SGS Thomson Microelectronics M58BW016DT, M58BW016DB, M58BW016BT, M58BW016BB, M58BW016 Datasheet

1/63May 2003

M58BW016BT, M58BW016BB

M58BW016DT, M58BW016DB

16 Mb i t ( 512Kb x32, B oot Bl oc k, Bur st)

3V Supply Flash Memories

PE4FEATU R ES SUMMA R Y

■ SUPPLY VOLTAGE

–V

DD

= 2.7V to 3. 6V for Program, Erase and

Read

–V

DDQ

= V

DDQIN

= 2.4V to 3.6V for I/O Buffers

–V

PP

= 12V for fast Program (optional)

■ HIGH PERFORMANCE

– Access Time: 80, 90 and 100ns

– 56MHz Effective Zero Wait-State Burst Read

– Synchronous B urst Reads

– Asynchronous Pa ge Reads

■ HARDWARE BLOCK PROTECT ION

–W

P pin Lock Program and Erase

■ SOFTWARE BLOCK PROTECTION

– Tuning Protection to Lock Program and

Erase with 64 b it User Programmable Password (M58BW016B version only)

■ OPTIMIZED for FDI DRIVERS

– Fast Program / Erase susp end latency

time < 6µs

– Comm on Fla sh Interface

■ MEMORY BLOCKS

– 8 Parameters Blocks (Top or Bottom)

– 31 Main Blocks

■ LOW POWER CONSUMPTION

– 5µA Typical Deep Power Down

– 60µA Typic al Standby

– Automatic Standby after Asynchronous Read

■ ELECTRONIC SIGNATURE

– Manufacturer Code: 20h

– Top Device Code M58BW 016xT: 8836h

– Bottom Device Code M58BW 016x B: 8835 h

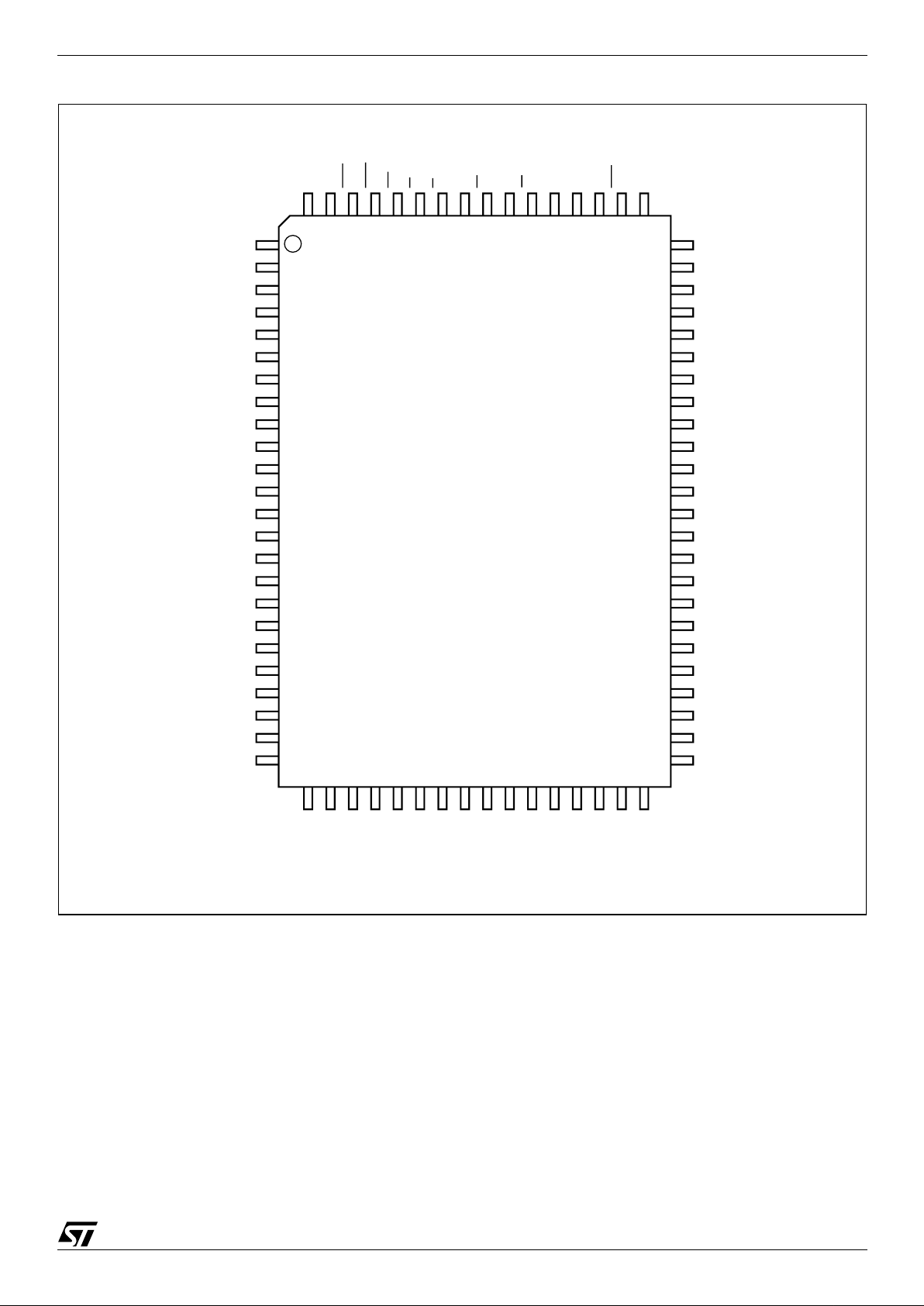

Figure 1. Packages

BGA

LBGA80 (ZA)

10 x 8 ball array

PQFP80 (T)

M58BW016BT, M58BW016BB, M58BW016D T, M58BW016DB

2/63

TABLE OF CONTENTS

SUMMARY DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. Logic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 1. Signal Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. LBGA Connections (Top view through package) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. PQFP Connections (Top view through package). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Block Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Tuning Block Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 2. Top Boot Block Addresses, M58BW016B T, M58BW016DT . . . . . . . . . . . . . . . . . . . . . . 11

Table 3. Bottom Boot Block Addresses, M58BW016B B , M58BW016DB . . . . . . . . . . . . . . . . . . . 12

SIGNAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Address Inputs (A0-A18). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Data Inputs/Outputs (DQ0-DQ31 ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Chip Enable (E). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Output Enable (G). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Output Disable (GD).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Write Enable (W). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Reset/Power-Down (RP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Latch Enable (L).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Burst Clock (K).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Burst Address Advance (B). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Valid Data Ready (R). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Write Protect (WP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Supply Volt a g e (V

DD)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Output Supply Voltage (V

DDQ

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Input Supply Voltage (V

DDQIN

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Program/Erase Supply Voltage (V

PP

).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Ground (V

SS

and V

SSQ

). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

BUS OPERATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Asynchronous Bus Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Asynchronous Bus Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 5

Asynchronous Latch Controlled Bus Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Asynchronous Page Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Asynchronous Bus Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Asynchronous Latch Controlled Bus Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Output Disable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Automatic Low Power.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Power-Down.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 6

Electronic Signature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

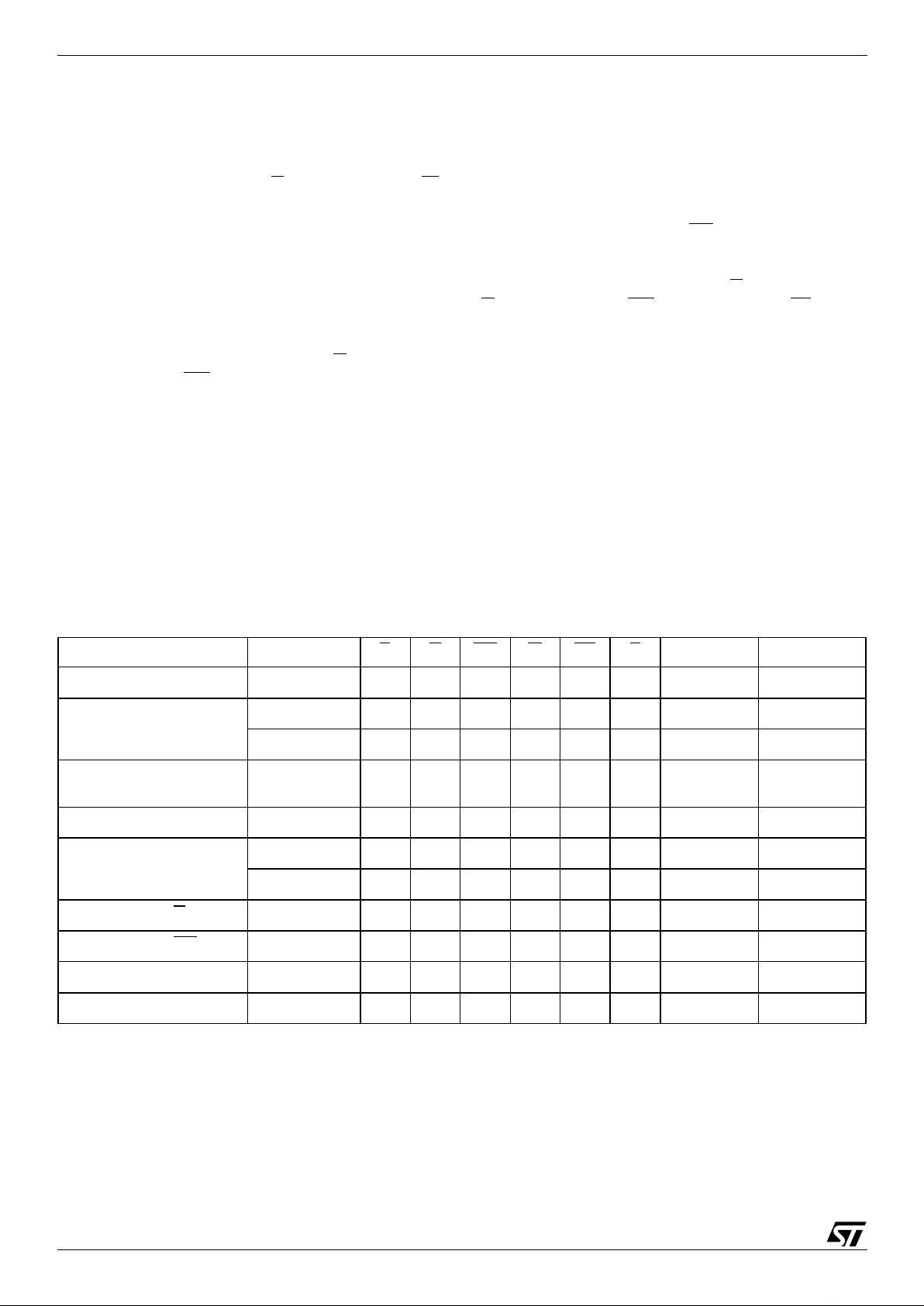

Table 4. Asynchronous Bus Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 5. Asynchronous Read Electronic Signature Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3/63

M58BW016BT, M58BW016BB, M58BW016DT, M58BW016DB

Synchronous Bus Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Synchronous Burst Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Synchronous Burst Read Suspend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

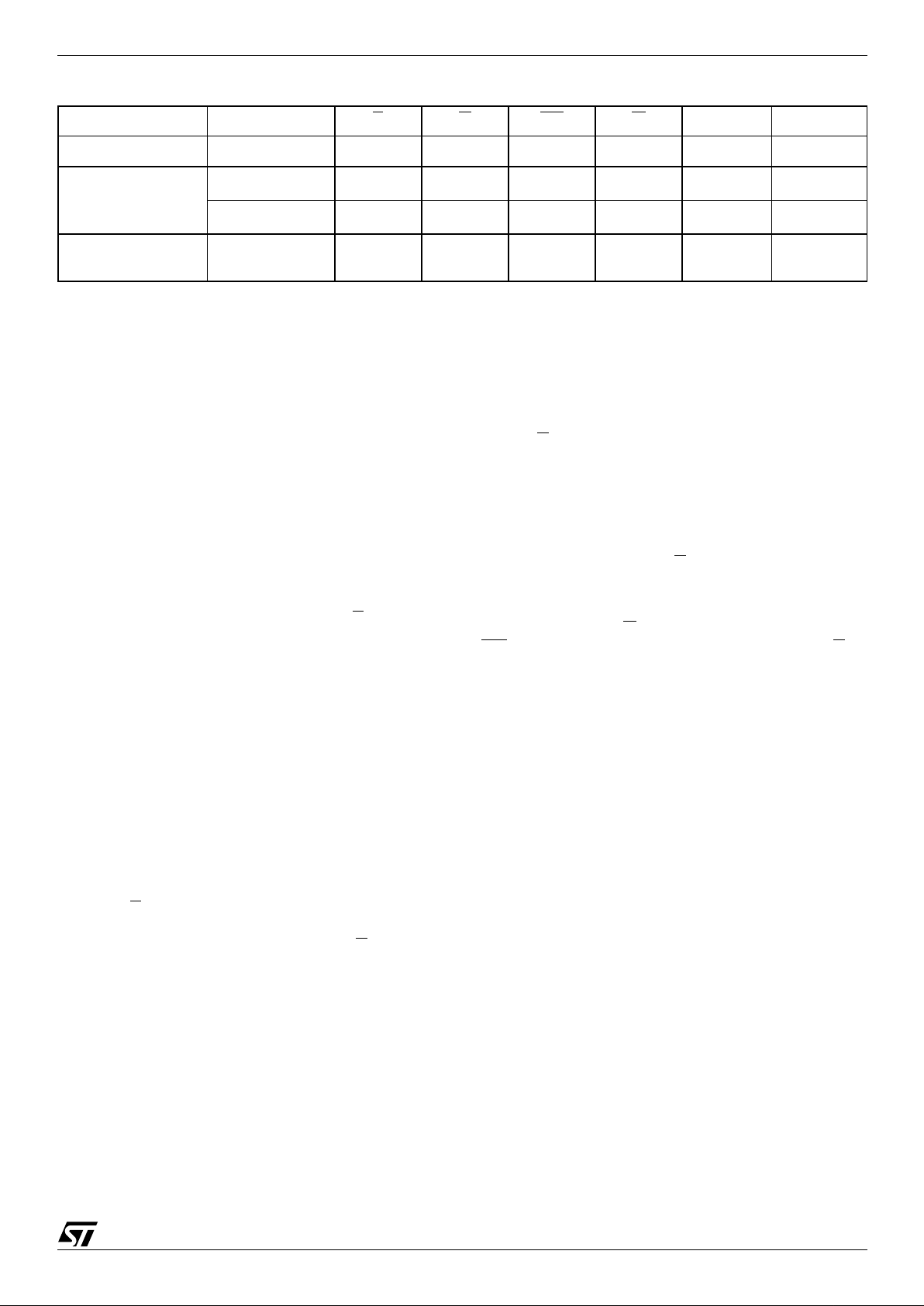

Table 6. Synchronous Burst Read Bus Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Burst Configuration Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Read Select Bit (M15) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

X-Latency Bits (M14-M11). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Y-Latency Bit (M9). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Valid Data Ready Bit (M8). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Burst Type Bit (M7).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Valid Clock Edge Bit (M6).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wrap Burst Bit (M3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Burst Length Bit (M2-M0).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

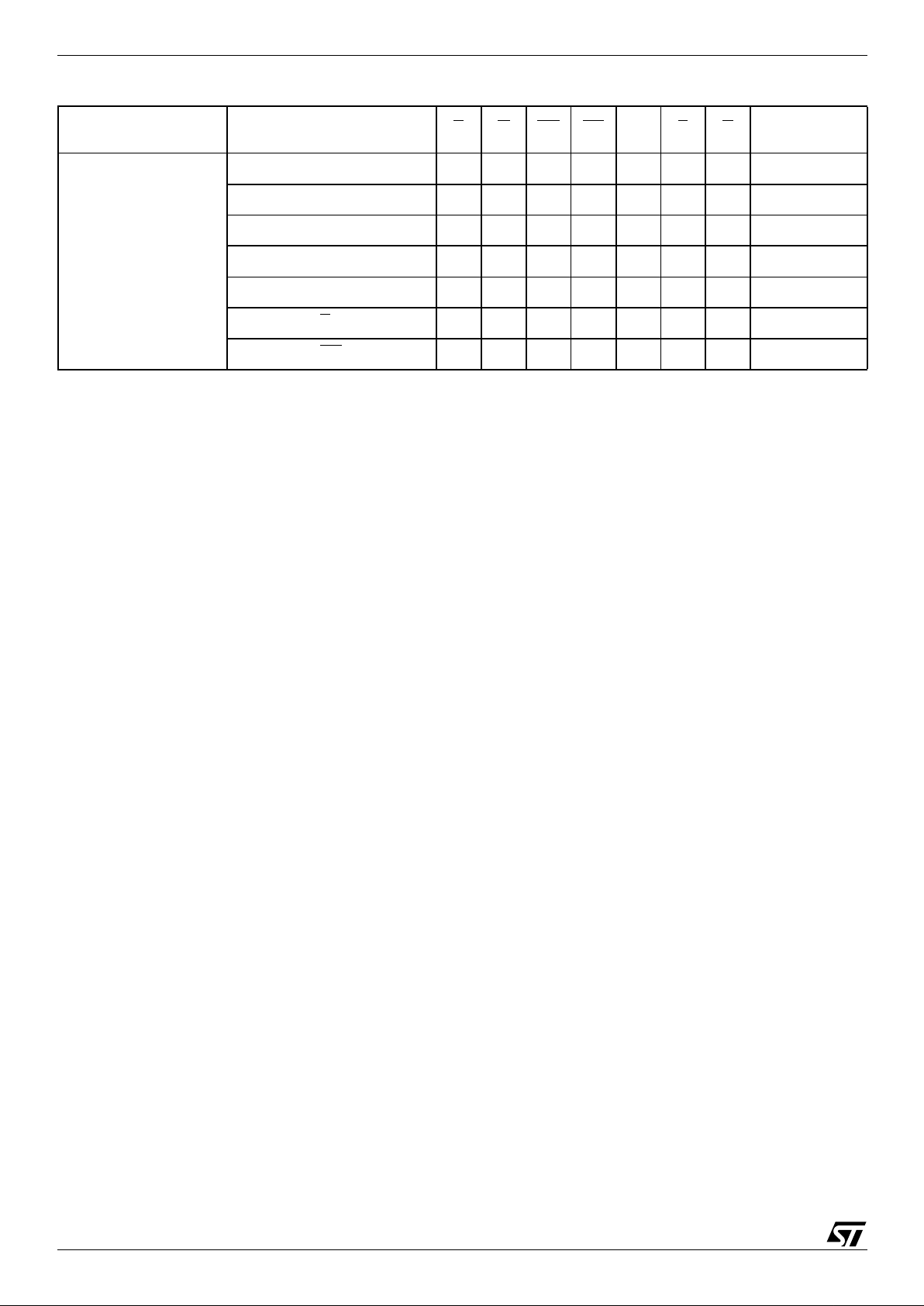

Table 7. Burst Configuration Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 8. Burst Type Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

COMMAND INTERFACE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Read Memory Array Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Read Electronic Signature Comma nd . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Read Query Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Read Status Register Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Clear Status Register Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Block Erase Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Program Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Program/Erase Suspend Comm and . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Program/Erase Resume Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Set Burst Configuration Register Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Tuning Protection Unlock Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Tuning Protection Program Command.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 9. Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 10. Program, Erase Times and Program Erase Endurance Cycles . . . . . . . . . . . . . . . . . . 27

STATUS REGISTER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Program/Erase Controller Status (Bit 7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Erase Suspend Status (Bit 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Erase Status (Bit 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Program Status, Tuning Protection Unlock Status (Bit 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

V

PP

Status (Bit 3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Program Suspend Status (Bit 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Block Protection Status (Bit 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Tuning Protection Status (Bit 0). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 11. Status Register Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

MAXIMUM RATING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 12. Absolute Maximum Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

M58BW016BT, M58BW016BB, M58BW016D T, M58BW016DB

4/63

DC and AC PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 13. Operating and AC Measurement Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 7. AC Measurement Input Output Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 8. AC Measurement Load Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 14. Device Capacitance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 15. DC Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 9. Asynchronous Bus Read AC Waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 16. Asynchronous Bus Read AC Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 10. Asynchronous Latch Controlled Bus Read AC Waveforms . . . . . . . . . . . . . . . . . . . . . 34

Table 17. Asynchronous Latch Controlled Bus Read AC Characteristics. . . . . . . . . . . . . . . . . . . 34

Figure 11. Asynchronous Page Read AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 18. Asynchronous Page Read AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 12. Asynchronous Write AC Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 13. Asynchronous Latch Controlled Write AC Waveform . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 19. Asynchronous Write and Latch Controlled Write AC Characteristics . . . . . . . . . . . . . . 38

Figure 14. Synchronous Burst Read (Data Valid from ’n’ Clock Rising Edge) . . . . . . . . . . . . . . . 39

Table 20. Synchronous Burst Read AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 15. Synchronous Burst Read (Data Valid from ’n’ Clock Rising Edge) . . . . . . . . . . . . . . . 40

Figure 16. Synchronous Burst Read - Continuous - Valid Data Ready Output. . . . . . . . . . . . . . . 41

Figure 17. Synchronous Burst Read - Burst Address Advance. . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 18. Reset, Power-Down and Power-up AC Waveform. . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 21. Reset, Power-Down and Power-up AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . 42

PACKAGE MECHANICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3

Figure 19. LBGA80 10x12mm - 8x10 ball array, 1mm pitch, Bottom View Package Outlin e . . . . 43

Table 22. LBGA80 10x12mm - 8x10 ball array, 1mm pitch, Package Mecha nical Data . . . . . . . . 43

Figure 20. PQFP80 - 80 lead Plastic Quad Flat Pack, Package Outline. . . . . . . . . . . . . . . . . . . . 44

Table 23. PQFP80 - 80 lead Plastic Quad Flat Pack, Package Mechanical Data. . . . . . . . . . . . . 44

PART NUMBERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 24. Ordering Information Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

APPENDIX A. COMMON FLASH INTERFACE - CFI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 25. Query Structure Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 26. CFI - Query Address and Data Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 27. CFI - Device Voltage and Timing Specification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 28. Device Geometry Definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 29. Extended Query information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

APPENDIX B. FLOW CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 21. Program Flowchart and Pseudo Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 22. Program Suspend & Resume Flowchart and Pseudo Code . . . . . . . . . . . . . . . . . . . . 50

Figure 23. Block Erase Flowchart and Pseudo Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 24. Erase Suspend & Resume Flowchart and Pseudo Code. . . . . . . . . . . . . . . . . . . . . . . 52

Figure 25. Unlock Device and Change Tuning Protection Code Flowchart . . . . . . . . . . . . . . . . . 53

5/63

M58BW016BT, M58BW016BB, M58BW016DT, M58BW016DB

Figure 26. Unlock Device and Program a Tuning Protected Block Flowchart. . . . . . . . . . . . . . . . 54

Figure 27. Unlock Device and Erase a Tuning Protected Block Flowchart. . . . . . . . . . . . . . . . . . 55

Figure 28. Power-up Sequence to Burst the Flash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 29. Command Interface and Program Erase Controller Flowchart (a). . . . . . . . . . . . . . . . 57

Figure 30. Command Interface and Program Erase Controller Flowchart (b). . . . . . . . . . . . . . . . 58

Figure 31. Command Interface and Program Erase Controller Flowchart (c) . . . . . . . . . . . . . . . . 59

Figure 32. Command Interface and Program Erase Controller Flowchart (d). . . . . . . . . . . . . . . . 60

Figure 33. Command Interface and Program Erase Controller Flowchart (e). . . . . . . . . . . . . . . . 61

REVISION HISTORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table 30. Document Revision History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

M58BW016BT, M58BW016BB, M58BW016D T, M58BW016DB

6/63

SUMMARY DESCRIPTION

The M58BW016B/D is a 16Mbit non-volatile Flash

memory that can be erased electrically at the block

level and programmed in-system on a DoubleWord basis using a 2.7V to 3.6V V

DD

supply for the

circuit and a V

DDQ

supply down to 2.4V for the In-

put and Output buffers. Optionally a 12V V

PP

supply can be used to provide fast program and erase

for a limited time and number of program/erase cycles.

The devices support Asynchronous (Latch Controlled and Page Read) and Synchronous Bus operations. The Synchronous B urst Read Interface

allows a high data tra nsfer rate controlled by the

Burst Clock, K, signal. It is capable of bursting

fixed or unlimited lengths of data. The burst type,

latency and length are configurable and can be

easily adapted to a large variety of system clock

frequencies and microprocessors. All Writes are

Asynchronous. On power-up the memory defaults

to Read mode with an Asynchronous Bus.

The device has a boot block architecture with an

array of 8 parameter bl ock of 64Kb each and 31

main blocks of 512Kb each. The parameter blocks

can be located at the top of the address space,

M58BW016BT, M58BW016DT or at the bottom,

M58BW016BB, M58B W016DB.

Program and Erase c ommands are written to the

Command Interface of the memory. An on-chip

Program/Erase Controller simplifies the process of

programming or erasing the memory by taking

care of all of the special operations that are required to update the memory contents. The end of

a Program or Erase operation can be detected and

any error conditions identified in the Status Regis-

ter. The command set required to control the

memory is consistent with JEDEC standards.

Erase can be suspended in order to perform either

Read or Program in any other block and t hen resumed. Program can be suspended t o Read dat a

in any other block and t hen resumed. E ach block

can be programmed and erased over 100,000 cycles.

All blocks are protected during power-up. The

M58BW016B features four different levels of block

protection to avoid unwanted program/erase operations. The WP

pin offers an hardware protect ion

on two of the parameter blocks and all of the main

blocks. The Program and Erase commands can

be password protected by the Tuning Protection

command. All Program or Erase operations are

blocked when Reset, RP,

is held low. The

M58BW016D offers the same protection features

with the exception of the Tuning Block Protection

which is disabled in the factory.

A Reset/Power-down mode is entered w hen the

RP

input is Low. In this mode the power consumption is lower than in the normal standby mode, the

device is write protect ed and bo th the S tatus and

the Burst Configuration Registers are cleared. A

recovery time is required when th e RP

input goes

High.

The memory is offered in PQFP80 (14 x 20mm)

and LBGA80 (1.0mm pitch) packages and it is

supplied with all the bits erased (set to ’1’).

7/63

M58BW016BT, M58BW016BB, M58BW016DT, M58BW016DB

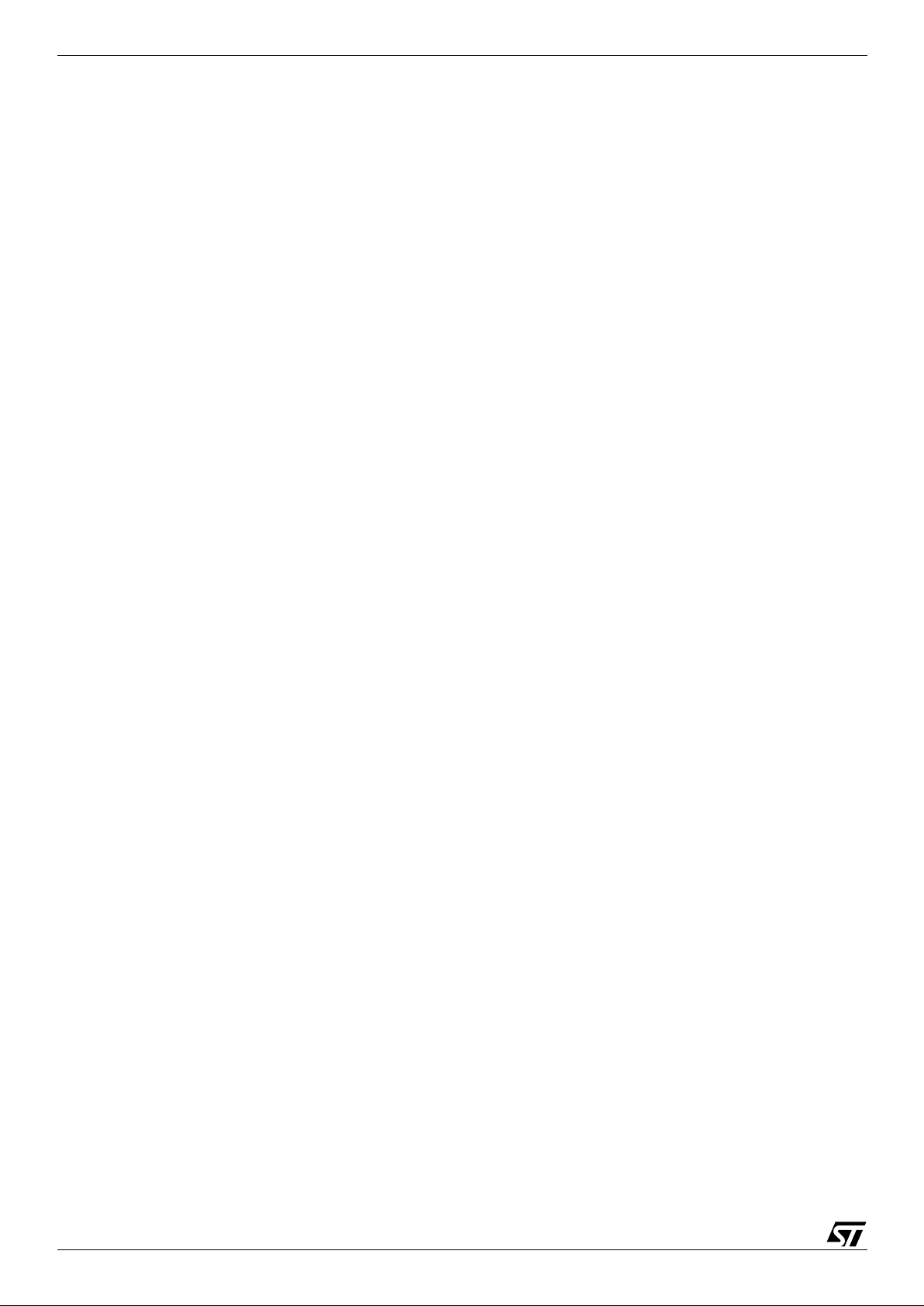

Figure 2. Logic Diagram Table 1. Signal Names

AI04155

A0-A18

L

DQ0-DQ31

V

DD

M58BW016DT

M58BW016DB

E

V

SS

RP

G

GD

V

DDQ

W

WP

R

K

V

PP

B

V

SSQ

V

DDQIN

M58BW016BT

M58BW016BB

A0-A18 Address inputs

DQ0-DQ7 Data Input/Output, Command Input

DQ8-DQ15

Data Input/Output, Burst Configuration

Register

DQ16-DQ31 Data Input/Output

B

Burst Address Advance

E

Chip Enable

G

Output Enable

K Burst Clock

L

Latch Enable

R Valid Data Ready (open drain output)

RP

Reset/Power-down

W

Write Enable

GD

Output Disable

WP

Write Protect

V

DD

Supply Voltage

V

DDQ

Power Supply for Output Buffers

V

DDQIN

Power Supply for Input Buffers only

V

PP

Optional Supply Voltage for Fast

Program and Fast Erase Operations

V

SS

Ground

V

SSQ

Input/Output Ground

NC Not Connected Internally

DU Don’t Use as Internally Connected

M58BW016BT, M58BW016BB, M58BW016D T, M58BW016DB

8/63

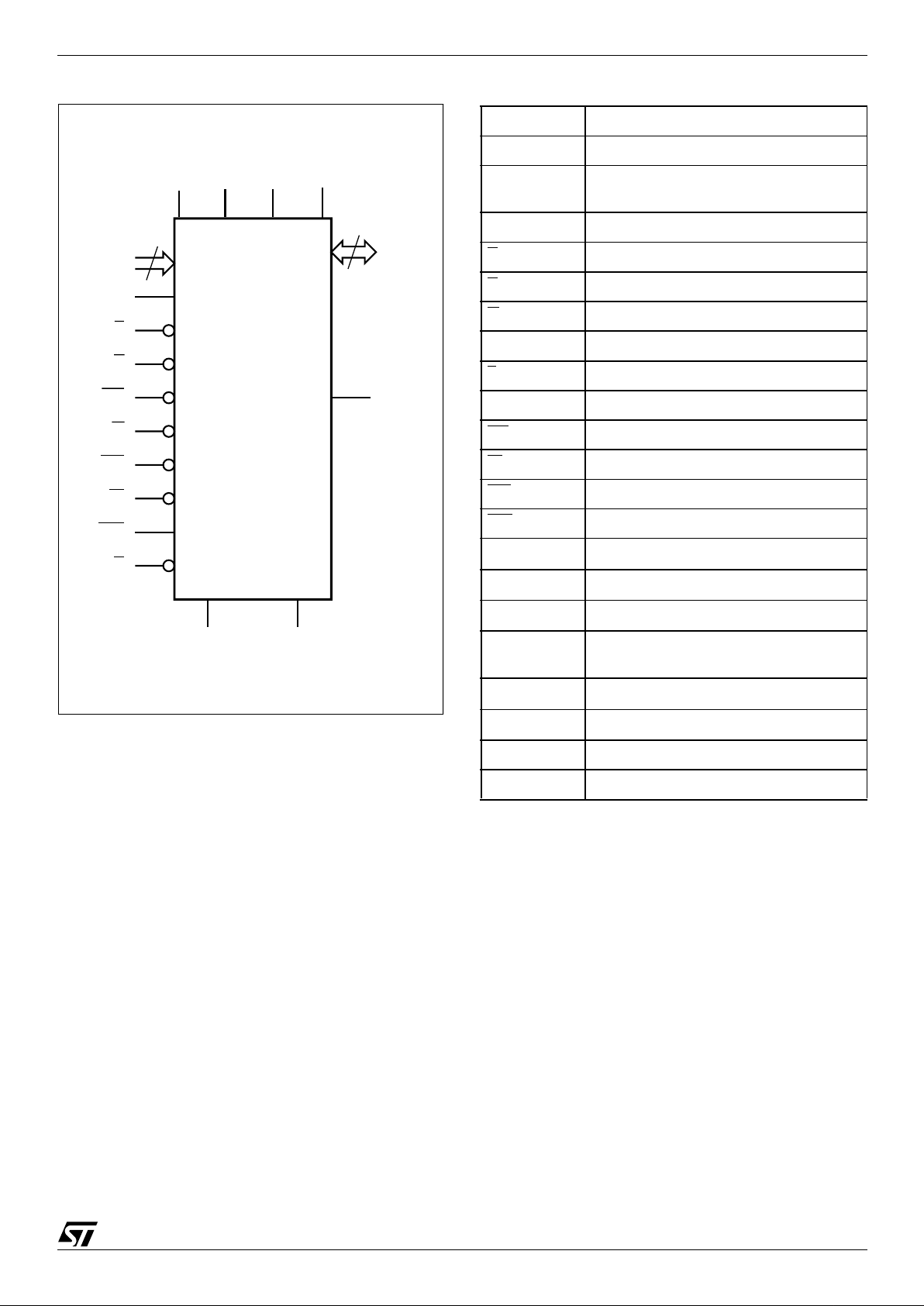

Figure 3. LBGA Conn ec ti ons (Top view through package)

AI04151b

B

DQ24DQ7V

SSQ

F

V

DDQ

DQ26DQ4V

DDQ

E

DQ29

V

SS

DQ0DQ3D

A0

DUA7A11A18A17C

A1

A4A5A8

RP

E

A13A16B

A2

A3A6

V

DD

V

PP

V

DD

A14A

87654321

DQ20DQ18DQ19DQ17DQ11DQ12DQ13

V

DDQ

DQ23DQ8V

DDQ

H

G

DU

GDW

V

DDQIN

DQ16RGLDQ14DQ15

K

J

A15 V

SS

A12 A9

A10 NC

DU DU DQ31 DQ30

DQ2 DQ28

DQ6 DQ25 V

SSQ

DQ10 DQ9 DQ21

WP

K

DU

DQ1 DQ27

DQ5 NC

DQ22

9/63

M58BW016BT, M58BW016BB, M58BW016DT, M58BW016DB

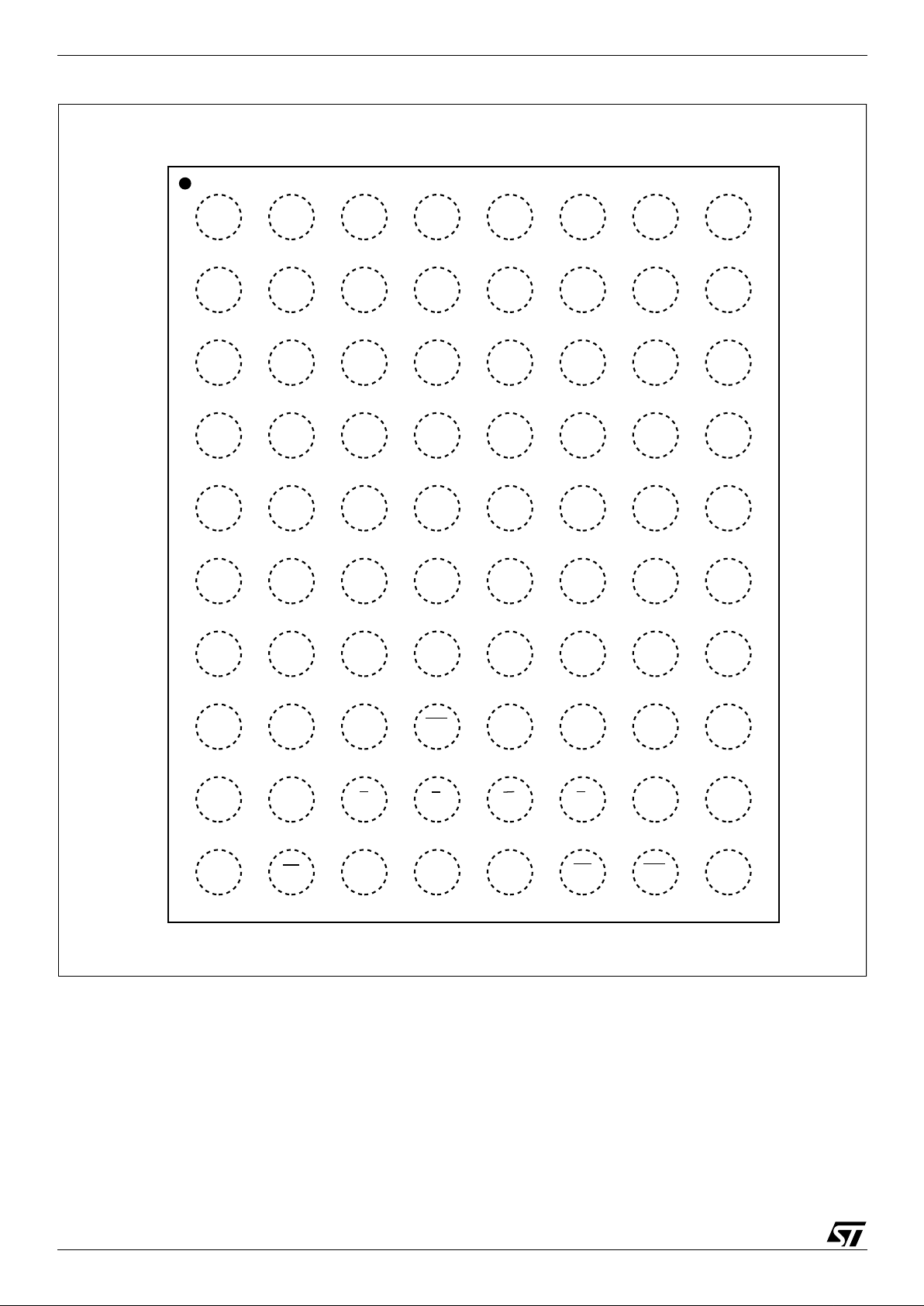

Figure 4. PQFP Connections (Top view through package)

AI04152b

12

1

73

M58BW016BT

M58BW016BB

53

V

DDQ

DQ24

DQ25

DQ18

DQ17

DQ16

DQ19

DQ20

DQ21

DQ22

DQ23

V

DDQ

DQ29

DQ26

DQ30

DU

DQ31

DQ28

DQ27

A2

A5

A3

A4

A0

A1

A11

V

SS

A12

A13

A14

A10

GDWPWDUG

V

SS

E

K

L

NC

B

RP

V

DDQ

DQ7

DQ6

DQ13

DQ14

DQ15

DQ12

DQ11

DQ10

DQ9

V

SSQ

DQ8

DQ2

DQ5

DQ0

NC

A18

A16

A17

DQ3

DQ4

V

SSQ

V

SSQ

A8

A6

A7

V

PP

V

DD

A9

A15

DQ1

V

DDQ

V

SSQ

R

V

DD

NC

V

DDQIN

24

25

32

40

41

64

65

80

M58BW016DT

M58BW016DB

M58BW016BT, M58BW016BB, M58BW016D T, M58BW016DB

10/63

Block Protection

The M58BW016B fe atures four different levels of

block protection. The M58BW016D h as the same

block protection with the exception of the Tuning

Block Protection, which is disabled in the factory.

■ Write Protect Pin, WP, - When WP is low, V

IL,

all the lockable parameter blocks (two upper

(Top ) or lower (B ottom)) and all the main blocks

are protected. When WP

is high (VIH) all the

lockable paramete r blocks a nd all the main

blocks are unprotected.

■ Reset/Power-Down Pin, RP, - If the device is

held in reset mode (RP

at VIL), no program or

erase operations can be performed on any

block.

■ Tuning Block Protection: M58BW016B

features a 64 bit password protection for

program and erase operations for a fixed

number of blocks After power-up or reset the

device is tuning protected. An Unlock command

is provided to allow program or erase operations

in all the blocks.

Aft er a de v i ce r es et t h e f i r st t w o k i nds of bl ock p r otection (W

P, RP) c an be c om bin ed t o give a flexible block protection. They do not affect the Tuning

Block Protection. When the two protections are

disabled, W

P and RP at VIH, the blocks locked by

the Tuning Block Protection cannot be modified.

All blocks are protected during power-up.

Tuning Bl ock P rot ection. The Tuning Block

Protection is a software f eature to protect certain

blocks from program or erase operat ions. It allo ws

the user to lock program and erase operations with

a user definable 64 bit code. It is only available on

the M58BW016B version.

The code is written once i n the Tuning Protection

Register and cannot be erased. When shipped the

flash memory will have the Tuning Protection

Code bits set to ‘1'. The user can program a ‘0’ in

any of the 64 positions. Once programmed it is not

possible to reset a bit t o ‘ 1’ a s the cells cannot be

erased. The Tuning Protection Register can be

programmed at any moment (after providing the

correct code), however once all bits are set to ‘0’

the Tuning Protection Code can no longer be altered .

The Tuning Protection Code locks the program

and erase operations of 2 parameter and 24 main

blocks, blocks 0, 1 and 15-38 for the bottom configuration and the blocks 0-23, 3 7 and 38 for the

top configuration.

The tuning b locks ar e "lo cked" if th e tuni ng pr otection code has not been provided, and “unlock ed"

once the correct code has been provided. The tuning blocks are locked af te r rese t o r power-u p. The

tuning protection status can be monitored in the

Status Register. Refer to the Status Register section.

Refer to the Command Interface section for the

Tuning Protection Block Un lock and Tuning Protection Program commands. See Appendix B, Figure 25, 26 and 27 for suggested flowcharts for

using the Tuning Block Protection commands. For

further information on the Tuning Block Protection

refer to Application Note, AN1361.

11/63

M58BW016BT, M58BW016BB, M58BW016DT, M58BW016DB

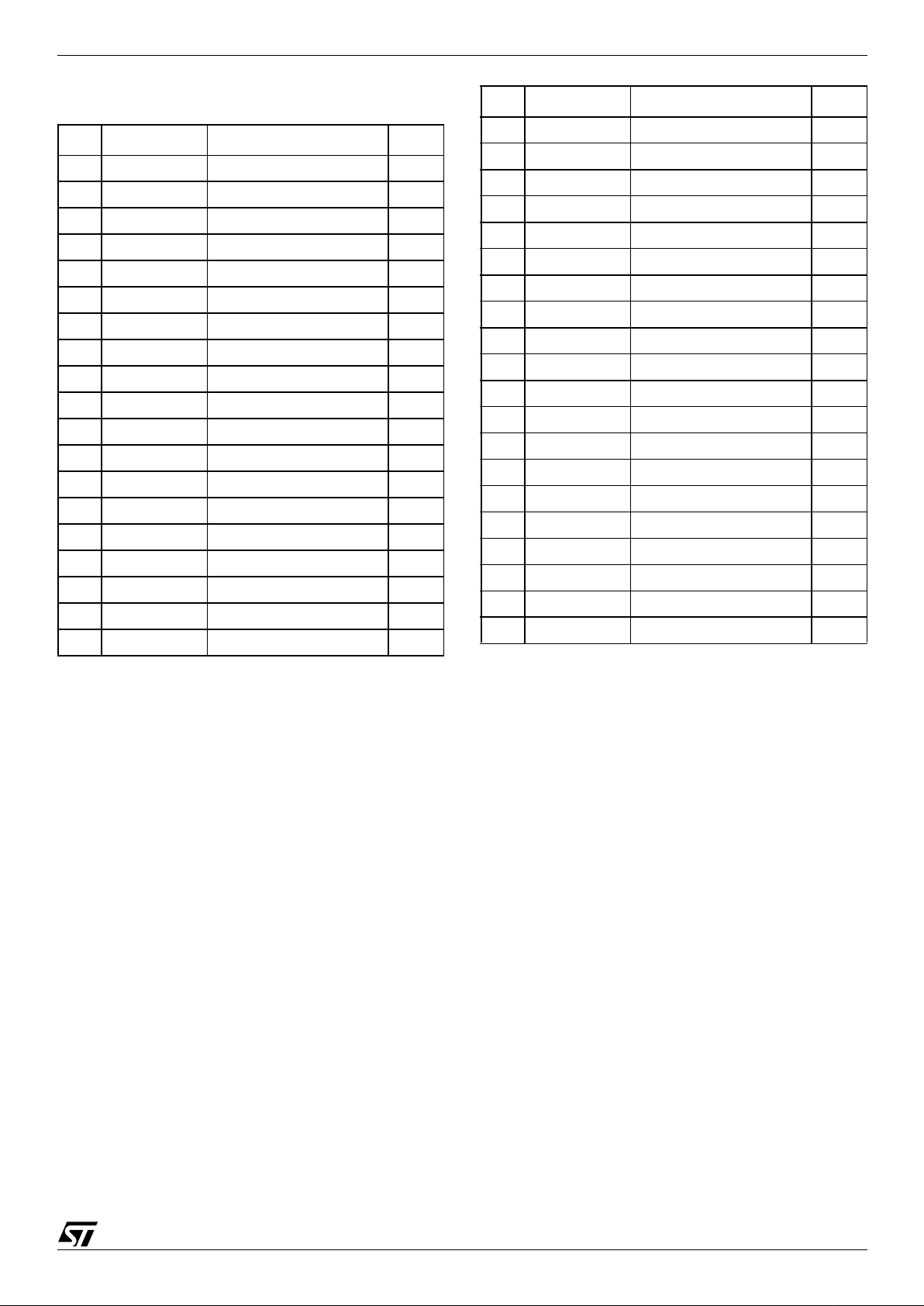

Table 2. Top Boot Block Addresses,

M58BW016BT, M58BW016DT

Note: 1. TP = Tuning Protected Block, only available for the

M58BW016B.

# Size (Kbit) Address Range

TP

(1)

38 64 7F800h-7FFFFh yes

37 64 7F000h-7F7FFh yes

36 64 7E800h-7EFFFh no

35 64 7E000h-7E7FFh no

34 64 7D800h-7DFFFh no

33 64 7D000h-7D7FFh no

32 64 7C800h-7CFFFh no

31 64 7C000h-7C7FFh no

30 512 78000h-7BFFFh no

29 512 74000h-77FFFh no

28 512 70000h-73FFFh no

27 512 6C000h-6FFFFh no

26 512 68000h-6BFFFh no

25 512 64000h-67FFFh no

24 512 60000h-63FFFh no

23 512 5C000h-5FFFFh yes

22 512 58000h-5BFFFh yes

21 512 54000h-57FFFh yes

20 512 50000h-53FFFh yes

19 512 4C000h-4FFFFh yes

18 512 48000h-4BFFFh yes

17 512 44000h-47FFFh yes

16 512 40000h-43FFFh yes

15 512 3C000h-3FFFFh yes

14 512 38000h-3BFFFh yes

13 512 34000h-37FFFh yes

12 512 30000h-33FFFh yes

11 512 2C000h-2FFFFh yes

10 512 28000h-2BFFFh yes

9 512 24000h-27FFFh yes

8 512 20000h-23FFFh yes

7 512 1C000h-1FFFFh yes

6 512 18000h-1BFFFh yes

5 512 14000h-17FFFh yes

4 512 10000h-13FFFh yes

3 512 0C000h-0FFFFh yes

2 512 08000h-0BFFFh yes

1 512 04000h-07FFFh yes

0 512 00000h-03FFFh yes

# Size (Kbit) Address Range

TP

(1)

M58BW016BT, M58BW016BB, M58BW016D T, M58BW016DB

12/63

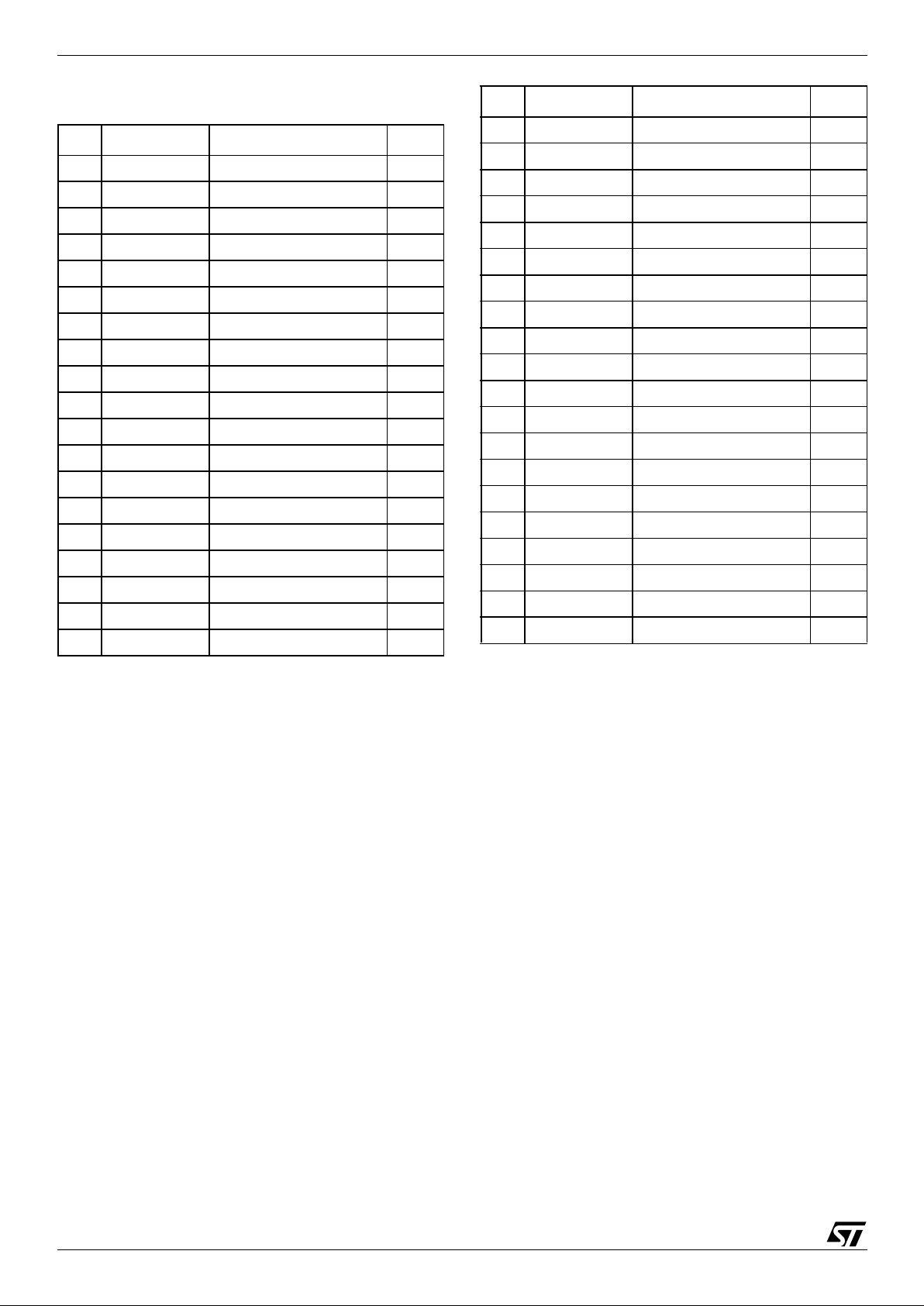

Table 3. Bottom Boot Block Addresses,

M58BW016BB, M58BW016DB

Note: 1. TP = Tuning Protected Block, only available for the

M58BW016B.

# Size (Kbit) Address Range

TP

(1)

38 512 7C000h-7FFFFh yes

37 512 78000h-7BFFFh yes

36 512 74000h-77FFFh yes

35 512 70000h-73FFFh yes

34 512 6C000h-6FFFFh yes

33 512 68000h-6BFFFh yes

32 512 64000h-67FFFh yes

31 512 60000h-63FFFh yes

30 512 5C000h-5FFFFh yes

29 512 58000h-5BFFFh yes

28 512 54000h-57FFFh yes

27 512 50000h-53FFFh yes

26 512 4C000h-4FFFFh yes

25 512 48000h-4BFFFh yes

24 512 44000h-47FFFh yes

23 512 40000h-43FFFh yes

22 512 3C000h-3FFFFh yes

21 512 38000h-3BFFFh yes

20 512 34000h-37FFFh yes

19 512 30000h-33FFFh yes

18 512 2C000h-2FFFFh yes

17 512 28000h-2BFFFh yes

16 512 24000h-27FFFh yes

15 512 20000h-23FFFh yes

14 512 1C000h-1FFFFh no

13 512 18000h-1BFFFh no

12 512 14000h-17FFFh no

11 512 10000h-13FFFh no

10 512 0C000h-0FFFFh no

9 512 08000h-0BFFFh no

8 512 04000h-07FFFh no

7 64 03800h-03FFFh no

6 64 03000h-037FFh no

5 64 02800h-02FFFh no

4 64 02000h-027FFh no

3 64 01800h-01FFFh no

2 64 01000h-017FFh no

1 64 00800h-00FFFh yes

0 64 00000h-007FFh yes

# Size (Kbit) Address Range

TP

(1)

13/63

M58BW016BT, M58BW016BB, M58BW016DT, M58BW016DB

SIGNAL DESCRIPTIONS

See Figure 2, Logic Diagram and Table 1, Signal

Names, for a brief overview of the signals connected to this device.

Address Inputs (A0-A18). The Address Inputs

are used to select the cells to access in the mem ory array during Bus Read operations either to

read or to program data to. During Bus Write operations they control the commands sent to the

Command Interface of the internal state m achine.

Chip Enable must be low when selecting the addresses.

The address inputs are latched on the rising edge

of Latch Enable L

or Burst Clock K, whichever occurs first, in a read operation.The address inputs

are latched on the rising edge of Chip Enable,

Write Enable or Lat ch Enable, whichever o ccurs

first in a Write operation. The address latch is

transparent when Latch Enable is low, V

IL

. The address is internally latched in a n E rase or P rogram

operation.

Data Inputs/Outputs (DQ0-DQ31). The Data Inputs/Outputs output the data stored at the selected

address during a Bus Read operation, or are used

to input the data during a program operation. During Bus Write operations they represent the commands sent to the Command Interface of the

internal state machine. When used to input data or

Write commands they are latched on the rising

edge of Write Enable or Chip Enable, whichever

occurs first.

When Chip Enable and Output Enable are both

low, V

IL

, and Output Disable is at V

IH,

the data bus

outputs data from the memory array, the Electronic Signature, the CFI Information or the contents of

the Status Register. The data bus is high impedance when the device is deselected with Chip Enable at V

IH

, Output E na ble at VIH, Outp u t Di sa b le

at V

IL

or Reset/Power-Down at VIL. The Status

Register content is output on DQ0-DQ7 and DQ8DQ31 are at V

IL

.

Chip Enable (E

). The Chip Enable, E, input acti-

vates the memory control logic, input buffers, decoders and sense amplifiers. Chip Enable, E

, at

V

IH

deselects the memory and reduces the power

consumption to the Standby level.

Output Enable (G

). The Output Enable, G, gates

the outputs through the data output buffers during

a read operation, whe n Output Disable GD

is at

V

IH

. When Output Enable G is at VIH, the outputs

are high impedance in dependentl y of Output Disable.

Output Disable (GD

). The Output Disable, GD,

deactivates the data output buffers. W hen Output

Disable, GD

, is at VIH, the outputs are driven by

the Output Enable. When Output Disable, GD

, is at

V

IL

, the outputs are high impedance independent-

ly of Output Enable. The Output Disable pin must

be connected to an external pull-up resistor as

there is no internal pull-up resistor to drive the pin.

Write Enable (W

). The Write Enable, W, input

controls writing to the Command Interface, Input

Address and Data latches. Both addresses and

data can be latched on the rising edge of Wri te Enable (also see Latch Enable, L

).

Reset/Power-Down (RP

). The Reset/Power-

Down, RP

, is used to apply a hardware reset to the

memory. A hardware reset is achie ved by hold ing

Reset/Power-Down Low, V

IL

, for at least t

PLPH

.

Writing is inhibited to protect data, the Command

Interface and the Program/Erase Controller are reset. The Status Register information is cleared and

power consumption is reduced to deep powerdown level. The device acts as deselected, that is

the data outputs are high impedance.

After Reset/Power-Down goes High, V

IH

, the

memory will be ready for Bus Read operations after a delay of t

PHEL

or Bus Write operat ions after

t

PHWL

.

If Reset/Power-Down goes low, V

IL

, during a Block

Erase, a Program or a Tuning Protection Program

the operation is aborted, in a time of t

PLRH

maxi-

mum, and data is altered and may be corrupted.

During Power-up power should be applied simulta-

neously to V

DD

and V

DDQ(IN)

with RP held at VIL.

When the supplies are stable RP

is taken to VIH.

Output Enable, G

, Chip Enable, E , and Write En-

able, W

, should be held at VIH during power-up.

In an application, it is recommended to associate

Reset/Power-Down pin, RP

, with the reset s ignal

of the microprocessor. Otherwise, if a reset operation occurs while the memory is performing an

erase or program operation, the memory may output the Status Register informa tion instead of being initialized to the default Asynchronous

Random Read.

See Table 21 a nd F igure 18, Reset , Po wer-Down

and Power-up Characteristics, for more details.

Latch Enable (L

). The Bus Interface can be con-

figured to latch the Address Inputs on the rising

edge of Latch Enable, L

, for Asynchronous Latch

Enable Controlled R ead or W rite or Synchronous

Burst Read operations. In Synchronous Burst

Read operations the address is latched on the active edge of the Clock when Latch Ena ble is Low,

V

IL

. Once latched, the addresses may change

without affecting the address used by the memory.

When Latch Enable is Low, V

IL

, the latch is trans-

parent. Latch Enable, L

, can remain at VIL for

Asynchronous Random Read and Write operations.

Burst Clock (K). The Burst Clock, K, is used to

synchronize the memory with the external bus dur-

M58BW016BT, M58BW016BB, M58BW016D T, M58BW016DB

14/63

ing Synchronous Burst Read operations. Bus signals are latched on the active edge of the Clock.

The Clock can be configured to have an active rising or falling edge. In Synchronous Burst Read

mode the address is latched on the first active

clock edge when Latch Enable is low, V

IL

, or on

the rising edge of Latch Enable, whichever occurs

first.

During Asynchronous bus operations the Clock is

not used.

Burst Address Advance (B

). The Burst Address

Advance, B

, controls the advancing of the address

by the internal address counter during Synchronous Burst Read operations.

Burst Address Advance, B

, is only sampled on the

active clock edge of the Clock when the X-latency

time has expired. If Burst Address Advance is

Low, V

IL

, the internal address counter advances. If

Burst Address Advance is High, V

IH

, the internal

address counter does not change ; the same dat a

remains on the Data Inputs/Outputs and Burst Address Advance is not sampl ed until the Y-latency

expires.

The Burst Address Advance, B

, may be tied to VIL.

Valid Data Ready (R). The Valid Data Ready

output, R, is an open drain output that can be

used, during Synchronous Burst Read operations,

to identify if the memory is ready to output data or

not. The Valid Data Ready output can be c onfigured to be active on the clock edge o f the invalid

data read cycle or one cycle before. Valid Data

Ready, at V

IH

, indicate s that new data is or will be

available. When Valid Data Ready is Low, V

IL

, the

previous data outputs remain active.

In all Asynchronous operations, Valid Data Ready

is high-impedance. It may be tied to other components with the same Valid Data Ready signal to

create a unique system Ready signal. The Val id

Data Ready output has an internal pull-up resistor

of around 1 MΩ powered from V

DDQ

, designers

should use an external pull-up resistor of the correct value to meet the external timing requirements for Valid Data Ready going to V

IH

.

Write Protect (WP

). The Write Protect, W P, pro-

vides protection against progra m or erase operations. When Write Protect, WP

, is at VIL the first

two (in the bottom configuration) or last two (in the

top configuration) parameter blocks and all main

blocks are locked. When Write Protect WP

is at

V

IH

all the blocks can be programmed or erased, if

no other protection is used.

Supply Voltage (V

DD

). The Supply Voltage, VDD,

is the core power supp ly. All internal circuits draw

their current from the V

DD

pin, including the Pro-

gram/Erase Controller.

Output Supply Voltage (V

DDQ

). The Output Sup-

ply Voltage, V

DDQ

, is the output buffer power supply

for all operati ons (Read, Pro gram and Era se) used

for DQ0-DQ31 when used as outputs.

Input Supply Voltage (V

DDQIN

). The Input Sup-

ply Voltage, V

DDIN

, is the power supply for all input

signal. Input signals are: K, B

, L, W, GD, G, E, A0-

A18 and D0-D31, when used as inputs.

Program/Erase Supp ly Voltage (V

PP

). The Pro-

gram/Erase Supply V oltage, V

PP

, is used for program and erase operations. The memory normally

executes program and erase operations at V

PP1

voltage levels. In a manufacturing environment,

programming may be speeded up by applying a

higher voltage level, V

PPH

, to the VPP pin.

The voltage level V

PPH

may be applied for a tot al

of 80 hours over a maximum of 1000 cycles.

Stressing the device beyond these limits could

damage the device.

Ground (V

SS

and V

SSQ

). The Ground VSS is the

reference for the internal supply voltage V

DD

. The

Ground V

SSQ

is the reference for the o utput and

input supplies V

DDQ,

and V

DDQIN

. It is essen t ial to

connect V

SS

and V

SSQ

together.

Note: A 0.1µF capacitor should be connected

between the Supply Voltages, V

DD

, V

DDQ

and

V

DDIN

and the Grounds, VSS and V

SSQ

to decouple the current surges from the power supply.

The PCB track widths must be sufficient to carry the currents required during all o perations

of the parts, see Table 15, DC Characteristics,

for maximum current supply requir ements.

Don’t Use (DU). This pin should not be used as it

is internally connected. Its voltage level can be between V

SS

and V

DDQ

or leave it unconnected.

Not Connected (NC). This pin is not physically

connected to the device.

15/63

M58BW016BT, M58BW016BB, M58BW016DT, M58BW016DB

BUS OPERATIONS

Each bus operations that controls the memory is

described in this section, see Tables 4, 5 and 6

Bus Operations, for a summary. The bus operation

is selected through the Burst Configuration Register; the bits in this register are described at the end

of this section.

On Power-up or after a Hardware Reset the memory defaults to Asynchronous Bus Read and Asynchronous Bus W rite, no other b us operation can

be performed until the Burst Control Register has

been configured.

The Electronic Signature, CFI or Status Register

will be r ead in a synchronous mode rega rdless of

the Burst Control Register settings.

Typically glitches of less than 5ns on Chip Enable

or Write Enable are ignored by the memory and do

not affect bus operations.

Asynchronous Bus Operation s

For asynchronous bus operations refer to Table 4

together with the following text.

Asynchronous Bus Read. Asynchronous Bus

Read operations read f rom the memory cells, or

specific registers (Electronic Signature, Status

Register, CFI and Burst Configuration Register) in

the Command Interface. A valid bus ope ration involves setting the desired address on the Address

Inputs, applying a Low signal, V

IL

, to Chip Enable

and Output Enable and keeping Write Enable and

Output Disable High, V

IH

. The Data Inputs/Outputs will output the value, see Figure 9, Asynchronous Bus Read AC Waveforms, and Table 16,

Asynchronous Bus Read AC Characteristics, for

details of when the output becomes valid.

Asynchronous Read is the default read mode

which the device enters on power-up or on return

from Reset/Power-Down.

Asynchronous Latch Controlled Bus Read.

Asynchronous Latch Controlled Bus Read operations read from the memory cells or specific registers in the Command Interface. The address is

latched in the memory before the value i s output

on the data bu s, allowing the address to c hange

during the cycle without affecting the address that

the memory uses.

A valid bus operati on involves s etting the d esired

address on the Address Inputs, setting Chip Enable and Latch Enable Low, V

IL

and keeping Write

Enable High, V

IH

; the address is latched on the rising edge of Latch Enabl e. Once latched, the Address Inputs can change. Set Output Enable Low,

V

IL

, to read the data on the Data Inputs/Outputs;

see Figure 1, Asynchronous Latch Controlled Bus

Read AC Waveforms and Table 17, Asynchronous Latch Controlled Bus Read AC Ch aracteristics for details on when the output becomes valid.

Note that, since the Latch Enable input is transparent when set Low, V

IL

, Asynchronous Bus Read

operations can be performed when the memory is

configured for Asynchronous Latch Enable bus

operations by holding Latch Enable Low, V

IL

throughout the bus operation.

Asynchronous P age R e ad. Asynchronous

Page Read operations are used to read from several addresses within the same memory page.

Each memory page is 4 Double-Words and is addressed by the address inputs A0 and A1.

Data is read internally and stored in the Page Buffer. Valid bus operations are the same as Asynchronous Bus Read operations but with different

timings. The first read operation within the page

has identical timings, subsequent reads within the

same page have much shorter acce ss ti mes. If the

page changes then the normal, longer timings apply again. Page Read does not support Latched

Controlled Read.

See Figure 11, Asynchronous Page Read AC

Waveforms and Table 18, Asynchronous Page

Read AC Characteristics for details on when the

outputs become valid.

Asynchronous Bus Write. Asynchronous Bus

Write operations write to the Command Interface

in order to send commands to the memory or to

latch addresses and input data to program. Bus

Write operations are asynchronous, the clock, K,

is don’t care during Bus Write operations.

A valid Asynchronous Bus W rite operation begins

by setting the desired address on the A ddress Inputs, and setting Chip Enable, Write Enable and

Latch Enable Low, V

IL

, and Output Enable High,

V

IH

, or Output Disable Low, VIL. The Address Inputs are latched by the Command Interface on the

rising edge of Chip Enable or Write Enable, whichever occurs first. Commands and Input Data are

latched on the rising edge of Chip Enable, E

, or

Write Enable, W

, whichever occurs first. Output

Enable must remain High, and Output Disable

Low, during the whole Asynchronous Bus Write

operation.

See Figure 12, Asynchronous Write AC Waveforms, and Table 19, Asynchronous Write and

Latch Controlled Write AC Charact eristics, for details of the timing requirements.

Asynchronous Latch Controlled Bus Write.

Asynchronous Latch Controlled Bus Write operations write to the Command Interface in order to

send commands to the memory or to latch addresses and input data t o program. Bus W rite operations are asynchronous, the c lock, K, is don’t

care during Bus Write operations.

A valid Asynchronous Latch Controlled Bus Write

operation begins by setting the desired address on

M58BW016BT, M58BW016BB, M58BW016D T, M58BW016DB

16/63

the Address Inputs and pulsing Latch Enable Low,

V

IL

. The Address Inputs are latc hed by the Command Interface on the rising edge of Latch Enable,

Write Enable or Chip Enable, whichever occurs

first. Commands and Input Data are latched on the

rising edge of Chip Enable, E

, or Write Enable, W,

whichever occurs first. Output Enable must remain

High, and Output Dis able Low, during the whole

Asynchronous Bus Write operation.

See Figure 13, Asynchronous Latch Controlled

Write AC Waveforms, and Table 19, Asynchronous Write and Latch Controlled Write AC Characteristics, for details of the timing requirements.

Output Disable. The data outputs are high impedance when the Output Enable, G

, is at VIH or

Output Disable, GD

, is at VIL.

Standby. When Chip Enable is High, V

IH

, and the

Program/Erase Controller is id le, the memory enters Standby mode, the power consumption is reduced to the standby level and the Data Inputs/

Outputs pins are placed in the high impedance

state regardless of Output Enable, Write Enable or

Output Disable inputs.

Automatic Low Power. If there is no change in

the state of the bus for a short period of time during

Asynchronous Bus Re ad operations the memory

enters Auto Low Pow er mode where the internal

Supply Current is reduced to the Auto-Standby

Supply Current. The Data Inputs/Outputs will still

output data if a Bus Read operation is in progress.

Automatic Low Power is only available in Asynchronous Read modes.

Power-Down . The memory is in Power-down

when Reset/Power-Down, RP

, is at VIL. The power consumption is reduced to the power-down level and the outputs are high impedance,

independent of the Chip Enable, E

, Output Enable,

G

, Ou t put D i sa b l e, GD , or Wri te Enable, W, inputs.

Electronic Signature. Two codes identifying the

manufacturer and the device can be read from the

memory allowing programming equipment or applications to autom atically mat ch their interface to

the characteristics of the memory. The Electronic

Signature is output by giving the Read Electronic

Signature command. The manufacturer code is

output when all the Address inputs are at V

IL

. The

device code is output when A1 is at V

IH

and all the

other address pins are at V

IL

. See Table 5. Issue

a Read Memory Array command to return to Read

mode.

Table 4. Asynchronous Bus Operations

Note: X = Don’ t Ca re

Bus Operation Step E G GD W RP L A0-A18 DQ0-DQ31

Asynchronous Bus Read

V

IL

V

IL

V

IH

V

IH

V

IH

V

IL

Address Data Output

Asynchronous Latch

Controlled Bus Read

Address Latch

V

IL

V

IH

V

IH

V

IL

V

IH

V

IL

Address High Z

Read

V

IL

V

IL

V

IH

V

IH

V

IH

V

IH

X Data Output

Asynchronous Page

Read

V

IL

V

IL

V

IH

V

IH

V

IH

X Address Data Output

Asynchronous Bus Write

V

IL

V

IH

X

V

IL

V

IH

V

IL

Address Data Input

Asynchronous Latch

Controlled Bus Write

Address Latch

V

IL

V

IL

V

IH

V

IH

V

IH

V

IL

Address High Z

Write

V

IL

V

IH

X

V

IL

V

IH

V

IH

X Data Input

Output Disable, G

V

IL

V

IH

V

IH

V

IH

V

IH

X X High Z

Output Disable, GD

V

IL

V

IL

V

IL

V

IH

V

IH

X X High Z

Standby

V

IH

XXX

V

IH

X X High Z

Reset/Power-Down X X X X

V

IL

X X High Z

17/63

M58BW016BT, M58BW016BB, M58BW016DT, M58BW016DB

Table 5. Asynchronous Read Electronic Signature Operation

Note: 1. x= B or D version of the device.

2. BCR= Burst Configuration Register.

Synchronous Bus Operations

For synchronous bus o perations refer to Table 6

together with the following text.

Synchronous Burs t R ea d. Synchronous Burst

Read operations are used to read from the memory at specific times synchronized to an external reference clock. The burst type , length and latency

can be configured. The different configurations for

Synchronous Burst Read operations are described in the Burst Configuration Register section. Refer to Figures 5 and 6 for examples of

synchronous burst operations.

In continuous burst read, one burst read operation

can access the entire memory sequentially by

keeping the Burst Address Advance B

at VIL for

the appropriate number of clock cycles. At the end

of the memory address space t he burst read restarts from the beginning at address 000000h.

A valid Synchronous Burst Read operation begins

when the Burst Clock is active and Chip Enable

and Latch Enable are Low, V

IL

. The burst start address is latched and loaded into the internal B urst

Address Counter on the valid Burst Clock K edge

(rising or falling depending on the value of M6) or

on the rising edge of Latch Ena ble, whichev er occurs first.

After an initial memory latency time, the memory

outputs data each clock cycl e (or two clo ck cycl e s

depending on the value of M9). The Burst Address

Advance B input controls the memory burst output.

The second burst output is on the nex t cloc k valid

edge after the Burst A ddress Advance B

has been

pulled Low.

Valid Data Ready, R, monitors if the memory burst

boundary is exceeded and the Burst Controller of

the microprocessor needs to insert wait states.

When Valid Data Ready is Low on the active clock

edge, no new data is available and the memory

does not increment the internal address counter at

the active clock edge even if Burst Address Advance, B

, is Low.

Valid Data Ready may be configured (by bit M8 of

Burst Configuration Regist er) to be valid imm ediately at the valid clock edge or one data cycle before the valid clock edge.

Synchronous Burst Read will be suspended if

Burst Address Advance, B

, goes High, VIH.

If Output Enable is at V

IL

and Output Disable is at

V

IH

, the last data is still valid.

If Output Enable, G

, is at VIH or Output Disable,

GD

, is at VIL, but the Burst Address Advance, B, is

at V

IL

the internal Burst Addres s Counter is incre-

mented at each Burst Clock K valid edge.

The Synchronous Burst Read timing diagrams

and AC Characteristics are described in the AC

and DC Parameters section. See Figures 14 , 15,

16 and 17, and Table 20.

Synchronous Burst Read Suspend. During a

Synchronous Burst Read operation it is possible to

suspend the operation, freeing the data bus for

other higher priority devices.

A valid Synchronous Burst Read operation is suspended when b oth Output Enable an d Burst Address Advance are H igh, V

IH

. The Burst Address

Advance going High, V

IH

, stops the burst counter

and the Output Enable going High, V

IH

, inhibits th e

data outputs. The Synchronous Burst Read operation can be resumed by setting Output Enable

Low.

Code Device E G GD W A18-A0 DQ31-DQ0

Manufacturer All

V

IL

V

IL

V

IH

V

IH

00000h 00000020h

Device

M58BW016xT

(1)

V

IL

V

IL

V

IH

V

IH

00001h 00008836h

M58BW016xB

(1)

V

IL

V

IL

V

IH

V

IH

00001h 00008835h

Burst Configuration

Register

V

IL

V

IL

V

IH

V

IH

00005h

BCR

(2)

M58BW016BT, M58BW016BB, M58BW016D T, M58BW016DB

18/63

Table 6. Synchronous Burst Read Bus Operations

Note: 1. X = Don't Care, VIL or VIH.

2. M15 = 0, Bit M15 is in the Burst Configuration Register.

3. T = transition, see M6 in the Burst Configurati on Regist er for detail s on the acti ve edge of K.

Bus Operation Step E G GD RP

K

(3)

L B

A0-A18

DQ0-DQ31

Synchronous Burst

Read

Address Latch

V

IL

V

IH

X

V

IH

T

V

IL

X Address Input

Read

V

IL

V

IL

V

IH

V

IH

T

V

IH

V

IL

Data Output

Read Suspend

V

IL

V

IH

X

V

IH

X

V

IH

V

IH

High Z

Read Resume

V

IL

V

IL

V

IH

V

IH

T

V

IH

V

IL

Data Output

Burst Address Advance

V

IL

V

IH

X

V

IH

T

V

IH

V

IL

High Z

Read Abort, E

V

IH

XX

V

IH

X X X High Z

Read Abort, RP

XXX

V

IL

X X X High Z

19/63

M58BW016BT, M58BW016BB, M58BW016DT, M58BW016DB

Burst Configuration Register

The Burst Configuration Register is used to configure the type of bus access that the memory will

perform.

The Burst Configuration Register is set through

the Command Interface and will retain its information until it is re-configured, the device is reset, or

the device goes into Reset/Power-Down mode.

The Burst Configuration Register bits are described in Table 7. They specify the selection of

the burst length, burst type, burst X and Y latencies and the Read operat ion. Refer to Figures 5

and 6 for examples of sync hronous burst configurations.

Read Select Bit (M15). The Read Select bit,

M15, is used to switch between asynchronous and

synchronous Bus Read operations. When the

Read Select bit is set to ’1’, Bus Read operations

are asynchronous; when the Read Select but is

set to ’0’, Bus Read operations are synchronous.

On reset or power-up the Read Select bit is set

to’1’ for asynchronous accesses.

X-Latency Bits (M14-M11). The X-Latency bits

are used during Synchronous Bus Read operations to set the number of clock cycles between

the address being latched and the first data becoming available. For correct operation the X-Latency bits can only assume the values in Table 7,

Burst Configuration Register. The X -Latency bits

should also be selected in conjunction with Table ,

Burst Performance to ensure valid settings.

Y-Latency Bit (M9). The Y-Latency bit is used

during Synchronous Bus Read operations to set

the number of clock cycles between consecutive

reads. The Y-Latency value depends on both the

X-Latency value and the setting in M9.

When the Y-Latency i s 1 the data changes each

clock cycle; when the Y-Latency is 2 the data

changes every se cond clock cycle. See Tab le 7,

Burst Configuration Register and Table , Burst

Performance, for valid combinations of the Y-Latency, the X-Latency and the Clock frequency.

Valid Data Ready Bit (M8). The Valid Data

Ready bit controls the timing of the Valid Data

Ready output pin, R. When the Valid Data Ready

bit is ’0’ the Valid Data Ready output pin is driven

Low for the active clock edge when invalid data is

output on the bus. When the Valid Data Ready bit

is ’1’ the Valid Data Ready output pin is driven Low

one clock cycle prior to invalid data being output

on the bus.

Burst Type B it (M7). The Burst Type bit is used

to configure the sequence of addresses read as

sequential or interleaved. When the Burst Type bit

is ’0’ the memory outputs from interleaved addresses; when the Burst Type bit is ’1’ the memory

outputs from sequential addresses. See Tables 8,

Burst Type Definition, for the sequence of addresses output from a given starting address in

each mode.

Valid Clock Edge Bit (M6). The Valid Clock

Edge bit, M6, is used to configure the active e dge

of the Clock, K, during Synchronous Burst Read

operations. When the Valid Clock Edge bit is ’0’

the falling edge of the Clock is the active edge;

when the Valid Clock Edge bit is ’1’ the rising edge

of the Clock is active.

Wrap Burst Bit (M3). The burst reads can be

confined inside the 4 or 8 Double-Word boundary

(wrap) or overcome the boundary (no wrap). The

Wrap Burst bit is used t o select between wrap and

no wrap. When the Wrap Burst bit is set to ‘0’ the

burst read wraps; when it is set to ‘1’ the burst read

does not wrap.

Burst Length Bit (M2-M0). The Burst Length bits

set the maximum number of Double-Words that

can be output durin g a Synchronous Burst Read

operation before the address wraps. Burst lengths

of 4 or 8 are available for both the Sequential and

Interleaved burst types, and a continuous burst is

available for the Sequential type.

Table 7, Burst Configuration Register gives the

valid combinations of the Burst Length bits that the

memory accepts; Table 8, Burst Ty pe Definition,

gives the sequence of addresses output from a

given starting address for each length.

If either a Continuous or a No Wrap Burs t Read

has been initiated the device will output data synchronously. Depending on the starting address,

the device activates the Valid Dat a Ready output

to indicate that a delay is necessary before the

data is output. If t he s tarting address is align ed t o

an 8 Double Word boundary, the continuous burst

mode will run without activating the Valid Data

Ready output. If the starting address is not aligned

to an 8 Double Word boundary, Valid Data Ready

is activated to indicate that the device needs an internal delay to read the successive words in the array.

M10, M5 and M4 are reserved for future use.

M58BW016BT, M58BW016BB, M58BW016D T, M58BW016DB

20/63

Table 7. Burst Configuration Register

Note: 1. 4 - 2 - 2 - 2 is not allowed.

2. X latenci es can be calculat ed as: (t

AVQV

– t

LLKH

+ t

QVKH

) + t

SYSTEM MARGIN

< (X - 1 ) t

K. (X

is an integer number from 4 to 8 and t

K

is the clock period).

3. Y latencie s c an be calculated as: t

KHQV

+ t

SYSTEM MARGIN

+ t

QVKH

< Y t

K.

4. t

SYSTEM MARGIN

is the time m argin requi red for the c al culation.

Bit Description Value Description

M15 Read Select

0 Synchronous Burst Read

1 Asynchronous Read (Default at power-on)

M14 Reserved

M13-M11

X-Latency

(2)

001 Reserved

010

4, 4-1-1-1

(1)

011 5, 5-1-1-1, 5-2-2-2

100 6, 6-1-1-1, 6-2-2-2

101 7, 7-1-1-1, 7-2-2-2

110 8, 8-1-1-1, 8-2-2-2

M10 Reserved

M9

Y-Latency

(3)

0 One Burst Clock cycle

1 Two Burst Clock cycles

M8 Valid Data Ready

0 R valid Low during valid Burst Clock edge

1 R valid Low one data cycle before valid Burst Clock edge

M7 Burst Type

0 Interleaved

1 Sequential

M6 Valid Clock Edge

0 Falling Burst Clock edge

1 Rising Burst Clock edge

M5-M4 Reserved

M3 Wrapping

0 Wrap

1 No wrap

M2-M0 Burst Length

001 4 Double-Words

010 8 Double-Words

111 Continuous

21/63

M58BW016BT, M58BW016BB, M58BW016DT, M58BW016DB

Table 8. Burst Type Definition

M 3

Starting

Addressx4Sequentialx4Interleaved

x8

Sequential

x8

Interleaved

Continuous

0 0 0-1-2-3 0-1-2-3 0-1-2-3-4-5-6-7 0-1-2-3-4-5-6-7 0-1-2-3-4-5-6-7-8-9-10..

0 1 1-2-3-0 1-0-3-2 1-2-3-4-5-6-7-0 1-0-3-2-5-4-7-6 1-2-3-4-5-6-7-8-9-10-11..

0 2 2-3-0-1 2-3-0-1 2-3-4-5-6-7-0-1 2-3-0-1-6-7-4-5 2-3-4-5-6-7-8-9-10-11-12..

0 3 3-0-1-2 3-2-1-0 3-4-5-6-7-0-1-2 3-2-1-0-7-6-5-4 3-4-5-6-7-8-9-10-11-12-13..

0 4 – – 4-5-6-7-0-1-2-3 4-5-6-7-0-1-2-3 4-5-6-7-8-9-10-11-2-13-14..

0 5 – – 5-6-7-0-1-2-3-4 5-4-7-6-1-0-3-2 5-6-7-8-9-10-11-12-13-14..

0 6 – – 6-7-0-1-2-3-4-5 6-7-4-5-2-3-0-1 6-7-8-9-10-11-12-13-14-15..

0 7 – – 7-0-1-2-3-4-5-6 7-6-5-4-3-2-1-0 7-8-9-10-11-12-13-14-15-16..

0 8 – – – – 8-9-10-11-12-13-14-15-16-17..

1 0 0-1-2-3 – 0-1-2-3-4-5-6-7 – 0-1-2-3-4-5-6-7-8-9-10..

1 1 1-2-3-4 – 1-2-3-4-5-6-7-8 – 1-2-3-4-5-6-7-8-9-10-11..

1 2 2-3-4-5 – 2-3-4-5-6-7-8-9 – 2-3-4-5-6-7-8-9-10-11-12..

1 3 3-4-5-6 – 3-4-5-6-7-8-9-10 – 3-4-5-6-7-8-9-10-11-12-13..

1 4 4-5-6-7 –

4-5-6-7-8-9-10-

11

– 4-5-6-7-8-9-10-11-12-13-14..

1 5 5-6-7-8 –

5-6-7-8-9-10-11-

12

– 5-6-7-8-9-10-11-12-13-14..

1 6 6-7-8-9 –

6-7-8-9-10-11-

12-13

– 6-7-8-9-10-11-12-13-14-15..

1 7 7-8-9-10 –

7-8-9-10-11-12-

13-14

– 7-8-9-10-11-12-13-14-15-16..

1 8 8-9-10-11 –

8-9-10-11-12-13-

14-15

– 8-9-10-11-12-13-14-15-16-17..

M58BW016BT, M58BW016BB, M58BW016D T, M58BW016DB

22/63

Figure 5. Example Burst Configuration X-1-1-1

Figure 6. Example Burst Configuration X-2-2-2

AI03841

K

DQ

L

ADD

VALID

DQ

DQ

DQ

DQ

4-1-1-1

5-1-1-1

6-1-1-1

7-1-1-1

8-1-1-1

0123456789

VALIDVALIDVALIDVALID

VALIDVALIDVALIDVALID

VALID

VALID

VALIDVALIDVALID

VALID

VALID

VALID

VALID

VALIDVALID

VALID

AI04406b

K

L

ADD

DQ

VALID

DQ

DQ

DQ

5-2-2-2

6-2-2-2

7-2-2-2

8-2-2-2

0123456789

VALID

VALID

VALID

VALID

VALID

VALID

VALID

VALID

NV

NV

NV

NV

NV

NV

NV

NV

NVNV

NV=NOT VALID

23/63

M58BW016BT, M58BW016BB, M58BW016DT, M58BW016DB

COMMAND INTERFACE

All Bus Write operations to the memory are in terpreted by the Command Interface. Commands

consist of one or more sequential Bus Write operations. The Commands are summarized in Tab le

9, Commands. Refer to Table 9 in conjunction with

the text descriptions below.

Read Memory Array Command

The Read Memory Array command returns the

memory to Read mode. One Bus Write cycle is required to issue the Read Memory Array command

and return the memory to Read mode. Subsequent read operations will output the addressed

memory array data. Once the command is issued

the memory remains in Read mode u ntil another

command is issued. From Read mode Bus Read

commands will access the memory array.

Read Electronic Signature Command

The Read Electronic Signat ure command is used

to read the Manufacturer Code, the Device Code

or the Burst Configuration Register. One Bus Write

cycle is required to issue the Read Electronic Signature command. Once the command is issued

subsequent Bus R ead operations, depending on

the address specified, read the Manufacturer

Code, the Device Code or the Burst Configuration

Register until another command is issued; see Table 5, Read Electronic Signature.

Read Query Command.

The Read Query Command is used t o read data

from the Common Flash Interface (CFI ) Memory

Area. One Bus Write cycle is required to issue the

Read Query Command. O nce the c om ma nd is issued subsequent Bus Read op erations, depending on the address specified, read from the

Common Flash Interface Memory Area. See Appendix A, Tables 25, 26, 27, 28 and 29 for det ails

on the information contained in the Common Flash

Interface (CFI) memory area.

Read Status Register Command

The Read Status Register command is used to

read the Status Register. One Bus Write cycle is

required to issue the Read Status Register command. Once the command is issued subsequent

Bus Read operations read the Status Register until another command is issued.

The Status Register information is present on t he

output data bus (DQ1-DQ7) when Chip Enable E

and Output Enable G are at VIL and Output Disable is at V

IH

.

An interactive update of the Status Register bits is

possible by toggling Output Enable or Output Disable. It is also possible during a Program or Erase

operation, by disactivating the device with Chip

Enable at V

IH

and then reactivating it with Chip En-

able and Output Enable at V

IL

and Output Disable

at V

IH

.

The content of the Status Register may also be

read at the completion of a Program, Erase or

Suspend operation. During a Block Erase, Program, Tuning Protection Program or Tuning Protection Unlock command, DQ7 indicates the

Program/Erase Controller status. It is valid until

the operation is completed or suspended.

See the sectio n on t he Stat us Register and Ta ble

11 for details on the definitions of the Status Register bits

Clear Status Register Command

The Clear Status Register command can be used

to reset bits 1, 3, 4 and 5 in the Status Register to

‘0’. One Bus Write is required to issue the Clear

Status Register command. On ce the comm and is

issued the memory returns t o its previous mode,

subsequent Bus Read operations conti nue to output the same data.

The bits in the Status Register are s ticky and do

not automatically return to ‘0’ when a new Program, Erase, Block Protect or Block Unprotect

command is issued. If any error occurs then it is

essential to clear any error bits in the Status Register by issuing the Clear Status Register command before attempting a new Program, Erase or

Resume command.

Block Erase Command

The Block Erase c ommand can be used to erase

a block. It sets all of the bits in the block to ‘1’. All

previous data in the block is lost. If the block is protected then the Erase operation will abort, the data

in the block will not be changed and the Status

Register will output the error.

Two Bus Write operations are required to issue the

command; the first write cycle sets up t he Block

Erase command, the second write cycle confirms

the Block erase command a nd latches the block

address in the internal state machine and starts

the Program/Erase Controller. The sequence is

aborted if the Confirm command is not given and

the device will output the Status Register Data with

bits 4 and 5 set to '1'.

Once the command is issued subsequent Bus

Read operations read the Status Register. See the

section on the Status Register for details on the

definitions of the Status Register bits. During the

Erase operation the memory will only accept the

Read Status Register command and the Program/

Erase Suspend command. All other commands

will be igno re d .

The command can be executed using either V

DD

(for a normal erase operation) or VPP (for a fast

erase operation). If V

PP

is in the V

PPH

range when

M58BW016BT, M58BW016BB, M58BW016D T, M58BW016DB

24/63

the command is issued then a fast erase operation

will be exec uted, otherwis e the ope ration wi ll use

V

DD

. If VPP goes below the VPP Lockout Voltage,

V

PPLK

, during a fast erase the operation aborts,

the Status Register V

PP

Status bit is set to ‘1’ and

the command must be re-issued.

Typical Erase times are given in Table 10.

See Appendix B, Figure 23, Block Erase Flowchart

and Pseudo Code, for a suggested flowchart on

using the Block Erase command.

Program Command.

The Program command is used to program the

memory array. Two Bus Write operations are required to issue the command; the first write cycle

sets up the Program com mand, the secon d write

cycle latches the address and data to be programmed in the int ernal state machine a nd starts

the Program/Erase C ontroller. A program operation can be aborted by writing FFFFFFFFh to any

address after the program set-up command has

been given.

Once the command is issued subsequent Bus

Read operations read the Status Register. See the

section on the Status Register for details on the

definitions of the Status Register bits. During the

Program operation the memory will only accept

the Read Status Register com mand and th e Program/Erase Suspend command. All other commands will be ignored.

If Reset/Power-down, RP

, falls to V

IL

during pro-

gramming the operation will be aborted.

The command can be executed using either V

DD

(for a normal program operation) or VPP (for a fast

program operation). If V

PP

is in the V

PPH

range

when the command is issued then a fast program

operation will be executed, otherwise the operation will us e V

DD

. If VPP goes below the VPP Lock-

out Voltage, V

PPLK

, during a fast program the

operation aborts and the Status Register V

PP

Status bit is set to ‘1’. As data integrity cannot be guaranteed when the program operation is aborted, the

memory block must be erased and reprogrammed.

See Appendix B, Figure 21, Program Flowchart

and Pseudo Code, for a suggested flowchart on

using the Program command.

Program/Erase Suspend Command

The Program/Erase Suspend co mm and is u sed to

pause a Program or Erase operation. The command w ill only be accept ed during a Pro gram or

Erase operation. It can be i ssued at any tim e during a program or eras e operation. The c ommand

is ignored if the device is already in suspend

mode.

One Bus Write cycle is required to i ssue the P rogram/Erase Suspend command and pause the

Program/Erase Controller. Once the command is

issued it is necessary to poll the Program/Erase

Controller Status bit (bit 7) to find out when the

Program/Erase Controller has paused; no other

commands will be accepted until the Program/

Erase Controller has paused. After the Program/

Erase Controller has paused, the memory will continue to output the Status Register until another

command is issued.

During the polling period between issuing the Program/Erase Suspend command and the Program/

Erase Controller pausing it is possible for the operation to complete. Once the Program/Erase

Controller Status bit (bit 7) i ndicates that t he Program/Erase Controller is no longer active, the Program Suspend Status bit (bit 2) or the Erase

Suspend Status bit (bit 6) can be used to determine if the operation has completed or is suspended. For timing on the delay between issuing the

Program/Erase Suspend command and the Program/Erase Controller pausing see Table 10.

During Program/Erase Suspend the Read Memory Array, Read Status Register, Read Electronic

Signature, Read Query and Program/Erase Resume commands will be accepted by the Command Interface. Additionally, if the suspended

operation was Erase then the Program and the

Program Suspend com mands will also b e accep ted. When a program operation is completed inside

a Block Erase Suspend the Read Memory Array

command must be issued to reset the device in

Read mode, then the Erase Resume command

can be issued to complete the whole sequence.

Only the blocks not being e rased m ay b e read or

programmed correctly.

See Appendix B, Figure 22, Program Suspend &