3Axis - 2g/6g LINEAR ACCELEROMETER

■ 3V TO 5.25V SINGLE SUPPLY OPERATION

■ THE SENSITIVITY IS ADJUSTED WITH A

TOTAL ACCURACY OF ±10%

■ THE OUTPUT VOLTAGE, OFFSET,

SENSITIVITY AND TEST VOLTAGE ARE

RATIOMETRIC TO THE SUPPLY VOLTAGE

■ DEVICE SENSITI VITY IS ON-CHI P FACTORY

TRIMMED

■ EMBEDDED SELF TEST

■ HIGH SHOCK SURVIVABILITY

DESCRIPTION

The LIS3L02AQ is a three-axis linear accelerometer that includes a sensing eleme nt and an IC interface able to take the information from the

sensing element and to provide an analog signal

to the external world.

The sensing element, capable to detect the acceleration, is manufactured using a dedicated process called THELMA (Thick Epi-Poly Layer for

Microactuators and Accelerometers) developed

by ST to produce inertial sensors and actuators in

silicon.

The IC interface instead is manufactured us ing a

CMOS process that allows high level of integration

to design a dedicated circuit which is trimmed to

better match the sensing element characteristics.

The LIS3L02AQ has a user selectable full scale of

LIS3L02AQ

INERTIAL SENSOR:

PRODUCT PREVIEW

QFN-44

ORDERING NUMB ER: LIS3L 02AQ

2g, 6g and it is capable of measuring accelerations

over a maximum bandwidth of 4.0 K Hz for the X

and Y axis and 2.5KHz for the Z axis. The device

bandwidth may be reduced by using external capacitances. A self-test capability allows the user to

check the functi o n ing of th e syst e m.

The LIS3L02AQ is available in plastic SMD package and it is specified over a temperature range

extending from -40°C to +85°C.

The LIS3L02AQ b elongs to a fam ily of products

suitable for a variety of applications:

– Antitheft systems

– Inertial navigation

– Virtual reality input devices

– Vibration Monitoring, recording and com pen-

sation

– Appliance control

– Robotics

BLOCK DIAGRAM

S1X

S1Y

S1Z

rot

S2Z

S2Y

S2X

VOLTAGE & CURRENT

REFERENCE

February 2003

This is preliminary information on a new product now in development. Details are subject to change without notice.

MUX

TRIMMING CIRCUIT

TEST INTERFACE

AMPLIFIE R

DEMUX

CLOCK

&

PHASE GENERATOR

S/HCHARGE

S/H

S/H

&

Routx

Routy

Routz

Voutx

Vouty

Voutz

1/7

LIS3L02AQ

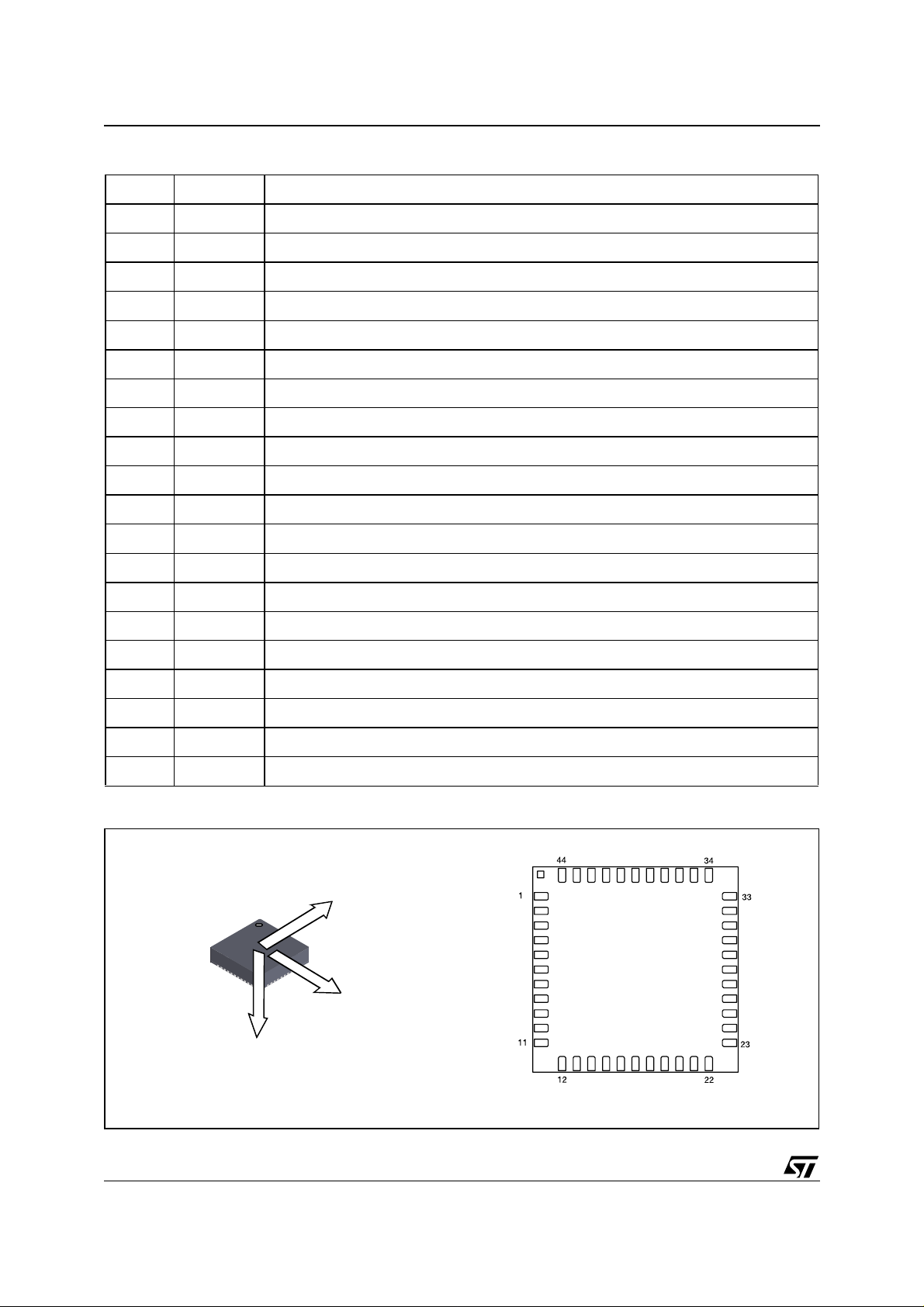

PIN DESCRIPTION

N° Pin Function

1 to 3 NC Internally not connected

4 GND 0V supply

5 Vdd Power supply

6 Vouty Output Voltage

7 ST Self Test (Logic 0: normal mode; Logic 1: Self-test)

8 Voutx Output Voltage

9-13 NC Internally not connected

14 PD Power Down (Logic 0: normal mode; Logic 1: Power-Down mode)

15 Voutz Output Voltage

16 FS Full Scale selection (Logic 0: 2g Full-scale; Logic 1: 6g Full-scale)

17-18 Reserved Leave unconnected

19 NC Internally not connected

20 Reserved Leave unconnected

21 NC Internally not connected

22-23 Reserved Leave unconnected

24-25 NC Internally not connected

26 Reserved Connect to Vdd or GND

27 Reserved Leave unconnected or connect to Vdd

28 Reserved Leave unconnected or connect to GND

29-44 NC Internally not connected

PIN CONNECTION (Top view )

1

Z

Y

X

DIRECTION OF THE

DETECTABLE

ACCELERATIONS

GND

Vdd

Vouty

Voutx

NCNCNCNCNCNCNCNCNCNCNC

NC

NC

NC

LIS3L02AQ

ST

NC

NC

NC

FS

PD

NC

NC

Voutz

Reserved

Reserved

Reserved

ReservedNCReserved

NC

NC

NC

NC

NC

Reserved

Reserved

Reserved

NC

NC

Reserved

2/7

LIS3L02AQ

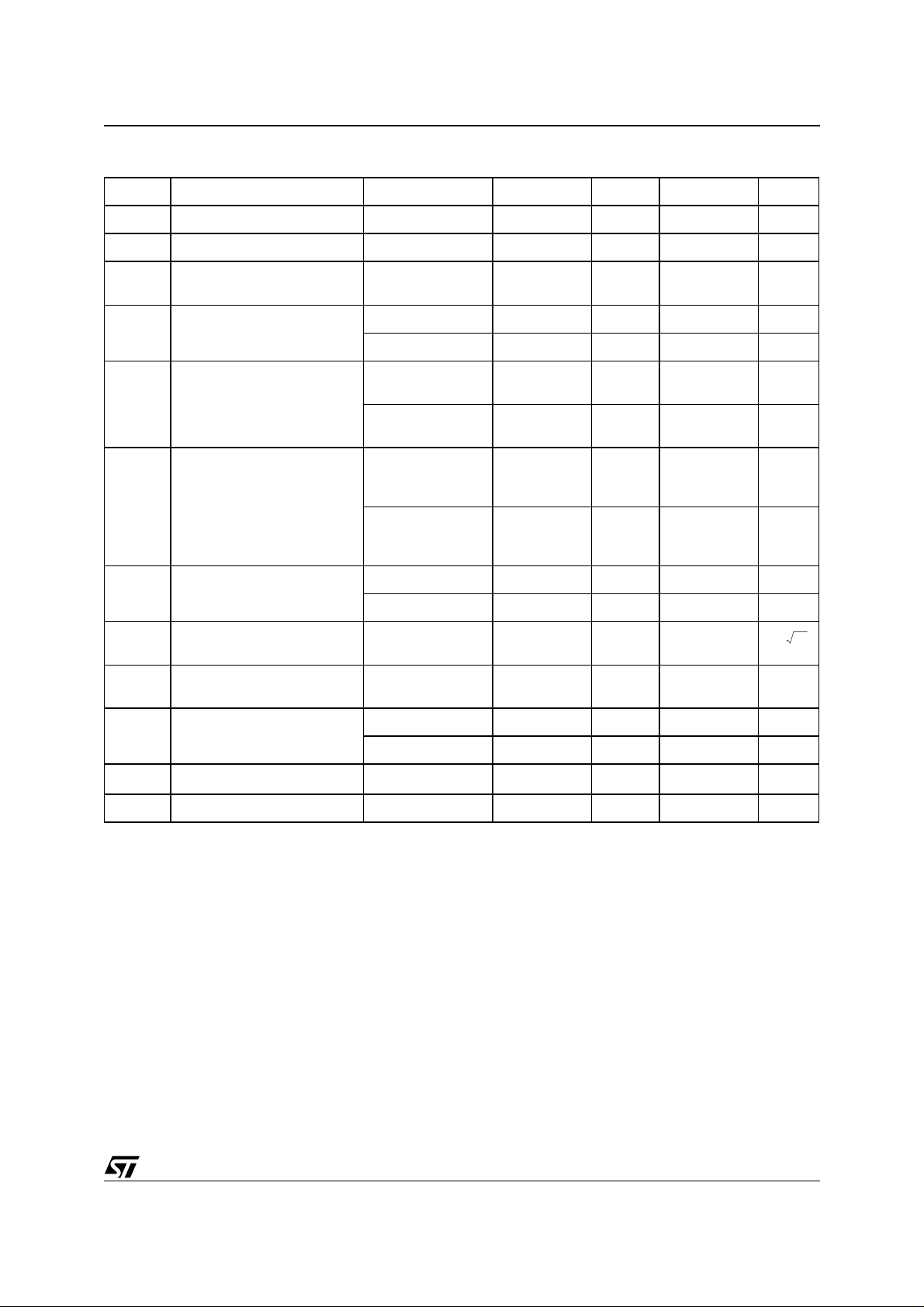

ELECTRICAL CHARACTERISTCSS(Temperature range -40°C to +85°C)

Symbol Parameter Test Condition Min. Typ. Max. Unit

Vdd Supply voltage 3 5.25 V

Idd Supply current 1.0 mA

Voff Zero-g level T = 25°C

ratiometric to Vdd

Ar Acceleration range 0V on FS pin ±1.8 ±2.0 ±2.2 g

Vdd on FS pin ±±6.0 g

So Sensitivity ratiometric to Vdd T = 25°C

NL Non Linearity Best fit straight line

fuc Sensing Element Resonant

Frequency

an Acceleration noise density Vdd=5V

Vt Self test output voltage

Ratiometric to Vdd

Vst Self test input Logic 0 level 0 0.8 V

Full-scale = 2g

T = 25°C

Full-scale = 6g

X, Y axis

Full-scale = 2g

Best fit straight line

Z axis

Full-scale = 2g

X, Y axis 4.0 KHz

Z axis 2.5 KHz

Full-scale = 2g

T = 25°C

@ 5V

Vdd/2-10% Vdd/2 Vdd/2+10% V

Vdd/5–10% Vdd/5 Vdd/5+10% V/g

Vdd/15–10% Vdd/15 Vdd/15+10% V/g

±0.3 %

±0.6 %

100

TBD V

µg/

Hz

Logic 1 level 2.8 Vdd V

Rout Output impedance 100

Cload Capacitive load drive 320 pF

kΩ

1 FUNCTIONALITY

1.1 Sensing element

The THELMA proces s is utilized to c reate a surfac e micro-mach ined accelerom eter. The technolo gy allows to carry out suspended silicon structures which are attached to the substrate in a few points called

anchors and free to move on a plane parallel to the subst rate itself. To b e com pati ble with the tradi tional

packaging techniques a cap is placed on top of t he sensing element to avoi d blockin g the moving p arts

during the molding phase.

The equivalent circuit for the sensing element is shown in t he below figure; when a linear acceleration is

applied, the proof mass di splaces from its nominal po sition, c ausing an imbalance in t he cap acitive hal fbridge. This imbalance is measured using charge integration in response to a voltage pulse applied to the

sense capacitor.

The nominal value of the capacitors, at steady state, is few pF and when an acceleration is applied the

maximum variation of the capacitive load is few tenth of pF.

3/7

Loading...

Loading...