5V & 12V SPINDLE AND VCM MOTORS DRIVER

■

12V & 5V (±10%) OPERATION

■

REGISTER BASED ARCHITECTURE

■

3 WIRE SERIAL COMMUNICATION

INTERFACE UP TO 33 MHZ

■

BCD TECHNOLOGY

L7250

PRODUCT PREVIEW

Spindle Motor Controller

■

INTERNAL POWER DEVICE 0.9 OHM MAX

VALUE @ 125°C (SINK+SOURCE)

■

2.5A PEAK CURRENT CAPABILITY

■

ST SMOOTHDRIVE SINUSOIDAL PWM

COMMUTATION

■

DEDICATED ADC FOR POWER SUPPLY

VOLTAGE COMPENSAT IO N

■

SPINDLE CURRENT LIMITING VIA FIXED

FREQUENCY PWM OF SPINDLE POWER

OUTPUTS AT THE SMOOTHDRIVE PWM

RATE

■

SYNCHRONOUS RECTIFICATION DURING

PWM TO REDUCE POWER DISSIPATION

■

CURRENT SENSING VIA EXTERNAL

CURRENT SENSE RESISTOR

■

INDUCTIVE SENSE POSITION START UP

DRIVEN BY µPROCESSOR

■

SPINDLE BRAKING DURING POWER DOWN

CONDITION

Voice Coil Motor Driver with Ramp Load/Unload

■

INTERNAL POWER DEVICE 0.9 OHM MAX

VALUE @ 125°C (SINK+SOURCE)

■

2A PEAK CURRENT CAPABILITY

■

15 BIT LINEAR DAC FOR CURRENT

COMMAND, WITH INTERNAL REFERENCE

VOLTAGE

■

SENSE AMPLIFIER GAIN SWITCH

■

CLASS AB OUTPUT STAGE WITH ZERO

DEAD-BAND AND MINIMAL CROSSOVER

DISTORTION

■

RAMP LOAD AND UNLOAD CAPABILITY AS

WELL AS CONSTANT VOLTAGE RETRACT

■

EXTERNAL CURRENT SENSE RESISTOR IN

SERIES WITH MOTO R .

■

HIGH CMRR (>70DB) AND PSRR (>60DB)

SENSE AMP

■

EXTERNAL CURRENT CONTROL LOOP

COMPENSATION

■

HIGH BANDWIDTH VCM CURRENT

CONTROL LOOP CAPABI L ITY

■

HIGH PSRR, LOW OFFSET, LOW DRIFT GM

LOOP

ORDERING NUMBER: L7250

■

VCM VOLTAGE MODE, CONTROLLED BY

TQFP64

VCM DAC

■

GM LOOP OFFSET CALIBRATION SCHEME

INCLUDES A COMPAR ATOR ON THE

ERROR AMP

Auxiliary Functions

■

3.3V AND 1.8V LINEAR REGULATOR

CONTROLLER

■

NEGATIVE VOLTAG E REGUL ATOR

■

INTERNAL ISOFET 0.1 OHM @125C

■

POWER MONITOR OF 12V, 5V, 3.3V AND

1.8V

■

SHOCK SENSOR CIRCUIT TAKES INPUTS

FROM PIEZO OR CHARGING ELEMENT

■

10 BIT ADC WITH 4 MUXED INPUTS

■

THERMAL SENSE CIRCUIT AND OVER

TEMPERATURE SHUT DOWN

■

CHARGE PUMP BOOST VOLTAGE

GENERATOR FOR HIGH SIDE GATE DRIVE

■

ANALOG PINS AVAILABL E TO ENTER

SIGNALS TO BE CONVERTED BY THE

INTERNAL ADC

DESCRIPTION

L7250 is a power IC for driving the SPINDLE and

VCM motors, suitable for 5V & 12V application. The

spindle system includes integrated power FETs

which are driven using ST's Smoothdrive pseudo-sinusoidal commutation technology. The voice coi l motor (VCM) system includes integrated power FETs,

as well as ramp load and unload capability. Linear

3.3V and1.8V volt age regulators ar e include d, as wel l

as a negative regulator.

Power monitoring of VCC5, VCC12, and of the two

positive voltage regulators is also included.L7250

uses a 3 wire serial interface: S_DATA, S_CLK and

S_ENABLE

July 2001

This is preliminary information on a new product now in development. Details are subject to change without notice.

1/46

L7250

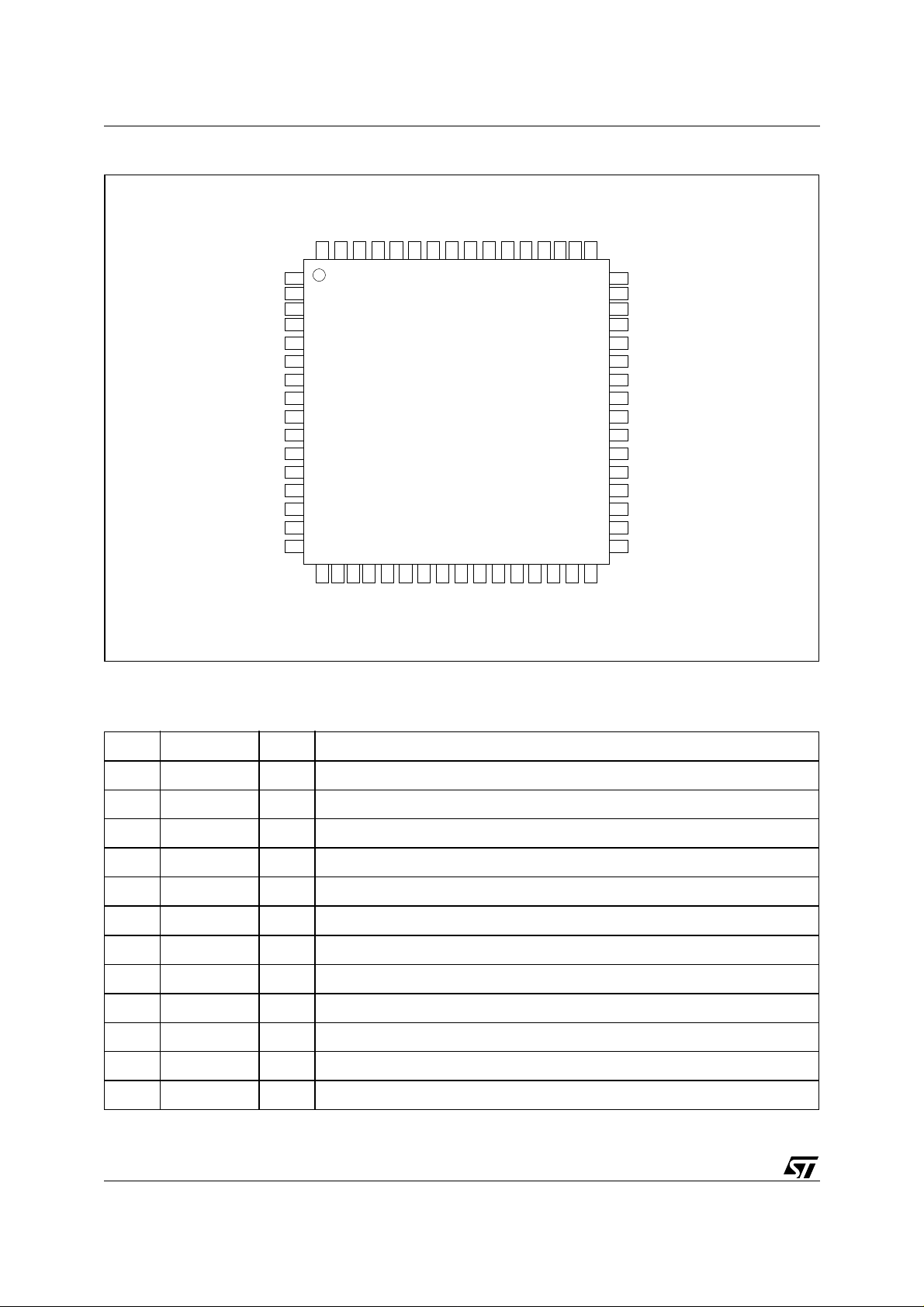

PIN CONNECTION

(Top view)

VCV1

VCV2

VCMP1

VCMP2

VCMGND1

VCMGND2

CPOSC

VCC5

DIG_GND

N_DRV

N_FEED

N_COMP

25_BASE

25_FEED

33_BASE

33_FEED

CT

OUTU1

RSEN4

VBOOST

64

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

OUTU2

CPOSCH

61

62

63

20212223242526272829303132

191718

RSEN3

60

59

58

VCV3

OUTV1

OUTV2

55

56

57

VCV4

VM1

VM2

53

54

Rsense

OUTW2

OUTW1

514950

52

RSEN2

48

RSEN1

47

VCMN2

46

VCMN1

45

VCMGND4

44

VCMGND3

43

SNS_N

42

SNS_P

41

SNS_OUT

40

ERR_OUT

39

ERR_IN

38

DAC_OUT

37

SCLK

36

SYSClk

35

SDATA

34

33

SEN

ZC

Skin

SkFin

CPOR

CBRAKE

VREF25

AGND

NPOR

Skout

SkFout

Timer1

SkDout

CalCoarse

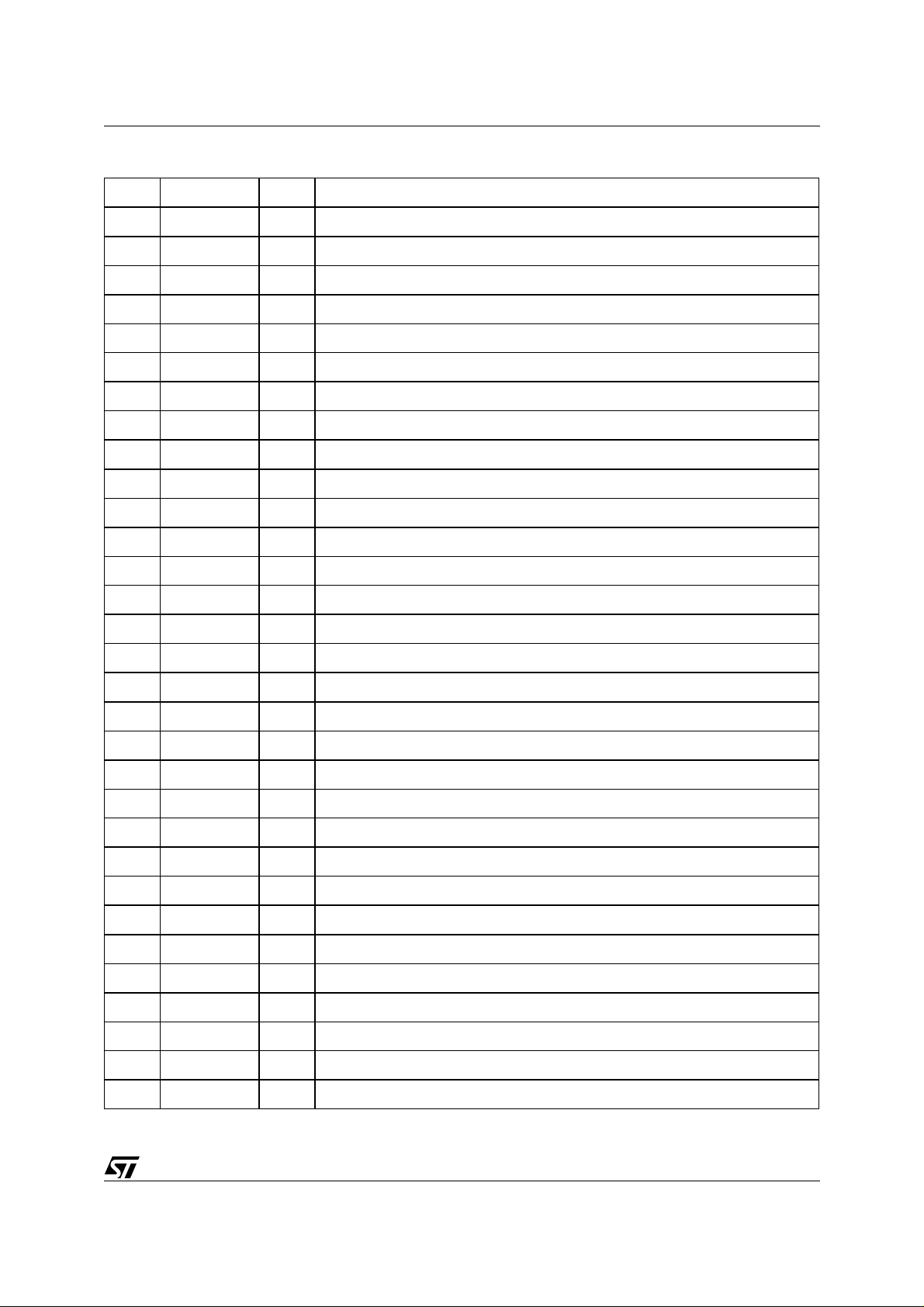

PIN DESCRIPTI ON

N° Pin V Description

1 VCV1 S12 12V power supply

2 VCV2 S12 12V power supply and POR sensing threshold

3 VCMP1 O12 VCM positive output

4 VCMP2 O12 VCM positive output

5 VCMGND1 gnd VCM power ground

6 VCMGND2 gnd VCM power ground

7 CPOSC O12 Charge pump oscillator

8 VCC5 S5 5V power supply

9 DIG_GND gnd Digital & Switching regulator ground

10 N_DRV O5 Neg Reg ext FET gate driver

11 N_FEED I5 Neg Reg feedback

Test

ADaux

VCMBEMF

12 N_COMP IO5 Neg Reg error output

2/46

L7250

PIN DESCRIPTI ON

N° Pin V Description

13 25_BASE O5 Reg 1.8V ext NPN base

14 25_FEED I5 Reg 1.8V feedback

15 33_BASE O5 Reg 3.3V ext NPN base

16 33_FEED IO5 Reg 3.3 V feedback

17 CPOR IO5 POR delay capacitor

18 NPOR O5 POR output signal

19 CBRAKE IO5 Spindle brake capacitor

20 AGND gnd analog gnd

21 VREF25 IO5 2.5V reference

22 ZC O5 Spindle zero crossing

23 Skin I5 Shock sensor input

24 Skout O5 Shock sensor 1st opamp output

25 SkFin I5 Shock sensor filter input

26 SkFout O5 Shock sensor filter output

(continued)

27 SkDout O5 Shock sensor output

28 Timer1 IO5 Timer 1 for unload procedure

29 CalCoarse I5 VCM BEMF coarse calibration

30 ADaux I5 auxiliary input for the ADC

31 VCMBEMF O5 VCM BEMF processor output

32 Test IO5 used for testing porpouse (*)

33 SEN I5 Serial enable

34 SDATA IO5 Serial data

35 SYSClk I5 System clock

36 SCLK I5 Serial clock

37 DAC_OUT O5 VCM DAC output

38 ERR_IN I5 VCM error opamp input

39 ERR_OUT O5 VCM error opamp output

40 SNS_OUT O5 VCM sense opamp output

41 SNS_P I12 VCM sense opamp positive input

42 SNS_N I12 VCM sense opamp negative input

43 VCMGND3 gnd VCM power ground

3/46

L7250

PIN DESCRIPTI ON

N° Pin V Description

44 VCMGND4 gnd VCM power ground

45 VCMN1 O12 VCM negative output

46 VCMN2 O12 VCM negative output

47 RSEN1 O12 Spindle power sensing resitor

48 RSEN2 O12 Spindle power sensing resitor

49 Rsense I5 Spindle sensing resistor input

50 OUTW1 O12 Spindle phase C output

51 OUTW2 O12 Spindle phase C output

52 VM1 IO12 Vmotor

53 VM2 IO12 Vmotor

54 VCV4 S12 12V power supply

55 VCV3 S12 12V power supply

56 OUTV1 O12 Spindle phase B output

57 OUTV2 O12 Spindle phase B output

(continued)

58 RSEN3 O12 Spindle power sensing resitor

59 RSEN4 O12 Spindle power sensing resitor

60 OUTU1 O12 Spindle phase A output

61 OUTU2 O12 Spindle phase A output

62 CT I12 Spindle central tap

63 CPOSCH IO20 Charge pump diodes connection

64 VBOOST IO20 Charge Pump voltage

(*) used al so to set the IC power supply applicati on. If this pin is pull-up exter nal l y the L7250 be came a 5V appl i cation

S = Supply ; IO = Input/Output ; I = Input ; O = Output ; gnd = Ground.

4/46

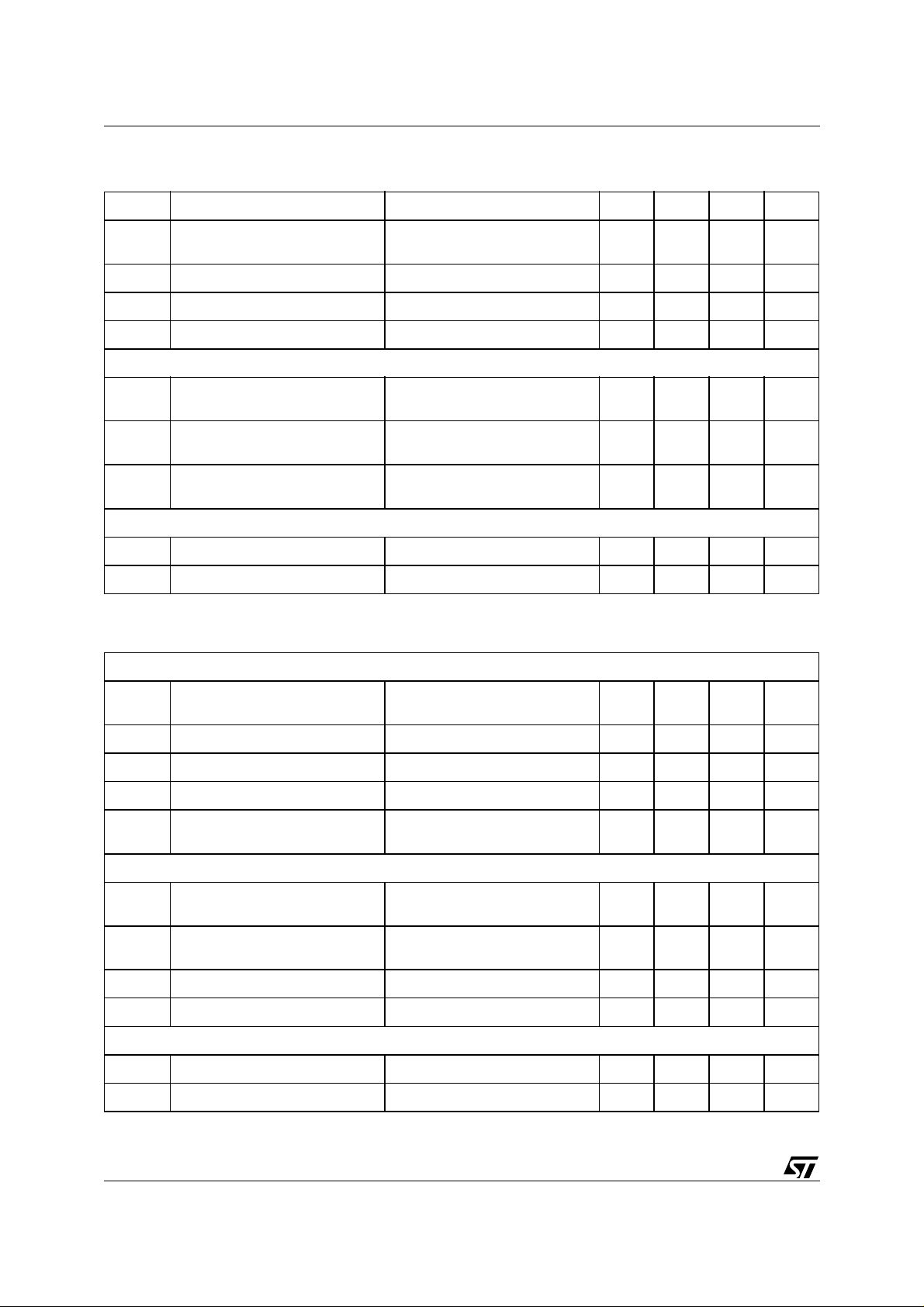

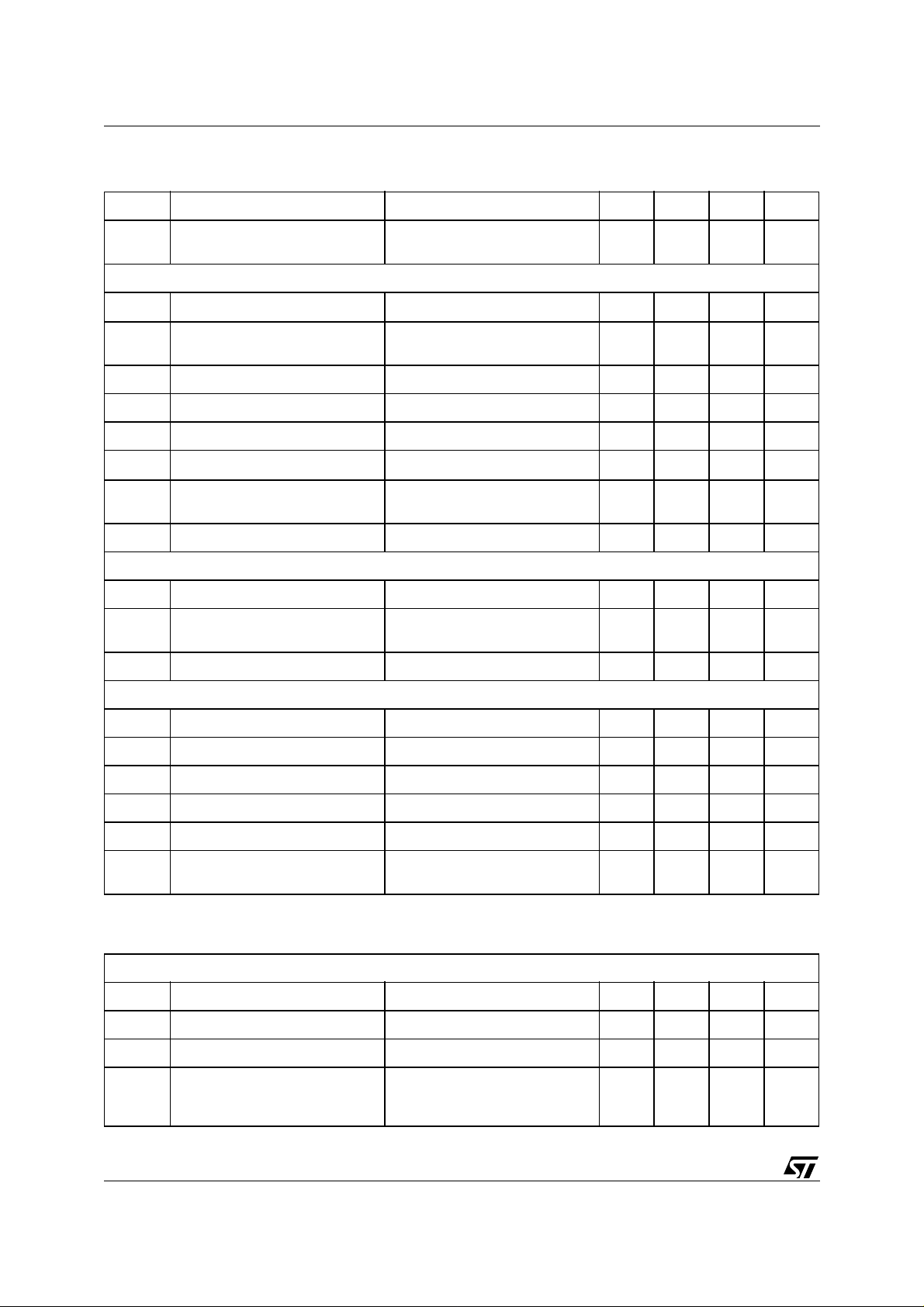

ELECTRICAL CHARACTERISTCS

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

VCV1,VCV2,VCV3,VCV4 14 V

VCC5 maximum voltage 6 V

L7250

OUTU1,OUTU2,OUTV1,OUTV2,OUTW1,OUTW2

VCMP1,VCMP2,VCMN1,VCMN2

VM1,VM2

Digital Input Voltage -0.3 to VCC5 V

Operating free-air temperature 0 to 70 °C

Storage Temperature -55 to 150 °C

-1V to 16 V

ELECTRICAL CHARACTERISTCS

POWER SUPPLY [VCC5 & VCV] VCC5 = 5V ±10%, VCV = 12V ±10%. T

Symbol Parameter Test Condition Min. Typ. Max. Unit

POWER MONITOR, SUPPLY CURRENTS, ETC.

Icc5 VCC5 Operating current Spindle and VCM enabled, no

load

Ivcv VCV + VRET Operating current Spindle and VCM enabled, no

load

CHARGE PUMP VOLTAGE BOOSTER

VBOOSTCharge pump output voltage VCV = 12V

Iload = 5mA

= 25°C (unless otherwise specified)

amb

9mA

44 mA

18.5 V

VBOOS

Tfreq

POWER MONITOR

vt5 VCC5 threshold 4.0 4.175 4.35 V

vt12 VCC12 threshold 9 9.5 10 V

hv5 VCC5 hysteresis 40 100 160 mV

hv12 VCC12 hysteresis 100 200 300 mV

vt33 V33 Threshold 2.7 2.8 2.9 V

hv33 V33 Hysteresis 20 40 60 mV

vt18 V18 Threshold (at pin 25_FEED) 1.07 1.12 1.17 V

hv18 V18Hysteresis 25 50 75 mV

NPOR

Switching frequency 1 MHz

NPOR low level output voltage VCV > 4.5V Iol = 5mA 0.75 V

low

5/46

L7250

ELECTRICAL CHARACTERISTCS

POWER SUPPLY [VCC5 & VCV] VCC5 = 5V ±10%, VCV = 12V ±10%. T

(continued)

= 25°C (unless otherwise specified)

amb

Symbol Parameter Test Condition Min. Typ. Max. Unit

NPOR

NPOR internal pull_up resistor to

pull

6Kohm

V33

CPOR

CPOR

CPOR charging current Vout = 0V 5 uA

Ic

CPOR low level output voltage VCV > 4.5V Iol = 1mA 50 mV

low

Vref25 2.5V reference voltage -5% 2.5 +5% V

THERMAL WARNING AND THERMAL SHUTDOWN

T

warn

Thermal warming temperature Characterized, tested by

130 140 150 °C

correlation.

Tsoff Thermal Shutdown temperature Characterized, tested by

150 165 180 °C

correlation

Thys Thermal Hysteresis valid for both temperature

20 25 30 °C

thresholds

VM ISOLATION FET

IsoR Rds ON @ 125°C , I=2.5A 0.1 Ohm

IsoI Continuous current 2.5 A

SPINDLE DRIVER SECTION

POWER STAGE

Rds(on) Total output ON resistance

@ 125°C, I=2.5A 0.9 Ω

(Source + Sink)

Idsx Output leakage current -200 -500 µA

CTlkg Centarl tap leakage 1 µA

DiodeFw Clamp diode forward voltage If = 2.5A 0.6 1.2 V

Slew Output slew rate OUTx 10% to 90%

40 V/µS

Reg04H ‘b7b6b5’ = 011

BACK EMF COMPARATOR

Vie Common mode input voltage

Guaranteed by design 0 VM V

range.

Vr Input voltage range where output

Guaranteed by design -1 VM+1 V

shall not invert.

BEMFoff BEMF input offset CT = 6V -15 +15 mV

BEMFhy BEMF hysteresys CT = 6V 50 mV

SPINDLE CURRENT LIMITING

Iin RSENSE Input bias current. 0 < Vin < 3.3V 1 µA

CURoff Comparator offset -15 +15 mV

6/46

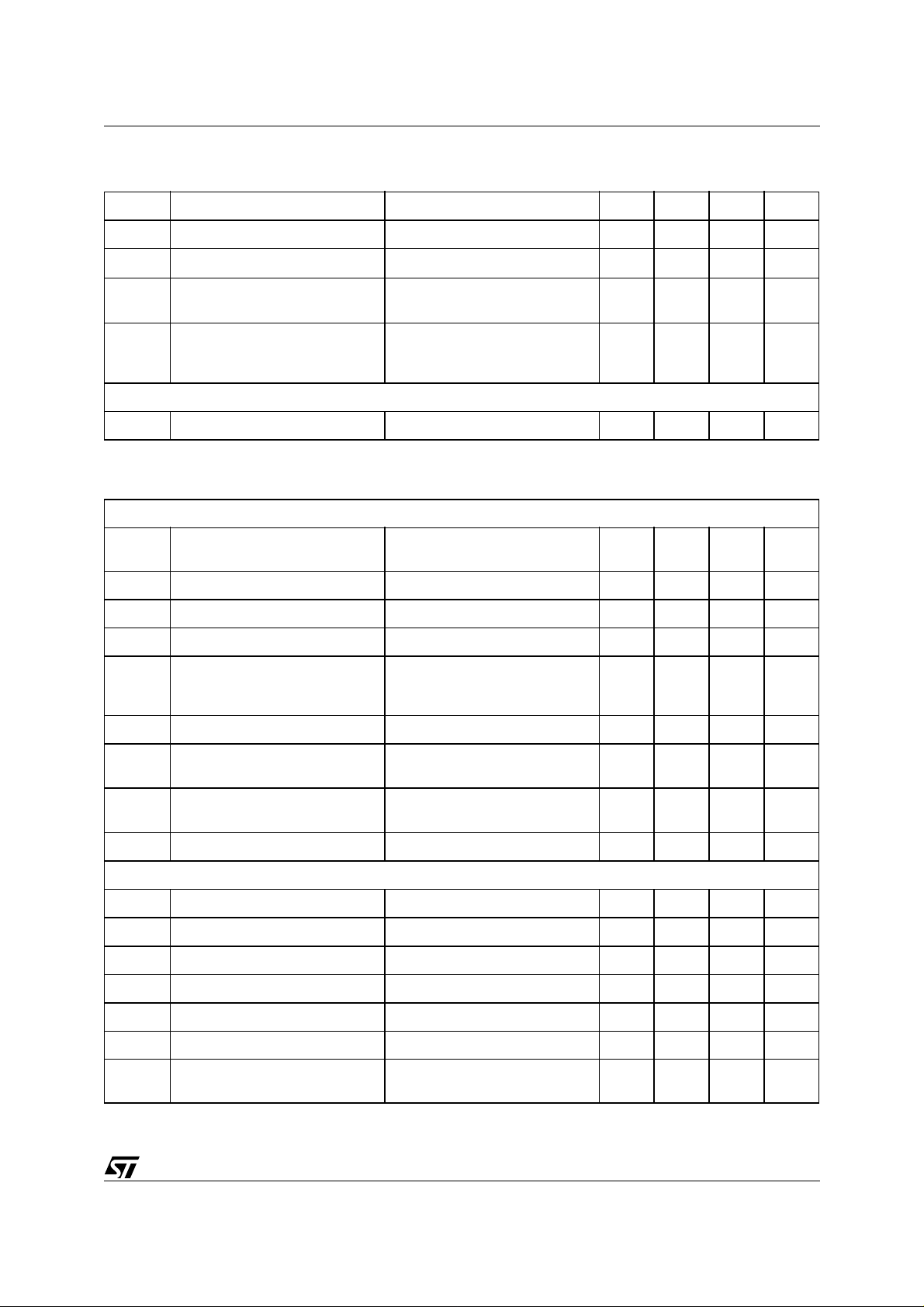

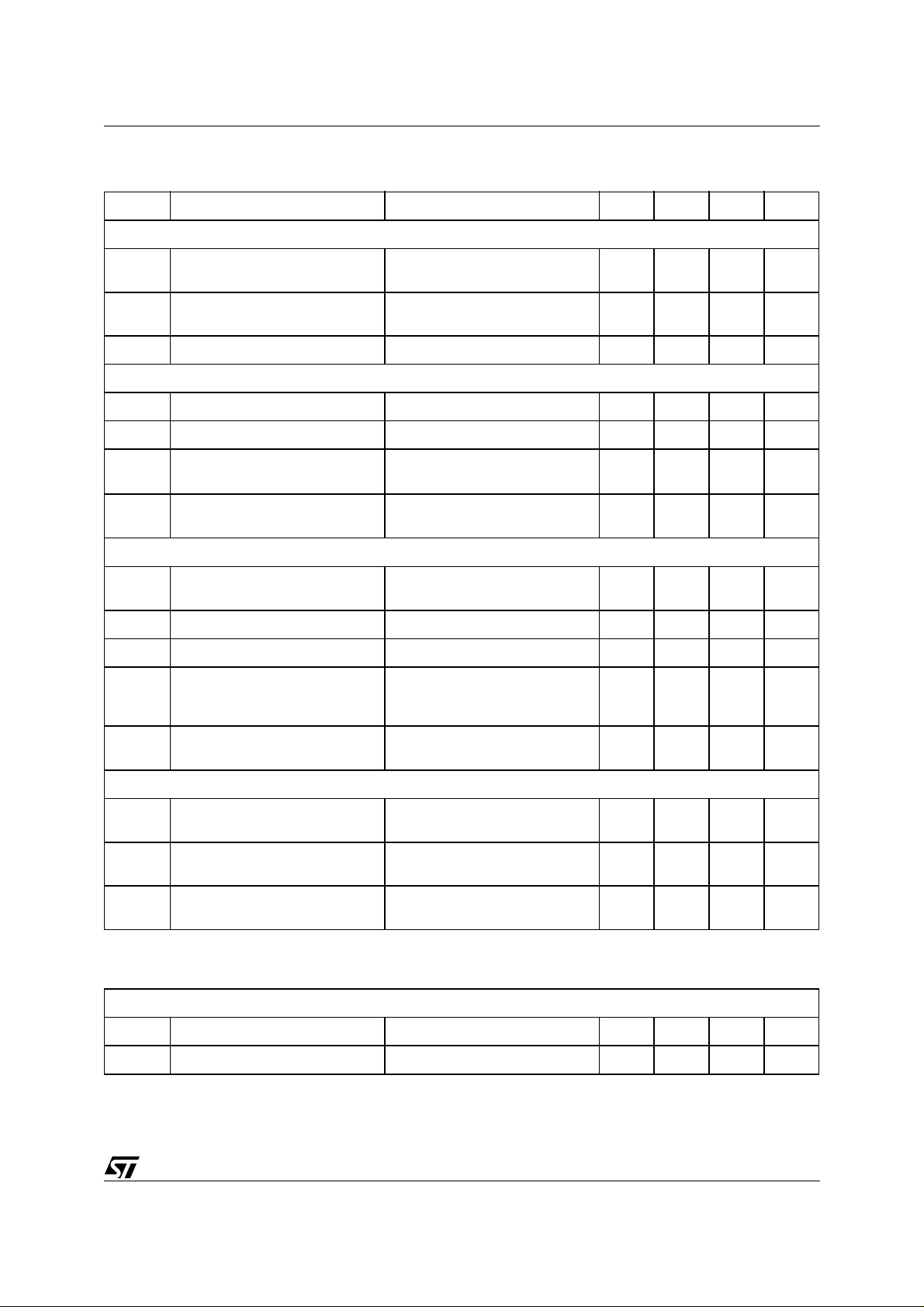

L7250

ELECTRICAL CHARACTERISTCS

POWER SUPPLY [VCC5 & VCV] VCC5 = 5V ±10%, VCV = 12V ±10%. T

(continued)

= 25°C (unless otherwise specified)

amb

Symbol Parameter Test Condition Min. Typ. Max. Unit

CURdacr

CUR

CUR

CUR

DAC resolution 3 bit

DAC output Reg04H ‘b4b3b2’ = 000 250 mV

dac_L

DAC output Reg04H ‘b4b3b2’ = 111 600 mV

dac_H

DAC linearity -10 +10 mV

lin

Cbrake

Icbrake VCbrake leakage VCbrake=5V 1 µA

VCM SECTION

CURRENT SENSE AMPLIFIER

Vts Common mode input voltage

GBD - not tested -0.6 VM+1 V

range.

Sns _vof

Sns_gai n0

f Input offset voltage -12 12 mV

Differential Voltage GAIN0 Reg09H ‘b7’ = 0 -5% 4.5 +5%

Sns _gain1

Sns_low

Sns_high

sns_slew

Sns_band

sns _cmrr

sns _svrr

Differential Voltage GAIN1 Reg09H ‘b7’ = 1 -5% 16 +5%

VSENSE output saturation

voltage

Iload=+/-1mA

Vin_diff=+/- 500m V

4.75

250 mV

V

Output slew rate Cload=50pF 1 V/µs

-3dB Bandwidth Guaranteed by design 200 400 kHz

Common mode rejection ratio f < 10 KHz, tested at DC only

CMRR=A

V DIFF/AV CM

70 dB

supply voltage rejection ratio VCV f < 10 KHz, tested at DC only 60 dB

ERROR SUMMING AMPLIFIER

err _gain Voltage gain no load 60 dB

err _band

Unity gain bandwidth Guaranteed by design 4 MHz

err _slew Output Slew Rate Cload=50pF 1.5 V/µS

err _ibias

Input bias current 1 µA

err _off Input offset voltage -10 0 10 mV

err_svrr supply voltage rejection ratio f < 10 KHz, tested at DC only 60 dB

err _clamp

Low output (clamp) voltage Isink = 1 mA, referred to Vref25 TBD V

low

7/46

L7250

ELECTRICAL CHARACTERISTCS

POWER SUPPLY [VCC5 & VCV] VCC5 = 5V ±10%, VCV = 12V ±10%. T

Symbol Parameter Test Condition Min. Typ. Max. Unit

err _clamp

high

VCM OUTPUT DRIVERS

PWR_Gain

Rds(on) Total output ON resistance

PWR_Lkg

DiodeFw Clamp diode forward voltage If = 2A 0.6 1.2 V

THD Total Harmonic Distortion characterized no tested 1 %

PWR_Slew

PWR_B

and

Icross Static Shoot-through current Guaranteed by design 0 mA

VCM CURRENT CONTROL LOOP STATIC AND DYNAMIC CHARACTERISTICS

IVCMoff Total offset current Rs=0.2 -75 75 mA

High output (clamp) voltage Isource = 1mA, referred to Vref25 TBD V

Power amplifier differential gain. Io = ±1A, Rload = 8Ω 14 15 16 V/V

(Source + Sink)

Output leakage current 600 uA

VCMN or VCMP slew rate RL = 8 ohms 1 V/us

Power Amp -3dB Bandwidth Driving ERROUT = VDACREF,

(continued)

@ 125°C, I=2A .9 Ω

Guaranteed by design

= 25°C (unless otherwise specified)

amb

250 500 kHz

DIVCMoff

Gm_psrr Gm loop VSRR of VCV -1 1 mA/V

VCM LINEAR DAC

DAC_res Resolution 15 bit

DAC_out Full Scale Output Voltage wrt VDACREF 0.96 1 1.04 V

DAC_off Mid-Scale Error wrt VDACREF -12 12 mV

DAC_DNL

DAC_INL

DAC_Co

nvT

VCM LOAD/UNLOAD

ADC

ADC_res

ADC_DNL

ADC_INL

Total offset current drift

temperature coefficient

Differential Non linearity Guaranteed Monotonicity ±1 LSB

Integral Non Linearity ±64 LSB

Conversion time 90% from 3FFFh to 0020h 3 µs

resolution 10 bit

Differential Non Linearity 1 LSB

Integral Non Linearity 3 LSB

Guaranteed by design .2

mA/oC

ADC_Co

nvT

8/46

Conversion time 40 ADC

Clock

cycles

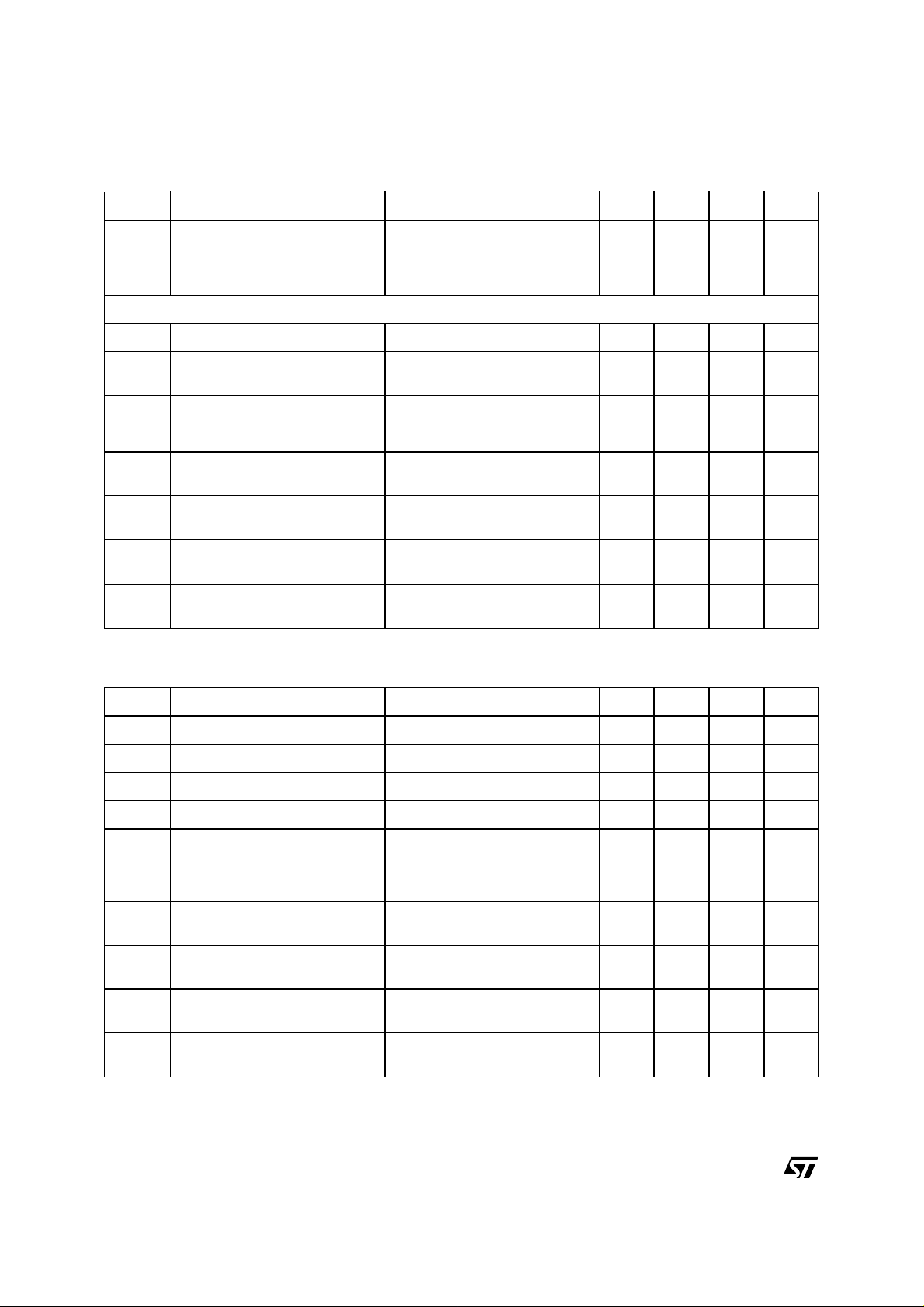

L7250

ELECTRICAL CHARACTERISTCS

POWER SUPPLY [VCC5 & VCV] VCC5 = 5V ±10%, VCV = 12V ±10%. T

Symbol Parameter Test Condition Min. Typ. Max. Unit

ADC AUXILIARY INPUT

AUX_ran

ge0

AUX_ran

ge1

AUX_Ibias

VCM VOLTAGE AMPLIFIER

V olt_gain

Volt_off Input offset -15 +15 mV

Vo lt

_cmrr

Volt

_svrr

BEMF processor amplifier

CalCoar

seIn

Input range 0 Reg06H ‘b3’ = 0

Input range 1 Reg06H ‘b3’ = 1

Input bias -100 100 µA

Voltage gain 0.165 V/V

Common mode rejection ratio f < 10 KHz, tested at DC only

supply voltage rejection ratio f < 10 KHz, tested at DC only 60 dB

Calcoarse voltage input range 0.5 2 V

(continued)

Referred to Vref25

Referred to Vref25

CMRR=A

V DIFF/AV CM

= 25°C (unless otherwise specified)

amb

±1 V

±2.25 V

46 dB

Gain1 First stage gain Vcontrol = 1.25 V 1.91 V/V

Gain2 Second stage gain 16 V/V

Offset Residual input offset after

calibration

Rout BEMF amp output resistance (pin

31)

ULOAD @ POR

Timer1_V

Timer1_I Timer1 Discharging Current 2 µA

Timer1_T

VOLTAGE REGULATORS

1.8 AND 3.3 LINEAR REGULATOR

V18 feed 1.8V feedback Voltage -5% 1.25 +5% V

V33 OUT

Timer1 Charging Voltage 2.5 V

Timer1 Low threshold 0.2 V

3.3V Output Voltage -5% 3.3 +5% V

Vcontrol = 1.25V

(Measured between VCMN and

SNS_P pins)

-3 +3 mV

500 ohm

9/46

L7250

ELECTRICAL CHARACTERISTCS

POWER SUPPLY [VCC5 & VCV] VCC5 = 5V ±10%, VCV = 12V ±10%. T

Symbol Parameter Test Condition Min. Typ. Max. Unit

V18

IDRIVE

V33

IDRIVE

NEGATIVE REGULATOR

FREQ0 Oscillator frequency Default configuration 500 KHz

FREQ1 Oscillator frequency TestRegister = ‘00001001’

VoutH High level output voltage TBD V

VoutL Low level output voltage TBD V

VNEerr

OFFS

VNEGerr

BIAS

Vneg_err

_cmrr

Vneg_err

_svrr

Output base current drive

Feedback input offset -10 10 mV

Feedback input bias 0 1 µA

Common mode rejection ratio f < 10 KHz, tested at DC only

supply voltage rejection ratio VCV f < 10 KHz, tested at DC only 60 dB

(continued)

or = ‘00101001’

CMRR=A

V DIFF/AV CM

= 25°C (unless otherwise specified)

amb

1 MHz

46 dB

15 mA

SHOCK SENSOR

SkIgain0 Input OPAMP gain0 Reg02H ‘b7’ = 0 10 V/V

SkIgain1 Input OPAMP gain1 Reg02H ‘b7’ = 1 80 dB

SkIoff Input OPAMP offset -15 +15 mV

SkIinput Input OPAMP input impedance Reg02H ‘b7’ = 0 10 Mohm

SkFgain Filter OPAMP open loop gain 80 DB

SkFband Filter OPAMP unity gain

bandwidth

SkFoff Filter OPAMP offset voltage -10 +10 MV

SkOThH0

SkOThH1

SkOThL0

SkOThL1

Output window comparator

VthHigh

Output window comparator

VthHigh

Output window comparator

VthLow

Output window comparator

VthLow

Guaranteed by design 5 Mhz

Referred to Vref25 ;

Reg02H ‘b6’ = 0

Referred to Vref25 ;

Reg02H ‘b6’ = 1

Referred to Vref25;

Reg02H ‘b6’ = 0

Referred to Vref25;

Reg02H ‘b6’ = 1

200 mV

500 mV

200 mV

500 mV

10/46

L7250

ELECTRICAL CHARACTERISTCS

POWER SUPPLY [VCC5 & VCV] VCC5 = 5V ±10%, VCV = 12V ±10%. T

Symbol Parameter Test Condition Min. Typ. Max. Unit

SERIAL PORT

Voh Logic Output voltage high Ioh=1mA 2.7 V

Vol Logic Output voltage low Iol=1mA 0.5 V

Vih L ogic input high Iih=1uA 2.2 V

Vil Logic input low Iil=-1uA 0.5 V

Iih Logic high input current Internal Pulldown Resistor

Iil Logic low input current -1.00 µA

(continued)

Vin = 3.3V

= 25°C (unless otherwise specified)

amb

33 µA

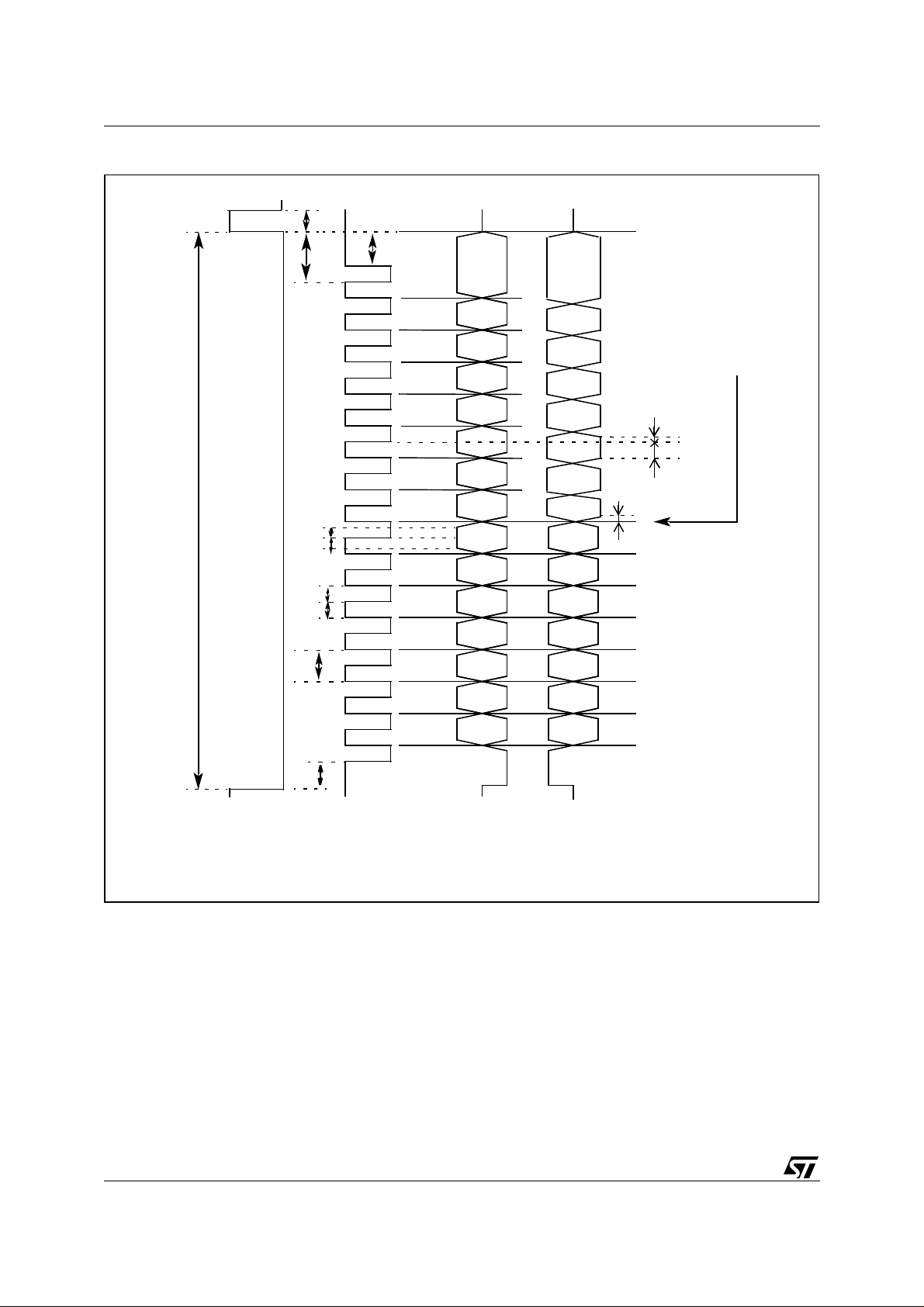

1 SERIAL PORT

The serial port is a bidirectional three pi n interface, using SDATA, SCLK and SE N to addr ess and communi cate

with sixteen 8 bit registers in the L7250. These registers include the status register, Spindle control registers,

VCM control registers, sinewave drive registers, and test mode register. These registers are cleared to zero at

power up.

1.1 Default comunication modes setting (bit 7, Reg05H ) = 0

After the SEN falling edge, the internal state machine is waiting for the first SCLK falling edge. This means that

if the SCLK line starts from an high level the first falling edge, respecting the setup time Tefcf, is considered,

and is used to read the R/W bit. During a writing process the internal state machine must see 16 SCLK falling

edges to validate the operation. The write mode is started if the R/W bit is low on the first falling edge of SCLK.

The read mode is started if the R/W bit is high on the first falling edge of SCLK. The ID, Address, and Data are

all then subsequently read by the L7250 on the falling edges of SCLK. (See Figure 1)

The microcontroller has to read the data on the falling edge of the SCLK signal. After the hold time (Tedh) the

data line switches to the next data without a tri-state phase.During a read mode the last address bit is read by

L7250 on the eighth falling edge of SCLK. The internal state machine then turns the SDATA bit around for the

L7250 to assume control at the next SCLK rising edge (the first rising edge after the 8th SCLK falling edge).

11/46

L7250

Figure 1. Default serial port timing diagram (bit 7, Reg05H = 0)

Teh

Tcfer

Tcrer

D1 D0

D2

D0

Tedh

D5 D4 D3

D6

D6 D5 D4 D3 D2 D1

D7

Tdly

Tcdd

L 7250 takes bus control

Tcds Tcdh

A1 A0 D7

A2

A1 A0

A2

Tcc Tch Tcl

ID2 ID2 A2

ID2 ID2 A2

ID 2

Tefcf

SEN

Note1: During writing process L7250 latches the data on the SC LK falling edge (the ASI C is writing on the SCLK

rising edge)

Note2: During reading process L7250 takes the bus control on the next SCLK rising edge after the 8th SCLK

falling edge

The L7250 write the data on the SCLK falling edge respecting the data hold time (Tedh)

Note3: The ID number for the L7250 is ID1=ID2=ID3=1

12/46

SCLK

W

SDATA

(w rite)

ID 2

R

SDATA

(read)

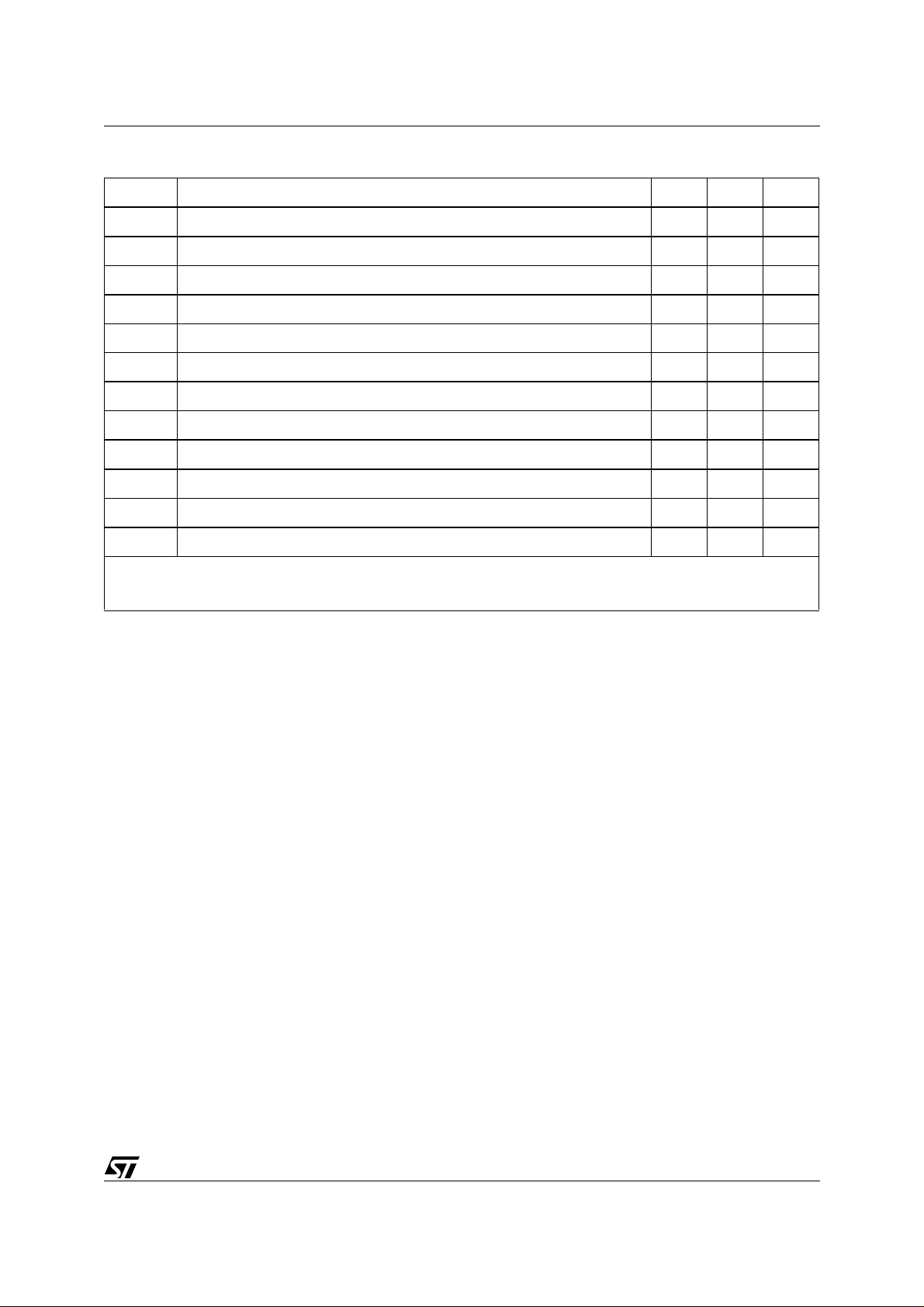

1.2 Default serial port timing Table

Symbol Parameter Min Max Unit

Tcc Serial clock period 30 ns

Tch Serial clock high time 13 ns

Tcl Serial clock low time 13 ns

Tcds Serial data setup time to clock falling edge (write mode) 5 ns

Tcdh Serial clock falling edge to serial data hold time (write mode) 4 ns

Tedh Serial clock falling edge to serial data hold time (read mode) 5 ns

Tcdd Serial data setup time to clock falling edge (read mode) 5 ns

Tel Serial Enable low time 490 ns

Teh Serial Enable high time 30 ns

Tefcf Serial Enable falling edge to serial clock falling edge 17 ns

Tcfer Serial clock falling edge to Serial enable rising edge 17 ns

Tdly SDATA turn around delay time 0 ns

L7250

Note 1: All specifications with respect to 50% of signal switching thresholds

Note 2: Reading mode tested at M ax 20Mhz

1.3 Inverted clock comunication modes (bit 7, Reg05H) = 1

To set the bit7, Reg05H to 1, entering this different comunication mode, a writing process using the default comunication protocol (see the above paragraph) must be used.

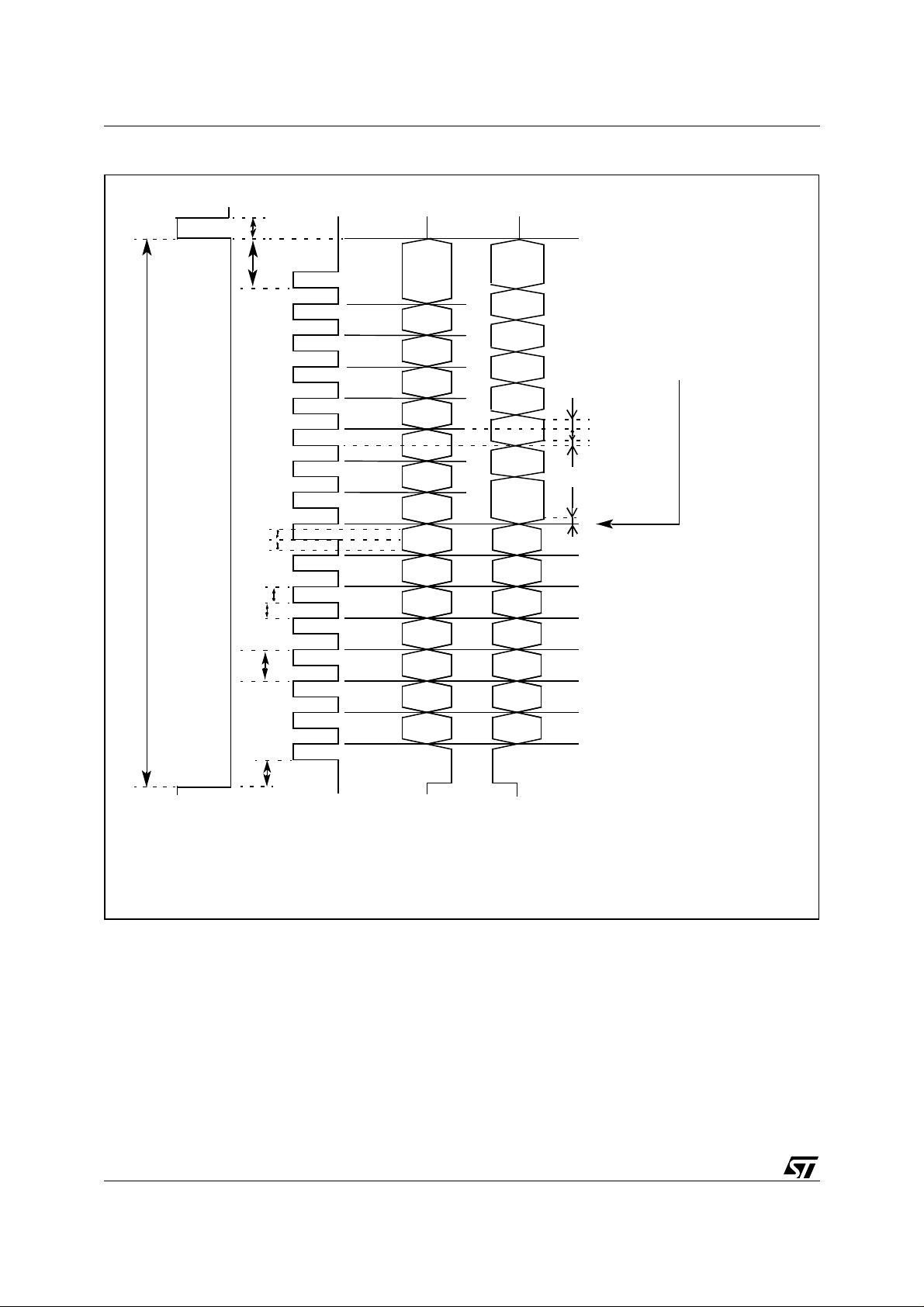

After the SEN falling edge, the internal state machine is waiting for the first SCLK rising edge. This means that

if the SCLK line starts from a low level the first rising edge, respecting the setup time Tefcr, is considered, and

is used to read the R/W bit. The internal state machine must see 16 SCLK rising edges to validate the write

operation. The write mode is started if the R/W bit is low on the first rising edge of SCLK. The read mode is

started if the R/W bit is h igh on the first rising ed ge of SCLK. The ID, Address, and Data are a ll then subsequently read by the L7250 on the rising edges of SCLK (See Figure 2).

The microcontroller has to r ead (l atch) the data on the falli ng edge of the SCLK signal. L7250 pr esents the data

on the SCLK rising edge. During a read mode the last address bit is latched by the L7250 on the eighth rising

edge of SCLK. The internal state machine then turns the SDATA bit around for the L7250 to ass ume control at

the next SCLK falling edge (the first falling edge after the 8th SCLK rising edge).

13/46

L7250

Figure 2. Inverted clock serial port timing diagram (bit 7, Reg05H = 1)

Teh

Tcrer

D1 D0

D2

D0

Tedh

D5 D4 D3

D6

Tel

D6 D5 D4 D3 D2 D1

D7

Tdly

Tvld

L7250 takes bus control

Tcdh

Tcds

A1 A0 D 7

A1 A0

Tcl

A2

A2

Tch

Tcc

ID 2 ID2 A2

ID 2 ID2 A2

ID 2

Tefcr

SEN

Note1: During writi ng proc ess L7250 l atches the data on the SCLK ris ing ed ge ( the ASIC is w riting on the S CLK

falling edge)

Note2: During reading proces s L7250 takes the bus c ontrol on the next SCLK falling edge after the 8th SCLKrising edge

The L7250 write the data on the SCLK rising edge and it is expec ting the ASIC to latches the data on the SCLK

falling edge

Note3: The ID number for the L7250 is ID1=ID2=ID3=1

14/46

SCLK

W

SDATA

(w rite)

R

SDATA

ID 2

(read)

Loading...

Loading...