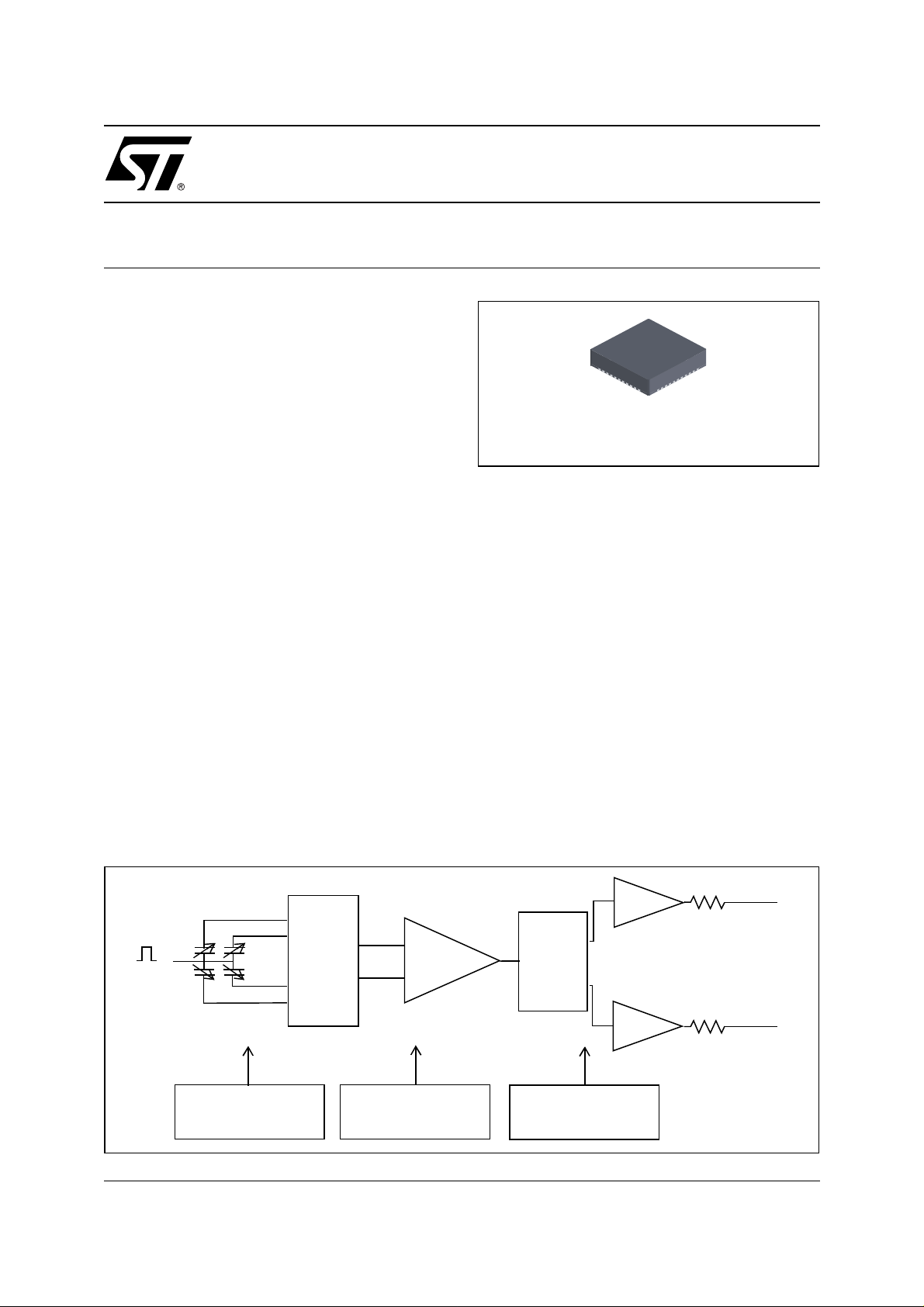

2Axis - 2g/6g LINEAR ACCELEROMETER

■ 3V TO 5.25V SINGLE SUPPLY OPERATION

■ THE SENSITIVITY IS ADJUSTED WITH A

TOTAL ACCURACY OF ±10%

■ THE OUTPUT VOLTAGE, OFFSET,

SENSITIVITY AND TEST VOLTAGE ARE

RATIOMETRIC TO THE SUPPLY VOLTAGE

■ DEVICE SENSITI VITY IS ON-CHI P FACTORY

TRIMMED

■ EMBEDDED SELF TEST

■ HIGH SHOCK SURVIVABILITY

DESCRIPTION

The LIS2L02AQ is a dual-axis linear accelerometer

that includes a sensing element and an IC interface

able to take the information from the sensing el ement

and to provide an analog signal to the exter nal wor ld.

The sensing element, capable to detect the acceleration, is manufactured using a dedicated process

called THELMA (Thick Epi-Poly Layer for Microactuators and Accelerometers) developed by ST to produce inertial sensors and actuators in silicon.

The IC interface instead is manufactured using a

CMOS process that allow s high l evel o f integration to

design a dedicated circuit which is trimmed to better

match the sensing element characteristics.

The LIS2L02AQ has a user selectable full scale of

2g, 6g and it is capable of measuring accelerations

LIS2L02AQ

INERTIAL SENSOR:

PRODUCT PREVIEW

QFN-44

ORDERING NUMBER: LIS2L02AQ

over a maximum bandwidth of 4.0 K Hz for both the X

and Y axis. The device bandwidth m ay be r educed by

using external capacitances. A self-test capability allows the user to check the functioning of the system.

The LIS2L02AQ is available in plastic SMD package

and it is specified over a temperature range extending from -40°C to +85°C.

The LIS2L02AQ belongs to a family of products suitable for a variety of applications:

– Antitheft systems

– Inertial navigation

– Virtual reality input devices

– Vibration Monitoring, recording and com pen-

sation

– Appliance control

– Robotics

BLOCK DIAGRAM

S1X

S1Y

rot

S2Y

S2X

VOLTAGE & CURRENT

REFERENCE

December 2002

This is preliminary information on a new product now in development. Details are subject to change without notice.

MUX

TRIMMING CIRCUIT

TEST INTERFACE

AMPLIFIE R

DEMUX

CLOCK

&

PHASE GENERATOR

S/HCHARGE

S/H

&

Routx

Routy

Voutx

Vouty

1/6

LIS2L02AQ

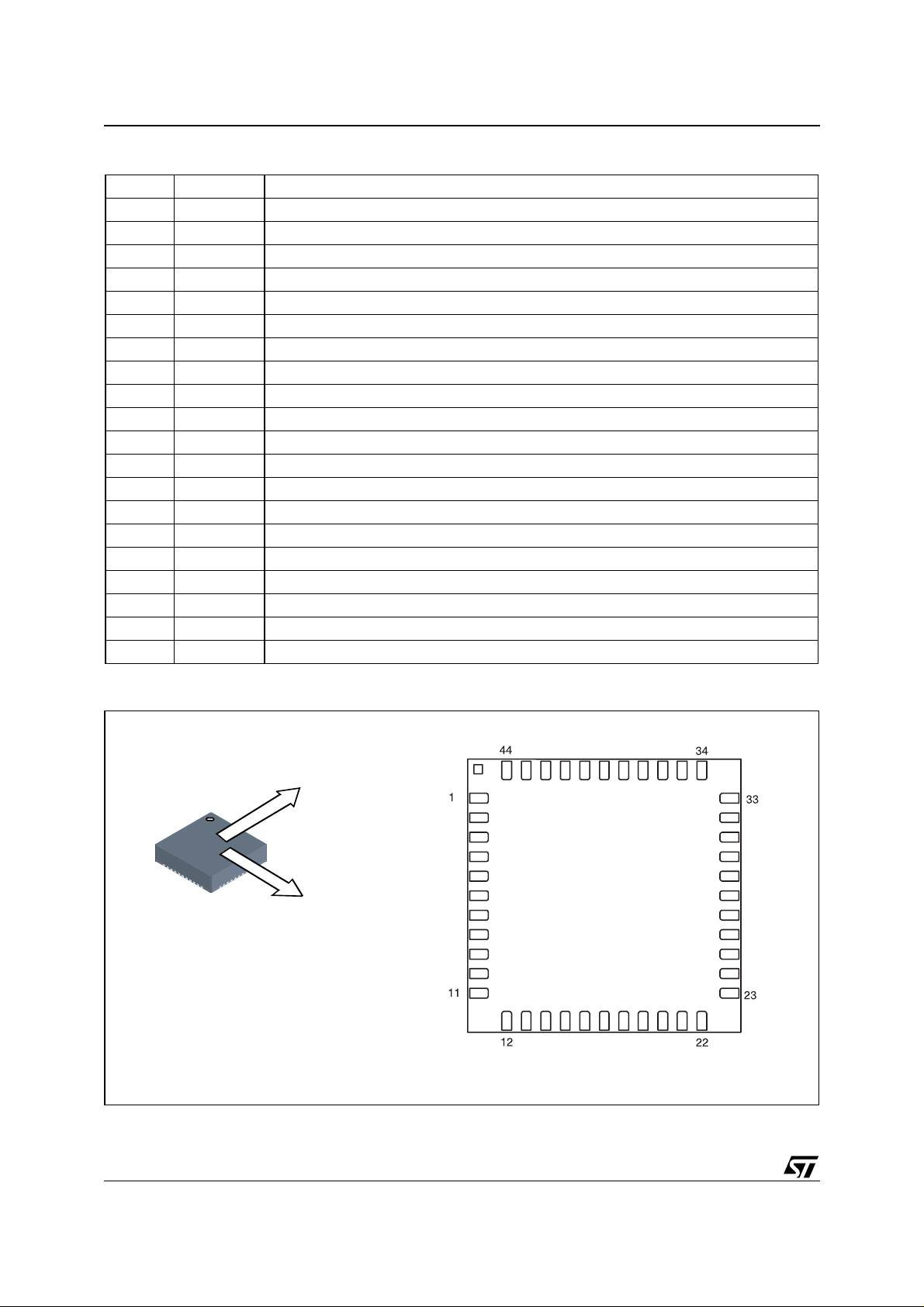

PIN DESCRIPTION

N° Pin Function

1 to 3 NC Internally not connected

4 GND 0V supply

5 Vdd Power supply

6 Vouty Output Voltage

7 ST Self Test (Logic 0: normal mode; Logic 1: Self-test)

8 Voutx Output Voltage

9-13 NC Internally not connected

14 PD Power Down (Logic 0: normal mode; Logic 1: Power-Down mode)

15 NC Internally not connected

16 FS Full Scale selection (Logic 0: 2g Full-scale; Logic 1: 6g Full-scale)

17-18 Reserved Leave unconnected

19 NC Internally not connected

20 Reserved Leave unconnected

21 NC Internally not connected

22-23 Reserved Leave unconnected

24-25 NC Internally not connected

26 Reserved Connect to Vdd or GND

27 Reserved Leave unconnected or connect to Vdd

28 Reserved Leave unconnected or connect to GND

29-44 NC Internally not connected

PIN CONNECTION

(Top view)

1

DIRECTION OF THE

DETECTABLE

ACCELERATIONS

NCNCNCNCNCNCNCNCNCNCNC

Y

NC

NC

NC

GND

X

Vdd

Vouty

ST

Voutx

NC

NC

NC

NC

NCPDNC

LIS2L02AQ

FS

Reserved

Reserved

NC

Reserved

Reserved

Reserved

NC

NC

NC

NC

NC

Reserved

Reserved

Reserved

NC

NC

Reserved

2/6

LIS2L02AQ

ELECTRICAL CHARACTERISTCS

(Temperature range -40°C to +85°C)

Symbol Parameter Test Condition Min. Typ. Max. Unit

V

V

Supply voltage 3 5.25 V

dd

Supply current 1.0 mA

I

dd

Zero-g level T

off

amb

= 25°C

Vdd/2-10% Vdd/2 Vdd/2+10% V

ratiometric to Vdd

A

Acceleration range 0V on FS pin ±1.8 ±2.0 ±2.2 g

r

V

on FS pin ±6.0 g

dd

Sensitivity ratiometric to

S

o

V

dd

T

= 25°C

amb

Full-scale = 2g

= 25°C

T

amb

Vdd/5–10% Vdd/5 Vdd/5+10% V/g

Vdd/15–10% Vdd/15 Vdd/15+10% V/g

Full-scale = 6g

N

Non Linearity Best fit straight line

L

±0.3 %

X, Y axis

Full-scale = 2g

Sensing Element

f

uc

X, Y axis 4.0 KHz

Resonant Frequency

a

Acceleration noise

n

density

V

Self test output voltage

t

Ratiometric to Vdd

Vdd = 5V

Full-scale = 2g

T

= 25°C

amb

@ 5V

50

µg/

100 mV

Hz

V

Self test input Logic 0 level 0 0.8 V

st

Logic 1 level 2.8 V

R

C

Output impedance 100 kΩ

out

Capacitive load drive 320 pF

load

dd

V

1 FUNCTIONALITY

1.1 Sensing element

The THELMA process is utilized to create a surface micro-machined accelerometer. The technology allows to

carry out suspended silicon structures which are attached to the substrate in a few points called anchors and

free to move on a plane parallel to the substrate itself. To be compatible with the traditional packaging techniques a cap is placed on top of the sensing element to avoid blocking the moving parts during the molding

phase.

The equivalent circui t for the sensing element is s hown in the below figure; when a l inear acc eleration is appl ied,

the proof mass displaces from its nominal pos ition, causi ng an imbalance in the capacitiv e half- bridge. This imbalance is measured using charge integration in response to a voltage pulse applied to the sense capacitor.

The nominal value of the capacitors, at steady state, is few pF and when an acceleration is applied the maximum

variation of the capacitive load is few tenth of pF.

3/6

LIS2L02AQ

Figure 1. Equivalent electrical circuit

C

ps1

C

pr

C

ps2

C

ps1

C

pr

C

ps2

R

s1

S1x

C

s1x

R

r

C

s2x

S2x

R

s2

R

s1

S1y

C

s1y

R

r

C

s2y

S2y

R

s2

rot

1.2 IC Interface

The complete signal processing uses a fully differential structure, while the final stage converts the differential

signal into a single-ended one to be compatible with the external world.

The first stage is a low-noise capacitive amplifier that implements a Correlated Double Sampling (CDS) at its

output to cancel the offset and the 1/f noise. The produced signal is then sent to two different S&Hs, one for

each channel, and made available to the outside.

The low noise input amplifier operates at 200 kHz while the two S&Hs operate at a sampling frequency of 66

kHz. This allows a large oversampling ratio, which leads to in-band noise reduction and to an accurate output

wavefor m .

All the analog par ameters (output offs et vol tage and sensitivity) are ratiometr ic to the v oltage supply . Increas ing

or decreasing the voltage supply, the sensitivity and the offset will increase or decrease linearly. The feature

provides the cancellation of the error related to the voltage supply along an analog to digital conversion chain.

1.3 Factory calibration

The IC interface is factory calibrated to provide to the final user a device ready to operate. The parameters which

are trimmed are: gain, offset, common mode and internal clock frequency.

The trimming values are stored inside the device by a poly-fuse structur e. Any time the device is turned on, the

memorized bits are downloaded into the registers to be employed during the normal operation. The poly-fuse

approach allows the final user to utilize the device without any need for further calibration

4/6

LIS2L02AQ

mm inch

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 1.70 1.80 1.90 0.067 0.071 0.075

A1 0.19 0.21 0.007 0.008

b 0.20 0.25 0.30 0.008 0.01 0.012

D 7.0 0.276

E 7.0 0.276

e 0.50 0.020

J 5.04 5.24 0.198 0.206

K 5.04 5.24 0.198 0.206

L 0.38 0.48 0.58 0.015 0.019 0.023

P 45 REF 45 REF

OUTLIN E AND

MECHANI CAL DATA

QFN-44 (7x7x1.8mm)

Quad Flat Package No lead

M

G

M

34

33

23

22

N

44

1

11

12

44

1

DETAIL "N"

SEATING PLANE

DETAIL G

5/6

LIS2L02AQ

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any patent or patent r i ght s of STMi croelectr oni cs. Spec i fications mentioned i n this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics product s are not

authorized for use as cri tical comp onents in lif e support devi ces or systems without express written approva l of STMicroel ectronics.

The ST logo is a registered trademark of STMicroelectronics

2002 STMicroelectronics - All Ri ghts Rese rved

Austra lia - Brazil - Canada - Chi na - F i nl and - Franc e - Germany - Hong Kong - In di a - Israel - Ita l y - J apan -Malaysia - Malta - Morocco -

Singap ore - Spain - Sw eden - Switze rl and - Unit ed K i ngdom - United States .

STMicroelectronics GROUP OF COMPANIES

http://www.s t. com

6/6

Loading...

Loading...