SGS Thomson Microelectronics M87C257 Datasheet

256K (32K x 8) UV EPROM and OTP EPROM

INTEGRA TE D ADDRE SS LATCH

FA ST ACCESS TIME: 45ns

LOW POWER “CMOS” CONSUMPTION:

– Active Current 30mA

– Standby Current 100µA

PROGRAMMING VOLTAGE: 12.75V

ELECTRONI C S IG NATURE for AUTOM ATED

PROGRAMMING

PROGRAM MING T IM ES of ARO UND 3sec.

(PRESTO II ALGORITHM)

DESCRIP TION

The M87C257 is a high speed 262,144 bit UV

erasable and electrically programmable EPROM.

The M87C257 incorporates latches for all address

inputs to minimize chip count, reduce cost, and

simplify the design of multiplexed bus systems.

The Window Ceramic Frit-Seal Dual-in-Line package has a transparent lid which allows the user to

expose the chip to ultraviolet light to erase the bit

pattern. A new pattern can then be written to the

device by following the programming procedure.

For applications where the content is pr ogrammed

only one time and erasure is not required, the

M87C257 is offered in Plas tic Leaded Chip Carrier ,

package.

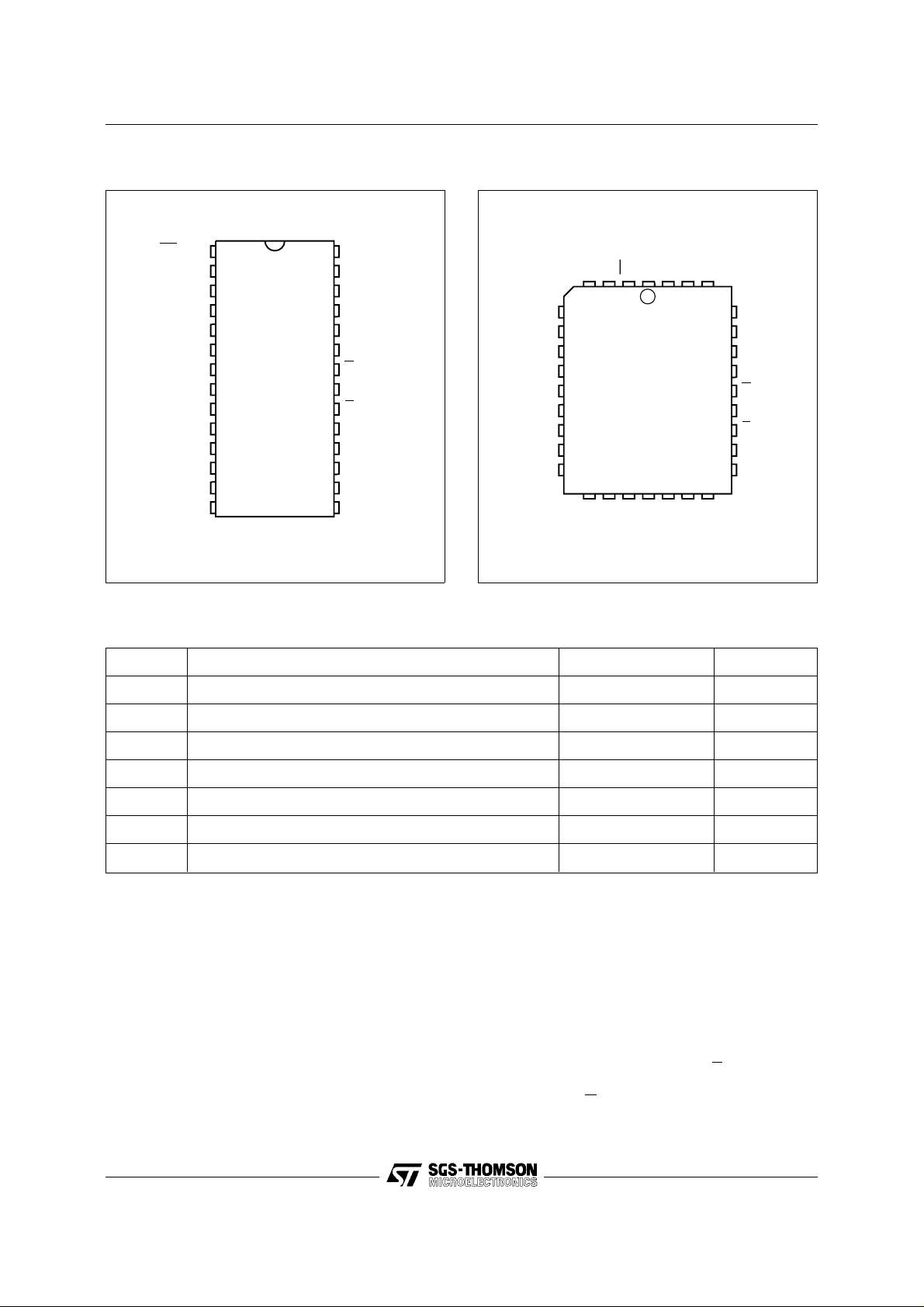

ADDRESS LATCHED

28

1

FDIP28W (F)

Figure 1. Logic Diag ra m

V

CC

15

A0-A14

E

M87C257

M87C257

PLCC32 (C)

8

Q0-Q7

G

T able 1. Signal Names

A0 - A14 Address Inputs

Q0 - Q7 Data Outputs

E Chip Enable

G Output Enable

ASV

PP

V

CC

V

SS

June 1996 1/13

Address Strobe / Program Supply

Supply Voltage

Ground

ASV

PP

V

SS

AI00928B

M87C257

Figure 2A. DIP Pin Connecti on s

ASV

PP

A12

A7

A6

A5

A4

A3

A2

A1

A0

Q0

Q2

SS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

M87C257

28

27

26

25

24

23

22

21

20

19

18

17

16

15

AI00929

V

CC

A14

A13

A8

A9

A11

G

A10

E

Q7

Q6

Q5Q1

Q4

Q3V

Figure 2B. LCC Pin Conn ecti ons

PP

CC

A13

DU

32

DU

V

Q3

A14

Q4

25

Q5

A8

A9

A11

NC

G

A10

E

Q7

Q6

AI00930

ASV

A7

A12

1

A6

A5

A4

A3

A2

9

M87C257

A1

A0

NC

Q0

17

Q1

Q2

SS

V

Warning: NC = Not Connected, DU = Dont’t Use.

Tab l e 2. Absolu te Maxi mu m Ratin gs

Symbol Parameter Value Unit

T

A

T

BIAS

T

STG

(2)

V

IO

V

CC

(2)

V

A9

V

PP

Notes: 1. Except for the rating "Operating Temperature Range", stresses above those lis ted in the Table "Absolute Maximum Ratings"

2. Minimum DC voltage on Input or Output is –0.5V with possible undershoot to –2.0V for a period less than 20 ns. Maximum DC

Ambient Operating Temperature –40 to 125 °C

Temperature Under Bias –50 to 125 °C

Storage Temperature –65 to 150 °C

Input or Output Voltages (except A9) –2 to 7 V

Supply Voltage –2 to 7 V

A9 Voltage –2 to 13.5 V

Program Supply Voltage –2 to 14 V

may cause permanent damage to the device. These are stress ratings only and operation of the device at these or any other

conditions above those indicated in the Operating sections of this specificat ion is not implied. Exposure to Abs olute Maxi mum

Rating conditions for extended periods may affect device reliability . Refer also to the SGS-THOMS O N SURE Program and other

relevant quality documents.

voltage on Output is V

+0.5V with possible ove rshoot to VCC +2V for a period less than 20ns.

CC

DEVICE OPER ATION

The modes of operation of the M87C257 are listed

in the Operating Modes. A single power supply is

required in the read mode. All inputs are T TL levels

except for V

and 12V on A9 for Elect ronic S igna-

PP

ture.

(1)

Read Mode

The M87C257 has two control functions, both of

which must be logically active in order to obtain

data at the outputs. Chip Enable (

E) is the power

control and should be used for device selection.

Output Enable (

G) is the output control and should

2/13

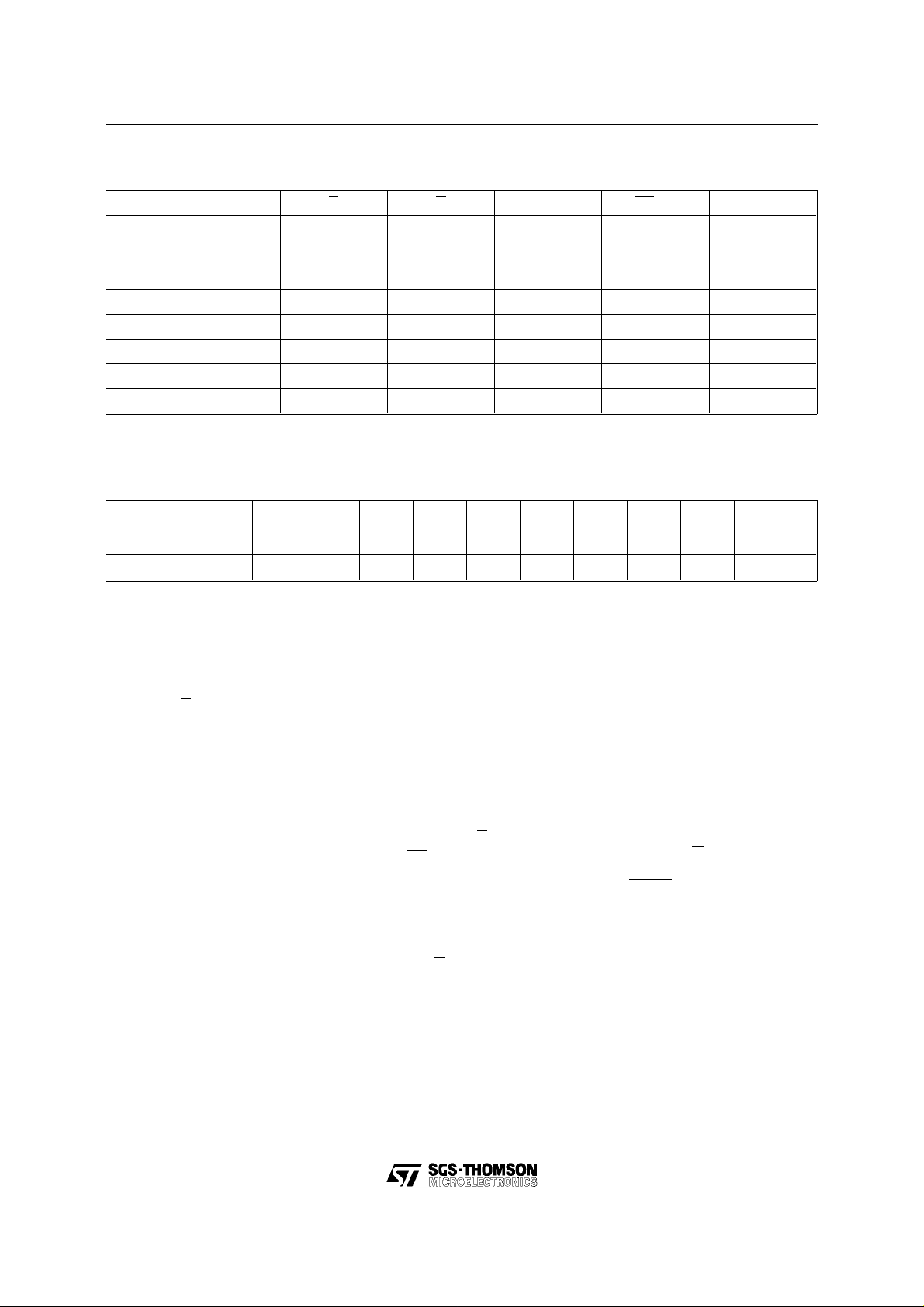

T ab le 3. Operating Modes

M87C257

Mode E GA9ASV

Read (Latched Address) V

Read (Applied Address) V

Output Disable V

Program V

Verify V

Program Inhibit V

Standby V

Electronic Signature V

Note: X = VIH or VIL, VID = 12V ± 0.5V

IL

IL

IL

Pulse V

IL

IH

IH

IH

IL

V

IL

V

IL

V

IH

IH

V

IL

V

IH

X X X Hi-Z

V

IL

XVILData Out

XVIHData Out

X X Hi-Z

XVPPData In

XVPPData Out

XVPPHi-Z

V

ID

PP

V

IL

T ab le 4. Electron ic Sig natu r e

Identifier A0 Q7 Q6 Q5 Q4 Q3 Q2 Q1 Q0 Hex Data

Manufacturer’s Code V

Device Code V

IL

IH

be used to gate data to the output pins, independent of device selection. Assuming that the

addresses are stable (

), the address access time (t

V

IL

delay from

E to output (t

the output after delay of t

G, assuming that E has been low and the ad-

of

AS = VIH) or latched (AS =

ELQV

GLQV

dresses have been stable for at least t

The M87C257 reduces the hardware interface in

multiplexed address-data bus systems. The processor multiplexed bus (AD0-AD7) may be tied to

the M87C257’s address and data pins. No separate address latch is needed because the

M87C257 latches all address inputs when

low.

Standby Mode

The M87C257 has a standby mode which reduces

the active current from 30mA to 100µA (Address

Stable). The M87C257 is placed in the standby

mode by applying a CMOS high signal to the

00100000 20h

10000000 80h

Two Line Output Control

Because EPROMs are usually used in larger mem-

) is equal to the

AVQV

). Data is available at

from the falling edge

AVQV-tGLQV

ory arrays, this product features a 2 line control

function which accommodates the use of multiple

memory connection. The two line control function

allows:

.

a. the lowest possible memory power dissipation,

b. complete assuranc e that output bus cont entio n

will not occur.

For the most efficient use of thes e two control lines,

E should be decoded and used as the primary

AS is

device selecting function, while

G should be made

a common connection to all devices in the array

and connected to the

READ line from the system

control bus. This ensures that all dese lected memory devices are in their low power standby mode

and that the output pins are only active when data

is desired from a particular memory device.

E

input. When in the standby mode, the outputs are

in a high impedance state, independent of the

G

input.

Q0 - Q7

Codes

3/13

M87C257

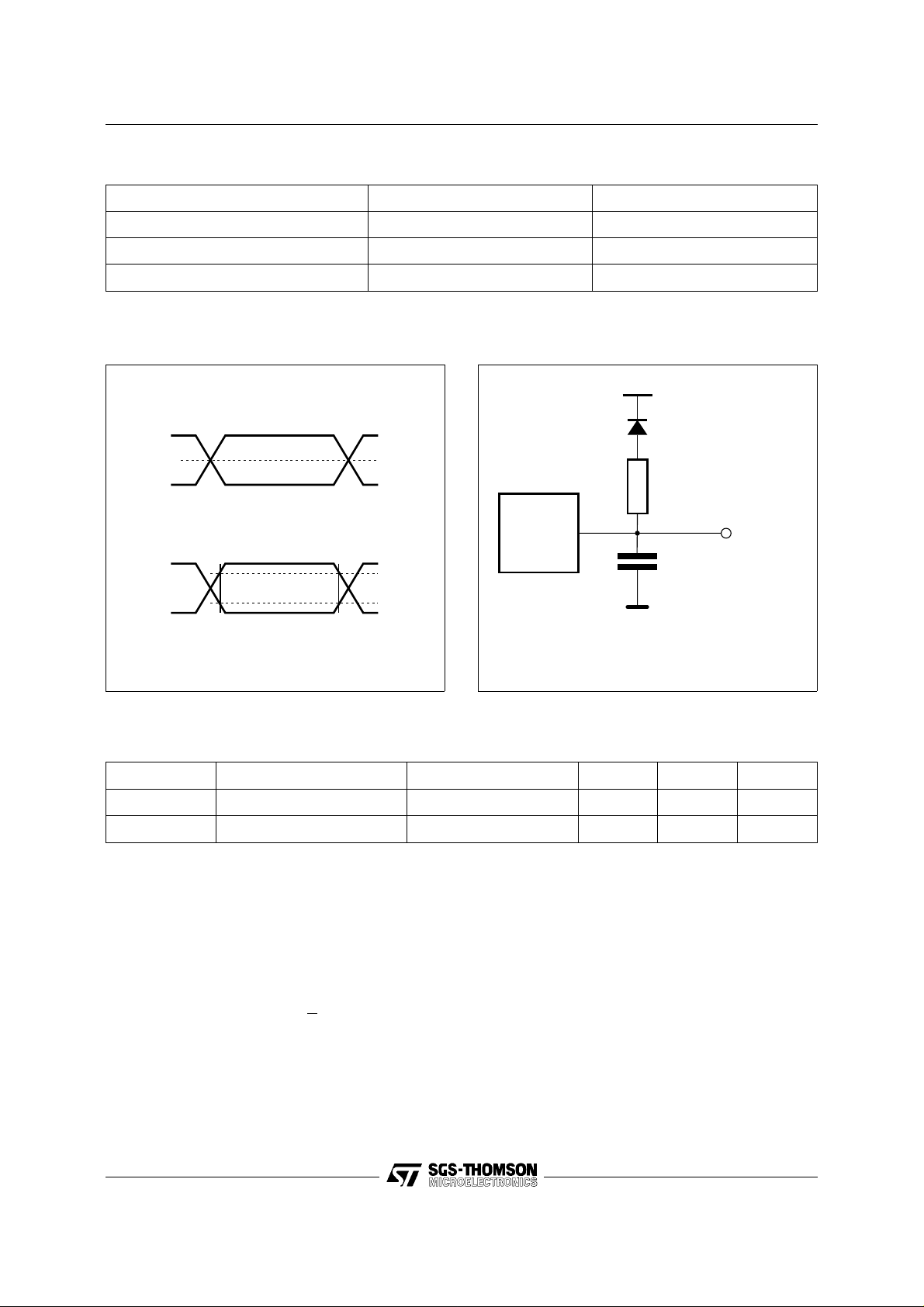

T ab le 5. AC Measurement Con ditions

High Speed Standard

Input Rise and Fall Times ≤ 10ns ≤ 20ns

Input Pulse Voltages 0 to 3V 0.4V to 2.4V

Input and Output Timing Ref. Voltages 1.5V 0.8V and 2V

Figure 3. AC Test ing Input Outp ut W avefo rm

High Speed

3V

1.5V

0V

Standard

2.4V

0.4V

T ab le 6. Capacitance

Symbol Parameter Test Condition Min Max Unit

C

IN

C

OUT

Note: 1. Sampled only , not 100% tested.

(1)

(TA = 25 °C, f = 1 MHz )

Input Capacitance VIN = 0V 6 pF

Output Capacitance V

2.0V

0.8V

AI01822

Figure 4. AC T est ing Load Circu it

1.3V

1N914

3.3kΩ

DEVICE

UNDER

TEST

CL = 30pF or 100pF

CL = 30pF for High Speed

CL = 100pF for Standard

CL includes JIG capacitance

= 0V 12 pF

OUT

OUT

AI01823

System Consi der atio n s

The power switching characteristics of Advance

CMOS EPROMs require careful decoupling of the

devices. The supply current, I

, has three seg-

CC

ments that are of interest to the system designer:

the standby current level, the active current level,

and transient current peaks that are produced by

the falling and rising edges of

E. The magnitude of

this transient current peaks is dependent on the

capacitive and inductive loading of the device at the

output. The associated transient vo ltage peaks can

be suppressed by complying with the two line

4/13

output control and by properly select ed decoupling

capacitors. It is recommended that a 0.1µF ceramic

capacitor be used on every device between V

CC

and VSS. This should be a high frequency capacitor

of low inherent inductance and should be placed

as close to the device as possible. In addition, a

4.7µF bulk electrolytic capacitor should be used

between V

and VSS for every eight devices. The

CC

bulk capacitor should be located near the power

supply connection point. The purpose of the bulk

capacitor is to overcome the voltage drop caused

by the inductive effects of PCB trac es.

Loading...

Loading...