L9825

1

2

3

4

5

6

7

8

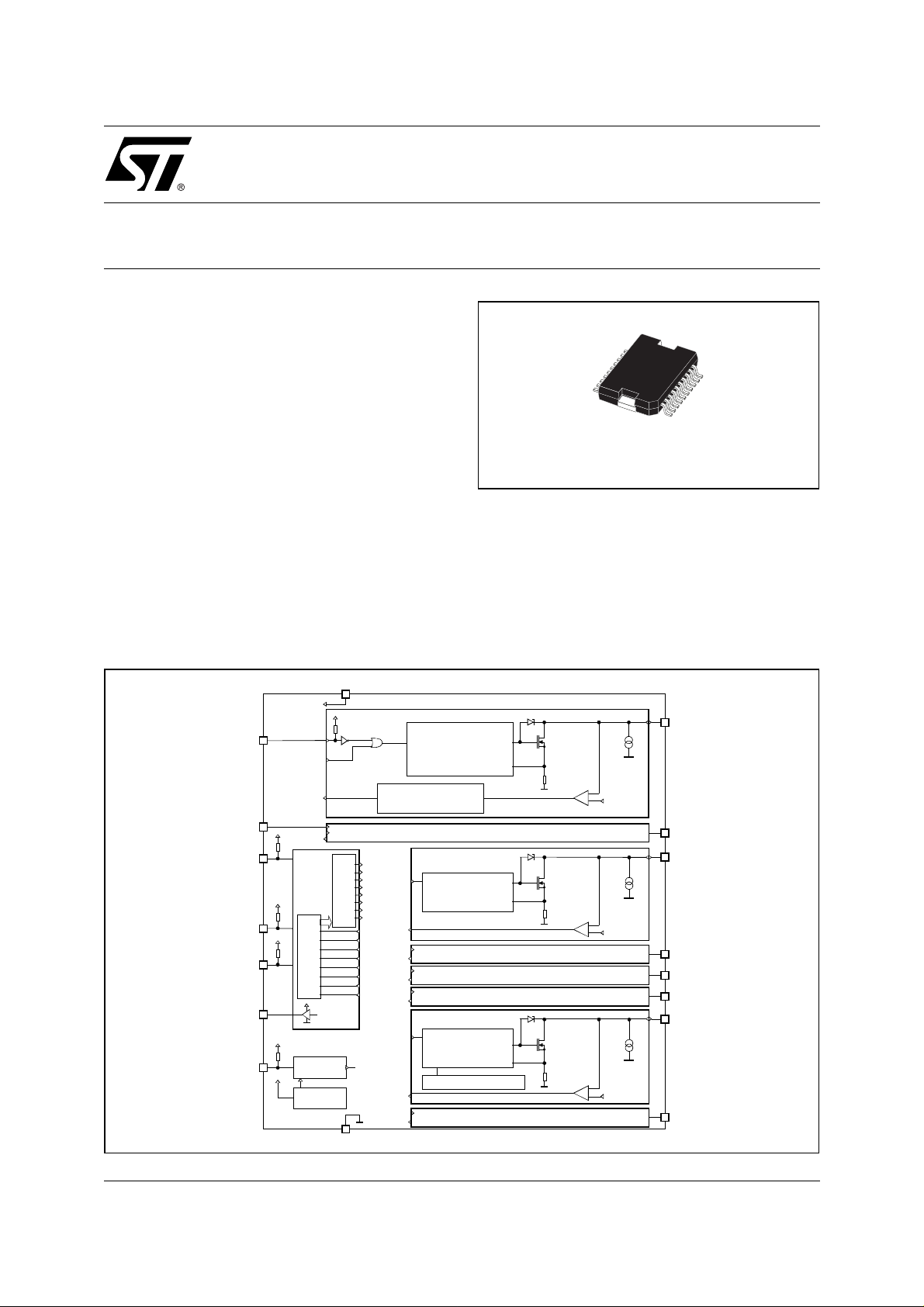

Octal Low-side Driver For Resistive and Inductive Loads With

Serial / Parallel Input Control, Output Protection and Diagnostic

PRODUCT PREVIEW

■

OUTPUTS CURRENT CAPABILITY UP TO

1A, R

■

PARALLEL CONTROL INPUTS FOR

OUTPUTS 1 AND 2

■

SPI CONTROL FOR OUTPUTS 1 TO 8

■

RESET FUNCTION WITH RESET SIGNAL AT

NRES PIN OR UNDERVOLTAGE AT V

■

INTRINSIC OUTPUT VOLTAGE CLAMPING

AT TYP. 50V

■

OVERCURRENT SHUTDOWN AT OUTPUTS

1 TO 6

■

SHORT CIRCUIT CURRENT LIMITATION

AND SELECTIVE THERMAL SHUTDOWN AT

OUTPUTS 7 AND 8

■

OUTPUT STATUS DATA AVAILA BLE ON THE

SPI

≤ 0,75Ω AT TJ = 25°C

ON

CC

PowerSO20

ORDERING NUMBER: L9825

DESCRIPTION

L9825 is a Octal Low-Side Driver Circuit, dedicated

for automotive applications. Output voltage clamping

is provided for flyback current recirculation, when inductive loads are driven. Chip Select and Serial Peripheral Interface for outputs control and diagnostic

data transfer. Parallel Control inputs for two outputs.

BLOCK DIAGRAM

V

CC

V

CC

NON1

Q1

Diag1

NON2

V

Q2

CC

V

CC

V

CC

V

CC

V

CC

Diag2

SPI

Shift Register

V

CC

Reset

Undervoltage

RESET

NCS

CLK

SDI

SDO

nRES

July 2001

This is preliminary information on a new product now in development. Details are subject to change without notice.

Interface

Outp ut Latc h

GND

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Q8

Diag1

Diag2

Diag3

Diag4

Diag5

Diag6

Diag7

Diag8

Reset

1

2

3

S

Latch / Driver

Fault Latch

S

Q3

Diag3

Q4

Diag4

Q5

Diag5

Q6

Diag6

S

Q7

Current Control

Overtemperature Detection

Diag7

Q8

Diag8

Latch / Driver

Latch / Driver

R

R

+

-

V

DG

CH1

CH2

R

+

-

V

DG

CH3

CH4

CH5

CH6

+

-

V

DG

CH7

CH8

OUT

I

OL

OUT

OUT

I

OL

OUT

OUT

OUT

OUT

I

OL

OUT

1/11

L9825

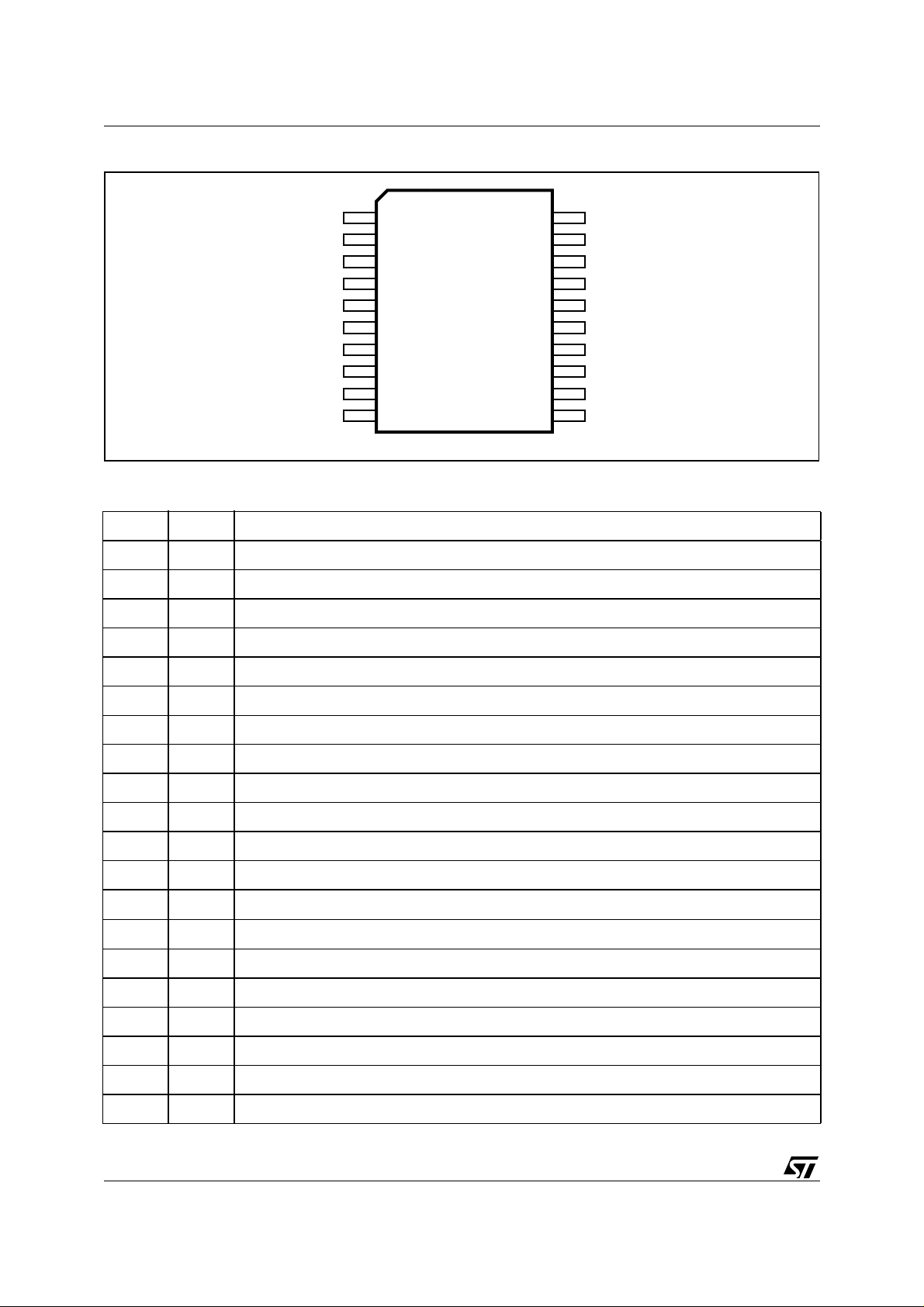

PIN CONNECTION

(Top view)

GND GND

NON1 NCS

SDO

OUT1

OUT3

OUT5

OUT7

SDI

CLK

GND

1

2

3

4

5

6

7

8

9

POWSO20

PIN DESCRIPTION

N° Pin Function

1 GND device ground

2 NON1 control input 1

3 SDO ser ial data outpu t

20

19

18

17

16

15

14

13

12

11

nRes

OUT8

OUT6

OUT4

OUT2

Vcc

NON2

GND10

4 Out 1 output 1

5 Out 3 output 3

6 Out 5 output 5

7 Out 7 output 7

8 SDI serial data input

9 CLK serial clock

10 GND device ground

11 GND device ground

12 NON2 control input 2

13 V

CC

supply voltage

14 Out 2 output 2

15 Out 4 output 4

16 Out 6 output 6

17 Out 8 output 8

18 nR es asynchronous nRes

19 NCS chip select (active low)

20 GND device ground

2/11

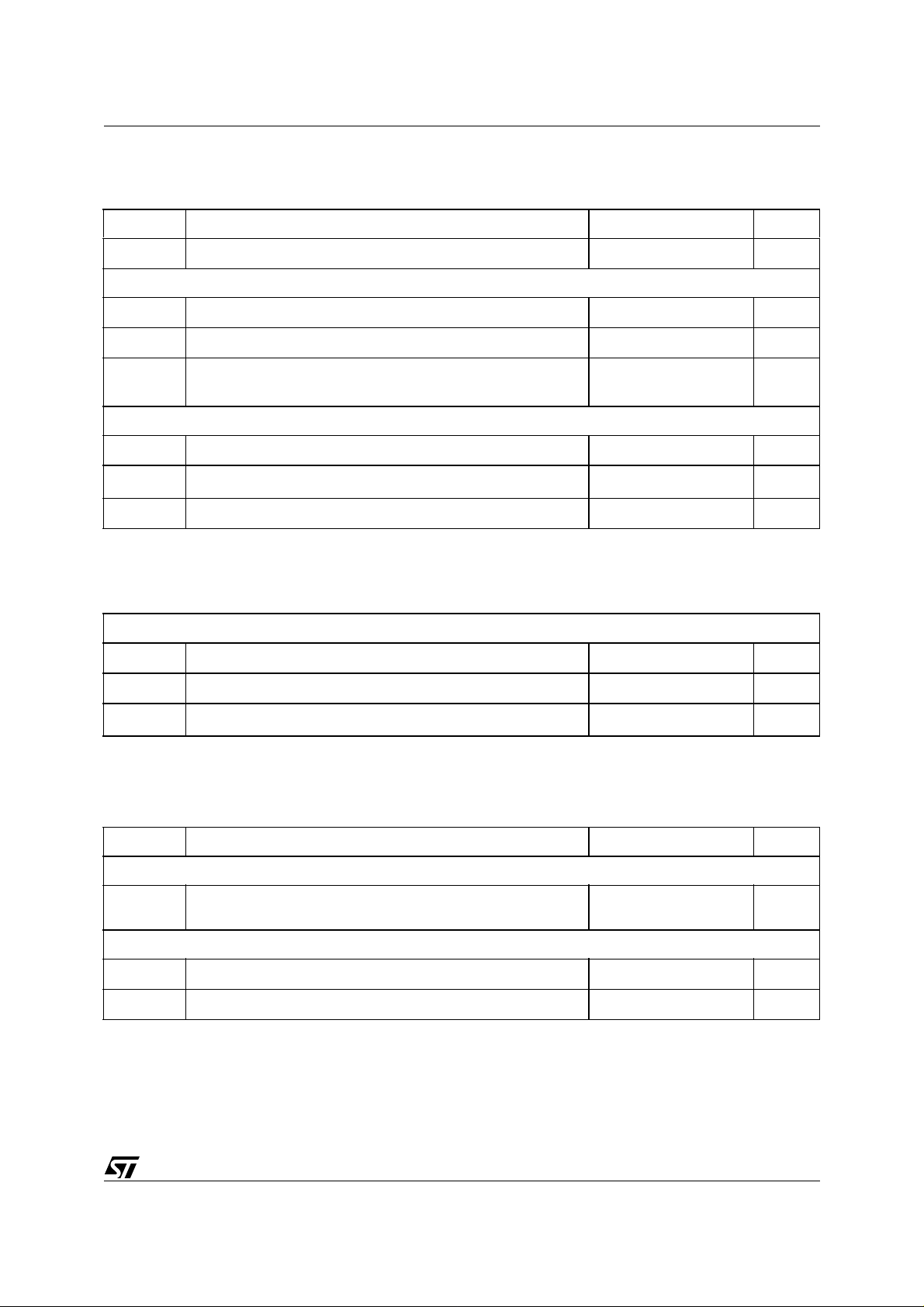

ABSOLUTE MAXIMUM RATINGS

For voltages and currents applied externally to the device:

Symbol Parameter Value Unit

L9825

V

CC

Inputs and data lines

V

IN

V

IN

I

IN

Supply voltage -0.3 to 7 V

(NONx, NCS, CLK, SDI, nRes)

Voltage (NONx, NCS, CLK, SDI) -0.3 to 7 V

Voltage (nRes) -0.3 to 7 V

Protection diodes current

1)

-20 to 20 mA

(T ≤ 1ms)

Outputs

Notes: 1. All inputs ar e protected against ESD according to MI L 883C; tested wi t h HBM at 2KV. It c orresponds to a dissipate d energy

(Out1 ... Out8)

V

I

E

OUTcl

OUTc

OUT

Continuous output voltage -1.0 to 45 V

Output current

Output clamp energy (I

E ≤ 0,2mJ.

2. Transient pul ses in accordance to DIN40839 part 1, 3 and ISO 7637 Pa rt 1, 3.

2)

≤ 0.5A) 20 mJ

OUT

-3 to 2.05 A

For currents determined within the device:

Outputs (Out1 ... Out8)

I

OUT

I

OUT

Output current (Out1 ... Out6) 2.05 A

Output current (Out7, Out8) 1.75 A

Total average-current all outputs

3. When oper ating the devi ce with short circuit at mor e than 2 outputs at the same tim e, damage due to electrical overstress m ay

occur.

3)

4.5 (Min.) A

THERMAL DATA

Symbol Parameter Value Unit

Thermal shutdown

T

JSC

Thermal resistance

R

thjc-one

R

thjc-all

Thermal shutdown threshold Min.

Typ.

150

165

Single output (junction case) Max. 13 °C/W

All outputs (junction case) Max. 1.6 °C/W

°C

°C

3/11

L9825

ELECTRICAL CHARACTERISTCS

(4.5V ≤ VCC ≤ 5.5V; -40°C ≤ TJ ≤ 150°C; unless otherwise specified)

Symbol Parameter Test Condition Min. Typ. Max. Unit

Supply voltage

I

ccSTB

I

ccOPM

∆I

Standby current without load 5 mA

Operating mode I

during reverse output

∆I

CC

CC

current

Inputs

(NONx. NCS, CLK, SDI, nRes)

V

V

V

R

C

Low level -0.3

INL

High level

INH

Hysteresis voltage 0.85 V

hyst

I

Input current VIN = V

IN

Pullup resistance 50 250 kΩ

IN

Input capacitanc e 10 pF

IN

Serial data outputs

V

SDOH

V

SDOL

I

SDOL

C

High output level I

Low output level I

Tristate leakage current NCS = high; 0V ≤ V

Output capacitance f

SDO

Outputs OUT 1 ... 8

OUT1 ... 8

= 500mA

5mA

SPI - CLK = 3MHz

NCS = LOW

SDO no load

I

= -3A 100 mA

out

0.2·V

CC

0.7·V

CC

CC

= -4mA

SDO

= 3,2mA 0.4 V

SDO

≤ V

SDO

= 300kHz 10 pF

SDO

CC

VCC -0.4

-10 10 µA

VCC+0.3

10 µA

V

V

V

I

OUTL1 - 8

I

OUTL1 - 8

I

OUTL1 - 8

V

R

DSon

C

Leakage current OUTx = OFF; V

Leakage current OUTx = OFF; V

Leakage current OUTx = OFF; V

Output clamp voltage 1mA ≤ I

clp

On resistance OUT 1 ... 8 I

Output capacitance V

OUT

Outputs short circuit protection

I

SBC

I

t

SCB

Overcurrent shutoff threshold OUT1 ... OUT6 1.05 1.4 2.05 A

Short circuit current limitation OUT7; OUT8 1.05 1.4 1.75 A

LIM

Delay shutdown for output 1 ... 6; I

4/11

= 25V; VCC =

OUTx

100 µA

5V

= 16V; VCC =

OUTx

100 µA

5V

= 16V; VCC =

OUTx

10 µA

1V

≤ I

; I

clp

outp

= 10mA

test

45 60 V

with correlation

= 500mA; Tj = +150°C 1.5 W

OUT

= 16V; f = 1MHz 300 pF

OUT

OUT

≤ 1/2 I

SBC

0.2 3 12 µs

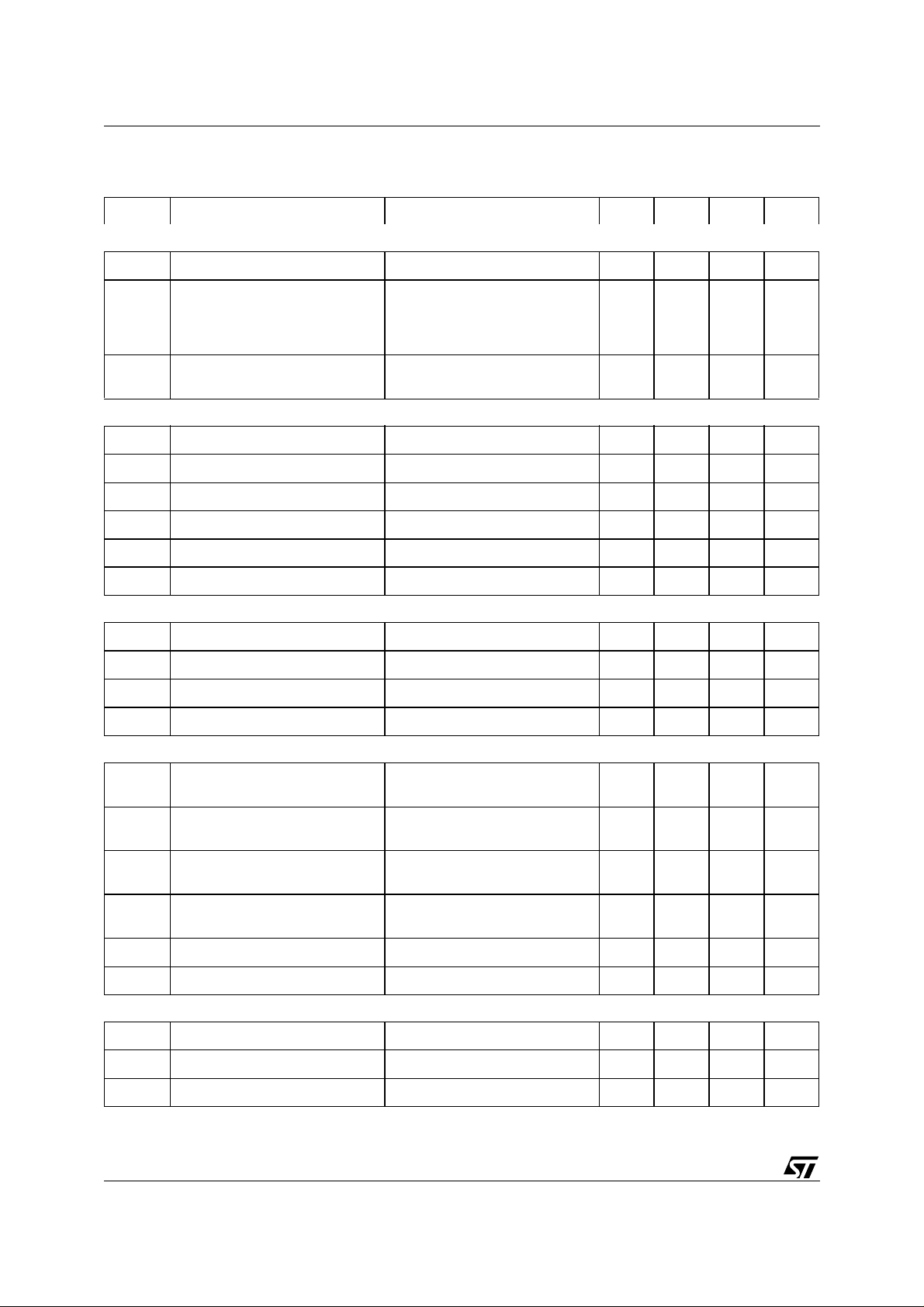

L9825

ELECTRICAL CHARACTERISTCS

≤

(4.5V

VCC ≤ 5.5V; -40°C ≤ TJ ≤ 150°C; unless otherwise specified)

(continued)

Symbol Parameter Test Condition Min. Typ. Max. Unit

Diagnostics

V

I

Diagnostic threshold voltage

DG

Open load detection sink current V

OL

t

Diagnostic detection filter time for

df

out

= V

DG

0.32·V

CC

0.4·V

CC

20 100 µA

15 50 µs

output 1 & 2 on each diagnostic

condition

Outputs timing

t

don1

t

don2

t

dUon1/dt

dUon2/dt

dUoff1/dt

dUoff2/dt

Turn ON delay of OUT 1 and 2 NON

Turn ON delay of OUT 3 to 8 NCS = 50% to V

Turn OFF delay of OUT 1 to 8 NCS = 50% to V

doff

Turn ON voltage slew-rate For output 3 to 8; 90% to 30% of

Turn ON voltage slew-rate For output 1 and 2; 90% to 30%

Turn OFF voltage slew-rate For output 1 to 8; 30% to 90% of

Turn OFF voltage slew-rate For output 1 to 8; 30% to 80% of

Serial diagnostic link

NCS = 50% to V

NON

V

of V

V

V

(Load capacitor at SDO = 100pF)

= 50% to V

1, 2

= 50% to V

1, 2

; RL = 500Ω; V

bat

; RL = 500Ω; V

bat

; RL = 500Ω; V

bat

; RL = 500Ω; V

bat

OUT

OUT

OUT

OUT

= 0.9·V

= 0.9·V

= 0.1·V

OUT

= 16V

bat

bat

= 16V

bat

= 0.9 · V

bat

= 0.9·V

bat

bat

bat

= 0.1·V

= 16V

bat

bat

0.7 3.5 V/µs

2 10 V/µs

2 10 V/µs

2 15 V/µs

clp

5µs

10 µs

10 µs

V

f

clk

t

clh

t

cll

t

pcld

t

csdv

t

sclch

t

hclcl

t

scld

t

hcld

t

sclcl

t

hclch

t

pchdz

Clock frequency 50% duty cycle 3 MHz

Minimum time CLK = HIGH 160 ns

Minimum time CLK = LOW 160 ns

Propagation delay

4.9V ≤ VCC ≤ 5.1V 100 ns

CLK to data at SDO valid

NCS = LOW to data at SDO

100 ns

active

CLK low before NCS low

Setup time CLK to NCS change H/L

100 ns

CLK change L/H after NCS = low 100 ns

SDI input setup time CLK change H/L after SDI data

20 ns

valid

SDI input hold time

SDI data hold after CLK change H/L

20 ns

CLK low before NCS high 150 ns

CLK high after NCS high 150 ns

NCS L/H to output data float 100 ns

NCS pulse filter time Multiple of 8 CLK cycles

5/11

L9825

FUNCTIONAL DESCRIPTION

General

The L9825 integrated circuit features 8 power low-side-driver outputs. Data is transmitted to the device using

the Serial Peripheral Interface, SPI protocol. Outputs 1 and 2 can be controlled parallel or serial. The power

outputs features voltage clamping function for flyback current recirculation and are protected against short circuit to Vbat.

The diagnostics recognizes two outputs fault conditions: 1) ov ercurr ent for outpu ts 1 to 6 , over curr ent and thermal overload for outputs 7 and 8 in switch-on co ndition and 2) open load or short to GND in switch- off condition

for all outputs. The outputs status can be read out via the serial interface.

The chip internal reset is a OR function of the external nRes signal and internally generated undervoltage nRes

signal.

Output Stages Control

Each output is controlled with its latch and with common reset line, which enables all eight outputs. Outputs 1

and 2 can be controlled also by its NON1, NON2 inputs. It allows PWM control independently on the SPI. These

inputs features internal pull-up resistors to assure that the outputs are switched off, when the inputs are open.

The control data are transmitted via the SDI input, the timing of the serial interface is shown in Fig. 1.

The device is selected with low NCS signal and the input data are transferred into the 8 bit shift register at every

falling CLK edge. The rising edge of the NCS latches the new data from the shift register to the drivers.

Figure 1. Timin g of the Serial Interface

NCS

tsclch thclcl tclh tcll tsclcl thclch

CLK

tcsdv tpcld tpchdz

SDO

SDI

not defined D8 D1

tscld

thcld

D8 D7 D1

The SPI register data are transfer red to the output l atch at r ising N CS edge. The digital filter between NCS and

the output latch ensures that the data are transferred only after 8 CLK cycles or multiple of 8 CLK cycles since

the last NCS falling edge. The NCS changes only at low CLK.

Table 1. Outputs Control

Outputs 1, 2: Outputs 3 to 8:

NON1,2 1 0 0 1

SPI-bit 1,2 0 0 1 1 SPI-bit 3...8 0 1

Output 1, 2 off on on on Output 3...8 off on

6/11

L9825

Figure 2.

Output Control register structure

MSB LSB

Q2 Q4 Q6 Q8 Q1 Q3 Q5 Q7

Control-bit output 7

Control-bit output 5

Control-bit output 3

Control-bit output 1

Control-bit output 8

Control-bit output 6

Control-bit output 4

Control-bit output 2

Power outputs characteristics for flyback current, outputs short circuit protection and diagnostics

For output currents flowing into the circuit the output vol tages are limited. The ty pical value of this vo ltage is 50V.

This function allows that the flyback current of a inducti ve load r ecircul ates into the circui t; the flyback energy is

absorbed in the chip.

Output short circuit protection for outputs 1 to 6 (dedicated for loads without inrush current): when the output

current exceeds the short circuit threshold, the corresponding output overload latch is set and the output is

switched off immediately.

Output short circuit protection for outputs 7 and 8 (dedicated for loads with inrush current, as lamps): when the

load current would exceed the short circuit limit value, the corresponding output goes in a current regulation

mode. The output current is determined by the output characteristics and the output voltage depends on the

load resistance. In this mode high power is dissipated in the output transis tor and its temperatur e increases rapidly. When the power transistor temperatur e exceeds the thermal shutdow n threshold, the ov erload latch is set

and the corresponding output switched off.

For the load diagnostic in output off condition each output features a diagnostic current sink, typ 60µA.

Diagnostics

The output voltage at all outputs is compared with the diagnostic threshold, typ 0.38 · V

.

CC

Outputs 1 and 2 features dedicated fault latches. The output status signal is filtered and latched. The fault latches are cleared dur ing NCS low. The latch stores the status bi t, so the first reading after the er ror occ urred might

be wrong. The second reading is right.

Table 2. Diagnostic for outputs 1 and 2

Output 1, 2 Output-voltage Status-bit Output-mode

off > DG-threshold high correct operation

off < DG-threshold low fault condition 2)

on < DG-threshold high correct operation

on > DG-threshold low fault condition 1)

Fault condition 1) "output short circuit to Vbat" : the output was switched on and the voltage at the output exceeded the diagnostics threshold due to overcurrent, the output overload latch was set and the output has been

switched off. The diagnostic bit is low.

7/11

L9825

g

g

g

g

g

g

Fault condition 2) "open load" or "output short circuit to GND" : the output is switched off and the voltage at the

output drops below the diagnostics threshold, because the load current is lower than the output diagnostic current source, the load is interrupted. The diagnostic bit is low.

For outputs 3 to 8 the output status signals, are fed directly to the SPI register.

Table 3. Diagnostic for outputs 3 to 8

Output 3 ... 8 Output-voltage Status-bit Output-mode

off > DG-threshold high correct operation

off < DG-threshold low fault condition 2)

on < DG-threshold high correct operation

on > DG-threshold low fault condition 1)

The fault condition 1) "output short circuit to Vbat" :

For outputs 3 to 6 is the same as of outputs 1 and 2.

For outputs 7 and 8 : the output was switched on and the voltage at the output exceeds the diagnostics thresh-

old. The output operates in current regulation mode or has been switched off due to thermal shutdown. The status bit is low.

Fault condition 2) "open load" or "output short circuit to GND" is the same as of outputs 1 and 2.

At the falling edge of NCS the output status data are transferred to the shift register. When NSC is low, data bits

contained in the shift register are transferred to SDO output et every rising CLK edge.

Figure 3. The Pulse Diagram to Read the Outputs Status Register

NCS

CLK

SDI

SDO

MSB

654321

MSB

654321

Figure 4. The Structure of the Outputs Status Register

MSB LSB

Diag2 Diag4 Diag6 Diag8 Diag1 Diag3 Diag5 Diag7

Dia

Diagnostic-bit output 5

Dia

Dia

Diagnostic-bit output 8

Dia

Dia

Dia

LSB

LSB

nostic-bit output 7

nostic-bit output 3

nostic-bit output 1

nostic-bit output 6

nostic-bit output 4

nostic-bit output 2

8/11

APPLICATION NOT ES

Figure 5. Typical Application Circuit Diagram

L9825

L9825

L9825

For higher current driving capability two outputs of the same kind can be paralleled. In this case the maximum

flyback energy should not exceed the limit value for single output.

The immunity of the circuit with respect to the transients at the output is verified during the characterization for

Test Pulses 1, 2 and 3a, 3b, DIN40839 or ISO7637 part 3. The Test Pulses are coupled to the outputs with

200pF series capacitor. All outputs withstand testpulses without damage.

The correct function of the c ircuit with t he Test Pulses coupled to the outputs is ver ified d uring the ch aracter ization for the typical application wi th R = 16W to 200W, L= 0 to 600mH loads. The Test Pulses are coupled to the

outputs with 200pF series capacitor.

9/11

L9825

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

mm inch

A 3.6 0.142

a1 0.1 0.3 0.004 0.012

a2 3.3 0.130

a3 0 0.1 0.000 0.004

b 0.4 0.53 0.016 0.021

c 0.23 0.32 0.009 0.013

D (1) 15.8 16 0.622 0.630

D1 9.4 9.8 0.370 0.386

E 13.9 14.5 0.547 0.570

e 1.27 0.050

e3 11.43 0.45 0

E1 (1) 10.9 11.1 0.429 0.437

E2 2.9 0.114

E3 5.8 6.2 0.228 0.244

G 0 0.1 0.000 0.004

H 15.5 1 5.9 0.610 0.626

h 1.1 0.043

L 0.8 1.1 0.031 0.043

N 10˚ (max.)

S

8˚ (max.)

T10 0.394

(1) "D and F" do not include mold flash or protrusions.

- Mold flash or protrusions shall not exceed 0.15 mm (0.006").

- Critical dimensions: "E", "G" and "a3"

OUTLINE AND

MECHANICAL DATA

JEDEC MO-166

PowerSO20

E2

h x 45

DETAIL B

BOTTOM VIEW

R

lead

a3

Gage Plane

E

DETAIL B

0.35

S

D1

L

c

a1

DETAIL A

slug

- C -

SEATING PLANE

GC

(COPLANARITY)

E3

NN

a2

A

b

DETAIL A

e3

H

D

T

1

e

1120

E1

10

PSO20MEC

10/11

L9825

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or oth erwise under any patent or patent rights of STMicroel ectronics. S pecificati ons mentioned in this publicati on are subje ct

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems wi t hout express written approval of STMicroelectro nics.

The ST logo is a registered trademark of STMicroelectronics

2001 STMi croelectr oni cs - All Rights Reserved

Australi a - Brazil - Chin a - Finland - France - Germany - Hong Ko ng - India - Italy - Ja pan - Malaysia - Mal ta - Morocco - Sin gapore - Spai n

STMicroelectronics GROUP OF COMPANIES

- Sweden - Sw itzerland - United Kingdom - U.S.A.

http://www.s t. com

11/11

Loading...

Loading...