 86 : PSRR measurement schematic

Rfeed

Vripple

Vcc

Cin

Rg

100 Ohms

1

Vin-

Vin+

7

Rin

3

Bypass

5

Standby

Cb

6

VCCGND

-

+

-

+

Bias

2

AV = -1

Vout 1

Vout 2

8

4

TS4972

■Principle of operation

• We fixed the DC voltage supply (Vcc)

• We fixed the AC sinusoidal ripple voltage

(Vripple)

• No bypass capacitor Cs is used

The PSRR value for each frequency is:

Vs-

RL

Vs+

-30

Cin=100nF

-40

Cb=1µF

-50

PSRR (dB)

-60

-70

10 100 1000 10000 100000

Cin=100nF

Cb=100µF

Vcc = 5, 3.3 & 2.6V

Rfeed = 22k, Rin = 22k

Rg = 100Ω, RL = 8

Tamb = 25°C

Frequency (Hz)

Ω

■Note on PSRR measurement

What is the PSRR

The PSRR is the Power Suppl y Rejection Ratio.

It's a kind of SVR in a determined frequency range.

The PSRR of a device, is the ratio between a

power supply disturbance and the result on the

output. We can say that the PSRR is the ability of

a device to m inimize the impact o f power supply

disturbances to the output.

?

PSRR dB() = 20 x Log10

Rms V

---------------------------------------- ----Rms Vs

ripple()

- Vs

()

+

-

Remark : The measure of the Rms voltage is not a

Rms selective measure but a full range (2 Hz to

125 kHz) Rms measure. It means that we

measure the effective Rms signal + the noise.

25/28

TS4972

Fig. 87 :TS4972 Footprint Recommendation (Non Solder Mask Defined)

500µm

500µm

500µm

500µm

500µm

Φ

Φ

Φ

Φ

Φ

=250µm

=250µm

=250µm

=250µm

=250µm

Φ

Φ

Φ

Φ

Φ

=400µm

=400µm

=400µm

=400µm

m

m

m

m

m

µ

µ

µ

µ

µ

500

500

500

500

500

m

m

m

m

m

µ

µ

µ

µ

µ

500

500

500

500

500

Solder mask opening

Solder mask opening

Solder mask opening

Solder mask opening

Solder mask opening

=400µm

500µm

500µm

500µm

500µm

500µm

Pad in Cu 35µm with Flash NiAu(6µm, 0.15µm)

Pad in Cu 35µm with Flash NiAu(6µm, 0.15µm)

Pad in Cu 35µm with Flash NiAu(6µm, 0.15µm)

Pad in Cu 35µm with Flash NiAu(6µm, 0.15µm)

Pad in Cu 35µm with Flash NiAu(6µm, 0.15µm)

75µm min.

75µm min.

75µm min.

75µm min.

75µm min.

100µm max.

100µm max.

100µm max.

100µm max.

100µm max.

150µm min.

150µm min.

150µm min.

150µm min.

150µm min.

Track

Track

Track

Track

Track

TOP VIEW OF THE DAISY CHAIN MECHANICAL DATA ( all drawings dimensions are in millimeters )

567

567

StdbyVccVin+

StdbyVccVin+

Vout1

8

8

Vout1

Vin Gnd

Vin Gnd

12

12

2.26 mm

2.26 mm

Vout2

Vout2

Bypass

Bypass

3

3

1.6 m m

1.6 m m

4

4

REMARKS

Daisy chain sample is featuring pins connection two by two. The schematic above is illustrating the way

connecting pins each other. This sample is used for testing continuity on board. PCB needs to be designed

on the opposite way, where pin connections are not done on daisy chain samples. By that way, just

connecting an Ohmeter between pin 8 and pin 1, the soldering process continuity can be tested.

ORDER CODE

Part Number

Temperature

Range

TSDC03IJT -40, +85°C

26/28

Package

J

•

Marking

DC3

TAPE & REEL SPECIFICATION ( top view )

User direction of feed

User direction of feed

User direction of feed

User direction of feed

A72

4972

A72

4972

TS4972

A72

4972

A72

4972

27/28

TS4972

12

3

76

5

8

4

Gnd

Bypass

Vout2

Stdby

Vcc

Vout1

Vin

+

Vin

PIN OUT (Top View) MARKING (Top View)

■ Balls are underneath

PACKAGE MECHANICAL DATA

FLIP CHIP - 8 BU MPS

0.5 0.5

0.5

■ Die size : (2.26mm ±10%) x (1.6mm ±10%)

■ Die height (including bumps) : 650µm ± 50

1.6

2.262.26

250µm

250µm

Information furnished is bel ieved to be accurate and reliable. However, STMicroe lectronics assumes no responsibility for the

consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from

its use. No li cense is granted by i mp lication or otherwise under any patent or patent rights of STMicroelec tron ic s. S pec ificat ions

mentioned in this publication ar e subject to change without notice. This publication supersedes and replaces all information

previously supplied. S TMicroelectronics products are not authorized for use as critica l components in life suppo rt devices or

systems without express written approval of STMicroelectronics.

Australi a - Brazil - Chi n a - Finland - F rance - Germ any - Hong Kong - India - It al y - Japan - Ma l aysia - Malta - Morocco

The ST logo is a registered trademark of STMicroelectronics

© 2003 STM icroelectronics - P r i n ted in Italy - All Rights Reserved

STMicr o el ectronics GROUP OF COMPA NI ES

Singapo re - Spain - Sweden - Switzerland - United Ki ngdom

http://www.st.com

■ Bumps diameter : 315µm ±15µm

■ Silicon thickness : 400µm ±25µm

0.5

■ Pitch: 500µm ±10µm

400µm

400µm

650µm

650µm

28/28

Loading...

Loading...