.FULL STEP - HALF STEP - QUARTER STEP

OPERATINGMODE

.BIPOLAROUTPUTCURRENT UP TO 1 A

.FROM 10 V UP TO 46 V MOTOR SUPPLY

VOLTAGE

.LOW SATURATION VOLTAGE WITH INTE-

GRATED BOOTSTRAP

.BUILTIN FASTPROTECTIONDIODES

.EXTERNALLY SELECTABLE CURRENT

LEVEL

.OUTPUT CURRENT LEVEL DIGITALLY OR

ANALOGUECONTROLLED

.THERMALPROTECTIONWITHSOFT INTER-

VENTION

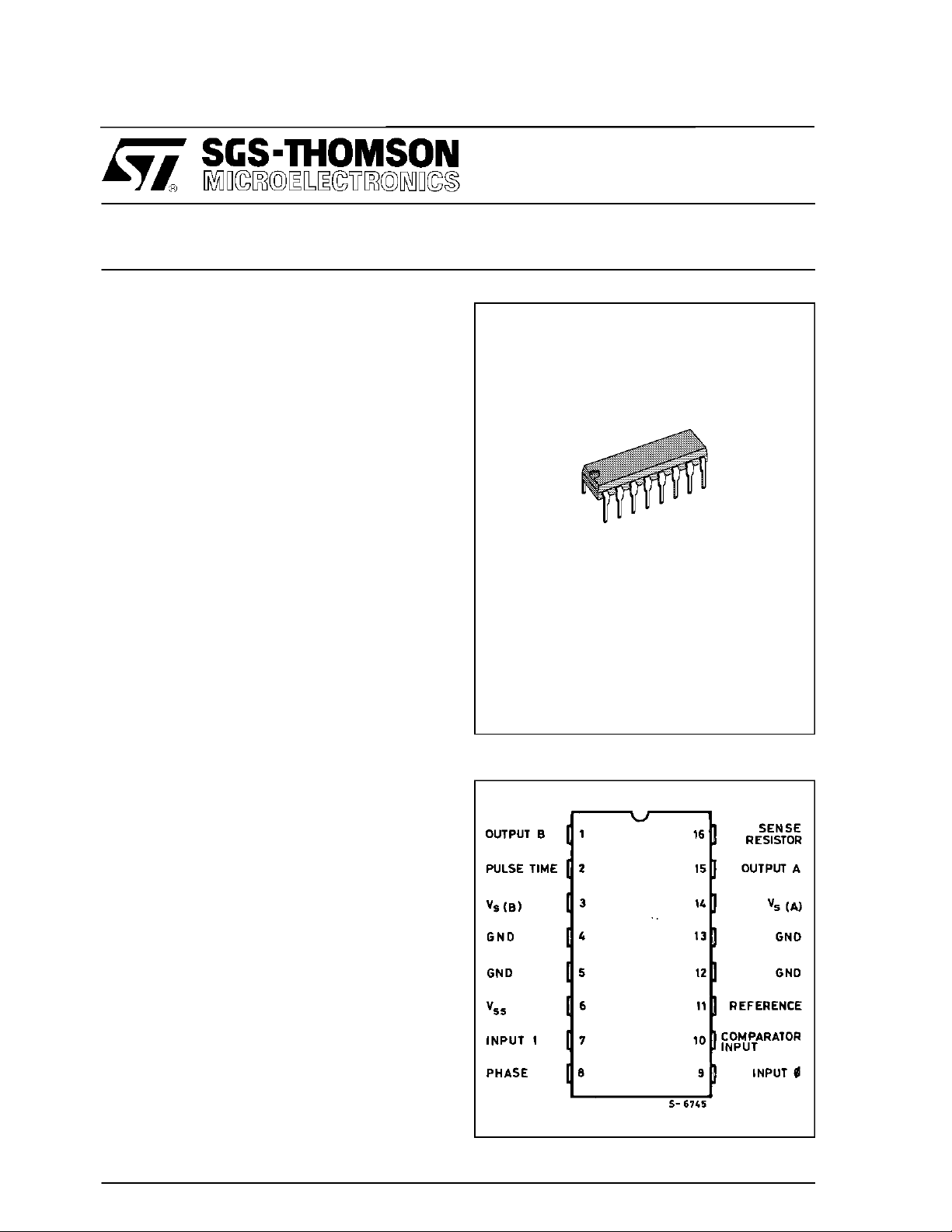

PBL3717A

STEPPER MOTOR DRIVER

Powerdip 12 + 2 + 2

(PlasticPackage)

ORDER CODE : PBL3717A

DESCRIP TION

ThePBL3717AisamonolithicICwhichcontrolsand

drives one phase of a bipolar stepper motor with

choppercontrolofthe phasecurrent.Currentlevels

maybeselectedinthreestepsbymeansoftwologic

inputswhich select one of threecurrent comparators.Whenbothof theseinputsare highthe device

isdisabled.Aseparatelogicinputcontrolsthedirectionof current flow.

A monostable,programmedby an externalRC network,sets the currentdecaytime.

Thepower sectionisa full H-bridge driver with four

internal clamp diodes for current recirculation. An

externalconnectiontotheloweremittersisavailable

for the insertion of a sensing resistor. Two

PBL3717Asand few external componentsform a

completesteppermotor drive subsystem.

The raccomendedoperating ambient temperature

rangesis from 0 to 70 °C.

ThePBL3717Aissuppliedina12+2+ 2leadPowerdippackage.

April1993

PIN CONNECTI ON (top view)

1/11

PBL3717A

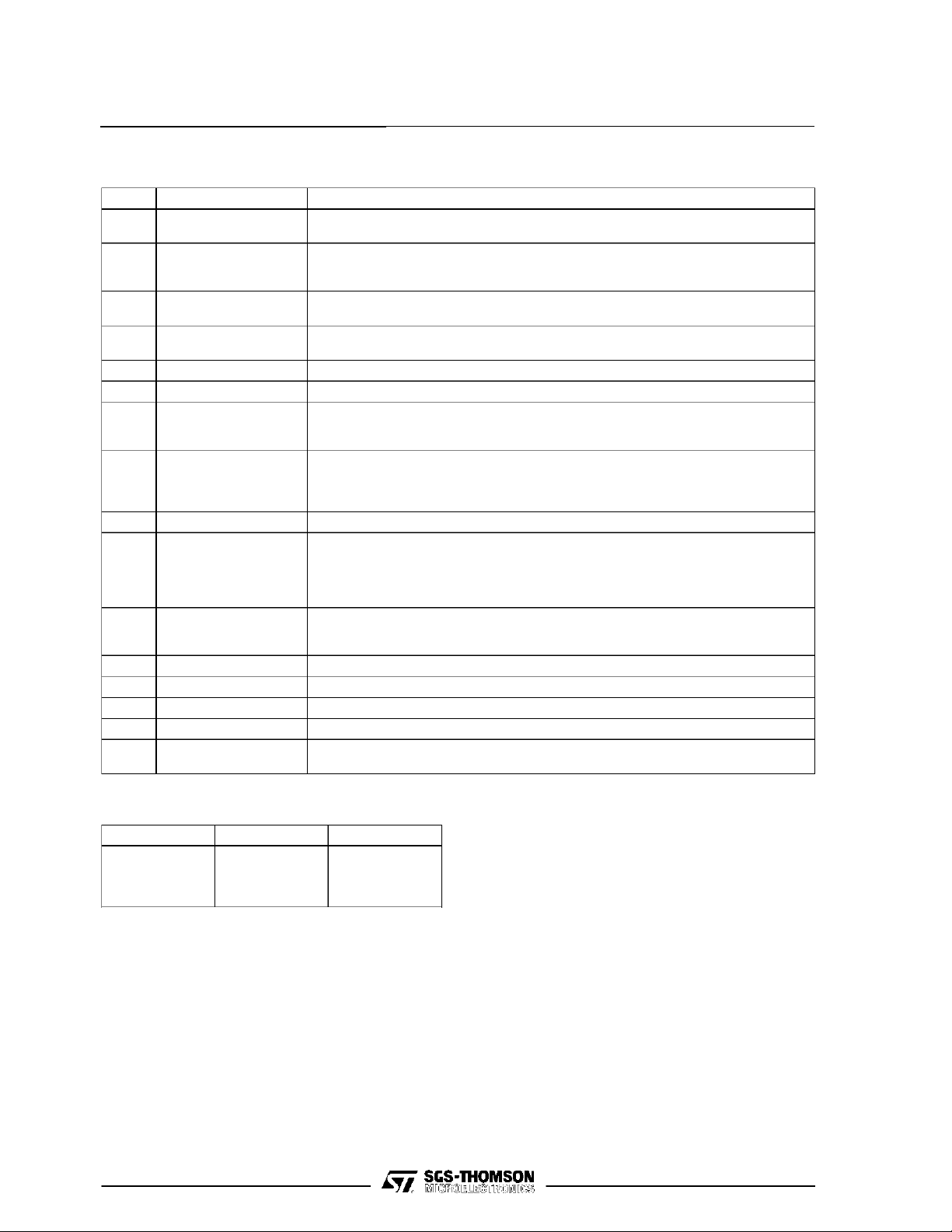

PIN FUNCTIONS

N° Name Function

1 UTPUT B Output Connection (with pin 15). The outputstage is a ”H” bridge formed by four

2 PULSE TIME A parallel RC network connected to this pin sets the OFF time of the lower power

3 SUPPLY VOLTAGE B Supply Voltage Input for Half Output Stage

4 GROUND Ground Connection. With pins 5, 12 and 13 also conducts heat from die to

5 GROUND See pin 4.

6 LOGIC SUPPLY Supply Voltage Input for Logic Circuitry

7 INPUT 1 This pin and pin 9 (INPUT 0) are logic inputs which select the outputs of the

8 PHASE This TTL-compatible logic input sets the directionof current flow through the

9 INPUT 0 See INPUT 1 (pin 7) .

10 COMPARATOR

INPUT

11 REFERENCE A voltage applied to this pin sets thereference voltage of the three comparators,

12 GROUND See pin 4.

13 GROUND See pin 4.

14 SUPPLY VOLTAGE A Supply Voltage Input for Half Output Stage. See also pin 13.

15 OUTPUT A See pin 1.

16 SENSE RESISTOR Connection to Lower Emitters of Output Stage for Insertion of Current Sense

transistors and four diodes suitable for switching applications.

transistors. The pulse generator is a monostable triggered by the rising edge of

the output of the comparators (t

= 0.69 RTCT).

off

See also pin 14.

printed circuit copper.

three comparators to set the current level. Current also depends on the sensing

resistor and reference voltage. See truth table.

load. A high level causes current to flow from OUTPUT A (source) to OUTPUT

B (sink). A schmitt trigger on this input provides good noise immunity and a delay

circuit prevents output stage short circuits during switching.

Input connected to the three comparators. The voltage across the sense resistor

is feedback to thisinput through the low pass filter R

transistor are disabled when the sense voltage exceeds the reference voltage of

. The lower power

CCC

the selected comparator. When this occursthe current decays for a time set by

R

TCT,toff

this determining the output current(also thus depending on R

INPUT 0 and INPUT 1).

= 0.69 RTCT.

and the two inputs

s

Resistor

TRUTH TABLE

Input 0 (pin 9) Input 1 (pin 7)

H

L

H

L

2/11

H

H

L

L

No Current

Low Current

Medium Current

High Current

BLOCK DIAGRAM

PBL3717A

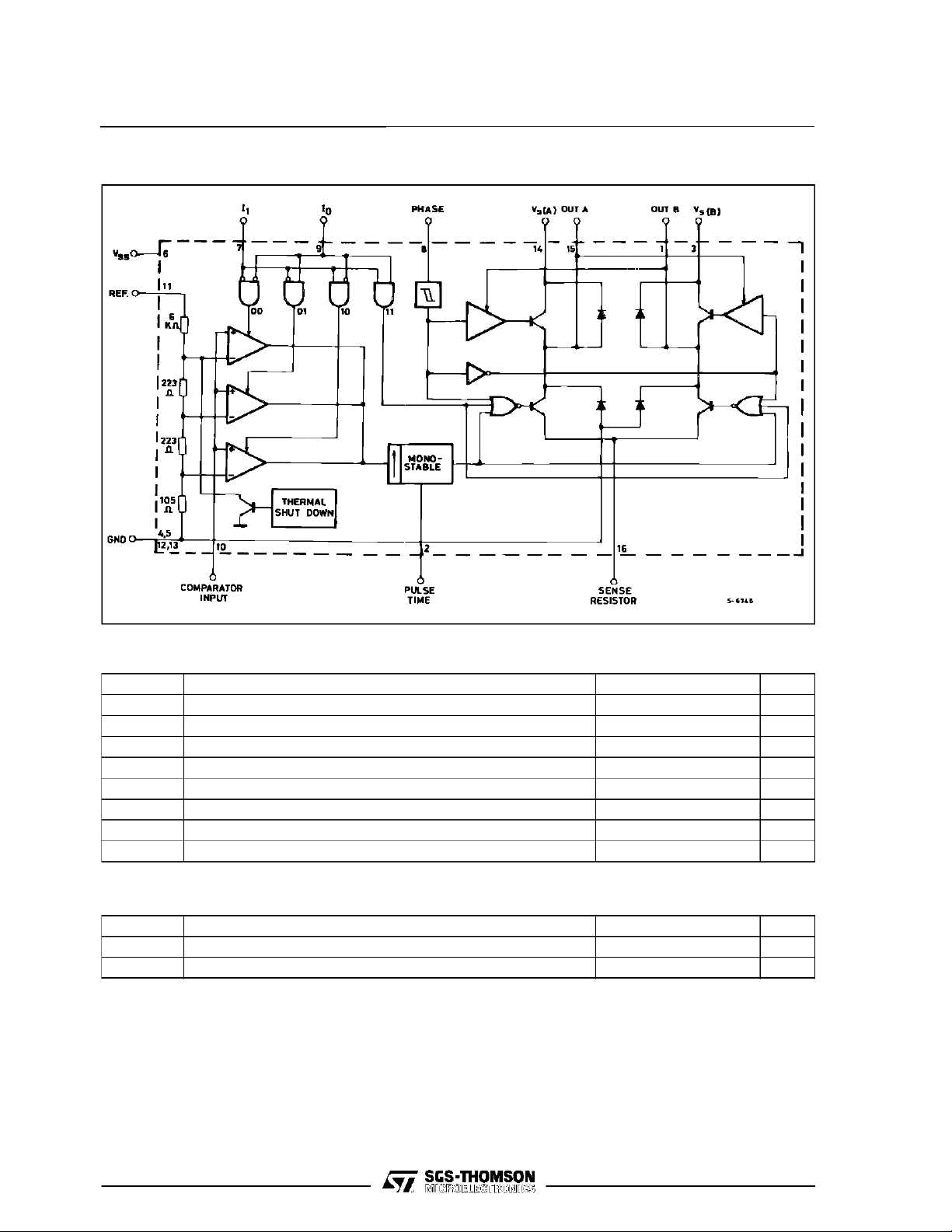

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

s

V

ss

V

V

c

V

r

I

o

T

stg

T

j

Power Supply Voltage 50 V

Logic Supply Voltage 7 V

Logic Input Voltage 6 V

i

Comparator Input V

ss

Reference Input Voltage 15 V

Output Current (DC operation) 1.2 A

Storage Temperature – 55 to + 150 °C

Operating Junction Temperature 150 °C

THERMAL DATA

Symbol Parameter Value Unit

R

th j-case

R

th j-amb

*

Solderedon a 35µ thick 20cm

Thermal Resistance Junction-pins 11 °C/W

Thermal Resistance Junction-ambient* 40 °C/W

2

P.C.board copper area.

3/11

PBL3717A

ELECTRICAL CHARACTERISTICS

(refer to the test circuit V

= 36V, VSS= 5V, T

S

Symbol Parameter Test Conditions Min. Typ. Max. Unit

V

V

I

Supply Voltage (pin 3, 14) 10 46 V

s

Logic Supply Voltage (pin 6) 4.75 5.25 V

ss

Logic Supply Current (pin 6) 7 15 mA

ss

Reference InputCurrent (pin 11) VR= 5V 0.75 1 mA

I

R

LOGIC INPUTS

V

V

I

Input Low Voltage (pins 7, 8, 9) 0.8 V

iL

Input High Voltage (pin 7, 8, 9) 2 V

iH

Low Voltage Input Current (pins 7, 8, 9) Vi= 0.4V pin 8

I

iL

High Voltage Input Current (pins 7, 8, 9) Vi= 2.4V 10 µA

iH

COMPARATORS

V

V

V

t

I

Comparator Low Threshold Voltage (pin 10) VR=5V Io=L

CL

Comparator Medium Threshold Voltage (pin 10) VR=5V Io=L

CM

Comparator High Threshold Voltage (pin 10) VR=5V Io=L

CH

I

Comparator Input Current (pin 10) ± 20 µA

C

Cutoff Time RT= 56kΩ CT= 820pF 25 35 µs

off

Turn Off Delay (see fig. 2) 2 µs

t

d

Output Leakage Current (pins 1, 15) Io=H I1= H 100 µA

off

SOURCE DIODE-TRANSISTOR PAIR

V

V

I

I

V

SLK

Saturation Voltage (pins 1, 15) IM= – 0.5A (see fig. 2)

sat

Saturation Voltage (pins 1, 15) IM= – 1A (see fig. 2)

sat

Leakage Current Vs= 46 V 300 µA

LK

Diode Forward Voltage IM= – 0.5A

F

Substrate Leakage Current when Clamped IM= – 0.5A

SINK DIODE-TRANSISTOR PAIR

V

I

V

Saturation Voltage (pins 1, 15) IM= 0.5A

sat

Leakage Current Vs= 46V 300 µA

LK

Diode Forward Voltage IM= 0.5A

F

=25oC unless otherwise specified)

amb

pins 7, 9

=H

I

1

=H

I

1

=H

I

1

Conduction Period

Recirculation Period

Conduction Period

Recirculation Period

=–1A

I

M

=–1A

I

M

=1A

I

M

=1A

I

M

ss

– 100

– 400µAµA

66 78 90 mV

236 251 266 mV

396 416 436 mV

1.7

2.1

1.1

1.35

2.1

2.8

1.7

2.5

1

1.25

1.3

1.7

25mA

1.1

1.35

1.6

2.3

1.1

1.5

1.4

2

V

V

V

V

V

mA

V

V

V

V

4/11

Figure 1 : Test and ApplicationCircuit

Figure 2 : WaveformswithMA Regulating(phase= 0)

PBL3717A

5/11

PBL3717A

Figure 3 : TwoPhaseBipolarStepperMotor Driver

Figure 4 : P.C. Board and ComponentLayout of the Circuit of fig. 3 (1 : 1 scale)

6/11

Figure 5 : Inputand OutputSequencesfor Half Stepand FullStep Operation

PBL3717A

APPLIC ATI O N INFO RMATIO NS

Figure 3 shows a typical application in which two

PBL3717Acontrolatwo phasebipolarsteppermotor.

Programming

ThelogicinputsI

andI1setat threedifferentlevels

0

the amplitude of the current flowing in the motor

windingaccordingtothetruthtableofpage2.Ahigh

levelon the ”PHASE” logic input sets the direction

ofthatcurrentfromoutputA to outputB; a lowlevel

from outputB to outputA.

It is recommended that unused inputs are tied to

pin 6 (V

) or pin 4 (GND) as appropriateto avoid

ss

noiseproblem.

The current levels can be varied continuously by

changingthe ref.voltageon pin 11.

Control ofthe Motor

Thesteppermotorcanrotateineitherdirectionsaccording to the sequenceof the input signals. It is

possibletoobtaina fullstep, a half step anda quarter step operation.

Full StepOperation

Both the windings of the stepper motor are energizedall the time withthe same current I

I

andI1remainfixedat whatevertorquevalueisre-

0

MA=IMB

.

quired.

Calling A the conditionwith winding A energizedin

one direction and A in the other direction, the sequencefor fullstep rotation is :

AB → AB → AB → ABetc.

Forthe rotationin the otherdirection the sequence

must be reserved.

Inthefullstepoperationthetorqueisconstanteach

step.

HalfStep Operation

Power is applied alternately to one winding then

bothaccording to the sequence:

AB → B → AB → A → AB → B → AB → Aetc.

Likefull step thiscan be doneat anycurrentlevel;

the torqueis not constantbut it is lowerwhen only

one windingis energized.

A coilis turnedoff bysetting I

and I1bothhigh.

0

7/11

PBL3717A

QuarterStep Operation

It ispreferable to realizethe quarterstep operation

at full power otherwise the steps will be of very irregularsize.

Theextraquarterstepsare addedto the half steps

sequencebyputtingonecoilonhalf currentaccordingto the sequence.

A

AB →

B → B →

2

__

A

B→ AB → A

2

B

→ A etc.

2

MotorSelection

As the PBL3717Aprovides constantcurrent drive,

withaswitchingoperation,caremustbetakentoselect stepper motors with low hysteresis losses to

preventmotorover heat.

Figure6 : SourceSaturationVoltageversus

OutputCurrent (recircuitperiod)

L -C Filter

To reduce EMI and choppinglossesin themotora

lowpass L -C filter can be inserted acrossthe outputsofthePBL3717Aasshownonthefollowingpicture.

−10

L ≈

1

10

LM C ≈

⋅ 10

4

L

Figure7 : SourceSaturationVoltageversus

OutputCurrent(conductionperiod)

Figure8 : Sink SaturationVoltageversus

OutputCurrent

8/11

Figure9 : ComparatorThreshold versus

JunctionTemperature

PBL3717A

MOUNTINGINSTRUCTIONS

The R

of the PBL 3717A can be reduced by

th j-amb

solderingthe GNDpinsto asuitablecopperareaof

the printedcircuit board or to an external heatsink.

Figure10 : Exampleof P.C. BoardCopper Area

whichis usedas Heatsink

Thediagramoffig. 11showsthemaximumdissipable power P

andthe R

tot

as a functionof the

th j-amb

side”α” oftwo equal squarecopperareashaving a

thichknessof35µ (seefig. 10).

Figure11 : Max.Dissipable Power andJunction-

AmbientThermalResistanceversus

size ”a”

9/11

PBL3717A

POWERDIP16 PACKAGE MECHANICAL DATA

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

a1 0.51 0.020

B 0.85 1.40 0.033 0.055

b 0.50 0.020

b1 0.38 0.50 0.015 0.020

D 20.0 0.787

E 8.80 0.346

e 2.54 0.100

e3 17.78 0.700

F 7.10 0.280

I 5.10 0.201

L 3.30 0.130

Z 1.27 0.050

mm inch

10/11

PBL3717A

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for

the consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from its

use. No license is granted by implication or otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specifications mentioned in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied. SGS-THOMSON Microelectronics products are not authorized for use as critical components in life support devices or

systems withoutexpress written approval of SGS-THOMSON Microelectronics.

1994 SGS-THOMSON Microelectronics - All Rights Reserved

Australia - Brazil - France - Germany - Hong Kong - Italy - Japan - Korea - Malaysia - Malta - Morocco - The Netherlands - Singapore -

SGS-THOMSON Microelectronics GROUP OF COMPANIES

Spain - Sweden - Switzerland - Taiwan - Thaliand - UnitedKingdom - U.S.A.

11/11

Loading...

Loading...