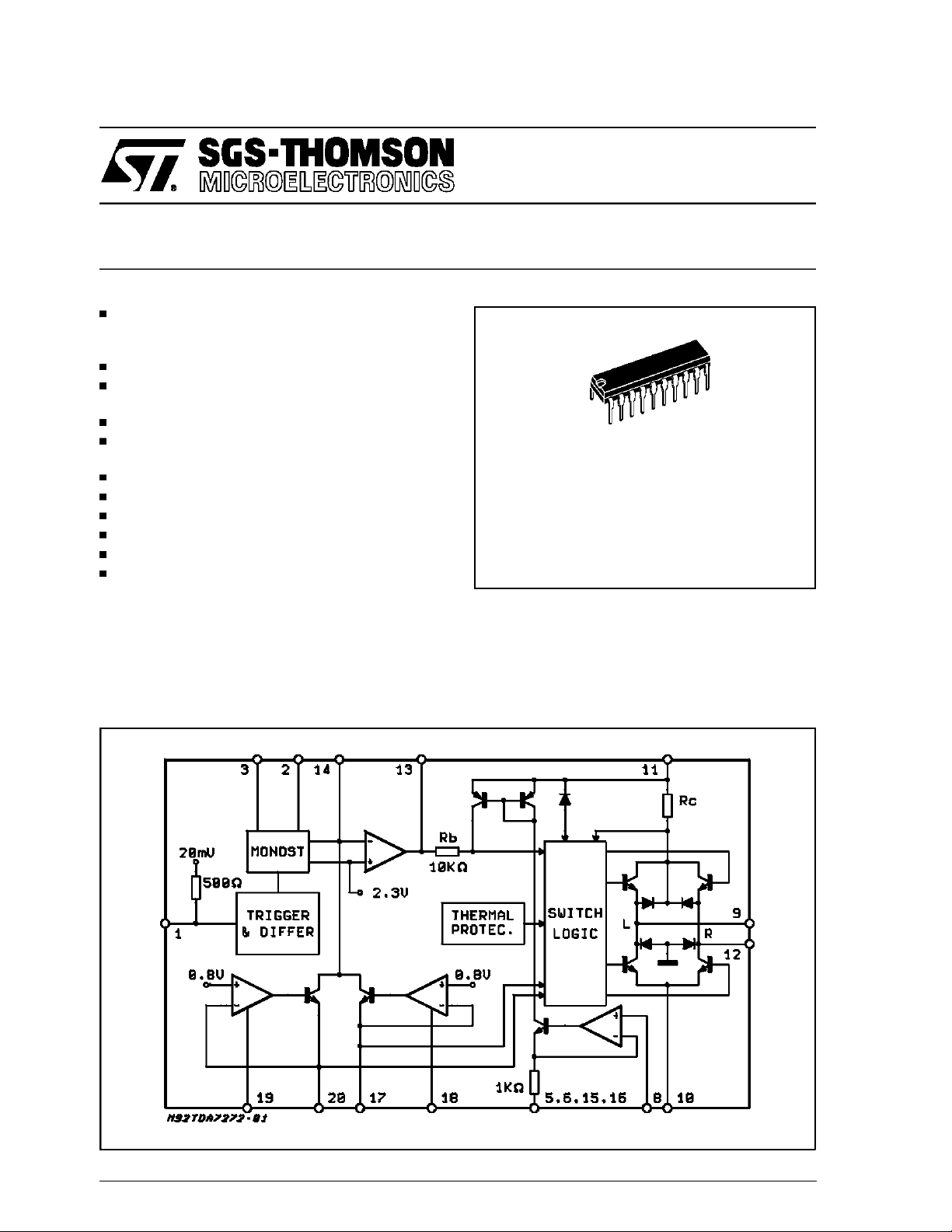

HIGH PERFORMANCE MOTOR SPEED REGULATOR

TACHIMETRIC SPEED REGULATION WITH

NO NEED FOR AN EXTERNAL SPEED PICKUP

V/I SUPPLEMENTARYPREREGULATION

DIGITAL CONTROL OF DIRECTION AND

MOTORSTOP

SEPARATESPEEDADJUSTMENT

5.5V TO 18V OPERATING SUPPLY VOLTAGE

1A PEAK OUTPUT CURRENT

OUTPUTCLAMP DIODESINCLUDED

SHORTCIRCUIT CURRENT PROTECTION

THERMAL SHUT DOWNWITH HYSTERESIS

DUMP PROTECTION (40V)

ESD PROTECTION

TDA7272A

Powerdip(16+2+2)

ORDERING NUMBER: TDA7272A

DESCRIPTION

TDA7272A are high performance motor speed

controller for small power DC motors as used in

cassetteplayers.

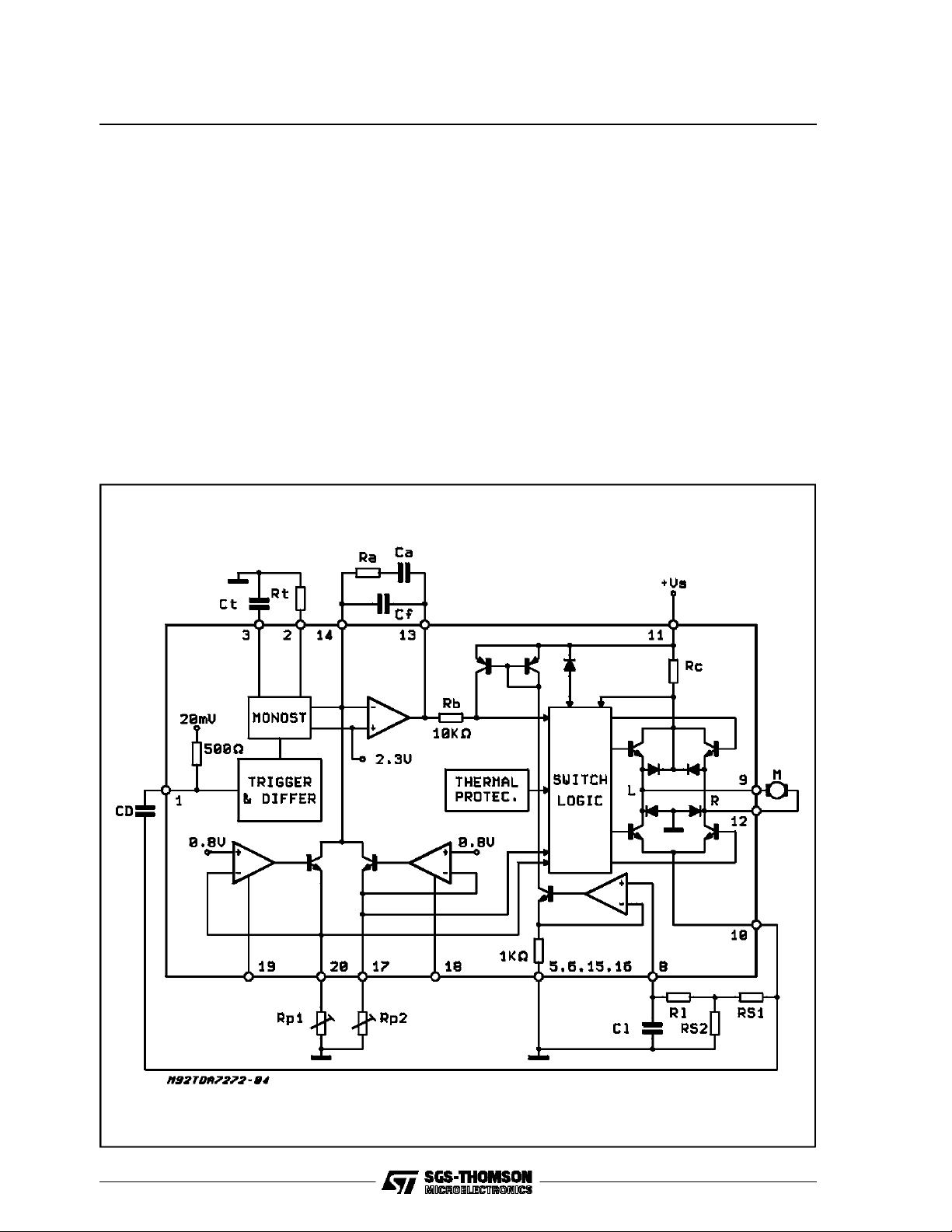

BLOCK DIAGRAM

Using the motor as a digital tachogenerator itself

the performance of true tacho controlled systems

isreached.

A dual loop control circuit provides long term stabilityand fast settling behaviour.

This is advanced information on a new product now in developmentor undergoing evaluation.Details aresubject to changewithout notice.

June 1992

1/16

TDA7272A

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

S

V

S

I

O

P

tot

T

op

T

stg

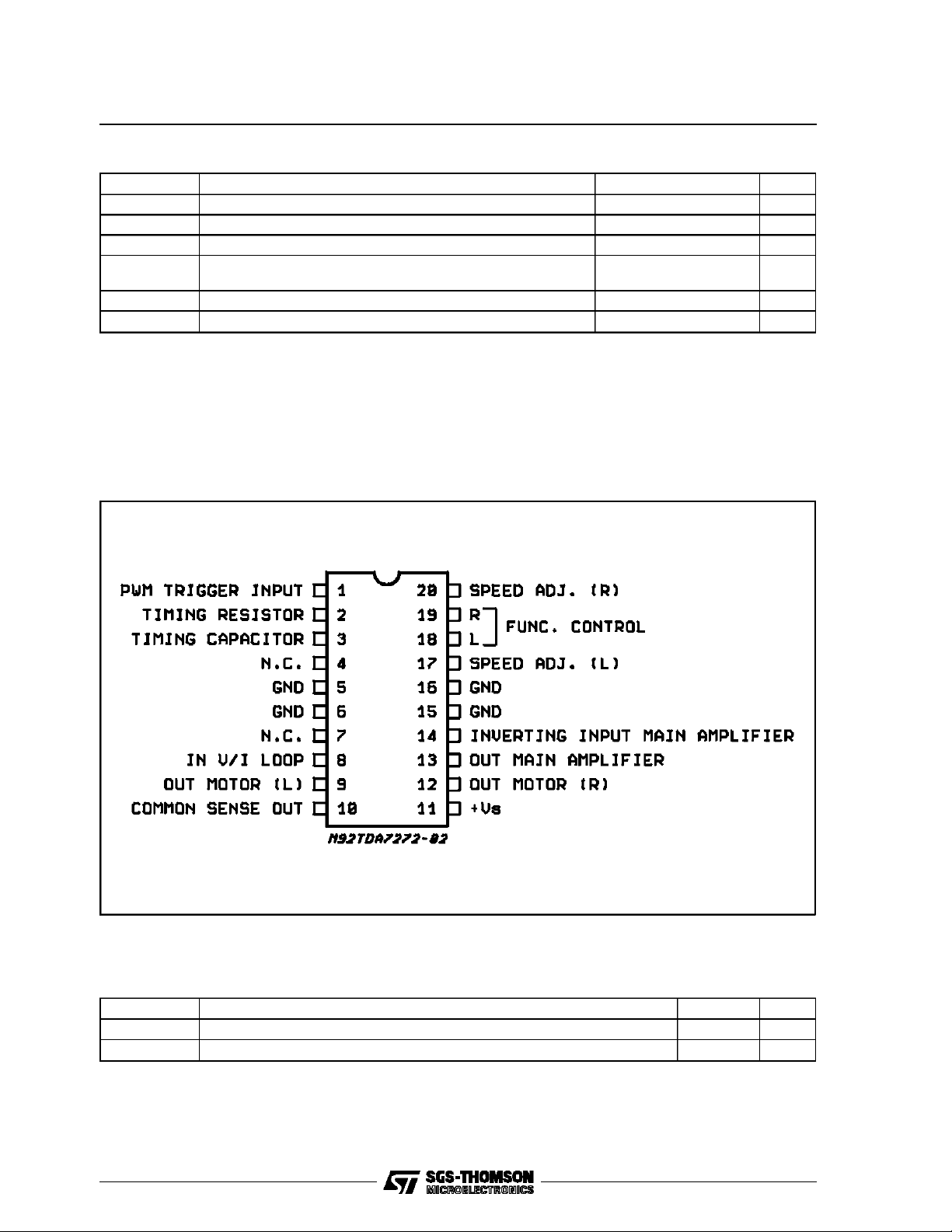

PIN CONNECTION (Topview)

DC Supply Voltage 24 V

Dump Voltage (300ms) 40 V

Output Current Internally limited

Power Dissipation at T

at T

pins

amb

=90°C

=70°C

4.3

1

Operating Temperature Range -40 to 85 °C

Storage Temperature -40 to 150 °C

W

W

THERMAL DATA

Symbol Parameter Value Unit

Thermal Resistance Junction-ambient max. 80 °C/W

Thermal Resistance Junction-pins max. 14 °C/W

2/16

R

th j-amb

R

th j-pins

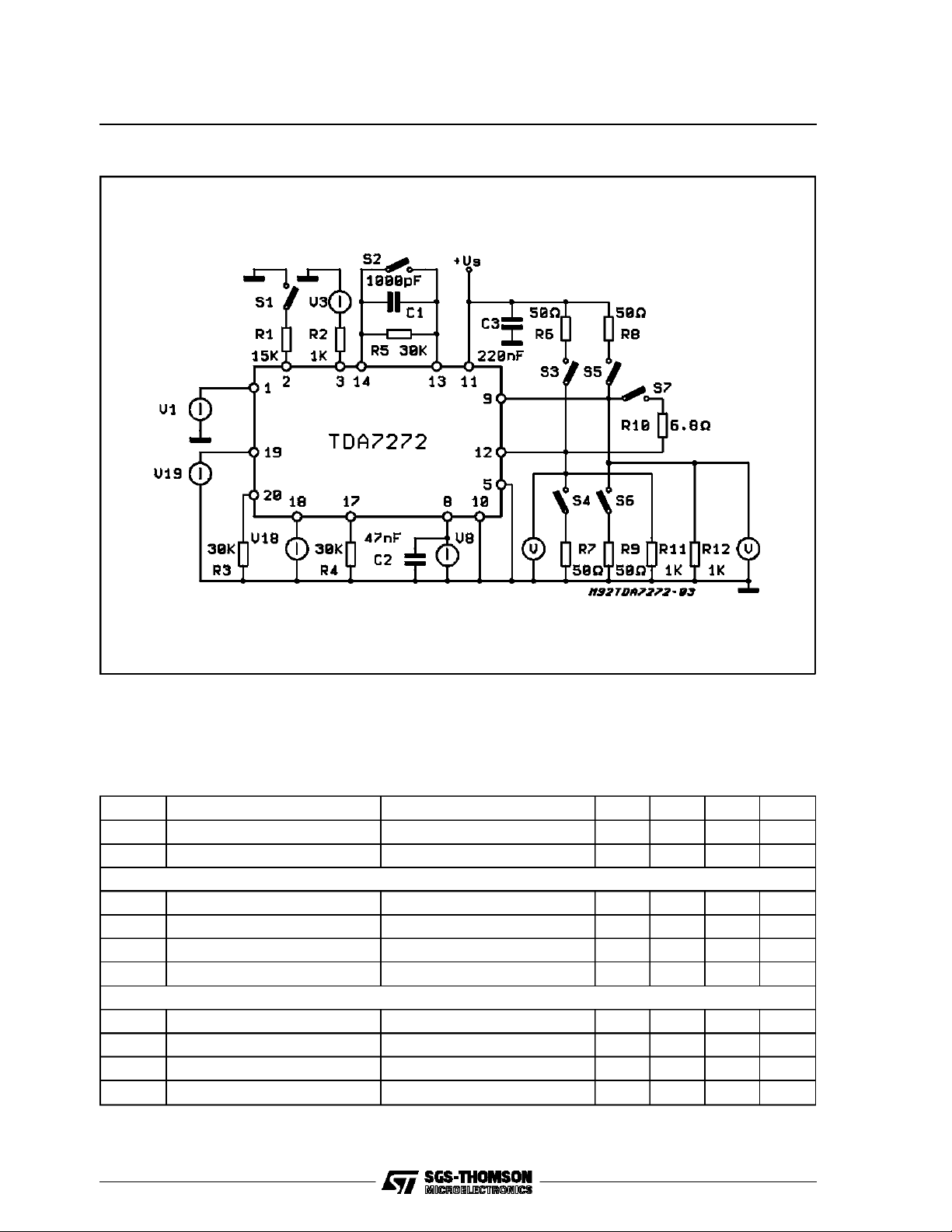

TEST CIRCUIT

TDA7272A

A

ELCTRICAL CHARACTERISTICS (T

=25°C; VS=13.5V unless otherwisespecified)

amb

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

I

Operating Supply Voltage 5.5 18 V

S

Supply Current No load 5 12 mA

S

OUTPUT STAGE

V

10,9,12

V

11,9,12

I

I

Output Currente Pulse 1 A

O

Output Currente Continuous 250 mA

O

Voltage Drop IO= 250mA 1.2 1.5 V

Voltage Drop IO= 250mA 1.7 2 V

MAIN AMPLIFIER

R

V

OFF

V

Input Resistance 100 KΩ

14

I

Bias Current 50 nA

b

Offset Voltage 1 5 mV

Reference Voltage Internal at non inverting input 2.3 V

R

3/16

TDA7272A

ELECTRICAL CHARACTERISTICS (Continued)

Symbol Parameter Test Conditions Min. Typ. Max. Unit

CURRENT SENSE AMPLIFIER

R

G

TRIGGER AND MONOSTABLE STAGE

V

R

V

T Low

V

V

V

2 REF

SPEED PROGRAMMING, DIRECTION CONTROL LOGICAND CURRENT SOURCE PROGRAMMING

V

18,19Low

V

18,19 High

I

18,19

V

17,20 REF

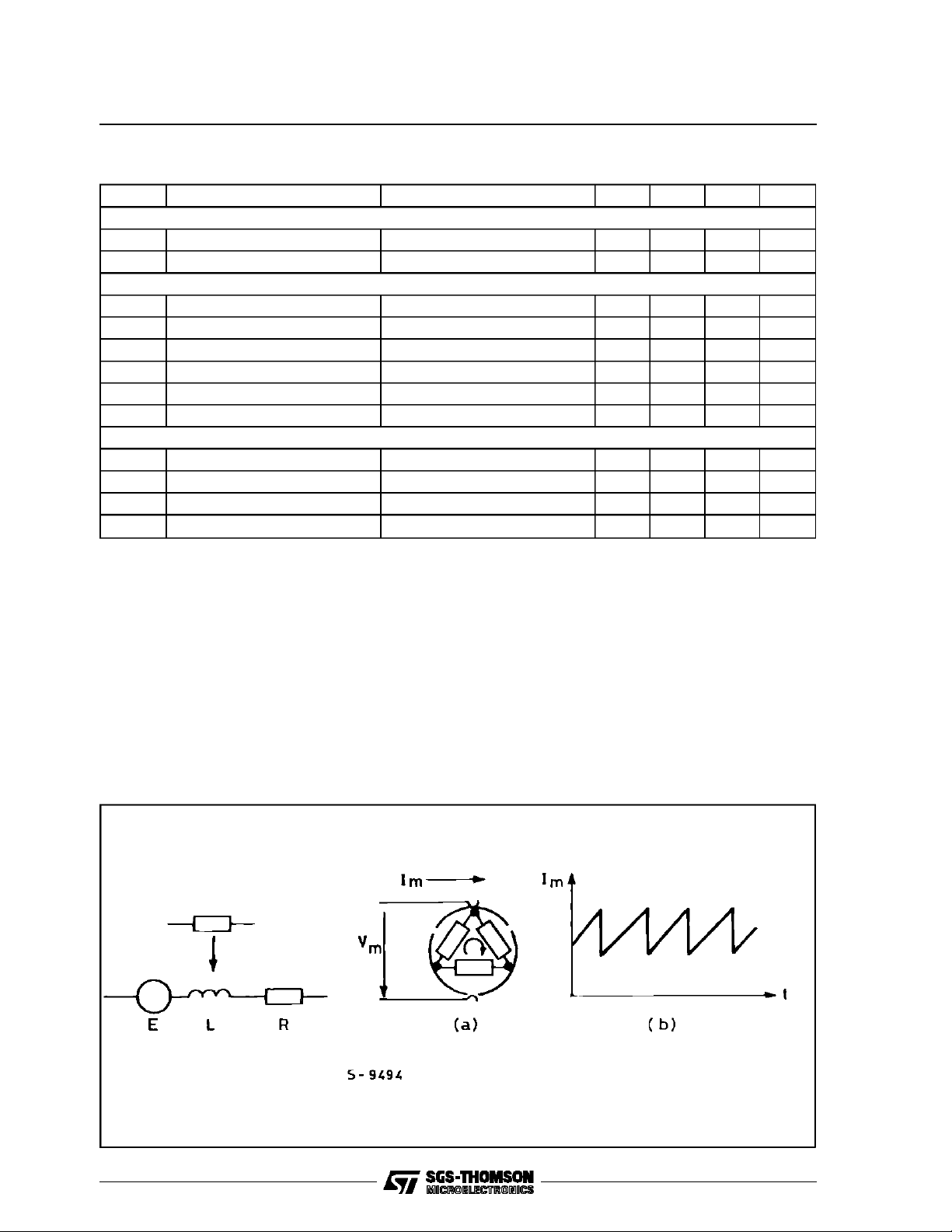

The TDA7272A novel applied solution is based

on a tachometer control system without using

such extra tachometer system. The information of

the actual motor speed is extracted from the motor itself. A DC motorwith an odd number of poles

generates a motor current which contains a fixed

number of discontinuities within each rotation. (6

for the 3 pole motor example on fig. 1)

Deriving this inherent speed information from the

motor current, it can be used as a replacement of

a low resolution AC tachometer system. Because

the settling time of the control loop is limited on

principleby the resolution in time of the tachome-

Figure1: Equivalent of a 3Pole DC Motor (a) and Typical motor CurrentWaveform (b).

Input Resistance 100 KΩ

8

Loop Gain 9

L

Input Allowed Voltage -0.7 3 V

IN1

Input Resistance 500 Ω

IN1

Trigger Level 0 V

Bias Voltage (pin 1) 15 20 25 mV

TB

Trigger Histeresis 10 mV

TH

Reference Voltage 750 800 850 mV

Input Low Level 0.7 V

Input High Level 2 V

Input Current 0 < V

Reference Voltage 735 800 865 mV

18,19<VS

2 µA

ter, this control principle offers a poor reaction

time for motors with a low number of poles. The

realized circuit is extended by a second feed forward loop in order to improve such system by a

fastauxiliary control path.

This additional path senses the mean output current and varies the output voltage according to

the voltage drop across the inner motor resistance. Apart from a current averaging filter, there

is no delay in such loop and a fast settling behaviour is reached in addition to the long term speed

motoraccuracy.

4/16

TDA7272A

BLOCK DESCRIPTION

The principle structure of the element is shown in

fig. 2. As to be seen, the motor speed information

is derived from the motor current sense drop

across the resistors R

; capacitor CD together

S

with the input impedance of 500 Ω at pin 1 realizes a high pass filter.

This pin is internally biased at 20 mV, each negative zero transition switches the input comparator.

A 10 mV hysteresisimproves the noise immunity.

The trigger circuit is followed by an internal delay

time differentiator.

Thus, the system becomes widely independent of

the applied waveform at pin 1, the differentiator

triggers a monostable circuit which provides a

constant current duration. Both, output current

magnitude and duration T, are adjustable by ex-

Figure2: ApplicationCircuit.

ternalelements CT and RT.

The monostable is retriggerable ; this function

prevents the system from fault stabilization at

higherharmonics of the nominal frequency.

The speed programming current is generated by

two separate external adjustable current sources.

A corresponding digital input signal enables each

current source for left or right rotation direction.

ResistorRP1 and RP2 define the speed, the logicalinputs are at pin 18 and 19.

At the invertinginput (pin 14) of the main amplifier

the referencecurrent is compared with the pulsed

monostableoutput current.

For the correct motor speed, the reference current matches the mean value of the pulsed

monostable current. In this condition the charge

of the feedbackcapacitorbecomes constant.

5/16

TDA7272A

The speedn of a k pole motor results :

10.435

n =

C

TkRP

and becomes independent of the resistor RT

which only determines the current level and the

duty cycle which should be 1 : 1 at the nominal

speedfor minimumtorque ripple.

The second fast loop consists of a voltage to current converter which is driven at pin 8 by the low

pass filter R

. The output current at this stage

L,CL

is injected by a PNP current mirror into the inner

resistor R

. So the driving voltage of the output

B

stage consists of the integrator output voltage

plus the fastloop voltagecontribution across R

.

B

The power output stage realizes different modes

dependingon the logic status at pin 18 and19.

- Normal operation for left and right mode :

each upper TR of the bridge is used as

voltage follower whereas the lower acts as

a switch.

- Stop mode where the upper half is open

and the lower is conductive.

- High impedance status where all power

elementsare switched-off.

The high impedance status is also generated

when the supply voltage overcomes the 5 V to 20

V operating range or when the chip temperature

exceeds150 °C.

A short circuit protection limits the output current

at 1.5 A. Integrated diodes clamp spikes from the

inductiveload both at V

and ground.

CC

The reference voltages are derived from a common bandgap reference. All blocks are widely

suppliedby an internal 3.5 V regulator which providesa maximum supply voltage rejection.

Figure3.

Figure4.

PIN FUNCTION AND APPLICATION INFORMATION

PIN 1

Trigger input. Receives a proper voltage which

contains the information of the motor speed. The

waveform can be derived directly by the motor

current (fig. 3). The external resistor generates a

propervoltage drop. Togetherwith the input resistance at pin 1 [R

pacitorC

realizea high passfilter which differen-

D

(1) = 500 Ω ] the external ca-

IN

tiates the commutation spikes of the motor

current. Thetrigger level is 0V.

The biasing of the pin 1 is 20 mV with a hysteresis of 10 mV. So the sensing resistance must be

chosen high enough in order to obtain a negative

spike of the least 30 mV on pin 1, also with minimum variationof motor current :

S

∆I

MOT

min.

30mV

≥

R

Such value can be too much high for the preregulation stage V-I and it could be necessary to split

6/16

them into 2 series resistors R

=RS1+RS2(see

S

fig. 4) as explained on pin 8 section.

The information can be taken also from an exter-

nal tachogenerator.Fig. 5 shows various sources

connections:

the input signal mustn’t be lower than 0.7 V.

Figure5.

TDA7272A

Pin 2

Timing resistor. An internal reference voltage

(V2 = 0.8 V) gives possibility to fix by an external

resistor (R

), from this pin and ground, the output

T

current amplitudeof the monostable circuit, which

will be reflected into the timing capacitor (pin 3) ;

the typicalvalue would be about 50 µ A.

Figure6.

Pin 3

Timing capacitor. A constant current, determined

by the pin 2 resistor, flowing into a capacitor between pin 3 andground provides the output pulse

width of the monostable circuit, the max voltage

at pin 3 is fixed by an internal threshold : after

reaching this value the capacitor is rapidly dischargedand the pulsewidth is fixed to the value :

= 2.88 RTCT(fig.6)

T

on

Pin 4

Not connected.

Pin 5

Ground.Connected with pins6, 15, 16.

Pin 6

Ground.Connected with pins5, 15, 16.

Pin7

Notconnected.

Pin8

Input V/I loop. Receives from pin 10, through a

low pass filter, the voltage with the information of

the current flowing into the motor and produces a

negativeresistanceoutput :

R

= −9RS(fig. 7)

out

Figure7.

For compensating the motor resistance and

avoidinginstability:

R

MOTOR

≤

R

S

The optimization of the resistor R

9

for the tacho-

S

metric controlmust not give a voltage too high for

the V/I stage : one solutioncan be to divide in two

parts, as shown in fig.8, with :

R

M

=

R

S2

10

and R

+ RS2≥

S1

30mV

∆ I mot min.

(seepin 1 sect.)

The low pass filter R

must be calculated in

L,CL

order to reduce the ripple of the motor commutation at least 20 dB. Another example of possible

pins 10-8 connections is showed on fig. 9. A

choke can be used in order to reduce the radiation.

7/16

TDA7272A

Figure8.

Figure9.

substrate diodes, protect the output from inductive vol-tage spikes during the transition phase

(fig.10)

Figure10.

Pin10

Common sense output. From this pin the output

current of the bridge configuration (motor current)

is fed into R

external resistor in order to gener-

S

ate a propervoltagedrop.

The drop is supplied into pin 1 for tachometric

control andinto pin 8 for V/I control (see pin 1 and

pin 8 sections).

Pin 9

Output motor left. The four power transistors are

realized as darlington structures. The arrangement is controlled by the logic status at pins 18

and 19.

As beforeexplained (see block description), in the

normal left or right mode one of the lower darlington becomes saturated whereas the other remains open. The upper half of the bridge operates in the linear mode.

In stop condition both upper bridge darlingtons

are off and both lower are on. In the high output

impedance state the bridge is switched completelyoff.

Connecting the motor between pins 9 and 12

both left or right rotation can be obtained. If only

one rotation sense is used the motor can be connectedat only one output, byusing only the upper

bridge half. Two motors can be connected each

at the each output : in such case they will work alternatively(see application section).

The internal diodes, together with the collector

8/16

Pin11

Supplyvoltage.

Pin12

Outputmotor right. (seepin 9 section)

Pin13

Output main amplifier. The voltage on this pin results from the tachometric speed control and

feedsthe output stage.

The value of the capacitorC

(fig. 11), connected

F

from pins 13 and 14, must be chosen low enough

in order to obtain a short reaction time of the

tachometricloop, and high enough in order to reduce the output ripple.

A compromise is reached when the ripple voltage

(peak-to-peak)V

C

F

V

FEM

RIP

=

withV

cle = 50 %. (see pin 2-3 section)

is equal to 0.1 V

ROP

= 2.3

+ I

MOT

C

V

RIP

⋅ R

10

T

( 1 −

MOT

MOTOR

R

T

)

R

P

and with duty cy-

:

TDA7272A

Figure11.

Figure12.

Figure13.

In order to compensate the behaviour of the

whole system regulator-motor-load (considering

axis friction, load torque, inertias moment of the

motor of the load. etc.) a RC series network is

also connected between pins 13 and 14 (fig. 12).

The value of C

and RAmust been chosen ex-

A

perimentallyas follows:

- Increase of 10 % the speed with respect to

the nominal value by connecting in parallel

to R

a resistor with value about 10 time

p

larger.

- Vary the R

and CAvalues in order to ob-

A

tain at pin 13 a voltage signal with shortresponse time and without oscillations. Fig.

13 shows the step response at pin 13 versus R

andCAvalues.

A

Pin 14

9/16

TDA7272A

Figure14. Figure15.

Inverting input of main amplifier. In this pin the

current reference programmed at pins 20, 17 is

compared with the current from the monostable

(streamof rectangularpulses).

In steady-state condition (constant motor speed)

the values are equal and the capacitor C

voltage

F

is constant.

This means for the speed n (min 1):

10.435

=

n

C

TkRP

where ”k” is the number of collector segments.

(poles)

The non inverting input of the main amplifier is internallyconnected to a referencevoltage (2.3 V).

Pin 15

Ground.

Pin 16

Ground.

Pin 17

Left speed adjustment. The voltage at this pin is

fixed to a referencevalue of 0.8 V. A resistor from

this pin and ground (fig. 14) fixes the reference

current which will be compared with the medium

output current of the monostablein order to fix the

speed of the motor at the programmed value.The

correct value of R

would be :

p

10.435

=

R

P

C

kn

T

n = motor speed, (min -1)

k = poles number

The control of speed can be done in different

way:

- speed separately programmed in two

sensesofrotation (fig. 14-15) ;

- only one speed for the two senses of rotation (fig. 16) ;

Figure16.

Figure17.

- speeds of the two sensesa bit different(i.e.

for compensating different pulley effects)

(fig. 17) ;

- speed programmed with a DC voltage (fig.

18)i.e. with DA converter;

10/16

TDA7272A

- fast forward, by putting a resistor. In this

Figure19.

case it is necessary that also at the higher

speed for the duty cycle to be significately

less than 1 (see value of R

T,CT

on pin 2,

pin 3 sections).

Fig. 19 shows the functioncontrolled with a µP.

Figure18.

Thetypical value of the threshold (L-H) is 1.2 V.

Pin19

Left functioncontrol. (see pin 18 sect).

Pin 18

Right functioncontrol. The voltagesapplied to this

Pin20

Rightspeed adjustment. (seepin 17 sect).

pin and to pin 19 determine the function, as

showed in the table.

CONDITION

Pin 18 Pin 19 Pin 12 Pin 9

L

H

L

H

L

L

H

H

OUTPUT FUNCTION

STOP

LEFT

RIGHT

OPEN

OUTPUT VOLTAGE

LOW

LOW

REG

HIGH IMP.

HIGH IMP.

LOW

REG

LOW

Figure20: Typicalapplication.

11/16

TDA7272A

Figure21: Tachoonly speed regulation.

Figure22: One direction regulatorof one motor , or alternatively of two motors.

12/16

Figure23: P.C.board and componentslayout of the circuits of Figg. 20, 21, 22.

A

TDA7272A

APPLICATIONSUGGESTION (Fig.20,21,22) - (For a 2000 r.p.m. 3 pole DC motor with R

Components

R

S1

R

S2

R

L;CL

C

D

R

T;CT

R

P1;RP2

C

F

R

A;CA

Recommended

value

1Ω Current sensing

1.5Ω Current sensing

22KΩ - 68nF Spike filtering. Slow V/I

Purpose If larger If smaller

Tacho loop do

tacho loop.

V/I loop.

Instability may

occur.

not regulate

Motor regulator;

undercompens.

High output

regulator

ripple.

response.

68nF Pulse transf. 33nF 100nF

15KΩ - 47nF Current source

programming to

obtain a 50%

duty cycle

47KΩ trim. Set of speed. Low speed. High speed 0

Polyester 100nF Optimization of

integrator ripple

and loop

response time.

220KΩ - 220nF Fast response

with no

Lower ripple,

slower tacho

regulator

response.

Depending on electrmechanical

system.

Higher ripple,

faster response.

overshoot.

Allowed range

Min. Max.

67KΩ 30KW

10nF 470nF

10nF 470nF

=16Ω)

M

0

0R

MOT

/9

13/16

TDA7272A

Figure24: Speedregulation vs. supply voltage

(circuit of fig. 20).

Figure26: In connectionwitha PresettableCounter and I/O peripheralthe TDA7271A/TDA7272Acon-

trols the speedthrough a D/A Converter.

TDA7272A

14/16

POWERDIP 20 PACKAGEMECHANICAL DATA

TDA7272A

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

a1 0.51 0.020

B 0.85 1.40 0.033 0.055

b 0.50 0.020

b1 0.38 0.50 0.015 0.020

D 24.80 0.976

E 8.80 0.346

e 2.54 0.100

e3 22.86 0.900

F 7.10 0.280

I 5.10 0.201

L 3.30 0.130

Z 1.27 0.050

mm inch

15/16

TDA7272A

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for the

consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from itsuse. No

license is granted by implication or otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specifications mentioned in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied.

SGS-THOMSON Microelectronics products are not authorized for use as critical components in life support devices or systems without express written approval of SGS-THOMSON Microelectronics.

1994 SGS-THOMSON Microelectronics - All RightsReserved

SGS-THOMSON Microelectronics GROUP OF COMPANIES

Australia - Brazil- France - Germany - Hong Kong - Italy - Japan - Korea - Malaysia - Malta - Morocco - The Netherlands- Singapore -

Spain - Sweden - Switzerland - Taiwan - Thaliand- United Kingdom - U.S.A.

16/16

Loading...

Loading...