1/2

DATA BRIEFING

September 2001

This is Brief Data from STMicroelectronics. Details are subject to change without notice. For complete data, please contact

your nearest Sales Office or SmartCard Products Divison, Rousset, France. Fax: (+33) 4 42 68 87 29.

SMARTCARD MCU

Ordering Information

For Package And Delivery

INTRODUCTION

The manufacturing process of Smartcards involves various components and technologies in

order to issue a finished product:

– micromodules,

– flat packages,

– wafers.

■ MICROMODULES

Dedicated package for Smartcard products, the

micromodule type depends on the size of the

product and on the application.

Table 1 lists all available micromodules.

■ FLAT PACKAGES

For applications which require surface mount technology, suitable for PC cards, or other security

modules, STMicroelectronics offers flat packages

listed In Table 2.

■ WAFERS

For issuer production need, ST offers sawn and

unsawn wafers deliveries, listed in Table 3.

Figure 1. Delivery form

Table 1. Micromodules in super 35 stand ard

tape

Table 2. Flat Packages

Table 3. Wafers

4

4

4

4

SO20

261a.ai

8” Wafer

Micromodule

Notch

Type Description

D1, D2 8 contacts for memory cards

D15 6 contacts for memory cards

D3, D4 8 contacts with ring MCU cards

D5

8 contacts for dual contact contactless

MCU cards

D68 8 contacts for MCU cards

D7

6 contacts for dual contact contactless

MCU cards

C7 Full contactless for MCU cards

D8 8 contacts for MCU cards

Type Description

O20 SO20 for MCU products

QF4 TQFP44 for MCU products

R20 SO20 on tape and reel for MCU products

Type Description

W00 Unsawn wafers, 750 µm thickness

W20 Unsawn wafers, 275 µm thickness

W40 Unsawn wafers, 180 µm thickness

S2x 280 µm sawn wafers on UV tape

R4x 180 µm sawn wafers on insolated UV tape

S4x 180 µm sawn wafers on UV tape

T4x 180 µm sawn wafers on blue tape

SMARTCARD MCU

2/2

Table 4. Ordering Information Scheme

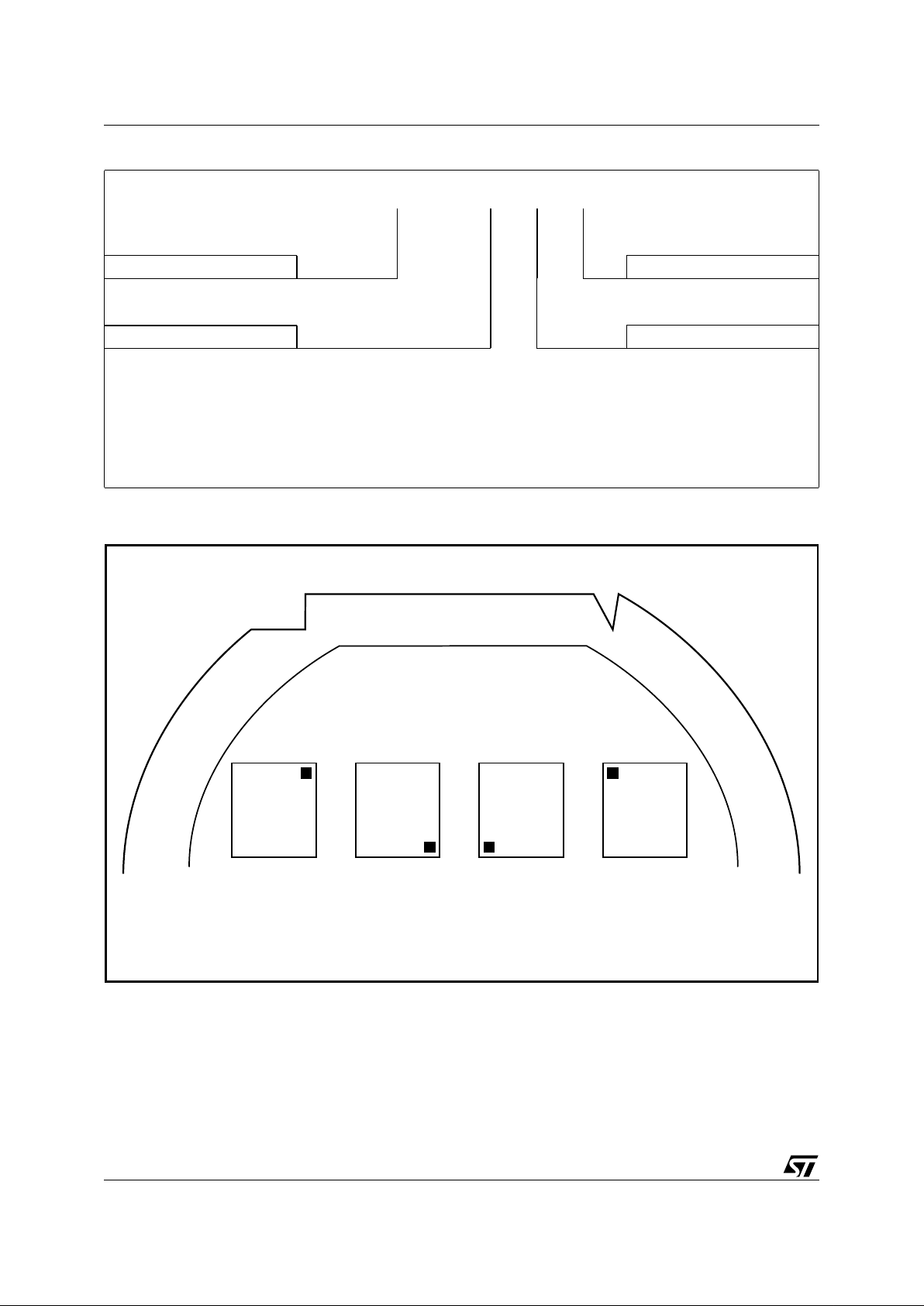

Note: *wher e “y ” i nd i cates th e sawing ori entat i on as show n i n F i gu re 2

Figure 2. Sawing orientation

Sawn wafers are scribed an d m ount ed in a frame

on adhesive tape. The orientation is defined by the

position of the GND pad on the die, viewed with

active area of product visible, relative to the notches of the frame (as shown in Figure 2). The orientation of the die with respect t o the plastic frame

notches is specified by the Customer.

One further concern, when specify ing devices to

be delivered in this form, is that wafers mounted

on adhesive tape must be used within a limited period from the mounting date:

– two months, if wafers a re stored at 25°C, 55%

relative h umidity

– six months, if wafers are stored at 4°C, 55% rel-

ative humidity

Example: ST19SF08C D45 XXX Z

Product name Pre-personalization name

“+” if no pre-personalization

Delivery Form Customer ROM code name

Dxx: Module contact or dual

Cxx: Contactless modules

Oxx: SO package

Wxx: Unsawn wafer

Sxy*: Sawn wafer (std UV tape)

Rxy*: Sawn wafer (insolated UV tape) or SO on tape and reel

AI02171

1ORIENTATION

GND

GND GND

GND

234

VIEW: WAFER FRONT SIDE

Loading...

Loading...