STEP DOWN CONTROLLER FOR HIGH DIFFERENTIAL

FEATURE

■ CONSTANT ON TIME TOPOLOG Y ALLO WS

OPERATION WITH LOWER DUTY THAN

PWM TOPOLOGY

■ VERY FAST LOAD TRANSIENTS

■ 5V V

■ 1.5V TO 28V INPUT VOLTAGE RANGE

■ 0.9V ±1% V

■

■ SELECTABLE SINKING MODE

■ LOSSLESS CURRENT LIMIT

■ REMOTE SENSING

■ OVP,UVP LATCHED PROTECTIONS

■ 600µA TYP QUIESCENT CURRENT

■ POWER GOOD AND OVP SIGNALS

■ PULSE SKIPPING AT LIGHT LOADS

APPLICATIONS

■ I/O BUS FOR CPU CORE SUPPLY

■ NOTEBOOK COMPUTERS

■ NETWORKING DC-DC

■ DISTRIBUTED POWER

SUPPLY

cc

REF

MINIMUM OUTPUT VOLTAGE AS LOW AS 0.9V

L6995

INPUT-OUTPUT CONVERSION

TSSOP20

ORDERING NUMBERS: L6995D

L6995DTR

DESCRIPTION

The device is a step-down controller specifically designed to provide extremely high efficiency conversion, with losses current sensing tecnique.

The "constant on-time" topology assures fast load

transient response. The embedded "voltage feed- forward" provides nearly constant switching frequency

operation.

An integrator can be introduced in the control loop to

reduce the static output voltage error.

The available remote sensing improve the static and

dynamic regulation recovering the wires voltage

drop. Pulse skipping technique reduces power consumption at light load. Drivers current capability allows output current in excess of 20A.

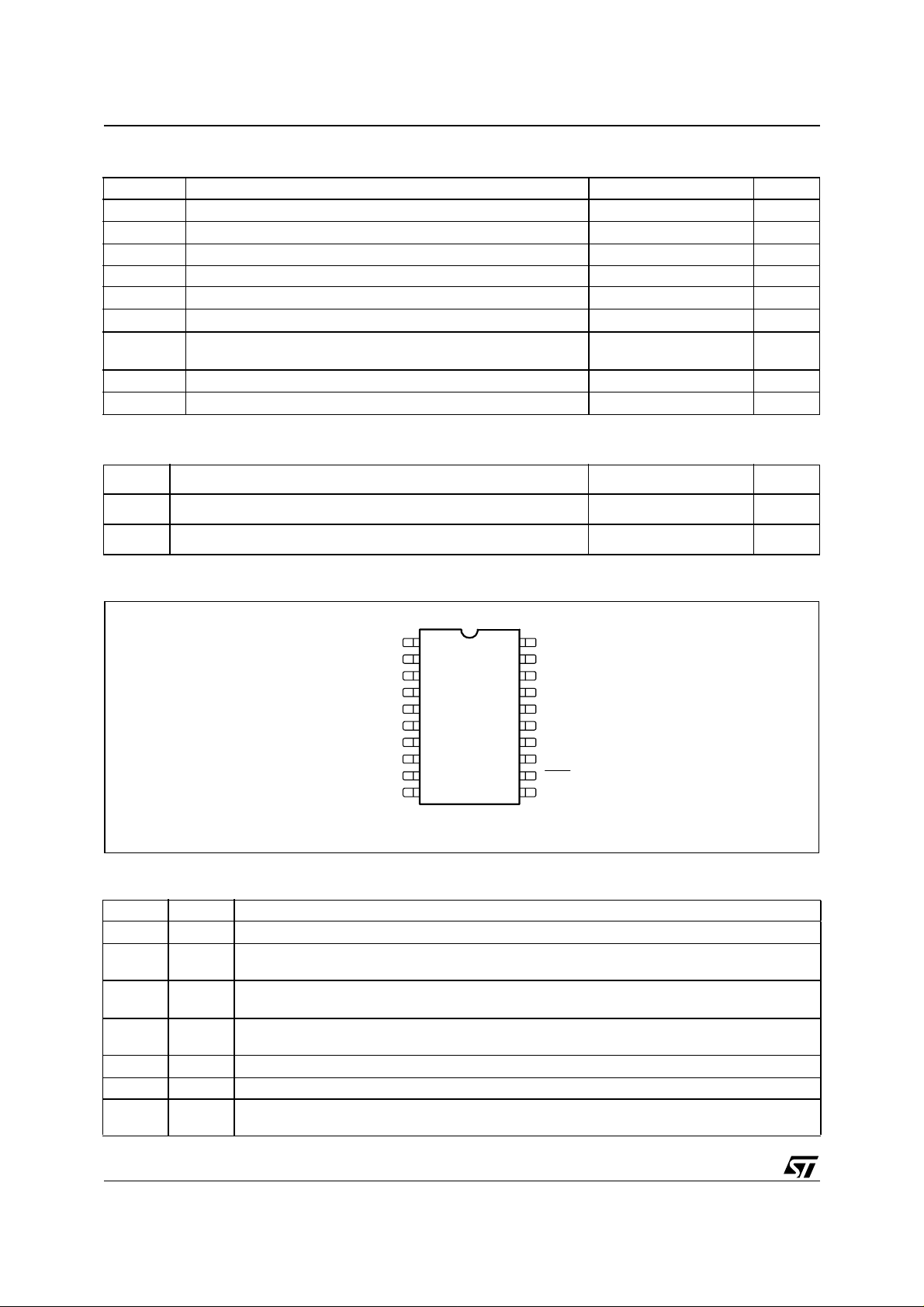

MINIMUM COMPONENT COUNT APPLICATION

Rin2 Rin1

5V

OSC

VDR

VCC

SHDN

RILIM

ILIM

L6995

SS

C

SS

BOOT

HGATE

PHASE

LGATE

PGND

GND

NOSKIP

VSENSE

INT

VFB

VREF

December 2002

This is preliminary information on a new product now in development. Details are subject to change without notice.

28V

C

HS

LS

VREF

CIN

D

BOOT

C

BOOT

L

DS

5V

C

OUT

Vo

0.9V

1/25

L6995

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

CC

V

DR

V

PHASE

P

tot

T

stg

THERMAL DATA

Symbol Parameter Value Unit

VCC to GND -0.3 to 6 V

V

to GND -0.3 to 6 V

DR

HGATE and BOOT, to PHASE -0.3 to 6 V

HGATE and BOOT, to PGND -0.3 to 36 V

PHASE -0.3-to 30 V

LGATE to PGND -0.3 to V

ILIM, VFB, VSENSE, NOSKIP, SHDN, PGOOD, OVP, VREF, INT,

SENSE

to GND

= 25°C 1 W

amb

GND

Power dissipation at T

-0.3 to V

+0.3 V

DR

+0.3 V

CC

Storage temperature range -40 to 150 °C

R

th j-amb

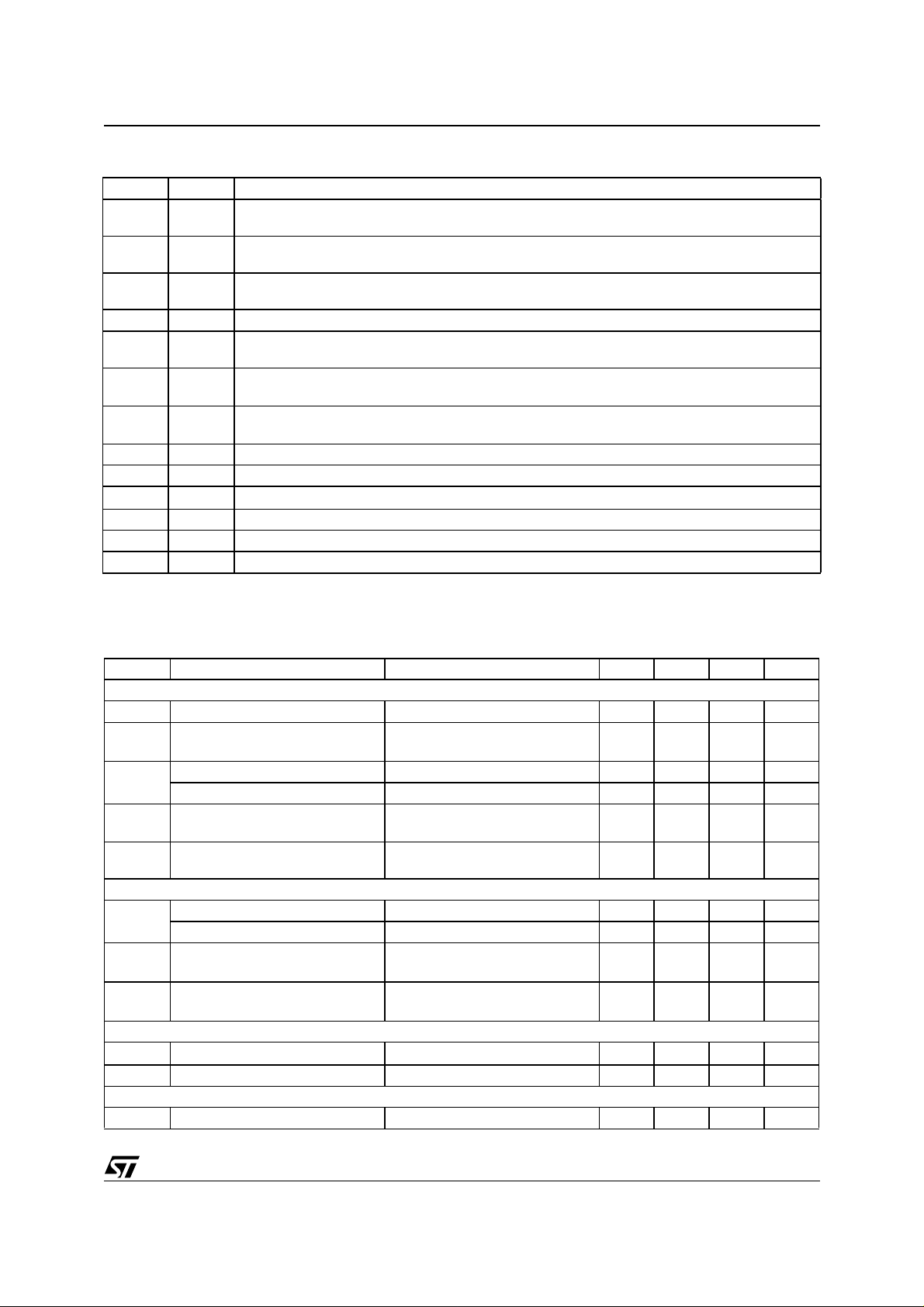

PIN CONNECTION

Thermal Resistance Junction to Ambient 125 °C/W

T

Junction operating temperature range 0 to 125 °C

j

(Top View)

NOSKIP

GNDSENSE

INT

INT

VSENSE

VCC

GND

VREF

VFB

OSC

2

3

4

5

6

7

8

9

10SS

TSSOP20

20

BOOT1

19

HGATE

18

PHASE

17

VDR

16

LGATE

15

PGND

14

PGOOD

13

OVP

12

SHDN

11

ILIM

PIN FUNCTION

N° Name Description

1 NOSKIP Connect to V

2 GNDSE

Remote ground sensing pin

NSE

3 INT Integrator output. Short this pin to VFB pin and connect it via a capacitor to V

integrator in the control loop. If the integrator is not used, short this pin to VREF.

4 VSENSEThis pin must be connected to the remote output voltage to detect overvoltage and undervoltage

conditions and to provide integrator feedback input.

5V

Supply voltage for IC core. Connect to 5V bus.

CC

6 GND Signal ground

7 VREF 0.9 V voltage reference. Connect max. a 10nF ceramic capacitor between this pin and ground.

This pin is capable to source or sink up to 250uA

to force continuous conduction mode and sink mode.

CC

to insert the

OUT

2/25

L6995

PIN FUNCTION

(continued)

N° Name Description

8 VFB PWM comparator feedback input. Short this pin to INT pin when using the integrator function, or

to VSENSE pin without integrator.

9 OSC Connect this pin to the input voltage through a voltage divider in order to provide the feed-

forward function. It cannot be left floating.

10 SS Soft start pin. A 5µA constant current charges an external capacitor which value sets the soft-

start time.

11 ILIM An external resistor connected between this pin and GND sets the current limit threshold.

12 SHDN Shutdown. When shorted to GND the device stops working; when high, it enables the normal

operation. It cannot be left floating.

13 OVP Open drain output. When in OVP condition, the internal transistor goes off. Connect this pin to

V

through a resistor.

CC

14 PGOOD Open drain output. The internal transistor is on during soft-start or in case of output voltage

faults. Connect this pin to V

through a resistor.

CC

15 PGND Low Side driver ground.

16 LGATE Low Side driver output.

17 V

Low Side driver supply.

DR

18 PHASE Return path of the High Side driver.

19 HGATE High side MOSFETS driver output.

20 BOOT Bootstrap capacitor pin. High Side driver is supplied through this pin.

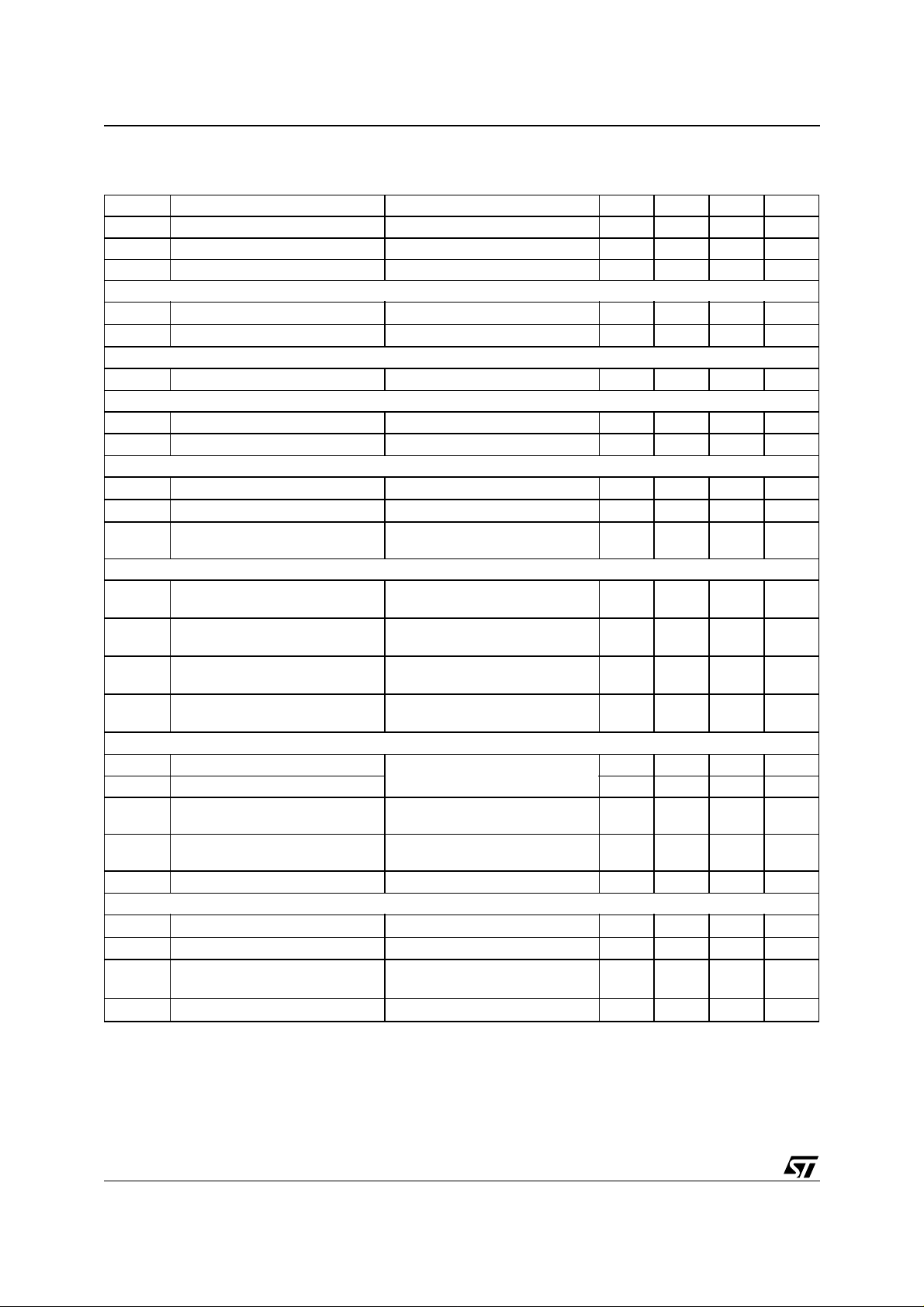

ELECTRICAL CHARACTERISTICS

= VDR = 5V; T

(V

CC

= 0°C to 85°C unless otherwise specified)

amb

Symbol Parameter Test Condition Min. Typ. Max. Unit

SUPPLY SECTION

Vin Input voltage range Vout=Vref Fsw=110Khz Iout=1A 1.5 28 V

V

,

CC

V

DR

V

Turn-onvoltage 4.2 4.4 V

CC

4.5 5.5 V

Tu r n-off voltage 4.1 4.3 V

Iqcc

(V

Iqcc

Driver quiescent current VFB > VREF 20 µA

)

DR

Quiescent current VFB > VREF 600 µA

(Vcc)

SHUTDOWN SECTION

SHDN Device On 1.2 V

Device Off 0.6 V

I

SH

(VDR)

I

SH

Driver quiescent current in

shutdown

Shut down current SHDN to GND 15 µA

SHDN to GND 5 µA

(VCC)

SOFT START SECTION

I

Soft Start current 4 6 µA

SS

SS Clamp Voltage 4 V

ON TIME

Ton On time duration VREF=VSENSE OSC=250mV 850 950 1050 ns

3/25

L6995

ELECTRICAL CHARACTERISTICS

(V

= VDR = 5V; T

CC

= 0°C to 85°C unless otherwise specified)

amb

(continued)

Symbol Parameter Test Condition Min. Typ. Max. Unit

VREF=VSENSE OSC=500mV 380 430 480 ns

VREF=VSENSE OSC=1V 220 250 280 ns

VREF=VSENSE OSC=2V 120 150 180 ns

OFF TIME

T

OFFMIN

Minimum off time 580 ns

K

OSC/TOFFMIN

OSC=250mV 0.4 0.45

VOLTAGE REFERENCE

VREF Voltage Accuracy 0µA < I

< 100µA 0.891 0.9 0.909 V

REF

PWM COMPARATOR

Input voltage offset -2 +2 mV

I

Input Bias Current 0.1 µA

FB

CURRENT LIMIT AND ZERO CURRENT COMPARATOR

K

C

PHASE-

ILIM input bias current I

Current Limit factor R

Zero Crossing Comparator offset -2 2 mV

to GND = 120KΩ 5 µA

LIM

=120 KΩ 0.85 1 1.15 µA

ILIM

GND

GATE DRIVERS

High side rise time V

=5V; C=7nF

DR

50 70 ns

HGATE - PHASE from 2 to 4.5V

High side fall time V

=5V; C=7nF

DR

50 70 ns

HGATE - PHASE from 2 to 4.5V

Low side rise time V

=5V; C=14nF

DR

50 70 ns

LGATE from 2 to 4.5V

Low side fall time V

=5V; C=14nF

DR

50 70 ns

LGATE from 2 to 4.5V

P

UVP/OVP PROTECTIONS

GOOD

OVP Over voltage trip with respect to V

REF

112 115 118 %

UVP Under voltage trip 66 69 72 %

PGOOD Upper threshold

V

rising 107 110 113 %

SENSE

(VSENSE/VREF)

PGOOD Lower threshold

V

falling 86 89 92 %

SENSE

(VSENSE/VREF)

V

PGOOD

I

SOURCE

=2mA 0.14 0.2 V

INTEGRATOR

INT Over Voltage Clamp V

INT Under Voltage Clamp V

-

V

SENSE

V

I

VSENSE

Integrator Input Offset Voltage -5 5 mV

REF

Input Bias Current 0.1 µA

= V

SENSE

SENSE

CC

= GND 0.82 0.84 0.86 V

1.04 1.07 1.1 V

4/25

Figure 1. Funct i on a l & Blo c k D iag ram

IN

V

5V

L6995

OUT

V

GNDVCCOVPPGOODSHDN

overvoltage comparator

VSENSE

+

1.15 VREF

-+undervoltage comparator

VSENSE

0.69 VREF

pgood comparators

SR

LS and HS anti-cross-conduction comparators

1.10 VREF

VSENSE

-

+

comp

V(LGATE)<0.5V

VSENSE

+

BOOT

VCC

0.89 VREF

-

HGATE

HS driver

level shifter

V(PHASE)<0.2V

RQ

comp

S

Toff min

PHASE

delay

VDR

Ton min

one-shot

PGND

LGATE

LS driver

Q

R

S

Ton

one-shot

OSC

VSENSE

Ton= Kosc V(VSENSE)/V(OSC)

Q

R

S

mode

no-skip

-

+

PHASE

zero-cross comparator

LS control

Ton

one-shot

OSC

VSENSE

mode

no-skip

Ton= Kosc V(VSENSE)/V(OSC)

NOSKIP

IC enable

control

soft-start

SS

5 uA

power management

ILIM

comparator

positive current limit

-

PHASE

+-+

+VREF

0.2

FB

HS control

VREF

pwm comparator

+

+

-

-

Gm

VREF

INT

VSENSE

SENSEGND

IN

V

OSC

1.236V

bandgap

VREF

1.416

Reference chain

0.9V

5/25

L6995

1 DEVICE DESCRIPTION

1.1 Constant On Time PWM topology

Figure 2. Loop block schem atic diagr am

Vin

R1

R2

One-shot generator

OSC

Vsense

Vref

FFSR

Q

R

HGATE

S

Q

+

LGATE

HS

LS

Vout

DS

-

PWM comparator

FB

R4

R3

The device implements a Constant On Time control scheme, where the Ton is the high side MOSFET on time

duration forced by the one-shot generator. The on time is directly proportional to VSENSE pin voltage and inverse to OSC pin voltage as in Eq1:

V

SENSE

Eq 1

where K

T

ON

= 250ns and τ is the internal propagation delay time (typ. 70ns). The system imposes in steady

OSC

state a minimum on time corresponding to V

responding Ton will not decrease. Connecting the OSC pin to a voltage partition from V

steady-state switching frequency F

== =

Eq 2

f

SW

K

OSC

V

OUT

-------------- -

V

IN

--------------------- -

V

OSC

1

---------- -

T

ON

τ+=

= 2V. In fact if the V

OSC

independent of VIN. It results:

SW

α

OSC

--------------

α

OUT

1

-------------- -

→ fSWK

K

OSC

α

OSC

OSC

OSCαOUT

voltage increases above 2V the cor-

to G N D, it a l lows a

IN

where

V

Eq 3

Eq 4

α

OSC

α

OUT

OSC

-------------- -

V

IN

V

FB

-------------- -

V

OUT

The above equations allow setting the frequency divide r ratio

such equations hold only if V

independent from the input voltage. The delay introduces a light dependenc e from V

R

2

--------------------==

R2R1+

R

4

--------------------==

R3R4+

α

once output voltage has been set; note that

<2V. Further the Eq2 shows how the system h as a sw itching frequenc y ideall y

OSC

OSC

. A minimum off-time con-

IN

strain of about 580ns is introduced in order to assure the boot capacitor charge and to limit the switching fre-

6/25

L6995

quency after a load transient as well as to mask PWM comparator output against noise and spikes.

The system has not an internal clock, b ecause this is a hysteretic control ler, so the turn on puls e will start if three

conditions are met contemporarily : the FB pin voltage i s low er than the refere nce voltage, the minimum o ff time

is passed and the current limit comparator is not triggered (i.e. the inductor current is below the current limit

value). The voltage on the OSC pin must range between 50mV and 2V to ensure the system linearity.

1.2 Closing the loop

The loop is closed connecting the output voltage (or the output divider middle point) to the FB pin. The FB pin

is linked internally to the comparator negative pin and the positive pin is connected to the reference voltage

(0.9V Typ.) as in Figure 2. When the FB goes lower than the reference voltage, the PWM comparator output

goes high and sets the flip-flop outpu t, turning on the hig h side MOSFET. This condition i s latched to av oid noise

spike. After the on-time (calculated as descr ibed in the previous section) the system resets the flip-flop and then

turns off the high side MOSFET and turns on the low side MOSFET. Internally the device has more complex

logic than a flip-flop to manage the transition in correct way. For more details refers to the Figure 1.

The voltage drop along ground and supply metals connecting output capacitor to the load is a source of DC

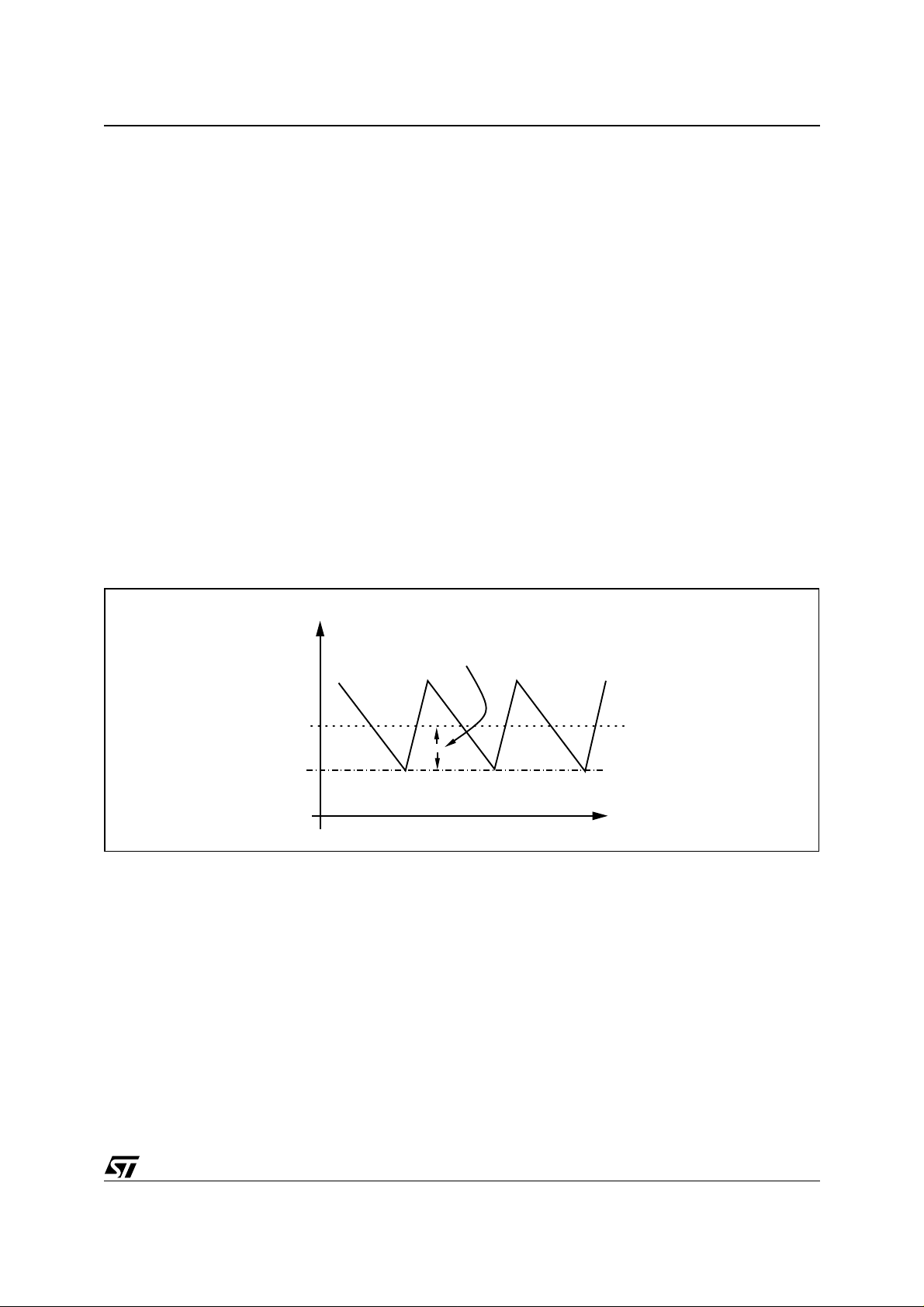

error. Further the system r egulates the o utput voltage v alley v alue not the aver age, as in the Fi gure 3 is show n.

So the voltage ripple on the output capacitor is a source of DC static error (as the PCB traces). To compensate

the DC errors, an integrator network must be introduced in the control lo op, by connectin g the output voltage to

the INT pin through a capacitor and the FB pin to the INT pin directly as in Figure 4. The internal integrator amplifier with the exter nal capac itor C

for output ripple.

introduces a D C pole i n the contr ol l oop. C

INT1

also provides an AC path

INT1

Figure 3. Valle y regulation

Vout

DC Error Offset

<Vout>

Vref

Time

The integrator amplifier generates a current, proportional to the DC errors, that increases the output capacitance

voltage in order to c ompensate the total static err ors. A v oltage clamper within the devi ce fo rces INT pi n v oltage

ranges from V

-50mV, V

REF

+150mV. This is useful to avoid or smooth output voltage overshoot during a load

REF

transient. Also, this means that the integrator is capable of recovering output error due to ripple when its peakto-peak amplitude is less than 150mV in steady state.

In case of the ripple amplitude is larger than 150mV, a capacitor C

can be connected between INT pin and

INT2

ground to reduce r ipple amplitu de at INT pin, otherw ise the integrator can operate out of its linear range. Choose

C

according to the following equation:

INT1

g

⋅

INTαOUT

Eq 5

INT1

where GINT=50 µs is the integrator transconductance,

is the close loop bandwidth. This equation also holds if C

--------------------------------- -=

⋅⋅

2 π F

u

α

is the output divider ratio given from Eq4 and F

OUT

is connected between INT pin and ground. C

INT2

INT2

is given by:

U

7/25

L6995

C

Eq 6

Where

INT2

--------------- -

C

INT1

∆

V

is the output ripple and ∆V

OUT

V

∆

OUT

------------------=

V

INT

INT

Figure 4. Integrator loop block diagram

Vin

R1

R2

Cint2

One-shot generator

OSC

From Vsense

Vref

FB

INT

Integrator amplifier

+

-

PWM comparator

+

is the ripple wanted at the INT pin (100mV typ).

PCB TRACES

FFSR

Q

R

HGA TE

S

Q

LGA TE

Vref

-

-

+

Vsense

Gndsense

HS

LS

DS

Vout

LOAD

Cint1

Respect to a traditional PWM controller, that has an internal osci llator setting the sw itchi ng frequency, in a hysteretic system the frequency can change with some parameters (input voltage, output current). In L6995 is implemented the voltage feed-forward circuit that allows constant switching frequency during steady-sate

operation with the input voltage variation. There are many factors affecting switching frequency accuracy in

steady-state operation. Some of these are internal as dead times, which depend on high side MOSFET driver.

Others related to the external components as high side MOSFET gate charge and gate resistance, voltage

drops on supply and ground rails, low side and high side RDSON and inductor parasitic resistance.

During a posi tive load trans ient, (the output current increases), the converter switches at its maxi mum frequency

(the period is TON+TOFFmin) to recover the output voltage drop. During a negative load transient, (the output

current decreases), the device stops to switch (high side MOSFET remains off).

1.3 Tran si t ion from PWM to PFM/PSK

To achieve high efficiency at light load condition s, PFM mode is provided. The PFM mode differs from the PWM

mode essentially for the off section; the on section is the same. In PFM after a turn-on cycle the system turnson the low side MOSFET, until the inductor current reaches the zero A value, when the zero-crossing comparator turns off the low side M OSFET. In this w ay the energy stor ed in the outp ut capaci tor wi ll not flow to gr ound,

through the low side MO SFET, but it w ill flow to the load. In PWM mode, after a turn on cy cle, the sy stem k eeps

the low side MOSFET on until the next turn-on cycle, so the energy stored in the output capacitor will flow

through the low side MOSFET to ground. The PFM mode is naturally implemented in hysteretic controller, in

fact in PFM mode the system reads the output vol tage with a comparator and then tur ns on the hig h side MOSFET when the output voltage goes down a reference value. The device works in discontinuous mode at light

load and in continu ous mode at high l oad. The transi tion fr om PFM to PWM oc curs when load current is around

half the inductor current ripple. This threshold value depends on V

, L, and V

IN

. Note that the higher the in-

OUT

8/25

Loading...

Loading...