®

TURBOSWITCHTM ULTRA-FAST HIGH VOLTAGE DIODE

MAIN PRODUCT CHARACTERISTI CS

STTA306B

I

F(AV)

V

RRM

(typ) 20 ns

t

rr

(max) 1.65 V

V

F

3 A

600 V

FEATURES AND BENEFITS

SPECIFIC TO FREEWHEEL MODE OPERATIONS:

FREEWHEEL OR BO OSTER DIODE.

ULTRA-FAST, AND SOF T RECOVERY.

VERY LOW OVERALL POWER LOSSES IN

BOTH THE DIODE AND THE COMPANION

TRANSISTOR.

HIGH FREQ UENC Y O PERA TIO NS.

DESCRIPTION

The TURBOSWITCH is a very high performance

series of ultra-fast high voltage power diodes.

TURBOSWITCH family drastically cuts losses in

both the diode and the associated switching IGBT

or MOSFET in all freewheel mode operations and

is particulary suitable and efficient in motor control

K

A

NC

DPAK

freewheel applications and in booster diode applications in Power Factor Control circuitries.

Packaged in DPAK, these 600V devices are particularly intended for use on 240V domestic mains.

ABSOLUTE RATINGS

(limiting values)

Symbol Parameter Value Unit

V

RRM

I

F(RMS)

I

FRM

I

FSM

Repetitive peak reverse voltage 600 V

RMS forward current 6 A

Repetitive peak forward current tp=5 µs F=5 kHz s quare 20 A

Surge non repetitive forward current tp=10 ms sinusoidal 35 A

Tj Maximum operating junction temper ature 125 °C

T

stg

TM : TURBOSWITCH is a trademark from STMicroelectronics

November 1999 - Ed: 3C

Storage temperature range - 65 to + 150

°

C

1/8

STTA306B

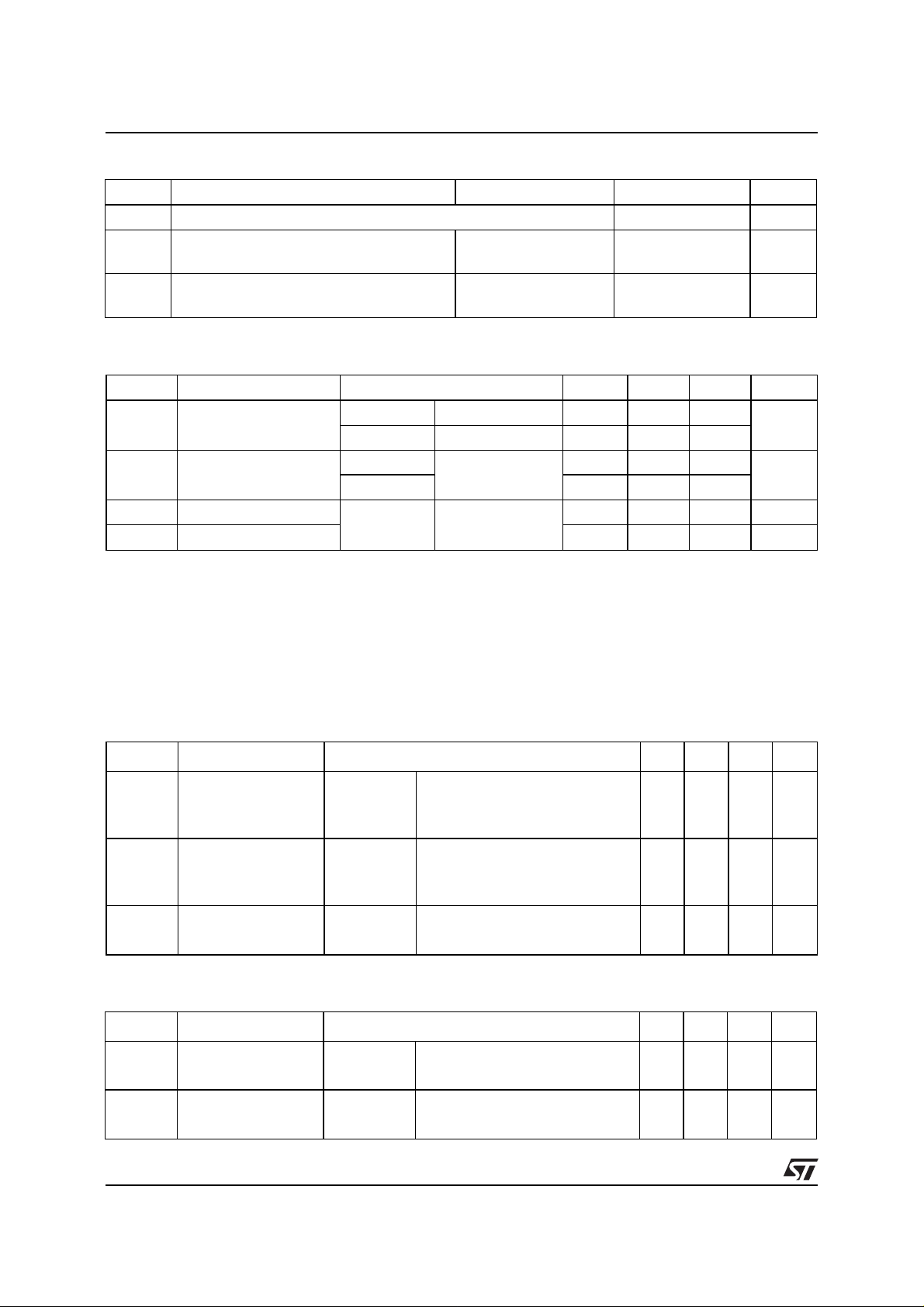

THERMAL AND POWER DATA

Symbol Parameter Tests conditions Value Unit

R

P

th (j-c)

P

max

Junction to case 6

Conduction power dissipation I

1

Total power dissipation

P

= P1 + P3 (P3 = 10% P1)

max

= 1.5A, δ = 0.5

F(AV)

T

= 110°C

c

= 108°C 2.8 W

T

c

2.5 W

STATIC ELECTRICAL CHARACTE RISTICS

Symbol Parameter Tests conditions Min. Typ. Max. Unit

V

** Forward voltage drop Tj = 25°CIF = 3 A 1.85 V

F

I

* Reverse leakage

R

current

V

Threshold voltage Ip < 3.I

to

Tj = 125°CI

Tj = 25°CV

Tj = 125°C 500 1200

F(AV)

= 3 A 1.3 1.65

F

= 0.8 X V

R

RRM

20

Tj = 125°C 1.15 V

Rd Dynamic resistance 175 m

Test pulse : * tp = 380 µs, δ < 2%

** tp = 5 ms, δ < 2%

°

C/W

µ

A

Ω

To evaluate the maximum conduction losses use the following equation :

P = V

x I

to

F(AV)

+ Rd x I

F2(RMS)

DYNAMIC ELECTRICAL CHARACTE RISTICS

TURN-OFF SWITCHING

Symbol P arameter Test conditions Min. Typ. M ax. Unit

t

I

rr

RM

Maximu m reve rse

Tj = 25° C IF=0.5A IR=1A Irr=0.25A

Tj = 125°C IF=3A VR=400V

recover y curre nt

S factor Softness factor Tj = 125°C V

I

=1A dIF/dt= -50A/µs

F

V

=30V

R

dI

/dt = -16A/µs

F

dI

/dt = -50A/µs2.0

F

=400V IF=3A

R

dI

/dt = -50A/µs

F

20

50

1.2

1.1 -

TURN-ON SWITCHING

Symbol Parameter Test conditions Min. Typ. Max. Unit

t

fr

Forward recovery

Tj = 25°C I

time

=3A dIF/dt = 16A/µs

F

Measured at 1.1 x V

Fmax

500 ns

ns

A

2/8

V

FP

Peak forward

Tj = 25°C IF=2A dIF/dt = 16A/µs10V

voltage

STTA306B

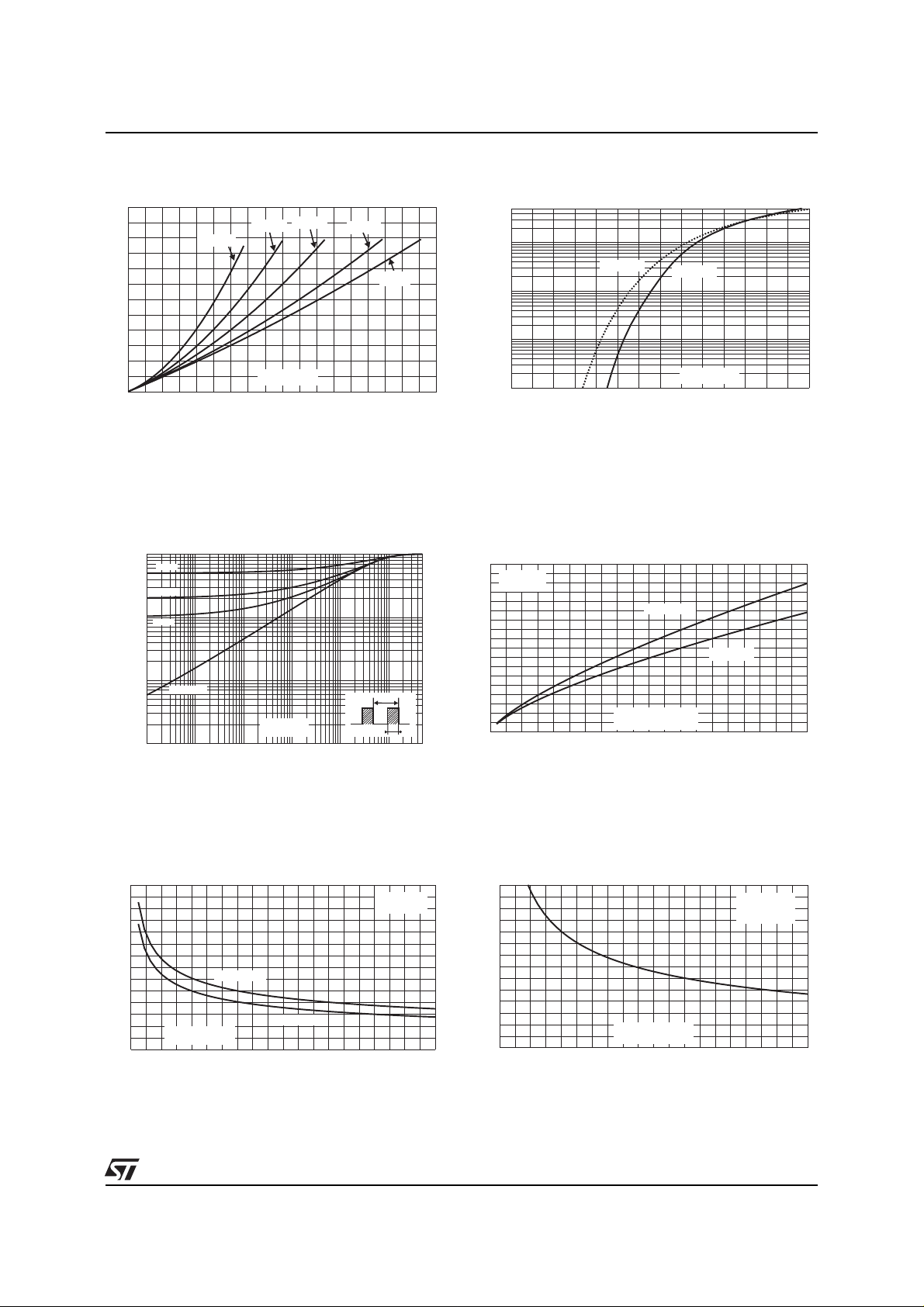

Fig. 1:

Conduction losses vers us average c urrent.

P1(W)

3.0

δ = 0.2

2.5

2.0

δ = 0.05

δ = 0.1

δ = 0.5

δ = 1

1.5

1.0

0.5

IF(av) (A)

0.0

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8

Fig. 3:

Relative variation of thermal transient

impedance junction to ambient versus pulse

duration (recommended pad layout).

Zth(j-a) (°C/W)

1E+0

δ = 0.5

δ = 0.2

1E-1

δ = 0.1

1E-2

1E-3

Single pulse

tp(s)

1E-3 1E-2 1E-1 1E+0 1E+1 1E+2 5E+2

δ

=tp/T

T

tp

Fig. 2:

Forward voltage drop versus forward

current (maximum values).

IFM(A)

5E+1

1E+1

Tj=125°C

1E+0

1E-1

1E-2

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

Fig. 4:

Peak rever se recove ry curr ent vers us dI

Tj=25°C

VFM(V)

(90% confidence).

IRM(A)

9

VR=400V

8

Tj=125°C

7

6

5

4

3

2

1

0

0 20 40 60 80 100 120 140 160 180 200

IF=2*IF(av)

IF=IF(av)

dIF/dt(A/µs)

/dt

F

Fig. 5:

Reverse recovery time versus dI

/dt (90%

F

confidence).

trr(ns)

350

300

250

200

150

IF=2*IF(av)

100

50

0

dIF/dt(A/µs)

0 20 40 60 80 100 120 140 160 180 200

IF=IF(av)

VR=400V

Tj=125°C

Fig. 6:

Softn ess factor (tb/ta) versu s dI

/dt (typical

F

values).

S factor

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0 20 40 60 80 100 120 140 160 180 200

dIF/dt(A/µs)

IF<2*IF(av)

VR=400V

Tj=125°C

3/8

Loading...

Loading...