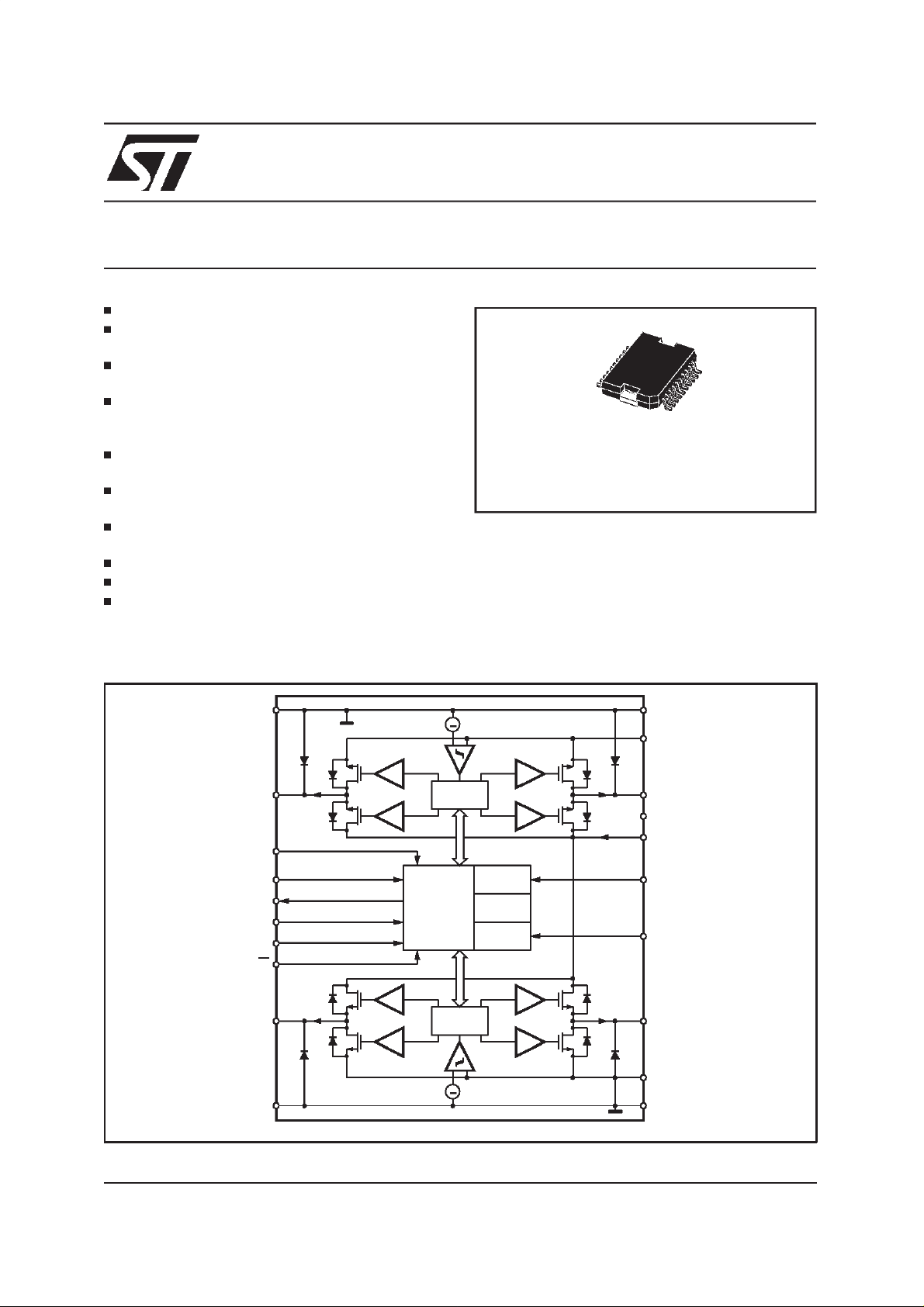

TWO-PHASESTEPPER MOTOR DRIVER

2 X 1.1A FULLBRIDGEOUTPUTS

INTEGRATEDCHOPPINGCURRENT REGU-

LATION

MINIMIZED POWER DISSIPATION DURING

FLYBACK

OUTPUT STAGES WITH CONTROLLED

OUTPUT VOLTAGE SLOPES TO REDUCE

ELECTROMAGNETICRADIATION

SHORT-CIRCUIT PROTECTION OF ALL

OUTPUTS

ERROR-FLAG FOR OVERLOAD,OPENLOAD

ANDOVERTEMPERATURE PREALARM

DELAYED CHANNEL SWITCH-ON TO REDUCE PEAK CURRENTS

MAX.OPERATINGSUPPLYVOLTAGE24V

STANDBYCONSUMPTIONTYPICALLY40µA

SERIALINTERFACE (SPI)

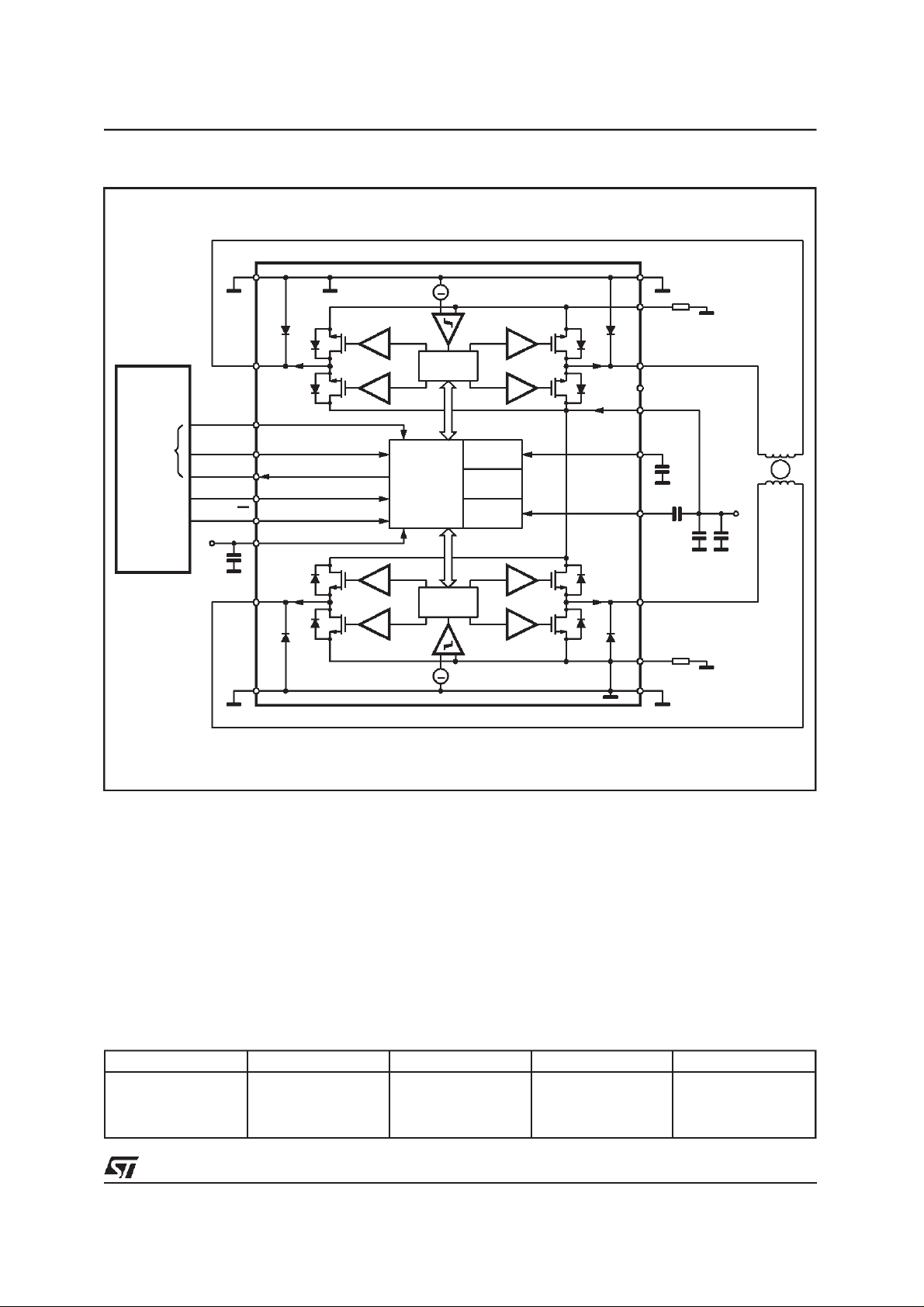

BLOCK DIAGRAM

L9935

PowerSO20

ORDERING NUMBER: L9935

DESCRIPTION

The L9935 is a two-phase stepper motor driver

circuit suited to drive bipolar stepper motors. The

device can be controlled by a serial interface

(SPI). All protections required to design a well

protected system (short-circuit, overtemperature,

cross conduction etc.) are integrated.

OUT

OUT

GND

SCK

SDI

SDO

VCC

CSN

GND

201

~

2

A1

3

4

5

6

7

8

EN

9

B1

10

DRIVER

COMMON

LOGIC

DRIVER

LOGIC

OSCILLATOR

DIAGNOSTIC

BIASING

LOGIC

~

19

18

17

16

15

14

13

12

11

D99AT415

GND

SR

OUT

N.C.

V

OSC

C

OUT

SR

GND

A

A2

S

DRV

B2

B

November 1999

1/19

L9935

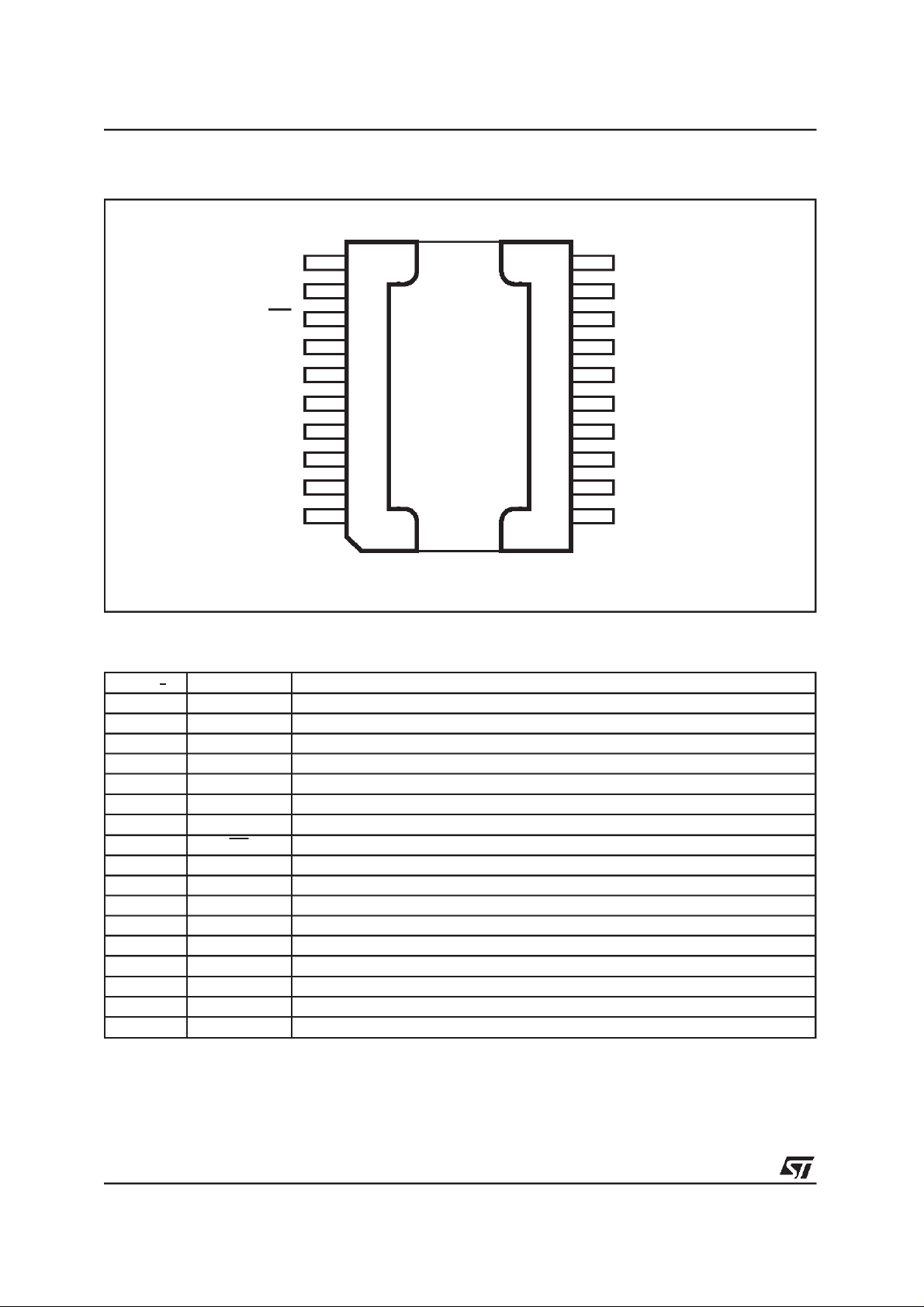

PIN CONNECTION

GND

OUT

B1

EN

CSN

VCC

SDO

SDI

SCK

OUT

A1

GND GND

10

9

8

7

6

5

4

3

2

1

D99AT416

11

12

13

14

15

16

17

18

19

20

GND

SR

OUT

C

DRV

OSC

V

S

N.C.

OUT

SR

B

B2

A2

A

PIN FUNCTIONS

o

Pin N

1,10,11,20 GND Ground. (All ground pins are internally connected to the frame of thedevice).

2 OUT

3 SCK Clock for serial interface (SPI)

4 SDI Serial data input

5 SDO Serial data output

6 VCC 5V logic suplly voltage

7 CSN Chip select (Low active)

8 EN Enable (Low active)

9 OUT

12 SR

13 OUT

14 C

15 OSC Oscillator capacitor or external clock

16 VS Supply voltage

17 NC Not connected

18 OUT

19 SR

Name Description

A1

B1

B

B2

DRV

A2

A

Output 1 of full bridge 1

Output 1 of full bridge 2

Cyrrent sense resistor of the chopper regulator for OUT

Output 2 of full bridge 2

Charge pump buffer capacitor

Output of full bridge 1

Current sense resistor of the chopper regulator for OUT

B

A

2/19

L9935

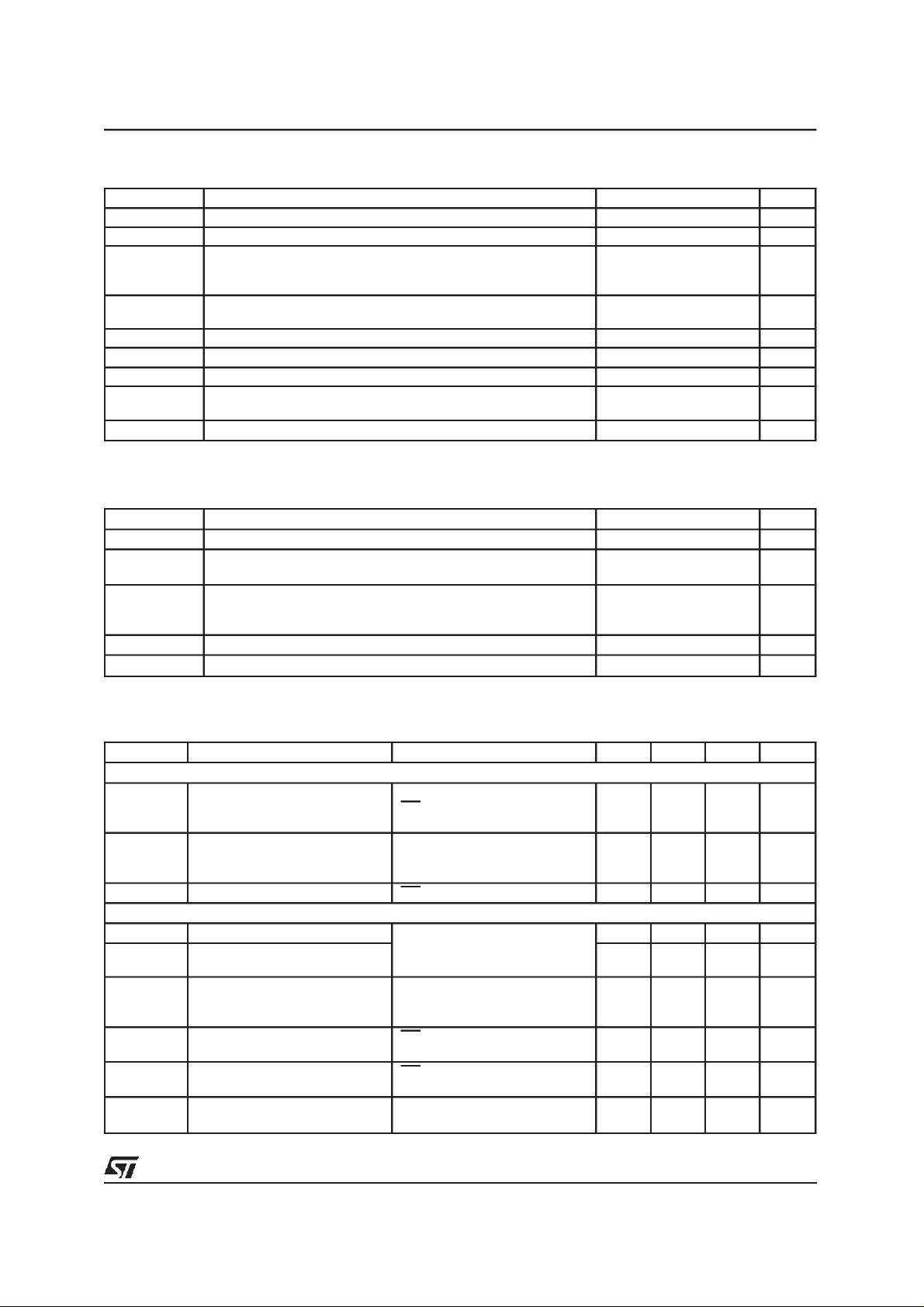

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

S

V

SPulsed

V

OUT (Ai/Bi)

I

OUT (Ai/Bi)

V

SRA/SRB

V

CC

V

CDRV

V

SCK,VSDI

V

CSN,VEN

V

OSC,VSDO

Note: ESD for allpins, except pins SDO, SRA and SRB, areaccording to MIL883C, tested at 2kV, corresponding to a maximum energy

dissipation of 0.2mJ. SDO, SRA and SRB pins are tested with800V.

THERMAL DATA

Symbol Parameter Value Unit

R

th j-case

R

th j-amb

R

th j-amb,FR4

T

S

T

SD

DC Supply Voltage -0.3 to 35 V

Pulsed supply voltage T < 400ms -0.3 to 40 V

Output Voltages internally clamped to V

or GND depending on the

current direction

DC Output Currents

Peak Output Currents (T/tp ≥ 10)

1.2

±

±2.5

Sense Resistor Voltages -0.3 to 6.2 V

Logic Supply Voltages -0.3 to 6.2 V

Charge Pump BufferVoltage versus V

,

Logic Input Voltages -2 to 8 V

S

-0.3 to 10 V

Oscillator Voltage Range, Logic Output -0.3 to VCC+0.3 V

Typical Thermal Resistance Junction to Case 5 °C/W

Typical Thermal Resistance Junction to Ambient

2

(6cm

Ground Plane 35µm Thhickness)

Typical Thermal Resistance Junction to Ambient

35 °C/W

8 °C/W

(soldered on a FR 4 board with through holes for heat transfer

and external heat sink applied)

Storage Temperature -40 to 150 °C

Typical Thermal Shut-Down Temperature 180 °C

S

A

A

ELECTRICALCHARACTERISTICS

erwise specified.)

1)

(8V ≤ V

≤ 24V; -40°C ≤ Tj≤ 150°C; 4.5V ≤ VCC≤ 5.5V, unless oth-

S

Symbol Parameter Test Condition Min. Typ. Max. Unit

SUPPLY

IS

I

SOP

I

CC

85

Total Supply Current

I

S+IVCC

(BothBridges Off)

Operating Supply Current I

5V Supply Current EN = LOW 1.4 10 mA

= 14V

V

S

EN = HIGH

T

≤ 85°C

J

=0

OUT Ai/Bi

f

= 30kHz

OSC

V

= 14V

S

40 100

4.5 mA

FULL BRIDGES

R

OUT, Sink

R

OUT, Source

R

OUT8, Sink

V

FWD

V

REV

t

r,tf

R

of Sink Transistors Current bit

DSON

RDSON of Source Transistors 0.4 0.7 Ω

RDSON of Sink Transistors +

R

of SourceTransistors

DSON

Forward Voltage of the DMOS

Body Diodes

combinations LL, LH,

V

12V

≥

S

Current bit

Combinations LL, LH,

V

=8V

S

EN = HIGH

I

= 1A; VS≥ 12V

FWD

Reverse DMOS Voltage EN = LOW

I

=1A

REV

Rise and Fall Time of Outputs

OUT

Ai/Bi

0.1...0.9 V

OUTVS

Chopping 550mA

= 14V

0.3 0.6 1.5

0.4 0.7 Ω

1.6 3 Ω

1 1.4 V

0.5 0.9 V

A

µ

s

µ

3/19

L9935

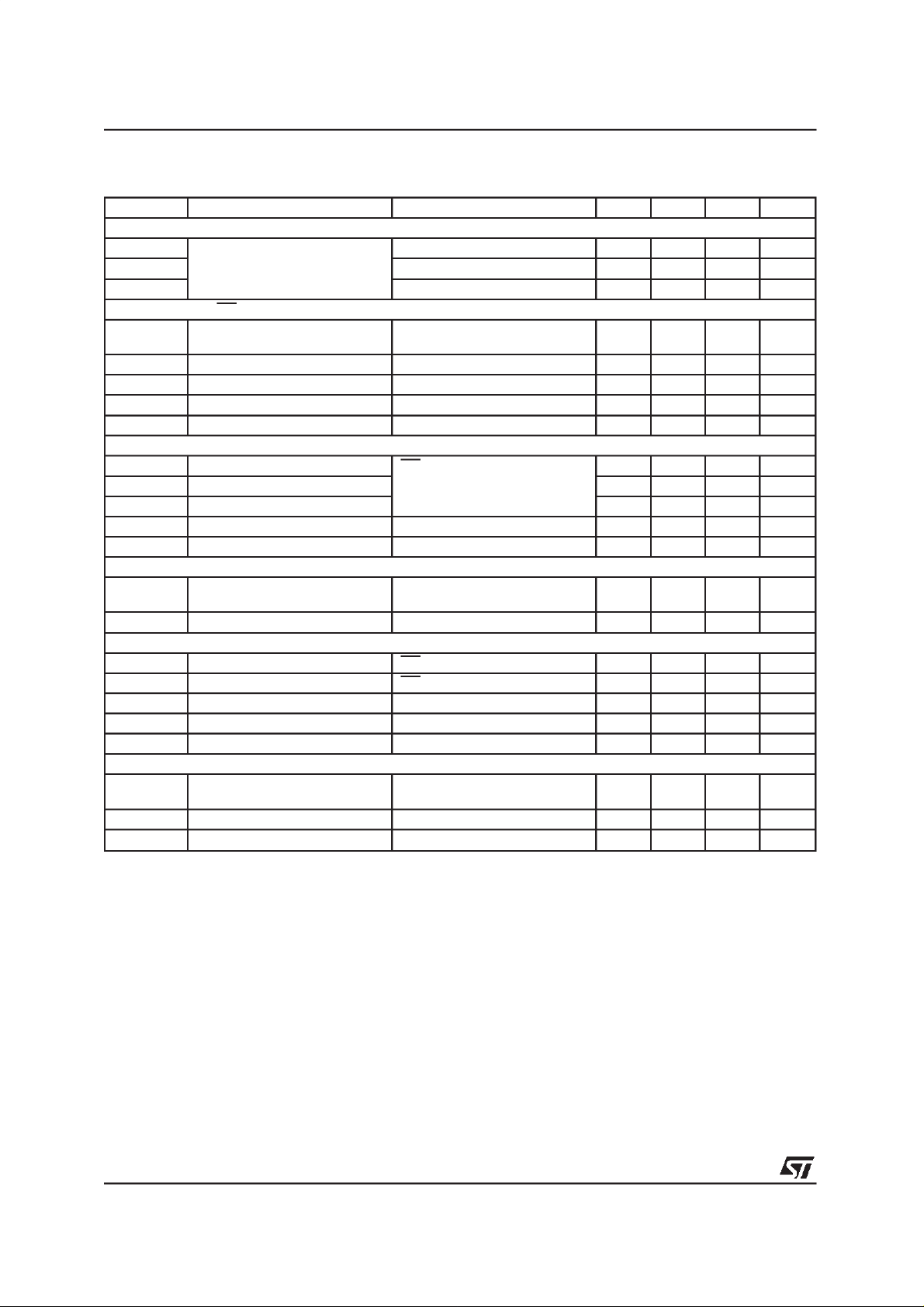

ELECTRICALCHARACTERISTICS

(continued)

Symbol Parameter Test Condition Min. Typ. Max. Unit

R

SWITCH OFF THRESHOLD OF THE CHOPPER (R

2)

V

V

V

SRHL

SRLH

SRLL

Voltage Drops Across R1⋅ R

(Voltage at Pin SRAor SRBvs.

GND)

Bit 5, 2 = H Bit 4, 1 = L 12 20 35 mV

2

Bit 5, 2 = L Bit4, 1 = H 160 180 210 mV

Bit 5, 4, 2, 1 = L 270 300 340 mV

1

⋅

= 0.33Ω)

2

ENABLE INPUT EN

V

EN High

High Input Voltage V

CC

V

-1.2V

V

EN low

V

EN Hyst

I

EN High

I

EN Low

Low Input Voltage 1.2 V

Enable Hysteresis 0.1 V

High Input Current V

High=VCC

Low Input Current VLOW = 0V -3 -10 -30

-10 0 10

µ

µ

A

A

LOGIC INPUTS SDI. SCK, CSN

V

V

V

I

HIGH

LOW

Hyst

HIGH

I

Low

High Input Voltage EN = LOW 2.6 8 V

Low Input Voltage -0.3 1 V

Hysteresis 0.8 1.2 1.6 V

High Input Current V

Low Input Current V

High=VCC

= 0V -3 -10 -30 µA

Low

-10 0 10 µA

LOGIC OUTPUTS (SDO)

V

SDO,High

High Output Voltage I

= -1mA VCC-1 V

SDO

CC

V

CC

V

-0.17

V

SDO,Low

Low Output Voltage ISDO = 1mA 0.17 1 V

OSCILLATOR

V

OSC, H

V

OSC, L

I

f

t

OSC

OSC

Start

High Peak Voltage EN = LOW 2.2 2.46 2.6 V

Low Peak Voltage EN = LOW 1 1.23 1.4 V

Charging/Discharging Current 45 62 80 µA

Oscillator Frequency C

Oscillator Startup Time EN = High→Low 2/f

= 1nF 20 25 31 kHz

OSC

osc

5/f

osc

8/f

osc

THERMAL PROTECTION

T

J-OFF

Thermal Shut-Down

160 180 200 °C

Temperature

T

J-ALM

∆T

MGN

1) Parameters are tested at 125°C. Values at 140°C are guaranteed by design and correlation.

2) Currents of combinations LH and LL are sensed at the external resistors. The Current of bit combination HL is sensed internally and

cannot be adjusted by changing the sense resistors.

Thermal Prealarm 130 160 °C

Margin Prealarm/Shut-Down 10 20 30 K

4/19

Figure1. General ApplicationCircuit Proposal.

GND 201 GND

2

OUT

SCK

A1

3

DRIVER

~

LOGIC

19 SR

18

17

16

OUT

N.C.

V

S

L9935

A

R1 0.33Ω

A2

+5V

100nF

SDI 4

SDO 5

CSN 7

EN 8

VCC 6

OUT

B1

GND 10

COMMON

LOGIC

9

SDI

INTERFACE

µC

Applicationhints:

C1 and C2 should be placed as close to the device as possible. Low ESR of C2 is advantageous. Peak currents through C1 and C2 may

reach 2A. Care should be taken that the resonance of C1, C2 together with supply wire inductances isnot the choppingfrequencyor a multiple

of it.

FUNCTIONAL DESCRIPTION

Basic structure

The L9935 is a dual full bridgedriver for inductive

Table 1.

15 OSC

14

C

DRV

13 OUT

12 SR

11 GND

C

OSC

1nF

C

Driver

100nF

C1

100nF

B2

B

R2 0.33Ω

D99AT417

DRIVER

LOGIC

~

OSCILLATOR

DIAGNOSTIC

BIASING

loads with a choppercurrentregulation.

Outputs A1and A2 belongto full bridge A

Outputs B1and B2 belongto full bridge B

The polarity of the bridges can be controlled by

bit0 and bit3 (for full bridge A, bit3, for full bridge

B, bit0). Bit5, bit4 (for full bridge A) and bit2, bit1

(for full bridge B) control the currents. Bit3 high

leads to output A1 high. Bit0 high leads to output

B1 high.

Current setting Table 1 using a 0.33W sense resistor.

STEPPER

MOTOR

POWER

SUPPLY

C2

10µF

bit5, bit2 bit4, bit1 IQX(Typ.) I

H

H

L

L

H

L

H

L

0

60mA

550mA

900mA

RX/max

0%

61%

100%

Remark

inernally sensed

5/19

L9935

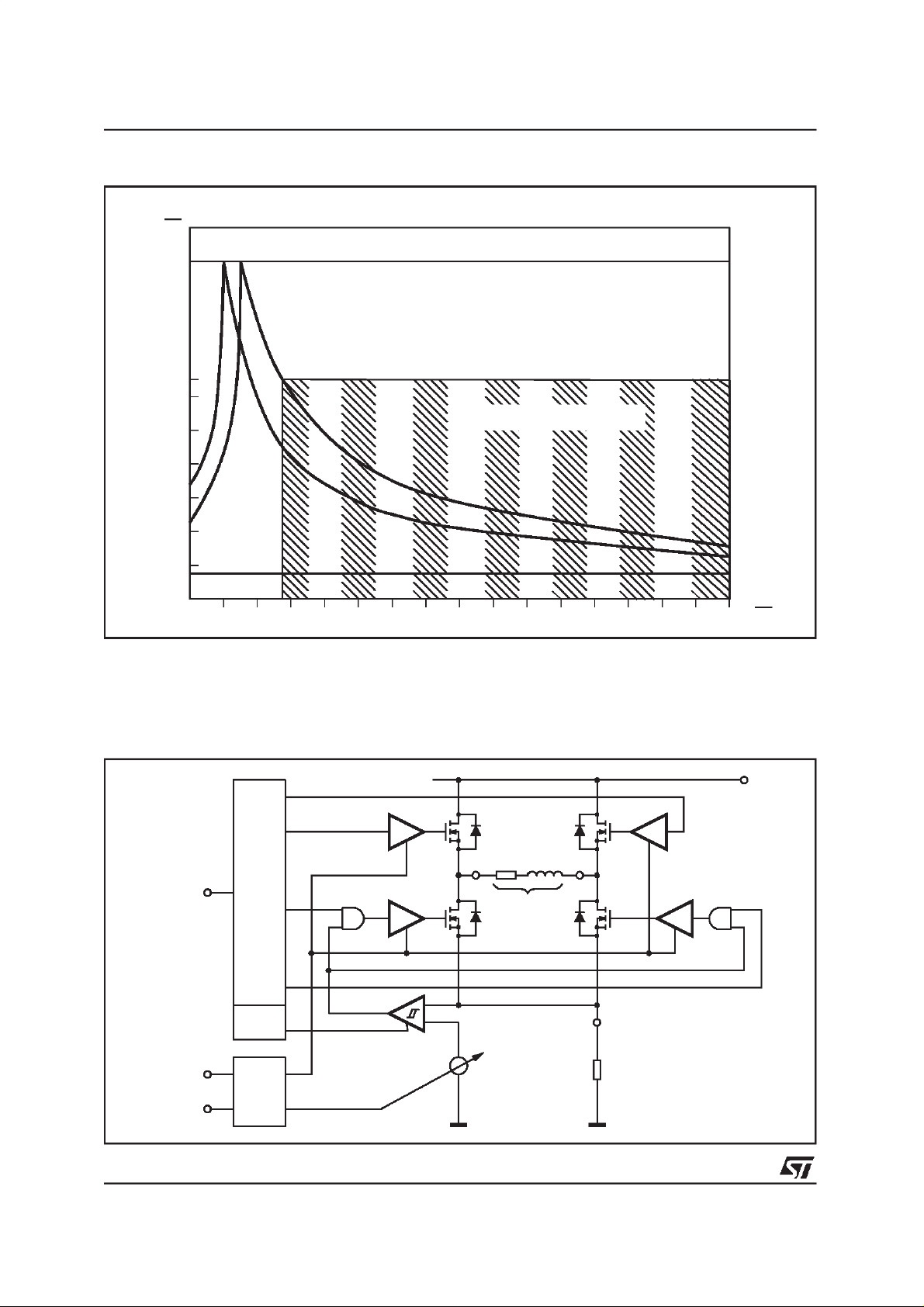

Figure 2. Typical average load current dependence on R

I

A

1.8

1.1

1

0.8

0.6

0.4

0.2

0.075

0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5 1.6

typical current limitation of high side transistor

limit recommended for usual application

suggested range of operation

Sense

I

LL

I

LH

I

HL

.

D99AT418

R

Ω

Full Bridge Function

Figure 3. Displays a full bridge including the current sense circuit.

M

11

11

M

12

COMP1

+

D

11

A

1

12

D

12

LOAD

D

21

A

D

22

6/19

bit3, (bit0)

bit5, (bit2)

bit4, (bit1)

DRIVE

LOGIC

τ

CURRENT

LOGIC

INHIBIT

ON HH

CURRENT ADJUST

D

D

M

21

2

M

22

R

1

R1EXTERNAL

SENSE RESISTOR

D

21

D

22

D99AT419

V

S

L9935

No current:

Bit 5, bit 4 (correspondingbit 2 and bit1 for bridge

B) both are HIGH, the current logic will inhibit all

drivers D

M

21,M22

11,D12,D21,D22

independentlyfrom the signal of the cur-

turning off M11,M12,

rent sense comparator comp 1.

Turningon:

Changing bit 5 or bit 4 or bothto LOW will turn on

either M

and M22or M21and M12(dependingon

11

the phase signal bit 3). Current will start to flow

through the load. The current will be sensed by

the drop acrossR

.

1

The threshold of the comparator comp1 depends

on the currentsettings of bit 5 and bit 4.

The current will rise until it exceeds the turn off

thresholdof comp 1.

Chopping:

Exceeding the threshold of comp 1 the drive logic

will turn off the sink transistor (M

or M22). The

12

sink transistor periodically is turned on again by

the oscillator. Immediately after turning on M

M

the comparator comp 1 will be inhibited for a

22

12

or

certain time to blank switch over spikes caused

by capacitiveload componentsup to 5 nF.

Turning off for example M

current through D

. (So now the free wheeling

11

will yield a flyback

12

current flows through M21, the load and D11).

This leads to a slow currentdecay during flyback.

Maximum duty cycles of more than 85% (at f

OSC

= 25kHz) are possible. In this case current flows

of both bridges will overlap(not shown in Fig. 5).

Reversingphase:

Suppose the current flowed via M

M

before reversing phase. Reversing phase

12

and M12will be turned off. So now the cur-

M

21

rent will flow through D

, the load and D11. This

22

, the load and

21

leads to a fastcurrent decay.

Chopper control by oscillator

Both chopping circuits work with offset phase.

One chopper will switch on the bridge at the

maximum voltage of the oscillator while the other

chopper will switch on the bridge at minimum

voltage of the oscillator.

MS1 and MS2 blank switching spikes that could

lead to errorsof the current control circuit.

Figure 4. Principal chopper control circuit.

OSC

C

OSC

OSCILLATOR

=

f

OSC

2.46V · C

i

OSC

OSC

RES1

RES2

MS1

RESET

DOMINANT

R

RSFF1

S

S

RSFF2

R

RESET

DOMINANT

Comp1

Dr1

Dr2

MOS DRIVERS

Comp2

inhibit

+

-

+

-

inhibit

SR

SR

A

B

MS2

D99AT420

7/19

L9935

Figure 5. Pulse diagram to explainoffset chopping.

V

OSC

V

SRA

V

SRB

total current consumption

current

threshold 1

current

threshold 2

turn off delay

due to slope

velocity control

I

VS

∆I

D99AT421

Using offset chopping the changes of the supply current remain half as large as using non offset chopping.

Turning off the oscillator for example by shorting pin OSC to ground will hinderturning on of the bridges

anymoreafter the comparatorshavegenerateda turn off signal.

External clocking is possible overdriving the charge and discharge currents of the oscillator for example

with a push pull logic gate. So severaldevices can be synchronized.

Protectionand Diagnosis Functions

The L9935 provides several protection functionsand error detection functions. Current limitation usually

is customer defined by the external current sense resistors. The current sensedthere is used to regulate

the current through the steppermotorwindingsby pulse width modulation.This PWM regulation protects

the sink transistors. The source transistorsare protected by an internalovercurrent shut down turning off

the source transistorsin case of overload.

Overloaddetectionof the source transistor will turn off the bridge and set the corresponding errorflag.

To turn on the bridge again a new byte must be written into the interface. (Rising slope of CSN resets

the overload error flag).

Both bridges use the same flags. To locate which bridge is affected by an error the bridges can be

tested individually (One bridge justis turned off to check for theerror in the other bridge).

Short from an Output to the Supply Voltage VS

The current will be limited by the pulse width modulator.The sink transistorwill turn off again after some

microseconds. The transistor will periodically be turned on again by the oscillator 8 times. After having

detected short 8 times the low side transistor will remain off until the next data transfer took place. After

detection of a short to VS we suggest to turn off the corresponding bridge to reduce power dissipation

for at least1ms.

8/19

L9935

Diagnosisof a Short to VS

During the short current through the sink transistor will rise more rapidly than under normal load conditions. Reaching a peak current of 1.5 times the maximum PWM current between typically 2µs and 5µs

t

ON

S

t

short

.

t

t

PWM

t

ON

t

short

t

PWM

t

ON

t

short

t

PWM

after turn on will be detectedas a short to V

Detecting a short the low side transistor will try to turn on again the next 7 trigger pulse of the oscillator.

Simultaneouslythe error flag will updated on each pulse.

Figure 6. Normal PWM current versus shortcircuit current and detection of short to VS..

IQshort threshold

PWM threshold

t

t

ON

shorttPWM

PWM

detection

signal (internal)

Short

detection

signal (internal)

Error 1

ton: turn on of the sink

ton+t1=t

ton+t

delay=tPWM

Betweent

Between t

on

short

: activation of short

short

: activation of PWM threshold

and t

and t

the over current detection is totally blanked.

short

the current threshold is set to 1.5 times the maximum PWM current (1.5 times

PWM

transistor

threshold

D99AT422

t

t

t

the current of current setting LL).

Overcurrentnow willset the error flag.

After t

the current threshold is the nominal PWM current set by the external resistor. Exceeding this

PWM

current will just turn off the sink transistor. This is considered as normal operation. The error flag is detachedfrom the comparatorafter tPWM so no error flag is set during normal pulse width modulation.

Short from an Output to Ground

The current throughthe short will be detected by the protection of the source transistor. The source transistor will turn off exceeding a current of typically 1.8A. Minimum overload detection current is 1.2A. To

obtain proper current regulation (by the sink transistors and not by source transistor shut down) the

maximum current of the PWMregulatorshould be set to a maximumvalue of 1.1A.

9/19

L9935

Diagnosisof a Short to Ground

Detecting an overload will set an overcurrent error (Error2 = LOW) (bit6). To reset the error flag a new

byte mustbe written into the interface.(Reset of the error flag takes place at the rising slope of CSN).

ShortedLoad

With a shorted load both, the sink- and the source protection or the PWM alone will respond. In either

case therewill be no flybackpulse.

Diagnosisof a Shorted Load

Shorting the load two events may takeplace:

- overload(of the high side transistor) while low side transistor overcurrent is detectedwill set the

followingcombinations:

bit6 = LOW

bit7 = HIGH

- overloadis marginal. So the low side drivermay turn off before overload is detected.This leads to the

combinationbit6 = HIGH and bit7 = LOW.

Open Load

An open load will not lead to any flyback pulses. Error detection will take advantageof theflyback pulse.

Missingthe flyback pulse after reversingthe polarity of a motor winding bit7 will become LOW.

Open load will not be tested in the low current mode (current bits HL) to avoidthe risk of instable diagnosis at low flayback currents. Open load immediately after reset or power down may on random be detected in the low current mode too. This diagnosishowever will not persist longer than 8 changesof polarity. We strongly suggest to test open load at a high current mode (combination LH or LL).

OvertemperaturePrealarm

Typically 20K before thermal shut down takes place an overtemperature prealarm (bit7 and bit6 low)

takes place. Typicallyovertemperatureprealarmtemperatureis between 150°Cand 160°C.

Applicationhints using a high resistivestepper motor

The L9935 was originally targeted on stepper chopping stepper motor application with typical resistances of 8..12W. Using motors with higher resistance will work too but diagnosisbehaviour will slightly

change. Thisparagraph shows the details that should be taken in account usingdiagnosis for high resistive motors.

Startup behaviour:

The device has simple digital filter to avoid triggering diagnosisat a single event that could be random

noise. This digital filter needs 4 chopping pulses to settle. Using a high resistive motor this chopping

does not take place. Instead the digital filter samples eachtime a polarty change takes place. So the first

three responsetelegramsafter resetmay show an ’open load’ error.

Input data High resistive motor (error bits) Low resistive motor (error bits)

Standby

1st telegram (550mA or 900mA) HH HH

Reverse phase (550mA or 900mA) XH HH

Reverse phase (550mA or 900mA) XH HH

Any data XH HH

Any data HH HH

H means check for HIGH at the error bits.

X means don’t care becausefilter is not yet settled.

10/19

L9935

Using 75mAchoppingimmediatelly after stand by:

The high resistive motor can be forced to chopping operation in the low current range. This leads to the

samebehaviouras using a low resistive motor.

Short to V

The short to VS flag is overwritteneach time the chopper comparator responds. Having detected a short

this flagonly can be reset by reachingchopping operation or resetting the circuit (ENN=1). For a high resistive motor thisleads to the following consequence: Once a short to VS is detected the error flag will

persist even if the short is removed again until either a reset (ENN=1) or chopping(for example in 75mA

mode) has taken place. We suggest to return to operation once a short to VS was detected by using the

low currentmode to reset the flag.

Limitation of the Diagnosis

The diagnosis depends on either detecting an overcurrent of more than typically 1.8A through the

source transistor or on not detecting a flyback pulse, or on detecting severe overcurrents of the sink

transistorimmediatelyafter turn on.

Smallcurrents bypassing the load will not be detected.

In the low current range (hold current) the flyback pulse (especially commutatingagainst the supply

voltage after changing phase) may (depending on the inductivity of the stepper motor windings) be

too short to be detected correctly. For this reason diagnosis using the flyback pulse is blanked at

phase reversalat hold current.

In the low current range (hold current) the current capability of the bridge is reduced on purpose.

Short to VS may not be detected.In stead the bridge may just chop likenormal operation.

Flyback pulse detection is not blanked during PWM regulation at hold current (here commutation

voltage is less than 1V thus providing a longer pulse duration.) This however should be taken in account using stepper motors with low inductivity (less than 0.5mH). Using motors with such a low inductivitythe flybackvoltage in hold mode may decay too fast.

Motors with extremely low ohmic resistance tend to pump up the current because current decay during flyback approaches zero while at bridge turn on the current will increase. This may lead to overcurrent detection. We suggest to use stepper motors with an ohmic resistanceof approximately 3Ω or

more.

Partial shorts of windings or shorts of stepper motors with coils in series may still yield a flyback pulses

that are accepted by the diagnosisas a proper signal.

Table 2. Error table.

detectionusing high resistivemotors:

S

Error 1

bit7

H H Normal operation

L H Shortto VS (sink overload immediately after turn on)

H L short to gnd (source overload, missing flyback is masked)

L L overtemperature prealarm

Error 2

bit6

Description

shorted load (no flyback)

open load (no flyback)

At stepping rates faster than 1ms/data transfer error flags indicating a short should be used to initiate a

pause of at least 1ms to allow the power bridges to cool down again.

11/19

L9935

Serial Data Interface (SPI)

The serial data interface itself consists of the pins SCL (serial clock), SDI (serial data input) and SDO

(serial data output).

To especially support bus controlled applications the additional signals EN (chip enable not) and CSN

(chip select not) are available.

Startup of the Serial Data Interface

Falling slope of EN activatesthe device.After t

Falling slope of CSN indicates start of frame. Data transfer (reading SDI into the register) takes place at

the rising slopes of SCK.

Data transfer of the register to SDO takes placeat the falling slopeof SCK.

Rising slope of CSN indicates end of frame. At the end of frame data will only be accepted if modulo 8

bit (modulo8 fallingslopes to SCK)have been transferred. If this is not the case the input will be ignored

and the bridges will maintain the same status as before.

SDO is a tristateoutput.

SDO is activewhile CSN = LOW, while CSN = HIGH SDO is high resistive.

Figure 7. SPI Data/ClockTiming.

t

en_sck

the device is readyto work.

en.sck

EN

CSN

SCK

SDI

SDO

A

X

CSN

SCK

MSB7 bit6 bit5 bit4 bit3 bit2 bit1 bit0

MSB7 bit6

t

1

t

1

bit5 bit4 bit3 bit2 bit1 bit0

CURRENT AERROR BITS

t

cl

tsut

t

ch

sh

CURRENT B POLARITY BPOLARITY A

t

1

t

Pd

t

1

12/19

SDI

SDO

bit7

td

bit7

bit0

t

zch

bit0

D99AT437

L9935

Test condition for all propagation times (unlessotherwise specified)

HIGH ≥ 3V; LOW ≤ 0.8V; t

Symbol Parameter Test Conditions Min. Typ. Max. Unit

f

SCLK

t

1

SCK-Frequency DC 2MHz

SCK stable before and after

CSN = 0

t

ch

t

cl

t

su

t

sh

t

d

t

zc

t

en_sck

t

pd

(*) Measured at a transitionfrom High impedance (Bridge off) to bridgeon. (Reversing polaritytakes about 1µs longerbecause the bridge first

turns off before turning on in reverse direction).

Width of SCK high pulse 200 ns

Width of SCK low pulse 200 ns

SDI setup time 80 ns

SDI hold time 80 ns

SDO delay time (CL = 50pF) 100 ns

SDO high Z CSN high 100 ns

Setup time ENABLEto SCK HIGH > VCC-1.2V 30 µs

Propagation delay SPI to

output Q

XX

Table of bits

bit5,bit4 : current range of bridge A (OutputsA1 and A2)

bit3 : polarityof bridge A

bit2,bit1 : current range of bridge B (OutputsB1 and B2)

bit0 : polarityof bridge B

bit7,bit6 : Error1and Error 2

=10ns, Enable: ENN Low < 0.8V, ENN High > Vcc-0.8V

r,tf

100 ns

2 (*) µs

Cascading severalDevices

Cascading several devices can be done using the SDO output to pass data to the next device. The

whole framenow consists of n byte. n is the number of devices used.

Figure 8. CascadingSeveral Steppermotor drivers.

no.1 no.2 no.3

SDO

SDOSDI

SDOSDI SDOSDI

µP

SCKCSN CSN

SCK

SCK

CSN

SCK

D99AT438

CSN

Figure 9. Control sequence for 3 Stepper motordrivers.

EN

CSN

SCK

SDO

of µP

Q

byte forno. 3 byte forno. 2 byte forno. 1

XX

D99AT439

13/19

L9935

Figure 10. Paralleling several Devices.

no.1

SDI SDO

SCK

µP

CSN1

CSN2

SDI SDO

SCK

CSN

no.2

SDI SDO

SCK

CSN

D99AT440

here usuallyonly one Steppermotor driver is selected at a time while all others are deselected.

ApplicationInformation

For driving a stepper motor we suggest to use the following codes. The columned ’SDO correct’ shows

the data returned at SDOin correctfunction. The columnes presented under ’Error cases’ display thediagnosis bits if errors are detected.

Examplesof control sequences

Full step mode control sequencesanddiagnosis response.

SDI SDO

bit 76543210 76543210 76 76 76 76 76 76 76 76 76 76 76 76543210

XX111111 SDO PRESENT LAST DATA OR 11111111 IN CASE PREV. STATE WAS STAND BY

XX011011

XX010011

XX010010

XX011010

XX011011

XX010011

XX010010

XX011010

*) Motorresistance approximatelly 10Ω and VS= 12V. So a short to ground only is detected on one branche of thebridge.Lower resistivity of

the motor may lead to detection of short to groundon both branches of the bridge leading to code 10 on all steps.

14/19

correct

11111111

11011011

11010011

11010010

11011010

11011011

11010011

11010010

A

O

P

E

N

11

11

01

11

01

11

01

11

O

N

11

11

11

01

11

01

11

01

B

A1

S

P

H

E

O

R

T

VS

11

11

01

01

01

11

01

01

Error cases and SDObit7, bit6

A1

B2

B1

A2

S

H

O

R

T

VS

11

01

01

11

01

01

01

11

S

H

O

R

T

VS

11

11

11

01

01

01

11

01

S

H

O

R

T

VS

11

01

01

01

11

01

01

01

*)

S

H

O

R

T

GND

11

10

01

11

10

10

01

11

A2

*)

S

H

O

R

T

GND

11

11

10

10

01

11

10

10

B1

*)

S

H

O

R

T

GND

11

10

10

01

11

10

10

01

B2

*)

S

H

O

R

T

GND

11

11

11

10

10

01

11

10

therm.

alarm

00

00

00

00

00

00

00

00

therm.

shut

down

(reset

operating

codes)

00111111

00111111

00111111

00111111

00111111

00111111

00111111

00111111

L9935

These sequences are intended to give the user a good starting point for his software development. Besides these two there are further possibilitieshow to implement control sequences for this device (other

currents,quartersstep etc.).

therm.

B2

B1

A2

A1

B2

B1

A2

A1

O

P

E

N

11

11

11

11

11

01

11

11

11

01

11

11

11

01

11

11

11

O

N

11

11

11

11

11

11

11

01

11

11

11

01

11

11

11

01

11

B

S

S

S

S

H

H

P

E

O

R

T

VS

11

11

11

11

11

01

01

01

01

01

11

11

01

01

01

01

01

O

R

T

VS

11

01

01

01

01

01

11

11

11

01

01

01

01

01

11

11

11

H

O

R

T

VS

11

11

11

11

11

11

11

01

01

01

01

01

11

11

11

01

01

H

O

R

T

VS

11

11

11

11

01

01

01

01

11

11

11

01

01

01

01

01

11

GND

*)

H

O

R

11

10

10

10

10

01

11

11

11

11

10

01

10

01

11

11

11

*)

S

S

H

O

R

T

T

GND

GND

11

11

11

11

11

11

10

10

10

01

11

11

11

11

10

10

10

11

11

11

11

10

10

10

01

11

11

11

11

10

10

10

01

11

*)

*)

S

H

O

R

T

S

H

O

R

T

GND

11

11

11

11

11

11

11

11

10

10

10

01

11

11

11

11

10

alarm

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

SDI SDO A

bit 76543210 76543210 76 76 76 76 76 76 76 76 76 76 76 76543210

XX111111

XX011111

XX011111

XX011111

XX011011

XX111011

XX010011

XX010111

XX010010

XX110010

XX011010

XX011110

XX011011

XX111011

XX010011

XX010111

XX010010

XX110010

previous code

11111111

11011111

11011111

11011111

11011111

11011011

11111011

11010011

11010111

11110010

11011010

11011110

11011011

11111011

11010011

11010111

11010010

therm.

shut

down

(reset

operating

codes)

00111111

00111111

00111111

00111111

00111111

00111111

00111111

00111111

00111111

00111111

00111111

00111111

00111111

00111111

00111111

00111111

00111111

Double errors: Double errors will create composite codes by an AND operation between columns of the

same dominance.Openand short to VS are the least dominant error codes. (first 6 error code columns).

Short to ground is the second dominant error code. detection of short to gnd will overwriteerror codes of

the least dominant kind (open, short to VS). Temperature prealarm and thermal shut down are the most

dominant error codes. Thermal prealarm returns error code 00 but the device stillis working and returns

the appropriateoperationcode (bits 0..5).

Thermal shutdown returnserror code 00 and turns off the device. The opcode returnedcorresponds the

action eventuallyperformed(bit 0..5 become 1).

For example open bridge A and simultaneously open bridge B will lead to error code 01 by performing

an AND operation betweenthe two correspondingcolumns.

*) Motorresistance approximatelly 10Ω and VS= 12V. So a short to ground only is detected on one branche of thebridge.Lower resistivity of

the motor may lead to detection of short to groundon both branches of the bridge leading to code 10 on all steps.

ElectromagneticEmission classification(EME)

Electromagnet i cEmiss i on classes presentedbelow are typical data found on benchtest. For detailedtest descriptionpleasereferto’ElectromagneticEmission (EME) Measurementof IntegratedCircuits, DC to 1GHz’ of

VDE/ZVEIworkgroup767.13andVDE/ZVEIworkgroup767.14or IECprojectnumber 47A1967Ed.This data

is targetedto boarddesignerstoallowanestimati onof emissi onfiltering effortrequi redinapplic ati on.

Pin EME class Remark

GND E 10 0 1Ωtest

V

CC

EN. SDI, CSN, CSK, SDO in tristate K h

SDO G f SDO in low-Z state, nodata transfer

Power output A

Power output A

1,A2,B1,B2

1,A2,B1,B2

E e Blocked with 100nFclosemto the device

E 5 f Sourcing output

6 f Sinkingoutput in chopping mode f

osc

=20kHz

ElectromagneticEmissionis not testedin production.

15/19

L9935

Figure 11. State diagram.

ST

AND

BY

turn on

DEVICE

CHECKS

ERRORS 11

short

to VS

OFF OFF

new

telegram

CHECKING

FOR

ERRORS

short to VS

ON

FOR

shor

to

shor

to VS

01

short to VS

new telegram

no error

t

to

VS

t

t

shor

no short

same polarity as before

shor

t

gnd

gnd

to

new

telegram

CHECKING

FOR

ON

ERRORS

11

10

short

to gnd

new telegram

same polarity

new telegram current = 0

shor

t

to gnd

no short

LOGIC

SELECTS

BRANCHE

DEPENDING

ON

PREVIOUS

STATE

new telegram

flyback OK

or reverse polarity

shor

t

to

gnd

different polarity

than before

ON

CHECKING

FLYBACK 6

new

telegram

missing

flyback

ON

01

D99AT441

Remark: Return to stand by is possiblefrom every state

Note: Reversingpolarityin low currentmode no flybackcheck will be performed.

ElectromagneticEmission classification(EME)

ElectromagneticEmissionclassespresentel below are typicaldata found on bench test. For detailed test

description please refer to ’ElectromagneticEmission(EME) Measurement of Integrated Circuits, DC to

1GHz’ of VDE/ZVEI work group 767.13 and VDE/ZVEI work group 767.14 or IEC project number 47A

1967Ed. This data is targeted to board designers to allow an estimation of emission filtering effort required in application.

Pin EME class Remark

GND E 10 o 1Ω test

V

CC

E e Blocked with 100nF close to the device

EN, SDI, CSN, SCK, SDO in tristate K h

SDO G f SDO in low-state, no data transfer

Power output A

Power output A

1,A2,B1,B2

1,A2,B1,B2

E 5 f Sourcing output

6 f Sinking output in chopping mode fOSC = 20kHz

ElectromagneticEmissionis not testedin production.

16/19

Figure 12. EMC Compatibilityfor L9935

L9935

Vbatt

100 H

47nF 47nF

GND 1/10/11/20

100 F

Vs

Out 1

Out 2

to motors

Out 3

Out 4

4* 2,2nF

17/19

L9935

18/19

L9935

Information furnished is believedto be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is

granted by implication or otherwise under any patent or patent rights of STMicroelectronics. Specification mentioned in this publication are

subject to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products

are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logois a registered trademark of STMicroelectronics

1999 STMicroelectronics – Printedin Italy – All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - China- Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malta - Morocco -

Singapore - Spain - Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

19/19

Loading...

Loading...