RBO40-40G/M/T

ApplicationSpecific Discretes

A.S.D.

FEATURES

PROTECTIONAGAINST”LOADDUMP”PULSE

40A DIODE TO GUARD AGAINST BATTERY

REVERSAL

MONOLITHIC STRUCTURE FOR GREATER

RELIABILITY

BREAKDOWNVOLTAGE: 24V min.

CLAMPINGVOLTAGE: ± 40V max.

COMPLIANTWITHISO /DTR 7637

DESCRIPTION

Designedto protectagainst batteryreversaland

loaddumpovervoltagesin automotiveapplications,thismonolithiccomponentoffersmultiple

functionsin thesamepackage:

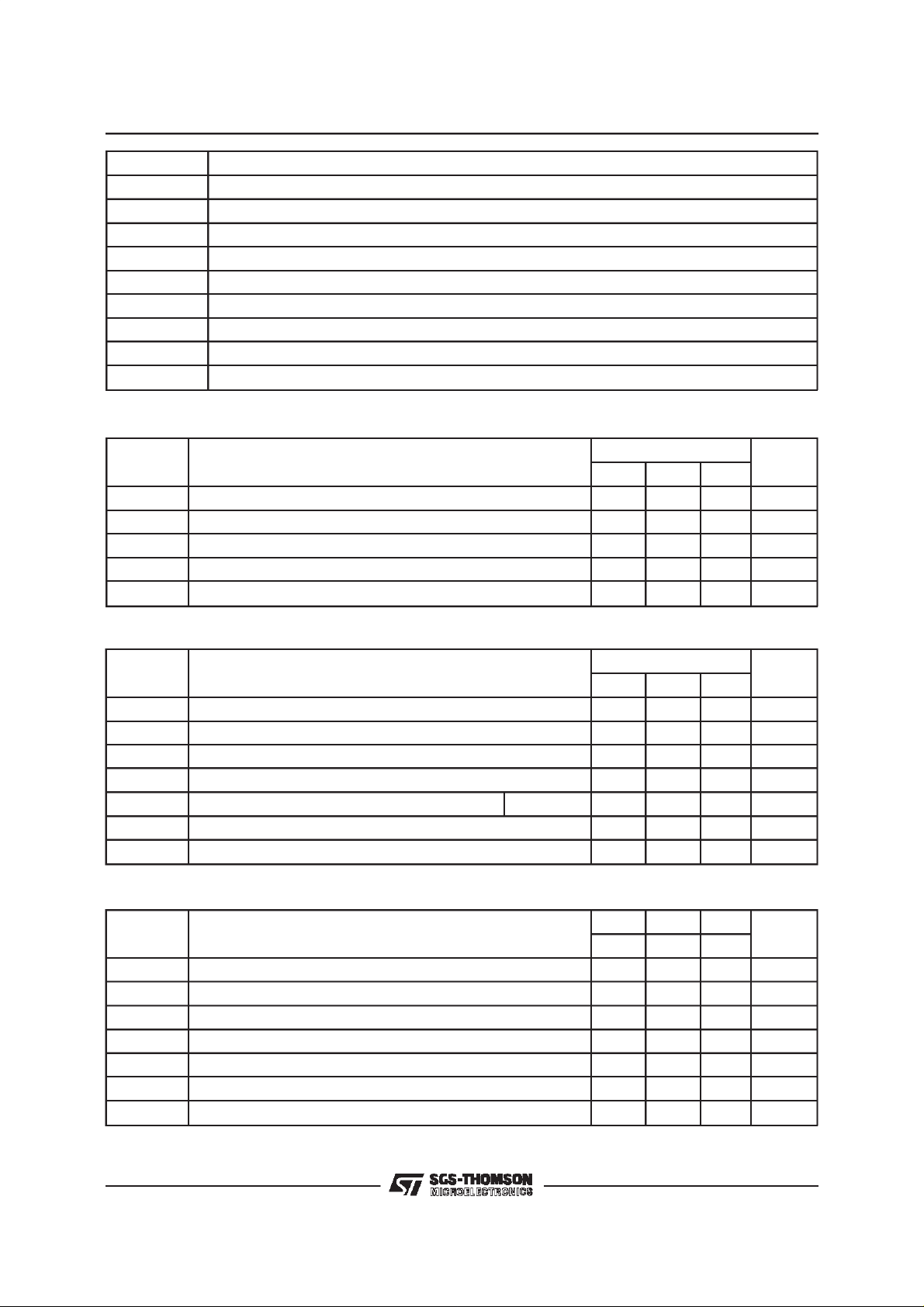

D1 : reversedbatteryprotection

T1 : clampingagainst negativeovervoltages

T2 : Transilfunctionagainst ”loaddump” effect.

TM

OVERVOL TAGEPROTECTIO NCIRCUIT(R BO)

REVERSEDBATTERYAND

D2PAK

RBO40-40G

PowerSO-10

RBO40-40M

TM

January1997 -Ed :3

TO220AB

RBO40-40T

FUNCTIONAL DIAGRAM

1

3

2

1/15

RBO40-40G / RBO40-40M / RBO40-40T

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

I

FSM

Non repetitivesurgepeak forward current

tp = 10ms 120 A

(DiodeD1)

I

F

V

PP

DC forwardcurrent (Diode D1) Tc = 75°C40 A

Peakload dump voltage (seenote 1and2)

80 V

5 pulses(1 minute between each pulse)

P

PP

Peakpulse power betweenInput andOutput

10/1000µs 1500 W

(TransilT1) Tj initial= 25°C

T

stg

Tj

T

L

Storagetemperature range

Maximumjunction temperature

Maximumlead temperatureforsolderingduring 10 s

- 40 to + 150

150

260 °C

at 4.5mm from casefor TO220AB

Note 1 :for a surge greater than the maximum value, the device will fail in short-circuit.

Note 2 : see Load Dump curves.

TM : PowerSO-10,TRANSIL and ASD are trademarks of SGS-THOMSON Microelectronics.

THERMAL RESISTANCE

Symbol Parameter Value Unit

Rth (j-c)

Junctionto case

RBO40-40M

RBO40-40G

RBO40-40T

1.0

1.0

1.0

°C

°C/W

Rth (j-a) Junctionto ambient RBO40-40T 60 °C/W

D1

I13

31

F

I

T1

V

31 VRM31

CL

Ex: VF13 . betweenPin 1andPin3 VBR32. between Pin 3 and Pin 2

T2

2

V

31

BR

V

IRM31

31

I

R

Ipp31

F13

V13

Ipp32

I

RM

I32

IR32

32

VRM32 V

32 V

R

B

1

V32

32

C

L

3

2

2/15

RBO40-40G / RBO40-40M / RBO40-40T

Symbol Parameter

V

RM31/VRM32

V

BR31/VBR32

I

R31/IR32

V

CL31/VCL32

V

F13

I

PP

αT Temperaturecoefficientof V

C

31/C32

C

13

Stand-offvoltage Transil T1/ Transil T2.

Breakdownvoltage Transil T1 / TransilT2.

LeakagecurrentTransilT1 /TransilT2.

ClampingvoltageTransilT1 /TransilT2.

Forwardvoltagedrop DiodeD1.

Peak pulse current.

.

BR

CapacitanceTransil T1/ TransilT2.

Capacitanceof DiodeD1

ELECTRICAL CHARACTERISTICS: DIODED1 (-40°C< T

amb

Symbol Test Conditions

V

V

V

V

C

F13

F13

F13

F13

13

IF= 40A 1.9 V

IF= 20A 1.45 V

IF=1A 1 V

IF= 100mA

F = 1MHz VR=0V

ELECTRICAL CHARACTERISTICS: TRANSILT1 (- 40°C<T

Symbol Test Conditions

V

BR 31

V

BR 31

I

RM 31

I

RM 31

V

CL 31

αT Temperaturecoefficient of V

C

31

IR=1 mA 22 35 V

IR=1 mA,T

=25°C2432V

amb

VRM=20 V 100 µA

VRM=20V,T

amb

=25°C

IPP=37.5A,Tjinitial= 25° C 10/1000µs40V

BR

F = 1MHz VR= 0 V 3000 pF

<+85°C)

<+85°C)

amb

Value

Min. Typ. Max.

0.95 V

3000 pF

Value

Min. Typ. Max.

10 µA

910-4/°C

Unit

Unit

ELECTRICAL CHARACTERISTICS : TRANSILT2 (- 40°C<T

Symbol Test Conditions

V

BR 32

V

BR 32

I

RM 32

I

RM 32

V

CL 32

α T Temperaturecoefficientof V

C

32

Note 1 : One pulse,see pulse definition in load dump testgenerator circuit.

IR=1 mA 22 35 V

IR=1 mA,T

=25°C2432V

amb

VRM=20 V 100 µA

VRM=20V,T

amb

=25°C

IPP= 20 A (note1) 40 V

BR

F = 1MHz VR=0 V 8000 pF

amb

<+85°C)

Value

Min. Typ. Max.

Unit

10 µA

910-4/°C

3/15

RBO40-40G / RBO40-40M / RBO40-40T

PRODUCTDESCRIPTION

1

2

BASICAPPLICATION

TheRBO has 3functionsintegratedonthe same

chip.

3

D1 : “Diode function” in order to protect against

reversedbattery operation.

T2: “Transil function” in order to protectagainst

positive surge generated by electric systems

(ignition,relay. ...).

T1: Protectionformotor drive application

(Seebelow).

* The monolithic multi-function protection

(RBO) has been developed to protect

sensitivesemiconductorsin car electron ic

modules against both overvoltage and

batteryreverse.

* In addition, the RBO circuit prevents

overvoltages generated by the module from

affecting the carsupply network.

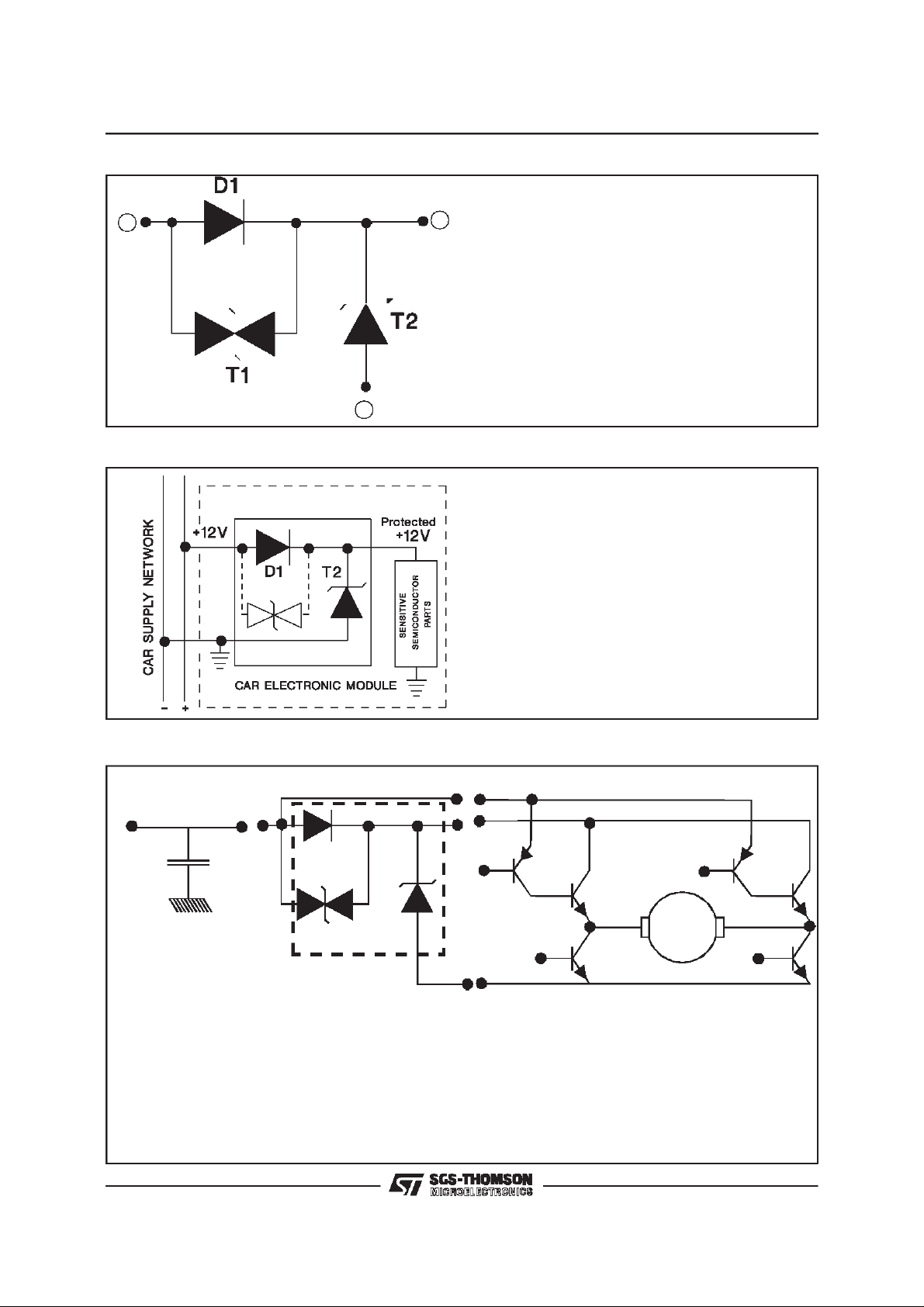

MOTORDRIVER APPLICATION

BATTERY

Filter

D1

T2

T1

MOTOR

RBO

DEVIC E MOTO R C ONTROL

In thisapplication,onehalfof the motordrivecircuitis suppliedthroughthe “RBO” and isthusprotected

as perits basicfunctionapplication.

The secondpart isconnecteddirectly to the“carsupplynetwork” and is protectedas follows:

- Forpositivesurges: T2(clampingphase)and D1in forward-biased.

- Fornegativesurges: T1(clampingphase) andT2 inforward-biased.

4/15

2

PINOUTconfigurationin D

PAK:

-Input (1) : Pin1

-Output (3) : Pin3

-Gnd (2) : Connectedto base Tab

Marking : Logo,datecode, RBO40-40G

PINOUTconfigurationin PowerSO-10:

-Input (1) : Pin1 to 5

-Output (3) : Pin6 to10

-Gnd (2) : Connectedto base Tab

Marking : Logo,datecode, RBO40-40M

RBO40-40G / RBO40-40M / RBO40-40T

D1

T2

T1

TAB

Pin 1

D1

Input (1)

Output (3)

T2

T1

Gnd (2)

Tab

Pin 6

PINOUTconfigurationin TO220AB:

-Input (1) : Pin1

-Output (3) : Pin3

-GND (2) : Connectedto baseTab

Marking : Logo,datecode, RBO40-40T

TOP VIEW

D1

T2

T1

(TAB)

5/15

RBO40-40G / RBO40-40M / RBO40-40T

LOADDUMP TESTGENERATORCIRCUIT (SCHAFFNER NSG506 C).Issued from ISO / DTR7637.

U(V)

Vbat

Open circuit (voltage curve)

Corresponding current wave with D.U.T.

(pulse test n°5)

I

Ipp

Ipp/2

90%

Vs

t

tr

offset

10% / 13.5V

10%

0

t

0

tp = 40ms

t

Impulse N°5

Vs(V) 66.5

Vbat(V) 13.5

Ri (Ω)2

t (ms)

200 (*)

tr (ms) <10

Number 5

60s between each pulse

(*) Generator setting

CALIBRATION METHODFOR SCHAFFNERNSG 506 C

1) With opencircuit (generatoris inopencircuit):

- calibrateVs

2) With shortcircuit(generatorisin shortcircuit):

-calibrateRi (Ri = 2Ω)

3) With D.U.T.

- calibratetp (tp= 40ms @ Ipp/2)

TypicalVoltage curve (open circuit)

typ. Vpp

V

Bat

20ms/div.

10.0V/div.

Typical Voltage andCurrent curvewith D.U.T.

typ.VCL

Ipp

20ms/div.

5.0V/div.

20ms/div.

3A/div.

6/15

RBO40-40G / RBO40-40M / RBO40-40T

Fig. 1 : Peak pulse power versus exponential

pulseduration(Tjinitial = 85°C).

Ppp(kW)

10.0

5.0

2.0

1.0

0.5

0.2

0.1

12 51020 50100

Transil T1

Tra nsil T 2

tp(ms)

Fig. 2-2 : Clamping voltage versus peak pulse

current (Tj initial = 85°C).

Exponential waveform tp = 1 ms and tp = 20 µs

(TRANSILT1).

Fig. 2-1 : Clamping voltage versus peak pulse

current (Tj initial = 85°C).

Exponential waveform tp = 40 ms and tp = 1 ms

(TRANSILT2).

V (V)CL

45.0

42.5

40.0

37.5

35.0

32.5

30.0

0.2 0.5 1 2 5 10 20 50 100

0.1

tp = 40ms

tp = 1ms

Ipp(A)

Fig. 3 : Relative variation of peak pulse power

versus junction temperature.

V (V)CL

55

50

45

p=1ms

40

t

tp = 20µs

35

30

A)

25

1 2 5 10 20 50 100 200 500

Ipp(

Ppp[Tj]/Ppp[Tj initial=85°C]

1.20

1.00

0.80

0.60

0.40

0.20

0.00

25 50 75 100 125 150 175

0

Tj initial (°C)

7/15

RBO40-40G / RBO40-40M / RBO40-40T

Fig. 4 :

Relative variation of thermal impedance

junctionto caseversuspulse duration.

Zth(j-c)/Rth(j-c)

1.0

0.5

0.2

0.1

1E-3 1E-2 1E-1 1E+0 1E+1

Fig. 5-2 :

Peak forwardvoltage drop versus peak

tp (s)

forwardcurrent(typicalvalues)- (DIODED1).

Fig. 5-1 :

Peakforward voltagedrop versus peak

forwardcurrent (typicalvalues) -(TRANSILT2).

V

FM(V)

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.1 0.2 0.5 1 2

Tj = 25°°C

Tj = 150°°C

5

10 20 50 100

IFM(A)

Fig.6 :Relative variation of leakage current

versus junction temperature.

V

FM(V)

3.5

3.5

3.0

3.0

2.5

2.5

2.0

2.0

1.5

1.5

1.0

1.0

0.5

0.5

0.2 0.5 1 5 20 50 100

0.2 0.5 2 1020 50100

0.1

0.1

Tj = 25°°C

Tj = 150°°C

ORDERINGINFORMATION

RBO 40 - 40 M

ReversedBattery&

Overvoltageprotection

IFM(A)

Package:

M = PowerSO-10

2

G=D

PAK

T =TO220AB

8/15

I

F(AV)

=40A

=40V

V

CL

PACKAGEMECHANICAL DATA

2

PAK Plastic

D

E

L2

L

L3

A1

B2

B

G

2.0 MIN.

FLATZONE

C2

RBO40-40G / RBO40-40M / RBO40-40T

DIMENSIONS

A

A 4.30 4.60 0.169 0.181

A1 2.49 2.69 0.098 0.106

A2 0.03 0.23 0.001 0.009

REF.

D

B 0.70 0.93 0.027 0.037

B2 1.40 0.055

C 0.45 0.60 0.017 0.024

C2 1.21 1.36 0.047 0.054

C

R

D 8.95 9.35 0.352 0.368

E 10.00 10.28 0.393 0.405

G 4.88 5.28 0.192 0.208

L 15.00 15.85 0.590 0.624

A2

L2 1.27 1.40 0.050 0.055

L3 1.40 1.75 0.055 0.069

R 0.40 0.016

V2

V2 0° 8° 0° 8°

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

FOOT-PRINT D

10.30

2

PAK

8.90

16.90

5.08

1.30

3.70

9/15

RBO40-40G / RBO40-40M / RBO40-40T

SOLDERINGRECOMMENDATION

The soldering process causes considerable

thermal stress to a semiconductor component.

This has to be minimized to assure a reliable and

extended lifetime of thedevice. The PowerSO-10

package can be exposed to a maximum

temperatureof 260°C for 10 seconds. However a

proper solderingof the packagecould be done at

215°C for 3 seconds. Any solder temperature

profile should be within these limits. As reflow

techniquesaremost commonin surfacemounting,

typical heating profilesare given in Figure 1,either

for mounting on FR4 or on metal-backed boards.

For each particular board, the appropriate heat

profile has to be adjusted experimentally. The

present proposal is just a starting point. In any

case, the following precautions have to be

considered:

- alwayspreheatthe device

- peak temperatureshould beat least30 °C

higherthanthe meltingpoint of thesolder

alloychosen

Fig. 1 :Typicalreflowsolderingheat profile

-thermalcapacityof thebase substrate

Voids pose a difficult reliability problem for large

surface mount devices. Such voids under the

package result in poor thermal contact and the

high thermal resistance leads to component

failures. The PowerSO-10 is designed from

scratch to be solely a surface mount package,

hence symmetry in the x- and y-axis gives the

package excellent weight balance.Moreover, the

PowerSO-10offersthe uniquepossibilityto control

easily the flatness and quality of the soldering

process. Both the top and the bottom soldered

edges of the package are accessible for visual

inspection(soldering meniscus).

Coplanarity between the substrate and the

package can be easily verified. The quality of the

solder joints is very importantfor two reasons : (I)

poor quality solder joints result directly in poor

reliability and (II) solder thickness affects the

thermal resistance significantly. Thus a tight

control of this parameter results in thermally

efficientandreliablesolder joints.

Temperature ( C)

250

o

o

245 C

o

215 C

200

Soldering

Cooli ng

150

Epoxy FR4

board

Preheating

100

Metal-backed

50

board

0

0 40 8 0 1 20 160 2 00 2 40 280 320 360

Time (s )

10/15

RBO40-40G / RBO40-40M / RBO40-40T

SUBSTRATESAND MOUNTINGINFORMATION

The use of epoxy FR4 boardsis quite commonfor

surface mounting techniques,however, their poor

thermal conductioncompromisesthe otherwise

outstanding thermal performance of the

PowerSO-10. Some methods to overcome this

limitationare discussedbelow.

One possibilityto improve the thermal conduction

is the use of large heat spreader areas at the

copper layer of the PC board. This leads to a

reductionof thermal resistanceto 35 °C for 6 cm

of theboard heatsink(seefig.2).

Use of copper-filledthroughholes on conventional

FR4 techniqueswillincrease the metallization and

Fig.2 :

Mountingon epoxyFR4head dissipationby extendingthe area ofthecopper layer

Copper foil

decrease thermal resistance accordingly. Using

a configurationwith 16holesunderthe spreaderof

the packagewith apitch of 1.8mm and a diameter

of 0.7 mm, the thermal resistance (junction heatsink) can be reduced to 12°C/W (see fig. 3).

Besidethe thermaladvantage, thissolutionallows

multi-layer boards to be used. However, a

drawback of this traditional material prevents its

use in very high power, high current circuits. For

instance, it is not advisable to surface mount

devices with currents greater than 10 A on FR4

2

boards. A Power Mosfet or Schottky diode in a

surfacemount power packagecan handleup to

around50 A ifbetter substratesare used.

FR4 board

Fig. 3 :

Mountingon epoxyFR4 byusing copper-filledthroughholesfor heattransfer

Copperfoil

heattransferheatsink

FR4board

11/15

RBO40-40G / RBO40-40M / RBO40-40T

A new technology available today is IMS - an

Insulated Metallic Substrate. This offers greatly

enhanced thermal characteristics for surface

mount components.IMS is a substrateconsisting

of threedifferentlayers,(I) thebasematerialwhich

is availableas an aluminiumor a copperplate, (II)

a thermal conductive dielectrical layer and (III) a

copper foil, whichcan be etched as a circuitlayer.

Using this material a thermalresistance of 8°C/W

with 40 cm

2

of board floating in air is achievable

(seefig. 4). If evenhigherpower is to bedissipated

an externalheatsink couldbe appliedwhich leads

to an R

that R

(j-a) of 3.5°C/W (see Fig. 5), assuming

th

(heatsink-air) is equal to R

th

(junction-heatsink). This is commonly applied in

practice, leading to reasonable heatsink

dimensions. Often power devices are defined by

Fig.4 :Mountingon metalbacked board

Copper foil

Insulation

consideringthe maximumjunction temperatureof

the device. In practice , however, this is far from

being exploited. A summary of various power

managementcapabilities is madein table1 based

on a reasonabledeltaT of70°Cjunctionto air.

The PowerSO-10 concept also represents an

attractive alternati ve to C.O.B. techniques.

PowerSO-10 offers devices fully tested at low

and high temperature. Mounting is simple - only

conventionalSMT isrequired - enabling the users

togetrid ofbondwire problemsand theproblemto

controlthe hightemperaturesoftsolderingas well.

An optimized thermal managementis guaranteed

th

through PowerSO-10 as the power chips must in

any case be mounted on heat spreaders before

beingmountedonto the substrate.

Fig. 5 :

Mounting on metal backed board with an

externalheatsinkapplied

Copper foil

FR4board

Alumini um

Aluminium

heatsink

TABLE1

PowerSo-10packagemountedon Rth(j-a) PDiss

1.FR4using the recommendedpad-layout

2

2.FR4withheatsink on board(6cm

)35°C/W 2.0 W

50 °C/W 1.5 W

3.FR4withcopper-filledthroughholes andexternalheatsink applied 12 °C/W 5.8 W

4. IMS floating inair (40cm

5. IMS with externalheatsinkapplied

2

)8°C/W 8.8 W

3.5 °C/W 20 W

12/15

PACKAGEMECHANICAL DATA

RBO40-40G / RBO40-40M / RBO40-40T

B

H

A1

Q

0.10A B

E3 E1

SEATING

PLANE

A

C

10

E

1

eB

0.25 M

6

E2

5

DETAIL”A”

D

h

D1

A

F

SEATING

PLANE

A1

L

DETAIL”A”

a

E4

DIMENSIONS

REF.

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

A 3.35 3.65 0.131 0.143

A1 0.00 0.10 0.00 0.0039

B 0.40 0.60 0.0157 0.0236

C 0.35 0.55 0.0137 0.0217

D 9.40 9.60 0.370 0.378

D1 7.40 7.60 0.291 0.299

E 9.30 9.50 0.366 0.374

E1 7.20 7.40 0.283 0.291

E2 7.20 7.60 0.283 0.299

DIMENSIONS

REF.

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

E3 6.10 6.35 0.240 0.250

E4 5.90 6.10 0.232 0.240

e 1.27 0.05

F 1.25 1.35 0.0492 0.0531

H 13.80 14.40 0.543 0.567

h 0.50 0.019

L 1.20 1.80 0.0472 0.0708

Q 1.70 0.067

a0° 8°0° 8°

13/15

RBO40-40G / RBO40-40M / RBO40-40T

FOOTPRINT

MOUNTINGPAD LAYOUT

RECOMMENDED

Dimensionsin millimeters Dimensionsin millimeters

HEADERSHAPE

SHIPPINGTUBE

C

B

A

Surfacemount film taping: contactsales office

A

B

C

Lengthtube

Quantityper tube

DIMENSIONS(mm)

TYP

18

12

0,8

532

50

14/15

PACKAGEMECHANICALDATA

TO220AB Plastic

RBO40-40G / RBO40-40M / RBO40-40T

DIMENSIONS

REF.

A 14.23 15.87 0.560 0.625

a1 4.50 0.177

a2 12.70 14.70 0.500 0.579

B 10.20 10.45 0.402 0.411

b1 0.64 0.96 0.025 0.038

b2 1.15 1.39 0.045 0.055

C 4.48 4.82 0.176 0.190

c1 0.35 0.65 0.020 0.026

c2 2.10 2.70 0.083 0.106

e 2.29 2.79 0.090 0.110

F 5.85 6.85 0.230 0.270

I 3.55 4.00 0.140 0.157

L 2.54 3.00 0.100 0.118

l2 1.45 1.75 0.057 0.069

l3 0.80 1.20 0.031 0.047

Millimeters Inches

Min. Max. Min. Max.

Information furnished is believedto be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility forthe

consequences of use of such information nor for any infringement of patents or other rights of third parties which may result fromits use.No

license is grantedby implicationor otherwise under any patent or patentrights of SGS-THOMSON Microelectronics.Specifications mentioned

in this publication are subjectto change withoutnotice. This publication supersedes andreplaces all informationpreviously supplied.

SGS-THOMSONMicroelectronics productsare notauthorized foruse as criticalcomponents in life support devices or systems without express

written approval of SGS-THOMSONMicroelectronics.

1997SGS-THOMSON Microelectronics -Printed inItaly - All rights reserved.

SGS-THOMSON MicroelectronicsGROUP OF COMPANIES

Australia- Brazil- Canada - China- France- Germany- Italy - Japan -Korea -Malaysia - Malta - Morocco

The Netherlands - Singapore - Spain- Sweden - Switzerland - Taiwan- Thailand - United Kingdom -U.S.A.

15/15

Loading...

Loading...