Datasheet M29W800AT90N6T, M29W800AT90N6, M29W800AT90N1T, M29W800AB90N1T, M29W800AB90N1 Datasheet (SGS Thomson Microelectronics)

...

1/33March 2000

M29W800AT

M29W800AB

8 Mbit (1Mb x8 or 512Kb x16, Boot Block)

Low Voltage Single Supply Flash Memory

■ 2.7V to 3.6V SUPPLY VOLTAGEfor

PROGRAM, ERASE and READ OPERATIONS

■ ACCESS TIME: 80ns

■ PROGRAMMING TIME: 10µs typical

■ PROGRAM/ERASE CONTROLLER(P/E.C.)

– Program Byte-by-Byte or Word-by-Word

– Status Register bits and Ready/Busy Output

■ SECURITY PROTECTION MEMORY AREA

■ INSTRUCTION ADDRESS CODING: 3 digits

■ MEMORY BLOCKS

– Boot Block (Top or Bottomlocation)

– Parameter andMain blocks

■ BLOCK, MULTI-BLOCK and CHIP ERASE

■ MULTI BLOCK PROTECTION/TEMPORARY

UNPROTECTION MODES

■ ERASE SUSPEND and RESUME MODES

– Read and Program another Block during

Erase Suspend

■ LOW POWER CONSUMPTION

– Stand-by and Automatic Stand-by

■ 100,000 PROGRAM/ERASE CYCLES per

BLOCK

■ 20 YEARS DATA RETENTION

– Defectivity below 1ppm/year

■ ELECTRONIC SIGNATURE

– Manufacturer Code:20h

– Top Device Code, M29W800AT: D7h

– Bottom Device Code, M29W800AB: 5Bh

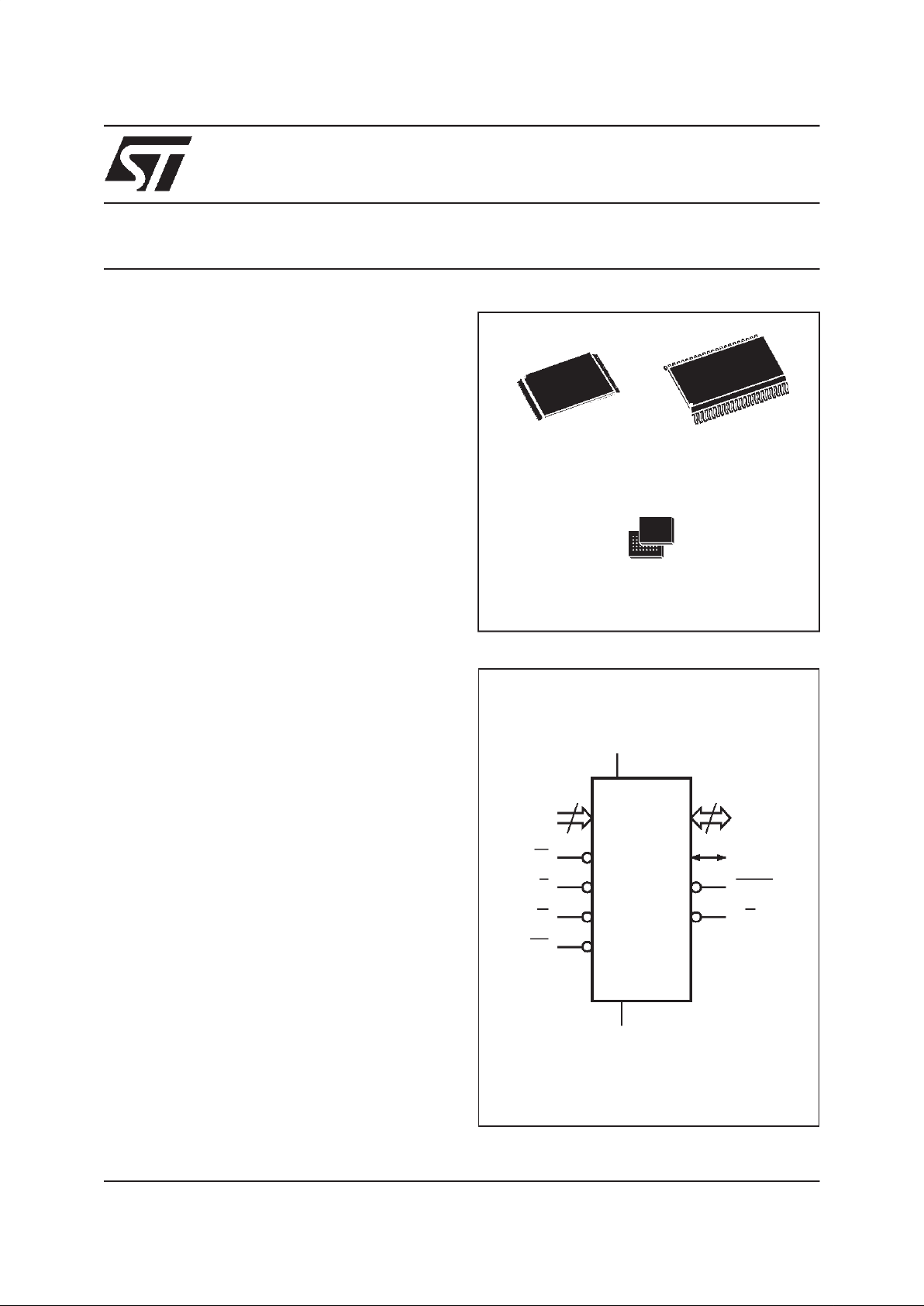

Figure 1. Logic Diagram

AI02599

19

A0-A18

W

DQ0-DQ14

V

CC

M29W800AT

M29W800AB

E

V

SS

15

G

RP

DQ15A–1

BYTE

RB

44

1

FBGA

TSOP48(N)

12 x 20mm

SO44 (M)

LFBGA48 (ZA)

8 x 6 solder balls

M29W800AT, M29W800AB

2/33

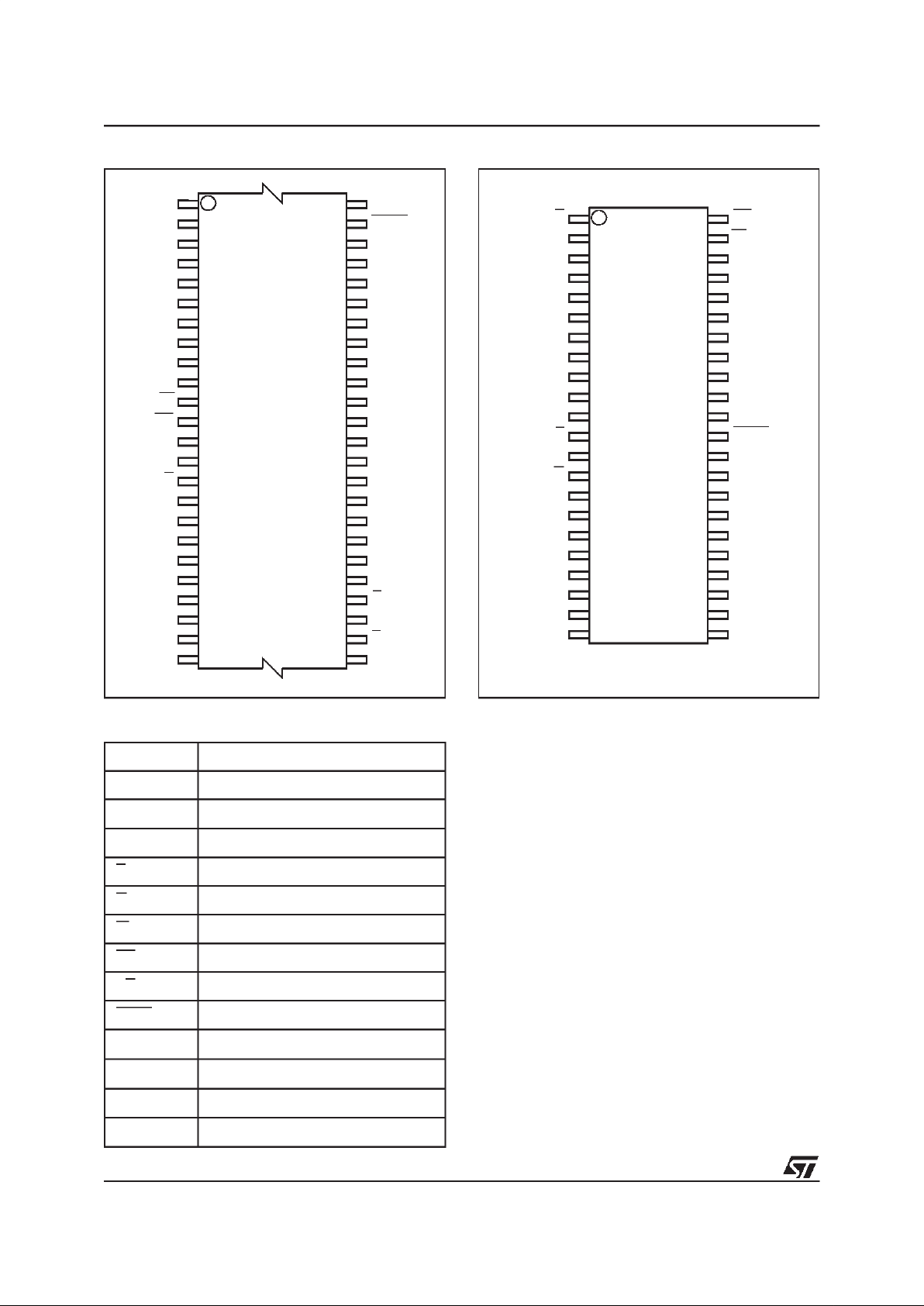

Figure 2. TSOP Connections

DQ3

DQ9

DQ2

A6

DQ0

W

A3

RB

DQ6

A8

A9

DQ13

A17

A10 DQ14

A2

DQ12

DQ10

DQ15A–1

V

CC

DQ4

DQ5

A7

DQ7

NC

NC

AI02179

M29W800T

M29W800B

12

1

13

24 25

36

37

48

DQ8

NC

NC

A1

A18

A4

A5

DQ1

DQ11

G

A12

A13

A16

A11

BYTE

A15

A14

V

SS

E

A0

RP

V

SS

Figure 3. SO Connections

G

DQ0

DQ8

A3

A0

E

V

SS

A2

A1

A13

V

SS

A14

A15

DQ7

A12

A16

BYTE

DQ15A–1

DQ5DQ2

DQ3

V

CC

DQ11

DQ4

DQ14

A9

W

RB

A4

RP

A7

AI02181

M29W800

T

M29W800B

8

2

3

4

5

6

7

9

10

11

12

13

14

15

16

32

31

30

29

28

27

26

25

24

2322

20

19

18

17DQ1

DQ9

A6

A5

DQ6

DQ13

44

39

38

37

36

35

34

33

A11

A10

DQ10

21

DQ12

40

43

1

42

41

A17 A8

A18

Table 1. Signal Names

A0-A18 Address Inputs

DQ0-DQ7 Data Input/Outputs, Command Inputs

DQ8-DQ14 Data Input/Outputs

DQ15A–1 Data Input/Output or Address Input

E Chip Enable

G Output Enable

W Write Enable

RP Reset/Block Temporary Unprotect

RB Ready/Busy Output

BYTE Byte/Word Organization

V

CC

Supply Voltage

V

SS

Ground

NC Not Connected Internally

DU Don’t Use as Internally Connected

DESCRIPTION

TheM29W800A isa non-volatile memory that may

be erased electrically at the blockor chiplevel and

programmed in-system on a Byte-by-Byte or

Word-by-Word basis using only a single 2.7V to

3.6V VCCsupply. For Program and Erase operations the necessary high voltages are generated

internally. The device can also be programmed in

standard programmers.

The array matrix organisation allowseach block to

be erased and reprogrammed without affecting

other blocks. Blocks can be protected against programing and erase on programming equipment,

and temporarily unprotected to make changes in

the application. Each block can be programmed

and erased over 100,000 cycles.

Instructions for Read/Reset, Auto Select for reading the Electronic Signature or Block Protection

status, Programming, Block and Chip Erase,

Erase Suspend and Resume are written to the device in cycles of commands to a Command Interface using standardmicroprocessor write timings.

The device is offered in TSOP48 (12 x 20mm),

SO44 and LFBGA48 0.8 mm ball pitch packages.

3/33

M29W800AT, M29W800AB

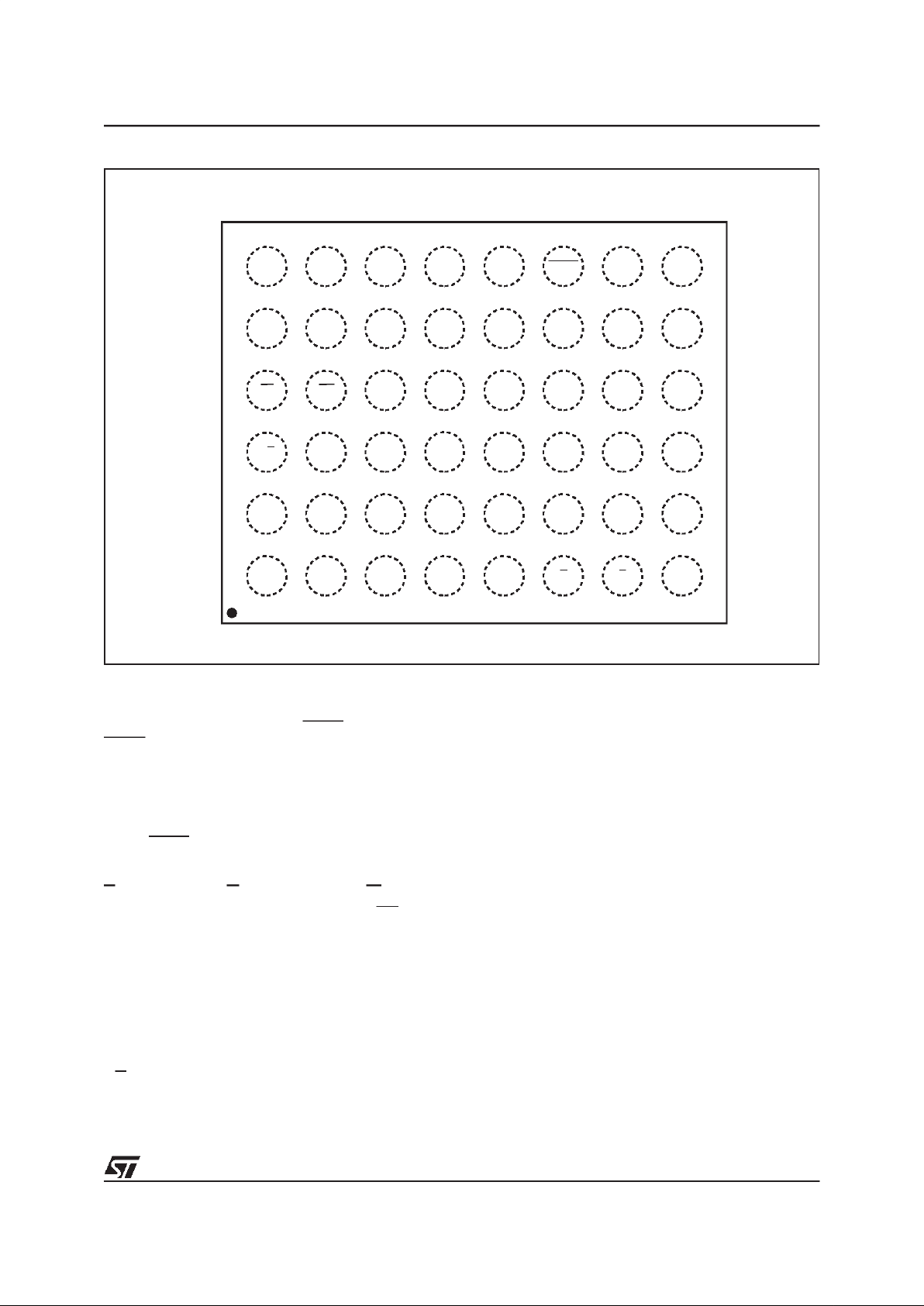

Figure 4. LFBGA Connections (Top view through package)

AI00656

D

E

F

87654321

B

C

A

V

SS

DQ15

A–1

A15A14A12A13

DQ3DQ11DQ10A18DURB

DQ1DQ9DQ8DQ0A6A17A7

GEA0 A4A3

DQ2

DQ6DQ13DQ14A10A8A9

DQ4V

CC

DQ12DQ5DUDURPW

A11 DQ7

A1 A2 V

SS

A5

DU

A16

BYTE

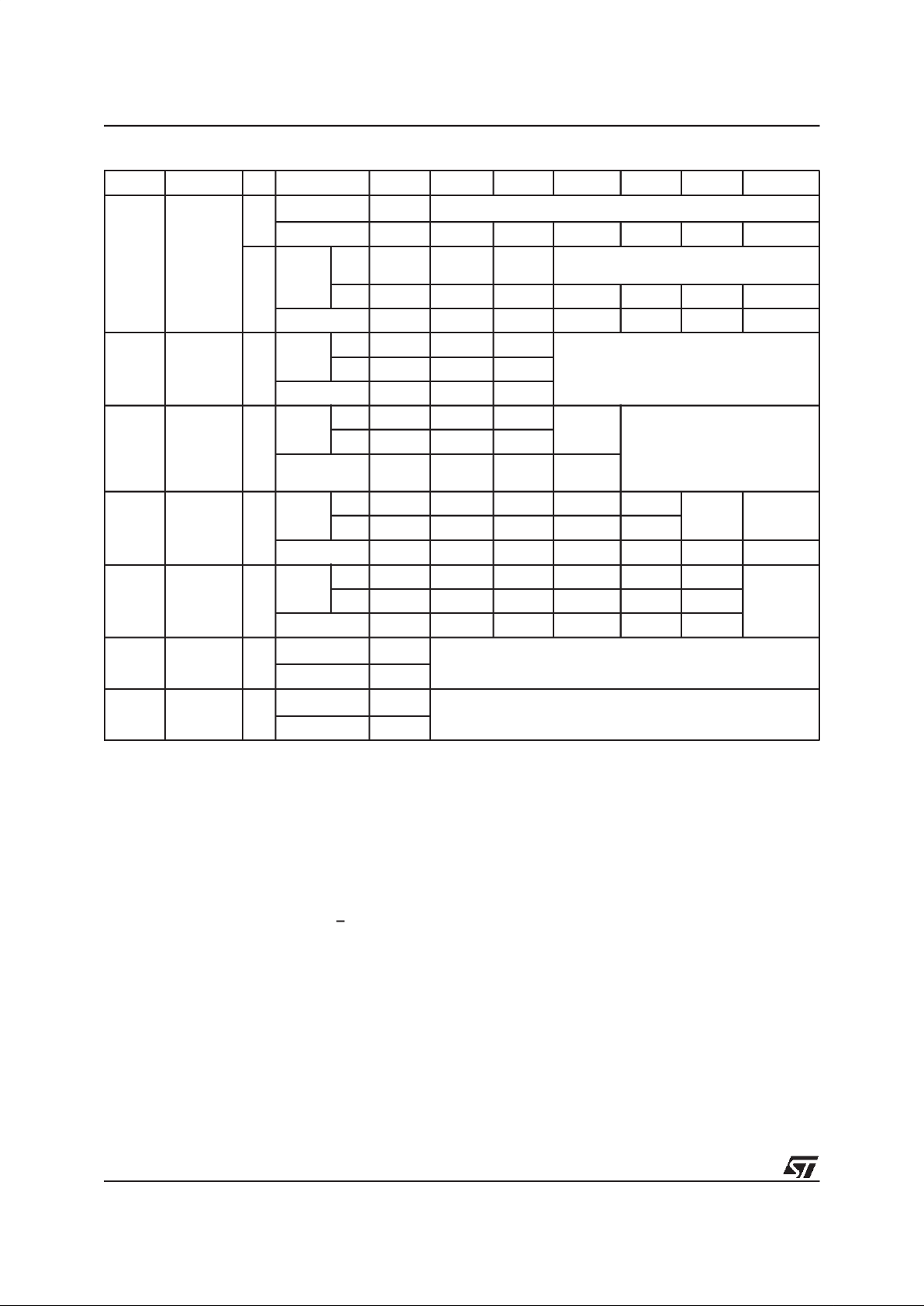

Memory Blocks

The devices featureasymmetrically blocked architecture providing system memoryintegration. Both

M29W800AT and M29W800AB devices have an

array of19blocks, one Boot Blockof 16KBytes or

8 KWords, two Parameter Blocks of 8 KBytes or 4

KWords, one Main Block of 32 KBytes or 16

KWords and fifteen Main Blocks of 64 KBytes or

32 KWords. The M29W800AT has the Boot Block

at the top of the memory address space and the

M29W800AB locates the Boot Block startingat the

bottom. The memory maps are showed in Figure

5.

Each block can be erased separately, any combi-

nation of blocks can be specified for multi-block

erase or theentirechip maybe erased. The Erase

operations are managed automatically by the P/

E.C. The block erase operation canbe suspended

in order to read from or program to any block not

being erased,and then resumed.

Block protection provides additional data security.

Each block can be separately protected or unprotected against Program or Erase on programming

equipment. All previously protected blocks can be

temporarily unprotected in the application.

Organisation

The M29W800A is organised as 1M x8 or 512K

x16 bits selectable by the BYTE signal. When

BYTE is Low the Byte-wide x8 organisation is selected and the address lines are DQ15A–1 and

A0-A18. The Data Input/Output signal DQ15A–1

acts as address line A–1 which selects the lower

or upper Byte of the memory word for output on

DQ0-DQ7, DQ8-DQ14remain at High impedance.

When BYTE isHigh the memory uses the address

inputs A0-A18 and the Data Input/Outputs DQ0DQ15. Memorycontrol isprovided by ChipEnable

E, Output Enable G and Write Enable W inputs.

A Reset/Block Temporary Unprotection RP tri-level input provides a hardware reset when pulled

Low, and when held High (at VID) temporarily unprotects blocks previously protected allowingthem

to be programed and erased. Erase and Program

operations are controlled by an internal Program/

Erase Controller (P/E.C.). Status Register data

output onDQ7 providesa Data Polling signal, and

DQ6 and DQ2 provide Toggle signals to indicate

the state of the P/E.C operations. A Ready/Busy

RB output indicates the completion of the internal

algorithms.

M29W800AT, M29W800AB

4/33

Bus Operations

The following operations can be performed using

the appropriate buscycles: Read (Array, Electronic Signature, Block Protection Status), Write command, Output Disable, Stan-by, Reset, Block

Protection, Unprotection,Protection Verify, Unprotection Verify and Block Temporary Unprotection.

See Tables 5and 6.

Command Interface

Instructions, made up of commands written in cycles, can begiven to the Program/Erase Controller

through a Command Interface (C.I.). For added

data protection,program orerase execution starts

after 4 or 6 cycles. The first, second, fourth and

fifth cycles are used to input Coded cycles to the

C.I. This Coded sequence is the same for all Program/Erase Controller instructions. The ’Command’ itself and its confirmation,when applicable,

are given on the third, fourth or sixth cycles. Any

incorrect commandor anyimproper command sequence will reset the device to Read Array mode.

Instructions

Seven instructions are defined to perform Read

Array, Auto Select (to read the Electronic Signature or Block Protection Status), Program, Block

Erase, ChipErase, Erase Suspend and EraseResume.

The internal P/E.C. automatically handles all timing and verification of the Program and Erase operations. The Status Register Data Polling,

Toggle, Error bits and the RB output may be read

at any time, during programmingor erase, tomonitor the progress of the operation.

Instructions are composed of up to six cycles. The

first two cycles input a Coded sequence to the

Command Interface which is common to all instructions (see Table 9).

The third cycle inputs the instruction set-up command. Subsequent cycles output the addressed

data, Electronic Signatureor Block Protection Status for Read operations. Inorder to give additional

data protection, the instructions for Program and

Block or Chip Erase require further command inputs. For a Program instruction, the fourth command cycle inputs the address and data to be

programmed. For an Erase instruction (Block or

Chip), the fourth and fifth cycles input a further

Coded sequence before the Erase confirm command on the sixth cycle. Erasure of a memory

block may be suspended, in order to read data

from another block or to program data in another

block, and then resumed. When power is first applied or if VCCfalls below V

LKO

, the command in-

terface is reset to Read Array.

Table 2. Absolute Maximum Ratings

(1)

Note: 1. Except for the rating ”Operating Temperature Range”, stresses above those listed in the Table ”Absolute Maximum Ratings” may

cause permanent damage to the device. These are stress ratings only and operation of the device at these or any other conditions

above those indicated in the Operating sections of this specification is not implied. Exposure to Absolute Maximum Rating conditions forextended periods mayaffect device reliability. Referalso to theSTMicroelectronics SURE Program and other relevantquality documents.

2. Minimum Voltage may undershoot to –2V during transition and for less than 20ns during transitions.

3. Depends on range.

Symbol Parameter Value Unit

T

A

Ambient Operating Temperature

(3)

–40 to 85 °C

T

BIAS

Temperature Under Bias –50 to 125 °C

T

STG

Storage Temperature –65 to 150 °C

V

IO

(2)

Input or Output Voltage –0.6 to 5 V

V

CC

Supply Voltage –0.6 to 5 V

V

(A9, E, G, RP)

(2)

A9, E, G, RP Voltage –0.6 to 13.5 V

5/33

M29W800AT, M29W800AB

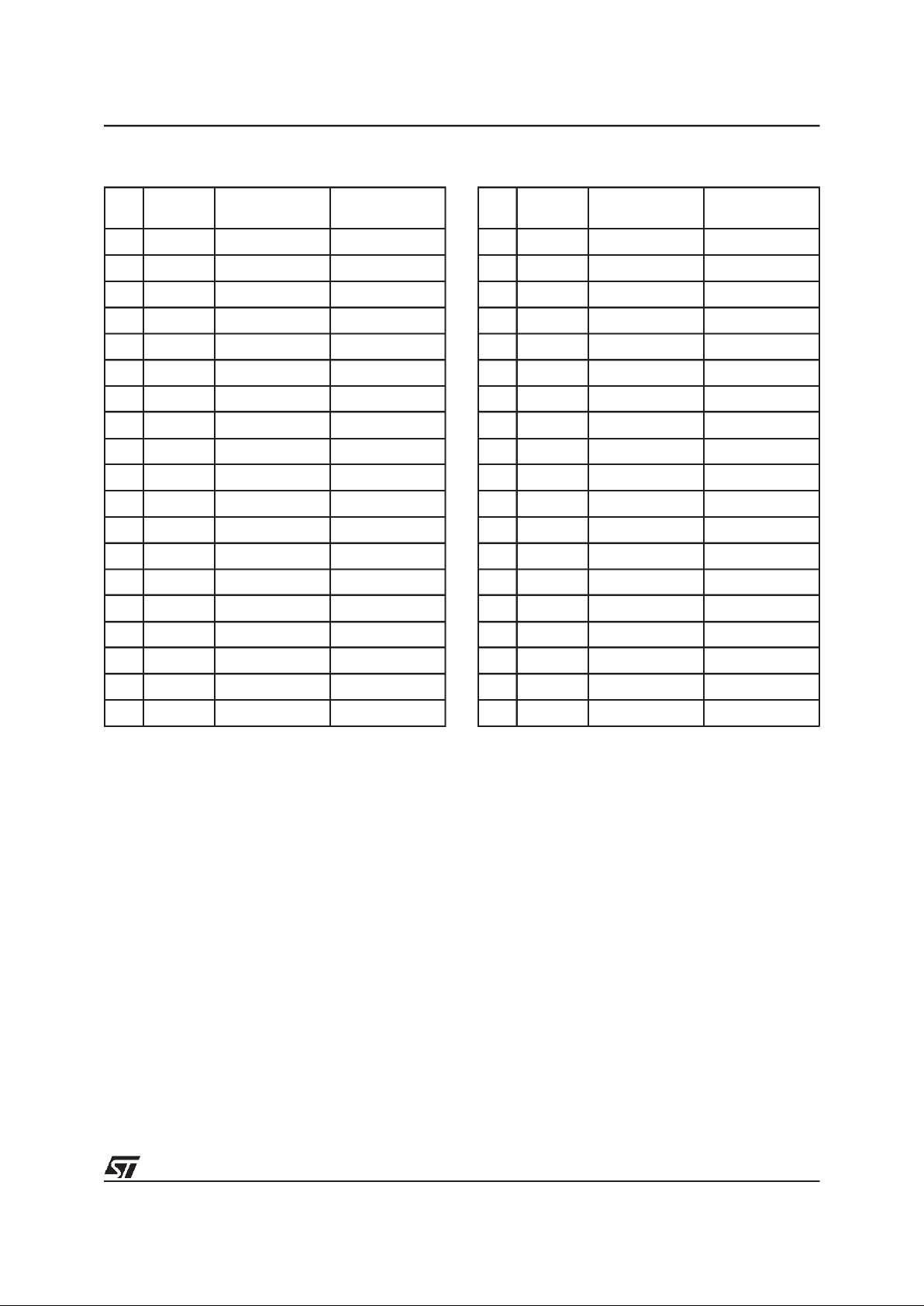

Table 3. Top Boot Block Addresses,

M29W800AT

#

Size

(Kbytes)

Address Range

(x8)

Address Range

(x16)

18 16 FC000h-FFFFFh 7E000h-7FFFFh

17 8 FA000h-FBFFFh 7D000h-7DFFFh

16 8 F8000h-F9FFFh 7C000h-7CFFFh

15 32 F0000h-F7FFFh 78000h-7BFFFh

14 64 E0000h-EFFFFh 70000h-77FFFh

13 64 D0000h-DFFFFh 68000h-6FFFFh

12 64 C0000h-CFFFFh 60000h-67FFFh

11 64 B0000h-BFFFFh 58000h-5FFFFh

10 64 A0000h-AFFFFh 50000h-57FFFh

9 64 90000h-9FFFFh 48000h-4FFFFh

8 64 80000h-8FFFFh 40000h-47FFFh

7 64 70000h-7FFFFh 38000h-3FFFFh

6 64 60000h-6FFFFh 30000h-37FFFh

5 64 50000h-5FFFFh 28000h-2FFFFh

4 64 40000h-4FFFFh 20000h-27FFFh

3 64 30000h-3FFFFh 18000h-1FFFFh

2 64 20000h-2FFFFh 10000h-17FFFh

1 64 10000h-1FFFFh 08000h-0FFFFh

0 64 00000h-0FFFFh 00000h-07FFFh

Table 4. Bottom Boot Block Addresses,

M29W800AB

#

Size

(Kbytes)

Address Range

(x8)

Address Range

(x16)

18 64 F0000h-FFFFFh 78000h-7FFFFh

17 64 E0000h-EFFFFh 70000h-77FFFh

16 64 D0000h-DFFFFh 68000h-6FFFFh

15 64 C0000h-CFFFFh 60000h-67FFFh

14 64 B0000h-BFFFFh 58000h-5FFFFh

13 64 A0000h-AFFFFh 50000h-57FFFh

12 64 90000h-9FFFFh 48000h-4FFFFh

11 64 80000h-8FFFFh 40000h-47FFFh

10 64 70000h-7FFFFh 38000h-3FFFFh

9 64 60000h-6FFFFh 30000h-37FFFh

8 64 50000h-5FFFFh 28000h-2FFFFh

7 64 40000h-4FFFFh 20000h-27FFFh

6 64 30000h-3FFFFh 18000h-1FFFFh

5 64 20000h-2FFFFh 10000h-17FFFh

4 64 10000h-1FFFFh 08000h-0FFFFh

3 32 08000h-0FFFFh 04000h-07FFFh

2 8 06000h-07FFFh 03000h-03FFFh

1 8 04000h-05FFFh 02000h-02FFFh

0 16 00000h-03FFFh 00000h-01FFFh

M29W800AT, M29W800AB

6/33

SIGNAL DESCRIPTIONS

See Figure 1 and Table 1.

Address Inputs (A0-A18). The address inputs

for thememory arrayarelatched duringa writeoperation on the falling edge at Chip Enable E or

Write Enable W. In Word-wide organisation the

address lines are A0-A18, in Byte-wide organisation DQ15A–1 acts as an additional LSB address

line. WhenA9 is raised to VID, eithera Read Electronic Signature Manufacturer or Device Code,

Block Protection Status ora Write BlockProtection

or BlockUnprotection isenableddepending on the

combination oflevels on A0, A1,A6, A12andA15.

Data Input/Outputs (DQ0-DQ7). These Inputs/

Outputs are used in theByte-wide and Word-wide

organisations. Theinput isdata to beprogrammed

in the memory array ora command tobe written to

the C.I.Both are latched onthe rising edge ofChip

Enable E or Write Enable W. The output is data

from the Memory Array, the Electronic Signature

Manufacturer or Device codes, the Block Protection Status or the Status register Data Polling bit

DQ7, the Toggle Bits DQ6 and DQ2, the Error bit

DQ5 ortheErase Timer bitDQ3. Outputs arevalid

when Chip Enable E andOutput Enable G are active. The output is high impedance when the chip

is deselected or the outputs are disabled and

when RP isat a Low level.

Data Input/Outputs (DQ8-DQ14 and DQ15A–

1). These Inputs/Outputs are additionally used in

the Word-wide organisation. When BYTE is High

DQ8-DQ14 and DQ15A–1 act as the MSB of the

Data Input or Output, functioning as described for

DQ0-DQ7 above, and DQ8-DQ15 are ’don’t care’

for command inputs or status outputs. When

BYTE is Low, DQ0-DQ14 are high impedance,

DQ15A–1 is the Address A–1 input.

Chip Enable (E). The Chip Enable input activates the memory control logic, input buffers, decoders andsense amplifiers.E Highdeselects the

memory and reduces the power consumption to

the stan-by level. E can also be used to control

writing to the command register and to the memory array, while W remains at a low level. The Chip

Enable must be forcedto VIDduring the Block Unprotection operation.

Output Enable (G). The Output Enable gates the

outputs through the data buffersduring a read operation. When G is High the outputs are High impedance. G must be forced to VIDlevel during

Block Protection and Unprotection operations.

Write Enable (W). This input controls writing to

the Command Register and Address and Data

latches.

Byte/WordOrganizationSelect (BYTE). The BYTE

input selects the output configuration for the device: Byte-wide (x8) mode or Word-wide (x16)

mode. When BYTE is Low, the Byte-wide mode is

selected andthe data is read and programmed on

DQ0-DQ7. In this mode, DQ8-DQ14 are at high

impedance and DQ15A–1 is the LSB address.

When BYTE is High, the Word-wide mode is selected and the data is read and programmed on

DQ0-DQ15.

Ready/Busy Output (RB). Ready/Busy is an

open-drain output and gives the internal state of

the P/E.C. of thedevice. When RB is Low, the device is Busy with a Program or Erase operation

and it will not accept any additional program or

erase instructions except the Erase Suspend instruction. WhenRB is High,the deviceis ready for

any Read, Program or Erase operation. The RB

will also be Highwhen the memory is put in Erase

Suspend or Stan-by modes.

Reset/Block Temporary Unprotect Input (RP).

The RP Input provides hardware reset and protected block(s) temporary unprotection functions.

Reset of the memory is achieved by pulling RP to

VILfor at least t

PLPX

. When the reset pulse is given, if the memory is in Read or Stan-by modes, it

will be available for new operations in t

PHEL

after

the rising edge of RP. If the memory is in Erase,

Erase Suspend or Program modes the reset will

take t

PLYH

during which the RB signal will be held

at VIL. Theend of thememory reset will be indicated by the rising edge of RB. A hardware reset during an Erase or Program operation will corrupt the

data being programmed or the sector(s) being

erased. See Tables 15, 16, and Figure 11.

Temporary block unprotection is made by holding

RP at VID. In this condition previously protected

blocks can be programmed or erased. The transition of RP from VIHto VIDmust slower than t

PH-

PHH

. See Tables 17, 18, and Figure 11. When RP

is returned from VIDto VIHall blocks temporarily

unprotected will be again protected.

VCCSupply Voltage. The power supply for all

operations (Read, Program and Erase).

VSSGround. VSSis the reference for all voltage

measurements.

7/33

M29W800AT, M29W800AB

DEVICE OPERATIONS

See Tables 5, 6 and 7.

Read. Read operations are used to output the

contents of the Memory Array, the Electronic Signature, theStatus Register or the BlockProtection

Status. Both Chip Enable E and Output Enable G

must below in ordertoread theoutput of the memory. A new operation is initiated either on the following edge of Chip Enable E or on any address

transition with E at VIL.

Write. Write operations are used to give Instruction Commands to the memory or to latch input

data to be programmed. A write operation is initiated whenChip Enable E isLow and Write Enable

W is Low with Output Enable G High. Addresses

are latchedon the falling edgeof W orEwhichever

occurs last. Commands and Input Data are

latched onthe rising edgeof Wor Ewhicheveroccurs first.

Output Disable. The data outputs are high impedance when the Output Enable G is High with

Write Enable W High.

Stan-by. The memory is in stan-by when Chip

Enable E isHigh and the P/E.C. is idle. The power

consumption is reduced to the stan-by level and

the outputs are high impedance, independent of

the Output Enable G or Write Enable Winputs.

Automatic Stan-by. After 150ns of bus inactivity

(no addresstransition, CE=VIL) andwhen CMOS

levels aredriving theaddresses, the chip automatically enters a pseudo-stan-by mode where consumption is reduced to the CMOS stan-by value,

while outputs stilldrive the bus (if G = VIL).

Electronic Signature. Two codes identifying the

manufacturer andthe devicecan beread from the

memory. The manufacturer’s code for STMicroelectronics is 20h, the device code is D7h for the

M29W800AT (Top Boot) and 5Bh for the

M29W800AB (Bottom Boot). These codes allow

programming equipment or applications to automatically match their interface to the characteristics ofthe M29W800A. TheElectronic Signature is

output by a Read operation when the voltage applied to A9 is at VIDandaddress inputs A1 isLow.

The manufacturer code is output when the Address input A0 is Low and the device code when

this input is High. Other Address inputs are ignored. The codes are output on DQ0-DQ7.

The Electronic Signature canalso be read, without

raising A9 to VID, by giving the memory the Instruction AS. If the Byte-wide configuration is selected the codes are output on DQ0-DQ7 with

DQ8-DQ14 at High impedance; if the Word-wide

configuration is selected the codes are output on

DQ0-DQ7 withDQ8-DQ15 at 00h.

Block Protection. Each block can be separately

protected against Program or Erase on programming equipment. Block protection provides additional data security, as it disables all program or

erase operations. This mode is activated when

both A9 and G are raised to VIDand anaddress in

the block is applied on A12-A18. Block protection

is initiated on theedge ofW fallingto VIL. Then after a delay of 100µs, the edge of W rising to V

IH

ends the protection operations. Block protection

verify is achieved by bringing G, E, A0 and A6 to

VILand A1 to VIH, while W is at VIHand A9 at VID.

Under these conditions, reading the data output

will yield 01h if the block defined by the inputs on

A12-A18 is protected. Any attempt to program or

erase a protected block will be ignored by the device.

Block Temporary Unprotection. Any previously

protected block can be temporarily unprotected in

order to change stored data. The temporary unprotection mode isactivatedby bringing RP toVID.

During the temporary unprotection mode the previously protected blocks are unprotected. A block

can beselected and data can bemodified by executing the Erase or Program instruction with the

RP signal held at VID. When RP is returned toVIH,

all the previously protected blocks are again protected.

Block Unprotection. All protected blocks can be

unprotected on programming equipment to allow

updating of bit contents. All blocks must first be

protected before theunprotection operation. Block

unprotection is activated when A9,G and E are at

VIDand A12, A15 at VIH. Unprotection is initiated

by the edge of W falling to VIL. After a delay of

10ms, the unprotection operation will end. Unprotection verify is achieved by bringing G and E to

VILwhileA0 is at VIL, A6and A1are at VIHandA9

remains at VID. In these conditions, reading the

output data willyield 00hif the block definedbythe

inputs A12-A18 has been successfully unprotected. Each block must be separately verified by giving its address in order to ensure that it has been

unprotected.

M29W800AT, M29W800AB

8/33

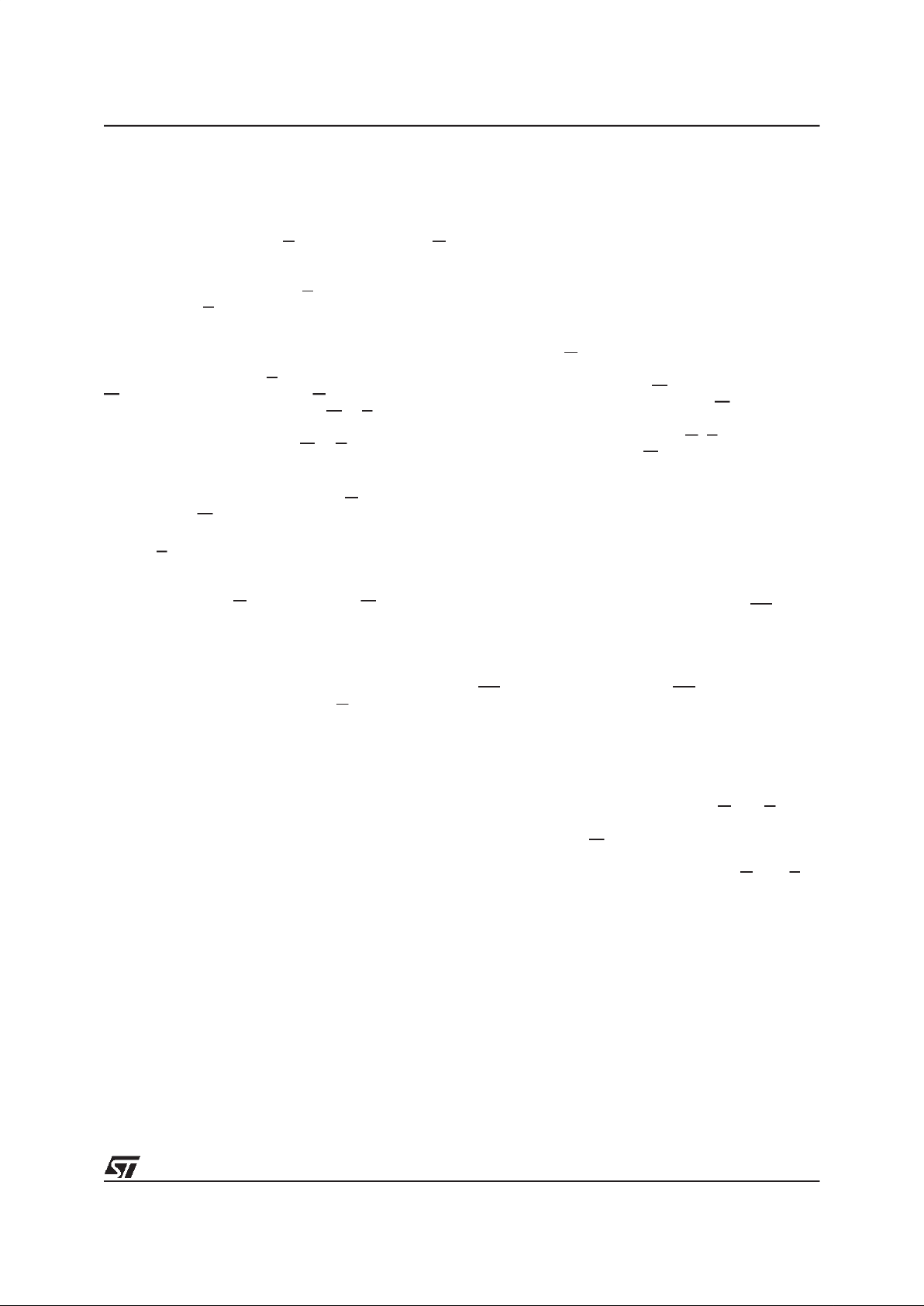

Table 5. User Bus Operations

(1)

Note: 1. X = VILor VIH.

2. Block Address must be given an A12-A18 bits.

3. See Table 7.

4. Operation performed on programming equipment.

Table 6. Read Electronic Signature (following AS instruction or with A9 = VID)

Table 7. Read Block Protection with AS Instruction

Operation E G W RP BYTE A0 A1 A6 A9 A12 A15

DQ0-

DQ7

DQ8-

DQ14

DQ15

A–1

Read Word

V

ILVIL

V

IH

V

IHVIH

A0 A1 A6 A9 A12 A15

Data

Output

Data

Output

Data

Output

Read Byte

V

ILVIL

V

IH

V

IH

V

IL

A0 A1 A6 A9 A12 A15

Data

Output

Hi-Z

Address

Input

Write Word

V

ILVIH

V

IL

V

IHVIH

A0 A1 A6 A9 A12 A15

Data

Input

Data

Input

Data

Input

Write Byte

V

ILVIH

V

IL

V

IH

V

IL

A0 A1 A6 A9 A12 A15

Data

Input

Hi-Z

Address

Input

Output Disable

V

ILVIH

V

IH

V

IH

X XXXX X X Hi-Z Hi-Z Hi-Z

Stan-by

V

IH

XX

V

IH

X XXXX X X Hi-Z Hi-Z Hi-Z

Reset X X X

V

IL

X XXXX X X Hi-Z Hi-Z Hi-Z

Block

Protection

(2,4)

VILVIDVILPulse V

IH

X XXX

V

ID

XX X X X

Blocks

Unprotection

(4)

VIDVIDVILPulse V

IH

X XXX

V

IDVIHVIH

XXX

Block

Protection

Verify

(2,4)

VILV

IL

V

IH

V

IH

X

V

ILVIHVILVID

A12 A15

Block

Protect

Status

(3)

XX

Block

Unprotection

Verify

(2,4)

VILV

IL

V

IH

V

IH

X

V

ILVIHVIHVID

A12 A15

Block

Protect

Status

(3)

XX

Block

Temporary

Unprotection

XX X

V

ID

X XXXX X X X X X

Org. Code Device E G W BYTE A0 A1

Other

Addresses

DQ0-

DQ7

DQ8-

DQ14

DQ15

A–1

Word-

wide

Manufact.

Code

V

IL

V

IL

V

IH

V

IH

V

IL

V

IL

Don’t Care 20h 00h 0

Device

Code

M29W800AT

V

IL

V

IL

V

IH

V

IH

V

IH

V

IL

Don’t Care D7h 00h 0

M29W800AB

V

IL

V

IL

V

IH

V

IH

V

IH

V

IL

Don’t Care 5Bh 00h 0

Code E G W A0 A1 A12-A18

Other

Addresses

DQ0-DQ7

Protected Block

V

IL

V

IL

V

IH

V

IL

V

IH

Block Address Don’t Care 01h

Unprotected Block

V

IL

V

IL

V

IH

V

IL

V

IH

Block Address Don’t Care 00h

9/33

M29W800AT, M29W800AB

Table 8. Commands

Hex Code Command

00h Invalid/Reserved

10h Chip Erase Confirm

20h Reserved

30h Block Erase Resume/Confirm

80h Set-up Erase

90h

Read Electronic Signature/

Block Protection Status

A0h Program

B0h Erase Suspend

F0h Read Array/Reset

INSTRUCTIONS AND COMMANDS

The Command Interface latches commands written to the memory. Instructions are made up from

one or more commands to perform Read Memory

Array, Read Electronic Signature, ReadBlockProtection, Program, Block Erase, Chip Erase, Erase

Suspend and Erase Resume. Commands are

made of address and data sequences. The instructions requirefrom 1 to6 cycles,thefirst or first

three ofwhich are always write operations used to

initiate the instruction. They are followed by either

further writecycles to confirm the firstcommand or

execute thecommand immediately. Commandsequencing must be followed exactly. Any invalid

combination of commands will reset the device to

Read Array. The increased number of cycles has

been chosentoassuremaximum datasecurity. Instructions are initialised by twoinitialCodedcycles

which unlock the Command Interface. In addition,

for Erase,instructionconfirmation is again preceded by the two Coded cycles.

Status Register Bits

P/E.C. statusis indicated during executionby Data

Polling on DQ7, detection of Toggle on DQ6 and

DQ2, or Error on DQ5 and Erase Timer DQ3 bits.

Any read attempt during Program or Erase command execution will automatically output these

five Status Registerbits. The P/E.C. automatically

sets bits DQ2, DQ3, DQ5, DQ6 and DQ7. Other

bits (DQ0, DQ1 and DQ4) are reserved for future

use and should be masked. See Tables10 and11.

Data Polling Bit (DQ7). When Programming operations are in progress, this bit outputs the complement of the bit being programmed on DQ7.

During Erase operation, it outputsa ’0’. After completion ofthe operation, DQ7 will outputthebit last

programmed or a ’1’ after erasing. Data Polling is

valid and only effective during P/E.C. operation,

that is after the fourth W pulse for programming or

after the sixth W pulse for erase. It must be performed at the address beingprogrammed or at an

address within the block being erased. If all the

blocks selectedfor erasureare protected, DQ7 will

be set to ’0’for about 100µs, and then return to the

previous addressed memory data value. See Figure 13for the Data Polling flowchartand Figure 12

for the Data Polling waveforms. DQ7 will also flag

the Erase Suspend mode by switching from ’0’ to

’1’ at the start of the Erase Suspend. In order to

monitor DQ7 in the Erase Suspend mode an address within a block being erased must be provided. For a Read Operation in Erase Suspend

mode, DQ7 will output ’1’ if the read is attempted

on a block being erased and thedata value onother blocks. DuringProgramoperation in EraseSuspend Mode, DQ7 will have the same behavior as

in the normal program execution outside of the

suspend mode.

Toggle Bit (DQ6). When Programming or Erasing operations are in progress, successive attempts to read DQ6 will output complementary

data. DQ6 will togglefollowing toggling ofeither G,

or E when G is low. The operation is completed

when two successive reads yield the same output

data. The next read will output the bit last programmed ora ’1’ after erasing. The toggle bitDQ6

is valid only during P/E.C. operations, that is after

the fourth W pulse for programming or after the

sixth W pulse for Erase. If the blocks selected for

erasure are protected, DQ6 will toggle for about

100µs and then return back to Read. DQ6 will be

set to ’1’ if a Read operation is attempted on an

Erase Suspend block. When erase is suspended

DQ6 will toggle during programming operations in

a block differentto the blockin Erase Suspend. Either E or G toggling will cause DQ6 to toggle. See

Figure 14 for Toggle Bit flowchart and Figure 15

for Toggle Bit waveforms.

M29W800AT, M29W800AB

10/33

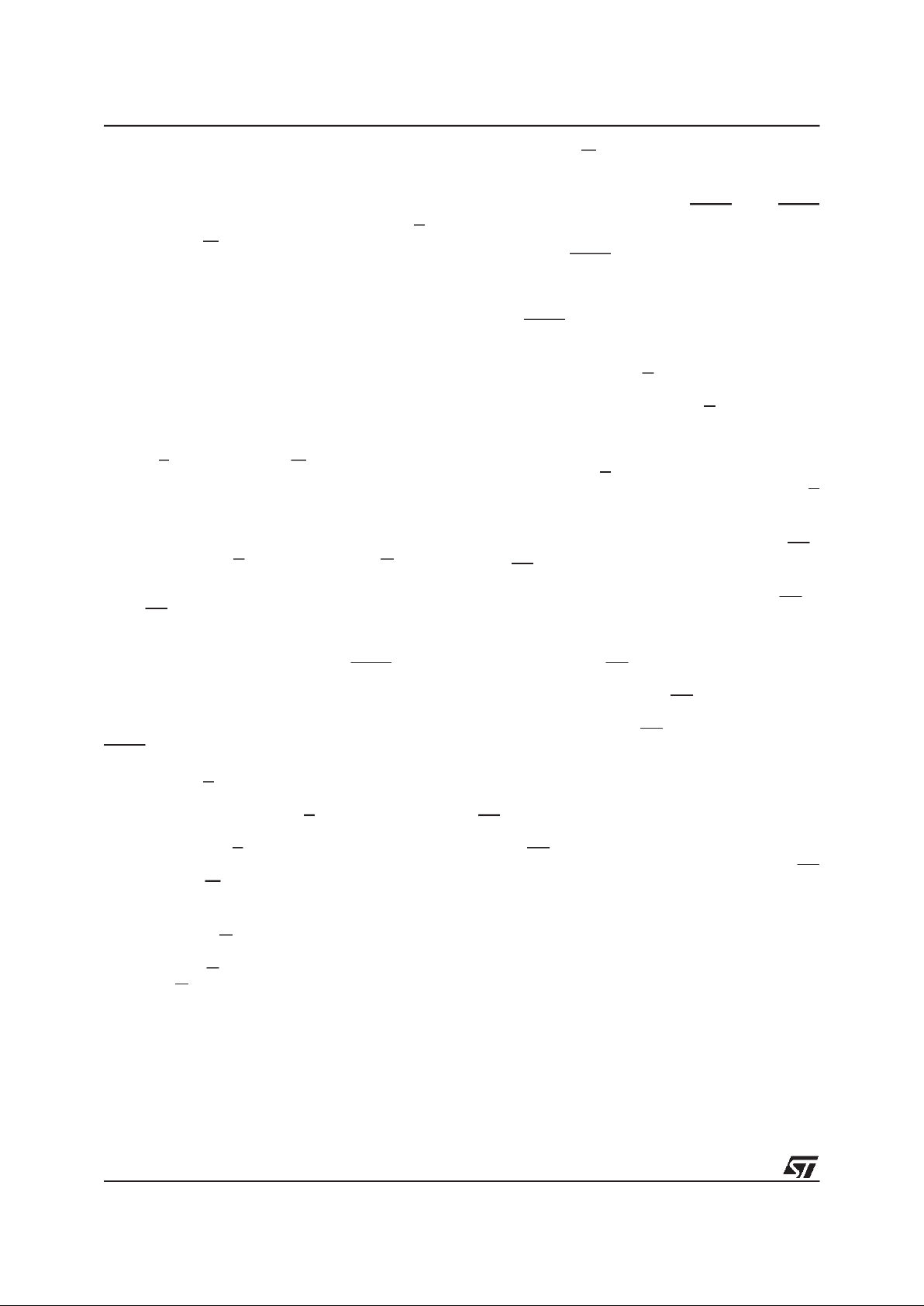

Table 9. Instructions

(1)

Note: 1. Commands not interpreted in this table will default to read array mode.

2. A wait of t

PLYH

is necessary after a Read/Reset command if the memory was in an Erase or Program mode before starting anynew

operation (see Tables 15, 16 and Figure 11).

3. X = Don’t Care.

4. The first cycles of the RD or AS instructions are followed by read operations. Any number of read cycles can occur after the command cycles.

5. Signature Address bits A0, A1, at V

IL

will output Manufacturer code (20h). Address bits A0 at VIHand A1, at VILwilloutput Device

code.

6. Block Protection Address: A0, at V

IL

,A1atVIHand A15-A18 within the Block will output the Block Protection status.

7. For Coded cycles address inputs A11-A18 aredon’t care.

8. Optional, additional Blocks addresses must be entered within the erase timeout delay after last write entry, timeout statuscan be

verified through DQ3 value (see Erase Timer Bit DQ3 description). When full command isentered, read Data Polling or Toggle bit

until Erase is completed or suspended.

9. Read Data Polling, Toggle bits or RB until Erase completes.

10. During Erase Suspend, Read and Data Program functions are allowed in blocks not being erased.

Mne. Instr. Cyc. 1st Cyc. 2nd Cyc. 3rd Cyc. 4th Cyc. 5th Cyc. 6th Cyc. 7th Cyc.

RD

(2,4)

Read/Reset

Memory Array

1+

Addr.

(3,7)

X Read Memory Array until anew write cycle is initiated.

Data F0h

3+

Addr.

(3,7)

Byte AAAh 555h AAAh

Read Memory Array until a new write cycle is

initiated.

Word 555h 2AAh 555h

Data AAh 55h F0h

AS

(4)

Auto Select 3+

Addr.

(3,7)

Byte AAAh 555h AAAh

Read Electronic Signature or Block Protection

Status until anew write cycle isinitiated. See Note

5 and 6.

Word 555h 2AAh 555h

Data AAh 55h 90h

PG Program 4

Addr.

(3,7)

Byte AAAh 555h AAAh

Program

Address

Read Data Polling or ToggleBit until

Program completes.

Word 555h 2AAh 555h

Data AAh 55h A0h

Program

Data

BE Block Erase 6

Addr.

(3,7)

Byte AAAh 555h AAAh AAAh 555h

Block

Address

Additional

Block

(8)

Word 555h 2AAh 555h 555h 2AAh

Data AAh 55h 80h AAh 55h 30h 30h

CE Chip Erase 6

Addr.

(3,7)

Byte AAAh 555h AAAh AAAh 555h AAAh

Note 9Word 555h 2AAh 555h 555h 2AAh 555h

Data AAh 55h 80h AAh 55h 10h

ES

(10)

Erase

Suspend

1

Addr.

(3,7)

X

Read until Togglestops, then read all the data needed from any Block(s)

not being erased then Resume Erase.

Data B0h

ER

Erase

Resume

1

Addr.

(3,7)

X

Read Data Polling or Toggle Bits until Erase completes or Erase is

suspended another time.

Data 30h

11/33

M29W800AT, M29W800AB

Table 10. Status Register Bits

Note: Logic level ’1’ is High, ’0’ is Low. -0-1-0-0-0-1-1-1-0- represent bit value in successive Read operations.

DQ Name Logic Level Definition Note

7

Data

Polling

’1’

Erase Complete or erase block

in Erase Suspend

Indicates the P/E.C. status, check during

Program orErase, and on completion before

checking bits DQ5 for program or Erase

Success.

’0’ Erase On-going

DQ

Program Complete or data of

non erase block during Erase

Suspend

DQ Program On-going

6 Toggle Bit

’-1-0-1-0-1-0-1-’ Erase or Program On-going

Successive reads output complementary

data on DQ6 while Programming or Erase

operations are on-going. DQ6 remains at

constant levelwhen P/E.C. operations are

completed or Erase Suspend is

acknowledged.

DQ Program Complete

’-1-1-1-1-1-1-1-’

Erase Complete or Erase

Suspend on currently

addressed block

5 Error Bit

’1’ Program or Erase Error

This bit is set to ‘1’ in the case of

Programming or Erase failure.

’0’ Program or Erase On-going

4 Reserved

3

Erase

Time Bit

’1’ Erase Timeout Period Expired

P/E.C. Erase operation has started. Only

possible command entry is Erase Suspend

(ES).

’0’ Erase Timeout Period On-going

An additional block to be erased in parallel

can be entered to the P/E.C.

2 Toggle Bit

’-1-0-1-0-1-0-1-’

Chip Erase, Erase or Erase

Suspend on the currently

addressed block.

Erase Errordue to thecurrently

addressed block

(when DQ5 = ‘1’).

Indicates the erase status and allows to

identify the erased block

1

Program on-going, Erase ongoing on another block or

Erase Complete

DQ

Erase Suspend read on non

Erase Suspend block

1 Reserved

0 Reserved

M29W800AT, M29W800AB

12/33

During the second cycle theCoded cycles consist

ofwriting the data55h ataddress555h inthe Bytewide configuration and at address 2AAh in the

Word-wide configuration. In the Byte-wide configuration the address lines A–1 to A10 are valid, in

Word-wide A0 to A11are valid,otheraddress lines

are ’don’t care’. The Coded cycles happen on first

and second cyclesof the command write or on the

fourth and fifth cycles.

Instructions

See Table9.

Read/Reset (RD) Instruction. The Read/Reset

instruction consists of one write cycle giving the

command F0h. It can be optionally preceded by

the two Coded cycles. Subsequent read operations will read the memory array addressed and

output the data read. A wait state of 10µs is necessary after Read/Reset prior to any valid read if

the memory was in an Erase mode when the RD

instruction is given. The Read/Reset command is

not accepted during Erase and erase Suspend.

Auto Select (AS) Instruction. This instruction

uses the two Coded cycles followed by one write

cycle giving thecommand 90hto address AAAh in

the Byte-wide configurationor address 555hinthe

Word-wide configuration for command set-up. A

subsequent read will output the manufacturer

code and the device code or the block protection

status depending on the levels of A0 and A1. The

manufacturer code, 20h, is output when the addresses lines A0and A1are Low,thedevice code,

EEh for Top Boot, EFh for Bottom Boot is output

when A0 is High with A1 Low.

The AS instruction also allows access tothe block

protection status. After giving the AS instruction,

A0 is set to VILwith A1 at VIH, while A12-A18 define the address of the block to be verified.A read

in these conditions will output a 01h if the block is

protected and a 00h if the block is not protected.

Program (PG)Instruction. This instruction uses

four write cycles. Both for Byte-wide configuration

and for Word-wide configuration. The Program

command A0h is written to address AAAh in the

Byte-wide configuration or to address 555h in the

Word-wide configuration on the third cycle after

two Coded cycles. A fourth write operation latches

the Addresson the falling edge of W or E and the

Data to bewritten on therising edge and starts the

P/E.C. Read operations outputtheStatus Register

bits after the programming has started. Memory

programming is madeonly by writing ’0’in place of

’1’. Status bits DQ6 and DQ7 determine if programming ison-going and DQ5 allows verification

of any possible error. Programming at an address

not in blocks being erased is also possible during

erase suspend. In this case, DQ2 will toggle at the

address being programmed.

Table 11. Polling and Toggle Bits

Note: 1. Toggle ifthe address iswithin a block being erased.

’1’if the address is within a block not being erased.

Mode DQ7 DQ6 DQ2

Program DQ7 Toggle 1

Erase 0 Toggle Note 1

Erase Suspend Read

(in Erase Suspend

block)

1 1 Toggle

Erase Suspend Read

(outside Erase Suspend

block)

DQ7 DQ6 DQ2

Erase Suspend Program DQ7 Toggle N/A

Toggle Bit (DQ2). This toggle bit, together with

DQ6, can be used to determine the device status

during theErase operations. Itcan alsobe used to

identify the block being erased. During Erase or

Erase Suspend a read from a block being erased

will cause DQ2 to toggle. A read from a block not

being erased will set DQ2 to ’1’ during erase and

to DQ2 during Erase Suspend. During Chip Erase

a read operation will cause DQ2 to toggle as all

blocks arebeing erased. DQ2 willbe set to’1’during program operation and when erase is complete. After erase completion and if the error bit

DQ5 is set to ’1’,DQ2 will toggleif the faulty block

is addressed.

Error Bit (DQ5). This bit is set to ’1’ by the P/E.C.

when there is a failure of programming, block

erase, or chip erase that results in invalid data in

the memory block. In case of an error in block

erase or program, the block in which the error occurred or to which the programmed data belongs,

must be discarded. The DQ5 failure condition will

also appear if a user tries to program a ’1’ to a location that is previously programmed to ’0’. Other

Blocks may still beused. The errorbit resets after

a Read/Reset(RD) instruction. In caseof success

of Program or Erase, the error bit will be set to ’0’.

Erase Timer Bit(DQ3). This bit is set to ’0’by the

P/E.C. when the last block Erase command has

been entered to the Command Interface and it is

awaiting the Erase start. When the erase timeout

period is finished, after 50µsto90µs, DQ3 returns

to ’1’.

Coded Cycles

The two Coded cycles unlock theCommand Interface. Theyare followedby an input command or a

confirmation command. The Coded cycles consist

of writing the data AAh at address AAAh in the

Byte-wide configuration and at address 555h in

the Word-wide configuration during the first cycle.

13/33

M29W800AT, M29W800AB

Figure 5. AC Testing Input Output Waveform

AI01417

3V

0V

1.5V

Figure 6. AC Testing Load Circuit

AI01968

0.8V

OUT

CL= 30pF or 100pF

CLincludes JIG capacitance

3.3kΩ

1N914

DEVICE

UNDER

TEST

Table 13. Capacitance

(1)

(TA=25°C, f = 1 MHz)

Note: Sampled only, not 100% tested.

Table 14. DC Characteristics

(TA= 0 to 70°C, –20 to 85°C or –40 to 85°C; VCC= 2.7V to 3.6V)

Note: 1. Sampled only, not 100% tested.

Symbol Parameter Test Condition Min Max Unit

C

IN

Input Capacitance

V

IN

=0V

6pF

C

OUT

Output Capacitance

V

OUT

=0V

12 pF

Symbol Parameter Test Condition Min

Typ.

Max Unit

I

LI

Input Leakage Current

0V ≤ V

IN

≤ V

CC

±1

µA

I

LO

Output Leakage Current

0V ≤ V

OUT

≤ V

CC

±1 µA

I

CC1

Supply Current (Read by Word)

E=V

IL

,G=VIH,f=6MHz

310mA

I

CC2

Supply Current (Read by Word)

E=V

IL

,G=VIL, f = 6MHz

4.5 10 mA

I

CC3

Supply Current (Stan-by) E = VCC±0.2V 30 100 µA

I

CC4

(1)

Supply Current

(Program or Erase)

Byte program, Block or

Chip Erase in progress

20 mA

V

IL

Input Low Voltage –0.5 0.8 V

V

IH

Input High Voltage

0.7 V

CC

VCC+ 0.3

V

V

OL

Output Low Voltage

I

OL

= 1.8mA

0.45 V

V

OH

Output High Voltage CMOS

I

OH

= –100µAVCC–0.4V

V

V

ID

A9 Voltage(Electronic Signature) 11.5 12.5 V

I

ID

A9 Current (Electronic Signature)

A9 = V

ID

30 100 µA

V

LKO

(1)

Supply Voltage (Erase and

Program lock-out)

2.0 2.3 V

Table 12. AC Measurement Conditions

Input Rise and Fall Times ≤10ns

Input Pulse Voltages 0 to 3V

Input and Output Timing Ref. Voltages 1.5V

M29W800AT, M29W800AB

14/33

Table 15. Read AC Characteristics

(TA= 0 to 70°C, –20 to 85°C or –40 to 85°C)

Note: 1. Sampled only, not 100% tested.

2. G may be delayed byup to t

ELQV-tGLQV

after the falling edge of E without increasing t

ELQV

.

3. To be considered only if the Reset pulse is given while thememory is inErase or Program mode.

Symbol Alt Parameter

Test

Condition

M29W800AT / M29W800AB

Unit

80 90

V

CC

= 3.0V to 3.6V

CL = 30pF

VCC= 3.0V to 3.6V

CL = 30pF

Min Max Min Max

t

AVAV

t

RC

Address Validto Next

Address Valid

E=V

IL,

G=V

IL

80 90 ns

t

AVQV

t

ACC

Address Validto Output

Valid

E=V

IL,

G=V

IL

80 90 ns

t

AXQX

t

OH

Address Transition to

Output Transition

E=V

IL,

G=V

IL

00

ns

t

BHQV

t

FHQV

BYTE Switching High to

Output Valid

50 50 ns

t

BLQZ

t

FLQZ

BYTE Switching Low to

Output High Z

50 50 ns

t

EHQX

t

OH

Chip Enable High to Output

Transition

G=V

IL

00ns

t

EHQZ

(1)

t

HZ

Chip Enable High to Output

Hi-Z

G=V

IL

30 30 ns

t

ELBH

t

ELBL

t

ELFH

t

ELFL

Chip Enable to BYTE

Switching Low or High

55ns

t

ELQV

(2)

t

CE

Chip Enable Low to Output

Valid

G=V

IL

80 90 ns

t

ELQX

(1)

t

LZ

Chip Enable Low to Output

Transition

G=V

IL

00ns

t

GHQX

t

OH

Output Enable High to

Output Transition

E=V

IL

00ns

t

GHQZ

(1)

t

DF

Output Enable High to

Output Hi-Z

E=V

IL

30 30 ns

t

GLQV

(2)

t

OE

Output Enable Lowto

Output Valid

E=V

IL

35 35 ns

t

GLQX

(1)

t

OLZ

Output Enable Lowto

Output Transition

E=V

IL

00ns

t

PHEL

t

RH

RP High to Chip Enable

Low

50 50 ns

t

PLYH

(1, 3)

t

RRB

t

READY

RP Low to Read Mode 10 10 µs

t

PLPX

t

RP

RP Pulse Width 500 500 ns

15/33

M29W800AT, M29W800AB

Table 16. Read AC Characteristics

(TA= 0 to 70°C, –20 to 85°C or –40 to 85°C)

Note: 1. Sampled only, not 100% tested.

2. G may be delayed byup to t

ELQV-tGLQV

after the falling edge of E without increasing t

ELQV

.

3. To be considered only if the Reset pulse is given while thememory is inErase or Program mode.

Symbol Alt Parameter

Test

Condition

M29W800AT / M29W800AB

Unit

100 120

V

CC

= 2.7V to 3.6V

CL = 30pF

VCC= 2.7V to 3.6V

CL = 30pF

Min Max Min Max

t

AVAV

t

RC

Address Validto Next

Address Valid

E=V

IL,

G=V

IL

100 120 ns

t

AVQV

t

ACC

Address Validto Output

Valid

E=V

IL,

G=V

IL

100 120 ns

t

AXQX

t

OH

Address Transition to

Output Transition

E=V

IL,

G=V

IL

00

ns

t

BHQV

t

FHQV

BYTE Switching High to

Output Valid

50 60 ns

t

BLQZ

t

FLQZ

BYTE Switching Low to

Output High Z

50 60 ns

t

EHQX

t

OH

Chip Enable High to Output

Transition

G=V

IL

00ns

t

EHQZ

(1)

t

HZ

Chip Enable High to Output

Hi-Z

G=V

IL

30 30 ns

t

ELBH

t

ELBL

t

ELFH

t

ELFL

Chip Enable to BYTE

Switching Low or High

55ns

t

ELQV

(2)

t

CE

Chip Enable Low to Output

Valid

G=V

IL

100 120 ns

t

ELQX

(1)

t

LZ

Chip Enable Low to Output

Transition

G=V

IL

00ns

t

GHQX

t

OH

Output Enable High to

Output Transition

E=V

IL

00ns

t

GHQZ

(1)

t

DF

Output Enable High to

Output Hi-Z

E=V

IL

30 30 ns

t

GLQV

(2)

t

OE

Output Enable Lowto

Output Valid

E=V

IL

40 50 ns

t

GLQX

(1)

t

OLZ

Output Enable Lowto

Output Transition

E=V

IL

00ns

t

PHEL

t

RH

RP High to Chip Enable

Low

50 50 ns

t

PLYH

(1, 3)

t

RRB

t

READY

RP Low to Read Mode 10 10 µs

t

PLPX

t

RP

RP Pulse Width 500 500 ns

M29W800AT, M29W800AB

16/33

Figure 7. Read Mode AC Waveforms

AI02182

tAVAV

tAVQV tAXQX

tELQX tEHQX

tGLQV

tGLQX

tGHQX

VALID

A0-A18/

A–1

E

G

DQ0-DQ7/

DQ8-DQ15

tELQV

VALID

ADDRESS VALID

AND CHIP ENABLE

OUTPUT ENABLE DATA VALID

BYTE

tBLQZtELBL/tELBH

tEHQZ

tGHQZ

tBHQV

Note: Write Enable (W) = High.

17/33

M29W800AT, M29W800AB

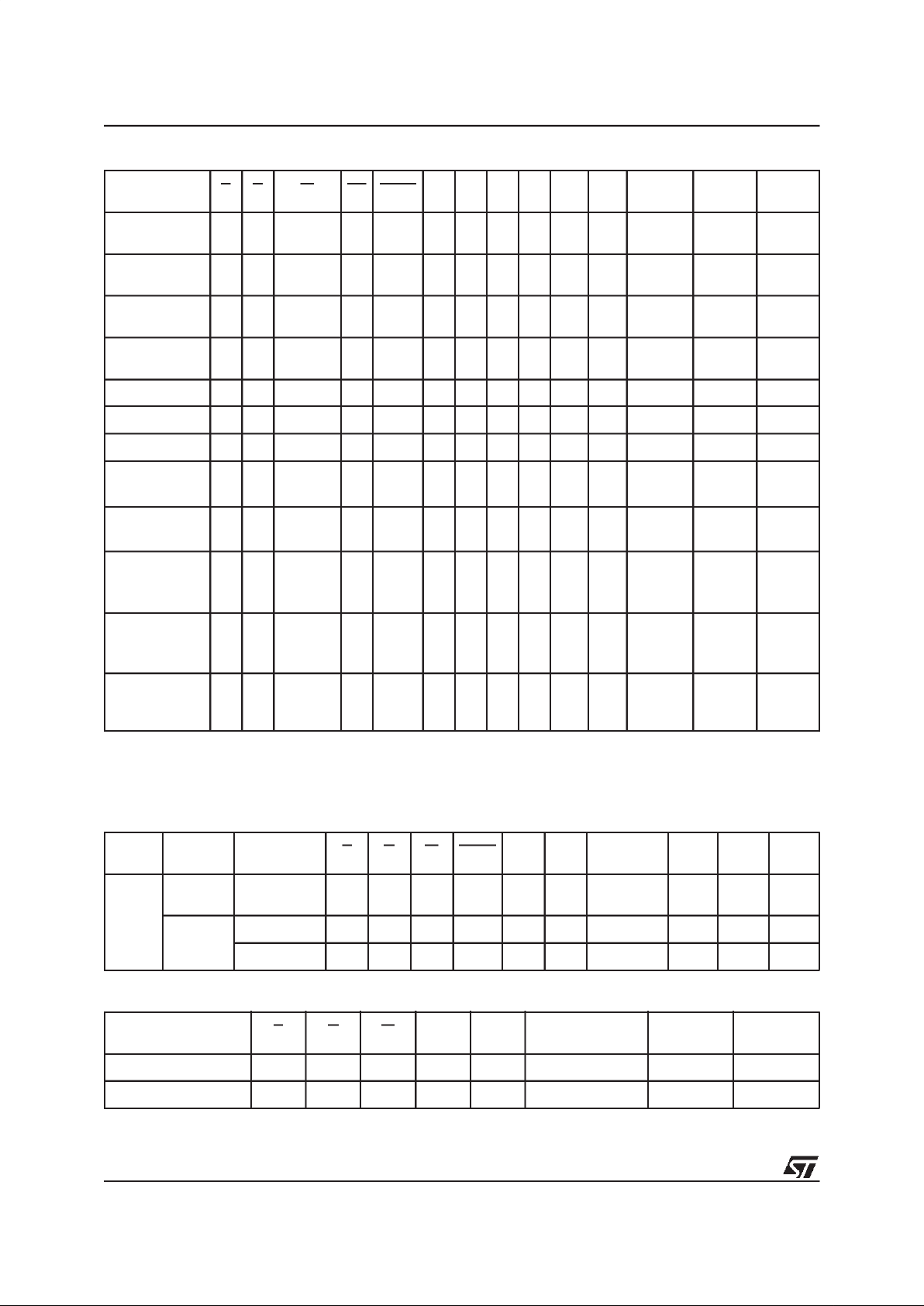

Table 17. Write AC Characteristics, W Controlled

(TA= 0 to 70°C, –20 to 85°C or –40 to 85°C)

Note: 1. Sampled only, not 100% tested.

2. This timing is for Temporary Block Unprotection operation.

Symbol Alt Parameter

M29W800AT / M29W800AB

Unit

80 90

V

CC

= 3.0V to 3.6V

CL = 30pF

VCC= 3.0V to 3.6V

CL = 30pF

Min Max Min Max

t

AVAV

t

WC

Address Valid to Next Address Valid 80 90 ns

t

AVWL

t

AS

Address Valid to Write Enable Low 0 0 ns

t

DVWH

t

DS

Input Valid to Write Enable High 35 45 ns

t

ELWL

t

CS

Chip Enable Low to Write Enable Low 0 0 ns

t

GHWL

Output Enable High to Write Enable Low 0 0 ns

t

PHPHH

(1, 2)

t

VIDR

RP Rise Time to V

ID

500 500 ns

t

PHWL

(1)

t

RSP

RP High to Write Enable Low 4 4 µs

t

PLPX

t

RP

RP Pulse Width 500 500 ns

t

VCHEL

t

VCSVCC

High to Chip Enable Low

50 50 µs

t

WHDX

t

DH

Write Enable High to Input Transition 0 0 ns

t

WHEH

t

CH

Write Enable High to Chip Enable High 0 0 ns

t

WHGL

t

OEH

Write Enable High to Output Enable Low 0 0 ns

t

WHRL

(1)

t

BUSY

Program Erase Valid to RB Delay 90 90 ns

t

WHWL

t

WPH

Write Enable High to Write Enable Low 30 30 ns

t

WLAX

t

AH

Write Enable Low to Address Transition 45 45 ns

t

WLWH

t

WP

Write Enable Low to Write Enable High 35 35 ns

Block Erase (BE) Instruction. This instruction

uses a minimum of six write cycles. The Erase

Set-up command 80h is written to address AAAh

in the Byte-wide configuration or address 555h in

the Word-wide configuration on third cycle after

the two Coded cycles. The Block Erase Confirm

command 30h issimilarly written onthesixth cycle

after anothertwo Coded cycles.During theinput of

the second command an address within the block

to beerased is givenandlatched into the memory.

Additional block Erase Confirm commands and

block addresses can be written subsequently to

erase other blocks in parallel,without further Coded cycles. The erase will start after the erase timeout period (seeErase TimerBit DQ3description).

Thus, additional Erase Confirmcommandsforother blocks must begiven withinthisdelay.The input

of a new Erase Confirm command will restart the

timeout period. The status of the internal timer can

be monitored through thelevel of DQ3,if DQ3is ’0’

the Block Erase Command has been given and

the timeout is running, if DQ3 is ’1’, thetimeout has

expired and the P/E.C. is erasing the Block(s). If

the second command given is not an erase confirm or if the Coded cycles are wrong, the instruction aborts, and the device isreset to Read Array.

It is not necessary to program the block with 00h

as the P/E.C. will do this automatically before to

erasing to FFh. Read operations after thesixth rising edge ofW or E outputthe status registerstatus

bits.

M29W800AT, M29W800AB

18/33

Table 18. Write AC Characteristics, W Controlled

(TA= 0 to 70°C, –20 to 85°C or –40 to 85°C)

Note: 1. Sampled only, not 100% tested.

2. This timing is for Temporary Block Unprotection operation.

Symbol Alt Parameter

M29W800AT / M29W800AB

Unit

100 120

V

CC

= 2.7V to 3.6V

CL = 30pF

VCC= 2.7V to 3.6V

CL = 30pF

Min Max Min Max

t

AVAV

t

WC

Address Valid to Next Address Valid 100 120 ns

t

AVWL

t

AS

Address Valid to Write Enable Low 0 0 ns

t

DVWH

t

DS

Input Valid to Write Enable High 45 50 ns

t

ELWL

t

CS

Chip Enable Low to Write Enable Low 0 0 ns

t

GHWL

Output Enable High to Write Enable Low 0 0 ns

t

PHPHH

(1, 2)

t

VIDR

RP Rise Time to V

ID

500 500 ns

t

PHWL

(1)

t

RSP

RP High to Write Enable Low 4 4 µs

t

PLPX

t

RP

RP Pulse Width 500 500 ns

t

VCHEL

t

VCSVCC

High to Chip Enable Low

50 50 µs

t

WHDX

t

DH

Write Enable High to Input Transition 0 0 ns

t

WHEH

t

CH

Write Enable High to Chip Enable High 0 0 ns

t

WHGL

t

OEH

Write Enable High to Output Enable Low 0 0 ns

t

WHRL

(1)

t

BUSY

Program Erase Valid to RB Delay 90 90 ns

t

WHWL

t

WPH

Write Enable High to Write Enable Low 30 30 ns

t

WLAX

t

AH

Write Enable Low to Address Transition 45 50 ns

t

WLWH

t

WP

Write Enable Low to Write Enable High 35 50 ns

During the execution of the erase by the P/E.C.,

the memory accepts only the Erase Suspend ES

and Read/Reset RD instructions. Data Polling bit

DQ7 returns ’0’ while the erasure is in progress

and ’1’ whenit has completed. The Toggle bit DQ2

and DQ6 toggle during the erase operation. They

stop when erase is completed. After completion

the Status Register bit DQ5 returns ’1’ if there has

been anerasefailure. In such asituation, theToggle bit DQ2 can be used to determine whichblock

is notcorrectlyerased. Inthe case of erase failure,

a Read/ResetRD instructionis necessary in order

to reset the P/E.C.

Chip Erase (CE) Instruction. This instruction

uses sixwrite cycles. The Erase Set-up command

80h is written to address AAAh in the Byte-wide

configuration or the address 555h in the Word-

wide configuration on the third cycle after the two

Coded cycles. The Chip Erase Confirmcommand

10h is similarly written on the sixth cycle after another two Coded cycles. If the second command

given is not an erase confirm or if the Coded cycles are wrong, the instruction aborts and the device is reset to Read Array. It is not necessary to

program the array with 00h first as the P/E.C. will

automatically do this before erasing it to FFh.

Read operations afterthe sixthrising edge of W or

E output the Status Register bits. During the execution of the erase by the P/E.C., Data Polling bit

DQ7 returns ’0’,then ’1’oncompletion. TheToggle

bits DQ2 and DQ6 toggle during erase operation

and stop when erase is completed. After completion the Status Register bit DQ5 returns ’1’if there

has been an Erase Failure.

19/33

M29W800AT, M29W800AB

Figure 8. Write AC Waveforms, W Controlled

Note: Address are latched on the falling edge of W, Data is latched onthe rising edge of W.

AI02183

E

G

W

A0-A18/

A–1

DQ0-DQ7/

DQ8-DQ15

VALID

VALID

V

CC

tVCHEL

tWHEH

tWHWL

tELWL

tAVWL

tWHGL

tWLAX

tWHDX

tAVAV

tDVWH

tWLWHtGHWL

RB

tWHRL

Erase Suspend (ES)Instruction. The Block

Erase operation may be suspended by this instruction which consists of writing the command

B0h without any specific address. No Coded cycles are required. It permits reading of data from

another block and programming in another block

while anerase operationisin progress.Erase suspend is accepted only during the Block Erase instruction execution. Writing this command during

Erase timeout will, in addition to suspending the

erase, terminate the timeout. The Toggle bit DQ6

stops toggling when the P/E.C. is suspended. The

Toggle bits will stop toggling between 0.1µs and

15µs after the Erase Suspend (ES) command has

been written.The device will then automatically be

set to Read Memory Array mode. When erase is

suspended, a Read from blocks being erased will

output DQ2 toggling and DQ6 at ’1’.A Read from

a block notbeing erased returnsvalid data. During

suspension the memory will respond only to the

Erase Resume ER and the Program PG instructions. A Program operation can be initiated during

erase suspend in one of the blocks not being

erased. Itwill result inboth DQ2 and DQ6 toggling

when the data is being programmed. A Read/Reset command willdefinitively abort erasureand result in invalid data in the blocks being erased.

Erase Resume (ER) Instruction. If an Erase

Suspend instruction was previously executed, the

erase operation may be resumed by giving the

command 30h, at any address, and without any

Coded cycles.

M29W800AT, M29W800AB

20/33

Table 19. Write AC Characteristics, E Controlled

(TA= 0 to 70°C, –20 to 85°C or –40 to 85°C)

Note: 1. Sampled only, not 100% tested.

2. This timing is for Temporary Block Unprotection operation.

Symbol Alt Parameter

M29W800AT / M29W800AB

Unit

80 90

V

CC

= 3.0V to 3.6V

CL = 30pF

VCC= 3.0V to 3.6V

CL = 30pF

Min Max Min Max

t

AVAV

t

WC

Address Valid to Next Address Valid 80 90 ns

t

AVEL

t

AS

Address Valid to Chip Enable Low 0 0 ns

t

DVEH

t

DS

Input Valid to Chip Enable High 35 45 ns

t

EHDX

t

DH

Chip Enable High to Input Transition 0 0 ns

t

EHEL

t

CPH

Chip Enable High to Chip Enable Low 30 30 ns

t

EHGL

t

OEH

Chip Enable High to Output Enable Low 0 0 ns

t

EHRL

(1)

t

BUSY

Program Erase Valid to RB Delay 80 90 ns

t

EHWH

t

WH

Chip Enable High to Write Enable High 0 0 ns

t

ELAX

t

AH

Chip Enable Low to Address Transition 45 45 ns

t

ELEH

t

CP

Chip Enable Low to Chip Enable High 35 35 ns

t

GHEL

Output Enable High Chip Enable Low 0 0 ns

t

PHPHH

(1, 2)

t

VIDR

RP Rise TIme to V

ID

500 500 ns

t

PHWL

(1)

t

RSP

RP High to Write Enable Low 4 4 µs

t

PLPX

t

RP

RP Pulse Width 500 500 ns

t

VCHWL

t

VCSVCC

High to Write Enable Low

50 50 µs

t

WLEL

t

WS

Write Enable Low to Chip Enable Low 0 0 ns

POWER SUPPLY

Power Up

The memory Command Interface is reset on power up to Read Array. The device does not accept

commands on the first rising edge of W, if both W

and E are at VILwith G at VIHduring power-up.

Any write cycle initiation is blocked when VCCis

below V

LKO

.

Supply Rails

Normal precautions must be taken for supply voltage decoupling; each device in a system should

have the VCCrail decoupled with a 0.1µFcapacitor

close to the VCCand VSSpins. The PCB trace

widths should be sufficient to carry the VCCprogram and erase currents required.

21/33

M29W800AT, M29W800AB

Table 20. Write AC Characteristics, E Controlled

(TA= 0 to 70°C, –20 to 85°C or –40 to 85°C)

Note: 1. Sampled only, not 100% tested.

2. This timing is for Temporary Block Unprotection operation.

Symbol Alt Parameter

M29W800AT / M29W800AB

Unit

100 120

V

CC

= 2.7V to 3.6V

CL = 30pF

VCC= 2.7V to 3.6V

CL = 30pF

Min Max Min Max

t

AVAV

t

WC

Address Valid to Next Address Valid 100 120 ns

t

AVEL

t

AS

Address Valid to Chip Enable Low 0 0 ns

t

DVEH

t

DS

Input Valid to Chip Enable High 45 50 ns

t

EHDX

t

DH

Chip Enable High to Input Transition 0 0 ns

t

EHEL

t

CPH

Chip Enable High to Chip Enable Low 30 30 ns

t

EHGL

t

OEH

Chip Enable High to Output Enable Low 0 0 ns

t

EHRL

(1)

t

BUSY

Program Erase Valid to RB Delay 90 90 ns

t

EHWH

t

WH

Chip Enable High to Write Enable High 0 0 ns

t

ELAX

t

AH

Chip Enable Low to Address Transition 45 50 ns

t

ELEH

t

CP

Chip Enable Low to Chip Enable High 35 50 ns

t

GHEL

Output Enable High Chip Enable Low 0 0 ns

t

PHPHH

(1,2)

t

VIDR

RP Rise TIme to V

ID

500 500 ns

t

PHWL

(1)

t

RSP

RP High to Write Enable Low 4 4 µs

t

PLPX

t

RP

RP Pulse Width 500 500 ns

t

VCHWL

t

VCSVCC

High to Write Enable Low

50 50 µs

t

WLEL

t

WS

Write Enable Low to Chip Enable Low 0 0 ns

M29W800AT, M29W800AB

22/33

Figure 9. Write AC Waveforms, E Controlled

Note: Address are latched on the falling edge of E, Data is latched on the rising edge of E.

Figure 10. Read and Write AC Characteristics, RP Related

AI02184

E

G

W

A0-A18/

A–1

DQ0-DQ7/

DQ8-DQ15

VALID

VALID

V

CC

tVCHWL

tEHWH

tEHEL

tWLEL

tAVEL

tEHGL

tELAX

tEHDX

tAVAV

tDVEH

tELEHtGHEL

RB

tEHRL

AI02091

RB

W

RP

tPLPX

tPHWL

tPLYH

tPHPHH

E

tPHEL

23/33

M29W800AT, M29W800AB

Table 21. Data Polling and Toggle Bit AC Characteristics

(1)

(TA= 0 to 70°C, –20 to 85°C or –40 to 85°C)

Note: 1. All other timings are defined in Read ACCharacteristics table.

Table 22. Data Polling and Toggle Bit AC Characteristics

(1)

(TA= 0 to 70°C, –20 to 85°C or –40 to 85°C)

Note: 1. All other timings are defined in Read ACCharacteristics table.

Symbol Parameter

M29W800AT / M29W800AB

Unit

80 90

V

CC

= 3.0V to 3.6V

CL = 30pF

VCC= 3.0V to 3.6V

CL = 30pF

Min Max Min Max

t

EHQ7V

Chip Enable High to DQ7 Valid

(Program, E Controlled)

10 2400 10 2400 µs

Chip Enable High to DQ7 Valid

(Chip Erase, EControlled)

1.0 60 1.0 60 sec

t

EHQV

Chip Enable High to Output Valid(Program) 10 2400 10 2400 µs

Chip Enable High to Output Valid(Chip Erase) 1.0 60 1.0 60 sec

t

Q7VQV

Q7 Valid to Output Valid (Data Polling) 35 35 ns

t

WHQ7V

Write Enable High to DQ7 Valid

(Program, W Controlled)

10 2400 10 2400 ms

Write Enable High to DQ7 Valid

(Chip Erase, W Controlled)

1.0 60 1.0 60 sec

t

WHQV

Write Enable High to Output Valid (Program) 10 2400 10 2400 µs

Write Enable High to Output Valid (Chip Erase) 1.0 60 1.0 60 sec

Symbol Parameter

M29W800AT / M29W800AB

Unit

100 120

V

CC

= 2.7V to 3.6V

CL = 30pF

VCC= 2.7V to 3.6V

CL = 30pF

Min Max Min Max

t

EHQ7V

Chip Enable High to DQ7 Valid

(Program, E Controlled)

10 2400 10 2400 µs

Chip Enable High to DQ7 Valid

(Chip Erase, EControlled)

1.0 60 1.0 60 sec

t

EHQV

Chip Enable High to Output Valid(Program) 10 2400 10 2400 µs

Chip Enable High to Output Valid(Chip Erase) 1.0 60 1.0 60 sec

t

Q7VQV

Q7 Valid to Output Valid (Data Polling) 40 50 ns

t

WHQ7V

Write Enable High to DQ7 Valid

(Program, W Controlled)

10 2400 10 2400 ms

Write Enable High to DQ7 Valid

(Chip Erase, W Controlled)

1.0 60 1.0 60 sec

t

WHQV

Write Enable High to Output Valid (Program) 10 2400 10 2400 µs

Write Enable High to Output Valid (Chip Erase) 1.0 60 1.0 60 sec

M29W800AT, M29W800AB

24/33

Figure 11. Data Polling DQ7 AC Waveforms

AI02185

E

G

W

A0-A18/

A–1

DQ7

IGNORE

VALID

DQ0-DQ6/

DQ8-DQ15

ADDRESS (WITHIN BLOCKS)

DATA OUTPUT VALID

tAVQV

tEHQ7V

tGLQV

tWHQ7V

VALID

tQ7VQV

DQ7

DATA POLLING (LAST) CYCLE

MEMORY

ARRAY

READ CYCLE

DATA

POLLING

READ CYCLES

LAST WRITE

CYCLE OF

PROGRAM

OR ERASE

INSTRUCTION

tELQV

25/33

M29W800AT, M29W800AB

Table 23. Program, Erase Times and Program, Erase Endurance Cycles

(TA= 0 to 70°C; VCC= 2.7V to 3.6V)

Note: 1. Excluded the time required to execute bus cycles sequence for program operation.

Parameter

M29W800AT / M29W800AB

Unit

Min Typ

Typical after

(1)

100k W/E Cycles

Max

Chip Erase (Preprogrammed, V

CC

= 2.7V)

10 10 sec

Chip Erase (V

CC

= 2.7V) 15 15 sec

Main Block Erase (V

CC

= 2.7V)

1.5 15 sec

Chip Program (Byte)

(1)

10 10 sec

Chip Program (Word)

(1)

5 5 sec

Byte/Word Program 10 10 µs

Program/Erase Cycles (per Block) 100,000 cycles

Figure 12. Data Polling Flowchart

READ DQ5 &

DQ7

at VALID ADDRESS

START

READ DQ7

FAIL PASS

AI01369

DQ7

=

DATA

YES

NO

YES

NO

DQ5

=1

DQ7

=

DATA

YES

NO

Figure 13. Data Toggle Flowchart

READ

DQ2, DQ5 &DQ6

START

READ DQ2, DQ6

FAIL PASS

AI01873

DQ2,

DQ6

=

TOGGLE

NO

NO

YES

YES

DQ5

=1

NO

YES

DQ2,

DQ6

=

TOGGLE

M29W800AT, M29W800AB

26/33

Figure 14. Data Toggle DQ6, DQ2 AC Waveforms

AI02186

E

G

W

A0-A18/

A–1

DQ6,DQ2

tAVQV

STOP TOGGLE

LAST WRITE

CYCLE OF

PROGRAM

OF ERASE

INSTRUCTION

VALID

VALID

VALIDIGNORE

DATA

TOGGLE

READ CYCLE

MEMORY ARRAY

READ CYCLE

tWHQV

tEHQV

tELQV

tGLQV

DATA

TOGGLE

READ CYCLE

DQ0-DQ1,DQ3-DQ5,DQ7/

DQ8-DQ15

Note: All other timings are as a normal Read cycle.

27/33

M29W800AT, M29W800AB

Table 24. Security Block Instruction

Note: 1. Address bits A10-A19 are don’t care for coded address inputs.

2. Data bits DQ8-DQ15 are don’t care for coded address inputs.

Mne. Instr. Cyc.

Unlock Cycle

2nd Cyc.

1st Cyc.

RDS

Read

Security

Data

1

Addr.

(1)

AAh

Read OTPData until a new write cycle is initiated.

Data

(2)

B8h

Figure 15. Security Block Address Table

Security

Memory Block

AI02746

TOP BOOT BLOCK

000FFh

Security

Memory Block

00000h

0E0FFh

0E000h

BOTTOM BOOT BLOCK

Security

Memory Block

TOP BOOT BLOCK

0007Fh

Security

Memory Block

00000h

0E01Fh

0E000h

BOTTOM BOOT BLOCK

BYTE Organisation (x8)

WORD Organisation (x16)

SECURITY PROTECTION MEMORY AREA

The M29W800A features a security protection

memory area.It consists of amemory block of 256

bytes or128 wordswhichis programmed in the ST

factory tostore a unique code thatuniquely identifies the part.

This memoryblock can beread by using the Read

Security Datainstruction (RDS)as shown in Table

24.

ReadSecurity Data (RDS)Instruction. This RDS

uses asingle write cycle instruction: the command

B8h is written to the address AAh. This sets the

memory to the Read Security mode. Any successive read attempt will output the addressed Security byte until a new write cycle is initiated.

M29W800AT, M29W800AB

28/33

Table 25. OrderingInformation Scheme

Devices are shipped from the factory with the memory content bits erased to ’1’.

For a list of available options (Speed, Package, etc...) or for further information on any aspect of this device, please contactthe ST Sales Office nearest to you.

Example: M29W800AT 80 N 1 T

Device Type

M29

Operating Voltage

W = 2.7 to 3.6V

Device Function

800A = 8 Mbit (1Mb x8 or 512Kb x16), Boot Block

Array Matrix

T = Top Boot

B = Bottom Boot

Speed

80 = 80 ns

90 = 90 ns

100 = 100 ns

120 = 120 ns

Package

N = TSOP48: 12 x 20 mm

M = SO44

ZA = LFBGA48: 0.8 mm pitch

Temperature Range

1=0to70°C

5=–20to85°C

6=–40to85°C

Option

T = Tape& Reel Packing

29/33

M29W800AT, M29W800AB

Table 26. Revision History

Date Description

November 1998 First issue

February 1999 Removed TSOP48 Package Reverse Pinout

March 1999 Program, Erase Times and Erase Endurance Cycles change

02/09/00

New document template

Document type: from Preliminary Data to Data Sheet

Program, Erase Times and Endurance Cycles change (Table23)

LFBGA Package Mechanical Data change (Table 29)

LFBGA Package Outline drawing change (Figure 18)

03/06/00 Program Erase Times change (Table 23)

M29W800AT, M29W800AB

30/33

Table 27. TSOP48 - 48 lead Plastic Thin Small Outline, 12 x 20mm, Package Mechanical Data

Symbol

mm inches

Typ Min Max Typ Min Max

A 1.20 0.0472

A1 0.05 0.15 0.0020 0.0059

A2 0.95 1.05 0.0374 0.0413

B 0.17 0.27 0.0067 0.0106

C 0.10 0.21 0.0039 0.0083

D 19.80 20.20 0.7795 0.7953

D1 18.30 18.50 0.7205 0.7283

E 11.90 12.10 0.4685 0.4764

e 0.50 – – 0.0197 – –

L 0.50 0.70 0.0197 0.0276

α 0° 5° 0° 5°

N48 48

CP 0.10 0.0039

Figure 16. TSOP48 - 48 lead Plastic Thin Small Outline, 12 x 20mm, Package Outline

Drawing is notto scale.

TSOP-a

D1

E

1N

CP

B

e

A2

A

N/2

D

DIE

C

LA1 α

31/33

M29W800AT, M29W800AB

Table 28. SO44 - 44 lead Plastic Small Outline, 525 mils body width, Package Mechanical Data

Symbol

mm inches

Typ Min Max Typ Min Max

A 2.42 2.62 0.0953 0.1031

A1 0.22 0.23 0.0087 0.0091

A2 2.25 2.35 0.0886 0.0925

B 0.50 0.0197

C 0.10 0.25 0.0039 0.0098

D 28.10 28.30 1.1063 1.1142

E 13.20 13.40 0.5197 0.5276

e 1.27 – – 0.0500 – –

H 15.90 16.10 0.6260 0.6339

L 0.80 – – 0.0315 – –

α 3° ––3°––

N44 44

CP 0.10 0.0039

Figure 17. SO44 - 44 lead Plastic Small Outline, 525 mils body width, Package Outline

Drawing is notto scale.

SO-b

E

N

CP

B

e

A2

D

C

LA1 α

H

A

1

M29W800AT, M29W800AB

32/33

Figure 18. LFBGA48 - 8 x 6 balls, 0.8 mm pitch,Bottom View Package Outline

Drawing is notto scale.

E1E

D1

D

eb

A2

A1

A

BGA-Z00

ddd

FD

FE

SD

SE

BALL ”A1”

Table 29. LFBGA48 - 8 x 6 balls, 0.8 mm pitch, Package Mechanical Data

Symbol

mm inch

Typ Min Max Typ Min Max

A 1.350 0.0531

A1 0.300 0.200 0.350 0.0118 0.0079 0.0138

A2 0.750 1.000 0.0295 0.0394

b 0.300 0.550 0.0118 0.0217

D 9.000 8.800 9.200 0.3543 0.3465 0.3622

D1 5.600 – – 0.2205 – –

ddd 0.150 0.0059

e 0.800 – – 0.0315 – –

E 6.000 5.800 6.200 0.2362 0.2283 0.2441

E1 4.000 – – 0.1575 – –

FD 1.700 – – 0.0669 – –

FE 1.000 – – 0.0394 – –

SD 0.400 – – 0.0157 – –

SE 0.400 – – 0.0157 – –

33/33

M29W800AT, M29W800AB

Information furnished is believed tobe accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use ofsuch information norfor any infringement of patents or other rights ofthird parties which may result from its use. Nolicense is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces allinformation previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is registered trademark of STMicroelectronics

2000 STMicroelectronics - All Rights Reserved

All other names are the property of their respective owners.

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia -Malta - Morocco-

Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

Loading...

Loading...