1/58April 1999

■ HIGH PERFORMANCE CPU

– HIGH PERFORMANCE 16-BIT CPU WITH

4-STAGE PIPELINE

– 80nsINSTRUCTION CYCLE TIME@ 25MHzCPU

CLOCK

– 400ns MULTIPLICATION (16 × 16 BITS)

– 800ns DIVISION (32 / 16 BIT)

– ENHANCED BOOLEAN BIT MANIPULATION FA-

CILITIES

– ADDITIONAL INSTRUCTIONS TO SUPPORTHLL

AND OPERATING SYSTEMS

– SINGLE-CYCLE CONTEXT SWITCHING SUP-

PORT

■ MEMORY ORGANIZATION

– UP TO 16 MBYTES LINEAR ADDRESS SPACE

FOR CODE AND DATA (1MBYTE WITH SSP

USED)

– 1 KBYTES ON-CHIP RAM

– 128KBYTES ON-CHIP FLASH MEMORY

– 4 INDEPENDENTLY ERASABLE BANKS OF

FLASH

■ FAST AND FLEXIBLE BUS

– PROGRAMMABLE EBC

– 8-BIT OR16-BIT EXTERNAL DATA BUS

– MULTIPLEXED OR DEMULTIPLEXED EXTER-

NAL ADDRESS/DATA BUSES

– FIVEPROGRAMMABLE CHIP-SELECT SIGNALS

– HOLD AND HOLD-ACKNOWLEDGE BUS ARBI-

TRATION SUPPORT

■ ON-CHIP BOOTSTRAP LOADER

■ FAIL-SAFE PROTECTION

– PROGRAMMABLE WATCHDOG TIMER

– OSCILLATOR WATCHDOG

■ INTERRUPT

– 8-CHANNEL INTERRUPT-DRIVEN SINGLE-CY-

CLE DATA TRANSFER FACILITIES VIA PERIPH-

ERAL EVENT CONTROLLER (PEC)

– 16-PRIORITY-LEVEL INTERRUPT SYSTEM

WITH 20 SOURCES, SAMPLE-RATE DOWN TO

40ns

■ TIMERS

– TWOGENERAL PURPOSE TIMERUNITS WITH5

TIMERS

■ CLOCK GENERATION

– ON-CHIP PLL

– DIRECT OR PRESCALED CLOCK INPUT

■ UP TO 77 GENERAL PURPOSE I/O LINES

■ IDLE AND POWER DOWN MODES

■ SERIAL CHANNELS

– SYNCHRONOUS/ASYNCHRONOUS

– HIGH-SPEEDSYNCHRONOUSSERIALPORTSSP

■ DEVELOPMENT SUPPORT

– C-COMPILERS, MACRO-ASSEMBLER PACKAG-

ES, EMULATORS, EVALUATION BOARDS,

HLL-DEBUGGERS, SIMULATORS, LOGIC ANALYZER DISASSEMBLERS, PROGRAMMING

BOARDS

■ PACKAGE

– 100-PIN THIN QUAD FLATPACK (TQFP)

PQFP100 (14 x 14 mm)

(Plastic Quad Flat Pack)

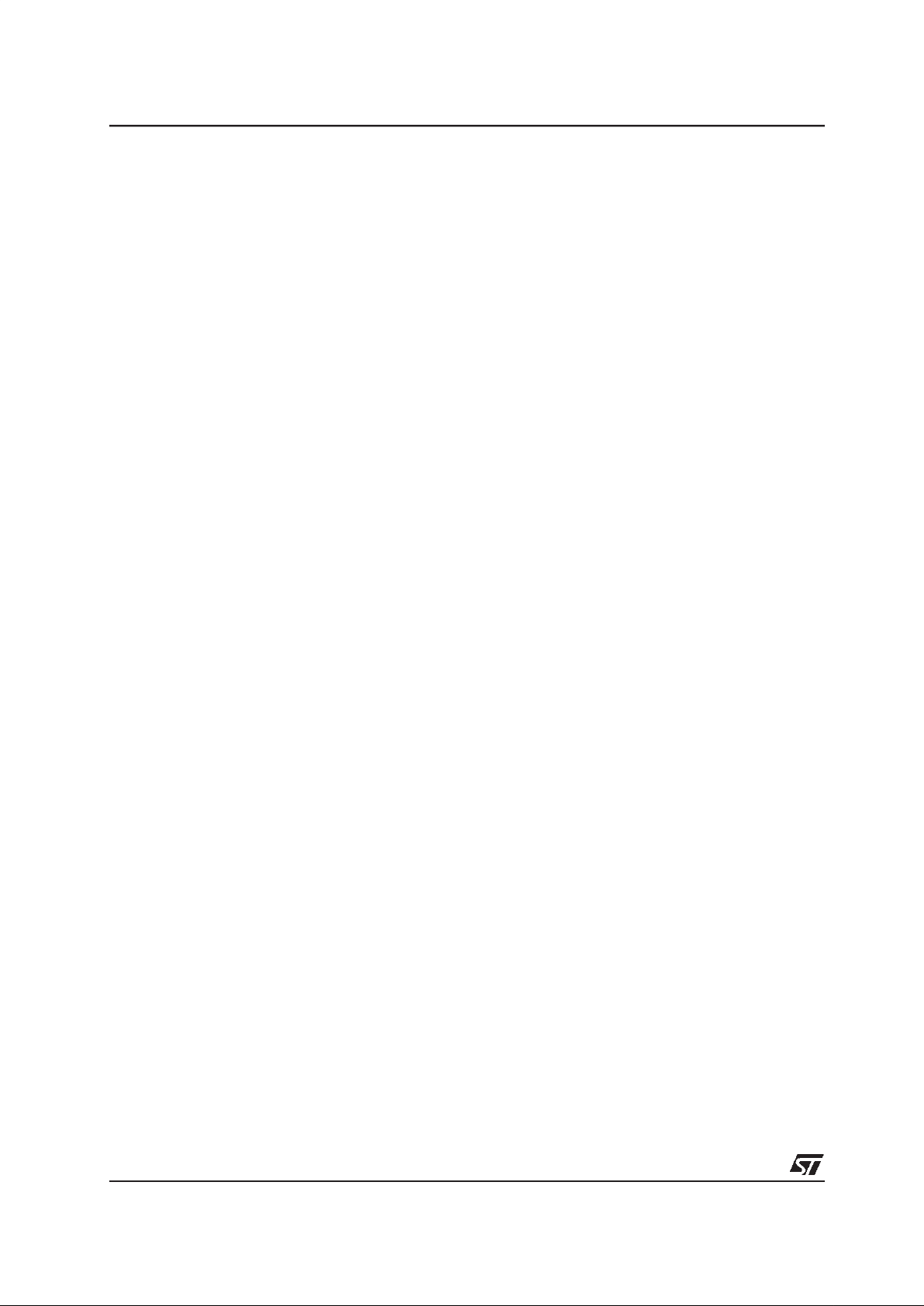

P.0

P.1

P.4

P.6

P.5

P.3 P.2

SSP

BRG

GPT1&2

ASC

BRG

FLASH

CPU

RAM

Watchdog

InterruptController

PEC

PLL

EBC

ST10F163

16-BIT MCU WITH 128KBYTE FLASH MEMORY

This is advance information on a new product now in development or undergoing evaluation. Details are subject tochange without notice.

ST10F163

2/58

I INTRODUCTION ........................................................................................................ 4

II PIN DATA ............................................................................................................. 5

III FUNCTIONAL DESCRIPTION ................................................................................... 9

IV MEMORY ORGANIZATION ....................................................................................... 10

V FLASH MEMORY ...................................................................................................... 10

V.1 PROGRAMMING/ERASING WITH ST EMBEDDED ALGORITHMKERNEL ............ 11

V.1.1 Return values ............................................................................................................. 13

V.1.2 Programming examples .............................................................................................. 13

V.2 FLASH MEMORY CONFIGURATION......................................................................... 14

V.3 FLASH PROTECTION ............................... ................................................................. 14

VI EXTERNAL BUS CONTROLLER .............................................................................. 15

VI.1 PROGRAMMABLE CHIP SELECT TIMING CONTROL ............................................. 15

VII CENTRAL PROCESSING UNIT (CPU) ..................................................................... 17

VIII INTERRUPT SYSTEM ............................................................................................... 18

IX GENERAL PURPOSE TIMER (GPT) UNIT ........................................... .................... 20

IX.1 GPT1 ........................................................................................................................... 20

IX.2 GPT2 ........................................................................................................................... 20

X PARALLEL PORTS ............................................................................... .................... 23

XI SERIAL CHANNELS ................................................................................................. 23

XII WATCHDOG TIMER .................................................................................................. 25

XIII OSCILLATOR WATCHDOG (OWD) ......................................................................... 25

XIV INSTRUCTION SET SUMMARY ................................. .............................................. 26

XV SPECIAL FUNCTION REGISTER OVERVIEW ......................................................... 28

XVI ELECTRICAL CHARACTERISTICS ......................................................................... 31

XVI.1 ABSOLUTE MAXIMUM RATINGS.............................................................................. 31

XVI.2 PARAMETER INTERPRETATION.............................................................................. 31

XVI.3 DC CHARACTERISTICS ............................................................................................ 31

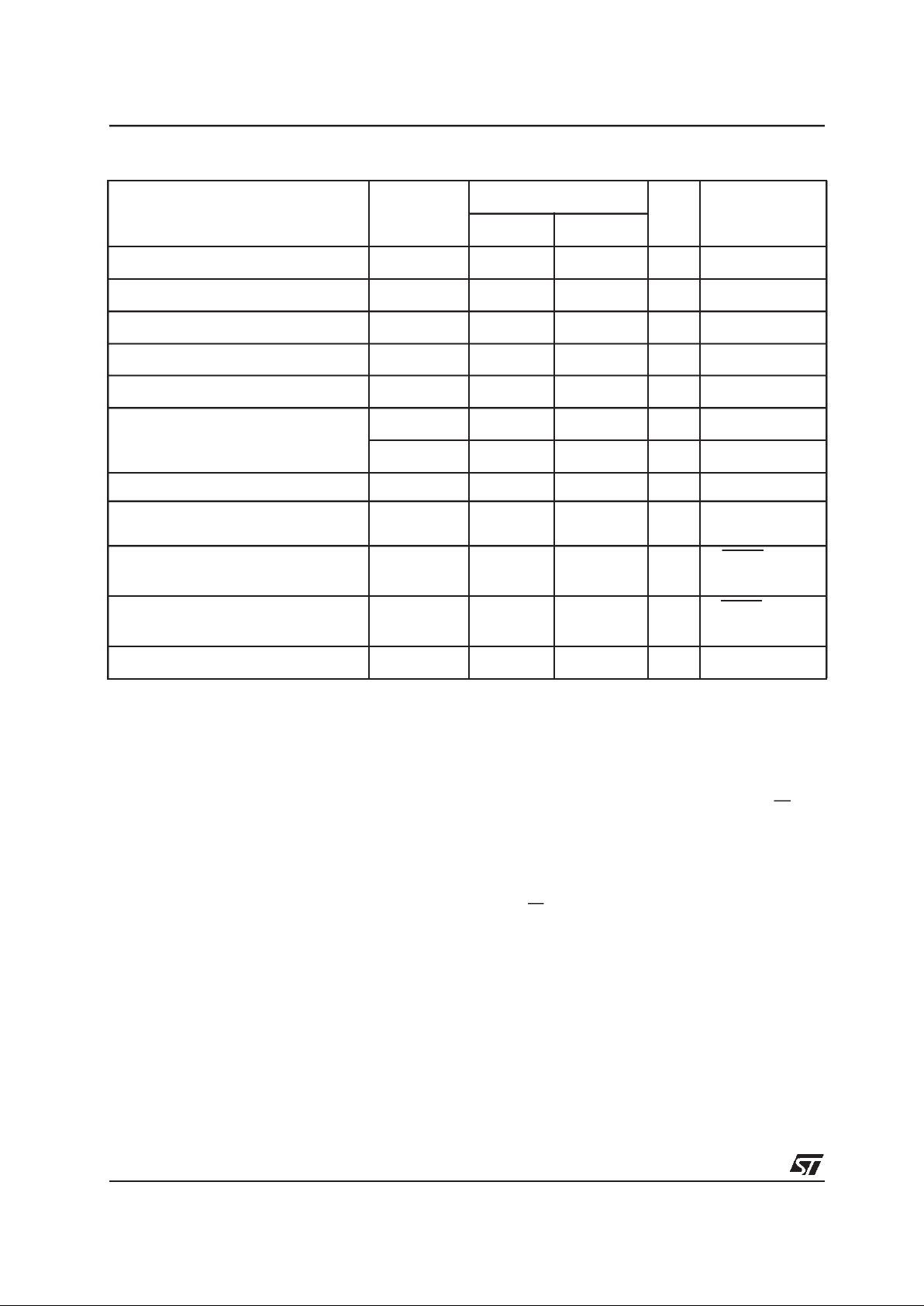

XVI.4 AC CHARACTERISTICS............................................................................................. 33

XVI.4.1 Test waveforms .......................................................................................................... 33

XVI.4.2 Definition of internal timing ......................................................................................... 34

XVI.4.3 Clock generation modes ............................................................................................. 34

XVI.4.4 Prescaler operation .................................................................................................... 35

XVI.4.5 Direct drive ................................................................................................................. 35

XVI.4.6 Oscillator Watchdog (OWD) ................................................................... .................... 35

TABLE OF CONTENTS Page

ST10F163

3/58

XVI.4.7 Phase locked loop ...................................................................................................... 35

XVI.4.8 Memory cycle variables .............................................................................................. 36

XVI.4.9 External clock drive XTAL1 .......................................... .............................................. 37

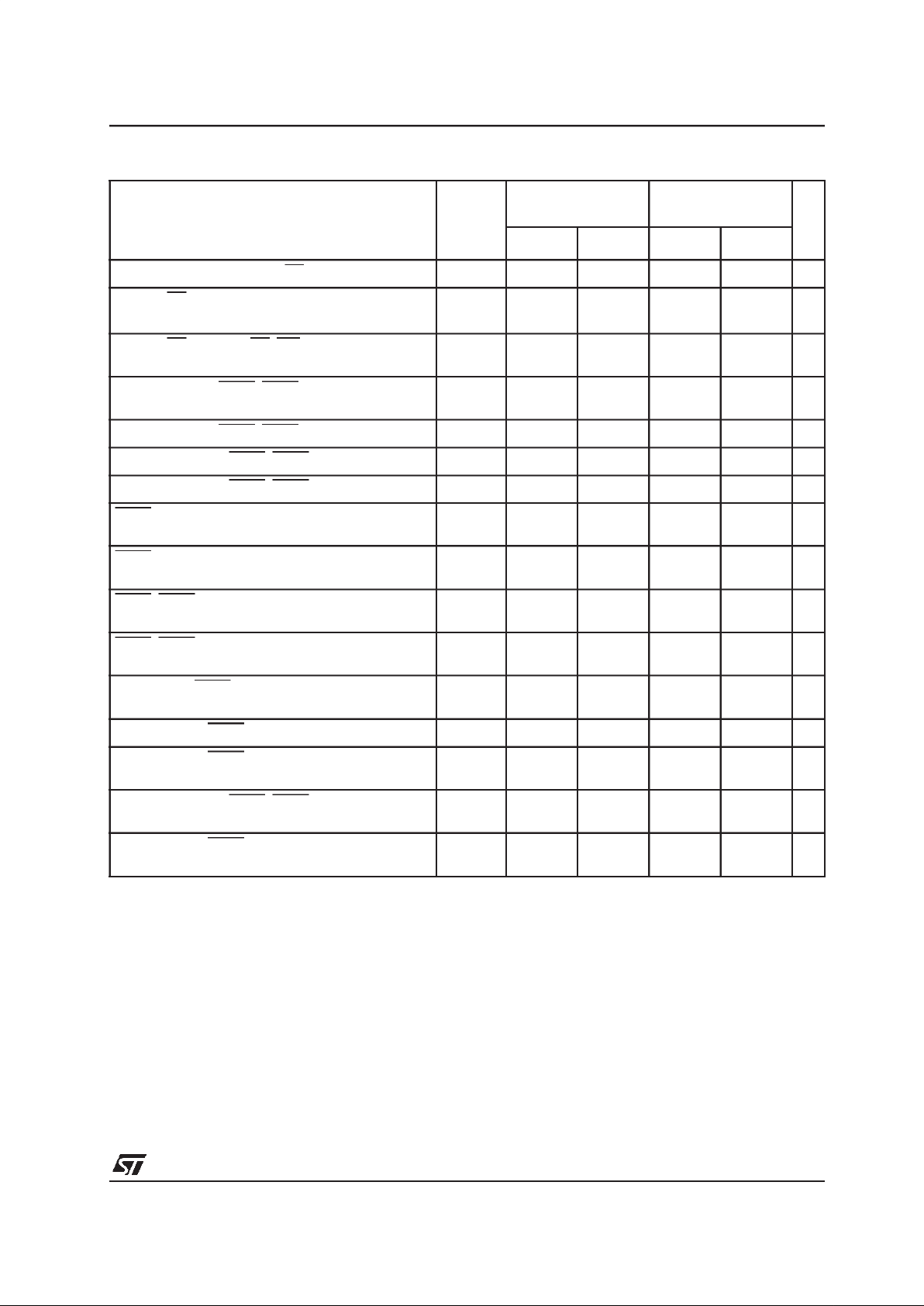

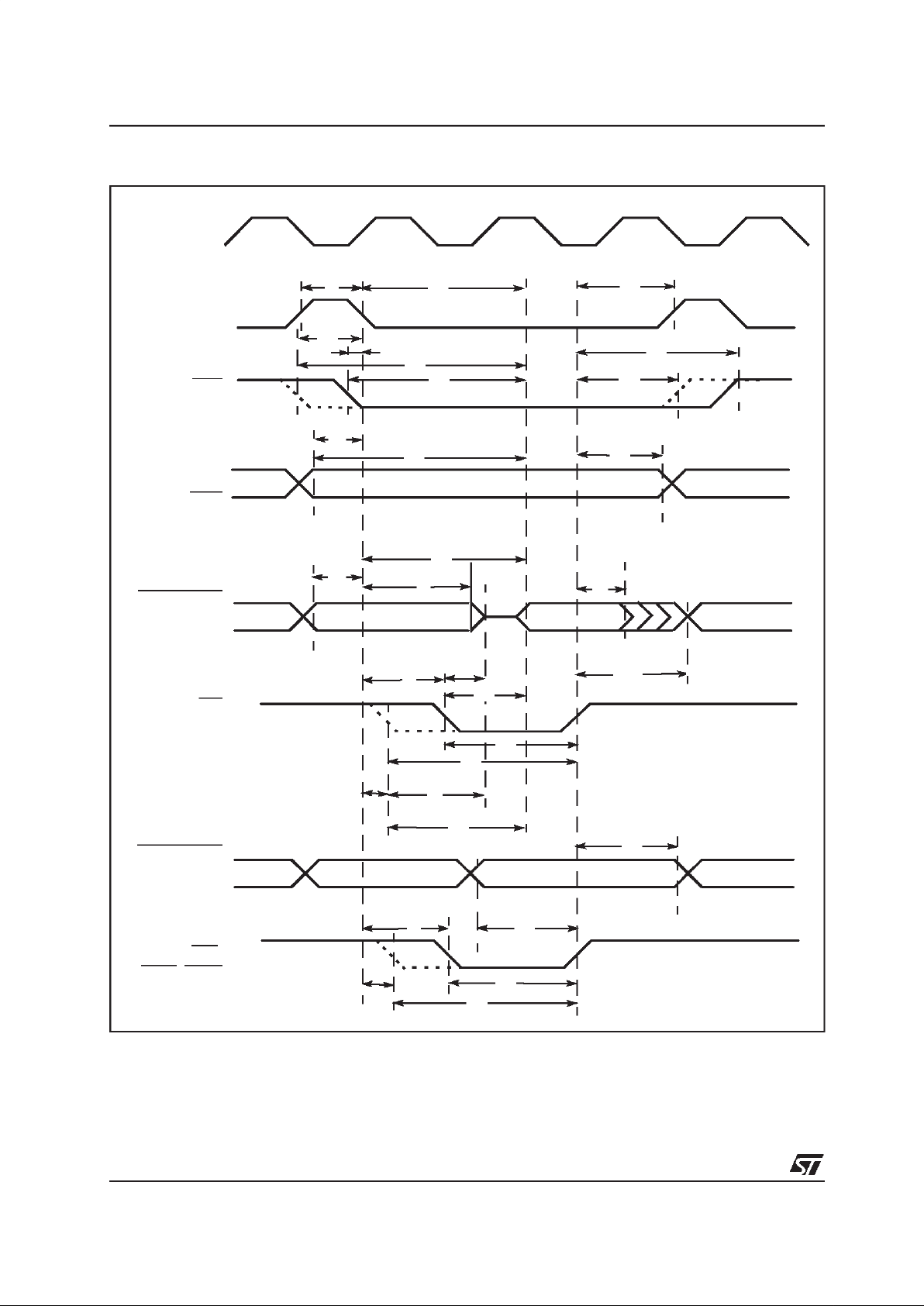

XVI.4.10 Multiplexed bus ...................................................................................... ....................38

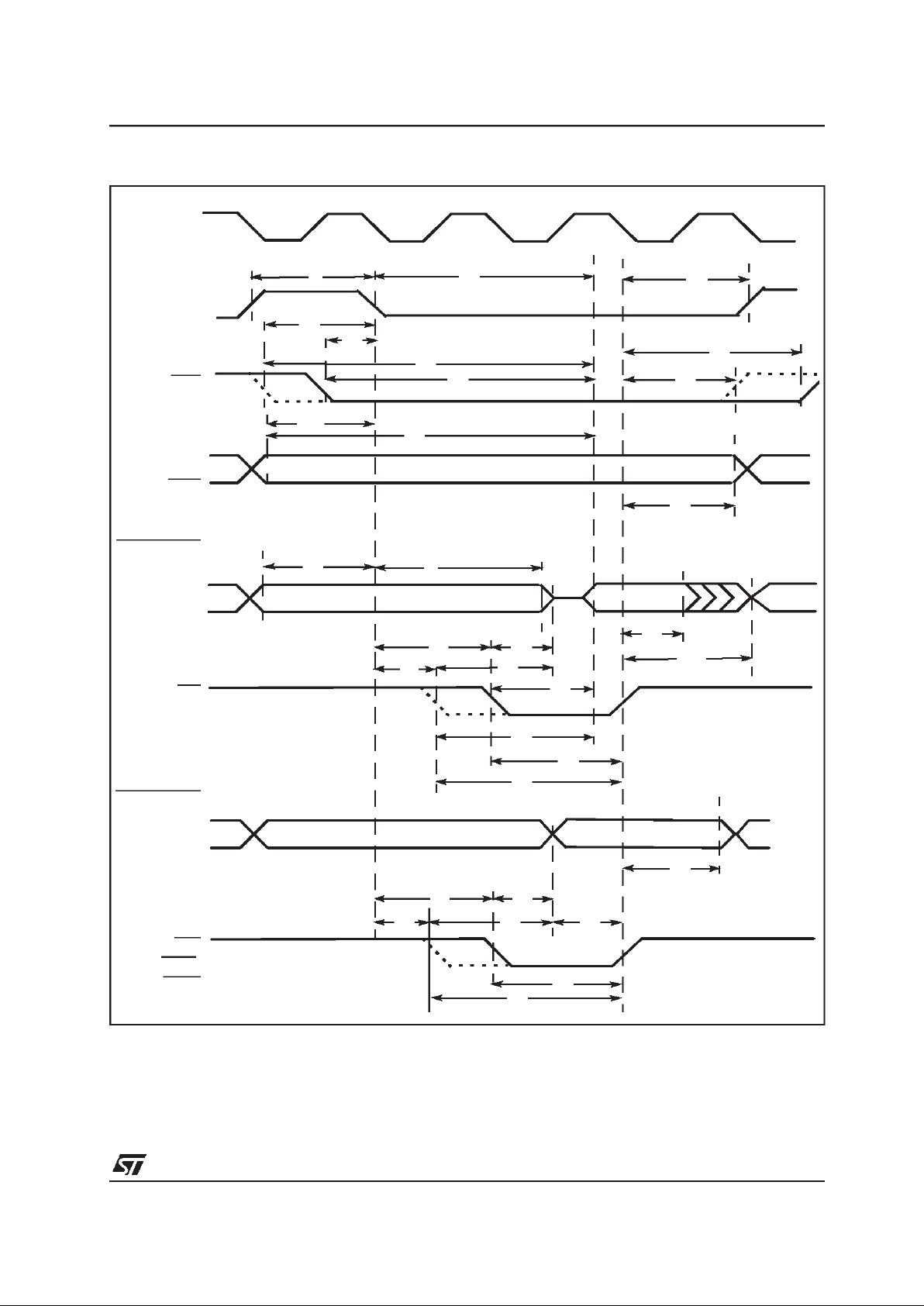

XVI.4.11 Demultiplexed bus ...................................................................................................... 44

XVI.4.12 CLKOUT and READY ................................................................................................ 50

XVI.4.13 External bus arbitration ........................................................................... .................... 52

XVI.4.14 Synchronous serial port timing ................................................................................... 54

XVII PACKAGE MECHANICAL DATA ........................................................................... 56

XVIII ORDERING INFORMATION ...................................................................................... 56

XIX REVISION HISTORY ................................ ................................................................. 57

ST10F163

4/58

I - INTRODUCTION

The ST10F163 is a Flash derivative of the

STMicroelectronics ST10 family of 16-bit microcontrollers. It combines high CPU performance

(up to 12.5 million instructions per second) with

high peripheral functionality and enhanced

IO-capabilities. 128KBytes of an electrically erasable and re-programmable Flash EPROM is provided on-chip.

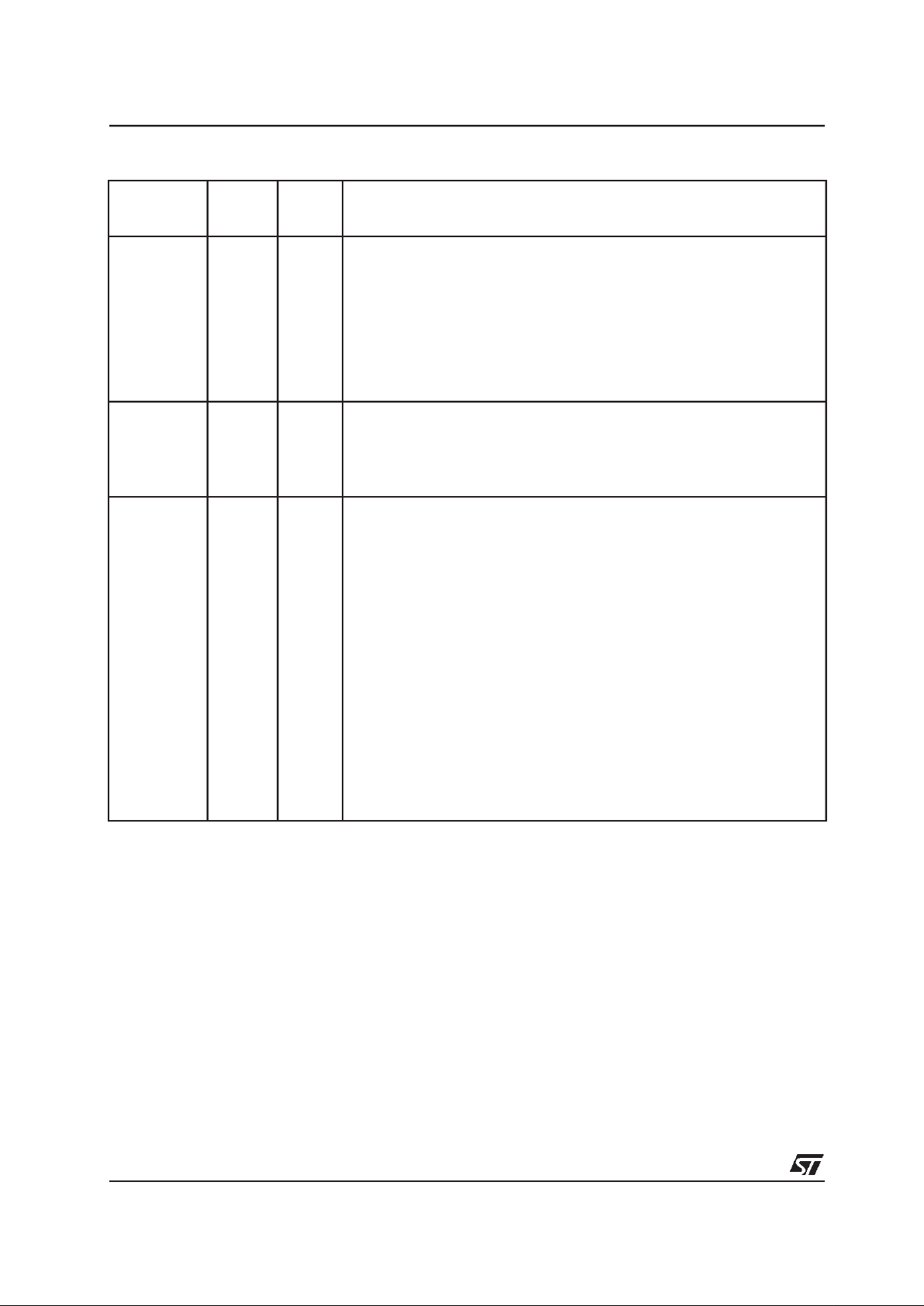

Figure 1 : Logic symbol

XTAL1

RSTIN

XTAL2

RSTOUT

NMI

EA

READY

ALE

RD

WR/WRL

Port 5

6-bit

Port 6

8-bit

Port 4

8-bit

Port 3

15-bit

Port 2

8-bit

Port 1

16-bit

Port 0

16-bit

V

DD

V

SS

ST10F163

ST10F163

5/58

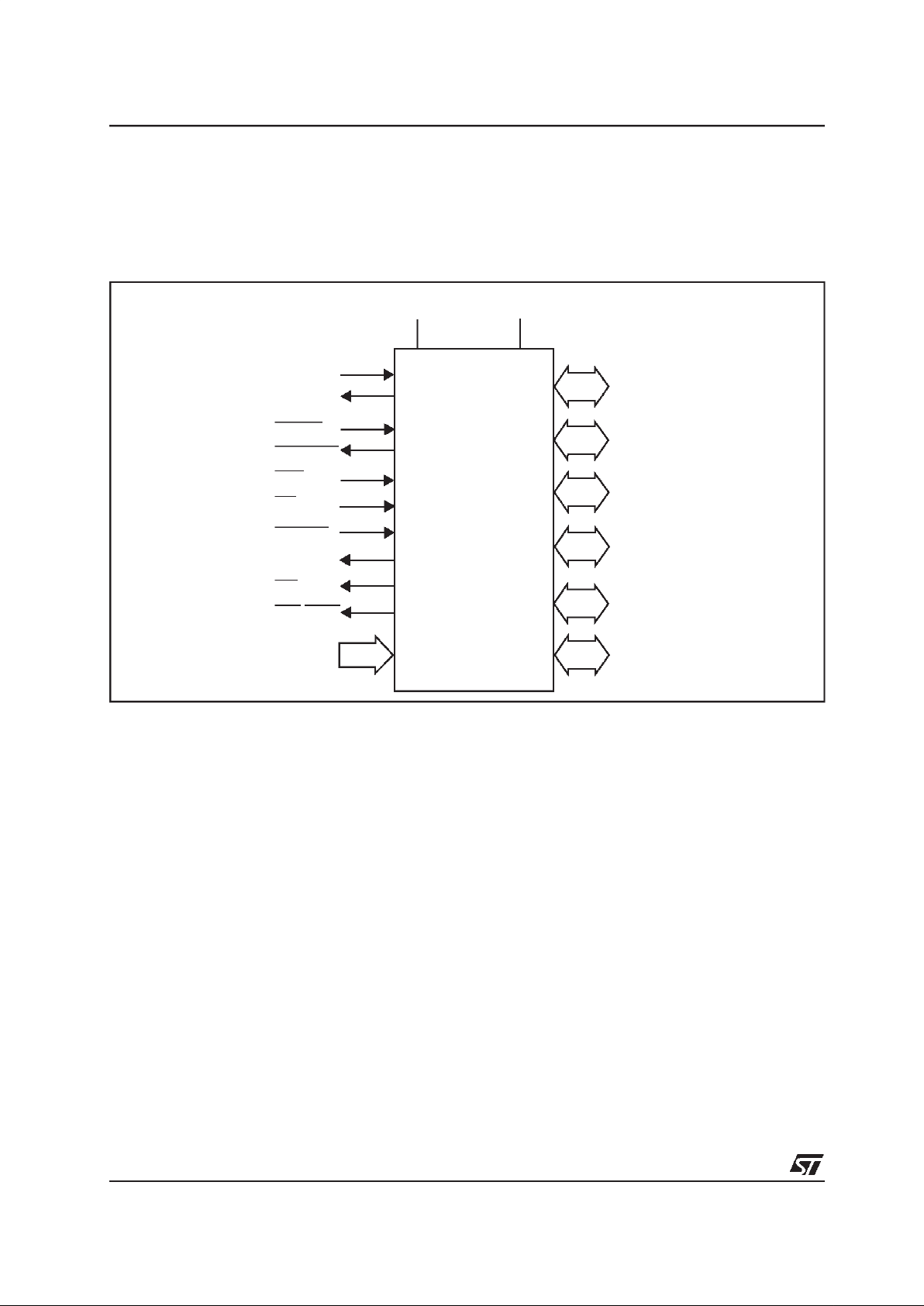

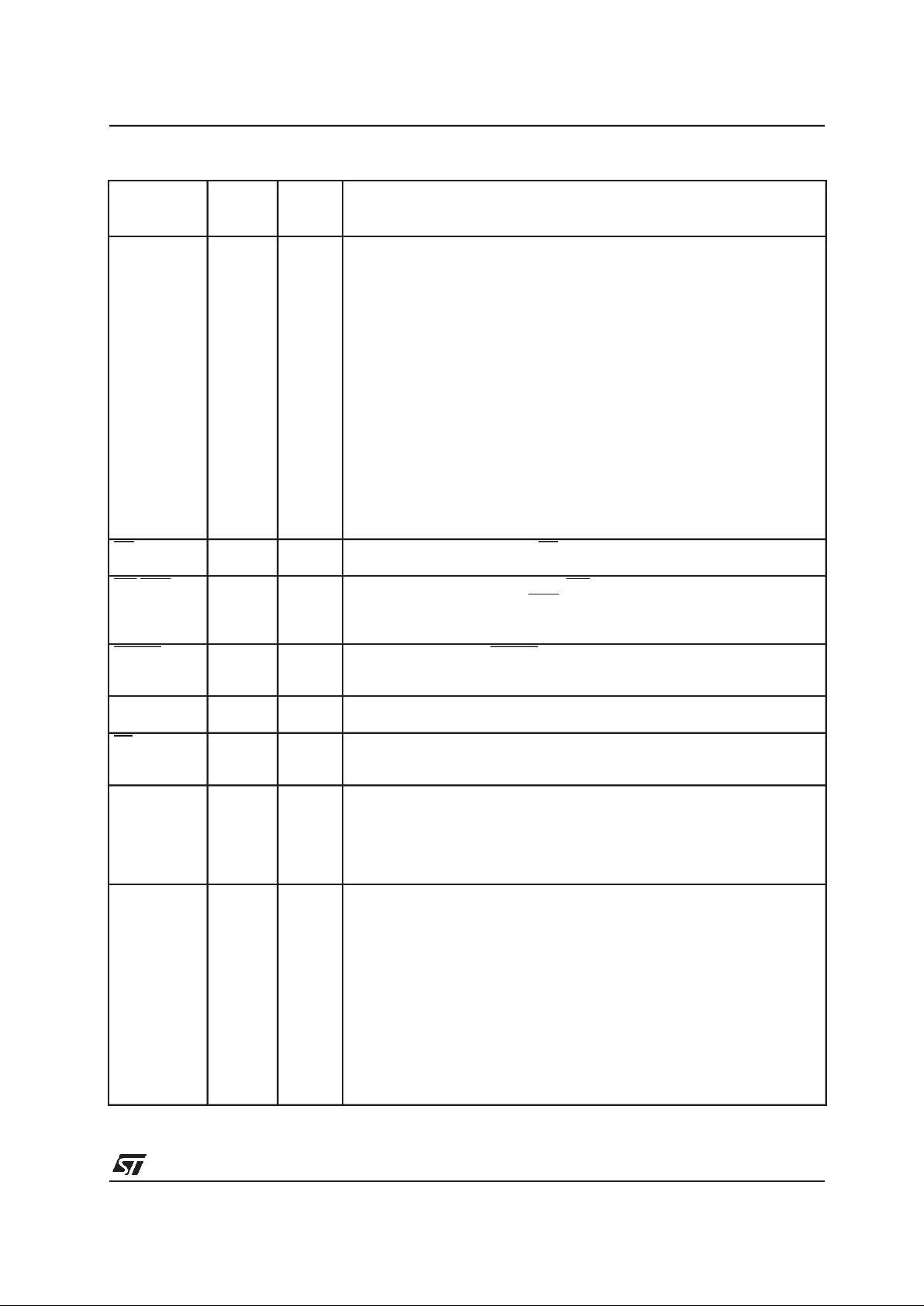

II - PIN DATA

Figure 2 : TQFP pin configuration (top view)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26 2728 2930 3132 3334 35 36 37 3839 40 4142 4344 4546 47484950

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

10099 9897 969594939291 90898887 8685848382818079787776

P5.13/T5IN

P5.14/T4EUD

P5.15/T2EUD

V

SS

XTAL1

XTAL2

V

DD

P3.0

P3.1/T6OUT

P3.2/CAPIN

P3.3/T3OUT

P3.4/T3EUD

P3.5/T4IN

P3.6/T3IN

P3.7/T2IN

P3.8

P3.9

P3.10/TxD0

P3.11/RxD0

P3.12/BHE/WRH

P3.13

P3.15/CLKOUT

P4.0/A16

P4.1/A17

P4.2/A18

P1H.6/A14

P1H.5/A13

P1H.4/A12

P1H.3/A11

P1H.2/A10

V

SS

V

DD

P1H.1/A9

P1H.0/A8

P1L.7/A7

P1L.6/A6

P1L.5/A5

P1L.4/A4

P1L.3/A3

P1L.2/A2

P1L.1/A1

P1L.0/A0

P0H.7/AD15

P0H.6/AD14

P0H.5/AD13

P0H.4/AD12

P0H.3/AD11

P0H.2/AD10

P0H.1/AD9

P0H.0/AD8

P5.12/T6IN

P5.11/T5EUD

P5.10/T6EUD

P2.15/EX7IN

P2.14/EX6IN

P2.13/EX5IN

P2.12/EX4IN

P2.11/EX3IN

P2.10/EX2IN

P2.9/EX1IN

P2.8/EX0IN

P6.7/BREQ

P6.6/HLDA

P6.5/HOLD

P6.4/CS4

P6.3/CS3

P6.2/CS2

P6.1/CS1

P6.0/CS0

NMI

RSTOUT

RSTIN

VDDV

SS

P1H.7/A15

P4.3/A19

V

SS

V

DD

P4.4/A20/SSPCE1

P4.5/A21/SSPCE0

P4.6/A22/SSPDAT

P4.7/A23/SSPCLK

RD

WR/WRL

READY

ALE

EA

V

DD

VSSV

PP

P0L.0/AD0

P0L.1/AD1

P0L.2/AD2

P0L.3/AD3

P0L.4/AD4

P0L.5/AD5

P0L.6/AD6

P0L.7/AD7

V

DD

V

SS

ST10F163

ST10F163

6/58

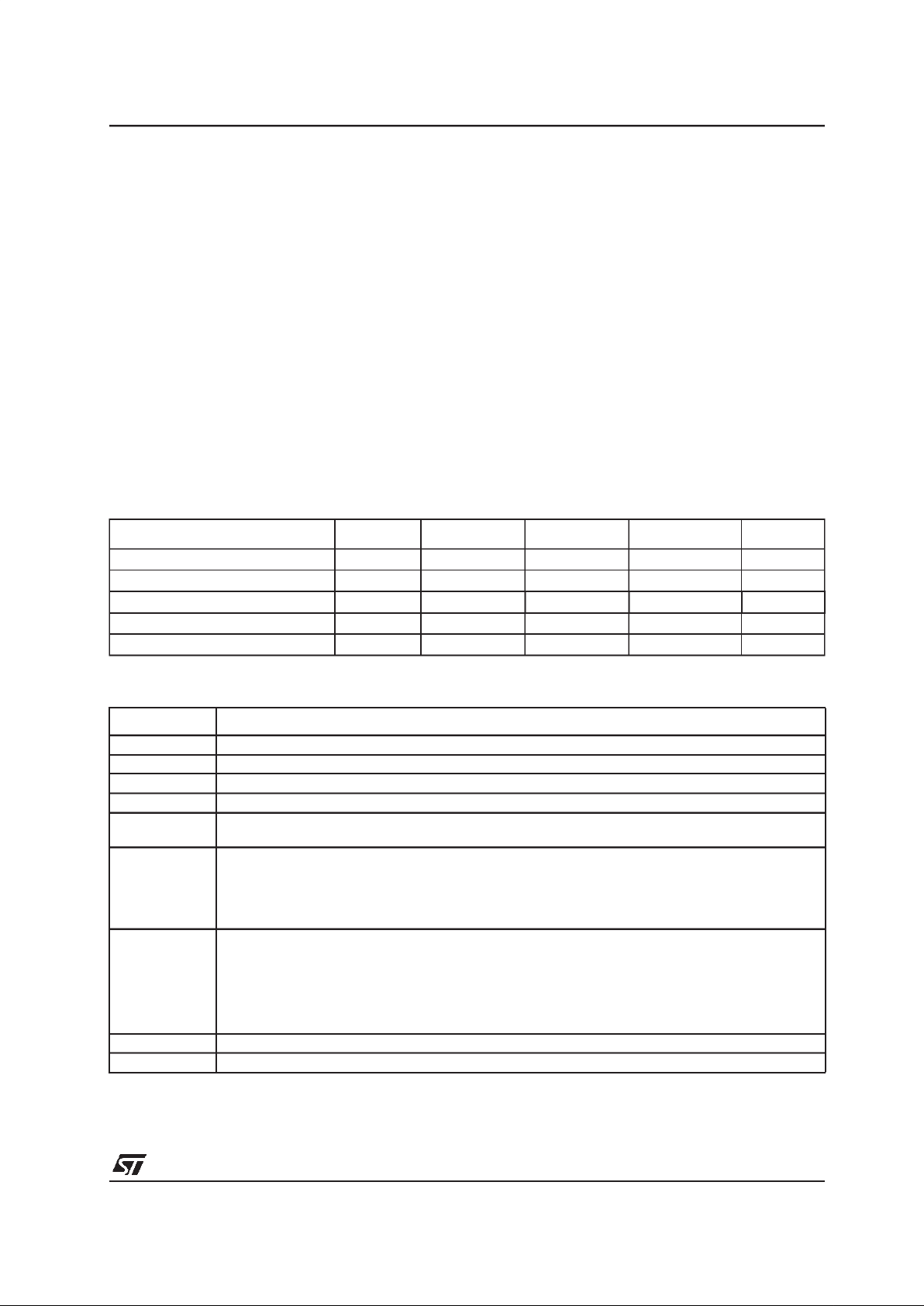

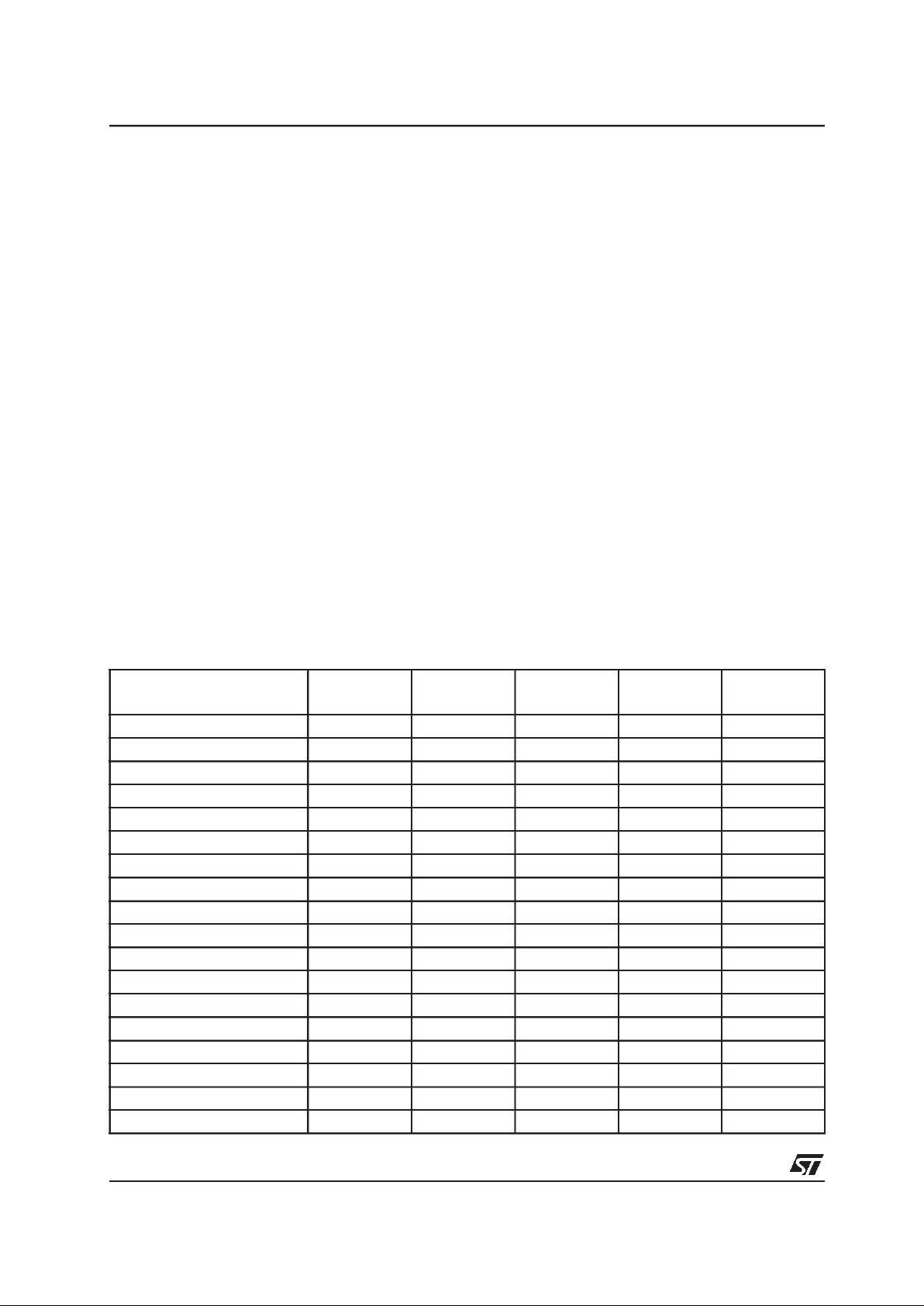

Table 1 : Pin definitions and functions

Symbol

Pin

Number(

TQFP)

Input (I)

Output

(O)

Function

P5.10 – P5.15 98-100

1- 3

I

I

6-bit input-only port with Schmitt-Trigger characteristics.

Port 5 pins alsoserve as timer inputs:

98 I P5.10 T6EUD GPT2 TimerT6 Ext.Up/Down Ctrl.Input

99 I P5.11 T5EUD GPT2 TimerT5 Ext.Up/Down Ctrl.Input

100 I P5.12 T6IN GPT2 Timer T6 Count Input

1 I P5.13 T5IN GPT2 TimerT5 Count Input

2 I P5.14 T4EUD GPT1 Timer T4 Ext.Up/Down Ctrl.Input

3 I P5.15 T2EUD GPT1 Timer T2 Ext.Up/Down Ctrl.Input

XTAL1 5 I XTAL1:Input to the oscillator amplifier and input to the internal clock generator

XTAL2 6 O XTAL2:Output of the oscillator amplifier circuit.

Toclock the device from an external source, drive XTAL1, while leaving XTAL2

unconnected. Minimum and maximum high/low and rise/fall times specified in

the AC Characteristics must be observed.

P3.0 – P3.13,

P3.15

8- 21

22

I/O

I/O

15-bit (P3.14 is missing) bidirectional I/O port, bit-wise programmable for input

or output via direction bits. For a pin configured as input, the output driver is put

into high-impedance state. Port 3 outputs can be configured as push/pull or

open drain drivers. The following Port 3 pins have alternate functions:

9 O P3.1 T6OUT GPT2 TimerT6 ToggleLatch Output

10 I P3.2 CAPIN GPT2 Register CAPREL Capture Input

11 IO P3.3 T3OUT GPT1 Timer T3 Toggle Latch Output

12 I P3.4 T3EUD GPT1 TimerT3 Ext.Up/Down Ctrl.Input

13 I P3.5 T4IN GPT1 TimerT4 Input for Count/Gate/Reload/Capture

14 I P3.6 T3IN GPT1 TimerT3 Count/Gate Input

15 I P3.7 T2IN GPT1 TimerT2 Input for Count/Gate/Reload/Capture

18 O P3.10 TxD0 ASC0 Clock/Data Output (Asyn./Syn.)

19 I/O P3.11 RxD0 ASC0 Data Input (Asyn.) or I/O (Syn.)

20 O P3.12 BHE Ext. Memory High Byte Enable Signal,

O WRH Ext. Memory High ByteWrite Strobe

22 O P3.15 CLKOUT System Clock Output (=CPU Clock)

ST10F163

7/58

P4.0 – P4.7 23-26

29-32

I/O 8-bit bidirectional I/O port, bit-wise programmable for input or output via direc-

tion bits. For a pin configured as input, the output driver is put into high-impedance state. For external bus configuration, Port 4 can be used to output the

segment address lines:

23 O P4.0 A16 Least Significant Segment Addr.Line

... ... ... ... ...

26 O P4.3 A19 Segment Address Line

29 O P4.4 A20 Segment Address Line

O SSPCE1 SSP Chip Enable Line 1

30 O P4.5 A21 Segment Address Line

O SSPCE0 SSP Chip Enable Line 0

31 O P4.6 A22 Segment Address Line

I/O SSPDAT SSP Data Input/Output Line

32 O P4.7 A23 Most Significant Segment Addr. Line

O SSPCLK SSP Clock Output Line

RD 33 O External Memory Read Strobe. RD is activated for every external instruction or

data read access.

WR/WRL 34 O External Memory Write Strobe. In WR-mode this pin is activated for every

external data write access. In WRL-mode this pin is activated for low byte data

write accesses on a 16-bit bus, and for every data write access on an 8-bit bus.

See WRCFG in register SYSCON for mode selection.

READY 35 I Ready Input. When the READY function is enabled, a high level at this pin dur-

ing an external memory access will force the insertion of memory cycle time

waitstates until the pin returns to a low level.

ALE 36 O Address Latch Enable Output. Can be used for latching the address into exter-

nal memory or an address latch in the multiplexed bus modes.

EA 37 I External Access Enable pin. A low level at this pin during and after Reset forces

the device to begin instruction execution out of external memory. A high level

forces execution out of theinternal flash EPROM.

PORT0:

P0L.0-P0L.7

P0H.0-P0H.7

41-48

51-58

I/O Two 8-bit bidirectional I/O ports P0L and P0H, bit-wise programmable for input

or output via direction bits. For a pin configured as input, the output driver is put

into high-impedance state.

In case of an external bus configuration, PORT0 serves as the address (A) and

address/data (AD) bus in multiplexed bus modes and as the data (D) bus in

demultiplexed bus modes.

Table 1 : Pin definitions and functions(continued)

Symbol

Pin

Number(

TQFP)

Input (I)

Output

(O)

Function

Demultiplexed bus modes

Data Path Width:

8-bit 16-bit

P0L.0 – P0L.7: D0 – D7 D0 - D7

P0H.0 – P0H.7: I/O D8 - D15

Multiplexed bus modes

Data Path Width: 8-bit 16-bit

P0L.0 – P0L.7: AD0 – AD7 AD0 - AD7

P0H.0 – P0H.7: A8 – A15 AD8 – AD15

ST10F163

8/58

PORT1:

P1L.0-P1L.7

P1H.0-P1H.7

59-66

67, 68

71-76

I/O Two 8-bit bidirectional I/O ports P1L and P1H, bit-wise programmable for input

or output via direction bits. For a pin configured as input, the output driver is put

into high-impedance state. PORT1 is used as the 16-bit address bus (A) in

demultiplexed bus modes and also after switching from a demultiplexed bus

mode to a multiplexed bus mode.

RSTIN 79 I Reset Input with Schmitt-Trigger characteristics. A low level at this pin for a

specified duration while the oscillator is running resets the device. An internal

pullup resistor permits power-on reset using only a capacitor connected to

V

SS

.

RSTOUT 80 O Internal Reset Indication Output. This pin is set to a low level when the part is

executing either a hardware-, a software- or a watchdog timer reset. RSTOUT

remains low until the EINIT (end of initialization) instruction is executed.

NMI 81 I Non-Maskable Interrupt Input. A high to low transition at this pin causes the

CPU to vector to the NMI trap routine. When the PWRDN (power down) instruction is executed, the NMI pin must be low in order to force the ST10R65 to go

into power down mode. If NMI is high, when PWRDN is executed, the part will

continue to run in normal mode.

If not used, pin NMI should be pulled high externally.

P6.0-P6.7 82-89 I/O 8-bit bidirectional I/O port, bit-wise programmable for input or output via direc-

tion bits. For a pin configured as input, the output driver is put into high-impedance state. Port 6 outputs can beconfigured as push/pull oropen drain drivers.

The following Port 6 pins have alternate functions:

82 O P6.0 CS0 Chip Select 0 Output

... ... ... ... ...

86 O P6.4 CS4 Chip Select 4 Output

87 I P6.5 HOLD External Master Hold Request Input

(Master mode: O, Slave mode: I)

88 I/O P6.6 HLDA Hold Acknowledge Output

89 O P6.7 BREQ Bus Request Output

P2.8 –P2.15 90 - 97 I/O Port 2 is an 8-bit bidirectional I/O port. It is bit-wise programmable for input or

output via direction bits. For a pin configured as input, the output driver is put

into high-impedance state. Port 2 outputs can be configured as push/pull or

open drain drivers.

The following Port 2 pins also serve for alternate functions:

90 I P2.8 EX0IN Fast External Interrupt 0 Input

... ... ... ... ...

97 I P2.15 EX7IN Fast External Interrupt 7 Input

V

PP

40 - Flash programming voltage. This pin accepts the programming voltage for the

on-chip flash EPROM. In the ST10F163, bit 4of SYSCON register serves as an

enable/disable control for the OWD.

V

DD

7, 28,38,

49, 69,

78

- Digital Supply Voltage:

+ 5 V during normal operation and idle mode.

> 2.5 Vduring power down mode

V

SS

4, 27,39,

50, 70,

77

- Digital Ground.

Table 1 : Pin definitions and functions(continued)

Symbol

Pin

Number(

TQFP)

Input (I)

Output

(O)

Function

ST10F163

9/58

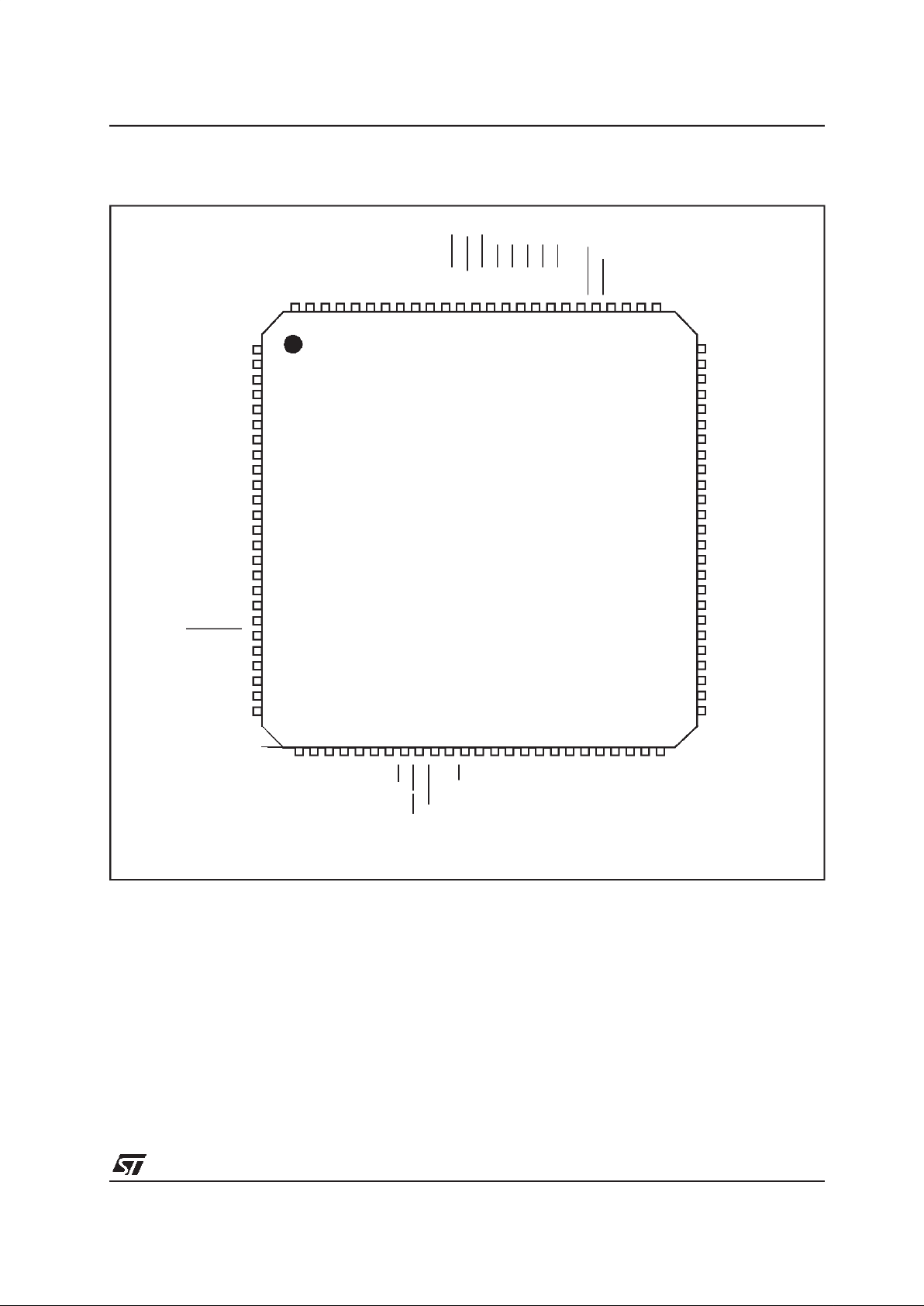

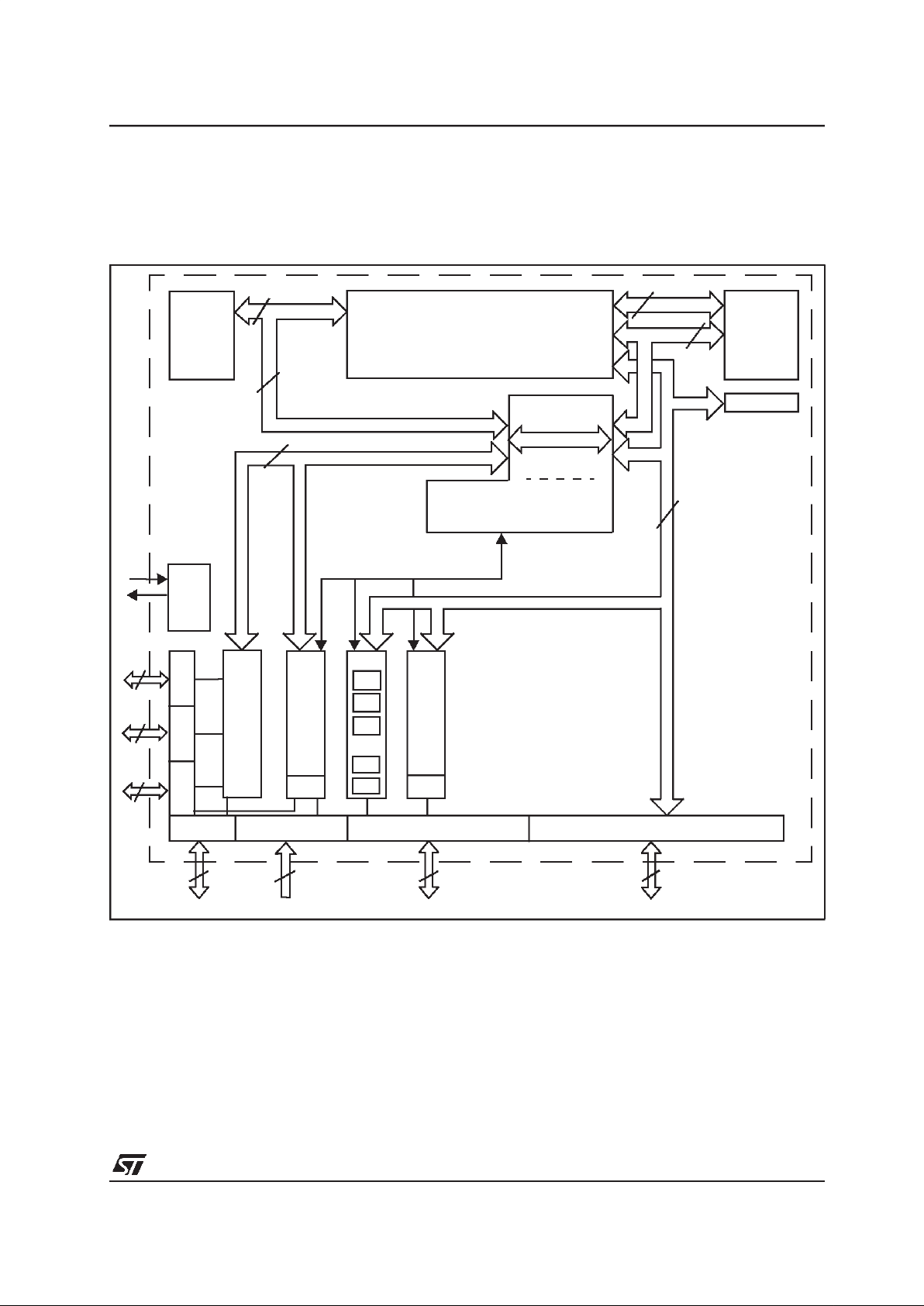

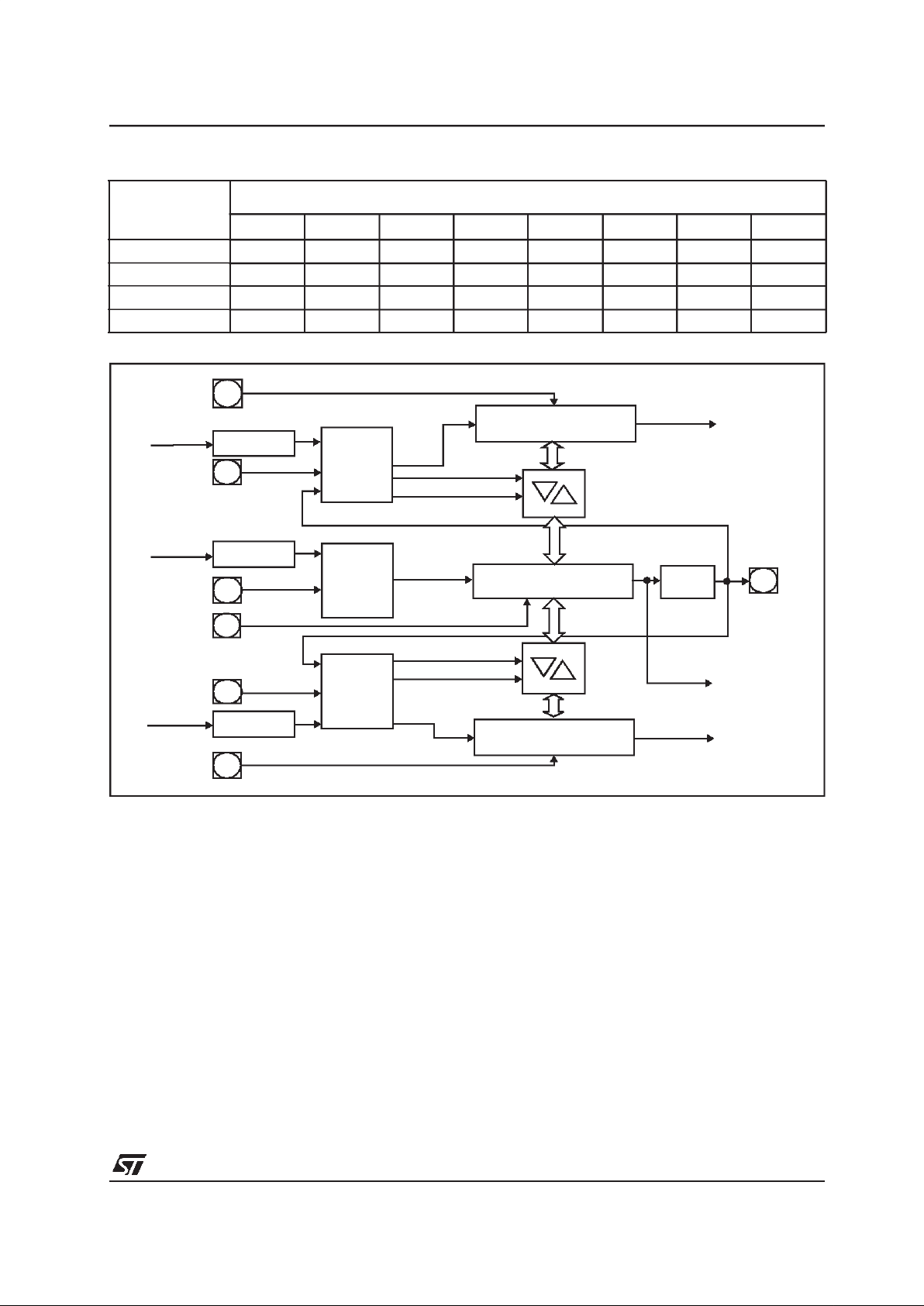

III - FUNCTIONAL DESCRIPTION

The architecture of the ST10F163 combines the

advantages of both RISC and CISC processors

and an advanced peripheral subsystem. The fol-

lowing block diagram gives anoverview of the different on-chip components and of the advanced,

high bandwidth internal busstructure.

Figure 3 : Block diagram

OSC.

Port 0

Port 1Port 4

Port 6

Port 5

Port 3

Port 2

Ext.

Bus

Controller

SSP

BRG

GPT1

T2

T3

T4

GPT2

T5

T6

ASC

(usart)

BRG

Internal

FLASH

Memory

CPU-Core

Internal

RAM

Watchdog

Interrupt Controller

16

16

8

8

8

156

32

16

PEC

16

16

16

16

PLL

ST10F163

10/58

IV - MEMORY ORGANIZATION

The memory spaceof the ST10F163is configured

in a Von-Neumann architecture. Code memory,

data memory, registers and I/O ports are organized within the same linear address space which

includes 16 MBytes. The entire memory space

can be accessed bytewise or wordwise. Particular

portions of the on-chip memory have additionally

been made directly bit addressable.

1 KByte of on-chip RAM is provided as a storage

for user defined variables, for the system stack,

general purposeregister banks and even forcode.

A register bank can consist of up to 16 wordwide

(R0 to R15) and/or bytewide (RL0, RH0, …, RL7,

RH7) General Purpose Registers (GPRs).

1024 bytes (2 * 512 bytes) of the address space

are reserved for the Special Function Register

areas (SFR space and ESFR space). SFRs are

wordwide registers which are used for controlling

and monitoring functions of the different on-chip

units. Unused SFR addresses are reserved for

other/future members of the ST10 family.

In order to meet the needs of system designs

where more memory is required than is provided

on chip, up to 16 MBytes of external RAM and/or

ROM can be connected to themicrocontroller.

V - FLASH MEMORY

The ST10F163 provides 128KBytes of on-chip,

electrically erasable and re-programmable Flash

EPROM. The flash memory is organized in 32 bit

wide blocks. This allows double word instructions

to be fetched in one machine cycle. The flash

memory can be used for both code and data storage. The flash memory is organized into four

banks of sizes 8K, 24K, 48K and 48Kbytes (table

2). Each of these banks can be erased indepen-

dently. This prevents unnecessary erasing of the

whole flash memory whenonly a partial erasing is

required (see Table 2).

Typicaltiming characteristics give 80µs forword or

double word programming and 800 ms for block

erasing, at 25mhz systemclock. the flashmemory

has a typicalendurance of 1000 erasing/programming cycles. the flash memory can be programmed, eitherin a programming board, or inthe

target system. the code to program or erase the

flash memory is executed from an external memory or from theon-chip ram, but not fromthe flash

memory itself. as a flexible and cost-saving alternative, the on-chip bootstrap loader may be used

to load and start the programmingcode.

the following considerations must be taken into

account forprogramming orerasing ‘on-line’in the

target system:

– While operationsare in progress, theflash mem-

ory can not be accessed as usual, no branch

can be made to the flash memory and no data

reads can be taken from the flash memory.

– If the two first blocks (8KB + 24KB) of the flash

memory are mapped to segment 0, no interrupt

or hardware trap must occur during programming or erasing, as this would require a ‘forbidden’ branch to the flashmemory.

A flash memory protection option, whenactivated,

prevents view access to the contents of the ROM

and the on-chip RAM, code operation from within

the flash memory continuesas normal. During the

initialization phase, thefirst two blocks of the flash

memory (8KB + 24KB) can be mapped to segment 0 (addresses 00000h to 07FFFh), or to segment 1 (addresses 10000h to 17FFFh). This

makes itpossible touse external memory for additional system flexibility.

Table 2 : FLASH memory bank organisation

Bank Addresses (Segment 0) Addresses (Segment 1) Size (bytes)

0

1

2

3

000000h to 001FFFh

002000h to 007FFFh

018000h to 023FFFh

024000h to 02FFFFh

010000h to 011FFFh

012000h to 017FFFh

018000h to 023FFFh

024000h to 02FFFFh

8K

24K

48K

48K

ST10F163

11/58

V.1- Programming/erasing with ST Embedded

Algorithm Kernel

In order to secure flash programming and erasing

operations, and also to simplify the software

development for programming and erasing the

Flash, the ST10F163 Flash is programmed or

erased by executing a specific sequence of

instructions (called ‘Unlock Sequence’) with command and parameters loaded into GPRs. The

Unlock Sequence’ invokes embedded kernel routines that checks the validity of the parameters

provided by the user, and decodes the command

(programming or erasing) and executesit.

When performing a programming command, the

Embedded Algorithm Kernel automatically times

the program pulse widths (taking in account the

CPU periodprovided as a parameter by the user)

and verifies proper cell programming.

When performing an erasing command, the

Embedded Algorithm Kernel automatically

pre-programs the bank to be erased if it is not

already programmed. During erase, the Embedded Algorithm Kernel automatically times the

erase pulse widths (taking in account the CPU

period provided as a parameter by the user) and

verifies proper cell erasing.

To start a program/erase operation, the user’s

application must performan ‘Unlock Sequence’ to

trigger the flash ST Embedded Algorithms Kernel

(STEAK). Before using STEAK, proper parameters must be assigned through the R0-R4 registers. TheR0 registeris the command register. The

other registers handle the address and data to be

programmed or sector to be erased. Table 3

defines the command sequence. A definition of

the codes used inTable3 is given in Table 4.

Note The read status for registers R1 to R3 is not used except for the return values, refer to “Return values” on page 13

Table 3 : Command -parameters definition

COMMAND R0 R1 R2 R3 R4

Single word programming 55Ash AddOff W nu 2TCL

Double Word programming DD4sh AddOff DWL DWH 2TCL

Block programming AA5sh BegAddOff EndAddOff SourceAddr 2TCL

Sector Erasing EEEEh 5555h Bnk Bnk 2TCL

Read Status 7777h nu nu nu 2TCL

Table 4 : Code definition

Abbreviation Definition

s Segment of the target flash memory cell

AddOff Segment Offset of thetarget flash memory cell which must be even an value (word-aligned address).

W Data (word) to be written in flash.

DWL,DWH Data (double word, DHL = low word, DWH = high word to be written in Flash,

BegAddOff Segment Offset ofthe FIRST target flash memory word to be written in a multiple programming com-

mand. This value must be even (word-aligned address)

EndAddOff Segment Offset of the LAST Target Flash Memory word to be written in a Multiple programming

command.

Must be even value (word-aligned address). The value D = (EndAddOff - BegAddOff) must be: 0 <=

D < 16384 (ie. up to one page (16 KBytes) can be written in the flash with one multi-word programming command).

SourceAdd Start address for the source data (block) to be programmed. This address uses implicitly the data

paging mechanism of the CPU. SourceAdd value must respect the rules:

- SourceAdd + (EndAddOff - BegAddOff) <16384.

- Page 0 and 1 canNOT be used forsource data if SYSCON bitROMS1 = ‘1’

Note: source data can be located in flash (Inpages 0, 1, 6, 7, 8, 9, 10 or 11 if bit ROMS1 = ‘0’, or in

pages 4, 5, 6, 7, 8, 9,10 or 11if bit ROMS1 = ‘1’.

Bnk Number of the Bank to be erased. Note that for security, R2 and R3 must hold the same value.

2TCL CPU clock period in nseconds (e.g. R4 = 40d means CPU frequency is 25MHz).

ST10F163

12/58

The Flash Unlock Sequence consists of two consecutive writes: the direct addressing mode and

the indirect addressing mode. The FCR must represent an even address in the active address

space of the flash memory. Rwn can be any

unused word GPR (R6 to R15), loaded with a

value that results in the same even address as for

FCR

For easier coding, the standard data paging

addressing schemeis overridden for the two MOV

instruction of the Flash Trigger Sequence (EXTS

instruction). This also locked both standard and

PEC interrupts and class A hardware traps. Must

be replace by ATOMICinstruction if standardDPP

addressing scheme must be preserved.

When the embedded programming/erasing algorithm returns to trigger point, information can be

collected through registerR0 so the user can take

specific actions. Table 5 lists all of the error codes

that can be returned in R0.

Note The Flash Embedded Presto Algorithms require at least 45 words on the Internal System Stack for proper operation. The program

verifies itself that there is enough free space on the System Stack before performing a programming or erasing operation (by

comparing SP value with STKOV+90d).

EXTS #1, #2 ; assumes flash is

mapped in seg 1

MOV FCR, R7 ; first part

MOV [R7], R7 ; second part

Table 5 : Error code definition

ERROR CODE MEANING

00h Operation was successful

01h ROMEN bit inside SYSCON is not set

02h Vpp voltage not present

03h Programming operation failed

04h Address value (R1) incorrect: not in Flash address area or odd

05h CPU period out of range (must be between 10 ns to 1000 ns)

06h Not enough free space on system stack for proper operation

07h Incorrect bank number (R2,R3) specified

08h Erase operation failed

09h Bad source address for multi-word programming command

0Ah Bad number of words to be copied in multi-word programming command: one

destination will be outof flash, or one source operand will be out of the source page

FFh Unknown or bad command

ST10F163

13/58

V.1.1- Return values

After a single or double word programming command, R0 contains error code, R1 remains

unchanged, R2 will contain the data in Flash for

location Segment+Segment Offset (R0.[3:0] with

R1), R3 will contain the data in Flash for location

Segment+Segment Offset +2 (R0[3:0] withR1+2),

R4 to R15 remain unchanged.

After a multi-word programming command, R0

contains error code, R1 will contains the last segment offset address of the last written word in

flash (failing flash address if R0 is not equal to

zero), R2 and R3 are undefined, R4 to R15

remain unchanged.

After erasing command, only R4 to R15 remain

unchanged, R0 will contain error code, R1 to R3

are undefined.

After status read command, R0 contains error

code, R1 contains flash embedded revision, R2

and R3 contains circuit identifiers (R2 = #0787h

and R3 = #0101h for this device), R4 to R15

remain unchanged.

V.1.2- Programming examples

Programming a double word:

Note For easier coding, the standard data paging addressing scheme is overrides for the two MOV instruction of the Flash Trigger

Sequence (EXTS instruction).This also locked both standard and PEC interrupts and class A hardware traps. Must be replace by

ATOMIC instruction if standard DPP addressing scheme must be preserved.

Programming a block of data:

Address 01’9000h to 01’9FFEh (inclusive) is to be programmed. Source data (data to be copied into

flash) is located in external RAM from address 03’1000h (to 03’1FFEh, implicitly):

; code hereafter assumes that flash is mapped in segment 1

; i.e. bit ROMS1 = ‘1’ in SYSCON register

; Flash must also be enabled, i.e. bit ROMEN = ‘1’ in SYSCON.

MOV R0, #PROGDW ; DD4xh: Double word programming command

OR R0, #01h ; Selects segment 1 in flash memory

MOV R1, #00224h ; Address to be programmed is 01’0224h

MOV R2, #03456h ; Data to be programmed at 01’0224h

MOV R3, #04567h ; Data to be programmed at 01’0226h

MOV R4, #050d ; 50ns is 20 MHz CPU clock frequency

MOV R7, #08000h ; R7 used for Flash trigger sequence

#define FCR 08000h

; Flash Unlock Sequence: consists in two consecutive writes, with the direct

addressing mode and then the indirect addressing mode. FCR must represent an

even address in the active address space of the Flash memory, and Rwn can be

any unused word GPR (R6 to R15)loaded with a value resulting in the same even

address than FCR

EXTS #1, #2 ; flash can be mapped in segment 0 or 1

MOV FCR, R7 ; first part

MOV [R7], R7 ; second part

NOP ; WARNING: place 2 NOP operations after

NOP ; the Unlock sequence to avoid all possible

; pipeline conflict in STEAK programs

; code hereafter assumes that flash is mapped in segment 1

; i.e. bit ROMS1 = ‘1’ in SYSCON register

; Flash must also be enabled, i.e. bit ROMEN = ‘1’ in SYSCON.

MOV R0, #PROGMW ; AA5xh: Multi word programming command

OR R0, #01h ; Selects segment 1 in flash memory

ST10F163

14/58

V.2- Flash memory configuration

The default memory configuration is determined

by the state of the EA pin at reset. This value is

stored in the Internal ROM enable bit: ROMEN of

the SYSCON Register.

When ROMEN=0, the internal ROM is disabled

and externalROM is used for start-up control.The

first 32KBytes of the flash memory area must be

re-mapped to segment 1, to enabletheir later use.

This is done by setting the ROMS1 bit of

SYSCON to 0. This is done by the externally supplied program, before the execution of the EINIT

instruction.

If program execution startsfrom external memory,

but access to the flash memory (re-mapped to

Bank 1) is required later, one of the following values has to be written to the SYSCON register,

before the end of initialization:

– If flash is to be mapped to segment 1:

xxx100xxxxxxxxxxb

(ROMS1=1,SGTDIS=0)

– If flash is to be mapped to segment 0:

xxx000xxxxxxxxxxb

(ROMS1=0,SGTDIS=0)

All other parts of the flash memory (addresses

18000h - 1FFFFh) remain unaffected.

The SGTDIS Segmentation Disable/Enable must

be set to 0 so that the 64KBytes of on-chip memory can be used in addition to the external boot

memory. The correct procedure for changing the

segmentation registers must be observed, to prevent unwanted trap conditions:

– Instructions that configure the internal memory

must only be executed from external memory

or from the internal RAM.

– Whenever the internalmemory is disabled,ena-

bled or re-mapped, the DPPs must be explicitly

(re)loaded to enable correct data accesses to

the internal memory and/or externalmemory.

V.3 - Flash protection

The flash protection mode, prevents the reading

of data operands in the flashmemory by anything

but a program executed from the flash memory

itself. Flash protection mode permits program

branches from, or into the flash memory, but does

not permit erasing and programming of the flash

memory.

Flash protection is controlled by the Protection

UPROM Programming Bit(UPROG). UPROG is a

’hidden’ one-time programmable bit. It is only

accessible in a special mode, entered, for example, via a flash EPROM programming board. If

UPROG is setto ‘1’,flash protection isactive after

reset. By default flash protection is disabled

(UPROG=0).

For deactivation of flash protection, where the

flash memory has to be reprogrammed with

updated program/variables, a zero value must be

written at every even address in the active

address spaceof the flash memory.This write can

only be done by an instruction executed from the

internal flash memory itself, e.g. MOV

FLASH,ZEROS.

MOV R1, #09000h ; First Flash Segment Offset Address

MOV R2, #09FFEh ; Last Flash Segment Offset Address

MOV R3, #01000h ; Source data address: use DPP2 as

; data page pointer

SCXT DPP2,#0Ch ; Source is in page 12 (0Ch): save previous

; DPP2 value and load it with source page

; number

MOV R4, #050d ; 50ns is 20 MHz CPU clock frequency

MOV R7, #08000h ; R7 used for Flash trigger sequence

#define FCR 08000h

EXTS #1, #2 ; flash can be mapped in segment 0 or 1

MOV FCR, R7 ; first part

MOV [R7], R7 ; second part

NOP ; WARNING: place 2 NOP operations after

NOP ; the Unlock sequence to avoid all possible

; pipeline conflict in STEAK programs

POP DPP2 ; restore DPP2

ST10F163

15/58

VI - EXTERNAL BUS CONTROLLER

All of the external memory accesses are performed by a particular on-chip External Bus Controller (EBC). It can be programmed either to

Single Chip Mode when no external memory is

required, or to one of four different external memory access modes:

– 16-/18-/20-/24-bit Addresses, 16-bit Data, De-

multiplexed

– 16-/18-/20-/24-bit Addresses, 16-bit Data, Multi-

plexed

– 16-/18-/20-/24-bit Addresses, 8-bit Data, Multi-

plexed

– 16-/18-/20-/24-bit Addresses, 8-bit Data, De-

multiplexed

In the demultiplexed bus modes, addresses are

output on PORT1 and data is input/output on

PORT0 or P0L, respectively. In the multiplexed

bus modes both addresses and data use PORT0

for input/output.

Important timing characteristics of the external

bus interface (Memory Cycle Time, Memory

Tri-State Time, Length of ALE and Read Write

Delay) have been made programmable. This

gives the choice of a wide range of different types

of memories and external peripherals. In addition,

up to 4 independent address windows may be

defined (via register pairs ADDRSELx / BUSCONx).

This gives access to different resources with different bus characteristics. These address windows are arranged hierarchically where

BUSCON4 overrides BUSCON3 and BUSCON2

overrides BUSCON1.

All accesses to locations not covered by these 4

address windows are controlled by BUSCON0.

Up to 5 external CS signals (4 windows plus

default) canbe generated in order tosave external

glue logic. Access to very slow memories is supported via a particular ‘Ready’ function.

A HOLD/HLDA protocol is available for bus arbitration so that external resources can be shared

with other bus masters. The bus arbitration is

enabled by setting bit HLDEN in register

SYSCON. After setting HLDEN once, pins

P6.7...P6.5 (BREQ, HLDA, HOLD) are automatically controlled by the EBC. In Master Mode

(default after reset) the HLDA pin is an output.

By setting bit DP6.7 to’1’ the Slave Mode is

selected where pin HLDA is switched to input.

This allows to directly connect the slave controller

to another master controller withoutglue logic.

For applications which require less than 16

MBytes of external memory space, this address

space can be restricted to 1 MByte, 256 KByte or

to 64 KByte. In this case Port 4 outputs four, two

or no address lines at all. If an address space of

16 MBytes is used,it outputs all 8 address lines.

Note When the on-chip SSP Module is to be used the segment

address output on Port 4 must be limited to 4 bits (i.e.

A19...A16) in order to enable the alternate function of the

SSP interface pins.

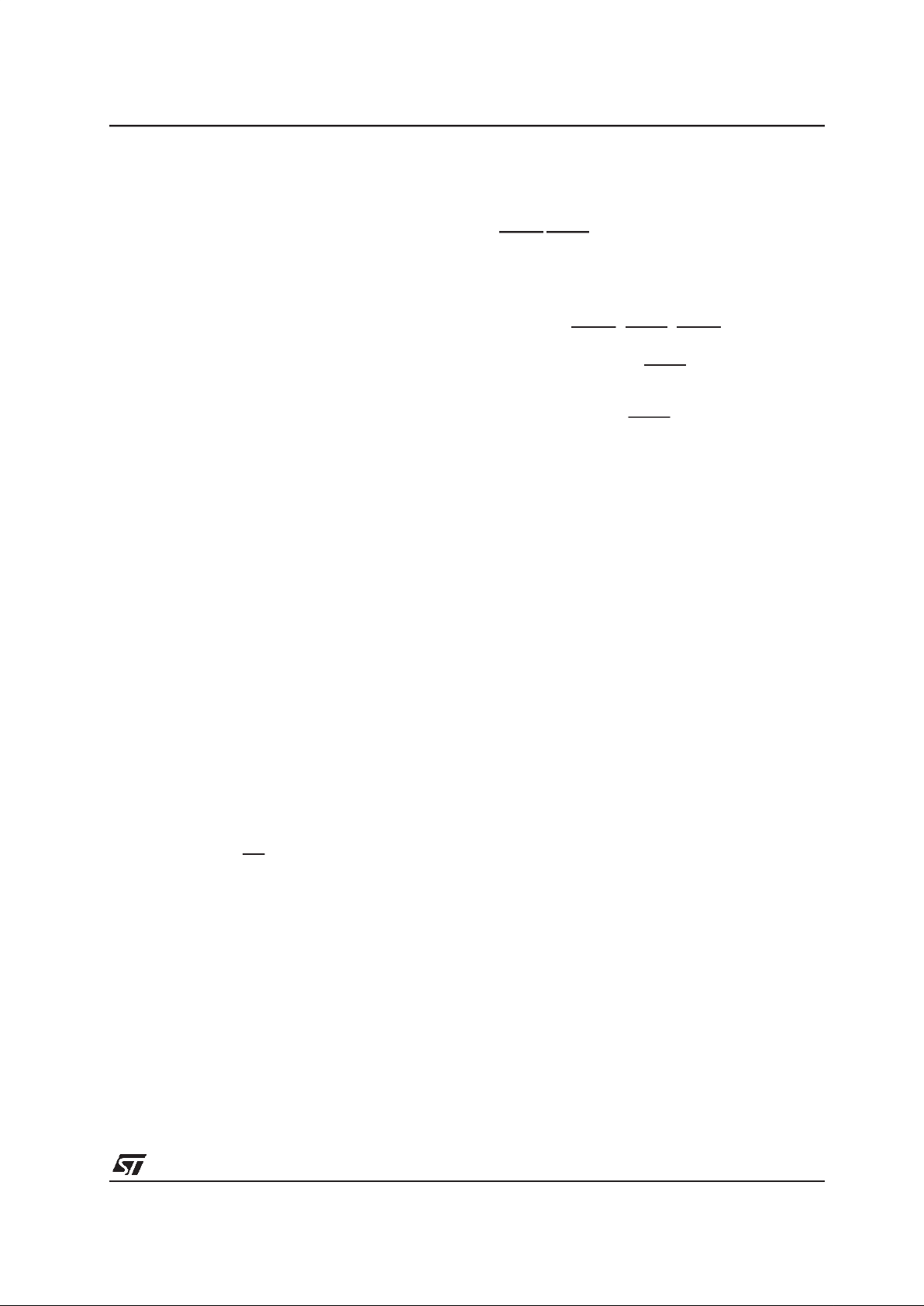

VI.1 - Programmable chip select timing control

The position of the CSx lines can be changed by

setting theCSCFG bit inthe SYSCON register. By

default the CSx lines change half a CPU clock

cycle after the rising edge of ALE (20ns @ f

CPU

=

25 MHz). With the CSCFG bit set (section

Figure VII -

), the CSx lines change with the rising

edge of ALE. In this case, the CSx lines and

address lines change at the same time.

ST10F163

16/58

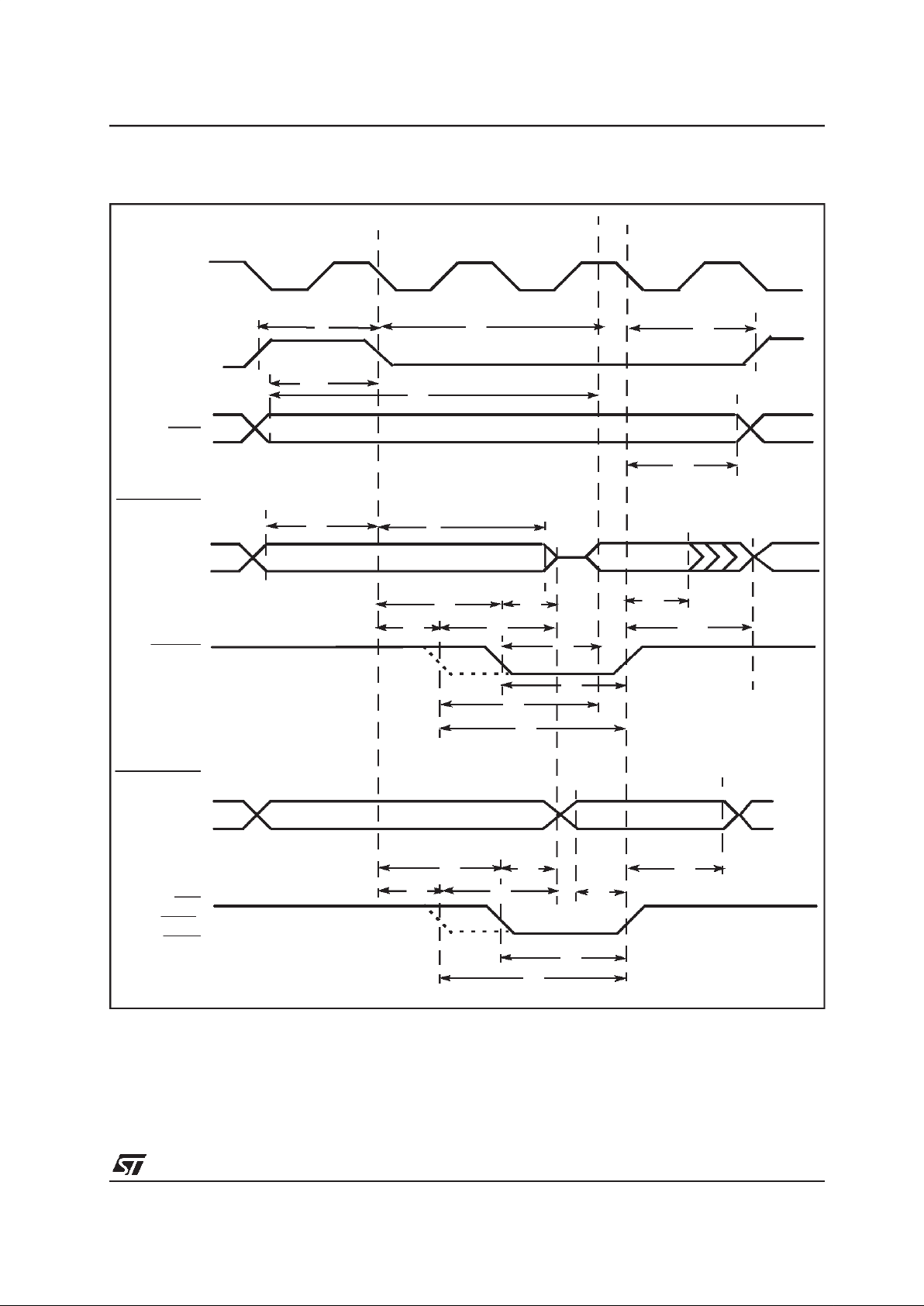

Figure 4 : Chip selectdelay

Delay

Normal CSx

RD

Address (P1)

ALE

Segment (P4)

NormalDemulti plexed

Bus Cycle

ALE Lengthen Demultiplexed

BusCycle

Unlatched CSx

WR

Data Data

Data

BUS(P0)

BUS(P0)

Read/Write

Delay

Read/Write

Data

ST10F163

17/58

VII - CENTRAL PROCESSING UNIT (CPU)

The main core of the CPU consists of a 4-stage

instruction pipeline, a 16-bit arithmetic and logic

unit (ALU) and dedicated SFRs. Additional hardware has been added for a separate multiply and

divide unit, a bit-mask generator and a barrel

shifter.

Based on these hardware provisions, most of the

ST10F163’s instructions can be executed in one

machine cycle. This requires 80ns at 25MHz CPU

clock. For example, shift and rotate instructions

are always processed in one machine cycle independent of the number of bits to be shifted. All

multiple-cycle instructions have been optimized

for speed: branches in 2 cycles,a 16 x 16 bit multiplication in 5 cycles and a 32-/16 bit division in

10 cycles. The ‘Jump Cache’ pipeline optimization, reduces the execution time of repeatedly performed jumps in aloop, from 2 cycles to 1 cycle.

The CPU includes an actual register context.This

consists of up to 16 wordwide GPRs physically

allocated in the on-chip RAM area. A Context

Pointer (CP) register determines the base

address ofthe activeregister bank to be accessed

by the CPU. The number of register banks is only

restricted by the available internal RAM space.

For easy parameter passing, one register bank

may overlap others.

A system stack ofup to 1024 bytes is provided as

a storage for temporary data. The system stack is

allocated in the on-chip RAM area, and it is

accessed by the CPU via the stack pointer (SP)

register. Two separate SFRs, STKOV and

STKUN, are implicitly compared against the stack

pointer value upon each stack access for the

detection of a stack overflow or underflow.

The basic instruction length is either 2 or 4 bytes.

Possible operand typesare bits, bytes andwords.

A variety of direct, indirect or immediate addressing modes exist.

Figure 5 : CPU block diagram

16

16

32

ROM

Internal

RAM

1KByte

R15

R0

General

Purpose

Registers

R0

R15

MDH

MLD

Barrel-Shift

Mul./Div.-HW

Bit-Mask Gen.

ALU

16-Bit

Context Ptr

SP

STKOV

STKUN

Exec. Unit

Instr. Ptr

Instr. Reg

4-Stage

Pipeline

PSW

SYSCON

BUSCON 0

BUSCON 1

BUSCON 2

BUSCON 3

BUSCON 4

ADDRSEL 1

ADDRSEL 2

ADDRSEL 3

ADDRSEL 4

Data Pg. Ptrs Code Seg. Ptr.

CPU

128KBytes

FLASH

ST10F163

18/58

VIII - INTERRUPT SYSTEM

With an interrupt response time from 200 ns to

480ns (in the case of internal program execution),

the ST10F163 reacts quickly to the occurrence of

non-deterministic events.

The architecture of the ST10F163 supports several mechanisms for fast and flexible response to

service requests that can be generated from various sources internal or external to the microcontroller. Any of these interrupt requests can be

programmed to being serviced by the Interrupt

Controller or by the Peripheral Event Controller

(PEC). In a standard interrupt service, program

execution is suspended and a branch to the interrupt vector table is performed. For a PEC service,

just one cycle is ‘stolen’ from the current CPU

activity. A PEC service is a single byte or word

data transfer between any two memory locations

with an additional increment of either the PEC

source or the destination pointer. An individual

PEC transfer counter is decremented for each

PEC service, except for the continuous transfer

mode. When this counter reaches zero, a standard interrupt is performed to the corresponding

source related vector location. PEC services are

suited to, for example, the transmission or reception of blocks of data. The ST10F163 has 8 PEC

channels, each of which offers fast interrupt-driven data transfer capabilities.

A separate control register which contains an

interrupt request flag, an interrupt enable flag and

an interrupt priority bitfield, exists for each of the

possible interrupt sources. Via its related register,

each source can be programmed to one ofsixteen

interrupt priority levels. Once having been

accepted by the CPU, an interrupt service can

only be interrupted by a higher prioritized service

request. For the standard interrupt processing,

each of the possible interrupt sources has a dedicated vector location.

Fast external interrupt inputs are provided to service external interrupts with high precision

requirements. These fast interrupt inputs, feature

programmable edge detection (rising edge, falling

edge or both edges).

Software interruptsare supportedby means of the

‘TRAP’ instruction in combination with an individual trap (interrupt) number.

Table 6 shows all of the possible ST10F163 interrupt sources and the corresponding hardware-related interrupt flags, vectors, vector

locations and trap (interrupt) numbers:

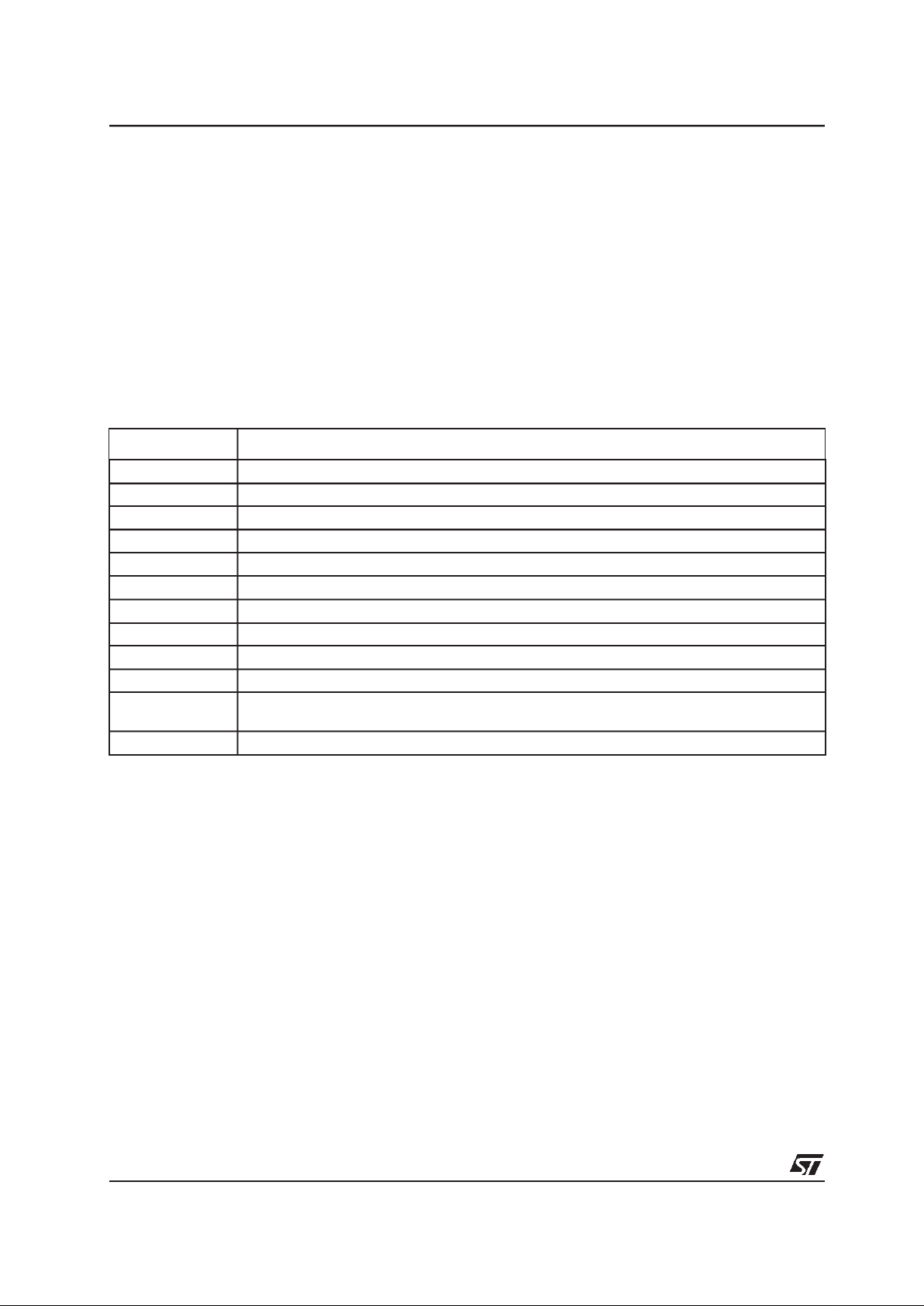

Table 6 : List of possible interrupt sources, flags,vector and trap numbers

Source of Interrupt or PEC

Service Request

Request

Flag

Enable

Flag

Interrupt

Vector

Vector

Location

Trap

Number

External Interrupt 0 CC8IR CC8IE CC8INT 00’0060h 18h

External Interrupt 1 CC9IR CC9IE CC9INT 00’0064h 19h

External Interrupt 2 CC10IR CC10IE CC10INT 00’0068h 1Ah

External Interrupt 3 CC11IR CC11IE CC11INT 00’006Ch 1Bh

External Interrupt 4 CC12IR CC12IE CC12INT 00’0070h 1Ch

External Interrupt 5 CC13IR CC13IE CC13INT 00’0074h 1Dh

External Interrupt 6 CC14IR CC14IE CC14INT 00’0078h 1Eh

External Interrupt 7 CC15IR CC15IE CC15INT 00’007Ch 1Fh

GPT1 Timer 2 T2IR T2IE T2INT 00’0088h 22h

GPT1 Timer 3 T3IR T3IE T3INT 00’008Ch 23h

GPT1 Timer 4 T4IR T4IE T4INT 00’0090h 24h

GPT2 Timer 5 T5IR T5IE T5INT 00’0094h 25h

GPT2 Timer 6 T6IR T6IE T6INT 00’0098h 26h

GPT2 CAPREL Register CRIR CRIE CRINT 00’009Ch 27h

ASC0 Transmit S0TIR S0TIE S0TINT 00’00A8h 2Ah

ASC0 Transmit Buffer S0TBIR S0TBIE S0TBINT 00’011Ch 47h

ASC0 Receive S0RIR S0RIE S0RINT 00’00ACh 2Bh

ASC0 Error S0EIR S0EIE S0EINT 00’00B0h 2Ch

ST10F163

19/58

The ST10F163 provides an excellent mechanism

to identify and to process exceptions orerror conditions that arise during run-time, called‘Hardware

Traps’.

Hardware traps cause an immediate

non-maskable system reaction which is similar to

a standard interrupt service (branching to a dedicated vector table location). The occurrence of a

hardware trap is additionally signified by an indi-

vidual bit in the trap flag register (TFR). Except

when another higher prioritized trap service is in

progress, a hardware trap will interrupt any actual

program execution. In turn, hardware trap services can normally not be interrupted by standard

or PEC interrupts.

Table 7 shows all of the possible exceptions or

error conditions that can arise during run time.

SSP Interrupt XP1IR XP1IE XP1INT 00’0104h 41h

PLL Unlock / OWD XP3IR XP3IE XP3INT 00’010Ch 43h

Table 6 : List of possible interrupt sources, flags,vector and trap numbers (continued)

Source of Interrupt or PEC

Service Request

Request

Flag

Enable

Flag

Interrupt

Vector

Vector

Location

Trap

Number

Table 7 : Exceptions or error conditions that can arise during run-time

Exception Condition

Trap

Flag

Trap

Vector

Vector

Location

Trap

Number

Trap

Priority

Reset Functions:

Hardware Reset RESET 00’0000h 00h III

Software Reset RESET 00’0000h 00h III

Watchdog Timer Overflow RESET 00’0000h 00h III

Class A Hardware Traps:

Non-Maskable Interrupt NMI NMITRAP 00’0008h 02h II

Stack Overflow STKOF STOTRAP 00’0010h 04h II

Stack Underflow STKUF STUTRAP 00’0018h 06h II

Class B Hardware Traps:

Undefined Opcode

UNDOPC BTRAP 00’0028h 0Ah I

Protected Instruction Fault

PRTFLT BTRAP 00’0028h 0Ah I

Illegal Word Operand Access

ILLOPA BTRAP 00’0028h 0Ah I

Illegal Instruction Access

ILLINA BTRAP 00’0028h 0Ah I

Illegal External Bus Access

ILLBUS BTRAP 00’0028h 0Ah I

Reserved [2Ch –3Ch] [0Bh – 0Fh]

Software Traps:

TRAP Instruction

Any

[00’0000h–

00’01FCh]

in steps of4h

Any

[00h – 7Fh]

Current

CPU

Priority

ST10F163

20/58

IX - GENERAL PURPOSE TIMER(GPT) UNIT

The GPT unit is a flexible multifunctional timer/

counter structure which is used for time related

tasks such as event timing and counting, pulse

width and duty cycle measurements,pulse generation, or pulse multiplication. The GPT unit contains five 16-bit timersorganized intotwo separate

modules GPT1 and GPT2. Each timer in each

module may operate independently in several different modes, or may be concatenated with

another timer of the same module.

IX.1 - GPT1

Each of the three timers T2, T3, T4 of module

GPT1 can be configured individually for one of

three basic modes of operation: timer, gated

timer, and counter mode. In Timer Mode, the

input clock for a timer is derived from the CPU

clock, divided by a programmable pre-scaler. In

counter Mode a timer is clocked in reference to

external events. Gated timer modesupports pulse

width or duty cycle measurement,where the operation of a timer is controlled by the ‘gate’ level on

an external input pin. Each timer has one associated port pin (TxIN) which servesas gate or clock

input.

Table 8 lists the timer input frequencies, resolution

and periods for each pre-scaler option at 25 MHz

CPU clock (see Table 8).

The count direction (up/down) for each timer is

programmable by software or is altered dynamically by an external signal on a port pin (TxEUD).

For example, this facilitates position tracking.

Timer T3has output toggle latches (TxOTL)which

changes state on each timer over-flow/underflow.

The state of this latch may be output on port pins

(TxOUT) e. g. for time out monitoring of external

hardware components, or may be used internally

to clock timers T2 and T4 for measuring long time

periods with high resolution.

In addition to their basic operating modes, timers

T2 and T4 may be configured as reloador capture

registers for timer T3. When used as reload or

capture registers, timers T2 and T4 are stopped.

The content of timer T3 is captured into T2 or T4

in response to a signal at their associated input

pins (TxIN). Timer T3 is reloaded with the contents of T2 or T4, triggered, either by an external

signal or by a selectable state transition of its toggle latch, T3OTL. When both T2 and T4 are configured to alternately reload T3 on opposite state

transitions of T3OTL with the low and high times

of a PWM signal, this signal can be constantly

generated without software intervention.

IX.2 - GPT2

The GPT2 module provides precise event control

and time measurement. It includestwo timers (T5,

T6) anda capture/reload register (CAPREL). Both

timers can be clocked with an input clock which is

derived from the CPU clock via a programmable

prescaler or with external signals. The count

direction (up/down) for each timer is programmable by software or may additionally be altered

dynamically by an external signal on a port pin

(TxEUD). Concatenation of the timers is supported via the output togglelatch (T6OTL) of timer

T6 which changes its state on each timer overflow/underflow.

The state of this latch may be used to clock timer

T5, or it may beoutput on aport pin (T6OUT).The

overflows/underflows of timer T6 can additionally

be used to clock the CAPCOM timers T0 or T1,

and to cause a reload from the CAPREL register.

The CAPREL registermay capture the contents of

timer T5 based on an external signal transition on

the corresponding port pin (CAPIN), and timer T5

may optionally be cleared after the capture procedure. This allows absolute time differences to be

measured or pulse multiplication to be performed

without software overhead.

Table 9 lists the timer input frequencies, resolution

and periods for each pre-scaler option at 25 MHz

CPU clock.

Table 8 : GPT1timer input frequencies, resolution and periods

f

CPU

= 25MHz

Timer InputSelection T2I / T3I / T4I

000

B

001

B

010

B

011

B

100

B

101

B

110

B

111

B

Pre-scaler factor 8 16 32 64 128 256 512 1024

Input Frequency 3.125MHz 1.563MHz 781.3kHz 390.6kHz 195.3kHz 97.66kHz 48.83kHz 24.41kHz

Resolution 320 ns 640 ns 128 ns 2.56 µs 5.12 µs 10.24 µs 20.48 µs 40.96 µs

Period 21.0 ms 41.9 ms 83.9 ms 167 ms 336 ms 671 ms 1.34 s 2.68 s

ST10F163

21/58

Table 9 : GPT2 timer input frequencies, resolution andperiod

f

CPU

= 25MHz

Timer Input Selection T5I / T6I

000

B

001

B

010

B

011

B

100

B

101

B

110

B

111

B

Pre-scaler factor 4 8 16 32 64 128 256 512

Input Frequency 6.25MHz 3.125MHz 1.563MHz 781.3kHz 390.6kHz 195.3kHz 97.66kHz 48.83kHz

Resolution 160ns 320 ns 640 ns 128 ns 2.56 µs 5.12 µs 10.24 µs 20.48 µs

Period 10.49ms 21.0 ms 41.9 ms 83.9 ms 167 ms 336 ms 671 ms 1.34 s

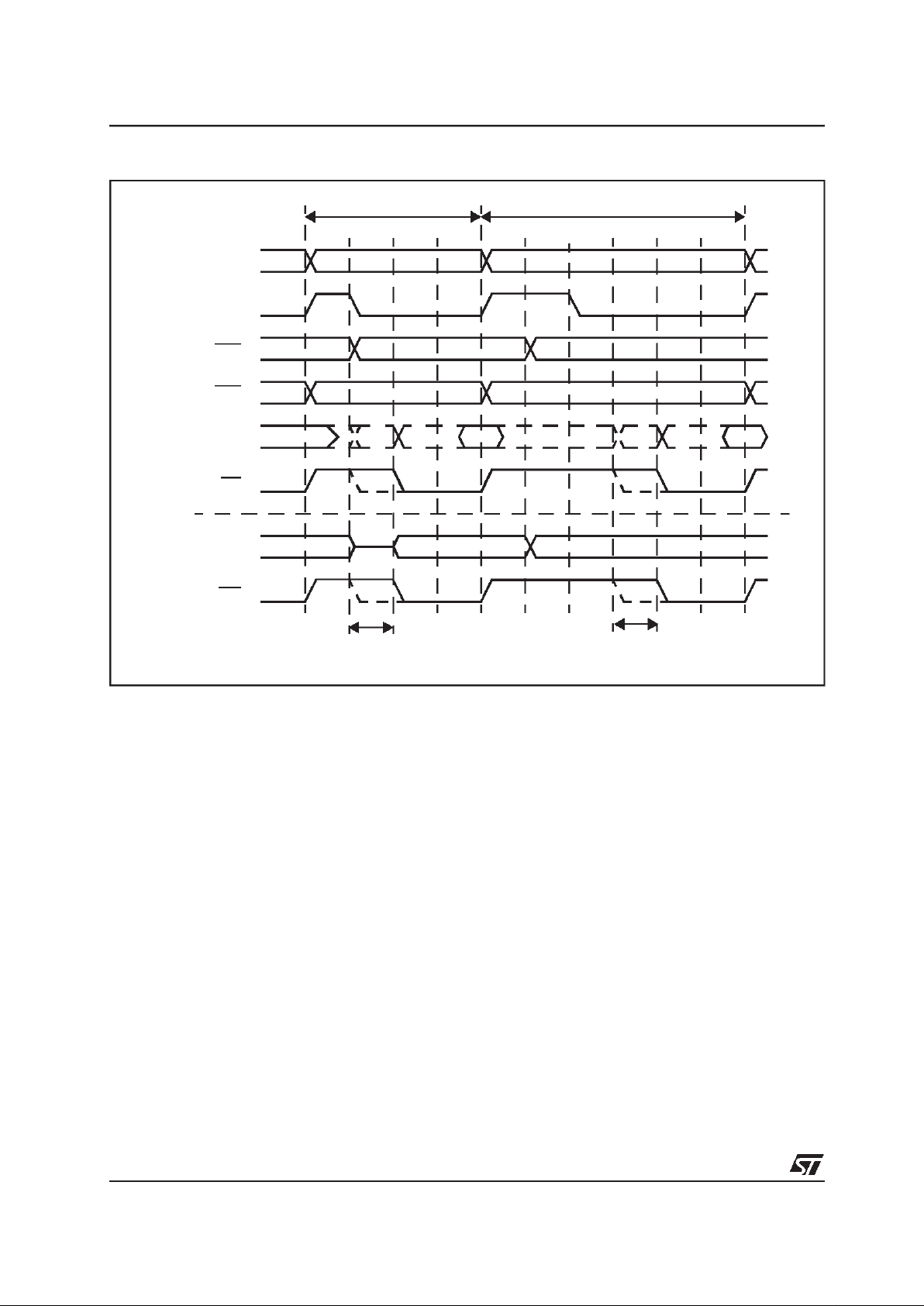

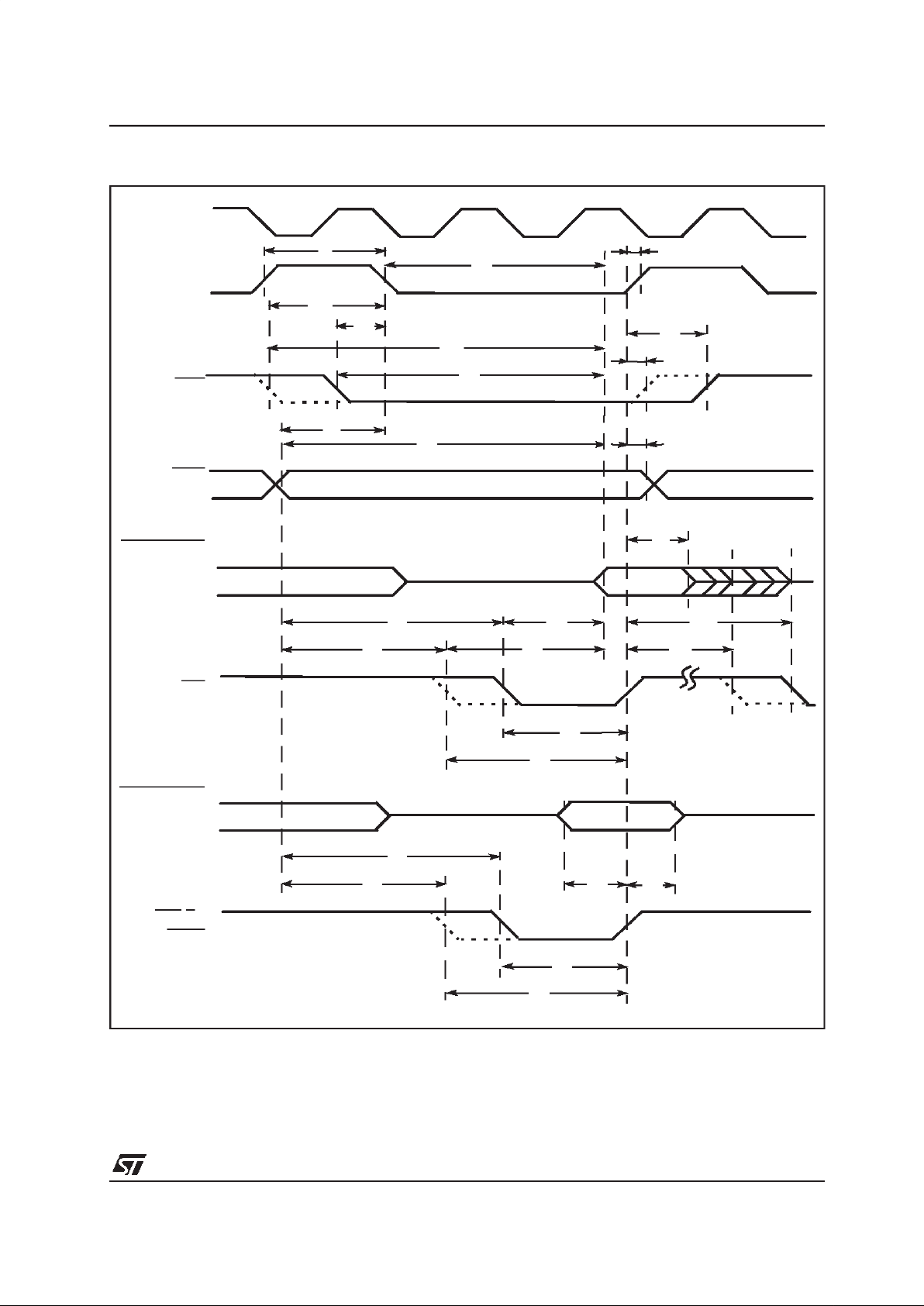

Figure 6 : Block diagram of GPT1

2nn=3...10

2

n

n=3...10

2

n

n=3...10

T2EUD

T2IN

CPU Clock

CPU Clock

CPU Clock

T3IN

T4IN

T3EUD

T4EUD

T2

Mode

Control

T3

Mode

Control

T4

Mode

Control

GPT1 TimerT2

GPT1 Timer T3

GPT1 TimerT4

T3OTL

Reload

Capture

U/D

U/D

Reload

Capture

Interrupt

Request

Interrupt

Request

Interrupt

Request

T3OUT

U/D

ST10F163

22/58

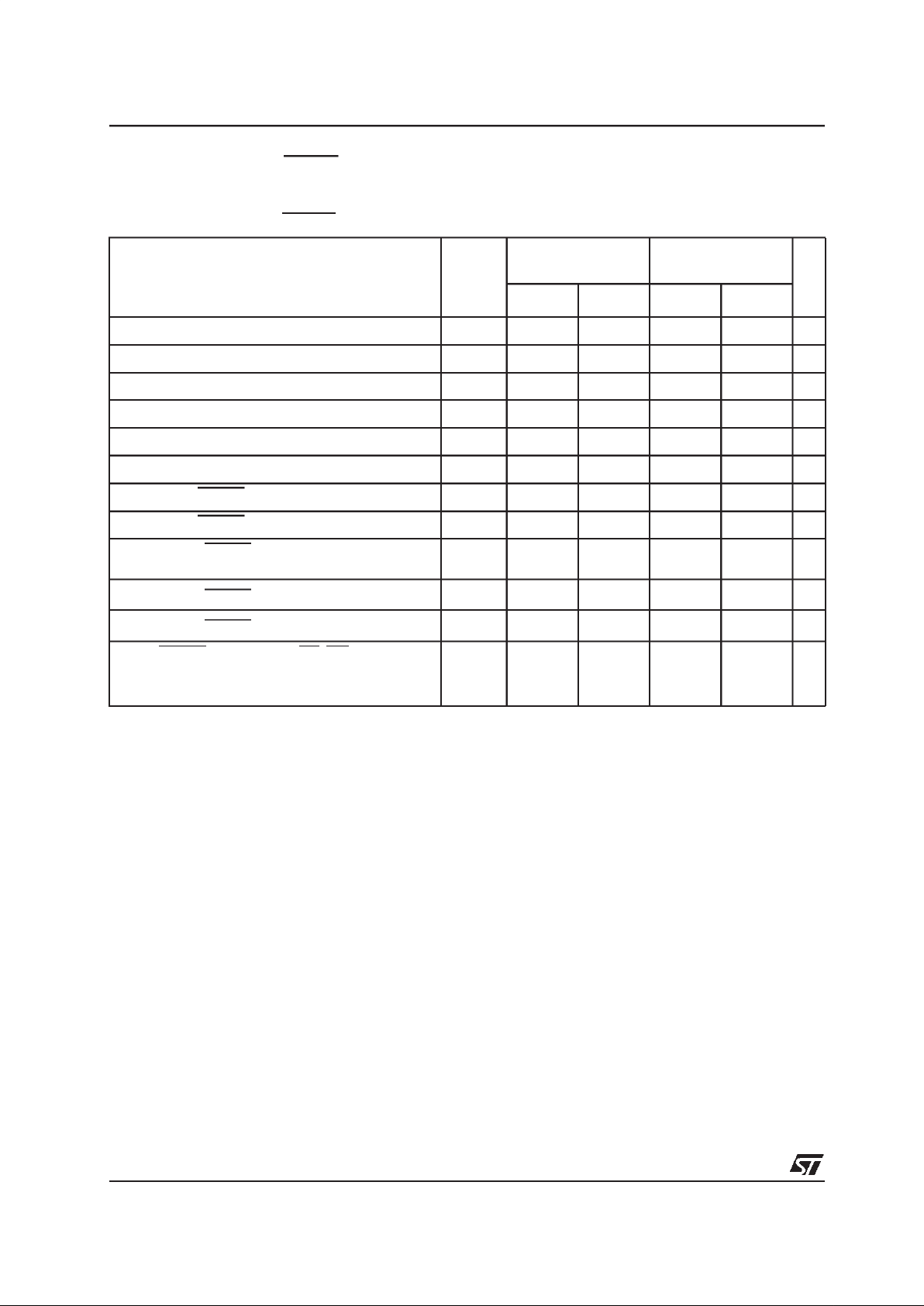

Figure 7 : Block diagram of GPT2

2nn=2...9

2

n

n=2...9

T5EUD

T5IN

CPUClock

CPUClock

T6IN

T6EUD

T5

Mode

Control

T6

Mode

Control

GPT2 Timer T5

GPT2Timer T6

U/D

Interrupt

Request

U/D

GPT2 CAPREL

T60TL

Toggle FF

T6OUT

CAPIN

Reload

Interrupt

Request

Capture

Clear

Interrupt

Request

ST10F163

23/58

X - PARALLEL PORTS

The ST10F163 provides up to 77 I/O lines which

are organized into six input/output ports and one

input port. All portlines are bit-addressable, and all

input/output lines are individually (bit-wise) programmable as, either inputsor outputsvia direction

registers. The I/O ports are true bidirectional ports

which are switched to high impedance state when

configured as inputs. The output drivers of three I/

O ports can be configured (pin by pin) for push/pull

operation or open-drainoperation via control registers. During the internalreset, all port pinsare configured as inputs. All port lines have associated,

programmable, alternate input or output functions.

PORT0 and PORT1 may be used as address and

data lines when accessing externalmemory. Port4

outputs the additional segment address bits A23/

19/17...A16 in systems where segmentation is

enabled to access more than 64 KBytes of memory.Port 6 provides optional bus arbitration signals

(BREQ, HLDA, HOLD) and chipselectsignals. Port

3 includes alternatefunctions of timers,serial interfaces, the optional bus control signal BHE and the

system clock output (CLKOUT). Port 5 is used for

timer control signals.All portlines thatare not used

for these alternate functions may be used as general purpose I/O lines.

XI - SERIAL CHANNELS

Serial communication with other microcontrollers,

processors, terminals or external peripheral com-

ponents is provided by two serial interfaces, an

Asynchronous/Synchronous Serial Channel

(ASC0) and a Synchronous Serial Port (SSP).

ASC0: The table below shows the baud rates for

the asynchronous/synchronous serial channel.

A dedicated baud rate generator is used to set up

all standard baud rateswithout oscillator tuning. 3

separate interrupt vectors are provided for transmission, reception, and erroneous reception. In

asynchronous mode, 8- or 9-bit data frames are

transmitted or received, preceded by a start bit

and terminated by one or two stop bits. For multiprocessor communication, a mechanism to distinguish address from data bytes has been included

(8-bit data + wake up bit mode). In synchronous

mode, the ASC0 transmits or receives bytes (8

bits) synchronously toa shiftclock which is generated by the ASC0. The ASC0 always shifts the

LSB first.Aloop backoption isavailable fortesting

purposes. A number of optional hardware error

detection capabilities have been included to

increase the reliability of data transfers. A parity

bit can automatically be generated on transmission or be checked on reception. Framing error

detection allows to recognize data frames with

missing stop bits. An overrun error will be generated, if the last character received has not been

read out of the receive buffer register by the time

the reception of a new characteris complete.

Note Thedeviationerrorsgiven inthe tableabovearerounded.Usinga baudratecrystalwillprovidecorrectbaudrateswithoutdeviationerrors.

Table 10 : Commonly used baud rates by reload value and deviation errors

S0BRS = ‘0’, f

CPU

= 25MHz S0BRS = ‘1’, f

CPU

= 25MHz

Baud Rate

(Baud)

Deviation Error Reload Value

Baud Rate

(Baud)

Deviation Error Reload Value

781250 ±0.0% 0000

H

520833 ±0.0% 0000

H

56000 +7.3% /-0.4% 000CH/ 000D

H

56000 +3.3% / -7.0% 0008H / 0009H

38400 +1.7% / -3.1% 0013

H

/ 0014

H

38400 +4.3% / -3.1% 000CH / 000DH

19200 +1.7% / -0.8% 0027

H

/ 0028

H

19200 +0.5% / -3.1% 001AH / 001BH

9600 +0.5% / -0.8% 0050

H

/ 0051

H

9600 +0.5% / -1.4% 0035H / 0036H

4800 +0.5% / -0.1% 00A1

H

/ 00A2

H

4800 +0.5% / -0.5% 006BH / 006CH

2400 +0.2% / -0.1% 0144

H

/ 0145

H

2400 +0.0% / -0.5% 00D8H / 00D9H

1200 +0.0% / -0.1% 028A

H

/ 028B

H

1200 +0.0% / -0.2% 01B1H / 01B2H

600 +0.0% / -0.1% 0515

H

/ 0516

H

600 +0.0% / -0.1% 0363H / 0364H

95 +0.4% / 0.4% 1FFF

H

/ 1FFF

H

75 +0.0% / 0.0% 1B1FH / 1B20H

63 +0.9% / 0.9% 1FFFH / 1FFFH

ST10F163

24/58

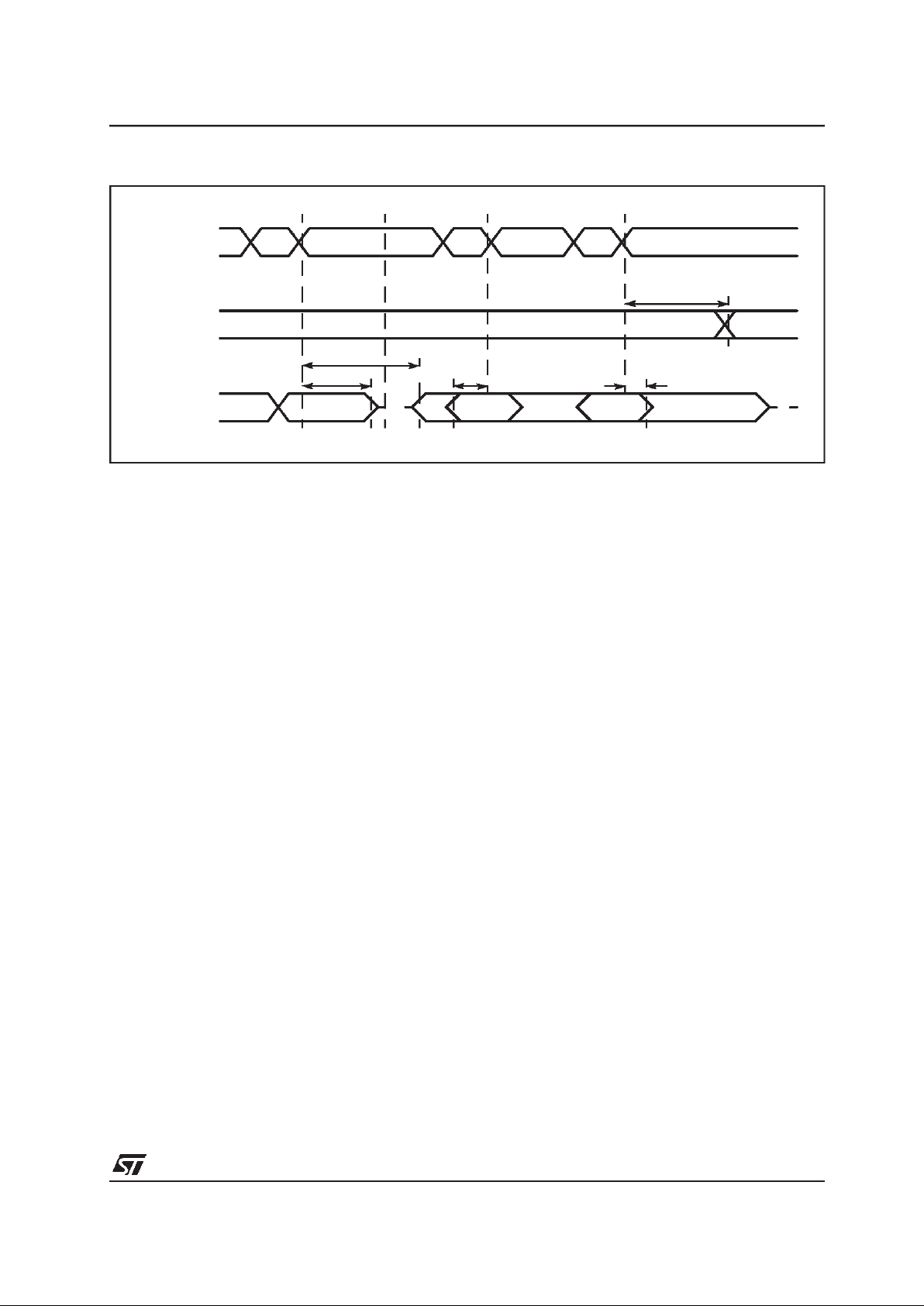

SSP: The Synchronous Serial Port provides

high-speed serial communication with external

slave devices such as EEPROM. The SSP transmits 1...3 bytes or receives 1 byte after sending

1...3 bytes synchronously to a shift clock which is

generated by the SSP.

The SSP canstart shifting withthe LSB or with the

MSB and is used to select shifting and latching

clock edgesas wellas theclock polarity. Up totwo

chip selectlines may be activatedin order todirect

data transfers to one or both of two peripheral

devices.

Table 11 : Synchronousbaud rate and SSPCKS reload values

SSPCKS Value Synchronous baud rate

000 SSP clock = CPU clock divided by 2 12.5 MBit/s

001 SSP clock = CPU clock divided by 4 6.25 MBit/s

010 SSP clock = CPU clock divided by 8 3.13 MBit/s

011 SSP clock = CPU clock divided by 16 1.56 MBit/s

100 SSP clock = CPU clock divided by 32 781 KBit/s

101 SSP clock = CPU clock divided by 64 391 KBit/s

110 SSP clock = CPU clock divided by 128 195KBit/s

111 SSP clock = CPU clock divided by 256 97.7 KBit/s

ST10F163

25/58

XII - WATCHDOG TIMER

The Watchdog Timer is a fail-safe mechanism

which the maximum malfunction time of the controller

The Watchdog Timer is always enabled after a

reset of the chip, and can only be disabled in the

time interval until the EINIT (end of initialization)

instruction has been executed. In this way the

chip’s start-up procedure is always monitored.

The software must be designed to service the

Watchdog Timer before it overflows. If, due to

hardware or software related failures, thesoftware

fails to do so, the Watchdog Timer overflows and

generates an internal hardware reset and pulls

the RSTOUT pin low in order to allow external

hardware components to be reset.

The Watchdog Timer is a 16-bit timer, clocked

with the system clock divided either by 2 or by

128. The high byte of the WatchdogTimer register

can be set to a pre-specified reload value (stored

in WDTREL) in order to allow further variation of

the monitored time interval. Each time it is serviced by the application software, the high byte of

the Watchdog Timer is reloaded. The Table12

shows the watchdog time range which for a

25MHz CPU clock. Some numbersare roundedto

3 significant digits.

XIII - OSCILLATOR WATCHDOG (OWD)

The Oscillator Watchdog (OWD) monitors the

clock signal generated by the on-chip oscillator

(either with a crystal or via external clock drive).

For this operation the PLL provides a clock signal

to supervise transitions on the oscillator clock.

This PLL clock is independent from the XTAL1

clock. When the expected oscillator clock transitions are missing, the OWD activates the PLL

Unlock/OWD interrupt node and supplies the CPU

with the PLL clock signal. Under these circumstances the PLL will oscillate with its basic frequency.

A low level onpin OWE disables the OWD’sinterrupt output, sothat theclock signalis derived from

the oscillator clock. The CPU clock source is only

switched back to the oscillator clock after a hardware reset.

When the direct-drive, or direct-drive-with- prescaler clock option is selected, an oscillator watchdog is implemented. This provides a fail-safe

mechanism in the case of a lossof external clock.

After reset, the Oscillator Watchdogis enabled by

default. To disable the OWD, the bit OWDDIS (bit

4 of SYSCON register) must be set. When the

OWD is enabled, PLL runs on free-running frequency, and increments the Oscillator Watchdog

counter. On each transition of XTAL1 pin, the

Oscillator Watchdog is cleared. If an external

clock failure occurs, then the Oscillator Watchdog

counter overflows (after16 PLL clockcycles). The

CPU clock signal is switched to the PLL free-running clock signal, and the Oscillator Watchdog

Interrupt Request (XP3INT) is flagged. The CPU

clock will not switch back to the external clock

even if a valid external clock exits on XTAL1 pin.

Only a hardware reset can switch the CPU clock

source back to direct clock input.

When the OWD is disabled, the CPU clock is

always fed from theoscillator input and the PLL is

switched off to decrease power supply current.

Note For security,rewrite WDTCON each time before the watchdog timer is serviced.

Table 12 : Watchdogtime range for 25MHz CPU clock

Reload value

in WDTREL

Prescaler for f

CPU

2 (WDTIN = ‘0’) 128 (WDTIN = ‘1’)

FF

H

20.48 µs 1.31 ms

00

H

5.24 ms 336 ms

ST10F163

26/58

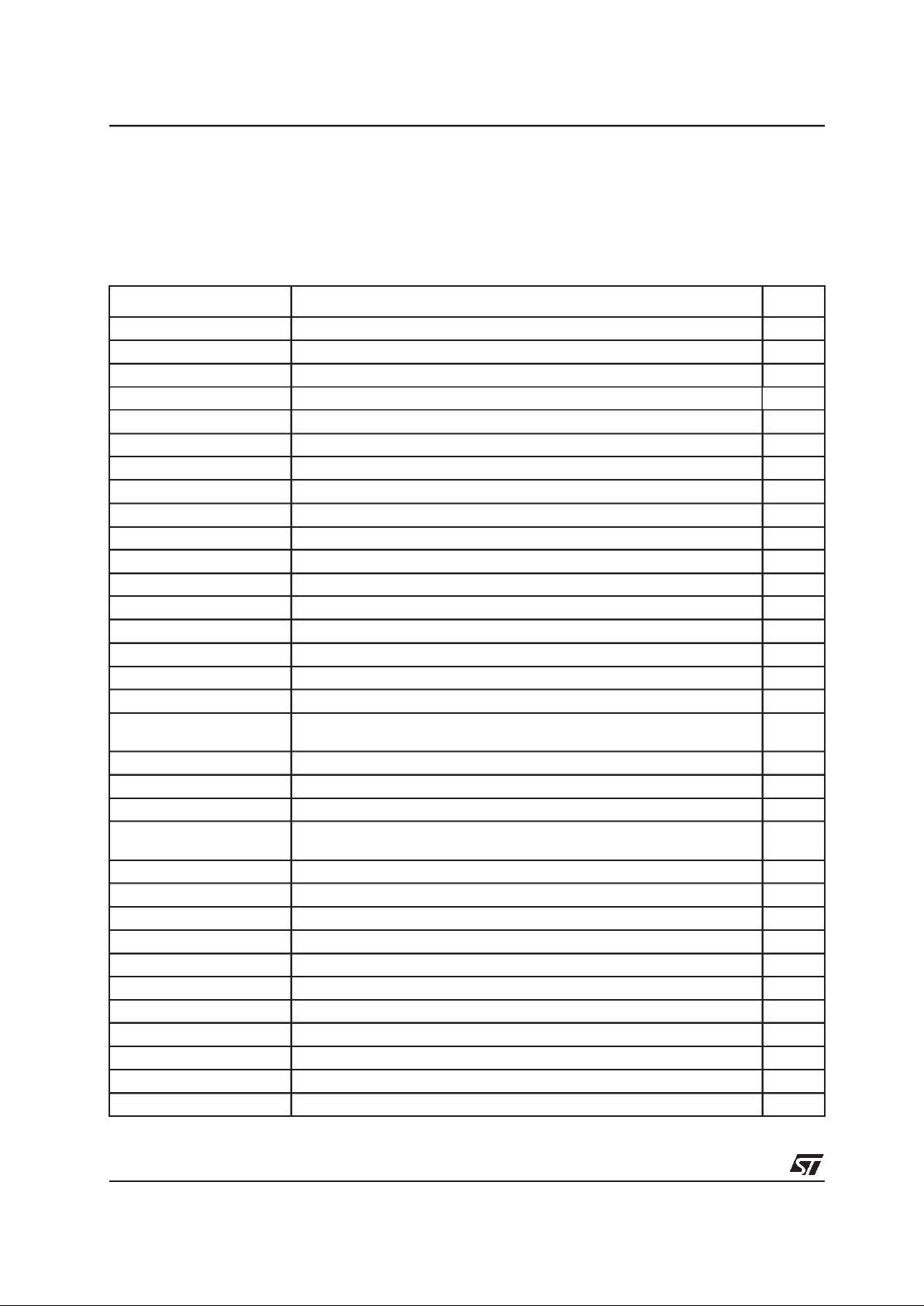

XIV - INSTRUCTION SET SUMMARY

The table below lists the instruction set of the

ST10F163.

More detailed information such as address

modes, instruction operation, parameters for con-

ditional execution of instructions, opcodes and a

detailed description of each instruction can be

found in the “ST10 Family Programming Man-

ual”

Table 13 : Instruction Set

Mnemonic Description Bytes

ADD(B) Add word (byte) operands 2 / 4

ADDC(B) Add word (byte) operands with Carry 2 / 4

SUB(B) Subtract word (byte) operands 2 / 4

SUBC(B) Subtract word (byte) operands with Carry 2 / 4

MUL(U) (Un)Signed multiply direct GPR by direct GPR (16-16-bit) 2

DIV(U) (Un)Signed divide register MDL by direct GPR (16-/16-bit) 2

DIVL(U) (Un)Signed long divide reg. MDby direct GPR (32-/16-bit) 2

CPL(B) Complement direct word (byte) GPR 2

NEG(B) Negate direct word (byte) GPR 2

AND(B) Bitwise AND, (word/byte operands) 2 / 4

OR(B) Bitwise OR, (word/byte operands) 2 / 4

XOR(B) Bitwise XOR, (word/byte operands) 2 /4

BCLR Clear direct bit 2

BSET Set direct bit 2

BMOV(N) Move (negated) direct bit to direct bit 4

BAND, BOR, BXOR AND/OR/XOR direct bit with direct bit 4

BCMP Compare direct bit todirect bit 4

BFLDH/L Bitwise modify masked high/low byte of bit-addressable direct word memory

with immediate data

4

CMP(B) Compare word (byte) operands 2 / 4

CMPD1/2 Compare word data to GPR and decrement GPR by 1/2 2 / 4

CMPI1/2 Compare word data to GPR and increment GPR by 1/2 2 / 4

PRIOR Determine number of shift cycles to normalize direct word GPR and store

result in direct word GPR

2

SHL / SHR Shift left/right direct word GPR 2

ROL / ROR Rotate left/right direct word GPR 2

ASHR Arithmetic (sign bit) shift right direct word GPR 2

MOV(B) Move word (byte) data 2 / 4

MOVBS Move byte operand to word operand with sign extension 2 / 4

MOVBZ Move byte operand to word operand. with zero extension 2 / 4

JMPA,JMPI, JMPR Jump absolute/indirect/relative if condition is met 4

JMPS Jump absolute to a code segment 4

J(N)B Jump relative if direct bit is (not) set 4

JBC Jump relative and clear bit if direct bit is set 4

JNBS Jump relative and set bit if direct bit is not set 4

ST10F163

27/58

CALLA, CALLI, CALLR Call absolute/indirect/relative subroutine if condition is met 4

CALLS Call absolute subroutine in any code segment 4

PCALL Push direct word register onto system stack and call

absolute subroutine

4

TRAP Call interrupt service routine via immediate trap number 2

PUSH, POP Push/pop direct word register onto/from system stack 2

SCXT Push direct word register onto system stack and update

register with word operand

4

RET Return from intra-segment subroutine 2

RETS Return from inter-segment subroutine 2

RETP Return from intra-segment subroutine and pop direct word register from sys-

tem stack

2

RETI Return from interrupt service subroutine 2

SRST Software Reset 4

IDLE Enter Idle Mode 4

PWRDN Enter Power Down Mode (supposes NMI-pin being low) 4

SRVWDT Service Watchdog Timer 4

DISWDT Disable Watchdog Timer 4

EINIT Signify End-of-Initialization on RSTOUT-pin 4

ATOMIC Begin ATOMIC sequence 2

EXTR Begin EXTended Register sequence 2

EXTP(R) Begin EXTended Page (and Register) sequence 2 / 4

EXTS(R) Begin EXTended Segment (and Register) sequence 2 /4

NOP Null operation 2

Table 13 : Instruction Set (continued)

Mnemonic Description Bytes

ST10F163

28/58

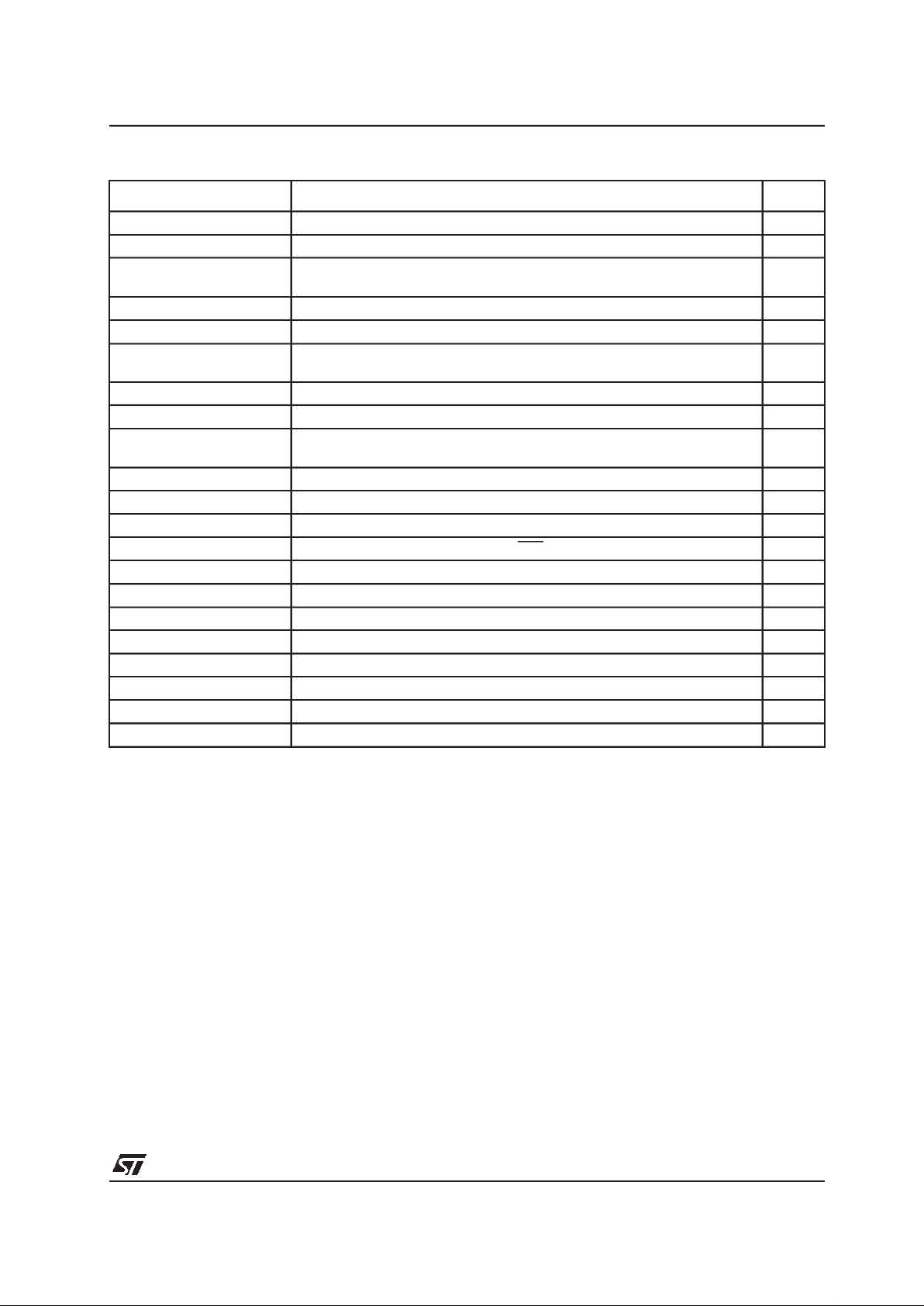

XV - SPECIAL FUNCTION REGISTER OVERVIEW

The following table lists SFRs in alphabetical

order. Bit-addressable SFRs are marked with the

letter “b” in column “Name”. SFRs within the

Extended SFR-Space (ESFRs) are marked with

the letter “E” in column “Physical Address”.Registers with on-chip X-peripherals (CAN) are marked

with the letter “X” in column physical address.

An SFR can be specified by its individual mnemonic name.

Depending on the selected addressing mode, an

SFR can be accessed via its physical address

(using the Data Page Pointers), or via its short

8-bit address (without using the Data Page Pointers).

Table 14 : SpecialFunction Register List

Name

Physical

Address

8-Bit

Address

Description

Reset

Value

ADDRSEL1 FE18h 0Ch Address Select Register 1 0000h

ADDRSEL2 FE1Ah 0Dh Address Select Register 2 0000h

ADDRSEL3 FE1Ch 0Eh Address Select Register 3 0000h

ADDRSEL4 FE1Eh 0Fh Address Select Register 4 0000h

BUSCON0 b FF0Ch 86h Bus Configuration Register 0 0XX0h

BUSCON1 b FF14h 8Ah Bus Configuration Register 1 0000h

BUSCON2 b FF16h 8Bh Bus Configuration Register 2 0000h

BUSCON3 b FF18h 8Ch Bus Configuration Register 3 0000h

BUSCON4 b FF1Ah 8Dh Bus Configuration Register 4 0000h

CAPREL FE4Ah 25h GPT2 Capture/Reload Register 0000h

CC8IC b FF88h C4h EX0IN Interrupt Control Register 0000h

CC9IC b FF8Ah C5h EX1IN Interrupt Control Register 0000h

CC10IC b FF8Ch C6h EX2IN Interrupt Control Register 0000h

CC11IC b FF8Eh C7h EX3IN Interrupt Control Register 0000h

CC12IC b FF90h C8h EX4IN Interrupt Control Register 0000h

CC13IC b FF92h C9h EX5IN Interrupt Control Register 0000h

CC14IC b FF94h CAh EX6IN Interrupt Control Register 0000h

CC15IC b FF96h CBh EX7IN Interrupt Control Register 0000h

CP FE10h 08h CPU Context Pointer Register FC00h

CRIC b FF6Ah B5h GPT2 CAPREL Interrupt Control Register 0000h

CSP FE08h 04h CPU Code Segment Pointer Register (read only) 0000h

DP0L b F100h E 80h P0L Direction Control Register 00h

DP0H b F102h E 81h P0h Direction Control Register 00h

DP1L b F104h E 82h P1L Direction Control Register 00h

DP1H b F106h E 83h P1h Direction Control Register 00h

DP2 b FFC2h E1h Port 2 Direction Control Register 0000h

DP3 b FFC6h E3h Port 3 Direction Control Register 0000h

DP4 b FFCAh E5h Port 4 Direction Control Register 00h

DP6 b FFCEh E7h Port 6 Direction Control Register 00h

DPP0 FE00h 00h CPU Data Page Pointer 0 Register (10 bits) 0000h

DPP1 FE02h 01h CPU Data Page Pointer 1 Register (10 bits) 0001h

DPP2 FE04h 02h CPU Data Page Pointer 2 Register (10 bits) 0002h

ST10F163

29/58

DPP3 FE06h 03h CPU Data Page Pointer 3 Register (10 bits) 0003h

EXICON b b F1C0h E E0h External Interrupt Control Register 0000h

IDCHIP F07Ch E 3Eh Device Identifier Register

0A3Xh

1)

IDMANUF F07Eh E 3Fh Manufacturer Identifier Register 0400h

IDMEM F07Ah E 3Dh On-chip Memory Identifier Register 3020h

IDPROG F078h E 3Ch Programming Voltage Identifier Register 9A40h

MDC b FF0Eh 87h CPU Multiply Divide Control Register 0000h

MDH FE0Ch 06h CPU Multiply Divide Register – High Word 0000h

MDL FE0Eh 07h CPU Multiply Divide Register – Low Word 0000h

ODP2 b F1C2h E E1h Port 2 Open Drain Control Register 0000h

ODP3 b F1C6h E E3h Port 3 Open Drain Control Register 0000h

ODP6 b F1CEh E E7h Port 6 Open Drain Control Register 00h

ONES FF1Eh 8Fh Constant Value 1’s Register (read only) FFFFh

P0L b FF00h 80h Port 0 Low Register (Lower half of PORT0) 00h

P0H b FF02h 81h Port 0 High Register (Upper half of PORT0) 00h

P1L b FF04h 82h Port 1 Low Register (Lower half of PORT1) 00h

P1H b FF06h 83h Port 1 High Register (Upper half of PORT1) 00h

P2 b FFC0h E0h Port 2 Register 0000h

P3 b FFC4h E2h Port 3 Register 0000h

P4 b FFC8h E4h Port 4 Register (8 bits) 00h

P5 b FFA2h D1h Port 5 Register (read only) XXXXh

P6 b FFCCh E6h Port 6 Register (8 bits) 00h

PECC0 FEC0h 60h PEC Channel 0 Control Register 0000h

PECC1 FEC2h 61h PEC Channel 1 Control Register 0000h

PECC2 FEC4h 62h PEC Channel 2 Control Register 0000h

PECC3 FEC6h 63h PEC Channel 3 Control Register 0000h

PECC4 FEC8h 64h PEC Channel 4 Control Register 0000h

PECC5 FECAh 65h PEC Channel 5 Control Register 0000h

PECC6 FECCh 66h PEC Channel 6 Control Register 0000h

PECC7 FECEh 67h PEC Channel 7 Control Register 0000h

PSW b FF10h 88h CPU Program Status Word 0000h

RP0H b F108h E 84h System Start-up Configuration Register (Rd. only) XXh

S0BG FEB4h 5Ah Serial Channel 0 Baud Rate Generator Reload Reg 0000h

S0CON b FFB0h D8h Serial Channel 0 Control Register 0000h

S0EIC b FF70h B8h Serial Channel 0 Error Interrupt Control Register 0000h

S0RBUF FEB2h 59h Serial Channel 0 Receive Buffer Register (read only) XXh

S0RIC b FF6Eh B7h Serial Channel 0 Receive Interrupt Control Register 0000h

Table 14 : SpecialFunction Register List (continued)

Name

Physical

Address

8-Bit

Address

Description

Reset

Value

ST10F163

30/58

S0TBIC b F19Ch E CEh Serial Channel 0 Transmit Buffer Interrupt Control

Reg

0000h

S0TBUF FEB0h 58h Serial Channel 0 Transmit Buffer Register (write

only)

00h

S0TIC b FF6Ch B6h Serial Channel 0 Transmit Interrupt Control Register 0000h

SP FE12h 09h CPU System Stack Pointer Register FC00h

SSPCON0 EF00h X --- SSP Control Register 0 0000h

SSPCON1 EF02h X --- SSP Control Register 1 0000h

SSPRTB EF04h X --- SSP Receive/Transmit Buffer XXXXh

SSPTBH EF06h X --- SSP Transmit Buffer High XXXXh

STKOV FE14h 0Ah CPU Stack Overflow Pointer Register FA00h

STKUN FE16h 0Bh CPU Stack Underflow Pointer Register FC00h

SYSCON b FF12h 89h CPU System Configuration Register

0xx0h

2)

T2 FE40h 20h GPT1 Timer 2 Register 0000h

T2CON b FF40h A0h GPT1 Timer 2 Control Register 0000h

T2IC b FF60h B0h GPT1 Timer 2 Interrupt Control Register 0000h

T3 FE42h 21h GPT1 Timer 3 Register 0000h

T3CON b FF42h A1h GPT1 Timer 3 Control Register 0000h

T3IC b FF62h B1h GPT1 Timer 3 Interrupt Control Register 0000h

T4 FE44h 22h GPT1 Timer 4 Register 0000h

T4CON b FF44h A2h GPT1 Timer 4 Control Register 0000h

T4IC b FF64h B2h GPT1 Timer 4 Interrupt Control Register 0000h

T5 FE46h 23h GPT2 Timer 5 Register 0000h

T5CON b FF46h A3h GPT2 Timer 5 Control Register 0000h

T5IC b FF66h B3h GPT2 Timer 5 Interrupt Control Register 0000h

T6 FE48h 24h GPT2 Timer 6 Register 0000h

T6CON b FF48h A4h GPT2 Timer 6 Control Register 0000h

T6IC b FF68h B4h GPT2 Timer 6 Interrupt Control Register 0000h

TFR b FFACh D6h Trap Flag Register 0000h

WDT FEAEh 57h Watchdog Timer Register (read only) 0000h

WDTCON FFAEh D7h Watchdog Timer Control Register

000xh

3)

XP1IC b F18Eh E C7h SSP Interrupt Control Register 0000h

XP3IC b F19Eh E CFh PLL unlock Interrupt Control Register 0000h

ZEROS b FF1Ch 8Eh Constant Value 0’s Register (read only) 0000h

1. The value depends on the siliconrevision and is given in the errata sheet.

2. The system configuration is selected during reset.

3. Bit WDTR indicates a watchdog timer triggered reset.

Table 14 : SpecialFunction Register List (continued)

Name

Physical

Address

8-Bit

Address

Description

Reset

Value

ST10F163

31/58

XVI - ELECTRICAL CHARACTERISTICS

XVI.1 - Absolute maximum ratings

– Ambient temperature under bias (TA): 0 to

+70 °C

– Storage temperature (TST):– 65 to +150 °C

– Voltage on VDDpins with respect to ground

(VSS):– 0.5 to +6.5 V

– Voltage on anypin with respect to ground (VSS):

–0.5 to VDD+0.5 V

– Input current on any pin during overload condi-

tion: –10 to +10 mA

– Absolute sum of all input currents during over-

load condition:|100 mA|

– Power dissipation:1.5 W

Note Stresses above those listed under “Absolute Maximum

Ratings” may cause permanent damage to the device. This

is a stress rating only and functional operation of thedevice

at these or any other conditions above those indicated in

the operational sections of this specification is not

guaranteed. Exposure to absolute maximum rating

conditions forextended periods may affect devicereliability.

During overload conditions (V

IN>VDD

or VIN<VSS)the

voltage on pins with respect to ground (V

SS

) must not

exceed the values defined by the Absolute Maximum

Ratings.

XVI.2 - Parameter Interpretation

The parameters listed in the Electrical Characteristics tables, Table15 to Table 18, give the characteristics of the ST10F163 and its demands on the

system.

Where the ST10F163 logic provides signals with

their respective timing characteristics, the symbol

“CC” for Controller Characteristics, is included in

the “Symbol” column.