July 2001 1/103

This is preliminary information on a new product now in development. Details are subject to change without notice.

L9805

Super Smart Power Motor Driver with 8-BIT MCU, CAN Interface, 16K EPROM, 256Bytes RAM,

128 Bytes EEPROM, 10 Bit ADC, WDG , 2 Timers , 2 PWM M odu les, Full H-Bridge Driv er

PROUCT PREVIEW

■

6.4-18V Supply Operating Range

■

16 MHz Maximum Oscillator Frequency

■

8 MHz Maximum Internal Clock Frequency

■

Oscillator Supervisor

■

Fully Static operation

■

-40°C to + 150°C Temperature Range

■

User EPROM/OTP: 16 Kbytes

■

Data RAM: 256 bytes

■

Data EEPROM: 128 bytes

■

64 pin HiQUAD64 package

■

10 multifunctional bidirectional I/O lines

■

Two 16-bit Timers, each featuring:

– 2 Input Captures

– 2 Output Compares

– External Clock input (on Timer 1)

– PWM and Pulse Generator modes

■

Two Programmable 16-bit PWM generator

modules.

■

CAN peripheral including Bus line interface

according 2A/B passive specifications

■

10-bit Analog-to-Digital Converter

■

Software Watchdog for system integrity

■

Master Reset, Power-On Reset, Low Voltage

Reset

■

70mΩ DMOS H-bridge.

■

8-bit Data Manipulation

■

63 basic Instructions and 17 main Addressing

Modes

■

8 x 8 Unsigned Multiply Instruction

■

True Bit Manipulation

■

Complete Development Support on DOS/

WINDOWS

TM

Real-Time Emulator

■

Full Software Package on DOS/WINDOWS

TM

(C-Compiler, Cross-Assembler, Debugger)

HiQUAD-64

ORDERING NUMBER: L9805

1

2/103

Table of Contents

103

L9805

1 GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 OTP, ROM AND EPROM DEVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 PIN OUT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 PIN DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5 REGISTER & MEMORY MAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2 CENTRAL PROCESSING UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2 CPU REGISTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 CLOCKS, RESET, INTERRUPTS & POWER SAVING MODES . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1 CLOCK SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1.1 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1.2 External Clock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 O SCILLATOR SAFEGUARD (DCSR). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.2.1 Dedicated Control Status Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3 W ATCHDOG SYSTEM (WDG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.4 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4 MISCELLANEOUS REGISTER (MISCR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.5 RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5.2 External Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5.3 Reset Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5.4 Power-on Reset - Low Voltage Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.6 INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.7 POWER SAVING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.7.2 Slow Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.7.3 Wait Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.7.4 Halt Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4 VOLTAGE REGULATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.1.1 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2 DIGITAL SECTION POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.1 VDD Short Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3 ANALOG SECTION POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3.1 VCC Short Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5 ON-CHIP PERIPHERALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.1 I/O PORTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.1.2 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.1.3 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.2 16-BIT TIMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3/103

Table of Contents

L9805

5.2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.2.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.2.3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.2.4 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.3 PWM GENERATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.3.2 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.3.3 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.4 PWM I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.4.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.4.2 PWMO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.4.3 PWMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.5 10-BIT A/D CONVERTER (AD10) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.5.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.5.2 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.5.3 Input Selections and Sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.5.4 Interrupt Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.5.5 Temperature Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.5.6 Precise Temperature Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.5.7 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5.6 CONTROLLER AREA NETWORK (CAN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.6.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.6.3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.6.4 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.7 CAN BUS TRANSCEIVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.7.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.7.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.7.3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.7.4 CAN Transceiver Disabling function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

5.8 POWER BRIDGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.8.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.8.2 Main Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.8.3 Functional Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.8.4 Interrupt generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5.8.5 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

5.8.6 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

5.9 EEPROM (EEP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 2

5.9.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

5.9.2 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

5.9.3 Register Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

6 INSTRUCTION SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

6.1 ST7 ADDRESSING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

6.2 INSTRUCTION GROUPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

7 ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

7.1 ABSOLUTE MAXIMUM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

7.2 POWER CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

4/103

L9805

7.3 PACKAGE MECHANICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

7.4 APPLICATION DIAGRAM EXAMPLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

7.5 DC ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

7.6 CONTROL TIMING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

7.7 O PERATING BLOCK ELECTRICAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . 100

5/103

L9805

1 GENERAL DESCRIPTION

1.1 INTRODUCTION

The L9805 is a Super Smart Power device suited

to drive resistive and inductive lo ads under software control. It includes a ST7 microcontroller and

some pheripherals. The microcontroller can execute the software contained in the program

EPROM/ROM and drive, through dedicated registers, the power bridge.

The internal voltage regulators rated to the automotive environment, PWM modules, CAN transceiver and controller, I SO 9141 transceiver, timers, temperature sensor and the AtoD converter

allow the device to realize by itself a complete application, in line with the most common mechatronic requirements.

1.2 OTP, ROM AND EPROM DEVICES

For development pu rposes the device is available

in plastic HiQuad package without window rating

in t he OTP c lass .

Mass production is supported by means of ROM

devices.

Engineering samples could be assembled using

window packages. These are generally referenced

as “EPROM devices”.

EPROM device s are erased by expos ure to high

intensity UV light admitted through the transparent

window. This exposure discharges the floating

gate to its initial state throug h induced photo current.

It is recommended to keep the L9805 device out of

direct sunlight, since the UV content of sunlight

can be sufficient to cause functional failure. Extended exposure to room level fluorescent lighting

may also cause erasure.

An opaque coating (paint, tape, label, etc...)

should be placed over the package window if the

product is to be operated under these lighting conditions. Covering the window also reduces I

DD

in

power-saving modes du e to photo-diode leakage

currents.

An Ultraviolet source of wave length 2537 Å yielding a total integrated dosage of 15 Watt-sec/cm

2

is

required to erase the EPROM. The device will be

erased in 40 to 45minutes if such a UV lamp with a

12mW/cm

2

power rating is placed 1 inch from the

device window without any interposed filters.

OTP and EPROM devices can be programmed by

a dedicated Eprom Programming Board and software that are part of the development tool-set.

6/103

L9805

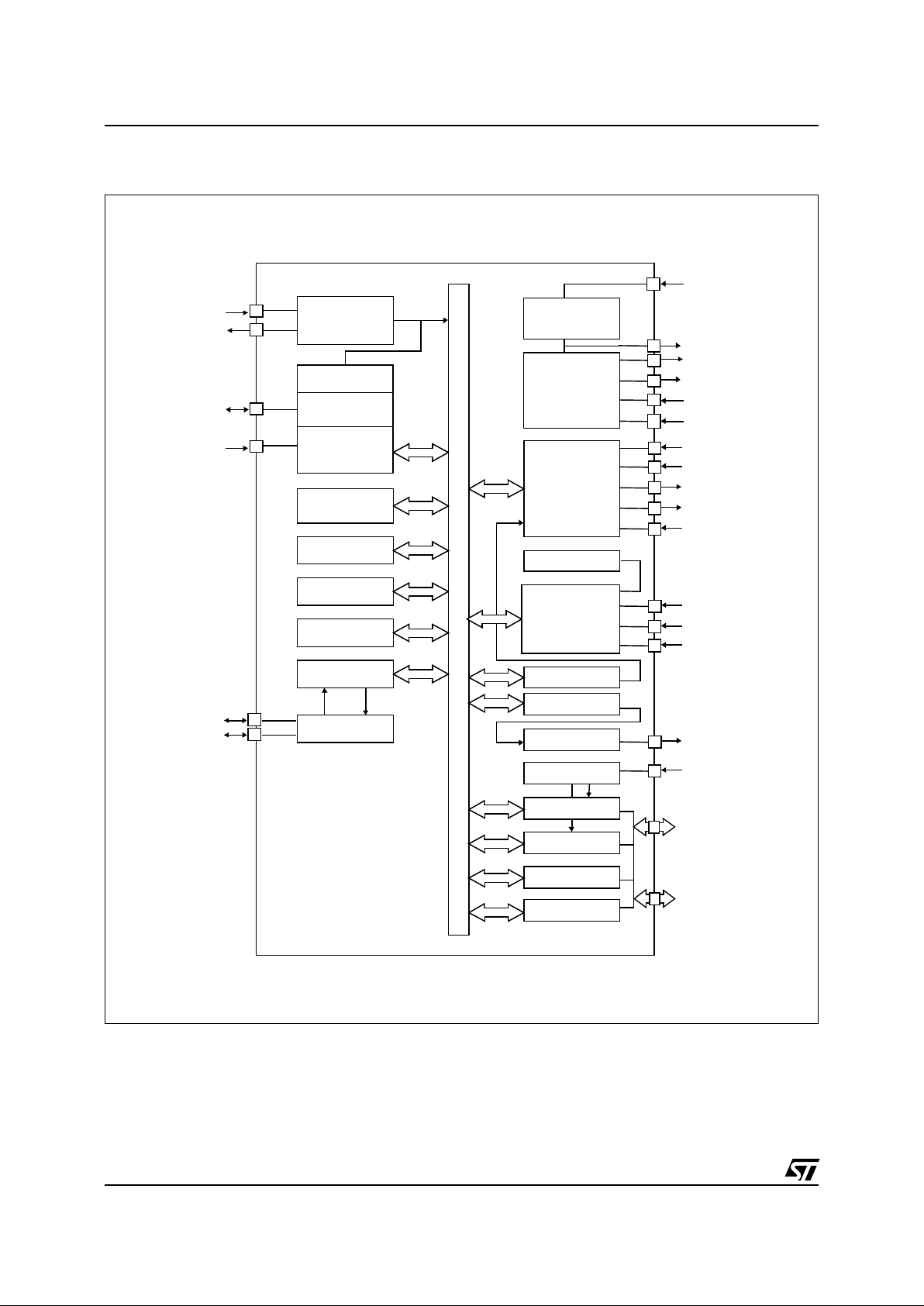

Figure 1. L9805 Block Diagram

8-BIT CORE

ALU

ADDRESS AND DATA BUS

OSCIN

OSCOUT

10-bit ADC

WATCHDOG

OSC

Internal

CLOCK

CONTROL

ROM/O TP/EPR OM

16K

PORT A

PA0 -> PA7

OSC SAFEGUARD

PORT B

PB0 -> PB1

TIMER 1

TIMER 2

PWM 2

PWM 1

PWMI

PWMO

PWMO

AD2

AD3

AD4

RAM 256B

EEPROM 128B

V

CC

V

DD

POWER

SUPPLY

VB2

PREREGULATOR

AGND

GND

NRESET

POWER

BRIDGE

VBR

VBL

PGND

OUTR

OUTL

CAN

CONTROLLER

CAN

TRANSCEIVER

CAN_H

CAN_L

RX TX

TEMP SENSOR

PWMI

VPP/TM

VB1

7/103

L9805

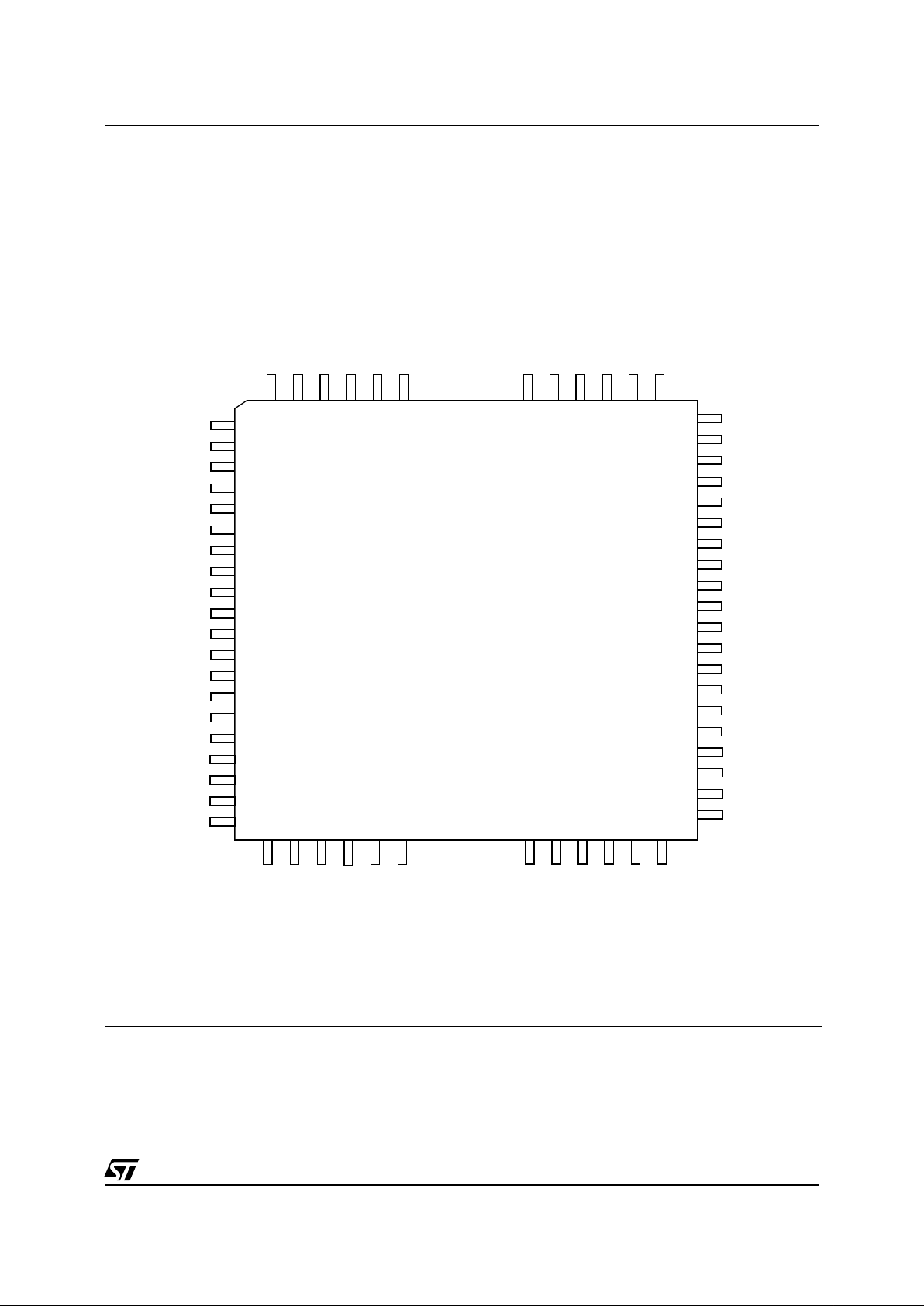

1.3 PIN OUT.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

64 63 62 61 60 59 58 57 56 55 54 53

52

51

50

49

17

18

19

20

21 22 23 24

29 30 31 32

25 26

27 28

NU

NU

NU

AD3

AD2

PA1/OCMP1_1

PA0/OCMP2_1

VPP/TM

VDD

OSCIN

OSCOUT

GND

NU

VBL

VBL

VBL

NU

NU

NU

NU

NU

PB1/EXTCLK_2

NU

NU

PWMO

PWMI

NRESET

CAN_H

CAN_L

GND

VDD

VB2

VB1

VBR

VBR

VBR

NU

NU

NU

NU

NU

NU

OUTL

OUTL

OUTL

PGND

PGND

OUTR

OUTR

OUTRNUNU

VCC

AGND

AD4

PA2/ICAP2_1

PA3/ICAP1_1

PGND

PGND

PA4/EXTCLK_1

PA5/OCMP2_2

PA6/OCMP1_2

PA7/ICAP2_2

PB0/ICAP1_2

8/103

L9805

1.4 PIN DESCRI PTION

AD2-AD4:

Analog input to ADC.

PA0/OCMP2_1-PA1/OCMP1_1:

I/Os or Output

compares on Timer 1.

Alternate function software

selectable (by setting OC2E or OC1 E in CR2 register: bit 6 or 7 at 0031h). When used as an alternate function, this pin is a pus h-pull output as requested by Timer 1. Otherwise, this pin is a triggered floating input or a push-pull output.

PA2/ICAP2_1-PA3/ICAP1_1:

I/

Os or Input cap-

tures on Timer 1.

Before using this I/O as alternate

inputs, they must be configured by software in input mode (DDR=0). In this case, these pins are a

triggered floating input. Otherwise (I/O function),

these pin are triggered floating inputs or push-pull

outputs.

PA4/EXTCLK_1:

PA4 I/O or External Clock on

Timer 1

. Before using this I/O as alternate input, it

must be configured by software in input mode

(DDR=0). In this case, this pin is a triggered floating input. Otherwise (I/O function), this pin is a triggered floating input or a push-pull output.

PA5/OCMP2_2-PA6/OCMP1_2:

I/Os or Output

Compares on Timer 2

. Alternate function software

selectable (by setting OC2E or OC1 E in CR2 register: bit 6 or 7 at 0041h). When used as alt ernate

functions, these pins are push-pull outputs as requested by Timer 2. Otherwise, these pins are triggered floating inputs or push-pull outputs.

PA7/ICAP2_2-PB0/ICAP1_2:

I/Os or Input Cap-

tures on Timer 2

. Before using these I/Os as alternate inputs, they must be configured by softw are

in input mode (DDR=0). In this case, these pins

are triggered floating inputs. Otherwise (I/O function), these pins are triggered floating inputs or

push-pull outputs.

PB1/EXTCLK_2:

PB1 I/O or External Clock on

Timer 2

. Before using this I/O as alternate input, it

must be configured by software in input mode

(DDR=0). In this case, this pin is a triggered floating input. Otherwise (I/O function), this pin is a triggered floating input or a push-pull output.

VPP/TM

: Input. This pin must be held low du ring

normal operating modes.

VDD

: Output. 5V Power supply for digital circuits,

from internal voltage regulator.

OSCIN:

Input Oscillator pin.

OSCOUT

: Output Oscillator pin.

GND:

Ground for digital circuits.

VBR:

Power supply for Right half-bridge.

OUTR:

Output of Left half-bridge.

PGND:

Ground for power transistor.

OUTL:

Output of Right half-bridge.

VBL:

Power supply for Left half-bridge.

VB1

: Power supply for voltage regulators.

VB2

: Pre-regulated voltage for analog circuits.

CAN_L:

Low side CAN bus output.

CAN_H:

High side CAN bus input.

NRESET:

Bidirectional. This active low signal forces the initialization of the MCU. This event is the

top priority non maskable interrupt. It can be us ed

to reset external peripherals.

PWMI:

PWM input.

Directly connected to Input

Capture 2 on Timer 2.

PWMO:

PWM output.

Connected to the output of

PWM2 module.

AGND:

Ground for all analog circuitry (except

power bridge)

.

VCC:

Output. 5V power supply for analog circuits,

from internal voltage regulator.

9/103

L9805

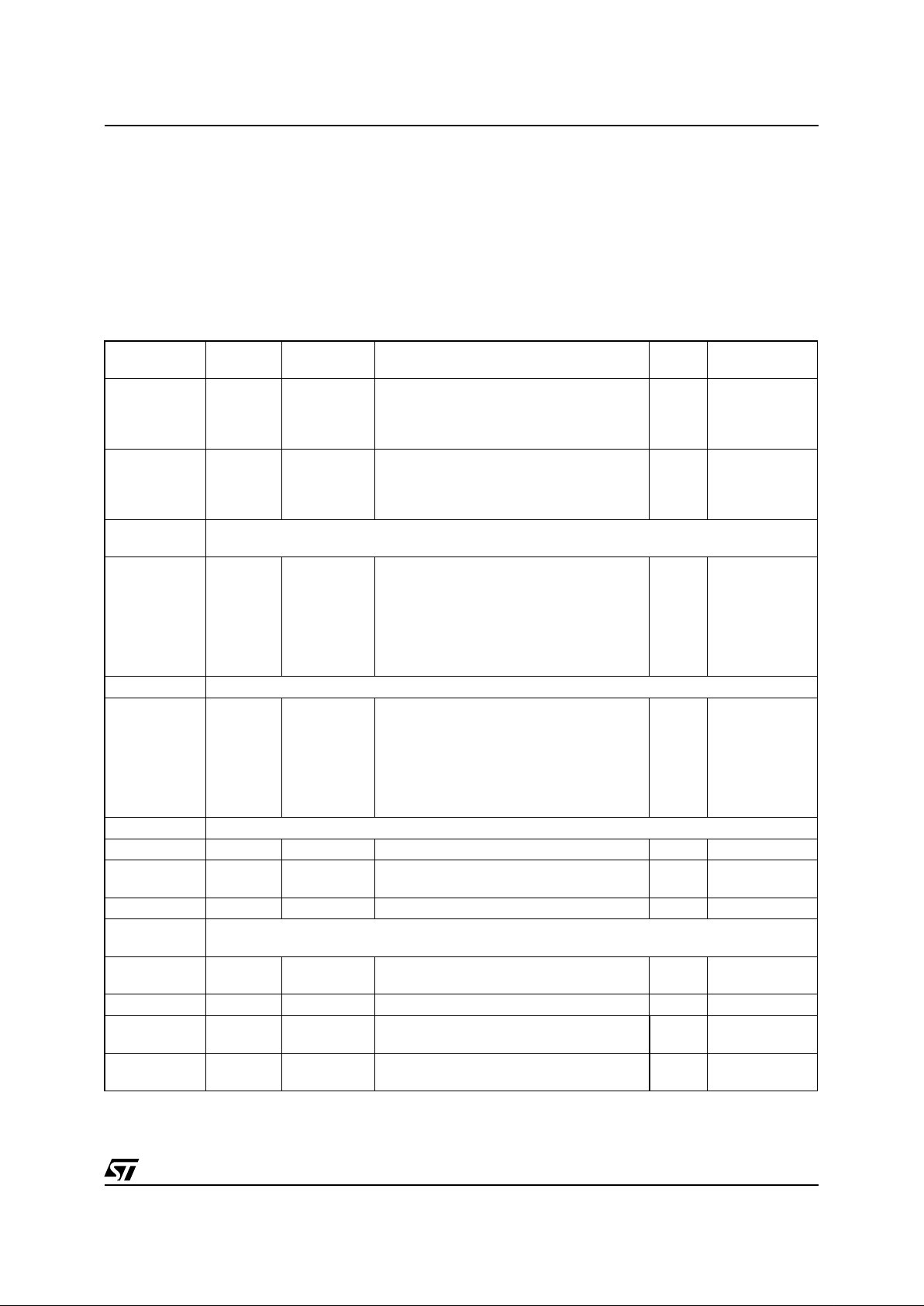

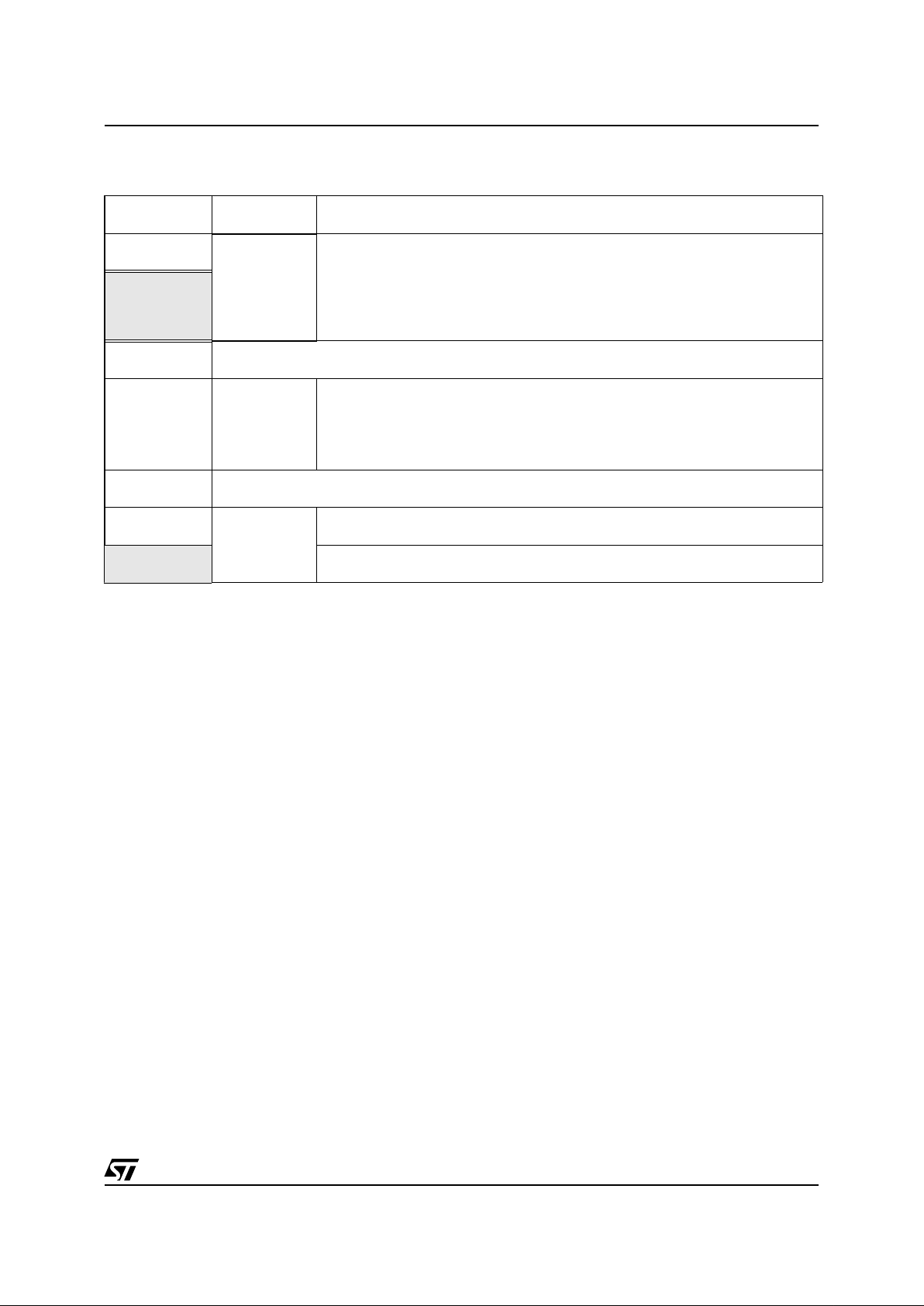

1.5 REGISTER & MEMORY MAP

As shown in the Table 1, the MCU is capable of

addressing 64K bytes of memories and I/O registers. In this MCU, 63742 of these bytes are user

acce ssib le.

The available memory locations consist of 128

bytes of I/O registers, 256 bytes of RAM, 128

bytes of EEPROM and 16Kbytes of user EPROM/

ROM. The RAM space includes 64bytes for the

stack from 0140h to 017Fh.

The highest address by tes contain the user re set

and interrupt vectors.

Table 1. Memory Map

Address Block

Register Label

Register name

Reset

Status

Remarks

0000h

0001h

0002h

0003h

Port A

PADR ..

PADDR ..

PAOR ..

Data Register

Data Direction Register

Option Register

Not Used

00h

00h

00h

R/W

R/W

R/W

Absent

0004h

0005h

0006h

0007h

Port B

PBDR ..

PBDDR ..

PBOR ..

Data Register

Data Direction Register

Option Register

Not Used

00h

00h

00h

R/W

R/W

R/W

Absent

0008h to

000Fh

RESERVED

0010h

0011h

0012h

0013h

0014h

0015h

0016h

PWM1

P1CYRH ..

P1CYRL ..

P1DRH ..

P1DRL ..

P1CR ..

P1CTH ..

P1CTL ..

PWM1 Cycle Register High

PWM1 Cycle Register Low

PWM1 Duty Register High

PWM1 Duty Register Low

PWM1 Control Register

PWM1 Counter Register High

PWM1 Counter Register Low

00h

00h

00h

00h

00h

00h

00h

R/W

R/W

R/W

R/W

R/W

Read Only

Read Only

0017h RESERVED

0018h

0019h

001Ah

001Bh

001Ch

001Dh

001Eh

PWM2

P2CYRH ..

P2CYRL ..

P2DRH ..

P2DRL ..

P2CR ..

P2CTH ..

P2CTL ..

PWM2 Cycle Register High

PWM2 Cycle Register Low

PWM2 Duty Register High

PWM2 Duty Register Low

PWM2 Control Register

PWM2 Counter Register High

PWM2 Counter Register Low

00h

00h

00h

00h

00h

00h

00h

R/W

R/W

R/W

R/W

R/W

Read Only

Read Only

001Fh RESERVED

0020h MISCR .. Miscellaneous Register 00h see Section 3.4

0021h

Power

Bridge

PBCSR .. Bridge Control Status Register 00h R/W

0022h DCSR .. Dedicated Control Status Register 00h R/W

0023h to

0029h

RESERVED

002Ah

002Bh

WDG

WDGCR ..

WDGSR ..

Watchdog Control Register

Watchdog Status Register

7Fh

00h

R/W

R/W

002Ch EEPROM EECR .. EEPROM Control register 00h R/W

002Dh

002Eh

EPROM

ECR1

ECR2

EPROM Control register 1

EPROM Control register 2

ST INTERNAL

USE ONLY

002Fh

0030h

CRC

CRCL

CRCH

CRCL Test Register

CRCH Test Register

ST INTERNAL

USE ONLY

10/103

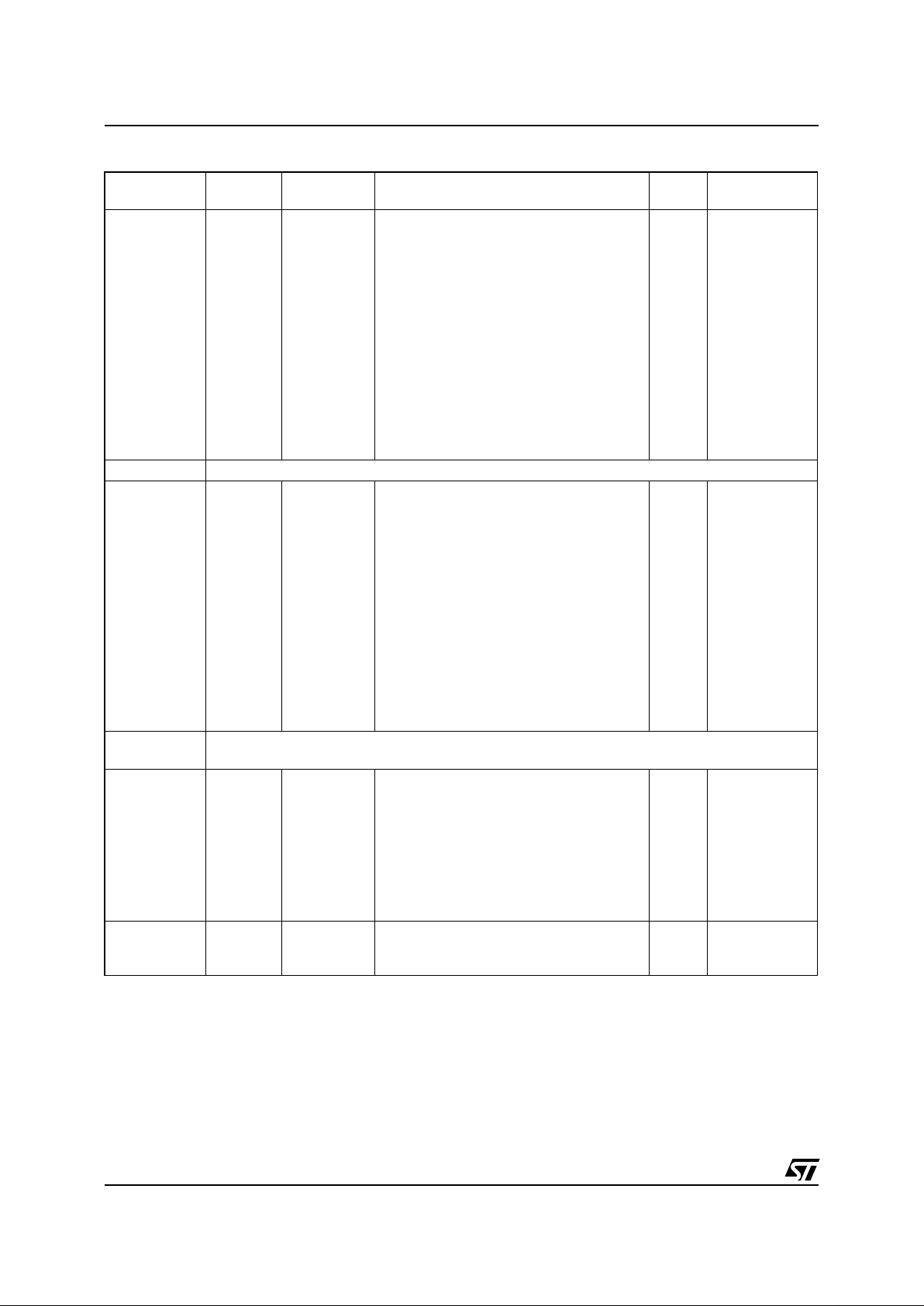

L9805

0031h

0032h

0033h

0034h-0035h

0036h-0037h

0038h-0039h

003Ah-003Bh

003Ch-003Dh

003Eh-003Fh

TIM1

T1CR2 ..

T1CR1 ..

T1SR ..

T1IC1HR ..

T1IC1LR ..

T1OC1HR ..

T1OC1LR ..

T1CHR ..

T1CLR ..

T1ACHR ..

T1ACLR ..

T1IC2HR ..

T1IC2LR ..

T1OC2HR ..

T1OC2LR ..

Timer 1 Control Register2

Timer 1 Control Register1

Timer 1 Status Register

Timer 1 Input Capture1 High Register

Timer 1 Input Capture1 Low Register

Timer 1 Output Compare1 High Register

Timer 1 Output Compare1 Low Register

Timer 1 Counter High Register

Timer 1 Counter Low Register

Timer 1 Alternate Counter High Register

Timer 1 Alternate Counter Low RegisteR

Timer 1 Input Capture2 High Register

Timer 1 Input Capture2 Low Register

Timer 1 Output Compare2 High Register

Timer 1 Output Compare2 Low Register

00h

00h

xxh

xxh

xxh

xxh

xxh

FFh

FCh

FFh

FCh

xxh

xxh

xxh

xxh

R/W

R/W

Read Only

Read Only

Read Only

R/W

R/W

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

R/W

R/W

0040h Reserved: Write Forbidden

0041h

0042h

0043h

0044h-0045h

0046h-0047h

0048h-0049h

004Ah-004Bh

004Ch-004Dh

004Eh-004Fh

TIM2

T2CR2 ..

T2CR1 ..

T2SR ..

T2IC1HR ..

T2IC1LR ..

T2OC1HR ..

T2OC1LR ..

T2CHR ..

T2CLR ..

T2ACHR ..

T2ACLR ..

T2IC2HR ..

T2IC2LR ..

T2OC2HR ..

T2OC2LR ..

Timer 2 Control Register2

Timer 2 Control Register1

Timer 2 Status Register

Timer 2 Input Capture1 High Register

Timer 2 Input Capture1 Low Register

Timer 2 Output Compare1 High Register

Timer 2 Output Compare1 Low Register

Timer 2 Counter High Register

Timer 2 Counter Low Register

Timer 2 Alternate Counter High Register

Timer 2 Alternate Counter Low Register

Timer 2 Input Capture2 High Register

Timer 2 Input Capture2 Low Register

Timer 2 Output Compare2 High Register

Timer 2 Output Compare2 Low Register

00h

00h

xxh

xxh

xxh

xxh

xxh

FFh

FCh

00h

00h

xxh

xxh

xxh

xxh

R/W

R/W

Read Only

Read Only

Read Only

R/W

R/W

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

R/W

R/W

0050h to

0059h

RESERVED

005Ah

005Bh

005Ch

005Dh

005Eh

005Fh

0060h to

006Fh

CAN

CANISR ..

CANICR ..

CANCSR ..

CANBRPR ..

CANBTR ..

CANPSR ..

CAN Interrupt Status Register

CAN Interrupt Control Register

CAN Control/Status Register

CAN Baud Rate Prescaler

CAN Bit Timing Register

CAN Page Selection

CAN First address to

last address of PAGE X

00h

00h

00h

00h

23h

00h

--

R/W

R/W

R/W

R/W

R/W

R/W

see page map-

ping and regis-

ter description

0070h

0071h

0072h

ADC

ADCDRH ..

ADCDRL ..

ADCCSR ..

ADC Data Register High

ADC Data Register Low

ADC Control/Status Register

00h

00h

20h

Read Only

Read Only

R/W

Address Block

Register Label

Register name

Reset

Status

Remarks

11/103

L9805

Address Block Description

0080h to

013Fh

RAM 256

Bytes

including

STACK 64

bytes (0140h

to 017Fh)

User variables and subroutine nesting

0140h to

017Fh

0180h to

0BFFh

RESERVED

0C00h to

0C7Fh

EEPROM 128

bytes

including 4 bytes reserved for temperature sensor trimming (see Section 5.5.6)

0C7CH: T0H

0C7DH: T0L

0C7EH: VT0H

0C7FH: VT0L

0C80h to

BFFFh

RESERVED

C000 to

FFDFh

EPROM 16K

bytes

(16384 bytes)

User application code and data

FFE0h to

FFFFh

Interrupt and Reset Vectors

12/103

L9805

2 CENTRAL PRO CESSING UNIT

2.1 INTRODUCTION

The CPU has a full 8-bit architecture. Six internal

registers allow efficient 8-bit data manipulation.

The CPU is capable of executing 63 basic instructions and features 17 main addressing modes.

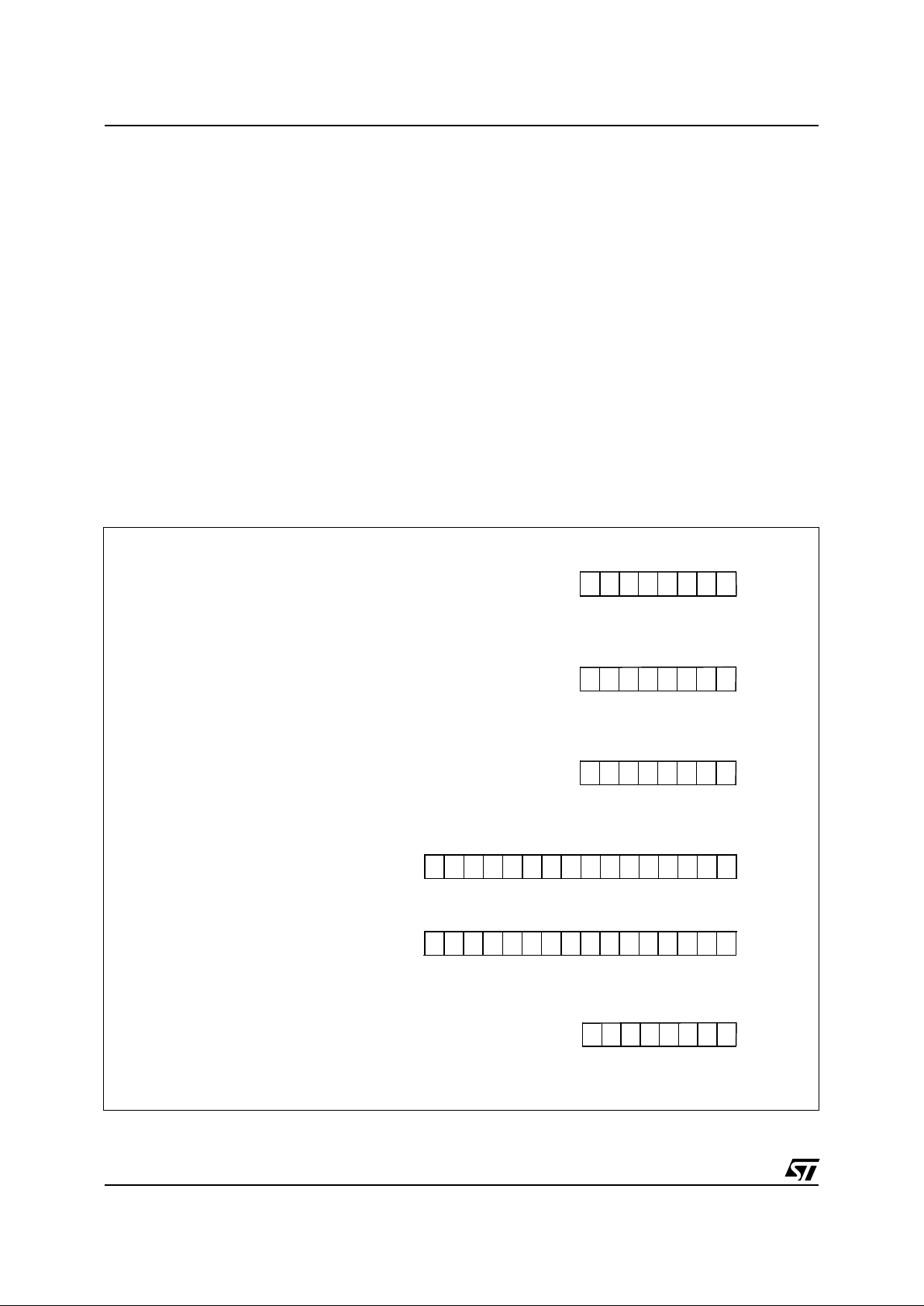

2.2 CPU REGISTERS

The 6 CPU registers are shown in the program ming model in F igure 2, on page 12. Following an

interrupt, all registers except Y are pushed onto

the stack in the order shown in Figure 3, on

page 13. They are popped from stack in the reverse order.

The Y register is not affected by these automatic

procedures. The interrupt routine must therefore

handle Y, if needed, through the PUS H and POP

instructions.

Accumulator (A).

The Accumulator is an 8-bit

general purpose register used to hold operands

and the results of the a rithmetic and logic calculations as well as data manipulations.

Index Registers (X and Y).

These 8-bit reg isters

are used to create ef fective address es or as temporary storage areas for data manipulation. The

Cross-Assembler generates a PRECEDE instruction (PRE) to indicate that the following instruction

refers to the Y register.

Program Counter (PC).

The program counter is a

16-bit register containing the address of the next

instruction to be executed by the CPU.

Figure 2. Organi z at io n of In t ernal CPU Regi st ers

ACCUMULATOR:

X INDEX REGISTER:

Y INDEX REGISTER:

STACK POINTER:

CONDITION CODE REGISTER:

PROGRAM COUNTER:

X = Undefined

15

RESET VALUE:

70

XXXXXXXX

RESET VALUE:

70

1X11X1XX

1C11HI NZ

RESET VALUE = RESET VECTOR @ FFFEh-FFFFh

RESET VALUE:

70

XXXXXXXX

RESET VALUE:

70

XXXXXXXX

70

15

70

01000000

RESET VALUE =0 0 0 0 0 0 0 1 0 1 1 1 1 1 1 1

13/103

L9805

CPU REGISTERS

(Cont’d)

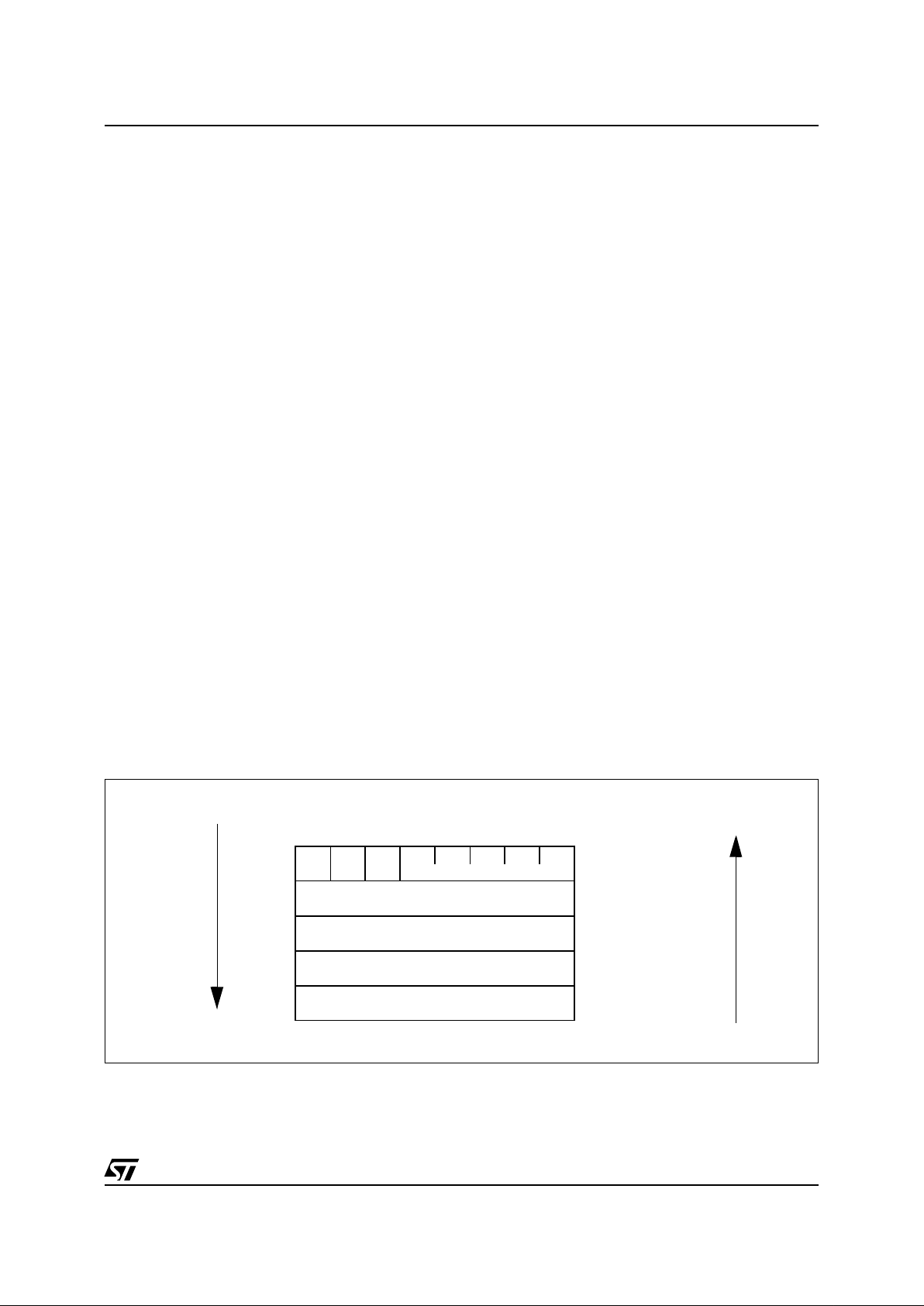

Stack Pointer (SP)

The Stack Pointer i s a 16-bit

register. Since the stack is 64 bytes deep, the

most significant bits are forced as indicated in

Figure 2, on page 12 in order to address the stack

as it is mapped in memory.

Following an MCU Reset, or after a Reset Stack

Pointer in stru ction (R SP), the S tac k Po inte r is s et

to point to the next free location in the s tack. It is

then decremented after data has been pushed

onto the stack and incremented before data is

popped from the stack.

Note:

When the lower limit is exceeded, the Stack

Pointer wraps around to the stack upper limit, without indicating the stack overflow. The previously

stored information is then overwritten and therefore lo s t.

The upper and lower limits of the stack area are

shown in the Memory Map.

The stack is used to save the CPU context durin g

subroutine calls or interrupts. The user may also

directly manipulate the stack by means of the

PUSH and POP instructions. In the cas e of an interrupt (refer to Figure 3), the PCL is stored at the

first location pointed to by t he SP. Then the other

registers are stored in the next locations.

– When an interrupt is received, the SP is decre-

mented and the context is pushed on the stack.

– On return from interrupt, the SP is incremented

and the context is popped from the stack.

A subroutine call occupies two locations and an interrupt five locations in the stack area.

Condition Code Register (CC)

The Condition

Code register is a 5-bit register which indicates the

result of the instruction just executed as well as the

state of the processor. These bits can be individually tested by a program and specified action taken

as a result of their state. The following paragraphs

describe each bit of the CC register in turn.

Half carry bit (H)

The H bit is set to 1 when a carry

occurs between bits 3 and 4 of t he ALU during an

ADD or ADC instruction. The H bit is useful in BCD

arithmetic subroutines.

Interrupt mask (I)

When the I bit is set to 1, all interrupts except the TRAP software interrupt are

disabled. Clearing this bi t enables interrupts to be

passed to the processor core. Interrupts requested

while I is set are latched and can be processed

when I is cleared (only one interrupt request per interrupt enable flag can be latched).

Negative (N)

When set to 1, t his bit indic ates that

the result of the last arithmetic, logical or data manipulation is negative (i.e. the most significant bit is

a logic 1).

Zero (Z)

When set to 1, this bit indicate s that the

result of the last arithmetic, logical or data manipulation is ze ro .

Carry/Borrow (C)

When set, C indicates that a

carry or borrow out of the ALU occured du ring the

last arithmetic operation. This bit is also affected

during execution of bit test, branch, shift, rotate

and store instructions.

Figure 3. Sta ck Manipulatio n on Inte rrupt

CONDITION CODE

ACCUMULATOR

X INDEX REGISTER

PCH

PCL

111

0

7

HIGHER ADDRESS

LOWER ADDRESS

CONTEXT RESTORED

CONTEXT SAVED

ON INTERRUPT

ON RETURN

14/103

L9805

3 CLOCKS, RESET, INTERRUPTS & POWER SAVI NG MODES

3.1 CLOCK SYSTEM

3.1.1 General Description

The MCU accepts either a Crystal or Ceramic resonator, or an external clock signal to drive the internal oscillator. The internal clock (f

CPU

) is de-

rived from the external os cillator frequency (f

OSC).

The external Oscillator clock is first divided by 2,

and an additional division factor of 2, 4, 8, o r 16

can be applied, in Slow Mode, to reduce the frequency of the f

CPU

; this clock signal is also routed

to the on-chip peripherals (except the CAN). The

CPU clock signal con si sts of a square wave with a

duty cycle of 50%.

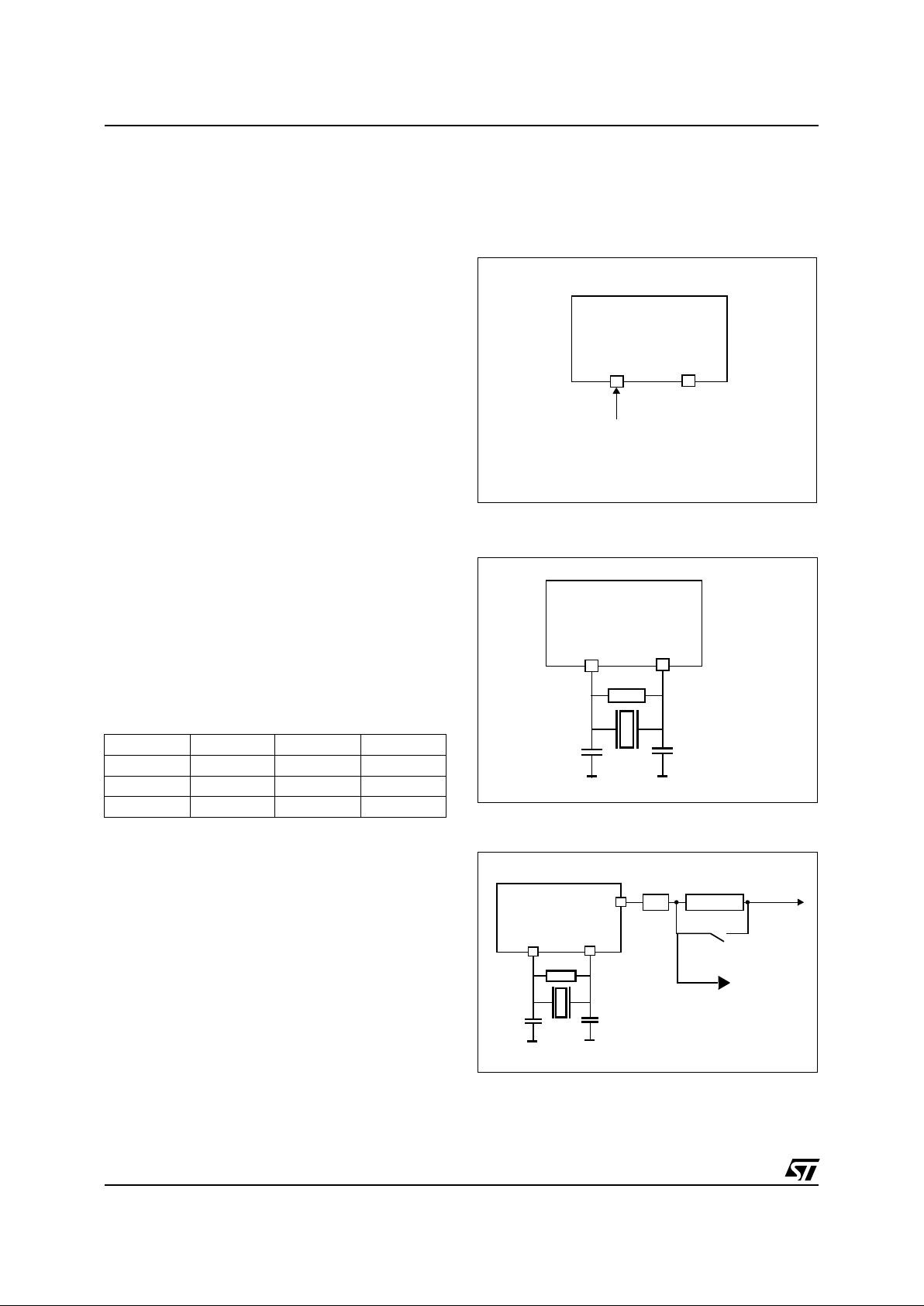

The internal oscillat or is designed to operate with

an AT-cut parallel resonant quartz crystal resonator in the frequency range specified for f

osc

. The

circuit shown in Figure 5 is recommended when

using a crystal, and Tab le 2 lists the recommended capacitance and feedback resistance values.

The crystal and associated components should be

mounted as close as p ossible to the input pins i n

order to minimize output distortion and start-up

stabilisation time.

Use of an external CMOS oscillator is recommended when crystals outside the specified frequency ranges are to be used.

Table 2. Recommended Values for 16 MHz

Crystal Resonator

Note:

R

SMAX

is the equivalent serial resistor of the

crystal (see crystal specification).

C

OSCIN,COSCOUT

:

Maximum total capacitances on

pins OSCIN and OSCOUT (the value includes the

external capacitance tied to the p in plus the parasitic capacitance of the board and of the device).

Rp:

External shunt resistance. Recommended val-

ue for oscillat o r sta bility is 1MΩ.

Figure 4. External Clock Source Connections

Figure 5. Crystal/Ceramic Resonator

Figure 6. Clock Prescaler Block Diagram

R

SMAX

40

Ω

60

Ω

150

Ω

C

OSCIN

56pF 47pF 22pF

C

OSCOUT

56pF 47pF 22pF

R

P

1-10 MΩ 1-10 MΩ 1-10 MΩ

OSC

in

OSC

out

EXTERNAL

CLOCK

NC

OSC

in

OSC

out

C

OSCin

C

OSCout

R

P

OSC

in

OSC

out

C

OSCin

C

OSCout

R

P

%2 %2,4,8,16

CPUCLK

to CPU and

Peripherals

to CAN

15/103

L9805

CLOCK SYSTEM

(Cont’d)

3.1.2 External Clock

An external clock may be applied to the OSCIN input with the OSCOUT pin not connected, as

shown on Figure 4. The t

OXOV

specifications does

not apply when usi ng an external clock input. T he

equivalent specification of the external clock

source should be used instead of t

OXOV

(see ).

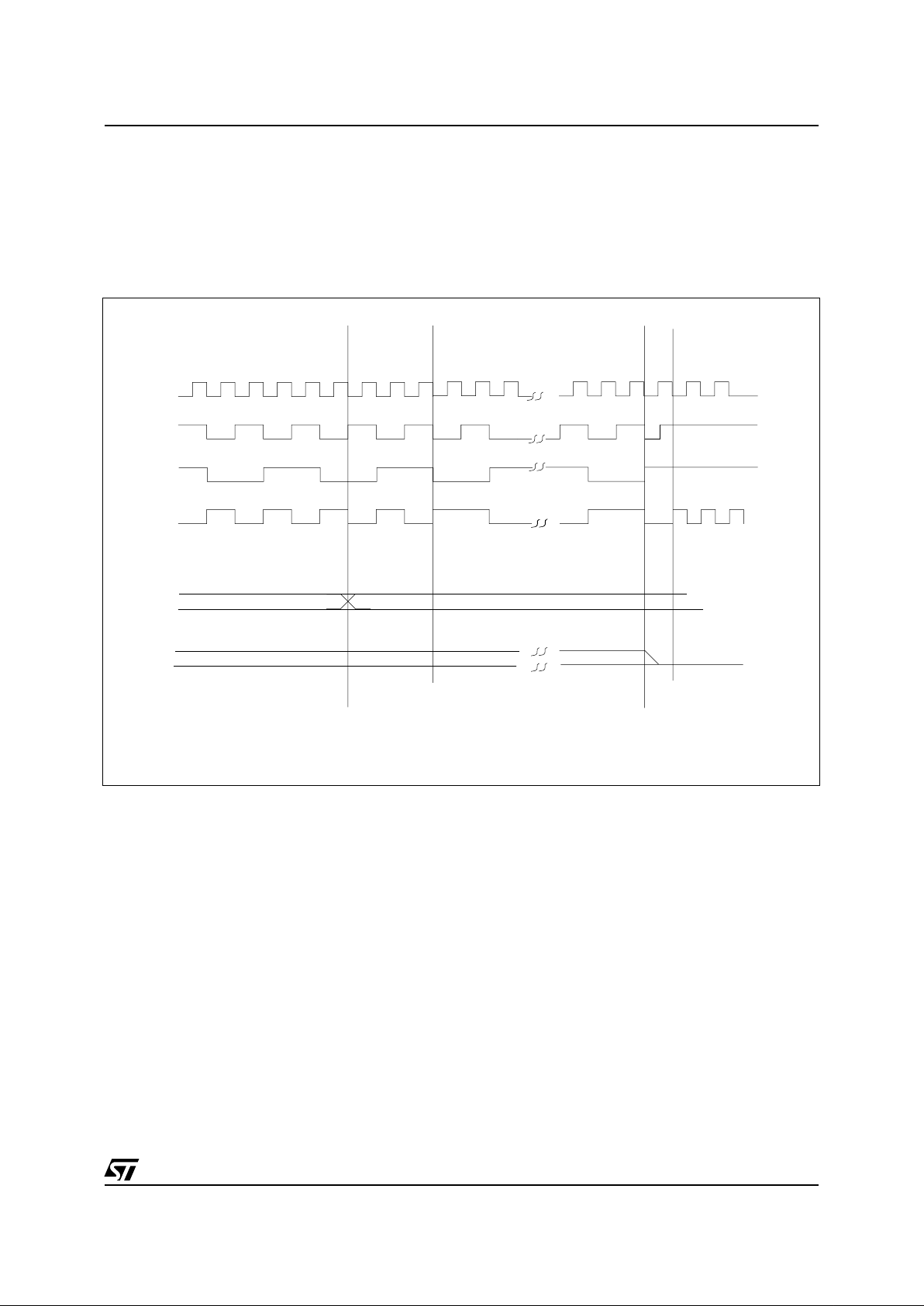

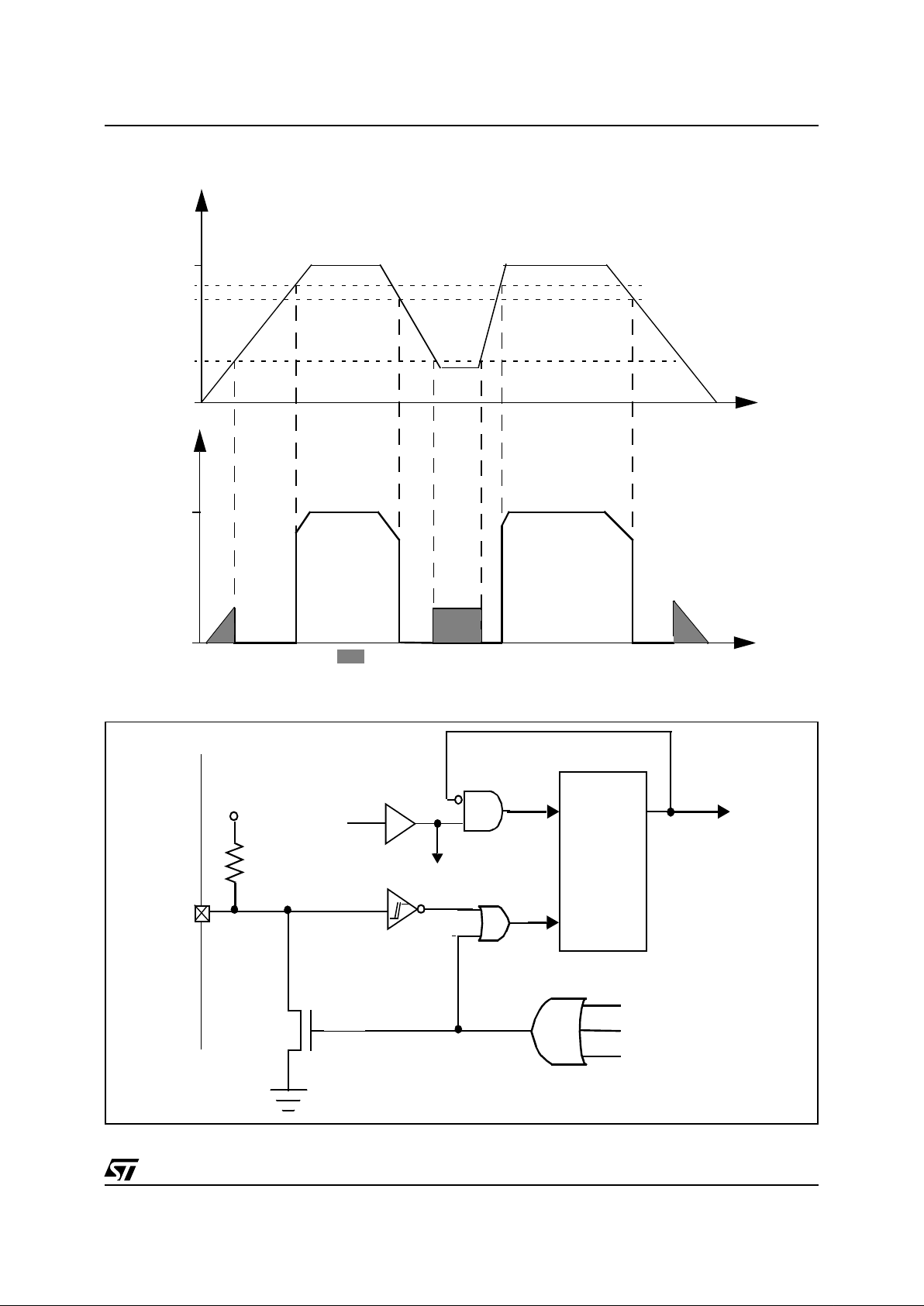

Figure 7. Timing Diagram for Internal CPU Clock Frequency transitions

b1 : b2

MISCELLANEOUS REGISTER

00

01

b0

1

1

0

OSC/2

OSC/4

OSC/8

CPU CLK

VR02062B

New frequency

requested

New frequency

active when

osc/4 & osc/8 = 0

Normal mode active

(osc/4 - osc/8 stoppe

d

Normal mode

requested

16/103

L9805

3.2 OSCILLATOR SAFEGUARD

The L9805 contains an oscilla tor safe guard function.

This function provides a real time check of the

crystal oscillator generating a reset condition when

the clock frequency has anomalous value.

If f

OSC<flow

, a reset is generated.

If f

OSC>fhigh,

a reset is generated.

A flag in the Dedicated Control Status Register indicates if the last reset is a safeguard reset.

At the output of reset state the safeguard is disable. To activate the safeguard SFGEN bit must be

set.

Notes:

Following a reset, the safeguard is disabled. Once activated it cannot be disabled, except

by a reset.

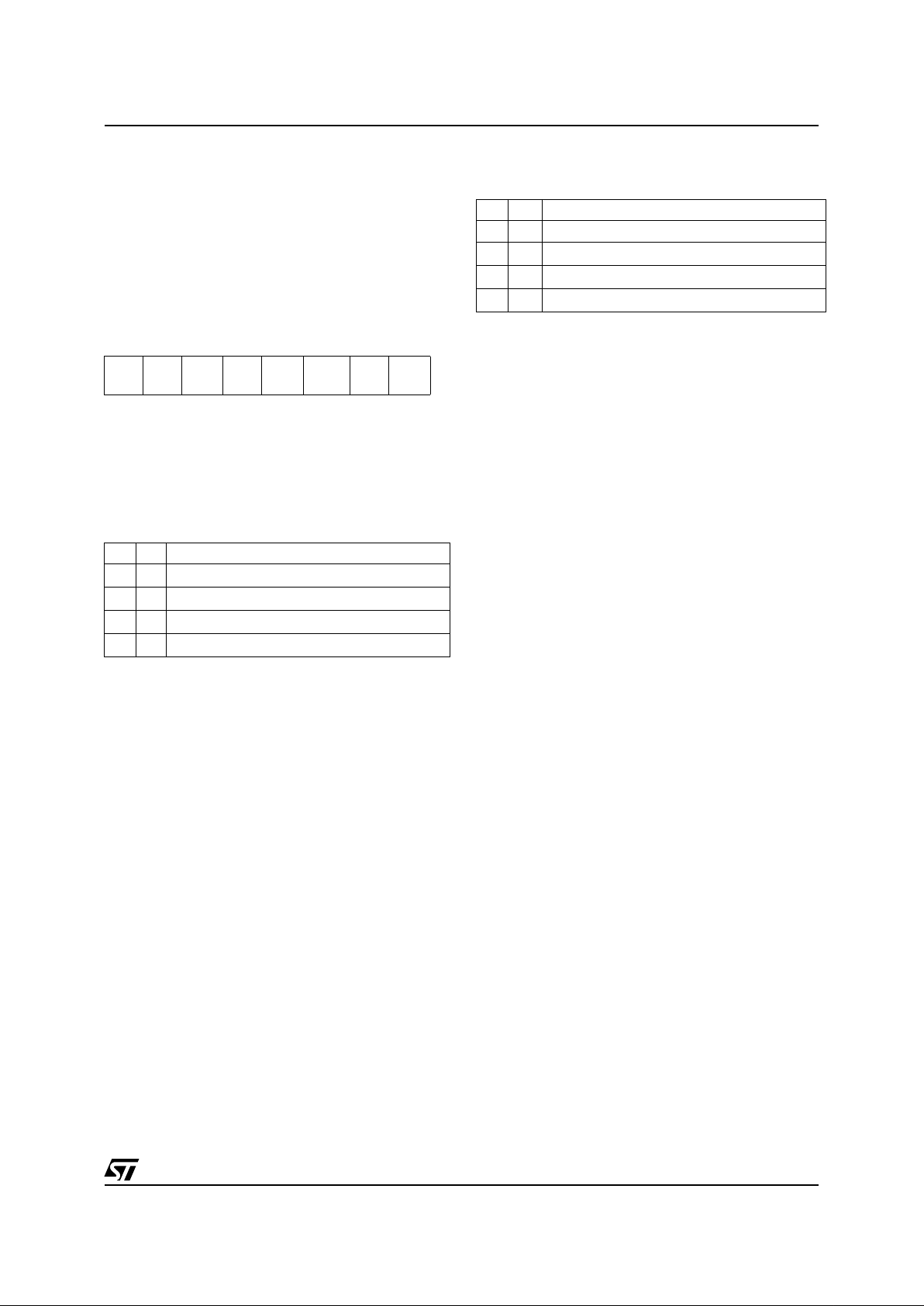

3.2.1 Dedicated Control Status Register

DCSR

Address 0022h - Read/Write

Reset Value:xx00 0000 (00h)

b6 =

SGFH:

Safeguard high flag. Set by an Oscillator Safeguard Reset generated for frequency too

high, cleared by software (writing zero) or Power

On / Low Voltage Reset. This flag is useful for distinguishing Safeguard Reset, Power On / Low

Voltage Reset and Watchdog Reset.

b7 =

SGFL:

Safeguard low flag. Set by an Oscillator Safeguard Reset generated for frequency too

low, cleared by software (writing zero) or Power

On / Low Voltage Reset. This flag is useful for distinguishing Safeguard Reset, Power On / Low

Voltage Reset and Watchdog Reset.

b5 =

SFGEN

: Safeguard enable when set. It’s

cleared only by hardware after a reset.

b4 =

CANDS

: CAN Transceiver disable. When this

bit is set the CAN transceiver goes in Power Down

Mode and does not work until this bit is reset.

CANDS is 0 after reset so the standard condition is

with the transceiver enabled. This bit can be used

by application requiring low power consumption

(see Section 5.7 for details).

b3,b2,b1 =

not used

b0 =

PIEN

: PWMI input enable. When set, the

PWMI input line is connected to Input Capture 2 of

Timer 2. Otherwise, ICAP2_2 is the alternate function of PA7. See Figure 31 for the explanation of

this function.

SGFL SGFH SFGEN CANDS

b3b2b

1

PIEN

17/103

L9805

3.3 WATCHDOG SYSTEM (WDG)

3.3.1 Introd uct i on

The Watchdog is used to detect the occurrence of

a software fault, usually generated by external interference or by unforeseen logical conditions,

which causes the application program to give up its

normal sequence. The Watchdog circuit generates

an MCU reset on expiry of a programmed time period, unless the program re freshes the counter’s

contents before it is decremented to zero.

3.3.2 Main Features

– Programm able Time r (64 increments of 12,288

CPU clock)

– Programmable Reset

– reset (if watchdog activated) after an HALT in-

struction or when bit timer MSB reaches zero

– Watchdog Reset indicated by status flag.

3.3.3 Functional Description

The counter value stored in the CR register (bits

T6:T0), is decremented every 12,288 machine cycles, and the length of the timeout period can b e

programmed by the user in 64 increments.

If the watchdog is activated (the W DGA bit is s et)

and when the 7-bit timer (bits T6:T0) rolls over

from 40h to 3Fh (T6 becom es cleared), it initiates

a reset cycle pulling low the reset pin for typically

500ns.

The application program must write in the CR register at regular intervals during normal operation to

prevent an MCU reset. The value to be stored in

the CR register must be between FFh and C0h

(see Table 1):

– The WDGA bit is set (watchdog enabled)

– The T6 bit is set to prevent generating an imme-

diate reset

– The T5:T0 bit contain the number of increments

which represents the time delay before the

watchdog produces a reset.

Table 3. Wat chdog Timin g (f

OSC

= 16 MHz)

Notes:

Following a reset, the watchdog is disabled. Once activated it cannot be disabled, except

by a reset.

The T6 bit can be used to gen erate a s oftware reset (the WDGA bit is set and the T6 bit is cleared).

If the watchdog is activated, the HALT instruction

will generate a Reset.

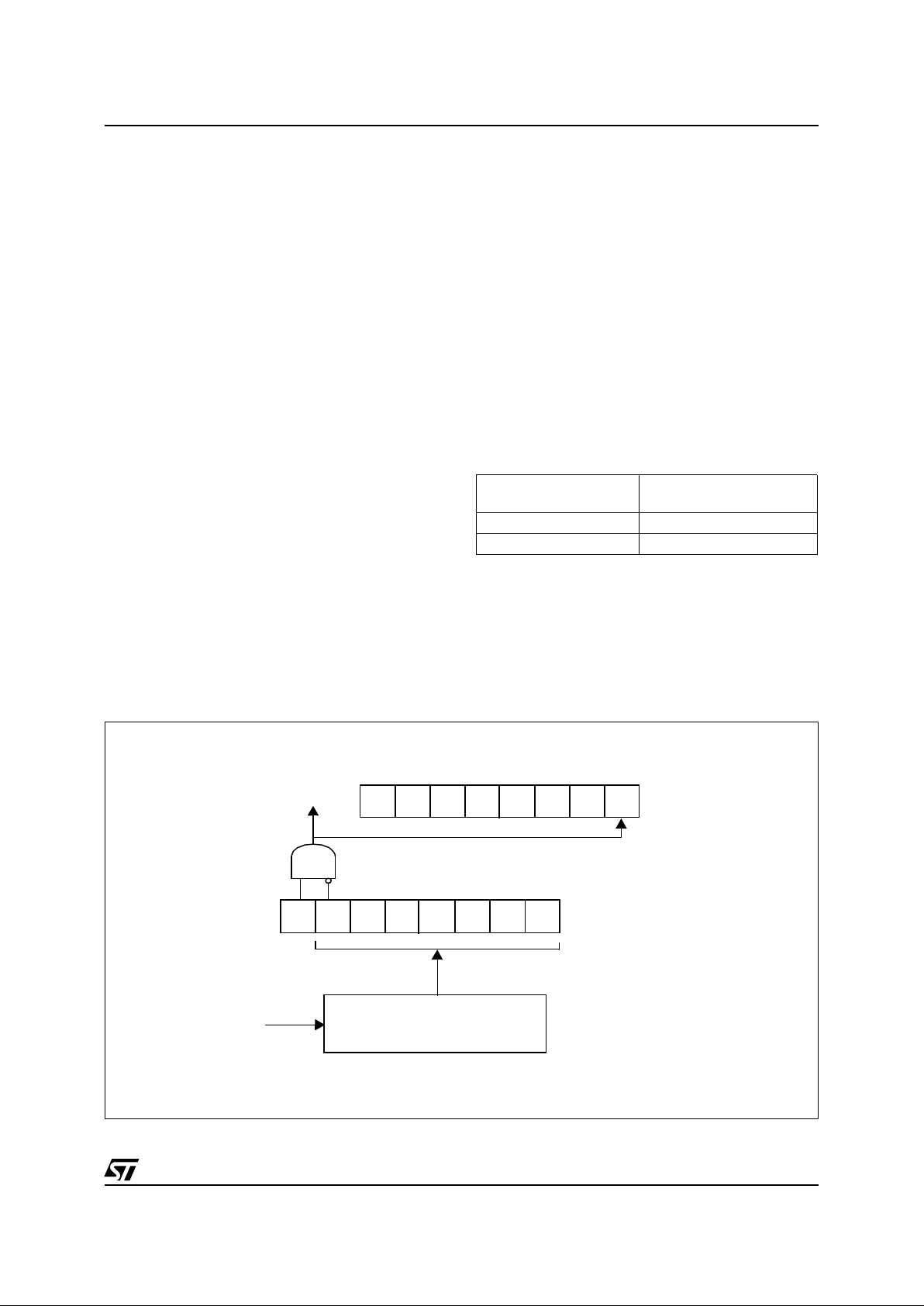

Figure 8. Functional Description

WDG Register initial

value

WDG timeout period (ms)

7Fh 98.3

C0h 1.54

RESET

WDGA

7-BIT DOWNCO UNTER

f

CPU

MSB LSB

CLOCK DIVIDE R

WDGF

WATCHDOG STATUS REGISTER (WDGSR)

WATCHDOG CONTROL REGIST ER (WDGCR)

÷12288

18/103

L9805

WATCHDOG SY ST E M

(Cont’d)

The Watchdog delay time is defined by bi ts 5 -0 of

the Watchdog register; bit 6 must always be set in

order to avoid generating an immediate reset.

Conversely, this can be used to generate a software reset (bit 7 = 1, bit 6 = 0).

The Watchdog must be reloaded before bit 6 is decremented to “0” to avoid a Reset. F ollowing a Reset, the Watchdog register will contain 7Fh (bits 0-

7).

If the circuit is not used as a Watchdog (i.e. bit 7 is

never set), bits 6 to 0 ma y be u se d as a simple 7bit timer, for instance as a real t ime clock. Since no

reset will be generated under these conditions, the

Watchdog control register must be monitored by

softw are.

A flag in the watchdog status register indicates if

the last reset is a watchdog reset or not, before

clearing by a write of this register.

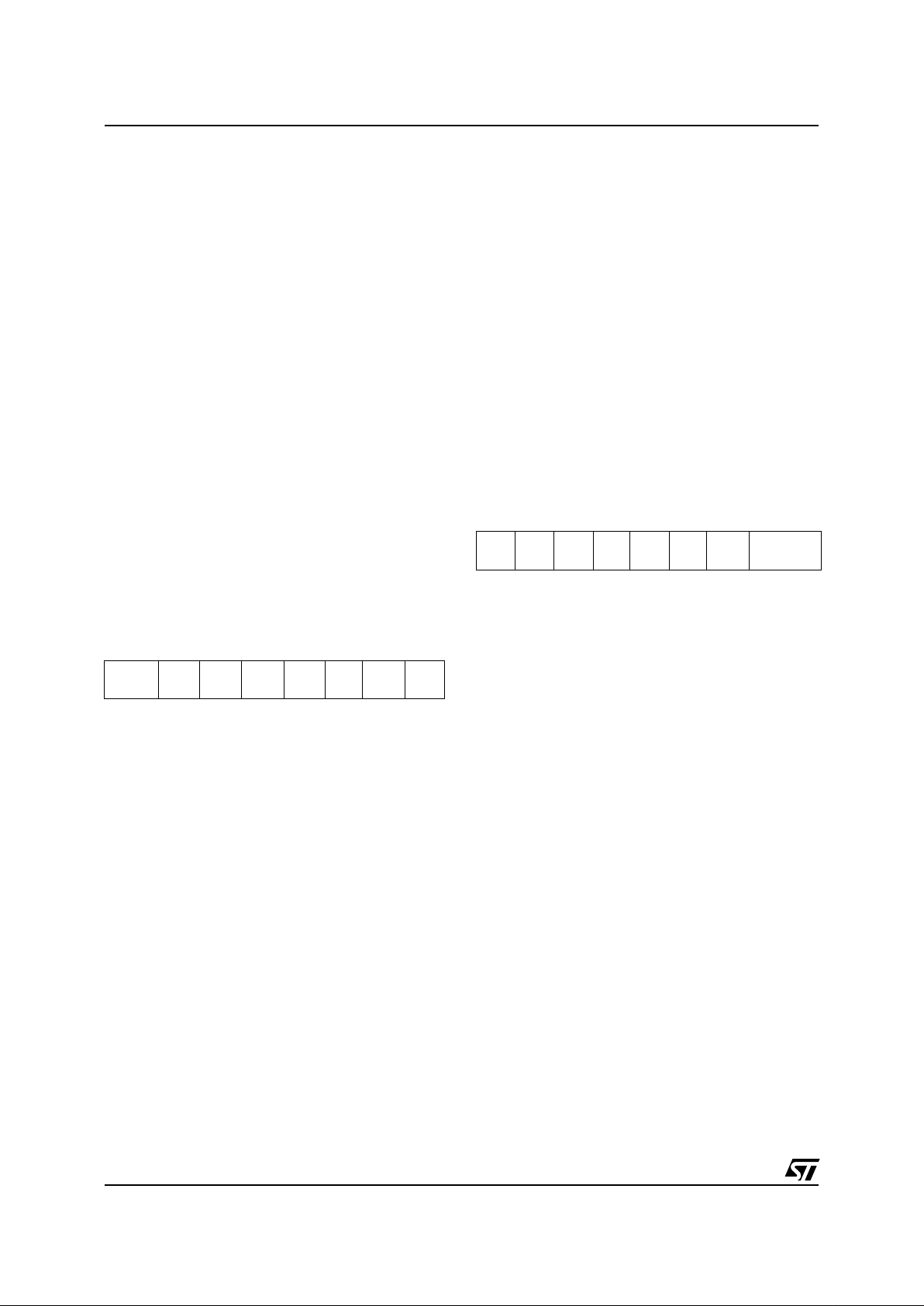

3.3.4 Register Description

3.3.4.1 Watchdog Control Register

(WDGCR)

Register Address: 002Ah — Read/Write

Reset Value: 0111 1111 (7Fh)

b7 =

WDGA:

Activation bit.

This bit is set by software and only cleared by

hardware after a reset. When WDGA = 1, the

watchdog can generate a reset.

0: Watchdog disabled

1: Watchdog enabled.

b6-0 =

T6-T0

: 7 bit timer (Msb to Lsb)

These bits contain the decremented value. A reset

is produced when it rolls over from 40h to 3Fh (T6

become cleared).

3.3.4.2 Watchdog Status Register

(WDGSR)

Register Address: 002Bh — Read/W rite

Reset Value

(*)

: 0000 0000 (00h)

b7-1 =

not used

b0 =

WDGF:

Watchdog flag. Set by a Watchdog

Reset, cleared by software (writing zero) or Power

On / Low Voltage Reset. This flag is useful for distinguishing Power On / Low Voltage Reset and

Watchdog Reset.

(*): Except in the case of Watchdog Reset.

70

WDGAT6T5T4T3T2T1T0

70

-------WDGF

19/103

L9805

3.4 MISCELLANEOUS REGISTER

(MISCR)

The Miscellaneous register allows the user to select the Slow operating mode and to set the clock

division prescaler factor. Bits 3, 4 determine the

signal conditions which will trigger an interrupt request on I/O pins having interrupt capability.

Register Address: 0020h — Read/Write

Reset Value:0000 0000 (00h)

b0 -

Slow Mode Select

0- Normal mode - Oscillator frequency / 2

(Reset state)

1- Slow mode (Bits b1 and b2 define the prescaler

factor)

b1, b2 -

CPU clock prescaler for Slow Mode

The selection issued from b3/b4 combination is

applied to PA[0]..PA[7],PB0,PB1 external interrupt. The selection can be made only if I bit in CC

register is reset (interrupt enabled).

b3, b4 can be written only when the Interrupt Mask

(I) of the CC (Condition Code) register is set to 1.

b5,b6,b7 =

not used

b7 b6 b5 b4 b3 b2 b1 b0

b2 b1 Option

00

Oscillator frequency / 4

10

Oscillator frequency / 8

01

Oscillator frequency / 16

11

Oscillator frequency / 32

b4 b3 Option

00

Falling edge and low level (Reset state)

10

Falling edge only

01

Rising edge only

11

Rising and Falling edge

20/103

L9805

3.5 RESET

3.5.1 Introd uct i on

There are four sources of Reset:

– NRESET pin (external source)

– Power-On Reset / Low Voltage Detection (Inter-

nal source)

– WATCHDOG (Internal Source)

– SAFEGUARD (Internal source)

The Reset Service Routine vector is located at ad-

dress FFFEh-FFFFh.

3.5.2 External Reset

The NRESET pin is both an in put and an opendrain output with integrated pull-up resistor. When

one of the internal Reset sources is active, the Reset pin is driven low to reset the whole application.

3.5.3 Reset Operation

The duration of the Reset condition, which is also

reflected on the output pin, is fixed at 4096 internal

CPU Clock cycles. A Reset signal originating from

an external source must have a duration of at least

1.5 internal CPU Clock cycl es in order to b e recognised. At the end of the Power-On Reset cycle, the

MCU may be held in t he Reset condition by an External Reset signal. The NRESET pin may thus be

used to ensure V

DD

has risen to a point where the

MCU can operate correctly before the user program is run. Following a Power-On Reset event, or

after exiting Halt mode, a 409 6 CPU Clock cycle

delay period is initiated in order to allow the oscil-

lator to sta bilise and to ensu re that recovery ha s

taken place from the Reset state.

During the Reset cycle, the device Reset pin acts

as an output that is pulsed low. In i t s high state, an

internal pull-up resistor of about 300KΩ is connected to the Reset pin. This resistor can be pulled

low by external circuitry to reset the device.

3.5.4 Power-on Reset - Low Voltage Detection

The POR/LVD function generates a static reset

when the supply voltage is below a reference value. In this way, the Power-On Reset and Low Voltage Reset function are provided, in order to keep

the system in safe condition when the voltage is

too low.

The Power-Up and Power-Down thresholds are

different, in order to avoid spurious reset when the

MCU starts running and sinks current from the

supply.

The LVD reset circuitry generates a reset when

V

DD

is below:

– V

ResetON

when V

DD

is rising

– V

ResetOFF

when VDD is falling

The POR/LVD function is explained in Figure 9.

Power-On Reset activates the reset pull up tran-

sistor performing a complete chip reset. In the

same way a reset can be triggered by the watchdog, by the safeguard or by external low level at

NRESET pin. An external capacitor connected between NRESET and ground can extend the power

on reset period if required.

21/103

L9805

Figure 9. Power Up/Down behaviour

Figure 10. Reset Block Diagram

= undefined value

5V

t

V

Reset UD

V

Reset OFF

V

Reset ON

5V

t

V

DD

POR/LVD

Internal

RESET

Oscillator

Signal

Counter

NRESET

to ST7

RESET

V

DD

Watchdog Reset

Safeguard Reset

POR/LVD Reset

300K

Reset

CLK

22/103

L9805

3.6 INTERRUPTS

A list of interrupt sources is given in Table 4 below,

together with relevant details for each source. Interrupts are serviced according to t heir order of pri ority, starting with I0, which has the highest priority, and so to I12, which has the lowest priority.

The following list describes the origins for each interrupt lev el:

– I0 connected to Ports PA0-PA7, PB0-PB1

– I1 connected to CAN

– I2 connected to Power Diagnostics

– I3 connected to Output Compare of Timer 1

– I4 connected to Input Capture of TImer 1

– I5 connected to Timer 1 Overflow

– I6 connected to Output Compare of Timer 2

– I7 connected to Input Capture of TImer 2

– I8 connected to Time r 2 Overflow

– I9 connected to ADC End Of Conversion

– I10 connected to PWM 1 Overflow

– I11 connected to PWM 2 Overflow

– I12 connected to EEPROM

Exit from Halt mode may only be triggered by an

External Interrupt on one of the following ports:

PA0-PA7 (I0), PB0-PB1 (I0), or by an Internal Interrupt coming from CAN peripheral (I1).

If more than one input pin of a group connected to

the same interrupt line are selected simultaneously, the OR of this signals generates the interrupt.

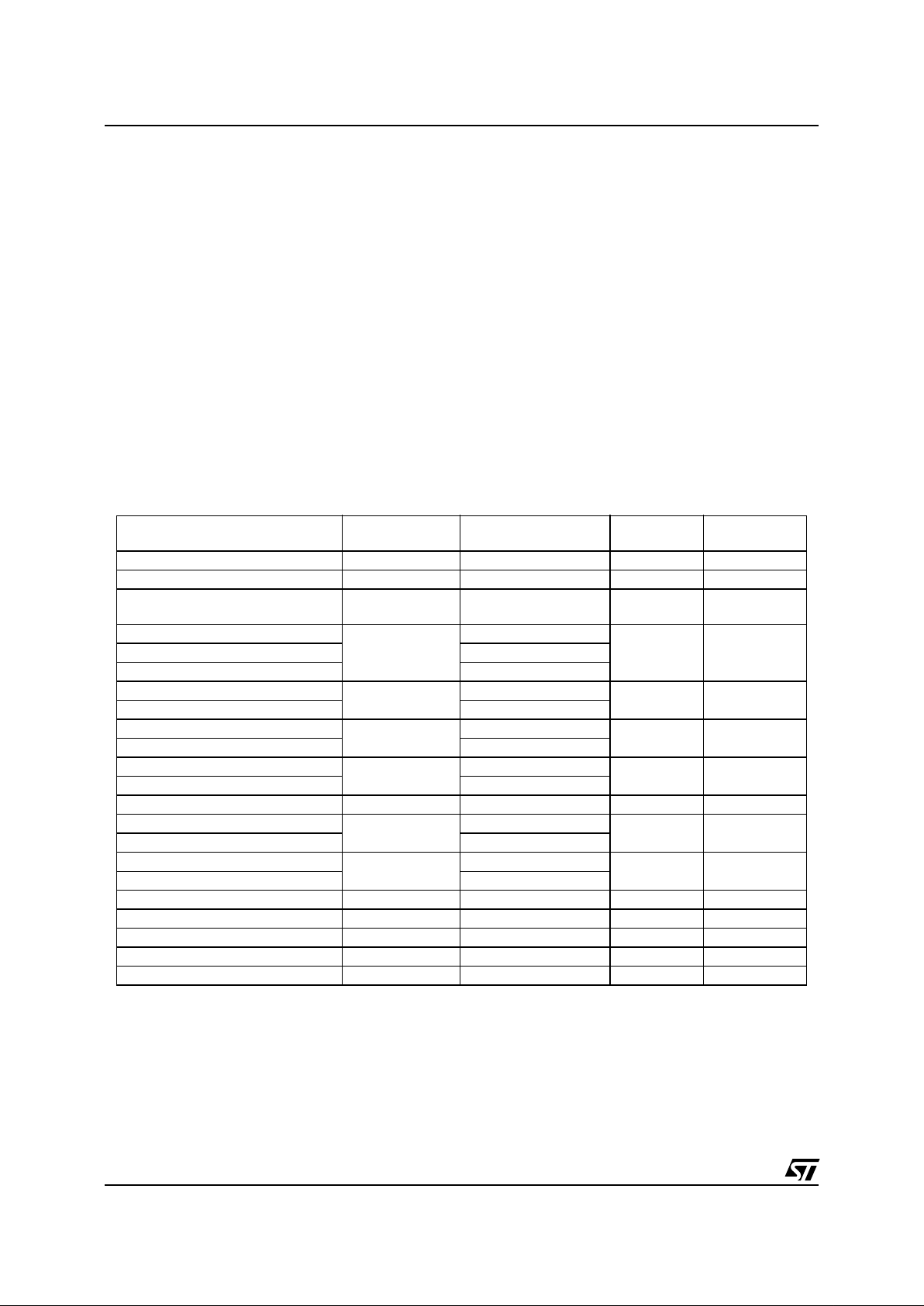

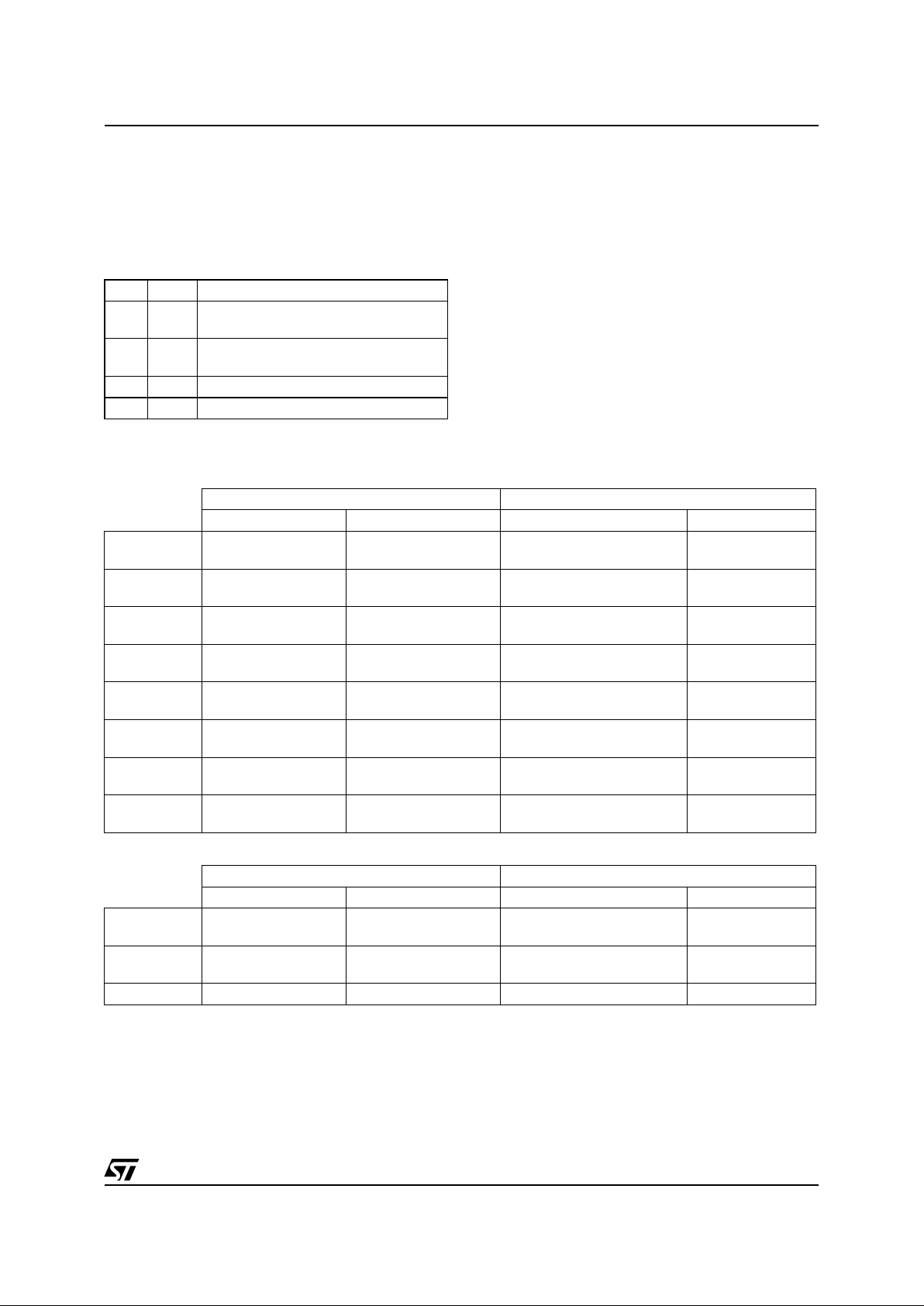

Table 4. Interrupt Mapping

Interrupts Register Flag name

Interrupt

source

Vector

Address

Reset N/A N/A - FFFEh-FFFFh

Software N/A N/A - FFFCh-FFFDh

Ext. Interrupt (Ports PA0-PA7,

PB0-PB1)

N/A N/A I0 FFFAh-FFFBh

Receive Interrupt Flag

CAN Status

RXIFi

I1 FFF8h-FFF9hTransmit Interrupt Flag TXIF

Error Interrupt Pending EPND

Power Bridge Short Circuit

Bridge Control

Status

SC

I2 FFF6h-FFF7h

Overtemperature OVT

Output Compare 1

Timer 1 Status

OCF1_1

I3 FFF4h-FFF5h

Output Compare 2 OCF2_1

Input Capture 1

Timer 1 Status

ICF1_1

I4 FFF2h-FFF3h

Input Capture 2 ICF2_1

Timer Overflow Timer 1 Status TOF_1 I5 FFF0h-FFF1h

Output Compare 1

Timer 2 Status

OCF1_2

I6 FFEEh-FFEFh

Output Compare 2 OCF2_2

Input Capture 1

Timer 2 Status

ICF1_2

I7 FFECh-FFEDh

Input Capture 2 ICF2_2

Timer Overflow Timer 2 Status TOF_2 I8 FFEAh-FFEBh

ADC End Of Conversion ADC Control EOC I9 FFE8h-FFE9h

PWM 1 Overflow N/A N/A I10 FFE6h-FFE7h

PWM 2 Overflow N/A N/A I11 FFE4h-FFE5h

EEPROM Programming EEPROM Control E2ITE I12 FFE2h-FFE3h

23/103

L9805

INTERRUPTS

(Cont’d)

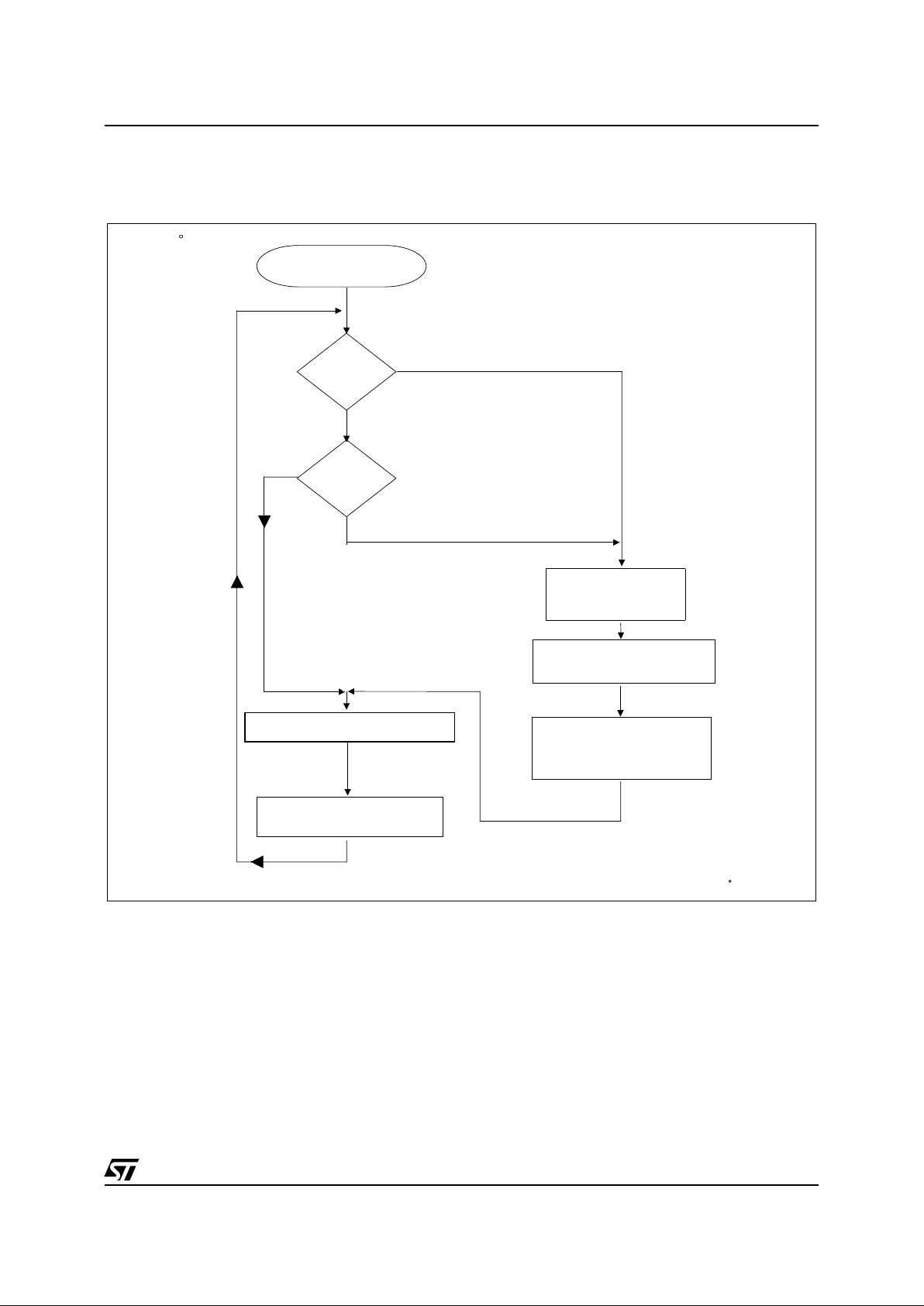

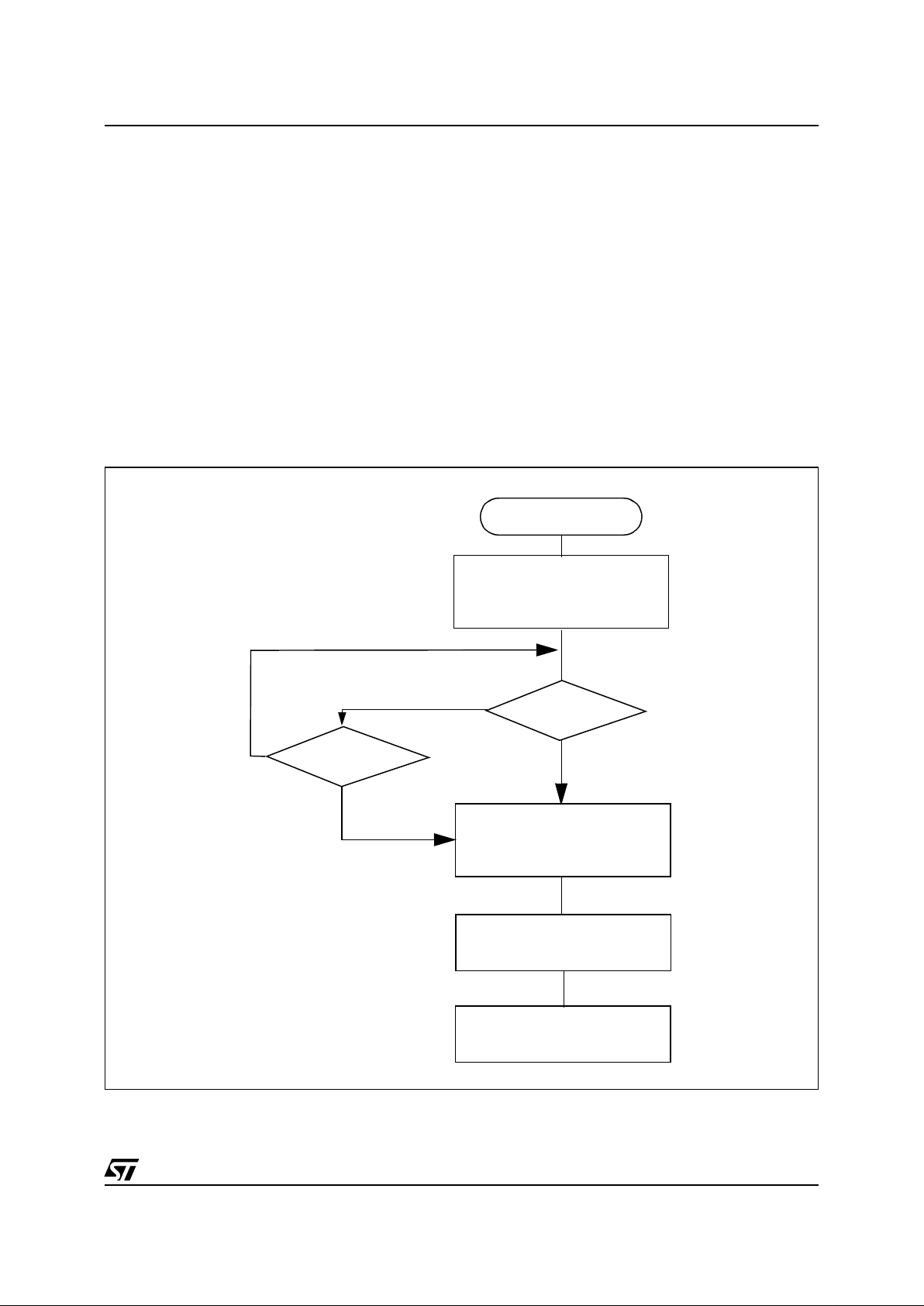

Figure 11. Inte rru pt P rocessing Flow c hart

Note

1. See Table 4

INTERRUPT

TRAP

FETCH NEXT

INSTRUCTION

OF APPROPRIATE INTERRUPT

SERVICE ROUTINE

EXECUTE INSTRUCTION

PUSH

PC,X,A,CC

SET I BIT TO 1

VR01172B

N

Y

LOAD PC

WITH APPROPRIATE

INTERRUPT VECTOR

(

1)

I BIT = 1

N

Y

ONTO STACK

24/103

L9805

3.7 POWER SAVI NG MO DE S

3.7.1 Introd uct i on

There are three Power Saving modes. The Slow

Mode may be selected by setting the relevant bit s

in the Miscellaneous register as detailed in Section

3.4. Wait and Halt m odes may be entered usin g

the WFI and HALT instructions.

3.7.2 Slow Mode

In Slow mode, the oscillator frequency can be d ivided by 4, 8, 16 or 32 rathe r than by 2. The CP U

and peripherals (except CAN, see Note) are

clocked at this lower frequency. Slow mode is

used to reduce power consumption.

Note:

Before entering Slow mode and to guarantee low power operations, the CAN Controller

must be placed by software in STANDBY mode.

3.7.3 Wait Mode

Wait mode places the MCU in a low power consumption mode by stopping the CPU. All peripherals remain active. During Wait mode , the I bit (CC

Register) is cleared, so as to enabl e all interrupt s.

All other registers and memory remain unchanged. The MCU will remain in Wait m ode until

an Interrupt or Reset occurs, whereupon the Program Counter branches to t he starting address of

the Interrupt or Reset Service Routine.

The MCU will remain in Wait mode until a Reset or

an Interrupt (coming from CAN, Timers 1 & 2,

EEPROM, ADC, PWM 1 & 2, I/O ports peripherals

and Power Bridge) occurs, causing its wake-up.

Refer to Figure 12 below.

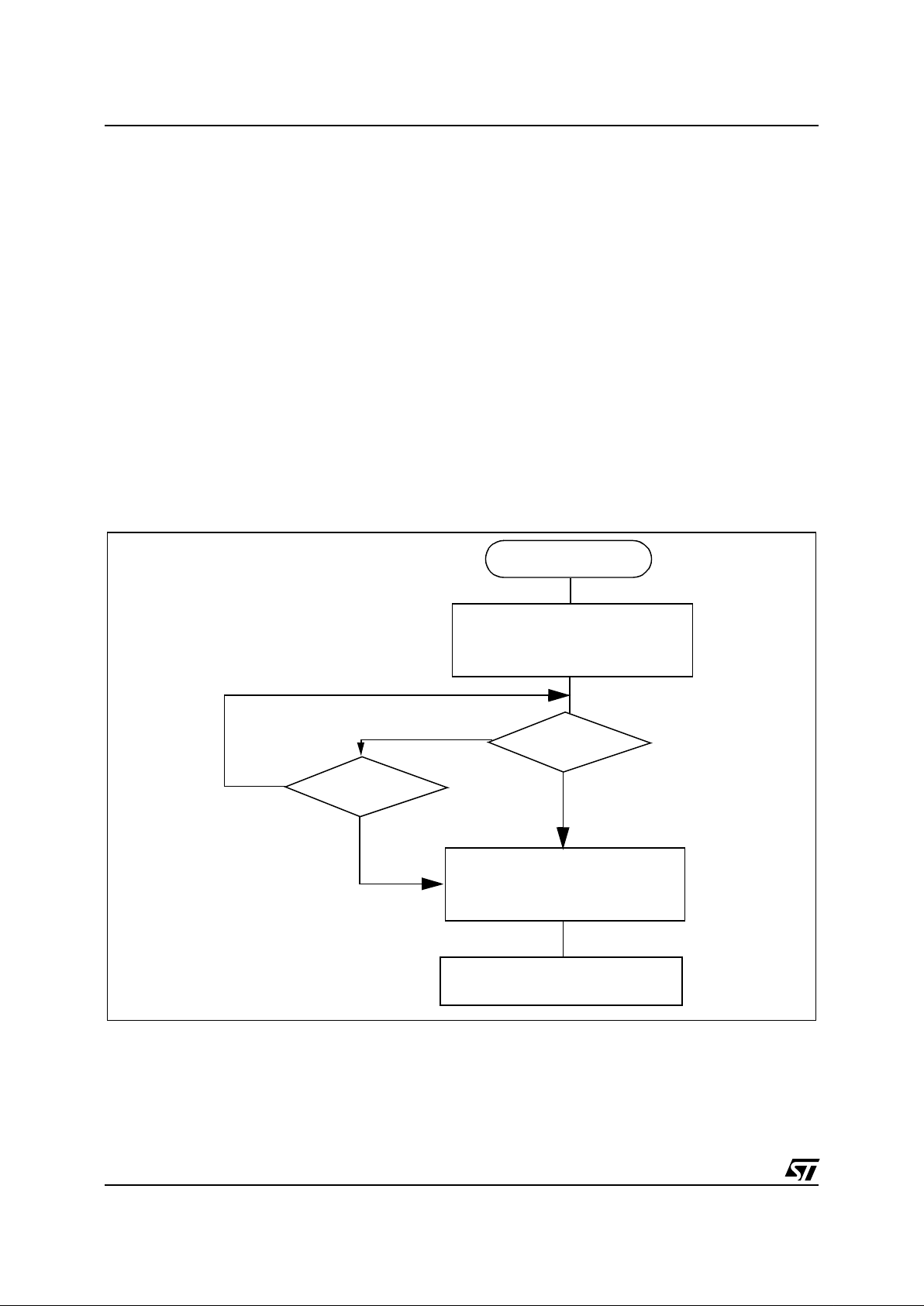

Figure 12. Wait Mode Flow Chart

WAIT INSTRUCTION

RESET

FETCH RESET VECTOR

OR SERVICE INTERRUPT

INTERRUPT

Y

N

N

Y

CPU CLOCK

OSCILLATOR

PERIPH. CLOCK

I-BIT

ON

ON

SET

ON

CPU CLOCK

OSCILLATOR

PERIPH. CLOCK

I-BIT

ON

ON

CLEARED

OFF

25/103

L9805

POWER SAVING MODES

(Cont’d)

3.7.4 Halt Mode

The Halt mode is the MCU lowest power consumption mode. The Halt mode is entered by executing the HALT instruction. The internal oscillator

is then turned off, causing all internal processing to

be stopped, including the operation of the on-chip

peripherals.

When entering Halt mode, the I bit in the CC Register is cleared so as to enable External Interrupts.

If an interrupt occurs, the CPU becomes active.

The MCU can exit the Halt mode upon reception of

either an external interrupt (I0), a internal interrupt

coming from the CAN peripheral (I1) or a reset.

The oscillator is then turned on and a stabilisation

time is provided before releasing CPU operat ion.

The stabilisation time is 4096 CPU clock cycles.

After the start up delay, the CPU continues operation by servicing the interrupt which wakes it up or

by fetching the reset vector if a reset wakes it up.

Note

The Halt mode cannot be used when the

watchdog or the Safeguard are enabled, if the

HALT instruction is executed while the watchdog

or safeguard system are enabled, a reset is automatically generated thus resetting the entire MCU.

Note

Halt Mode affects o nly the digital section of

the device. All the analog circuit remain in their

status, including ADC, voltage regulators, bus

transceivers and power bridge.

Figure 13. Hal t Mode Flow Cha rt

N

N

EXTERNAL

INTERRUPT

RESET

HALT INSTRUCTION

4096 CPU CLOCK

FETCH RESET VECTOR

OR SERVICE INTERRUPT

CYCLES DELAY

CPU CLOCK

OSCILLATOR

PERIPH. CLOCK

I-BIT

ON

ON

SET

ON

CPU CLOCK

OSCILLATOR

PERIPH. CLOCK

I-BIT

OFF

OFF

CLEARED

OFF

Y

Y

26/103

L9805

4 VOLTAGE REGULATO R

4.1 In troduc t ion

The on chip voltage regulator prov ides two regulated voltage, nominally 5V both. VCC supplies

ADC and the analog pe riphery and VDD supplies

the microcontroller and logic pa rts. These voltag e

are available at pins VDD and VCC to supply external components and c onnects a capacitors to

optimize EMI performance. A pre-regulator circuit

allows to connect external tantalum capacitors to a

lower (10V) voltage (VB2 pin).

4.1.1 Functional Description

The main supp ly v oltage is taken from V B 1 pin. A

voltage pre-regulator provides the regulated voltage on pin VB2. VB2 is the supply for the digital

and analog regulators. The bl ock diagram shows

the connections between the regulators and the

external pins.

In order to prevent negative spikes on the battery

line to propagate on the internal supply generating

spurious reset, a series diode suppl y VB1 pin is

recommended.

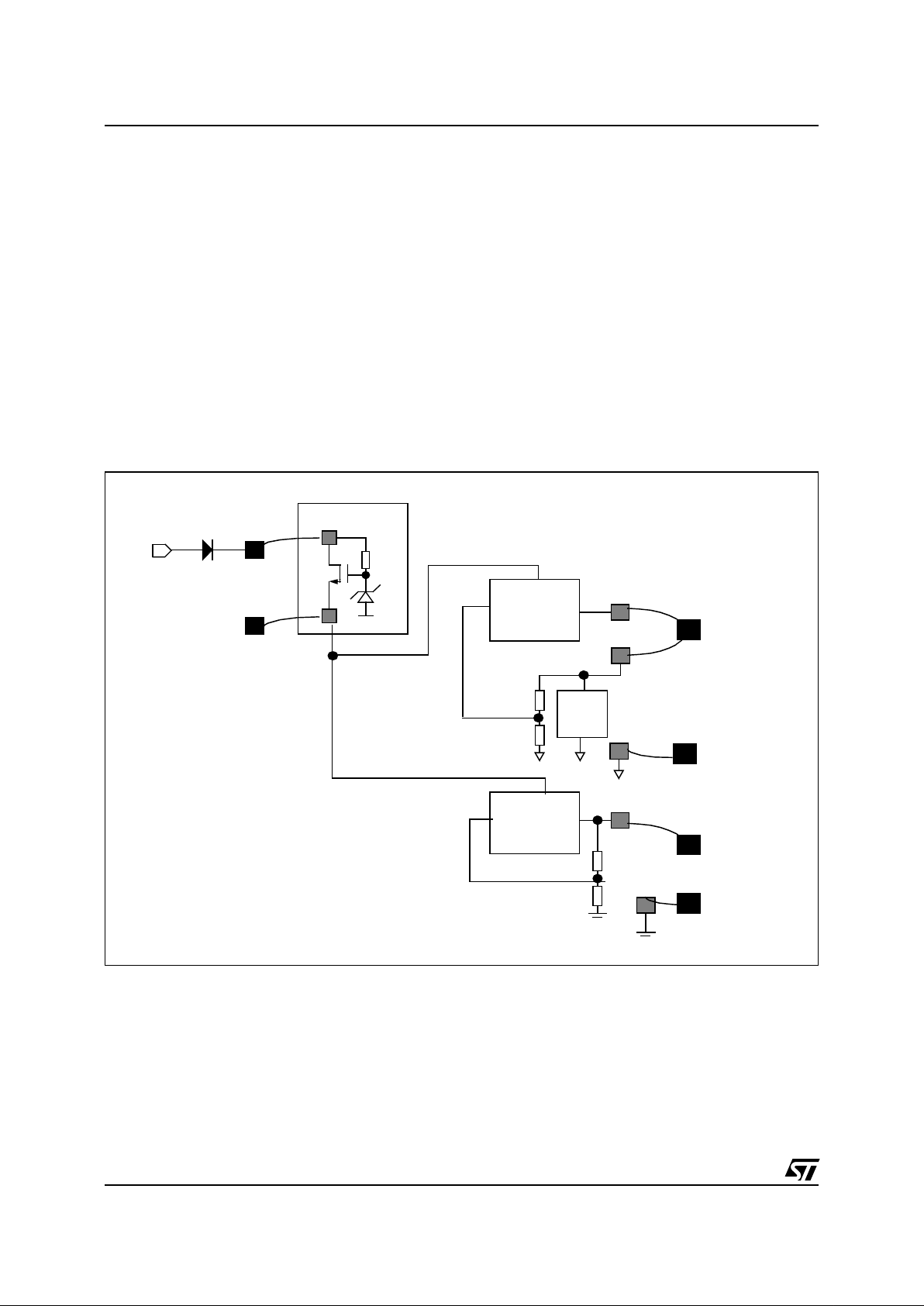

Figure 14. Vol ta ge regulation bl ock diagram

4.2 Digital Section Power Supply

The digital supply voltage VDD is available at pin

number 42 and 9. The digital ground GND is available at pin number 43 and 12.

Pin 42 and 43 are the actual voltage regulator output and external loads must be supply by these

pin. The 100nF compensation capacitor should be

connected as close as possible to pin 42 and 43.

Pin number 9 and 12 provide an external access to

the internal oscillator supply. Reson ator’s capacitors should be grounded on pin 12.

ADC

PRE-REGULATOR

VB1

VB2

force

ANALOG

VOLTAGE

REGULATOR

sense

VCC

AGND

DIGITAL

VOLTAGE

REGULATOR

VDD(42)

GND(43)

Battery

27/103

L9805

The application board can improve noise reduction

in the chip connecting directly pin 42 to pin 9 and

pin 43 to pin 12 u sing trac es as short as possible.

An additional capacitor mounted close to pin 9 and

12 can lead additional improvement.

4.2.1 VDD Short Circuit Protection

The output current o f the digital voltage regulator

is controlled by a circuit that limits it to a maximum

value (I

MAXVDD

). When the output current exceeds

this value the VDD voltage starts falling down. External loads must be chosen taking in account this

maximum current capability of the regulator.

4.3 Analog Section Power Supply

The analog supply voltage is available on VCC

pin. The external 100nF com pensation capacitor

should be placed as close as possibl e to this pin

and AGND pin.

VCC is the reference voltage f or the AD conversion and must be used to s upply ratiometric sensors feeding AD inputs. Any voltage drop between

VCC pin and the sensor supply pin on the application board, will cause the ADC to be inaccurate

when reading the sensor’s output.

4.3.1 VCC Short Circuit Protection

The output current of th e anal og v oltage regulat or

is controlled by a circuit that limits it to a maximum

value (I

MAXVCC

). When the output current exceeds

this value the VCC voltage starts falling down. External loads must be chosen taking in account this

maximum current capability of the regulator.

WARNING: The pin VB2 i s not short circuit protected so a short circuit on this pin will destroy the

device.

28/103

L9805

5 ON-CHIP PERIPHERALS

5.1 I/O PORTS

5.1.1 Introd uct i on

The internal I/O ports allow the transfer of data

through digital inputs and outputs, the interrupt

generation coming from an I/O and for specific

pins, the input/output of alternate signals for the

on-chip peripherals (TIMERS...).

Each pin can be programmed independently as

digital input (with or without interrupt generation)

or digital output.

5.1.2 Functional Description

Each I/O pin m ay be programmed indepen dently

as a digital input or a digital output, using the corresponding register bits.

Each port pin of the I/O Ports can be individual ly

configured under software control as either i nput

or output.

Each bit of a Data Direction Register (DDR) corresponds to an I/O pi n of the associated po rt. This

corresponding bit must be set to configure its associated pin as output and must be cleared to configure its associated pin as input. The Data Direction Registers can be read and written.

5.1.2.1 Input Mode

When DDR=0, the corresponding I/O is configured

in Input mode.

In this case, the output buffer is switched off, the

state of the I/O is readable through the Data Register address, but the I/O state comes directly from

the Schmitt-Trigger output and not from the Dat a

Register output.

5.1.2.2 Interrupt function

When an I/O is configured in Input with Interrupt

generation mode (DDR=0 and OR=1), a low level

or any transition on this I/O (according to the Miscellaneous register configuration - see Section

3.4, “b3, b4 External Interrupt Option”) will gener-

ate an Interrupt request to the CPU.

Each pin can independently generate an Interrupt

request. When at least one of the interrupt inp uts

is tied low, the port’s common interrupt will activate

a CPU interrupt input according to the e xternal interrupt option in the Miscellaneous Register.

5.1.2.3 Output Mode

When DDR=1, the corresponding I/O is configured

in Output mode. In this mode, the interrupt function

is disabled.

The output buffers c an be individually configured

as Open Drain or Push-Pull b y means of the Option Register.

The output buffer is activated according to the

Data Register’s content.

A read operation is directly performed from the

Data Register output.

5.1.2.4 Alternate function

A signal coming from a on-chip peripheral can be

output on the I/O.

In this case, the I/O is automaticall y configured in

output mode (without pull-up).

This must be controlled directly by the peripheral

with a signal coming from the peripheral which enables the alternate signal to be output.

The I/O’s state is readable as in normal mode by

addressing the corresponding I/O Data Register.

A signal coming from an I/O can be inpu t in a onchip peripheral.

Before using an I/O as Alternate Input, it must be

configured in Input without interrupt mode (DDR=0

and OR=0). So, bot h Alternat e In put co nfigurat ion

(with or without pull-up) and I/O input configuration

(with or without pull-up) are the same.

The signal to be input in the peripheral is taken after the Schmitt-trigger. The I/O’s state is reada ble

as in normal mode by address ing the corres ponding I/O Data Register.

29/103

L9805

I/O PO R T S

(Cont’d)

5.1.2.5 I/O Port Implementation

The I/O port register configurations are resumed

as following.

Port PA(7:0), Port PB(2:0)

RESET status: DR=0, DDR=0 and OR=0 (Input

mode, no interrupt).

These ports offer interrupt capabilities.

5.1.2.6 Dedicated Configurations

Table 5. Port A Configuration

Table 6. Port B Configuration

DDR OR MODE

00

input

no interrupt (pull-up enabled)

01

input

interrupt (pull-up enabled)

1 0 Open-Drain output

1 1 Push-Pull output

PORT A

I / O Function

Input Output Alternate Interrupt

PA0 triggered with pull-up push-pull/open drain

OCMP2_1: Output Compare

#2 Timer 1

wake-up interrupt

(I0)

PA1 triggered with pull-up push-pull/open drain

OCMP1_1: Output Compare

#1 Timer 1

wake-up interrupt

(I0)

PA2 triggered with pull-up push-pull/open drain

ICAP2_1: Input Capture #2

Timer 1

wake-up interrupt

(I0)

PA3 triggered with pull-up push-pull/open drain

ICAP1_1: Input Capture #1

Timer 1

wake-up interrupt

(I0)

PA4 triggered with pull-up push-pull/open drain

EXTCLK_1: External Clock

Timer 1

wake-up interrupt

(I0)

PA5 triggered with pull-up push-pull/open drain

OCMP2_2: Output Compare

#2 Timer 2

wake-up interrupt

(I0)

PA6 triggered with pull-up push-pull/open drain

OCMP1_2: Output Compare

#1 Timer 2

wake-up interrupt

(I0)

PA7 triggered with pull-up push-pull/open drain

ICAP2_2: Input Capture #2

Timer 2

wake-up interrupt

(I0)

PORT B

I / O Function

Input Output Alternate Interrupt

PB0 triggered with pull-up push-pull/open drain

ICAP1_2: Input Capture #1

Timer 2

wake-up interrupt

(I0)

PB1 triggered with pull-up push-pull/open drain

EXTCLK_2: External Clock

Timer 2

wake-up interrupt

(I0)

PB2

1)

Note 1. The PB2 bit is not connected to the external. It must be configured as an Input without interrupt, to be used only as an alter nate

function.

Not connected to pad Not connected to pad PWMI: PWM input

30/103

L9805

I/O PO R T S

(Cont’d)

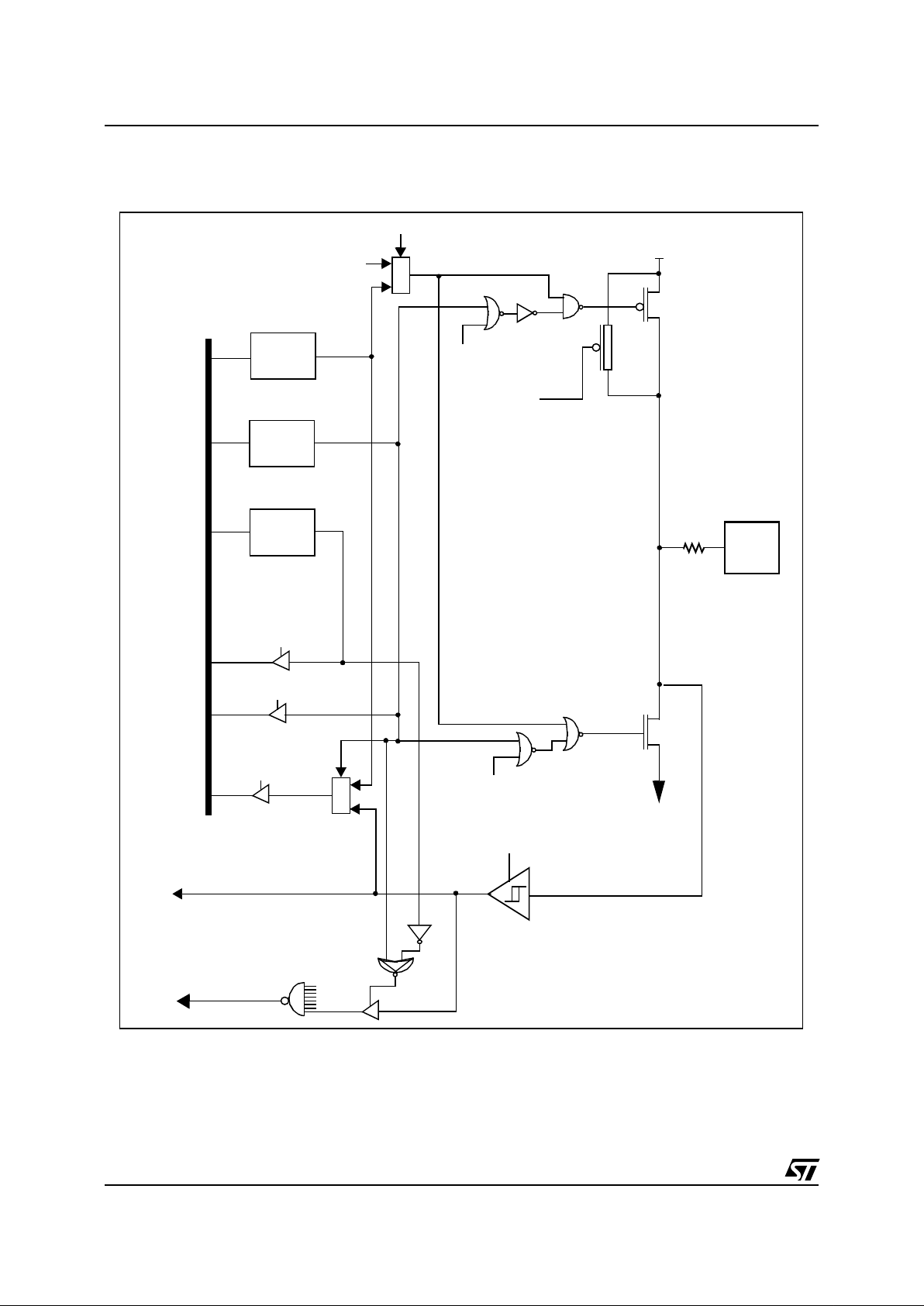

Figure 15

.

Ports PA0-PA7, PB0-PB1

I

DR

DDR

latch

latch

Data Bus

DR SEL

DDR SEL

VDD

PAD

M

U

X

Alternate

Alternate

digital enable

Alternate enable

Alternate

M

U

X

Alternate inpu t

output

P-BUFFER

N-BUFFER

1

0

1

0

OR

latch

OR SEL

from

other

bits

Interrupt

Pull-up

condition

enable

enable

GND

Loading...

Loading...