1/17

L9903

June 2000

This ispreliminary information ona new product now in development. Details are subject to change without notice.

■

OPERATING SUPPLY VOLTAGE 8V TO 20V,

OVERVOLTAGE MAX. 40V

■

OPERATING SUPPLY VOLTAGE 6V WITH

IMPLEMENTED STEPUP CONVERTER

■ QUIESCENT CURRENT IN STANDBY MODE

LESS THAN 50µA

■

ISO 9141 COMPATIBLE INTERFACE

■

CHARGE PUMP FOR DRIVING A POWER

MOS AS REVERSE BATTERY PROTECTION

■ PWM OPERATION FREQUENCY UP TO

30KHZ

■ PROGRAMMABLE CROSS CONDUCTION

PROTECTION TIME

■

OVERVOLTAGE, UNDERVOLTAGE, SHORT

CIRCUIT AND THERMAL PROTECTION

■

REAL TIME DIAGNOSTIC

DESCRIPTION

Control circuit for power MOS bridge driver in automotive applications with ISO 9141bus interface.

SO20

ORDERING NUMBER: L9903

PRODUCT PREVIEW

MOTOR BRIDGE CONTROLLER

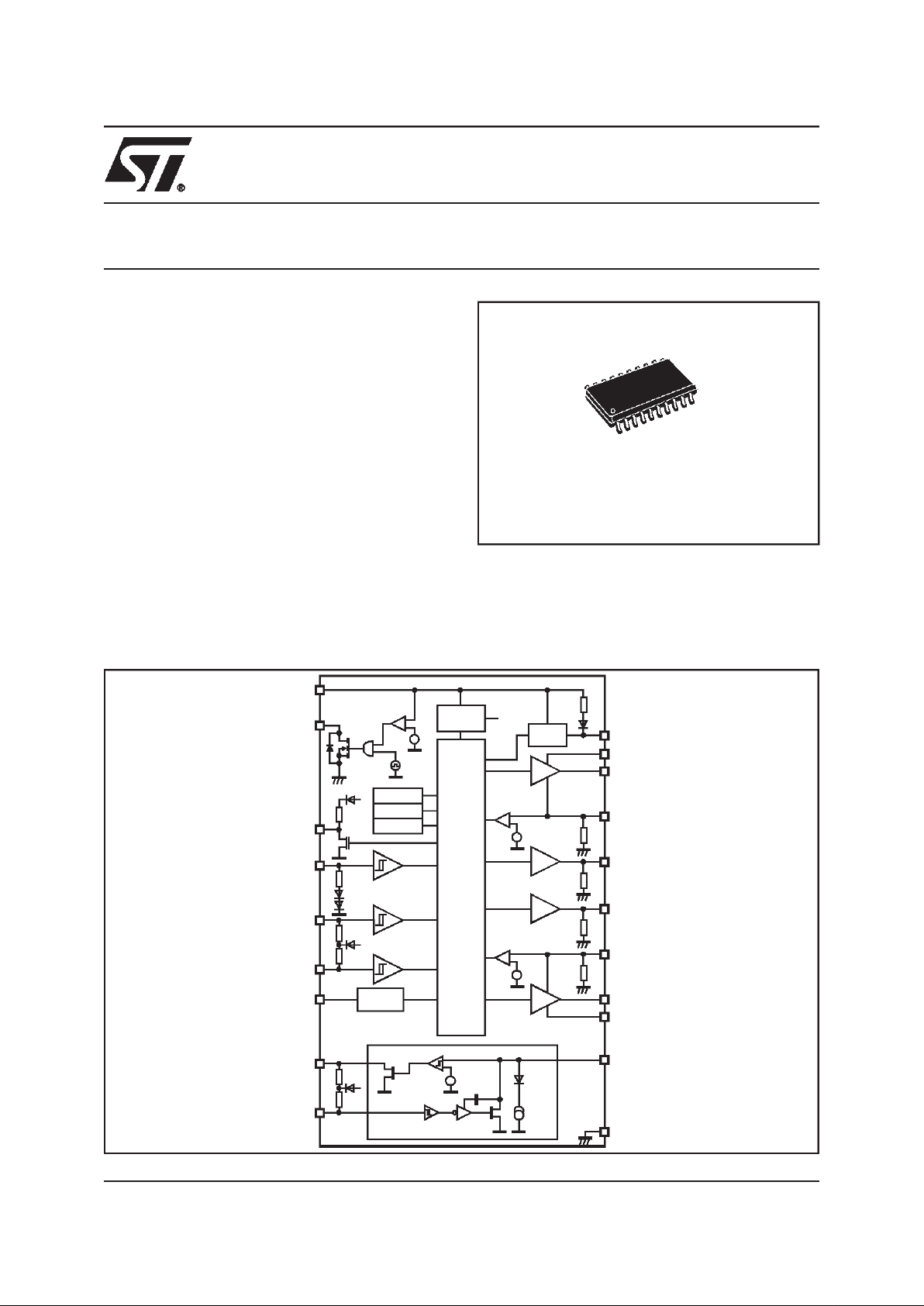

BLOCK DIAGRAM

VS

DIR

PWM

EN

RX

TX

CP

CB1

GH1

S1

GL1

CB2

GH2

S2

GL2

K

=

PR

VCC

=

=

ISO-Interface

VCC

GND

ST

Ref er enc e

BIAS

Char ge

pump

Control Logic

Overvoltage

Undervoltage

PWM

R

DIR

R

RX

R

TX

R

0.5 •V

VS

R

S2

R

GL2

R

GL1

R

S1

R

CP

R

EN

VCC

Timer

I

KH

V

S2TH

Thermalshutdown

V

S1TH

DG

VCC

R

DG

V

STH

f

ST

=

+

10

1

2

4

5

3

6

7

8

20

9

16

15

17

18

19

14

12

13

11

L9903

2/17

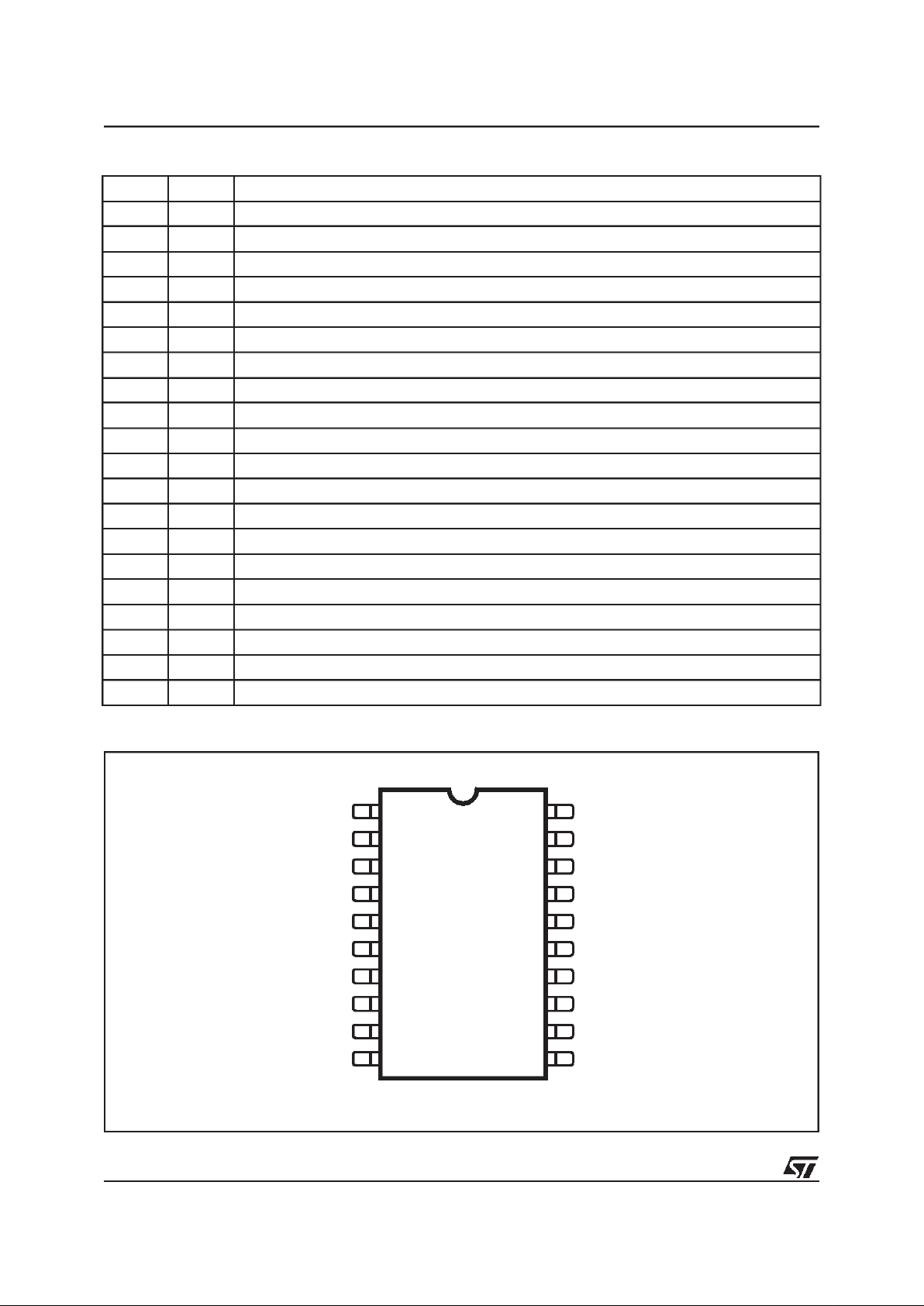

PIN FUNCTION

PIN CONNECTION (Top view)

N° Pin Description

1 ST Open Drain Switch for Stepup converter

2 DG Open drain diagnostic output

3 PWM PWM input for H-bridge control

4 EN Enable input

5 DIR Direction select input forH-bridge control

6 PR Programmable cross conduction protection time

7 RX ISO 9141 interface, receiver output

8 TX ISO 9141 interface, transmitter input

9 K ISO 9141 Interface,bidirectional communication K-line

10 VS Supply voltage

11 CP Charge pump for driving a power MOS as reverse battery protection

12 GH1 Gate driver for power MOS highside switch in halfbridge 1

13 CB1 External bootstrap capacitor

14 S1 Source/drain of halfbridge 1

15 GH2 Gate driver for power MOS highside switch in halfbridge 2

16 CB2 External bootstrap capacitor

17 S2 Source/drain of halfbridge 2

18 GL2 Gate driver for power MOS lowside switch in halfbridge 2

19 GL1 Gate driver for power MOS lowside switch in halfbridge 1

20 GND Ground

ST

DG

PWM

EN

DIR

RX

PR

TX

K GH1

CB1

S1

CB2

GH2

S2

GL2

GL1

GND1

3

2

4

5

6

7

8

9

18

17

16

15

14

12

13

11

19

10

20

VS CP

SO20

3/17

L9903

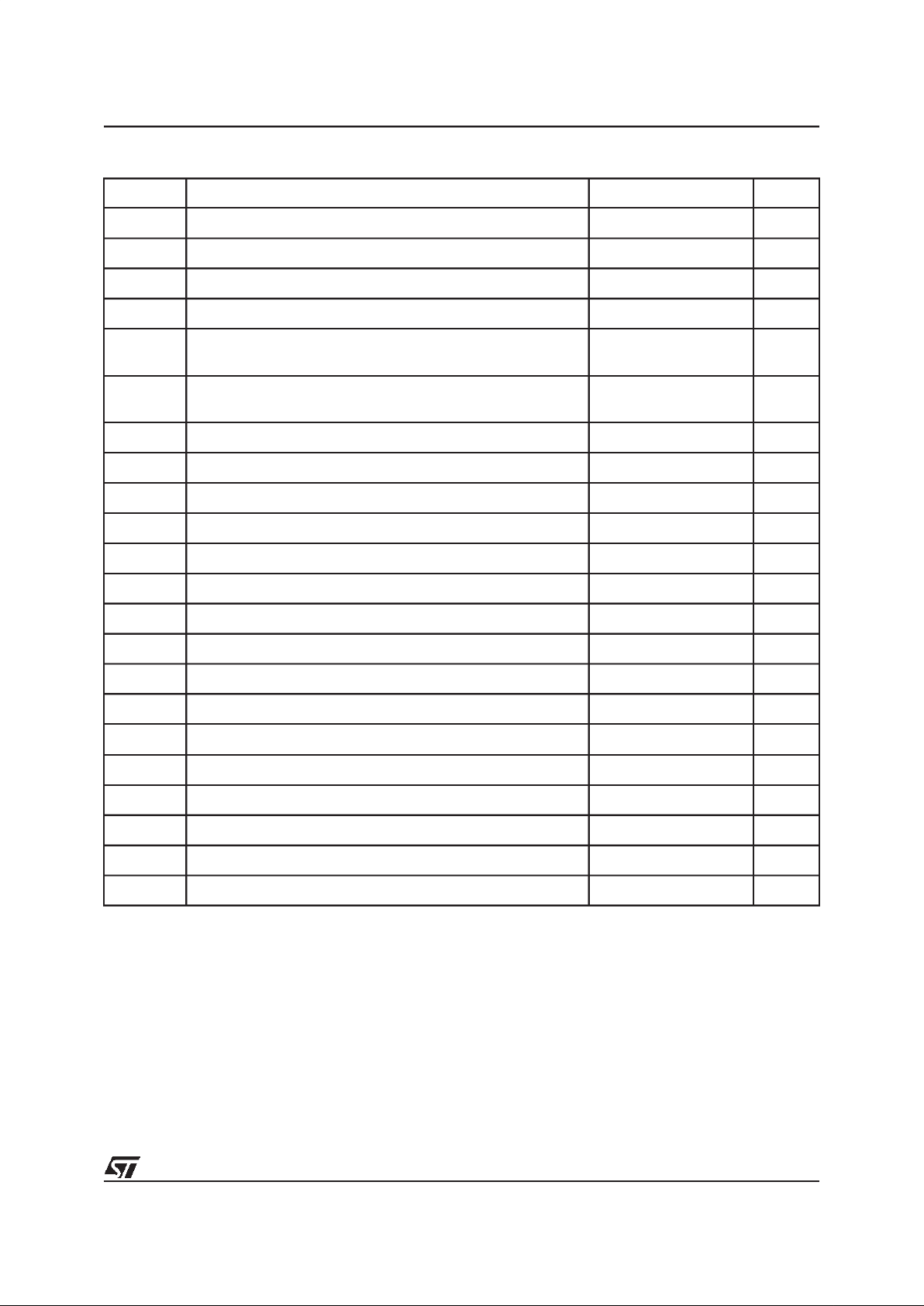

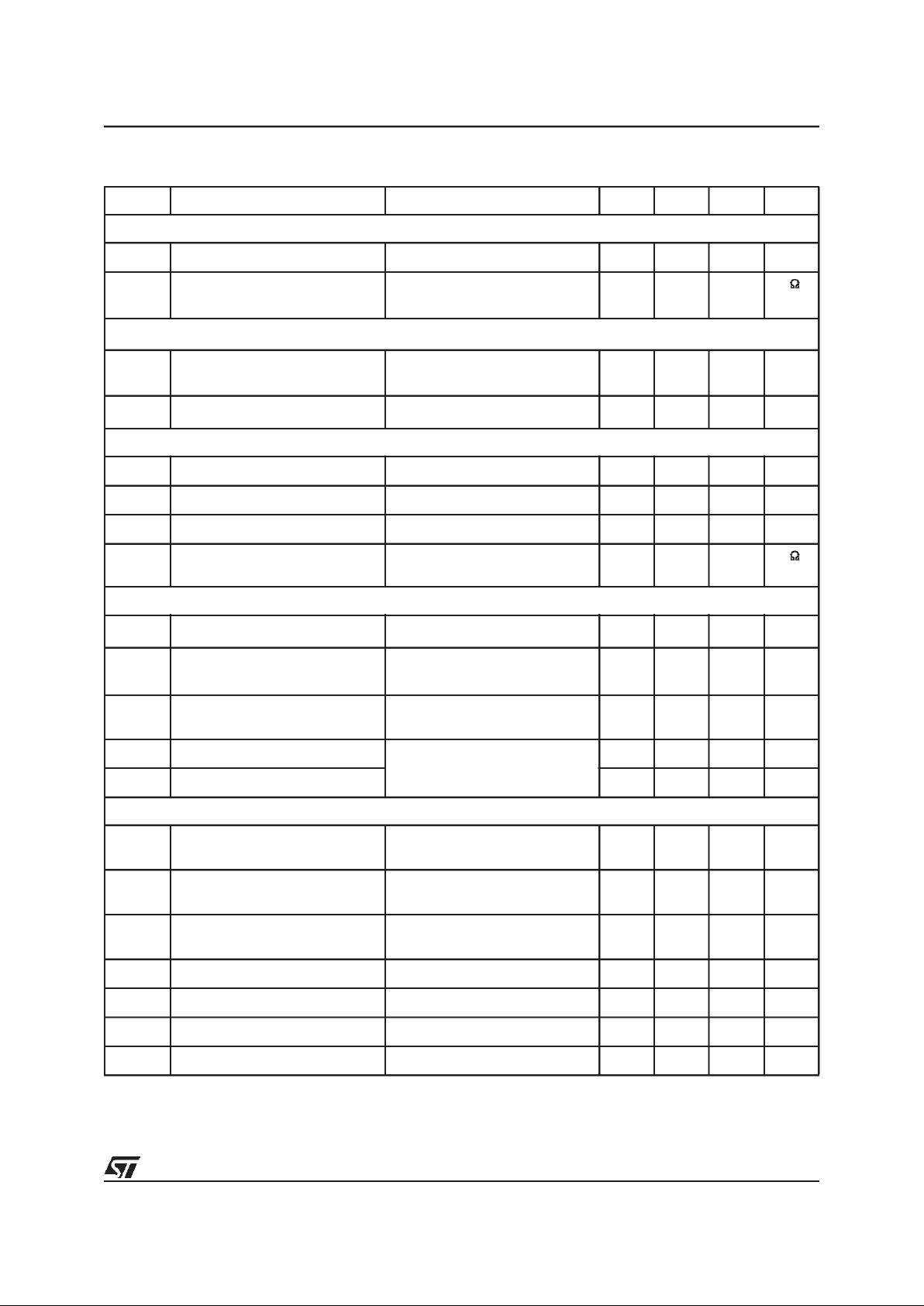

ABSOLUTEMAXIMUM RATINGS

For externally applied voltages or currents exceeding these limits damage of the device may occur!

All pins of the IC are protected against ESD. The verification is performed according to MIL883C, human body

model withR=1.5k

Ω, C=100pF and discharge voltage ±2kV, corresponding to a maximum discharge energy of

0.2mJ.

Symbol Parameter Value Unit

V

CB1,VCB2

Bootstrap voltage -0.3 to 40 V

I

CB1,ICB2

Bootstrap current -100 mA

V

CP

Charge pump voltage -0.3 to 40 V

I

CP

Charge pump current -1 mA

V

DIR,VEN

,V

PWM,VTX

Logic input voltage -0.3 to 7 V

I

DIR,IEN

,I

PWM,ITX

Logic input current ±1mA

V

DG,VRX

Logic output voltage -0.3 to 7 V

I

DG,IRX

Logic output current -1 mA

V

GH1,VGH2

Gate driver voltage -0.3 to VSX+10 V

I

GH1,IGH2

Gate driver current -1 mA

V

GL1,VGL2

Gate driver voltage -0.3 to 10 V

I

GL1,IGL2

Gate driver current -10 mA

V

K

K-line voltage -20 to V

S

V

V

PR

Programming input voltage -0.3 to 7 V

I

PR

Programming input current -1 mA

V

S1,VS2

Source/drain voltage -2 to VVS+2 V

I

S1,IS2

Source/drain current -10 mA

V

ST

Output voltage -0.3 to 40 V

I

ST

Step up output current -1 mA

V

VSDC

DC supply voltage -0.3 to 27 V

V

VSP

Pulse supply voltage (T £ 500ms) 40 V

I

VS

DC supply current -10 mA

L9903

4/17

THERMAL DATA

1. see application note 110 for SO packages.

ELECTRICALCHARACTERISTCS (8V < V

VS

< 20V, VEN=HIGH, -40°C≤ T

J

≤ 150°C, unless otherwise spec-

ified. The voltages are refered to GND and currents are assumed positive, when current flows into the pin.

Symbol Parameter Value Unit

T

J

Operating junction temperature -40 to 150 °C

T

JSD

Junction temperature thermal shutdown threshold min 150 °C

T

JSDH

Junction thermal shutdown hysteresis typ 15 °C

R

th j-amb

Thermal resistance junction to ambient

1)

85 °C/W

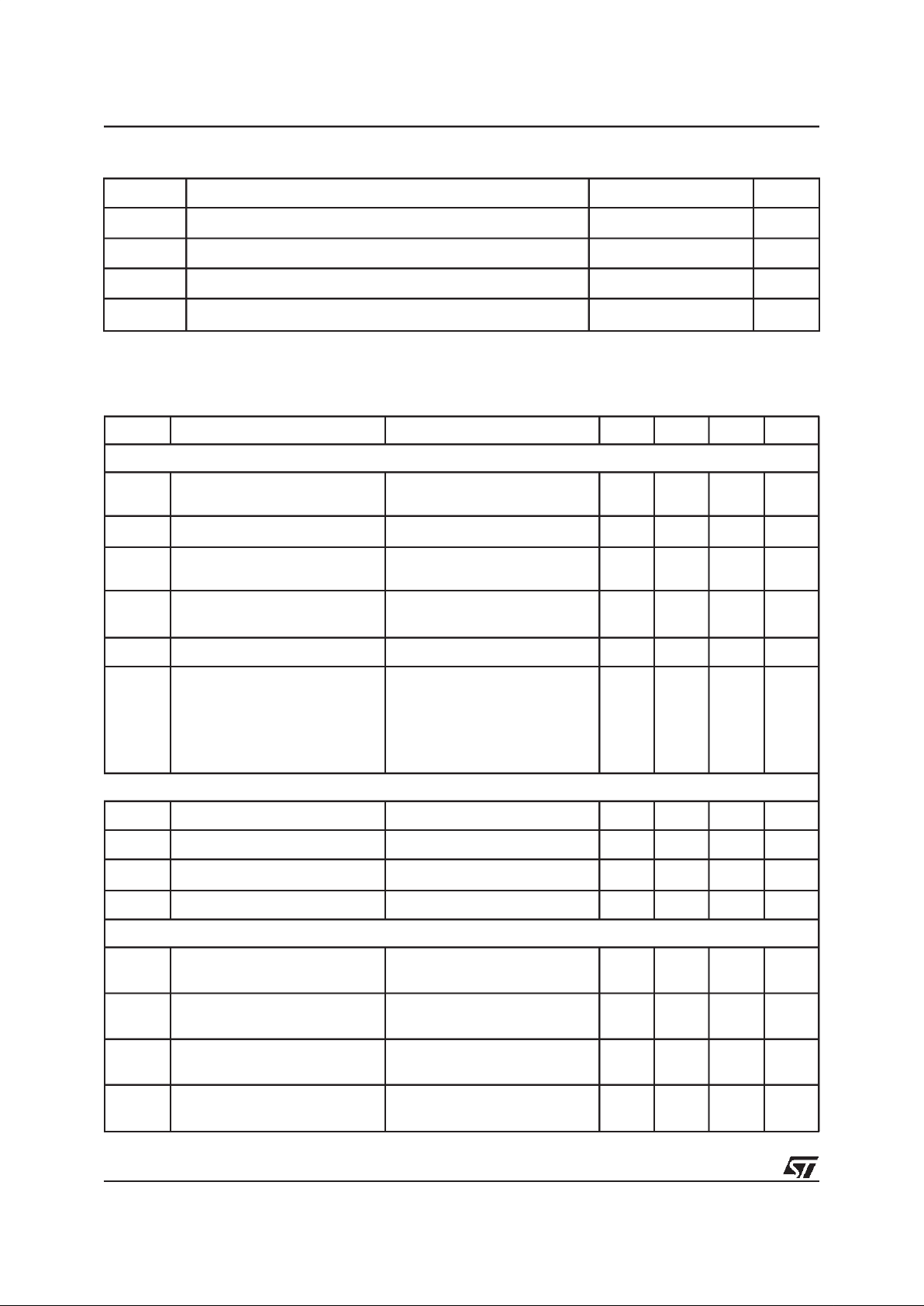

Symbol Parameter Test Conditio n Min. Typ. Max. Unit

Supply (VS)

V

VS OVH

Overvoltage disable HIGH

threshold

20 22 24 V

V

VSOVh

Overvoltagethreshold hysteresis

2)

1.6 V

V

VS UVH

Undervoltage disable HIGH

threshold

67V

V

VS UVh

Undervoltage threshold

hysteresis

2)

0.66 V

I

VSL

Supply current VEN=0;VVS= 13.5V; TJ<85°C50µA

I

VSH

Supply current VVS= 13.5V; VEN= HIGH;

V

DIR

= LOW;

f

PWM

= 20kHz; C

CBX

= 0.1µF;

C

GLX

= 4.7nF; C

GHX

= 4.7nF;

R

PR

=10kΩ;CPR= 150pF

20 mA

Enable input (EN)

V

ENL

Low level 1.5 V

V

ENH

High level 3.5 V

V

ENh

Hysteresis threshold

2)

1V

R

EN

Input pull down resistance VEN=5V 16 50 100 kΩ

H-bridge control inputs (DIR, PWM)

V

DIRL

V

PWML

Input low level 1.5 V

V

DIRH

V

PWMH

Input high level 3.5 V

V

DIRh

V

PWMh

Input threshold hysteresis

2)

1V

R

DIR

R

PWM

Internal pull up resistance

to internal VCC

3)

V

DIR

=0;V

PWM

= 0 16 50 100 kΩ

5/17

L9903

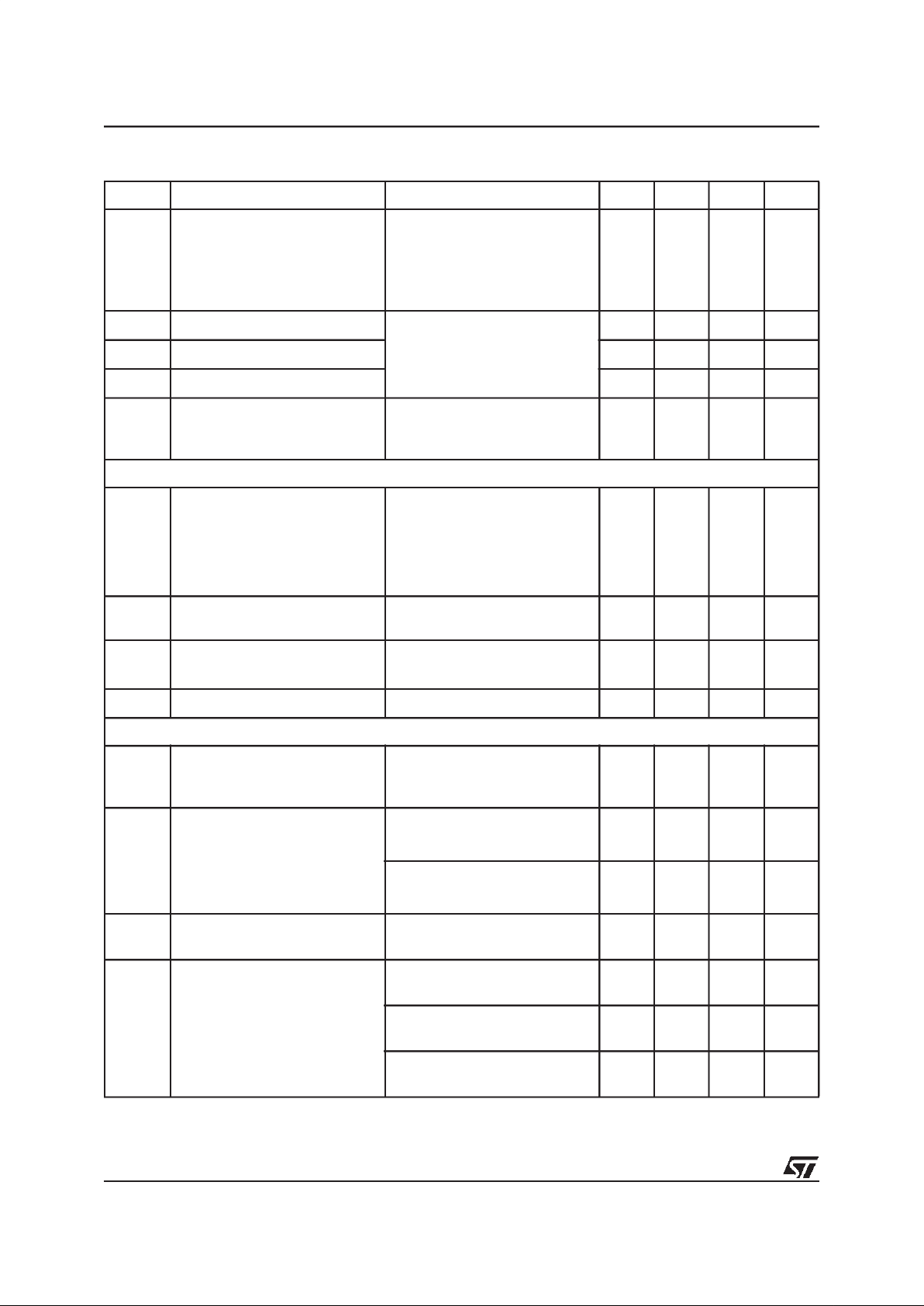

DIAGNOSTIC output (DG)

V

DG

Output drop IDG= 1mA 0.6 V

R

DG

Internal pull up resistance

to internal VCC

3)

VDG=0V 10 20 40 kΩ

Programmable cross conduction protection

4)

N

PR

Threshold voltage ratio V

PRH

/

V

PRL

RPR= 10kΩ

1.8 2 2.2

I

PR

Current capability

V

PR

=2V

-0.5 mA

ISO interface, transmission input(TX)

V

TXL

Input low level 1.5 V

V

TXH

Input high level 3.5 V

V

TXh

Input hysteresis voltage 2) 1 V

R

TX

Internal pull up resistance to

internal VCC 3)

VTX= 0 10 20 40 kΩ

ISO interface, receiver output (RX)

V

RXL

Output voltage high stage

TX = HIGH; I

RX

=0;VK=V

VS

4.5 5.5 V

R

RX

Internal pull up resistance

to internal VCC

3)

TX = HIGH;

V

RX

=0V

51020k

Ω

R

RXON

ON resistance to ground TX = LOW;

I

RX

=1mA

40 90 W

t

RXH

Output high delay time Fig. 1 0.5 µs

t

RXL

Output low delay time 0.5 µs

ISO interface, K-line (K)

V

KL

Input low level -20V 0.45 ·

V

VS

V

KH

Input high level 0.55 ·

V

VS

V

VS

V

Kh

Input hysteresis voltage 2) 0.025·

V

VS

0.8V

I

KH

Input current VTX= HIGH -5 25 µA

R

KON

ON resistance to ground VTX= LOW; IK=10mA 10 30 W

I

KSC

Short circuit current VTX= LOW 40 130 mA

f

K

Transmission frequency 60 100 kHz

2. not tested in production: guaranteed by design and verified in characterization

3. Internal V

VCC

is 4.5V ... 5.5V

4. see page 18 for calculation of programmable cross conduction protection time

Symbol Parameter Test Conditio n Min. Typ. Max. Unit

ELECTRICAL CHARACTERISTICS

(continued)

L9903

6/17

t

Kr

Rise time VVS= 13.5V; Fig. 1

External loads at K-line:

R

K

=510Ωpull up

to V

VS

CK= 2.2nF to GND

26µs

t

Kf

Fall time 26µs

t

KH

Switch high delay time 4 17 µs

t

KL

Switch low delay time 4 17 µs

t

SH

Short circuit detection time VVS= 13.5V;

TX= LOW

V

K

> 0.55 · V

VS

10 40 µs

Charge pump

V

CP

Charge pump voltage VVS=8V

V

VS

= 13.5V

V

VS

= 20V

V

VS

+

7V

V

VS

+

10V

V

VS

+

10V

VVS+

14V

V

VS

+

14V

V

VS

+14V

I

CP

Charging current

V

CP=VVS

+8V

V

VS

= 13.5V -50 -75 µA

t

CP

Charging time

2)

VCP=VVS+8V

V

VS

= 13.5V

C

CP

= 10nF

1.2 4 ms

f

CP

Charge pump frequency VVS= 13.5V 250 500 750 kHz

Drivers for external highside powerMOS

V

CB1

V

CB2

Bootstrap voltage VVS= 8V; I

CBX

=0;VSX=0

V

VS

=13.5V; I

CBX

=0;VSX=0

V

VS

= 20V; I

CBX

=0;VSX=0

7.5

10

10

14

14

14

V

V

V

R

GH1L

R

GH2L

ON-resistance of SINK stage

V

CBX

= 8V; VSX=0

I

GHX

= 50mA; TJ=25°C

10 W

V

CBX

= 8V; VSX=0

I

GHX

= 50mA; TJ=125°C

20 W

R

GH1H

R

GH2H

ON-resistance of SOURCE stage I

GHX

= -50mA; TJ=25°C

I

GHX

= -50mA; TJ= 125°C

10

20

W

W

V

GH1H

V

GH2H

Gate ON voltage (SOURCE) VVS=VSX= 8V;I

GHX

=0;

C

CBX

= 0.1µF

V

VS

+6.5V

V

VS

+14V

V

VS=VSX

= 13.5V; I

GHX

=0;

C

CBX

= 0.1µF

V

VS

+

10V

V

VS

+14V

V

VS=VSX

= 20V; I

GHX

=0;

C

CBX

= 0.1µF

V

VS

+10V

V

VS

+14V

Symbol Parameter Test Conditio n Min. Typ. Max. Unit

ELECTRICAL CHARACTERISTICS

(continued)

7/17

L9903

R

GH1

R

GH2

Gate discharge resistance EN = LOW 10 100 kΩ

R

S1

R

S2

Sink resistance 10 100 kΩ

Drivers for external lowside power MOS

R

GL1L

R

GL2L

ON-resistance of SINK stage I

GLX

= 50mA; TJ=25°C

I

GLX

= 50mA; TJ= 125°C

10

20

W

W

R

GL1H,

R

GL2H

ON-resistance of SOURCE stage I

GLX

= -50mA; TJ=25°C

I

GLX

= -50mA; TJ= 125°C

10

20

W

W

V

GL1H,

V

GL2H

Gate ON voltage (SOURCE) VVS= 8V; I

GLX

=0

V

VS

= 13.5V; I

GLX

=0

V

VS

= 20V; I

GLX

=0

7V

10V

10V

V

VS

V

VS

14V

R

GL1

R

GL2

Gate discharge resistance EN = LOW 10 100 kΩ

2. not tested in production: guaranteed by design and verified in characterization

Timing of thedrivers

t

GH1LH

t

GH2LH

Propagation delay time Fig. 2

V

VS

= 13.5V

V

S1=VS2

=0

C

CBX

= 0.1µF

RPR= 10kW

500 ns

t

GH1LH

t

GH2LH

Propagation delay time including

cross conduction protection time

t

CCP

Fig. 2

V

VS

= 13.5V

V

S1=VS2

=0

C

CBX

= 0.1µF

C

PR

= 150pF;

R

PR

= 10kΩ;

5)

0.7 1 1.3 µs

t

GH1HL

t

GH2HL

Propagation delay time 500 ns

t

GL1LH

t

GL2LH

Propagation delay time Fig. 2

V

VS

= 13.5V

V

S1=VS2

=0

C

CBX

= 0.1µF

R

PR

= 10kΩ

500 ns

t

GL1LH

t

GL2LH

Propagation delay time including

cross conduction protection time

t

CCP

Fig. 2

V

VS

= 13.5V

V

S1=VS2

=0

C

CBX

= 0.1µF

C

PR

= 150pF;

R

PR

= 10kΩ;

5)

0.7 1 1.3 µs

t

GL1HL

t

GL2HL

Propagation delay time 500 ns

Symbol Parameter Test Conditio n Min. Typ. Max. Unit

ELECTRICAL CHARACTERISTICS

(continued)

L9903

8/17

t

GH1r

t

GH2r

Rise time Fig. 2

V

VS

= 13.5V

V

S1=VS2

=0

C

CBX

= 0.1µF

C

GHX

= 4.7nF

C

GLX

= 4.7nF

R

PR

= 10kΩ;

1 µs

t

GH1f

t

GH2f

Fall time 1 µs

t

GL1r

t

GL2r

Rise time 1 µs

t

GL1f

t

GL2f

Fall time 1 µs

Short Circuit Detection

V

S1TH

V

S2TH

Threshold voltage 4 V

t

SCd

Detection time 5 10 15 µs

Step up converter (ST) (5.2V≤ V

VS

< 10V)

V

STH

ST disable HIGHthreshold 10 V

V

STh

ST disable threshold hysteresis

voltage

2)

12V

R

DSON

Open drain ON resistance

V

VS

= 5.2V;

I

ST

=50mA

20

Ω

f

ST

Clock frequency 50 100 149 kHz

2. not tested in production: guaranteed by design and verifiedin characterization

5. tested with differed values in production but guaranteed by design and verified in characterization

Symbol Parameter Test Conditio n Min. Typ. Max. Unit

ELECTRICAL CHARACTERISTICS

(continued)

9/17

L9903

Figure 1. Timing of the ISO-interface

Figure 2. Timing of the drivers for the external MOS regarding the inputs DIR and PWM

t

TX

V

0.3 • V

VCC

0.7 • V

VCC

0.3 • V

VCC

t

V

K

t

t

KL

t

KH

t

Kr

t

Kf

IK>I

KSC

80%

20%

0.55 • V

VS

0.45 • V

VS

V

RX

t

RXL

t

RXH

0.3

• V

VCC

0.7 • V

VCC

ON

OFF

open drain

tra nsi s tor at

K-pin

t

SH

t

t

PWM

or

DIR

GHX

GLX

80%

20%

t

t

GHXHL

t

GHXf

t

GHXr

t

GHXLH

t

GLXHL

t

GLXLH

t

GLXf

t

GLXr

80%

20%

L9903

10/17

Figure 3. I(V) characteristics of the K-Line for TX = HIGH and VVS=13.5V

Figure 4. Driving sequence

-20 -10 0 10 20

VK[V]

-0.5

-0.4

-0.3

-0.2

-0.1

0.0

0.1

0.2

IK [mA]

~

50k

Ω

~

5

0k

Ω

EN

DIR

PWM

braking

GH1

GL1

GH2

GL2

Note:

Before standby mode

(EN = low) a braking phase

is mandatory to discharge

the stored energy of the

motor.

11/17

L9903

Figure 5. Charging time of an external capacitor of 10nF connected to CP pin at VVS=8V and

VVS=13.5V

Figure 6. Application Circuit Diagram

01234

time [ms]

0

5

10

15

20

25

30

voltage [V]

Charging time of a 10nF load at CP

CP for VS=13.5V

CP for VS=8V

EN

D1

µC

GND

K-Line

C1

R

R

R

R

Voltage

Regulator

V

BAT

C

S2

C

S1

R

PR

C

PR

C

B1

B2

C

V

CC

M

VS

DIR

PWM

EN

RX

TX

CP

CB1

GH1

S1

GL1

CB2

GH2

S2

GL2

K

=

PR

VCC

=

=

ISO-Interface

VCC

GND

ST

Reference

BIAS

Charge

pump

Control Logic

Overvoltage

Undervoltage

PWM

R

DIR

R

RX

R

TX

R

0.5 • V

VS

R

S2

R

GL2

R

GL1

R

S1

R

CP

R

EN

VCC

Timer

I

KH

V

S2TH

Thermals hutdown

V

S1TH

DG

VCC

R

DG

V

STH

f

ST

=

+

10

1

2

4

5

3

6

7

8

20

9

16

15

17

18

19

14

12

13

11

R

1

Gate

Protection

L9903

12/17

FUNCTIONAL DESCRIPTION

General

The L9903 integrated circuit (IC)is designed to control four external N-channel MOStransistors in H-Bridge configuration for DC-motordrivinginautomotive applications. It includes an ISO9141 compatible interface. A typical

application is shown in fig.6.

Voltagesupply

The IC is supplied via an external reverse battery protection diode tothe VVSpin. The typical operating voltage

range is down to 8V.

Extendedsupply voltage range (ST)

The operating battery voltage range can be extended down to 6V using the additional components shown in

fig.7. A small inductor of L~150µH(I

peak

~500mA) in series to the battery supply builts up a step up converter

with the switching open drain output ST. The switching frequency is typical 100kHz with a fixed duty cycle of

50%. The step up converter startsbelow V

VS

< 8V, increases the supply voltage at the VS pin and switches off

at V

VS

> 10V to avoid EME at nominal battery voltage. The diode D2 in series with the ST pin is necessary only

for systems with negative battery voltage. No additional load can be driven by the step up converter.

Figure 7.

V

BAT

L1 D1

D2

C1 C2

VS

ST

V

STH

f

ST

=

-

+

L9903

13/17

L9903

FUNCTIONAL DESCRIPTION

(continued)

Controlinputs(EN, DIR, PWM)

The cmos level inputs drive the device as shown in fig.4 and described in the truth table.

The device is activated with enable input HIGH signal. For enable input floating (not connected) or VEN=0V the

device is in standby mode.When activating the device a wake-up time of 50µs is recommended to stabilize the

internal supplies.

The DIR and PWM inputs control the driver of the external H-Bridge transistors. The motor direction can be

choosen with the DIR input, the duty cycle and frequency with the PWM input. Unconnected inputs are defined

by internal pull up resistors. During wake-up and braking and before disactivating the IC via enable both inputs

should be driven HIGH.

Truth table:

Symbols: x Don’t care R:Resistive output TS:Thermal shutdown

0: Logic LOW or not active L: Output in sink condition OV:Overvoltage

1: Logic HIGH or active H: Output in source condition UV:Undervoltage

T: Tristate SC:Short Circuit

6. Only those external MOS transistors of the H-Bridge which are in short circuit condition are switchedoff. Allothers remain driven

by DIR and PWM.

Thermalshutdown

When the junctiontemperature exceeds T

JSD

all driver are switched in sink condition (L), the K- output is off and

the diagnostic DG is LOW until the junction temperature drops below T

JSD-TJHYST

.

OvervoltageShutdown

When the supply voltage VVSexceeds the overvoltage threshold V

VSOVH

all driver are switched in sink condi-

tion (L), the K- output is off and the diagnostic DG is LOW.

Status Controlinputs Device status

Driver stage for external

power MOS

Diagnostic Comment

EN DIR

PWM TS OV UV SC GH1 GL1 GH2 GL2 DG

1 0xxxxxxRRRR T standby mode

2 1xx1000LLLL L thermal

shutdown

3 1xx0100LLLL L overvoltage

4 1xx0010LLLL L undervoltage

5 1xx0001

X

6)

X

6)

X

6)

X

6

L

short circuit

6)

6 1000000LHHL H

7 1x10000HLHL H braking mode

8 1100000HLLH H

L9903

14/17

FUNCTIONAL DESCRIPTION

(continued)

Undervoltage Shutdown

For supply voltages below the undervoltage disable threshold the gate driver remains in sink condition (L) and

the diagnostic DG is low.

Short CircuitDetection

The output voltage at the S1 and S2 pin of the H-Bridge is monitoredbycomparators to detect shorts to ground

or battery. The activated external highside MOS transistor will be switched offifthe voltage drop remains below

the comparator threshold voltage V

S1TH

and V

S2TH

for longer than the short current detection time t

SCd

. The

transistor remains in off condition, the diagnostic output goes LOW until the DIR or PWM input status will be

changed. The status doesn’t change for the other MOS transistors. The external lowside MOS transistor will be

switched off if the voltage drop passes over the comparator threshold voltage V

S1TH

and V

S2TH

for longer than

the short current detection time t

SCd

. The transistor remains in off condition, the diagnostic output goes LOW

until the DIR or PWM input status will be changed. The status doesn’t change for the other MOS transistors.

Diagnostic Output (DG)

The diagnostic output provides a realtime error detection, if monitors the following error stacks: Thermal shutdown, overvoltage shutdown , undervoltage shutdown and short circuit shutdown. The open drain output with

internal pull up resistor is LOW if an error is occuring.

Bootstrapcapacitor (CB1,CB2)

To ensure, that the external power MOS transistors reach the required R

DSON

, a minimum gate source voltage

of 5V for logic level and 10V for standard power MOS transistors has tobeguaranteed. The highside transistors

require a gate voltage higher than the supply voltage. This is achieved with the internal chargepump circuit in

combination withthe bootstrap capacitor. The bootstrap capacitor ischarged, when the highside MOStransistor

is OFF and the lowside is ON. When the lowside is switched OFF, the charged bootstrap capacitor is able to

supply the gate driver of the highside power MOS transistor. For effective charging the values of the bootstrap

capacitors should be largerthan the gate-source capacitance of the power MOS and respect the required PWM

ratio.

Chargepump circuit (CP)

The reversebattery protection can be obtained with an external N-channel MOS transistor as shown infig.6. In

this case its drain-bulk diode provides the protection. The output CP is intended to drive the gate of this transistor above the battery voltage to switch on the MOS and to bypass the drain-bulk diode with the R

DSON

.The

CP has a connection to VS through an internal diode and a 20k

Ω resistor.

Gate drivers for the external N-channel power MOS transistors(GH1, GH2, GL1, GL2)

High level at EN activates the driver of the external MOS under control of the DIR and PWM inputs (see truth

table and driving sequence fig.4). The external power MOS gates are connected via series resistors to the device to reduce electro magnetic emission (EME) of the system. The resistors influence the switching behaviour.

They have to be choosen carefully. Too large resistors enlarge the charging and discharging time of the power

MOS gate and can generate cross current in the halfbridges. The driver assures a longer switching delay time

from source to sink stage in order to prevent the cross conduction.

The gate source voltage is limited to 14V. The charge/discharge current is limited by the R

DSON

of the driver.

The drivers are not protected against shorts.

15/17

L9903

FUNCTIONAL DESCRIPTION (continued)

Programmablecross conductionprotection

The external power MOS transistors in H-Bridge ( two half bridges) configuration are switched on with an additional delay time t

CCP

to prevent cross conduction in the halfbridge. The cross conduction protection time

t

CCP

isdetermined by the external capacitorCPRandresistor RPRat the PR pin. The capacitor CPRis charged

up to the voltage limitV

PRH

. A level change on the control inputs DIR and PWM switches off the concerned ex-

ternal MOS transistor and the charging source at the PR pin. The resistor R

PR

discharges the capacitor CPR.

The concerned external power MOS transistor will be switched on again when the voltage at PR reaches the

value of V

PRL

. After that the CPR will be charged again. The capacitor CPRshould be choosen between 100pF

and 1nF. The resistor R

PR

should be higher than 7kW. The delay time can be expressed as follows:

t

CCP=RPR·CPR

·lnN

PR

with NPR=V

PRH/VPRL

=2

t

CCP

= 0.69 · RPR·C

PR

ISO-Interface

The ISO-Interface provides the communication between the micro controller and a serial bus with a baud rate

up to 60kbit/s viaa single wire whichis V

BAT

and GND compatible. The logic level transmission input TX drives

the open drain K-output. The K output can be connected to a serial bus with a pull up resistor to V

BAT

. The K-

pin is protected against overvoltage, short to GND and VS and can be driven beyond V

VS

and GND. During lack

of V

VS

or GND the output shows high impedance characteristic. Theopen drain output RX with an internal pull

up resistor monitors the status at the K-pin to read the received data and control the transmitted data. Short

circuit condition at K-pin is recognized if the internal open drain transistor isn’t able to pull the voltage potential

at K-pin below the threshold of 0.45·VVS. Then the RX stays in high condition. A timer starts and switches the

open drain transistor after typ. 20µs off. A next low at the TX input resets the timerand the open drain transistor

switches on again.

Figure 8. Functional schematic of the ISO-interface

RX

TX

K

V

CC

R

RX

0.5

•V

VS

TX

R

T

SH

delay

=

R

S

Q

R

I

KH

L9903

16/17

110

1120

A

e

B

D

E

L

K

H

A1

C

SO20MEC

hx45°

SO20

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A 2.35 2.65 0.093 0.104

A1 0.1 0.3 0.004 0.012

B 0.33 0.51 0.013 0.020

C 0.23 0.32 0.009

0.013

D 12.6 13 0.496 0.512

E 7.4 7.6 0.291 0.299

e 1.27 0.050

H 10 10.65 0.394 0.419

h 0.25 0.75 0.010 0.030

L 0.4 1.27 0.016 0.050

K0°(min.)8°(max.)

OUTLINE AND

MECHANICAL DATA

Information furnished isbelieved to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of useof suchinformation nor for any infringement of patents or otherrightsofthird parties whichmay result from its use.No license is granted

by implicationor otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

2000 STMicroelectronics - All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India- Italy - Japan - Malaysia -Malta- Morocco - Singapore - Spain

- Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

17/17

L9903

Loading...

Loading...