SGS Thomson Microelectronics ST62T46BB6, ST62E46BF1, ST6246BB6, ST6246BB1, ST6246B Datasheet

September 1998 1/72

Rev. 2.5

ST62T46B/E46B

8-BIT OTP/EPROM MCU WITH LCD DRIVER,

EEPROM AND A/D CONVERTER

■ 3.0 to 6.0V Supply Operating Range

■ 8 MHz Maximum Clock Frequency

■

-40 to +85°C Operating Temperature Range

■

Run, Wait and Stop Modes

■ 5 Interrupt Vectors

■ Look-up Table capability in Program Memory

■

Data Storage in Program Memory:

User selectable size

■ Data RAM: 128 bytes

■ Data EEPROM: 128 bytes

■

User Programmable Options

■ 20 I/O pins, fully programmable as:

– Input with pull-up resistor

– Input without pull-up resistor

– Input with interrupt generation

– Open-drain or push-pull output

– Analog Input

– LCD segments (8 combiport lines)

■

4 I/O lines can sink up to 20mA to drive LEDs or

TRIACs directly

■ Two 8-bit Timer/Counter with 7-bit

programmable prescaler

■

Digital Watchdog

■

8-bit A/D Converter with 8 analog inputs

■ 8-bit Synchronous Peripheral Interface (SPI)

■ LCD driver with 27 segment outputs, 4

backplane outputs and selectable multiplexing

ratio.

■ 32kHz oscillator forstand-by LCD operation

■ Power Supply Supervisor (PSS)

■

On-chip Clock oscillator can be driven byQuartz

Crystal or Ceramic resonator

■ One external Non-Maskable Interrupt

■ ST6240-EMU2 Emulation and Development

System (connects to an MS-DOS PC via a

parallel port).

DEVICE SUMMARY

(See end of Datasheet for Ordering Information)

PSDIP56

CSDIP56W

DEVICE

OTP

(Bytes)

EPROM

(Bytes)

I/O Pins

ST62T46B 3884 - 12 to 20

ST62E46B 3884 12 to 20

337

2/72

Table of Contents

72

Document

Page

338

ST62T46B/E46B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1 GENERAL DESCRIPTION . . . . . . . ...............................................5

1.1 INTRODUCTION .........................................................5

1.2 PIN DESCRIPTIONS . . . . . . . . . . ............................................7

1.3 MEMORYMAP ..........................................................8

1.3.1 Introduction . . . . . . . . ................................................8

1.3.2 Program Space . . . . . . . . . . . . . . . . . . . . . . . . . . . ..........................9

1.3.3 Data Space . . . . . . . . ...............................................10

1.3.4 Stack Space . . . . . . . . . . . . . . . . . ......................................10

1.3.5 Data Window Register (DWR) . . . . . . . . . . . . . . . . . . . . .....................11

1.3.6 Data RAM/EEPROM Bank Register (DRBR)..............................12

1.3.7 EEPROM Description ...............................................13

1.4 PROGRAMMING MODES .................................................15

1.4.1 Option Byte . . . . . . . . ...............................................15

1.4.2 Program Memory . . . . ...............................................15

1.4.3 EEPROM Data Memory . . . . . . . . . . . . ..................................15

1.4.4 EPROMErasing....................................................15

2 CENTRAL PROCESSING UNIT .................................................16

2.1 INTRODUCTION ........................................................16

2.2 CPU REGISTERS . . . . . . . . ...............................................16

3 CLOCKS, RESET, INTERRUPTS AND POWER SAVING MODES . . . . . . . ..............18

3.1 CLOCKSYSTEM........................................................18

3.1.1 Main Oscillator . . . . . . . . . . ...........................................18

3.1.2 32 KHz STAND-BY OSCILLATOR . . . . . . . . . . ...........................19

3.2 RESETS...............................................................20

3.2.1 RESET Input ......................................................20

3.2.2 Power-on Reset . . . . . . . . . . . . . . . .....................................20

3.2.3 Watchdog Reset . . . . ...............................................21

3.2.4 Application Notes . . . . ...............................................21

3.2.5 MCU Initialization Sequence ..........................................21

3.3 DIGITAL WATCHDOG . . . . . . . . . . . . . . . .....................................23

3.3.1 Digital Watchdog Register (DWDR) . . . ..................................25

3.3.2 Application Notes . . . . ...............................................25

3.4 INTERRUPTS . . . . ......................................................27

3.4.1 Interrupt request . . . . . . . . . . . . . . . .....................................27

3.4.2 Interrupt Procedure . . . ..............................................28

3.4.3 Interrupt Option Register (IOR) . . . . ....................................29

3.4.4 Interrupt Sources . . . . ...............................................29

3.5 POWER SAVING MODES .................................................31

3.5.1 WAIT Mode . . . . . . . . ...............................................31

3.5.2 STOPMode.......................................................31

3.5.3 Exit from WAIT and STOP Modes . . . ...................................32

3/72

Table of Contents

Document

Page

339

4 ON-CHIP PERIPHERALS . . . ...................................................33

4.1 I/OPORTS.............................................................33

4.1.1 Operating Modes . . . . ...............................................34

4.1.2 Safe I/O State Switching Sequence . . . ..................................35

4.1.3 LCD alternate functions (combiports) ...................................37

4.1.4 SPI alternate functions . . . ............................................37

4.1.5 I/O Port Option Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ................38

4.1.6 I/O Port Data Direction Registers. . . ....................................38

4.1.7 I/O Port Data Registers . . . . ..........................................38

4.2 TIMER1&2............................................................39

4.2.1 TIMER 1 & 2 Operating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . .....41

4.2.2 Timer Interrupt . . . . . . . . . . ...........................................41

4.2.3 Application Notes . . . . ...............................................41

4.2.4 TIMER 1 Registers . .................................................42

4.2.5 TIMER 2 Registers . .................................................43

4.3 A/D CONVERTER (ADC) . . . ..............................................44

4.3.1 Application Notes . . . . ...............................................44

4.4 SERIAL PERIPHERAL INTERFACE (SPI) . . . . . . . . . . . . ........................46

4.5 LCD CONTROLLER-DRIVER . . . . ..........................................48

4.5.1 Multiplexing ratio and frame frequency setting . . . . ........................49

4.5.2 Segment and common plates driving. . ..................................49

4.5.3 LCDRAM.........................................................50

4.5.4 Stand by or STOP operation mode . . . . . . . . . . ...........................51

4.5.5 LCD Mode Control Register (LCDCR) . . . . .............................51

4.6 POWERSUPPLY SUPERVISOR DEVICE (PSS) ...............................52

4.6.1 PSS Operating Mode Description ......................................53

4.6.2 PSS Register . . . ...................................................54

5SOFTWARE ................................................................55

5.1 ST6 ARCHITECTURE . . . . . . . . . . . . . . . .....................................55

5.2 ADDRESSING MODES . . . . ...............................................55

5.3 INSTRUCTION SET . . . ...................................................56

6 ELECTRICAL CHARACTERISTICS. . . . . . . . . . . . ..................................61

6.1 ABSOLUTE MAXIMUM RATINGS. ..........................................61

6.2 RECOMMENDED OPERATING CONDITIONS. . . ..............................62

6.3 DC ELECTRICAL CHARACTERISTICS ......................................63

6.4 AC ELECTRICAL CHARACTERISTICS ......................................64

6.5 A/D CONVERTER CHARACTERISTICS. . . ...................................64

6.6 TIMER CHARACTERISTICS . . . ............................................65

6.7 SPI CHARACTERISTICS . . . ..............................................65

6.8 LCD ELECTRICAL CHARACTERISTICS . . . . . . . . . . ...........................65

6.9 PSS ELECTRICAL CHARACTERISTICS (WHEN AVAILABLE). . . . . . . . . . . . . . . .....65

7 GENERAL INFORMATION . . . . . . . . . . ...........................................66

7.1 PACKAGE MECHANICAL DATA. . . . ........................................66

7.2 PACKAGE THERMAL CHARACTERISTIC . . ..................................67

7.3 .ORDERING INFORMATION. . . ............................................67

4/72

Table of Contents

72

Document

Page

340

ST6246B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

1 GENERAL DESCRIPTION. . . ...................................................70

1.1 INTRODUCTION . . . . . . . . . . ...............................................70

1.2 ROM READOUT PROTECTION . . . ..........................................70

1.3 ORDERING INFORMATION . . . . . . . . ........................................72

1.3.1 Transfer of Customer Code . ..........................................72

1.3.2 Listing Generation and Verification . . . . . . . . . . ...........................72

5/72

ST62T46B/E46B

1 GENERAL DESCRIPTION

1.1 INTRODUCTION

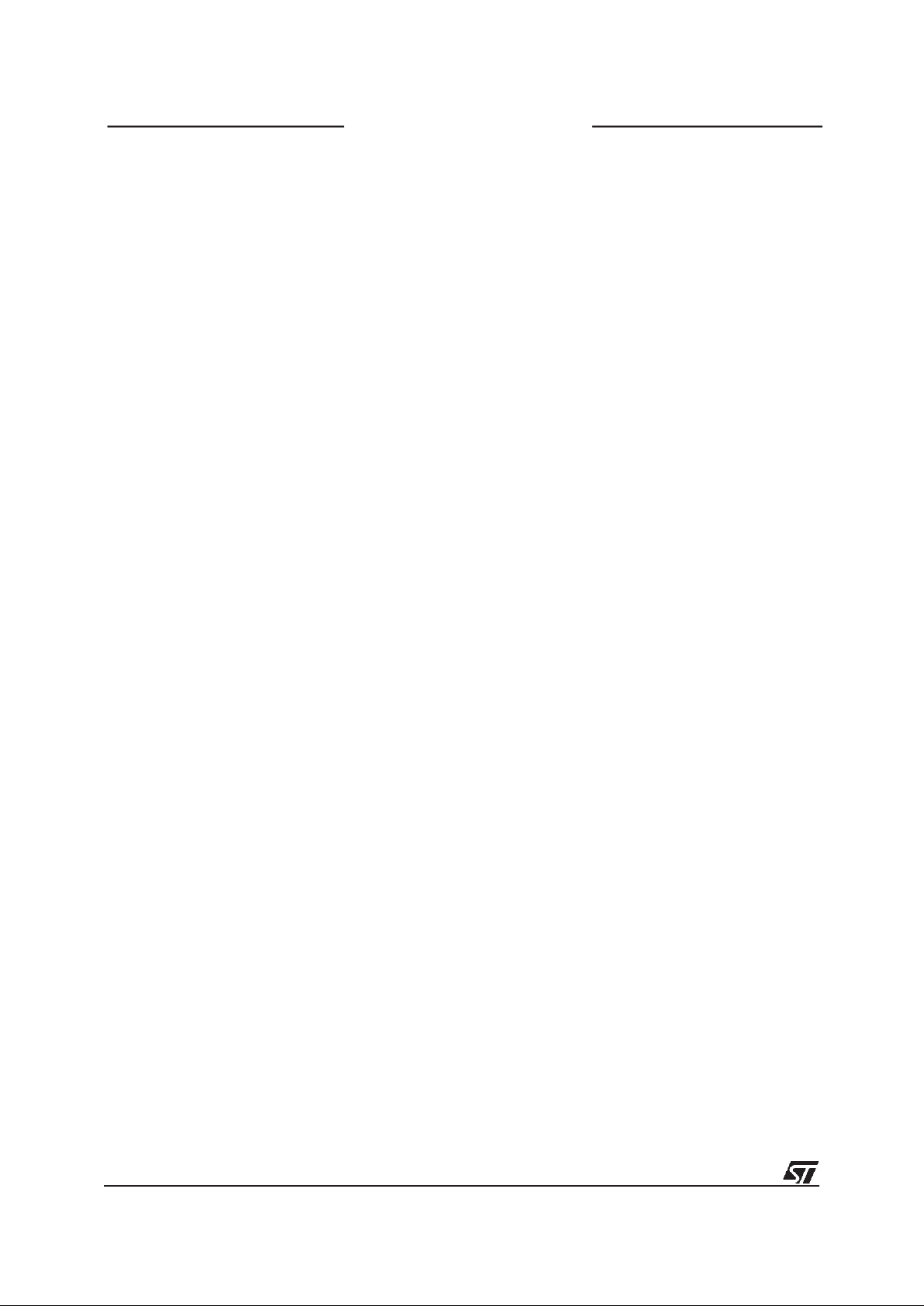

The ST62T46B and ST62E46B devices are low

cost members of the ST62xx 8-bit HCMOS family

of microcontrollers, which are targeted at low to

medium complexity applications. All ST62xx devices are based on a building block approach: a

common core is surrounded by a number of onchip peripherals.

The ST62E46B is the erasable EPROM version of

the ST62T46B device, which may be used to emulate the ST62T46B device, as well as the respective ST6246B ROM devices.

Figure 1. Block Diagram

TEST

NMI INTERRUPT

PROGRAM

PC

STACK LEVEL 1

STACK LEVEL 2

STACK LEVEL 3

STACK LEVEL 4

STACK LEVEL 5

STACK LEVEL 6

POWER

SUPPLY

OSCILLATOR

RESET

DATA ROM

USER

SELECTABLE

DATA RAM

PORT A

PORT B

TIMER 1

DIGITAL

8 BIT CORE

TEST/V

PP

8-BIT

A/D CONVERTER

PA4..PA7/Ain

V

DDVSS

OSCin OSCout RESET

WATCHDOG

Memory

PORT C

SPI (SERIAL

PERIPHERAL

INTERFACE)

128 Bytes

3884 bytes

DATA EEPROM

128 Bytes

PB0..PB3/Ain

PC0..PC7/S33..S40

S9..S16, S25..S32, S41..S43

COM1..COM4

(V

PP

on EPROM/OTP versions only)

PB4/20mA Sink

PB5/Scl/20mASink

PB6/Sin/20mA Sink

PB7/Sout/20mA Sink

VLCD

VLCD1/3

VLCD2/3

OSC 32kHz

TIMER 2

OSC32in

OSC32out

PSS

LCD DRIVER

POWER SUPPLY

SUPERVISOR

341

6/72

ST62T46B/E46B

INTRODUCTION (Cont’d)

OTP and EPROM devices are functionally identical. The ROM based versions offer the same functionality selecting as ROM options the options defined in the programmable option byte of the

OTP/EPROM versions.OTP devices offer all the

advantages of user programmability at low cost,

which make them the ideal choice in a wide range

of applications where frequent code changes, multiple code versions or last minute programmability

are required.

These compact low-cost devices feature two Timers comprising an 8-bit counter and a 7-bit programmable prescaler, EEPROM data capability, a

serial synchronous port interface (SPI), an 8-bit

A/D Converter with 8 analog inputs, a Digital

Watchdog timer, and a complete LCD controller

driver, making them well suited for a wide range of

automotive, appliance and industrial applications.

Figure 2. 56 Pin SDIP Package

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

VLCD

Ain/PA7

Ain/PA6

Ain/PA5

Ain/PA4

OSCout

OSCin

TEST/V

PP

(1)

V

DD

V

SS

S13

S12

S11

S10

S9

PB1/Ain

PB2/Ain

PB3/Ain

PB4*

PB5/Scl*

42

41

40

39

38

37

36

35

RESET

NMI

PB7/Sout*

PB6/Sin*

PSS

OSC32in

OSC32out

PB0/Ain

(1) VPPon EPROM/OTP only

1

2

3

4

5

6

7

8

9

10

11

12

13

14

43

44

45

46

47

48

PC3/S36

PC4/S37

PC5/S38

PC6/S39

PC7/S40

COM3

COM2

S41

S42

S43

PC2/S35

PC1/S34

PC0/S33

S32

S31

S26

S25

S16

S15

S14

56

55

54

53

52

51

50

49

COM4

COM1

VLCD1/3

VLCD2/3

S30

S29

S28

S27

*20mA sink

342

7/72

ST62T46B/E46B

1.2 PIN DESCRIPTIONS

VDDand V

SS

. Power is supplied to the MCU via

these two pins. VDDis the power connection and

VSSis the ground connection.

OSCin and OSCout. These pins are internally

connected to the on-chip oscillator circuit. A quartz

crystal, a ceramic resonator or an external clock

signal can be connected between these two pins.

The OSCin pin is the input pin, the OSCout pin is

the output pin.

RESET

. The active-low RESET pin is used to re-

start the microcontroller.

TEST/VPP. The TEST must be held at VSSfor nor-

mal operation (an internal pull-down resistor selects normal operating mode if TEST pin is not

connected). If TEST pin is connected to a +12.5V

level during the reset phase, the EPROM/OTP

programming Mode is entered.

NMI. The NMI pin provides the capability for asynchronous interruption, by applying an external non

maskable interrupt to the MCU.The NMI input is

falling edge sensitive withSchmitt trigger characteristics. The user can select as option the availability of an on-chip pull-up at this pin.

PA4-PA7. These 4 lines are organised as one I/O

port (A). Each line may be configured under software control as inputs with or without internal pullup resistors, input with interrupt generation and

pull-up resistor, open-drain or push-pull outputs, or

as analog inputs for the A/D converter.

PB0...PB7.

These 8 lines are organised as one I/O

port (B). Each line may be configured under software control as inputs with or without internal pullup resistors, input with interrupt generation and

pull-up resistor, open-drain or push-pull outputs,

analog inputs for the A/D converter. PB0..PB3 can

be used as analog inputs for the A/D converter ,

while PB7/Sout, PB6/Sin and PB5/Scl can be used

respectively as data out, data in and Clock pins for

the on-chip SPI. In addition, PB4..PB7 can sink

20mA for direct LED or TRIAC drive.

PC0-PC7. These 8 lines are organised as one I/O

port (C). Each line may be configured under software control as input with or without internal pullup resistor, input with interrupt generation and

pull-up resistor, open-drain or push-pull output, or

as LCD segment output S33..S40.

COM1-COM4

. These four pins are the LCD peripheral common outputs. They are the outputs of

the on-chip backplane voltage generator which is

used for multiplexing the 45 LCD lines allowing up

to 180 segments to be driven.

S9..S16, S25..S43. These pins are the 27 LCD peripheral segment outputs. S33..S40 are alternate

functions of the Port C I/O pins. (Combiports feature)

VLCD. Display voltage supply. It determines the

high voltage level on COM1-COM4 and S4-S48

pins.

VLCD1/3, VLCD2/3

. Display supply voltage inputs

for determining the display voltage levels on

COM1-COM4 and S4-S48 pins during multiplex

operation.

PSS

. This is the Power Supply Supervisor sensing

pin. When the voltage applied to this pin is falling

below a software programmed value the highest

priority (NMI) interrupt can be generated. This pin

has to be connected to the voltage to be supervised.

OSC32in and OSC32out. These pins are internally connected with the on-chip 32kHz oscillator

circuit. A 32.768kHz quartz crystal can be connected between these two pins if it is necessary to

provide theLCD stand-by clock and real time interrupt. OSC32in is the input pin, OSC32out is the

output pin.

343

8/72

ST62T46B/E46B

1.3 MEMORY MAP

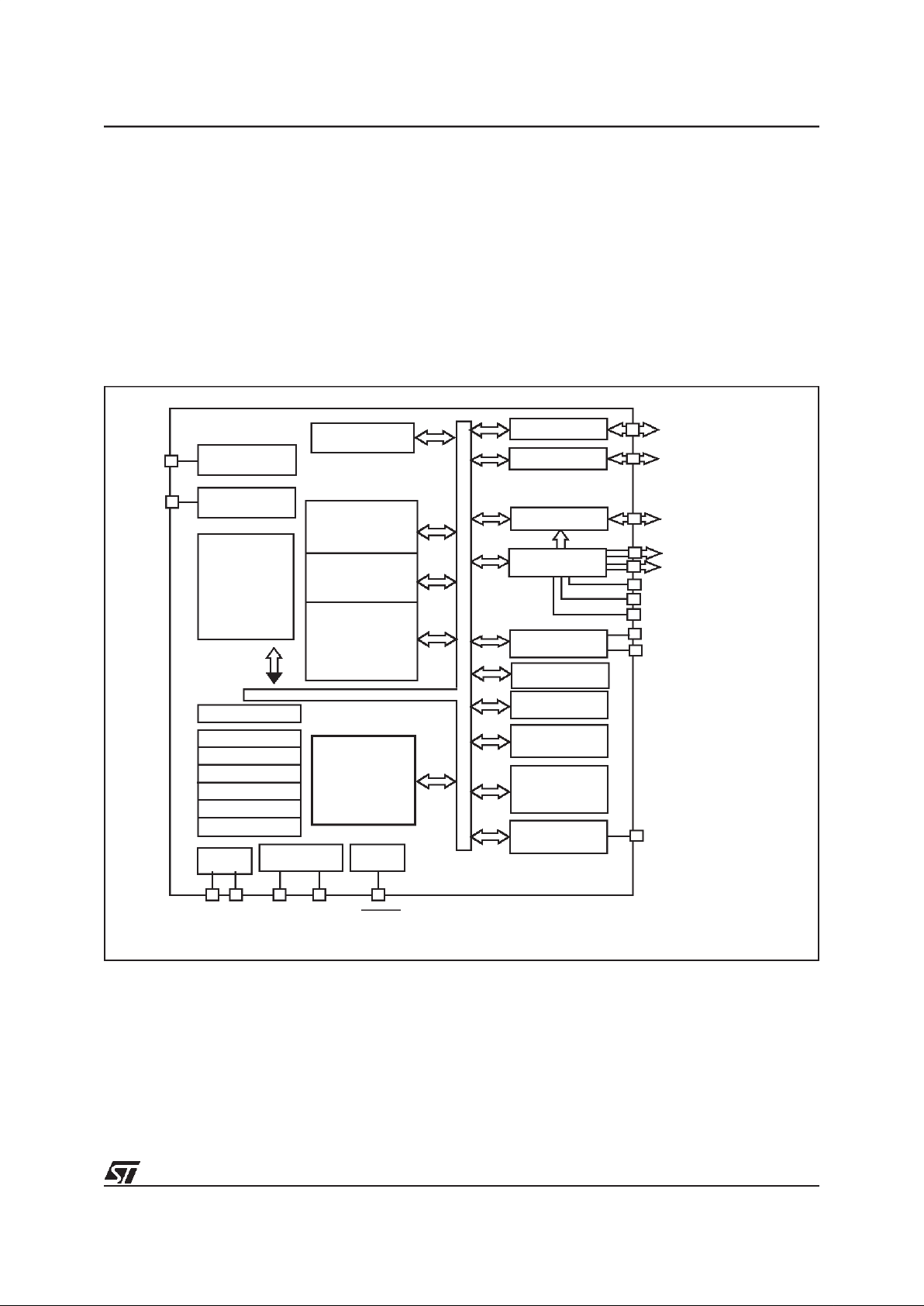

1.3.1 Introduction

The MCU operates in three separate memory

spaces: Program space, Data space, and Stack

space. Operation in these three memory spaces is

described in the following paragraphs.

Briefly, Program space contains user program

code in Program memory and user vectors; Data

space contains user data in RAM and in Program

memory, and Stack space accommodates six levels of stack for subroutine and interrupt service

routine nesting.

Figure 3. Memory Addressing Diagram

PROGRAM SPACE

PROGRAM

INTERRUPT &

RESET VECTORS

ACCUMULATOR

DATA RAM

BANK SELECT

WINDOW SELECT

RAM

X REGISTER

Y REGISTER

V REGISTER

W REGISTER

DATA READ-ONLY

WINDOW

RAM / EEPROM

BANKING AREA

000h

03Fh

040h

07Fh

080h

081h

082h

083h

084h

0C0h

0FFh

0-63

DATA SPACE

0000h

0FF0h

0FFFh

MEMORY

MEMORY

DATA READ-ONLY

MEMORY

VR01568

344

9/72

ST62T46B/E46B

MEMORY MAP (Cont’d)

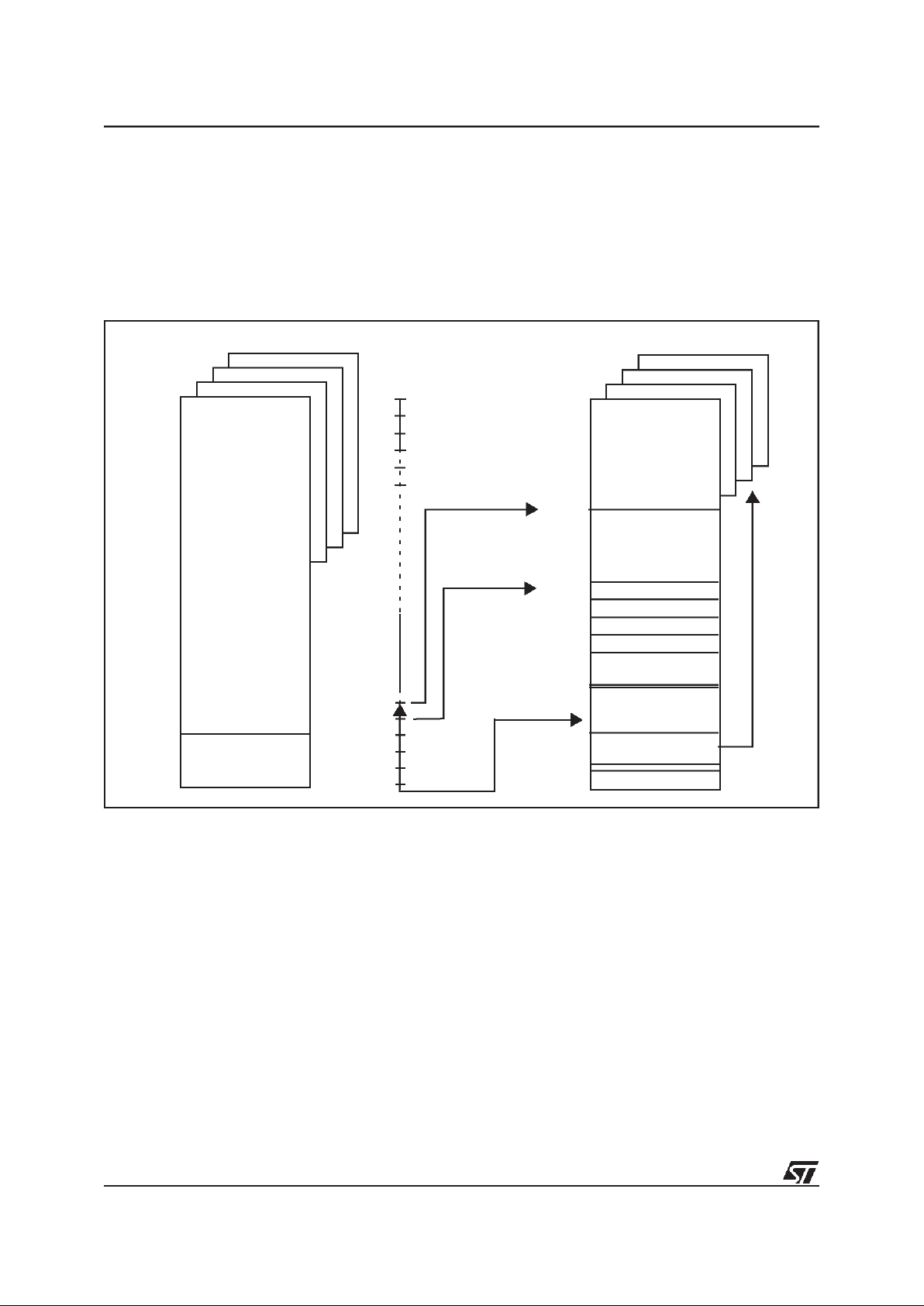

1.3.2 Program Space

Program Space comprises the instructions to be

executed, the data required for immediate addressing mode instructions, the reserved factory

test area and the user vectors. Program Space is

addressed via the 12-bit Program Counter register

(PC register).

1.3.2.1 Program Memory Protection

The Program Memory in OTP or EPROM devices

can be protected against external readout of memory by selecting the READOUT PROTECTION option in the option byte.

In the EPROM parts, READOUT PROTECTION

option can be disactivated only by U.V. erasure

that also results into the whole EPROM context

erasure.

Note:

Once the Readout Protection is activated, it

is no longer possible, even for STMicroelectronics,

to gain access to the Program memory contents.

Returned parts with a protection set can therefore

not be accepted.

Figure 4. ST62E46B/T46B Program

Memory Map

0000h

RESERVED

*

USER

PROGRAM MEMORY

(OTP/EPROM)

3872 BYTES

0F9Fh

0FA0h

0FEFh

0FF0h

0FF7h

0FF8h

0FFBh

0FFCh

0FFDh

0FFEh

0FFFh

RESERVED

*

RESERVED

INTERRUPT VECTORS

NMI VECTOR

USER RESET VECTOR

0080h

(*) Reserved areas should be filled with 0FFh

007Fh

345

10/72

ST62T46B/E46B

MEMORY MAP (Cont’d)

1.3.3 Data Space

Data Space accommodates all the data necessary

for processing the user program. This space comprises the RAM resource, the processor core and

peripheral registers, as well as read-only data

such as constants and look-up tables in Program

memory.

1.3.3.1 Data ROM

All read-only data is physically stored in program

memory, which also accommodates the Program

Space. The program memory consequently contains the program code to be executed, as well as

the constants and look-up tables required by the

application.

The Data Space locations in which the different

constants and look-up tables are addressed by the

processor core may be thought of as a 64-byte

window through which it is possible to access the

read-only data stored in Program memory.

1.3.3.2 Data RAM/EEPROM

In ST62T46B and ST62E46B devices, the data

space includes 60 bytes of RAM, the accumulator

(A), the indirect registers (X), (Y), the short direct

registers (V), (W), the I/O port registers, the peripheral data and control registers, the interrupt

option register and the DataROM Window register

(DRW register).

Additional RAM and EEPROM pages can also be

addressed using banks of 64 bytes located between addresses 00h and 3Fh.

1.3.4 Stack Space

Stack space consists of six 12-bit registers which

are used to stack subroutine and interrupt return

addresses, as well as the current program counter

contents.

Table 1. Additional RAM/EEPROM Banks.

Table 2. ST62T46B/E46B Data Memory Space

Device RAM EEPROM

ST62T46B/E46B 1 x 64 bytes 2 x 64 bytes

DATAand EEPROM

000h

03Fh

DATAROM WINDOW AREA

040h

07Fh

X REGISTER 080h

Y REGISTER 081h

V REGISTER 082h

W REGISTER 083h

DATARAM

084h

0BFh

PORT A DATAREGISTER 0C0h

PORT B DATAREGISTER 0C1h

SPI INTERRUPT DISABLE REGISTER 0C2h

PORT C DATAREGISTER 0C3h

PORT A DIRECTION REGISTER 0C4h

PORT B DIRECTION REGISTER 0C5h

PORT C DIRECTION REGISTER 0C6h

RESERVED 0C7h

INTERRUPT OPTION REGISTER 0C8h*

DATAROM WINDOWREGISTER 0C9h*

RESERVED 0CAh*

RAM/EEPROMBANK SELECT REGISTER 0CBh*

PORT A OPTION REGISTER 0CCh

RESERVED 0CDh

PORT B OPTION REGISTER 0CEh

PORT C OPTION REGISTER 0CFh

A/D DATAREGISTER 0D0h

A/D CONTROL REGISTER 0D1h

TIMER 1 PRESCALER REGISTER 0D2h

TIMER 1 COUNTER REGISTER 0D3h

TIMER 1 STATUS/CONTROLREGISTER 0D4h

TIMER 2 PRESCALER REGISTER 0D5h

TIMER 2 COUNTER REGISTER 0D6h

TIMER 2 STATUS/CONTROLREGISTER 0D7h

WATCHDOG REGISTER 0D8h

RESERVED 0D9h

PSS STATUS/CONTROLREGISTER 0DAh

32kHz OSCILLATORCONTROL REGISTER 0DBh

LCD MODE CONTROL REGISTER 0DCh

SPI DATAREGISTER 0DDh

RESERVED 0DEh

EEPROM CONTROL REGISTER 0DFh

LCD RAM

0E0h

0F7h

DATA RAM

0F8h

0FEh

ACCUMULATOR OFFh

* WRITEONLY REGISTER

346

11/72

ST62T46B/E46B

MEMORY MAP (Cont’d)

1.3.5 Data Window Register (DWR)

The Dataread-only memory window is located from

address 0040h to address 007Fh in Data space. It

allows direct reading of64 consecutive bytes located anywhere in program memory, between address 0000h and 1FFFh (top memory address depends on the specific device). All the program

memory can therefore be used to store either instructions or read-only data. Indeed, the window

can be moved in steps of 64 bytes along the programmemory by writing theappropriate code inthe

Data Window Register (DWR).

The DWR can beaddressed like any RAM location

in the Data Space, it is however a write-only register and therefore cannot be accessed using singlebit operations. This register is used to position the

64-byte read-only data window (from address 40h

to address 7Fh of the Data space) in program

memory in 64-byte steps. The effective address of

the byte to be read as data in program memory is

obtained by concatenating the 6 least significant

bits of the register address given in the instruction

(as least significant bits) and the content of the

DWR register (as most significant bits), as illustrated inFigure 5 below. For instance, when addressing location 0040h of the Data Space, with 0 loaded in the DWR register, the physical location addressed in program memory is 00h. The DWR register is not cleared on reset, therefore it must be

written to prior to the first access to the Data readonly memory window area.

Data Window Register (DWR)

Address: 0C9h — Write Only

Bits 6, 7 = Not used.

Bit 5-0 =

DWR5-DWR0:

Data read-only memory

Window Register Bits.

These are the Data readonly memory Window bits that correspond to the

upper bits of the data read-only memory space.

Caution:

This register is undefined on reset. Neither read nor single bit instructions may be used to

address this register.

Note:

Care is required when handling the DWR

register as it is write only. For this reason, the

DWR contents should not be changed while executing an interrupt service routine, as the service

routine cannot save and then restore the register’s

previous contents. If it is impossible to avoid writing to the DWR during the interrupt serviceroutine,

an image of the register must be saved in a RAM

location, and each time the program writes to the

DWR, it must also write to the image register. The

image register must be written first so that, if an interrupt occurs between the two instructions, the

DWR is not affected.

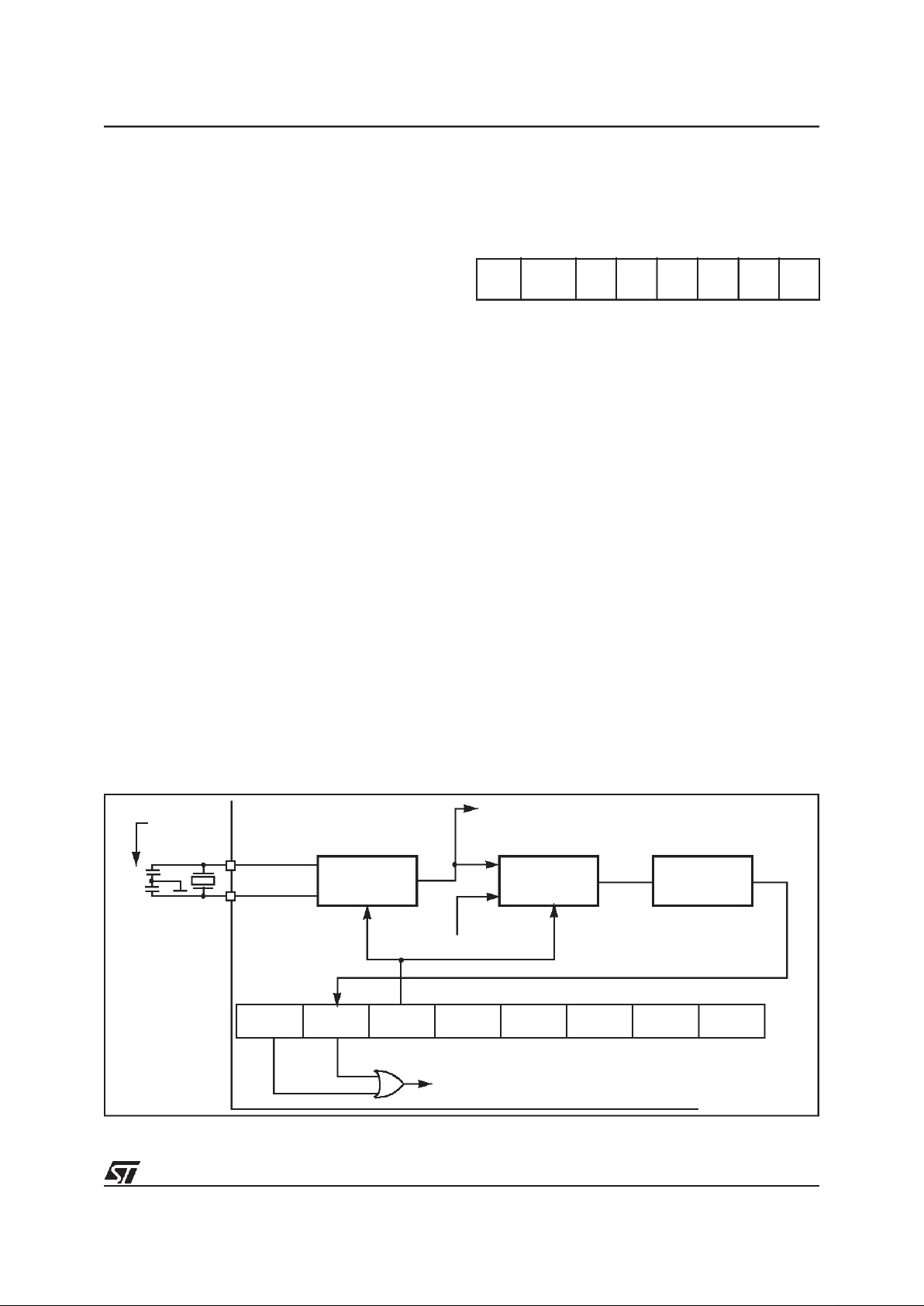

Figure 5. Data read-only memory Window Memory Addressing

70

- - DWR5 DWR4 DWR3 DWR2 DWR1 DWR0

DATA ROM

WINDOW REGISTER

CONTENTS

DATA SPACE ADDRESS

40h-7Fh

IN INSTRUCTION

PROGRAM SPACE ADDRESS

765432 0

543210

543210

READ

1

67891011

01

VR01573C

12

1

0

DATA SPACE ADDRESS

:

:

59h

000

0

1

00

1

11

Example:

(DWR)

DWR=28h

1100000001

ROM

ADDRESS:A19h

11

13

01

347

12/72

ST62T46B/E46B

MEMORY MAP (Cont’d)

1.3.6 Data RAM/EEPROM Bank Register

(DRBR)

Address: CBh — Write only

Bit 7-5 = These bits are not used

Bit 4 - DRBR4. This bit, when set, selects RAM

Page 2.

Bit 3 - DRBR3. This bit, when set, selects RAM

Page 1.

Bit2. These bits are not used.

Bit 1 - DRBR1. This bit, when set, selects

EEPROM Page 1.

Bit 0 - DRBR0. This bit, when set, selects

EEPROM Page 0.

The selection of the bank is made by programming

the Data RAM Bank Switch register (DRBR register) located at address CBh of the Data Space according to Table 1. No more than one bank should

be set at a time.

The DRBR register can be addressed like a RAM

Data Space at the address CBh; nevertheless it is

a write only register that cannot be accessed with

single-bit operations. This register is used to select

the desired 64-byte RAM/EEPROM bank of the

Data Space. The number of banks has to be loaded in the DRBR register and the instruction has to

point to the selected location as if it was in bank 0

(from 00h address to 3Fh address).

This register is not cleared during the MCU initialization, therefore it must be written before the first

access to the Data Space bank region. Refer to

the Data Space description for additional information. The DRBR register is not modified when an

interrupt or a subroutine occurs.

Notes :

Care is required when handling theDRBR register

as it is write only. For this reason, it is not allowed

to change the DRBR contents while executing interrupt service routine, as the service routine cannot save and then restore its previous content. If it

is impossible to avoid the writing of this register in

interrupt service routine, an image of this register

must be saved in a RAM location, and each time

the program writes to DRBR it must write also to

the image register. The image register must be

written first, so if an interrupt occurs between the

two instructions the DRBR is not affected.

In DRBR Register, only 1 bit must be set. Otherwise two or more pages are enabled in parallel,

producing errors.

Table 3. Data RAM Bank Register Set-up

70

- - - DRBR4 DRBR3 - DRBR1 DRBR0

DRBR ST62T46B/E46B

00h None

01h EEPROM Page 0

02h EEPROM Page 1

08h Not available

10h RAM Page 2

other Reserved

348

13/72

ST62T46B/E46B

MEMORY MAP (Cont’d)

1.3.7 EEPROM Description

EEPROM memory is located in 64-byte pages in

data space. This memory may be used by the user

program for non-volatile data storage.

Data space from 00h to3Fh is paged as described

in Table 4. EEPROM locations are accessed directly by addressing these paged sections of data

space.

The EEPROM does not require dedicated instructions forread orwrite access.Onceselected via the

Data RAM Bank Register, the active EEPROM

page is controlled by the EEPROM Control Register (EECTL), which is described below.

BitE20FF ofthe EECTL register mustbe resetprior

to any write or read access to the EEPROM. If no

bank has been selected, orif E2OFF is set, any access is meaningless.

Programming must be enabled by setting the

E2ENA bit of the EECTL register.

The E2BUSY bit of the EECTL register is set when

the EEPROM is performing a programming cycle.

Any access to the EEPROM when E2BUSY is set

is meaningless.

Provided E2OFF and E2BUSY are reset, an EEPROM location is read just like any other data location, also in terms of access time.

Writing to the EEPROM may be carried out in two

modes: Byte Mode (BMODE) and Parallel Mode

(PMODE). In BMODE, one byte is accessed at a

time, while in PMODE up to 8 bytes in the same

row are programmed simultaneously (with consequent speed and power consumption advantages,

the latter being particularly important in battery

powered circuits).

General Notes:

Data should be written directly to the intended ad-

dress in EEPROM space. There is no buffer memory between data RAM and the EEPROM space.

When the EEPROM is busy (E2BUSY = “1”)

EECTL cannot be accessed in write mode, it is

only possible to read the status of E2BUSY. This

implies that as long as the EEPROM is busy, it is

not possible to change the status of the EEPROM

Control Register. EECTL bits 4 and 5 are reserved

and must never be set.

Care is required when dealing with the EECTL register, as some bits are write only. For this reason,

the EECTL contents must not be altered while executing an interrupt service routine.

If it is impossible to avoid writing to this register

within an interrupt service routine, an image of the

register must be saved in a RAM location, and

each time the program writes to EECTL it must

also write to the imageregister. The image register

must be written to first so that, if an interrupt occurs between the two instructions, the EECTL will

not be affected.

Table 4. Row Arrangement for Parallel Writing of EEPROM Locations

Dataspace

addresses.

Banks 0 and 1.

Byte 01234567

ROW7 38h-3Fh

ROW6 30h-37h

ROW5 28h-2Fh

ROW4 20h-27h

ROW3 18h-1Fh

ROW2 10h-17h

ROW1 08h-0Fh

ROW0 00h-07h

Up to 8 bytes in each row may be programmed simultaneously in Parallel Write mode.

The number of available 64-byte banks (1 or 2) is device dependent.

349

14/72

ST62T46B/E46B

MEMORY MAP (Cont’d)

Additional Notes on Parallel Mode:

If the user wishes to perform parallel programming, the first step should be to set the E2PAR2

bit. From this time on, the EEPROM will be addressed in write mode, the ROW address will be

latched and it will be possible to change it only at

the end of the programming cycle, or by resetting

E2PAR2 without programming the EEPROM. After the ROW address is latched, the MCU can only

“see” the selected EEPROM row and any attempt

to write or read other rows will produce errors.

The EEPROM should not be read while E2PAR2

is set.

As soon as the E2PAR2 bit is set, the 8 volatile

ROW latches are cleared. From this moment on,

the user can load data in all or in part ofthe ROW.

Setting E2PAR1 will modify the EEPROM registers corresponding to the ROW latches accessed

after E2PAR2. For example, if the software sets

E2PAR2 and accesses the EEPROM by writing to

addresses 18h, 1Ah and 1Bh, and then sets

E2PAR1, these three registers will be modified simultaneously; the remaining bytes in the row will

be unaffected.

Note that E2PAR2 is internally reset at the end of

the programming cycle. This implies that the user

must set the E2PAR2 bit between two parallel programming cycles. Note that if the user tries to set

E2PAR1 while E2PAR2 is not set, there will be no

programming cycle and the E2PAR1 bit will be unaffected. Consequently, the E2PAR1 bit cannot be

set if E2ENA is low. The E2PAR1 bit can be set by

the user, only if the E2ENA and E2PAR2 bits are

also set.

EEPROM Control Register (EECTL)

Address: DFh — Read/Write

Reset status: 00h

Bit 7 = D7:

Unused.

Bit6 =E2OFF:

Stand-by Enable Bit.

WRITE ONLY.

Ifthisbitis settheEEPROMis disabled(anyaccess

willbe meaningless) andthepowerconsumption of

the EEPROM is reduced to its lowest value.

Bit 5-4 =

D5-D4

:

Reserved.

MUST be kept reset.

Bit 3 =

E2PAR1

:

Parallel Start Bit.

WRITE ONLY.

OnceinParallel Mode,assoonasthe usersoftware

sets the E2PAR1 bit, parallel writing of the 8 adjacent registers will start. This bit is internally reset at

the end of the programming procedure. Note that

less than 8 bytes can be written if required, the undefined bytes being unaffected by the parallel programming cycle;thisis explained in greater detail in

the Additional Notes on Parallel Mode overleaf.

Bit 2 = E2PAR2:

Parallel Mode En. Bit.

WRITE

ONLY. This bit must be set by the user program in

order to perform parallel programming. If E2PAR2

is set and the parallel start bit (E2PAR1) is reset,

up to 8 adjacent bytes can be written simultaneously. These 8 adjacent bytes are considered as a

row, whose address lines A7, A6, A5, A4, A3 are

fixed while A2, A1and A0 are the changing bits, as

illustrated in Table 4. E2PAR2 is automatically reset at the end of any parallel programming procedure. It can be reset by the user software before

starting the programming procedure, thus leaving

the EEPROM registers unchanged.

Bit 1 =

E2BUSY

:

EEPROM Busy Bit.

READ ONLY. This bit is automatically set by the EEPROM

control logic when the EEPROM is in programming mode. The user program should test itbefore

any EEPROM read or write operation; any attempt

to access the EEPROM while the busy bit is set

will be aborted and the writing procedure in

progress will be completed.

Bit 0 = E2ENA:

EEPROM Enable Bit.

WRITE ONLY. This bit enables programming of the EEPROM

cells. It must be set before any write to the EEPROM register. Any attempt to write to the EEPROM when E2ENA is low is meaningless and will

not trigger a write cycle.

Caution:

This register is undefined on reset. Neither read nor single bit instructions may be used to

address this register.

70

D7 E2OFF D5 D4 E2PAR1 E2PAR2 E2BUSY E2ENA

350

15/72

ST62T46B/E46B

1.4 PROGRAMMING MODES

1.4.1 Option Byte

The Option Byte allows configuration capability to

the MCUs. Option byte’s content is automatically

read, and the selected options enabled, when the

chip reset is activated.

It can only be accessed during the programming

mode. This access is made either automatically

(copy from a master device) or by selecting the

OPTION BYTE PROGRAMMING mode of the programmer.

The option byte is located in a non-user map. No

address has to be specified.

EPROM Code Option Byte

Bit 7. Reserved.

Bit 6 =

NMI PULL..

This bit must be set high to remove the NMI pin pull up resistor when it is low, a

pull up is provided.

Bit 5 =

PROTECT

. This bit allows the protection of

the software contents against piracy. When the bit

PROTECT is set high, readout of the OTP contents is prevented by hardware. No programming

equipment is able to gain access to the user program. When this bit is low, the user program can

be read.

Bit 4. Reserved.

Bit 3 =

WDACT

. This bit controls the watchdog activation. When it is high, hardware activation is selected. The software activation is selected when

WDACT is low.

Bit 2 = Reserved.Must be set to 1.

Bit 1-0 = Reserved.

The Option byte is written during programming ei-

ther by using the PC menu (PC driven Mode) or

automatically (stand-alone mode)

1.4.2 Program Memory

EPROM/OTP programming mode is set by a

+12.5V voltage applied to the TEST/VPPpin. The

programming flow of the ST62T46B/E46B is described in the User Manual of the EPROM Programming Board.

The MCUs can be programmed with the

ST62E4xB EPROM programming tools available

from STMicroelectronics.

1.4.3 EEPROM Data Memory

EEPROM data pages are supplied in the virgin

state FFh. Partial or total programming of EEPROM data memory can be performed either

through the application software, or through an external programmer. Any STMicroelectronics tool

used for the program memory (OTP/EPROM) can

also be used to program the EEPROM data memory.

1.4.4 EPROM Erasing

The EPROM of the windowed package of the

MCUs may be erased by exposure to Ultra Violet

light. The erasure characteristic of the MCUs is

such that erasure begins when the memory is exposed to light with a wave lengths shorter than approximately 4000Å. It should be noted that sunlights and some types of fluorescent lamps have

wavelengths in the range 3000-4000Å.

It is thus recommended that the window of the

MCUs packages be covered by an opaque label to

prevent unintentional erasure problems when testing the application in such an environment.

The recommended erasure procedure of the

MCUs EPROM is the exposure to short wave ultraviolet light which have a wave-length 2537A.

The integrated dose (i.e. U.V. intensity x exposure

time) for erasure should be a minimum of 15Wsec/cm2. The erasure time with this dosage is approximately 15 to 20 minutes using an ultraviolet

lamp with 12000µW/cm2power rating. The

ST62E46B should be placed within 2.5cm (1Inch)

of the lamp tubes during erasure.

70

-

NMI

PULL

PROTECT

- WDACT - - -

351

16/72

ST62T46B/E46B

2 CENTRAL PROCESSING UNIT

2.1 INTRODUCTION

The CPUCore of ST6devices is independent ofthe

I/O or Memory configuration. As such, it may be

thought of as an independent central processor

communicating with on-chip I/O, Memory and Peripherals via internal address, data, and control

buses. In-core communication is arranged as

shown in Figure 6; the controller being externally

linked to both the Reset and Oscillator circuits,

while the core islinked to the dedicated on-chip peripherals via the serial data bus and indirectly, for

interrupt purposes, through the control registers.

2.2 CPU REGISTERS

TheST6Family CPUcorefeaturessixregisters and

three pairs of flags available to the programmer.

These are described in the following paragraphs.

Accumulator (A). The accumulator is an 8-bit

general purpose register used in all arithmetic calculations, logical operations, and data manipulations. The accumulator can be addressed in Data

space as a RAM location at address FFh. Thus the

ST6 can manipulate the accumulator just like any

other register in Data space.

Indirect Registers (X, Y).These two indirect registers are used as pointers to memory locations in

Data space. They are used in the register-indirect

addressing mode. These registers can be addressed in the data space as RAM locations at addresses 80h (X) and 81h (Y). They can also be accessed with the direct, short direct, or bit direct addressing modes. Accordingly, the ST6 instruction

set can use the indirect registers as any other register of the data space.

Short Direct Registers (V, W). These two registers are used to save a byte in short direct addressing mode. They can be addressed in Data

space as RAM locations at addresses 82h (V) and

83h (W). They can also be accessed using the direct and bit direct addressing modes. Thus, the

ST6 instruction set can use the short direct registers as any other register of the data space.

Program Counter (PC). The program counter is a

12-bit register which contains the address of the

next ROM location to be processed by the core.

This ROM location may be an opcode, an operand, or the address of an operand. The 12-bit

length allows the direct addressing of 4096 bytes

in Program space.

Figure 6. ST6 Core Block Diagram

PROGRAM

RESET

OPCODE

FLAG

VALUES

2

CONTROLLER

FLAGS

ALU

A-DATA

B-DATA

ADDRESS/READ LINE

DATA SPACE

INTERRUPTS

DATA

RAM/EEPROM

DATA

ROM/EPROM

RESULTS TO DATA SPACE (WRITE LINE)

ROM/EPROM

DEDICATIONS

ACCUMULATOR

CONTROL

SIGNALS

OSCin

OSCout

ADDRESS

DECODER

256

12

Program Counter

and

6 LAYER STACK

0,01 TO 8MHz

VR01811

352

17/72

ST62T46B/E46B

CPU REGISTERS (Cont’d)

However, if the program space contains more than

4096 bytes, the additional memory in program

space can be addressed by using the Program

Bank Switch register.

The PC value is incremented after reading the address of the current instruction. To execute relative

jumps, the PC and the offset are shifted through

the ALU, where they are added; the result is then

shifted back into the PC. The program counter can

be changed in the following ways:

- JP (Jump) instructionPC=Jump address

- CALL instructionPC= Call address

- Relative Branch Instruction.PC= PC +/- offset

- Interrupt PC=Interrupt vector

- Reset PC= Reset vector

- RET & RETI instructionsPC= Pop (stack)

- Normal instructionPC= PC + 1

Flags (C, Z). The ST6 CPU includes three pairs of

flags (Carry and Zero), each pair being associated

with one of the three normal modes of operation:

Normal mode, Interrupt mode and Non Maskable

Interrupt mode. Each pair consists of a CARRY

flag and a ZERO flag. One pair (CN, ZN) is used

during Normal operation, another pair is used during Interrupt mode (CI, ZI), and a third pair is used

in the Non Maskable Interrupt mode (CNMI, ZNMI).

The ST6 CPU uses the pair of flags associated

with the current mode: as soon as an interrupt (or

a Non Maskable Interrupt) is generated, the ST6

CPU uses the Interrupt flags (resp. the NMI flags)

instead of the Normal flags. When the RETI instruction is executed, the previously used set of

flags is restored. It should be noted that each flag

set can only be addressed in its own context (Non

Maskable Interrupt, Normal Interrupt or Main routine). The flags are not cleared during context

switching and thus retain their status.

The Carry flag is set when a carry or a borrow occurs during arithmetic operations; otherwise it is

cleared. The Carry flag is also set to the value of

the bit tested in a bit test instruction; it also participates in the rotate left instruction.

The Zero flag is set if the result of the last arithmetic or logical operation was equal to zero; otherwise it is cleared.

Switching between the three sets of flags is performed automatically when an NMI, an interrupt or

a RETI instructions occurs. As the NMI mode is

automatically selected after the reset of the MCU,

the ST6 core uses at first the NMI flags.

Stack. The ST6 CPU includes a true LIFO hardware stack which eliminates the need for a stack

pointer. The stack consists of six separate 12-bit

RAM locations that do not belong to the data

space RAM area. When a subroutine call (or interrupt request) occurs, the contents of each level are

shifted into the next higher level, while the content

of the PC is shifted into the first level (the original

contents of the sixth stack level are lost). When a

subroutine or interrupt return occurs (RET or RETI

instructions), the first level register is shifted back

into the PC and the value of each level is popped

back into the previous level. Since the accumulator, in common with all other data space registers,

is not stored in this stack, management of these

registers should be performed within the subroutine. The stack will remain in its “deepest” position

if more than 6 nested calls or interrupts are executed, and consequently the last return address will

be lost. It will also remain in its highest position if

the stack is empty and a RET or RETI is executed.

In this case the next instruction will be executed.

Figure 7. ST6 CPU Programming Mode

l

SHORT

DIRECT

ADDRESSING

MODE

V REGISTER

WREGISTER

PROGRAM COUNTER

SIX LEVELS

STACK REGISTER

CZNORMAL FLAGS

INTERRUPTFLAGS

NMI FLAGS

INDEX

REGISTER

VA000423

b7

b7

b7

b7

b7

b0

b0

b0

b0

b0

b0b11

ACCUMULATOR

YREG.POINTER

XREG.POINTER

CZ

CZ

353

18/72

ST62T46B/E46B

3 CLOCKS, RESET, INTERRUPTS AND POWER SAVING MODES

3.1 CLOCK SYSTEM

3.1.1 Main Oscillator

The MCU features a Main Oscillator which can be

driven by an external clock, or used in conjunction

with an AT-cut parallel resonant crystal or a suitable ceramic resonator.

Figure 8 illustrates various possible oscillator configurations using anexternal crystalorceramic resonator, an external clock input. CL1an CL2should

have a capacitance in the range 12 to 22 pF for an

oscillator frequency in the 4-8 MHz range.

The internal MCU clock Frequency (F

INT

) is divided by 13 to drive the CPU core and by 12 to drive

the A/D converter and the watchdog timer, while

clock used to drive on-chip peripherals depends

on the peripheral as shown in the clock circuit

block diagram.

With an 8MHz oscillator frequency, the fastest machine cycle is therefore 1.625µs.

A machine cycleis the smallest unit oftime needed

toexecute any operation (forinstance, toincrement

the Program Counter). An instruction may require

two, four, or five machine cycles for execution.

Figure 8. Oscillator Configurations

Figure 9. Clock Circuit Block Diagram

OSC

in

OSC

out

C

L1n

C

L2

ST6xxx

CRYSTAL/RESONATOR CLOCK

OSC

in

OSC

out

ST6xxx

EXTERNAL CLOCK

NC

VA0016

VA0015A

MAIN

OSCILLATOR

Core

:13

:12

Timer 1 & 2

Watchdog

POR

f

INT

ADC

OSCin

OSCout

f

OSC

f

INT

OSC32in

OSC32out

32kHz

OSCILLATOR

MUX

LCD

CONTROLLER

DRIVER

EOCR bit 5

(START/STOP)

354

19/72

ST62T46B/E46B

CLOCK SYSTEM (Cont’d)

3.1.2 32 KHz STAND-BY OSCILLATOR

An additional 32KHz stand-by on chip oscillator allows to generate real time interrupts and to supply

the clock to the LCD driver with the main oscillator

stopped. This enables the MCU to perform real

time functions with the LCD display running while

keeping advantages of low power consumption.

Figure 10 shows the 32KHz oscillator block diagram.

A 32.768KHz quartz crystal must be connected to

the OSC32in and OSC32out pins to perform the

real time clock operation. Two external capacitors

of 15-22pF each must be connected between the

oscillator pins and ground. The 32KHz oscillator is

managed by the dedicated status/control register

32OCR.

As long as the 32KHz stand-by oscillator is enabled, 32KHz internal clock is available to drive

LCD controller driver. This clock is divide by 214to

generate interrupt request every 500ms . The periodic interrupt request serves as reference timebase for real time functions.

Note

: When the 32KHz stand-by oscillator is

stopped (bit 5 of the Status/Control register

cleared) the divider chain is supplied with a clock

signal synchronous with machine cycle (f

INT

/13),

this produces an interrupt request every 13x2

14

clock cycle (i.e. 26.624ms) with an 8MHz quartz

crystal.

32KHz Oscillator Register (32OCR)

Address: DBh - Read/Write

Bit 7 =EOSCI.

Enable Oscillator Interrupt

. This bit,

when set, enables the 32KHz oscillator interrupt

request.

Bit 6 = OSCEOC.

Oscillator Interrupt Flag

. This bit

indicates when the 32KHz oscillator has measured

a 500ms elapsed time (providing a

32.768KHzquartz crystal is connected to the

32KHz oscillator dedicated pins). An interrupt request can be generated in relation to the state of

EOSCI bit. This bit must be cleared by the user

program before leaving the interrupt service routine.

Bit 5 =

START/STOP

.O

scillator Start/Stop bit

.

This bit, when set, enables the 32KHz stand-by

oscillator and the free running divider chain is supplied by the 32KHz oscillator signal. When this bit

is cleared to zero the divider chain is supplied with

f

INT

/13.

This register is cleared during reset.

Note

:

To achieve minimum power consumption in STOP

mode (no system clock), the stand-by oscillator

must be switched off (real time function not available) by clearing the Start/Stop bit in the oscillator

status/control register.

Figure 10. 32KHz Oscillator Block Diagram

70

EOSCI OSCEOC S/S D4 D3 D2 D1 D0

OSC32KHz

EOSCI OSCEOC

START

STOP

XX XXX

INT

OSC32IN

OSC32OUT

2x15...22pF

32.768KHz

Crystal

f

INT

/13

OSC32KHz MUX

1

0

DIV 2

14

355

20/72

ST62T46B/E46B

3.2 RESETS

The MCU can be reset in three ways:

– by the external Reset input being pulled low;

– by Power-on Reset;

– by the digital Watchdog peripheral timing out.

3.2.1 RESET Input

The RESET pin may be connected to a device of

the application board in order to reset the MCU if

required. The RESET pin may be pulled low in

RUN, WAIT or STOP mode. This input can be

used to reset the MCU internal state and ensure a

correct start-up procedure. The pin is active low

and features a Schmitt trigger input. The internal

Reset signal is generated by adding a delay to the

external signal. Therefore even short pulses on

the RESET pin are acceptable, provided VDDhas

completed its rising phase and that the oscillator is

running correctly (normal RUN or WAIT modes).

The MCU is kept in the Reset state as long as the

RESET pin is held low.

If RESET activation occurs in the RUN or WAIT

modes, processing of the user program is stopped

(RUN mode only), the Inputs and Outputs are configured as inputs with pull-up resistors and the

main Oscillator is restarted. When the level on the

RESET pin then goes high, the initialization sequence is executed following expiry of the internal

delay period.

If RESET pin activation occurs in the STOP mode,

the oscillator starts up and all Inputs and Outputs

are configured as inputs with pull-up resistors.

When the level of theRESET pin then goes high,

the initialization sequence is executed following

expiry of the internal delay period.

3.2.2 Power-on Reset

The function of the POR circuit consists in waking

up the MCU at an appropriate stage during the

power-on sequence. At the beginning of this sequence, the MCU is configured in the Reset state:

all I/O ports are configured as inputs with pull-up

resistors and no instruction is executed. When the

power supply voltage rises to a sufficient level, the

oscillator starts to operate, whereupon an internal

delay is initiated, in order to allow the oscillator to

fully stabilize before executing the first instruction.

The initialization sequence is executed immediately following the internal delay.

The internal delay is generated by an on-chip counter.The internal reset line is released 2048internal

clock cycles after release of the external reset.

Notes:

To ensure correct start-up, the user should take

care that the reset signal is not released before the

VDDlevel is sufficient to allow MCU operation at

the chosen frequency (see Recommended Operating Conditions).

A proper reset signal for a slow rising VDDsupply

can generally be provided by an external RC network connected to theRESET pin.

Figure 11.Reset and Interrupt Processing

INT LATCH CLEARED

NMI MASK SET

RESET

( IF PRESENT )

SELECT

NMI MODE FLAGS

IS RESET STILL

PRESENT?

YES

PUT FFEH

ON ADDRESS BUS

FROM RESET LOCATIONS

FFE/FFF

NO

FETCH INSTRUCTION

LOAD PC

VA000427

356

21/72

ST62T46B/E46B

RESETS (Cont’d)

3.2.3 Watchdog Reset

The MCU provides a Watchdog timer function in

order to ensure graceful recovery from software

upsets. If the Watchdog register is not refreshed

before an end-of-count condition is reached, the

internal reset will be activated. This, amongst other things, resets the watchdog counter.

The MCU restarts just as though the Reset had

been generated by the RESET pin, including the

built-in stabilisation delay period.

3.2.4 Application Notes

No external resistor is required between VDDand

the Reset pin, thanks to the built-in pull-up device.

The POR circuit operates dynamically, in that it

triggers MCU initialization on detecting the rising

edge of VDD. The typical threshold is in the region

of 2 volts, but the actual value of the detected

threshold depends on the way in which VDDrises.

The POR circuit is

NOT

designed to supervise

static, or slowly rising or falling VDD.

3.2.5 MCU Initialization Sequence

When a reset occurs the stack is reset, the PC is

loaded with the address of the Reset Vector (located in program ROM starting at address 0FFEh). A

jump to the beginning of the user program must be

coded at this address. Following a Reset, the Interrupt flag is automatically set, so that the CPU is

in Non Maskable Interrupt mode; this prevents the

initialisation routine from being interrupted. The initialisation routine should therefore be terminated

by a RETI instruction, in order to revert to normal

mode and enable interrupts. If no pending interrupt

is present at the end of the initialisation routine, the

MCU will continue by processing the instruction

immediately following the RETI instruction. If, however, a pending interrupt is present, it will be serviced.

Figure 12.Reset and Interrupt Processing

Figure 13. Reset Block Diagram

RESET

RESET

VECTOR

JP

JP:2 BYTES/4 CYCLES

RETI

RETI: 1 BYTE/2 CYCLES

INITIALIZATION

ROUTINE

VA00181

V

DD

RESET

300kΩ

2.8kΩ

POWER

WATCHDOG RESET

CK

COUNTER

RESET

ST6

INTERNAL

RESET

f

OSC

RESET

ON RESET

VA0200B

357

22/72

ST62T46B/E46B

RESETS (Cont’d)

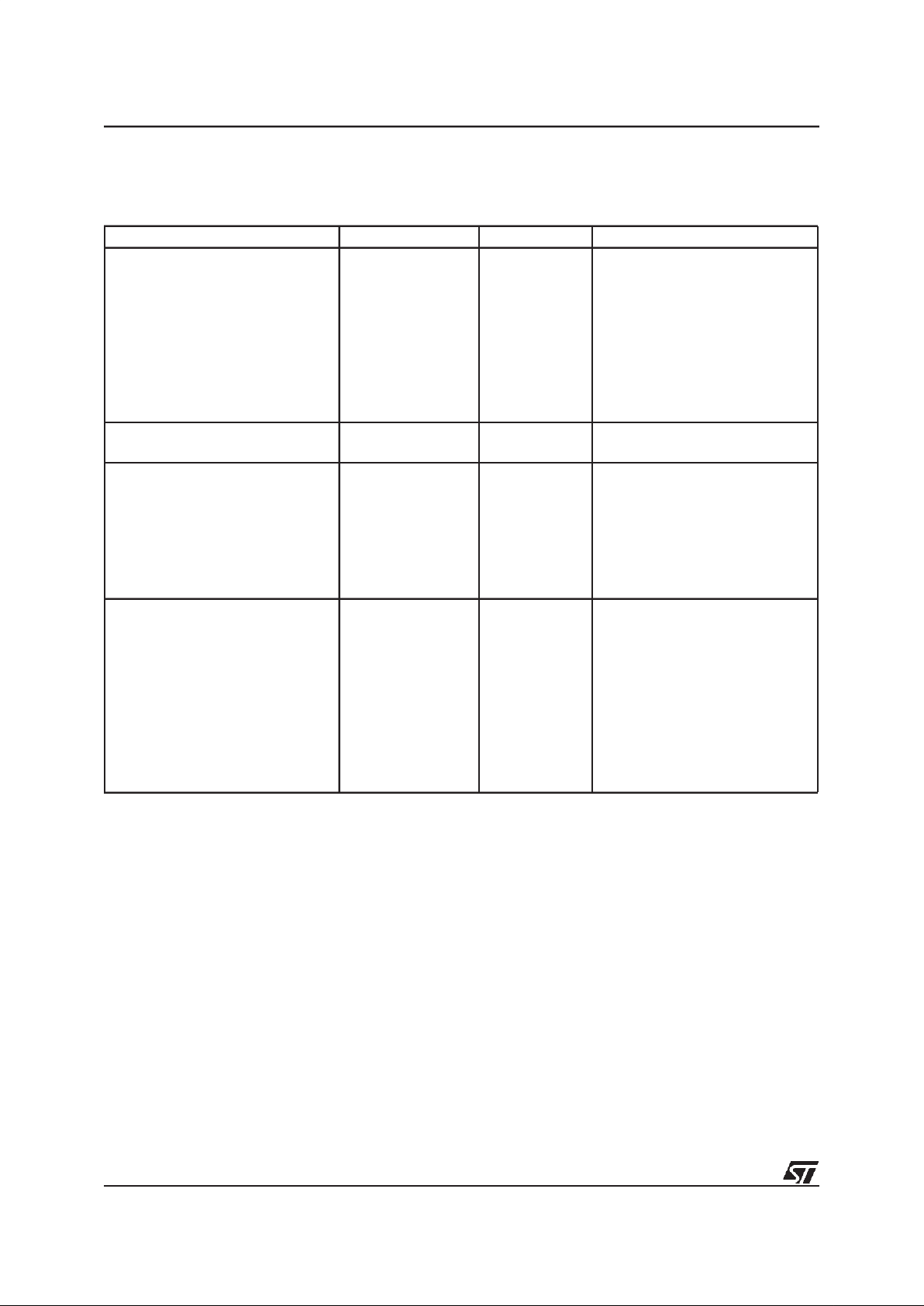

Table 5. Register Reset Status

Register Address(es) Status Comment

EEPROM Control Register

Port Data Registers

Port A,B Direction Register

Port A,B Option Register

Interrupt Option Register

SPI Registers

LCD Mode Control Register

32kHz Oscillator Register

0DFh

0C0h, 0C2h, 0C3h

0C4h to0C5h

0CCh, 0CEh

0C8h

0C2h to0DDh

0DCh

0DBh

00h

EEPROM enabled

I/O are Input with pull-up

Interrupt disabled

SPI disabled

LCD display off

Interrupt disabled

Port C Direction Register

Port C Option Register

0C6h

0CFh

FFh LCD Output

X, Y,V, W, Register

Accumulator

Data RAM

Data RAM Page REgister

Data ROM Window Register

EEPROM

A/D Result Register

080H TO083H

0FFh

084h to0BFh

0CBh

0C9h

00h to 03Fh

0D0h

Undefined As written if programmed

TIMER 1 Status/Control

TIMER 1 Counter Register

TIMER 1 Prescaler Register

TIMER 2 Status/Control

TIMER 2 Counter Register

TIMER 2 Prescaler Register

Watchdog Counter Register

A/D Control Register

0D4h

0D3h

0D2h

0D7h

0D5h

0D6h

0D8h

0D1h

00h

FFh

7Fh

00h

FFh

7Fh

FEh

40h

TIMER 1 disabled/Max count loaded

TIMER 2 disabled/Max count loaded

A/D in Standby

358

Loading...

Loading...