2-axis - ±2g/±8g smart digital output “piccolo” accelerometer

Feature

■ 2.16V to 3.6V supply voltage

■ 1.8V compatible IOs

■ <1mW power consumption

■ ±2g/±8g dynamically selectable Full-Scale

2

■ I

C/SPI digital output interface

■ Programmable interrupt generator

■ Click and double click recognition

■ Embedded high pass filter

■ Embedded self test

■ 10000g high shock survivability

■ ECOPACK® RoHS and “Green” compliant

(see Section 9)

LIS202DL

MEMS motion sensor

LGA-14

measuring accelerations with an output data rate

of 100Hz or 400Hz.

A self-test capability allows the user to check the

functioning of the sensor in the final application.

(3x5x0.9mm)

Description

The LIS202DL is an ultra compact low-power two

axes linear accelerometer. It includes a sensing

element and an IC interface able to provide the

measured acceleration to the external world

through I

The sensing element, capable of detecting the

acceleration, is manufactured using a dedicated

process developed by ST to produce inertial

sensors and actuators in silicon.

The IC interface is manufactured using a CMOS

process that allows to design a dedicated circuit

which is trimmed to better match the sensing

element characteristics.

The LIS202DL has dynamically user selectable

full scales of ±2g/±8g and it is capable of

Table 1. Device summary

2

C/SPI serial interface.

Part number Temp range, ° CPackage Packing

LIS202DL -40 to +85 LGA Tray

LIS202DLTR -40 to +85 LGA Tape and reel

The device may be configured to generate inertial

wake-up interrupt signals when a programmable

acceleration threshold is crossed at least in one of

the two axes. Thresholds and timing of interrupt

generators are programmable by the end user on

the fly.

The LIS202DL is available in plastic Thin Land

Grid Array package (TLGA) and it is guaranteed

to operate over an extended temperature range

from -40°C to +85°C.

The LIS202DL belongs to a family of products

suitable for a variety of applications:

– Motion activated functions

– Gaming and Virtual Reality input

devices

– Vibration Monitoring and Compensation

June 2007 Rev 1 1/36

www.st.com

36

Contents LIS202DL

Contents

1 Block diagram & pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Mechanical and electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Mechanical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4.1 Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4.2 Zero-g level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4.3 Self test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4.4 Click and double click recognition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Sensing element . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.2 IC interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Factory calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 Application hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Soldering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5 Digital interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1 I2C serial interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1.1 I2C operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 SPI bus interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2.1 SPI read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2.2 SPI write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2.3 SPI read in 3-wires mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Register mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7 Register description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2/36

LIS202DL Contents

7.1 WHO_AM_I (0Fh) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.2 CTRL_REG1 (20h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.3 CTRL_REG2 (21h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.4 CTRL_REG3 [Interrupt CTRL register] (22h) . . . . . . . . . . . . . . . . . . . . . . 22

7.5 HP_FILTER_RESET (23h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.6 STATUS_REG (27h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.7 OUT_X (29h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.8 OUT_Y (2Bh) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.9 WU_CFG_1 (30h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.10 WU_SRC_1 (31h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.11 WU_THS_1 (32h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.12 WU_DURATION_1 (33h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.13 WU_CFG_2 (34h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.14 WU_SRC_2 (35h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.15 WU_THS_2 (36h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.16 WU_DURATION_2 (37h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.17 CLICK_CFG (38h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.18 CLICK_SRC (39h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.19 CLICK_THSY_X (3Bh) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.20 CLICK_TimeLimit (3Dh) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.21 CLICK_Latency (3Eh) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.22 CLICK_Window (3Fh) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8 Typical performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.1 Mechanical characteristics at 25°C . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.2 Mechanical Characteristics derived from measurement in the -40°C to

+85°C temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.3 Electro-mechanical characteristics at 25°C . . . . . . . . . . . . . . . . . . . . . . . 33

9 Package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3/36

Block diagram & pin description LIS202DL

1 Block diagram & pin description

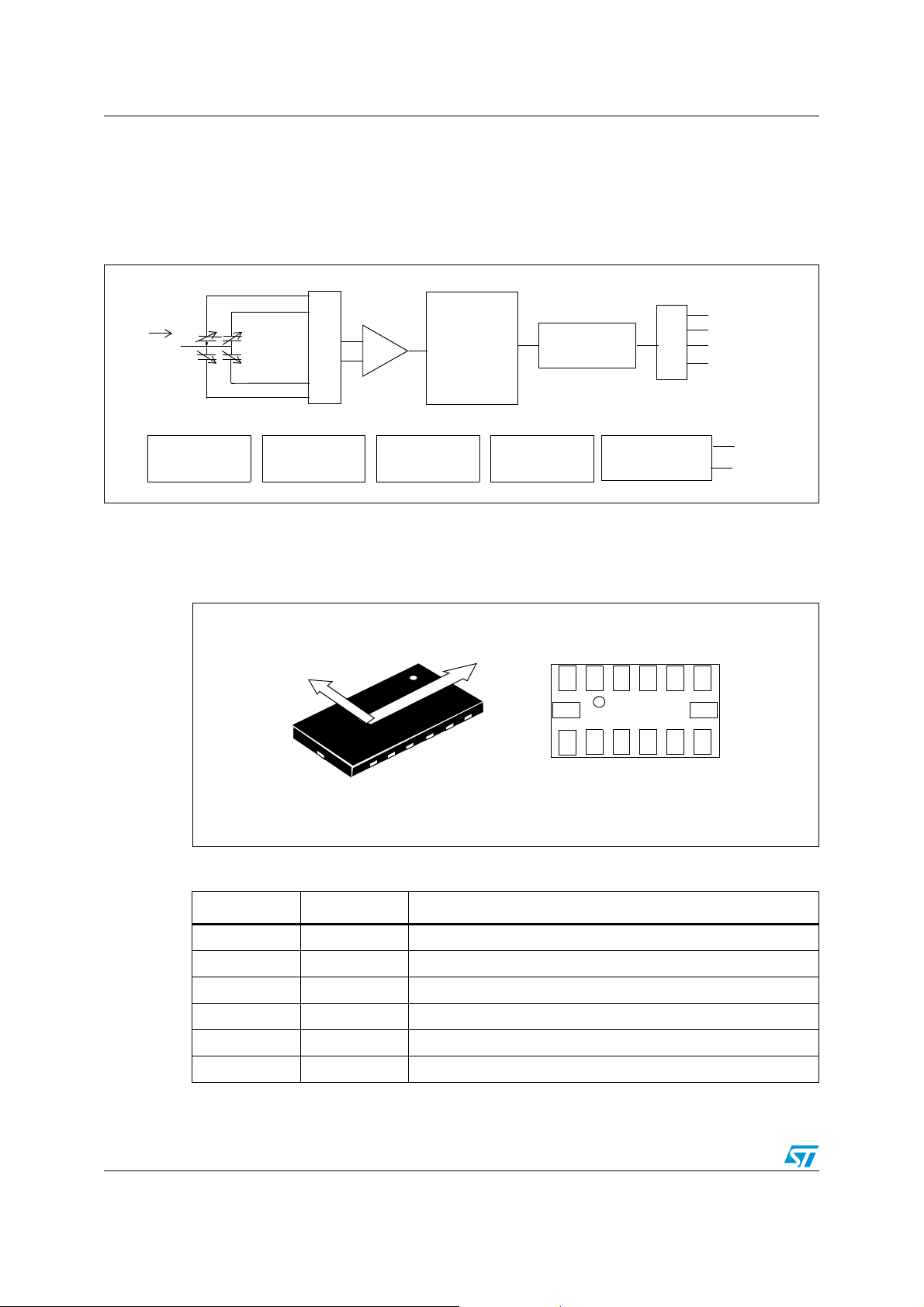

1.1 Block diagram

Figure 1. Block diagram

X+

I2C

SPI

CS

SCL/SPC

SDA/SDO/SDI

SDO

Y+

a

MUX

Y-

X-

CHARGE

AMPLIFIER

A/D

CONVERTER

CONTROL LOGIC

REFERENCESELF TEST

1.2 Pin description

Figure 2. Pin connection

Y

6

TOP VIEW

Table 2. Pin description

TRIMMING

CIRCUITS

1

CLOCK

CONTROL LOGIC

&

INTERRUPT GEN.

1

INT 1

INT 2

6

X

13

8

13 8

BOTTOM VIEW

Pin# Name Function

1 Vdd_IO Power supply for I/O pins

2 GND 0V supply

3 Reserved Connect to Vdd

4 GND 0V supply

5 GND 0V supply

6 Vdd Power supply

4/36

LIS202DL Block diagram & pin description

Table 2. Pin description (continued)

Pin# Name Function

7CS

SPI enable

2

C/SPI mode selection (1: I2C mode; 0: SPI enabled)

I

8 INT 1 Inertial interrupt 1

9 INT 2 Inertial interrupt 2

10 GND 0V supply

11 Reserved Connect to Gnd

12 SDO

SDA

13

SDI

SDO

14

SCL

SPC

SPI Serial Data Output

2

C less significant bit of the device address

I

2

I

C Serial Data (SDA)

SPI Serial Data Input (SDI)

3-wire Interface Serial Data Output (SDO)

2

I

C Serial Clock (SCL)

SPI Serial Port Clock (SPC)

5/36

Mechanical and electrical specifications LIS202DL

2 Mechanical and electrical specifications

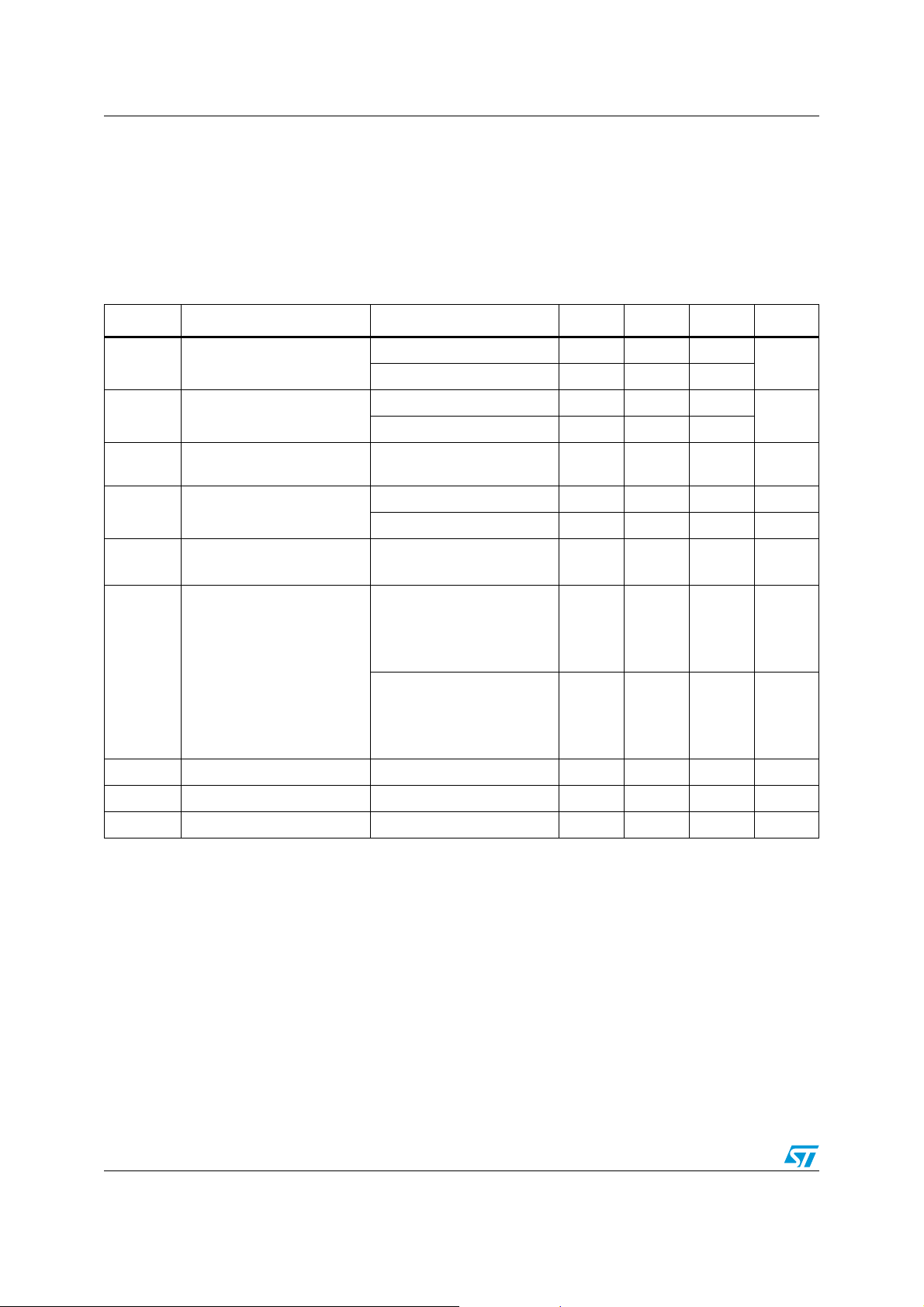

2.1 Mechanical characteristics

(All the parameters are specified @ Vdd=2.5V, T = 25°C unless otherwise noted)

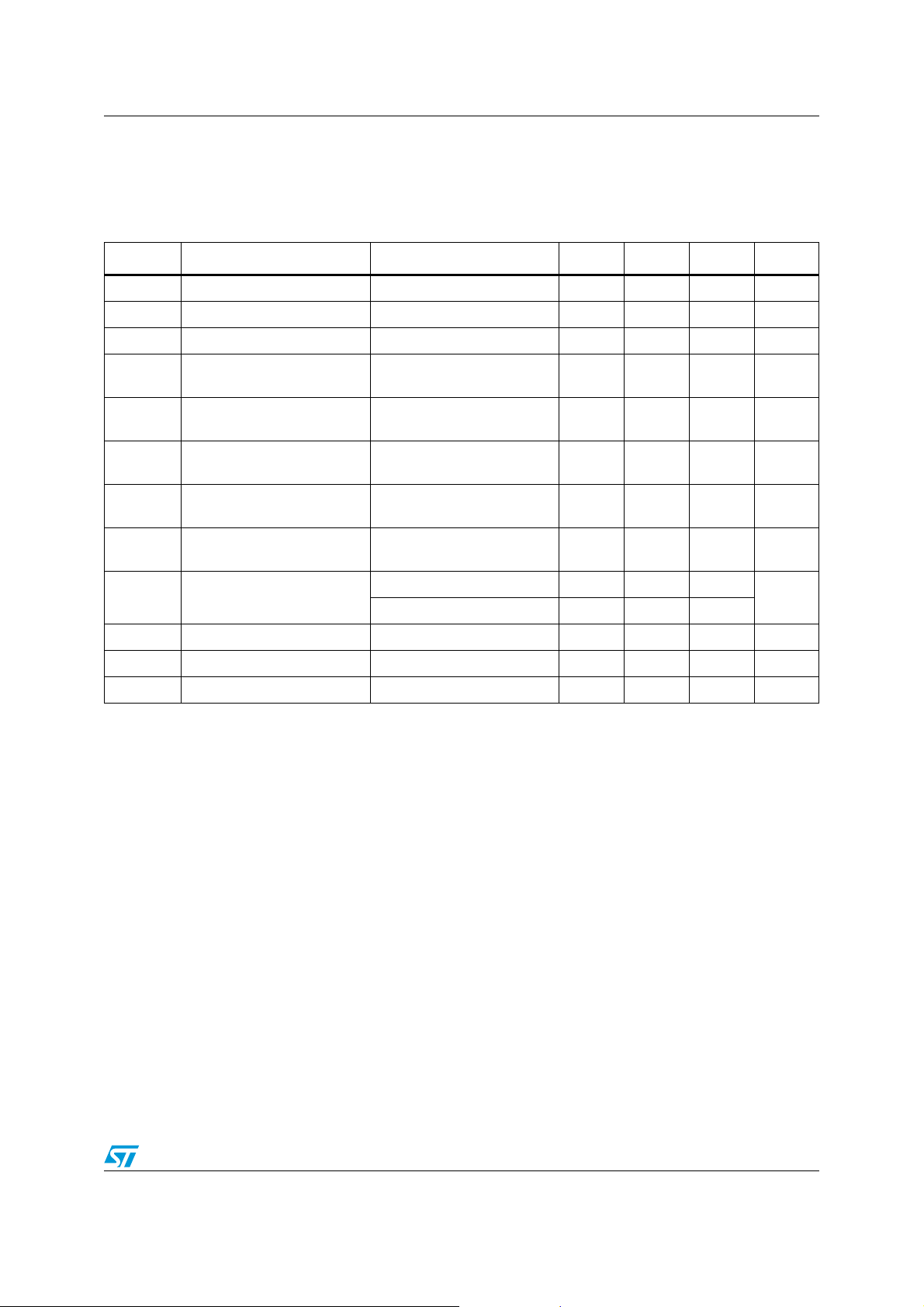

Table 3. Mechanical characteristics

Symbol Parameter Test conditions Min. Typ.

FS Measurement range

(3)

(1)

FS bit set to 0 ±2.0 ±2.3

(2)

Max. Unit

FS bit set to 1 ±8.0 ±9.2

FS bit set to 0 16.2 18 19.8

So Sensitivity

FS bit set to 1 64.8 72 79.2

TCSO

Ty Of f

TCOff

Sensitivity change vs

temperature

Typical zero-g level offset

accuracy

(4),(5)

Zero-g level change vs

temperature

FS bit set to 0 ±0.01 %/°C

FS bit set to 0 ±40 mg

FS bit set to 1 ±60 mg

Max delta from 25°C

±0.5 mg/°C

FS bit set to 0

Vst

Self test output

(6),(7),(8)

change

STP bit used

X axis

Vdd=2.16V to 3.6V

FS bit set to 0

STP bit used

Y axis

-32 -3 LSb

332LSb

Vdd=2.16V to 3.6V

BW System bandwidth

(9)

ODR/2 Hz

Top Operating temperature range -40 +85 °C

g

mg/digit

Wh Product weight 30 mgram

1. The product is factory calibrated at 2.5V. The device can be used from 2.16V to 3.6V

2. Typical specifications are not guaranteed

3. Verified by wafer level test and measurement of initial offset and sensitivity

4. Typical zero-g level offset value after MSL3 preconditioning

5. Offset can be eliminated by enabling the built-in high pass filter

6. If STM bit is used values change in sign for all axes

Self Test output changes with the power supply. Self test “output change” is defined as OUTPUT[LSb]

7.

-OUTPUT[LSb]

8. Output data reach 99% of final value after 3/ODR when enabling Self-Test mode due to device filtering

9. ODR is output data rate. Refer to table 3 for specifications

(Self-test bit on ctrl_reg1=0)

. 1LSb=4.6g/256 at 8bit representation, ±2.3g Full-Scale

(Self-test bit on ctrl_reg1=1)

6/36

LIS202DL Mechanical and electrical specifications

2.2 Electrical characteristics

(All the parameters are specified @ Vdd=2.5V, T= 25°C unless otherwise noted)

Table 4. Electrical Characteristics

Symbol Parameter Test conditions Min. Typ.

(1)

(2)

Max. Unit

Vdd Supply voltage 2.16 2.5 3.6 V

Vdd_IO I/O pins Supply voltage

(3)

1.71 Vdd+0.1 V

Idd Supply current T = 25°C, ODR=100Hz 0.3 0.4 mA

IddPdn

VIH

VIL Digital low level input voltage

VOH High level output voltage

VOL Low level output voltage

Current consumption in

power-down mode

Digital high level input

voltage

T = 25°C 1 5 µA

0.8*Vdd

_IO

0.2*Vdd

_IO

0.9*Vdd

_IO

0.1*Vdd

_IO

DR=0 100

ODR Output data rate

DR=1 400

BW System bandwidth

Ton Turn-on time

(5)

(4)

ODR/2 Hz

3/ODR s

V

V

V

V

Hz

Top Operating temperature range -40 +85

1. The product is factory calibrated at 2.5V. The device can be used from 2.16V to 3.6V

2. Typical specification are not guaranteed

3. It is possible to remove Vdd maintaining Vdd_IO without blocking the communication busses, in this condition the

measurement chain is powered off.

4. Filter cut-off frequency

5. Time to obtain valid data after exiting Power-Down mode

°C

7/36

Mechanical and electrical specifications LIS202DL

2.3 Absolute maximum ratings

Stresses above those listed as “absolute maximum ratings” may cause permanent damage

to the device. This is a stress rating only and functional operation of the device under these

conditions is not implied. Exposure to maximum rating conditions for extended periods may

affect device reliability.

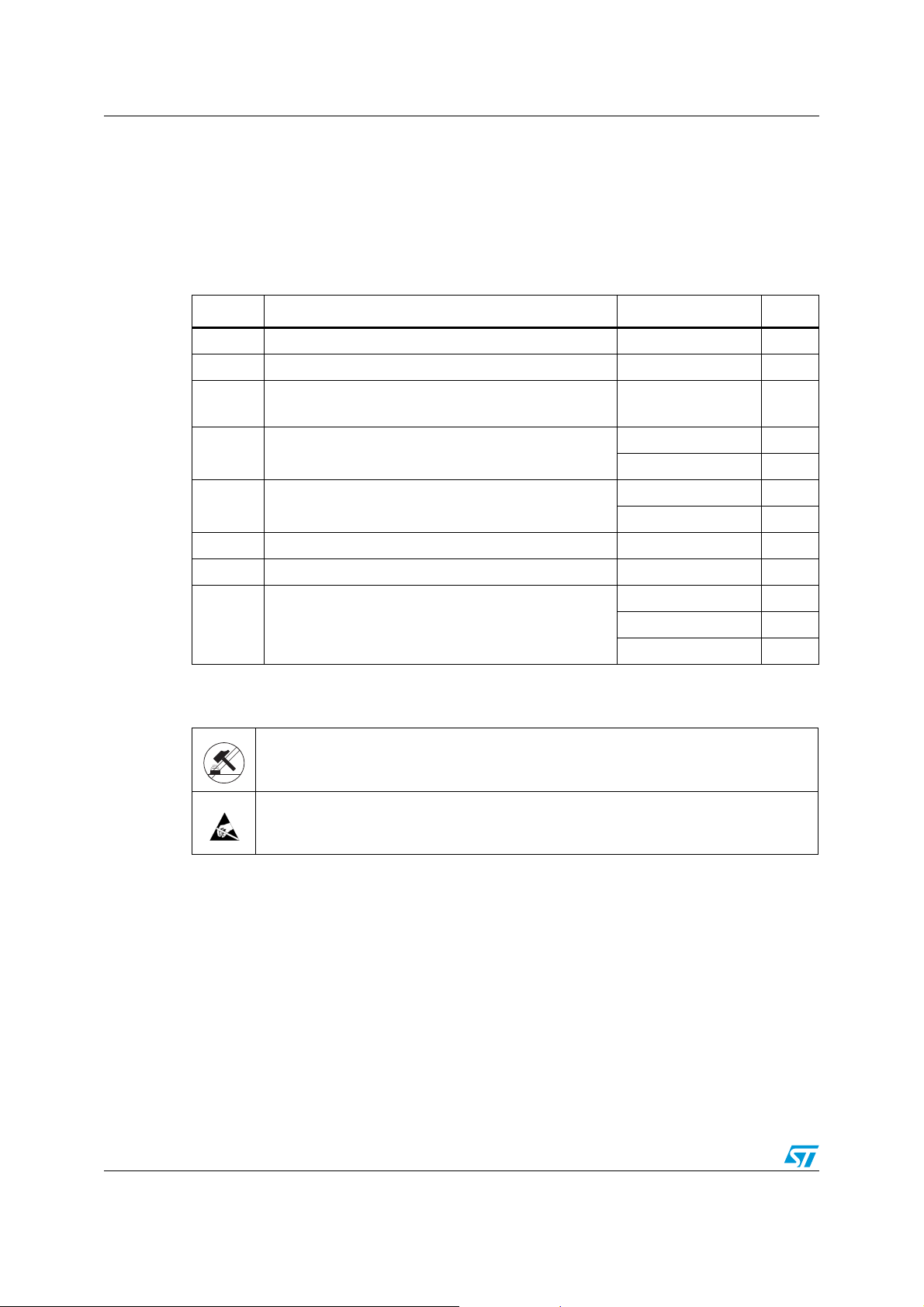

Table 5. Absolute maximum ratings

Symbol Ratings Maximum Value Unit

Vdd Supply voltage -0.3 to 6 V

Vdd_IO I/O pins supply voltage -0.3 to 6 V

Input voltage on any control pin

(CS, SCL/SPC, SDA/SDI/SDO)

Acceleration (any axis, powered, Vdd=2.5V)

-0.3 to Vdd_IO +0.3 V

3000g for 0.5 ms

10000g for 0.1 ms

A

Vin

POW

A

T

UNP

T

STG

Acceleration (any axis, unpowered)

Operating temperature range -40 to +85 °C

OP

Storage temperature range -40 to +125 °C

ESD Electrostatic discharge protection

Note: Supply voltage on any pin should never exceed 6.0V

This is a Mechanical Shock sensitive device, improper handling can cause permanent

damages to the part

This is an ESD sensitive device, improper handling can cause permanent damages to the

part

3000g for 0.5 ms

10000g for 0.1 ms

4.0 (HBM) kV

200 (MM) V

1500 (CDM) V

8/36

LIS202DL Mechanical and electrical specifications

2.4 Terminology

2.4.1 Sensitivity

Sensitivity describes the gain of the sensor and can be determined e.g. by applying 1g

acceleration to it. As the sensor can measure DC accelerations this can be done easily by

pointing the axis of interest towards the center of the earth, noting the output value, rotating

the sensor by 180 degrees (pointing to the sky) and noting the output value again. By doing

so, ±1g acceleration is applied to the sensor. Subtracting the larger output value from the

smaller one and dividing the result by 2 leads to the actual sensitivity of the sensor. This

value changes very little over temperature and also time. The Sensitivity Tolerance

describes the range of Sensitivities of a large population of sensors.

2.4.2 Zero-g level

Zero-g level Offset (TyOff) describes the deviation of an actual output signal from the ideal

output signal if no acceleration is present. A sensor in a steady state on a horizontal surface

will measure 0g in X axis and 0g in Y axis. The output is ideally in the middle of the dynamic

range of the sensor (content of OUT registers 00h, data expressed as 2’s complement

number). A deviation from ideal value in this case is called Zero-g offset. Offset is to some

extent a result of stress to MEMS sensor and therefore the offset can slightly change after

mounting the sensor onto a printed circuit board or exposing it to extensive mechanical

stress. Offset changes little over temperature, see “Zero-g level change vs. temperature”.

The Zero-g level tolerance (TyOff) describes the Standard Deviation of the range of Zero-g

levels of a population of sensors.

2.4.3 Self test

Self Test allows to check the sensor functionality without moving it. The Self Test function is

off when the self-test bit of ctrl_reg1 (control register 1) is programmed to ‘0‘. When the selftest bit of ctrl_reg1 is programmed to ‘1‘ an actuation force is applied to the sensor,

simulating a definite input acceleration. In this case the sensor outputs will exhibit a change

in their DC levels which are related to the selected full scale through the device sensitivity.

When Self Test is activated, the device output level is given by the algebric sum of the

signals produced by the acceleration acting on the sensor and by the electrostatic test-force.

If the output signals change within the amplitude specified inside Tab le 3 , then the sensor is

working properly and the parameters of the interface chip are within the defined

specifications.

2.4.4 Click and double click recognition

The click and double click recognition functions help to create man-machine interface with

little software overload. The device can be configured to output an interrupt signal on

dedicated pin when tapped in any direction.

If the sensor is exposed to a single input stimulus it generates an interrupt request on inertial

interrupt pins (INT1 and/or INT2). A more advanced feature allows to generate an interrupt

request when a “double click” stimulus is applied. A programmable time between the two

events allows a flexible adoption to the application requirements. Mouse-button like

application like clicks and double clicks can be implemented.

This function can be fully programmed by the user in terms of expected amplitude and

timing of the stimuli.

9/36

Functionality LIS202DL

3 Functionality

The LIS202DL is an ultracompact, low-power, digital output 2-axis linear accelerometer

packaged in a LGA package. The complete device includes a sensing element and an IC

interface able to take the information from the sensing element and to provide a signal to the

external world through an I

3.1 Sensing element

A proprietary process is used to create a surface micro-machined accelerometer. The

technology allows to carry out suspended silicon structures which are attached to the

substrate in a few points called anchors and are free to move in the direction of the sensed

acceleration. To be compatible with the traditional packaging techniques a cap is placed on

top of the sensing element to avoid blocking the moving parts during the moulding phase of

the plastic encapsulation.

When an acceleration is applied to the sensor the proof mass displaces from its nominal

position, causing an imbalance in the capacitive half-bridge. This imbalance is measured

using charge integration in response to a voltage pulse applied to the capacitor.

At steady state the nominal value of the capacitors are few pF and when an acceleration is

applied the maximum variation of the capacitive load is in pF range.

2

C/SPI serial interface.

3.2 IC interface

The complete measurement chain is composed by a low-noise capacitive amplifier which

converts the capacitive unbalancing of the MEMS sensor into an analog voltage that is

finally available to the user by analog-to-digital converters.

The acceleration data may be accessed through an I

device particularly suitable for direct interfacing with a microcontroller.

The LIS202DL features a Data-Ready signal (RDY) which indicates when a new set of

measured acceleration data is available thus simplifying data synchronization in the digital

system that uses the device.

The LIS202DL may also be configured to generate an inertial Wake-Up interrupt signal

accordingly to a programmed acceleration event along the enabled axes.

3.3 Factory calibration

The IC interface is factory calibrated for sensitivity (So) and Zero-g level (TyOff).

The trimming values are stored inside the device in a non volatile memory. Any time the

device is turned on, the trimming parameters are downloaded into the registers to be used

during the normal operation. This allows to use the device without further calibration.

2

C/SPI interface thus making the

10/36

LIS202DL Application hints

4 Application hints

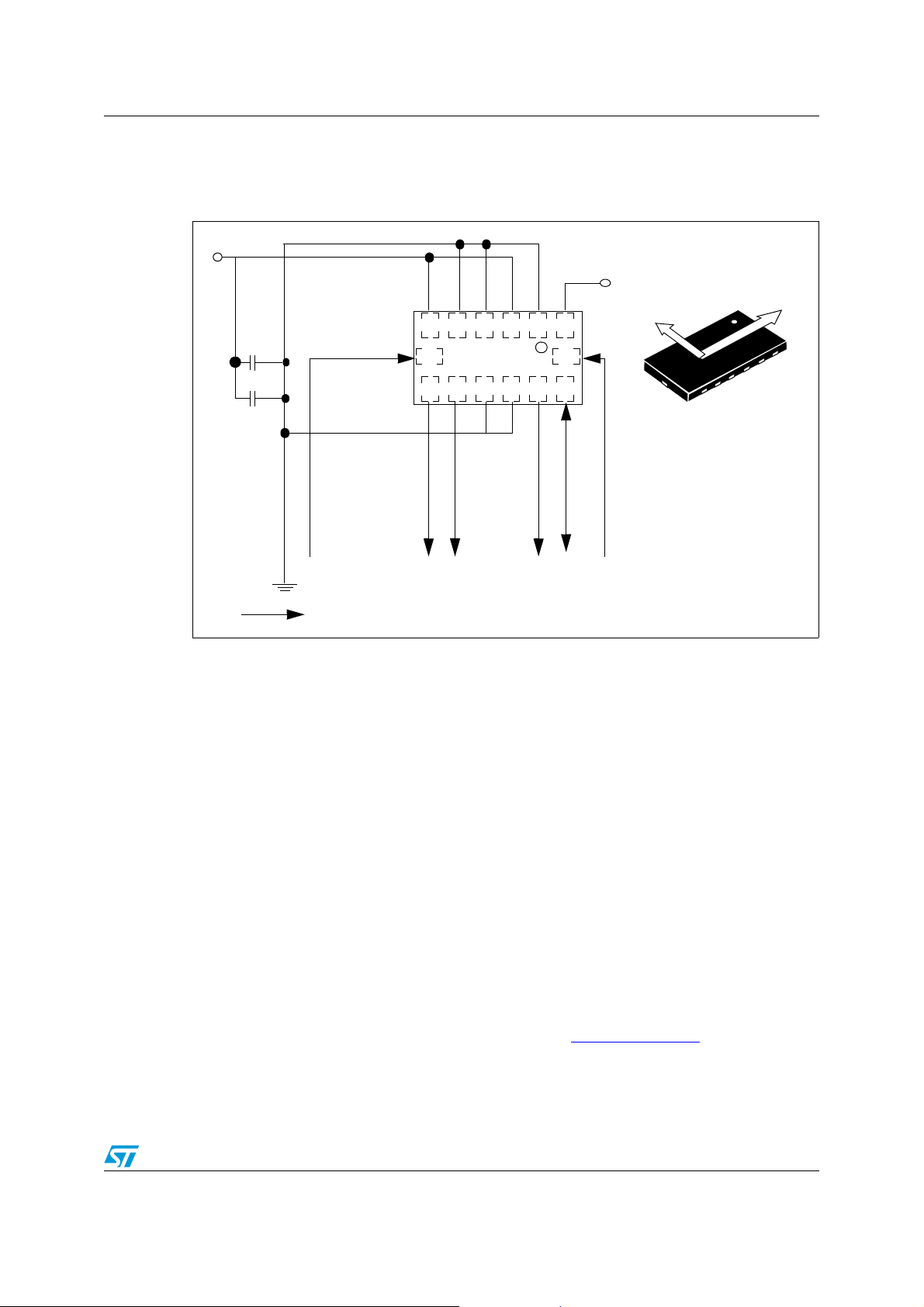

Figure 3. LIS202DL electrical connection

Vdd

10uF

100nF

GND

6

Top VIEW

8

CS

Digital signal from/to signal controller.Signal’s levels are defined by proper selection of Vdd_IO

INT_2

INT_1

1

SDO

Vdd_IO

13

SDA/SDI/SDO

SCL/SPC

Y

1

6

8

TOP VIEW

DIRECTION OF THE

DETECTABLE

ACCELERATIONS

13

The device core is supplied through Vdd line while the I/O pads are supplied through

Vdd_IO line. Power supply decoupling capacitors (100 nF ceramic, 10 µF Al) should be

placed as near as possible to the pin 6 of the device (common design practice).

X

All the voltage and ground supplies must be present at the same time to have proper

behavior of the IC (Figure 3: LIS202DL electrical connection). It is possible to remove Vdd

maintaining Vdd_IO without blocking the communication busses, in this condition the

measurement chain is powered off.

The functionality of the device and the measured acceleration data is selectable and

accessible through the I

2

C/SPI interface.When using the I2C, CS must be tied high while

SDO must be left floating.

The functions, the threshold an the timing of the two interrupt pins (INT 1 and INT 2) can be

completely programmed by the user though the I

4.1 Soldering information

The LGA package is compliant with the ECOPACK, RoHS and “green” standard. It is

qualified for soldering heat resistance according to JEDEC J-STD-020C. Pin #1 indicator is

electrically connected to pin 1. Leave pin 1 indicator unconnected during soldering. Land

pattern and soldering recommendation are available at www.st.com/mems

2

C/SPI interface.

.

11/36

Loading...

Loading...