5 BIT PROGRAMMABLE DUAL-PHASE CONTROLLER

■

2 PHASE OPERATION WITH

SYNCRHONOUS RECTIFIER CONTROL

■

ULTRA FAST LOAD TRANSIENT RESPONSE

■

INTEGRATED HIGH CURRENT GATE

DRIVERS: UP TO 2A GATE CURRENT

■

TTL-COMP A T I BLE 5 BIT P ROGR AMMABLE

OUTPUT CO MPLIANT WITH VRM 9.0

■

0.8% INTERNAL REFERENCE ACCURACY

■

10% ACTIVE CURRENT SHARING

ACCURACY

■

DIGITAL 2048 STEP SOFT-START

■

OVERVOLTAGE PROTEC T I O N

■

OVERCURRENT PROTECTION REALIZED

USING THE LOWER MOSFET'S R

SENSE RESISTOR

■

300 kHz INTERNAL OSCILLATOR

■

OSCILLATOR EXTERNALLY ADJUST ABLE

UP TO 600kHz

■

POWER GOOD OUTPUT AND INHIBIT

FUNCTI ON

■

REMOTE SENSE BUFFER

■

PACKAGE: SO-28

APPLICATION S

■

POWER SUPPLY FOR SERVERS AND

WORKSTATIONS

■

POWER SUPPLY FOR HIGH CURRENT

MICROPROCESSORS

■

DISTRIBUTED DC-DC CONVERTERS

dsON

OR A

L6917B

SO-28

ORDERING NUMB ERS :L691 7BD

L6917BDTR (Tape & Reel)

DESCRIPTION

The device is a power supply controller specifically

designed to provide a high performance DC/DC conversion for high current microprocessors.

The device implements a dual-phase step-dow n controller with a 180° phase-shift between each phase.

A precise 5-bit digital to analog converter (DAC) allows adjusting the output voltage from 1.100V to

1.850V with 25mV binary steps.

The high precision internal r eference ass ures the selected output voltage to be within ±0.8%. The high

peak current gate drive affor ds to hav e fast s witching

to the external power mos providing low switching

losses.

The device assures a fast protection against load

over current and load over/under vol t age. An internal

crowbar is provided turning on the low side mosfet if

an over-voltage is detected. In case of over-current,

the system works in Constant Current mode.

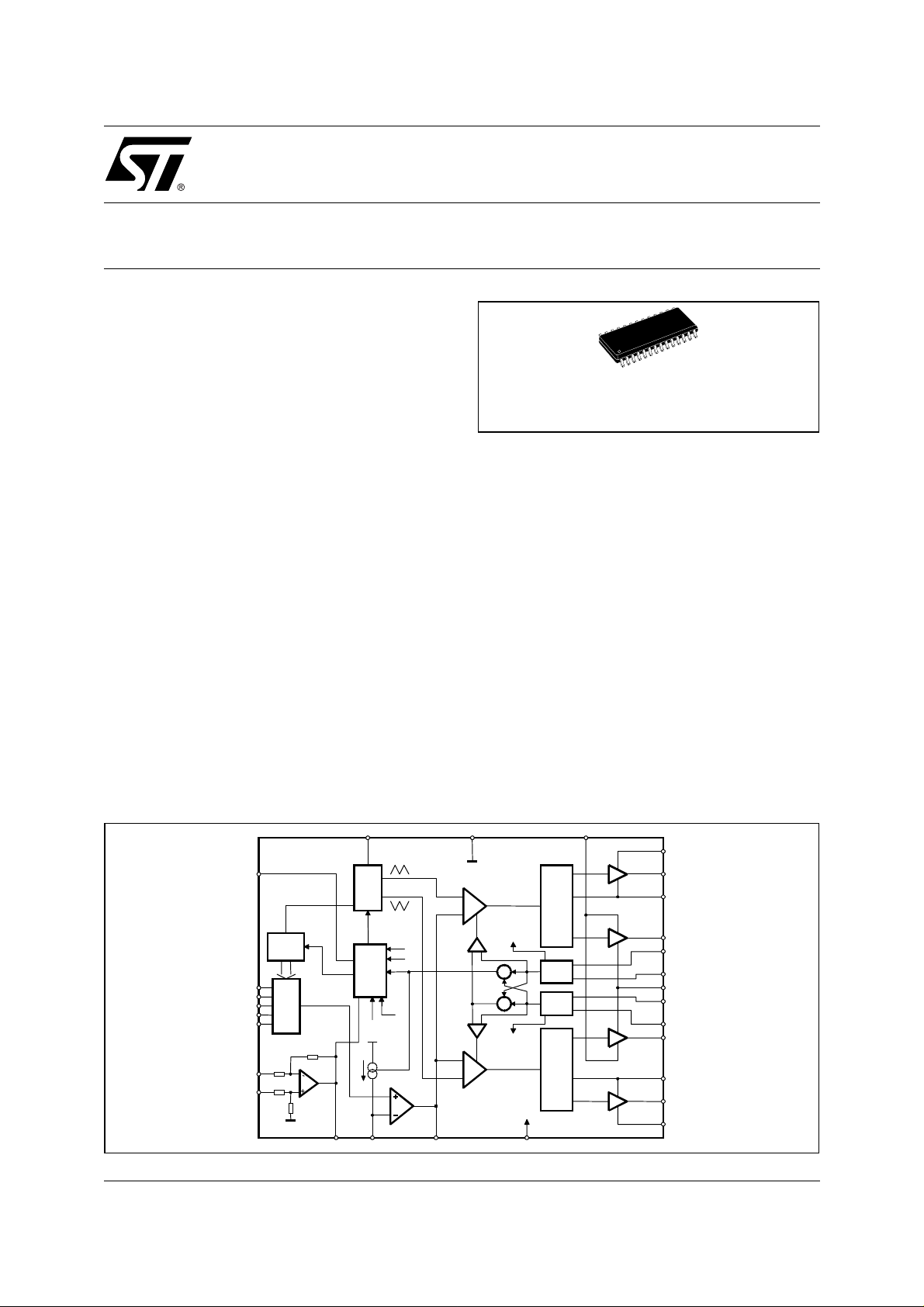

BLOCK DIAGRAM

September 2002

PGOOD

VID4

VID3

VID2

VID1

VID0

FBG

FBR

DIGITAL

SOFT START

DAC

10k

10k

10k

10k

REMOTE

BUFFER

VSEN

ROSC / IN H

2 PHASE

OSCILLATOR

LOGIC

AND

PROTECTIONS

CH1 OVER

CURRENT

IFB

FB

CH2 OVER

CURRENT

VCC

VCCDR

ERROR

AMPLIFIER

SGND VCCDR

PWM1

-

+

CH 1 OVER

CURRENT

CURRENT

CORRECT ION

TOTAL

+

CURRENT

AVG

CURRENT

< >

CH 2 OVER

CURRENT

CURRENT

CORRECT ION

+

-

PWM2

LOGIC PWM

ADAPTIVE ANTI

CROSS-CONDUCTION

CURRENT

READING

CURRENT

READING

LOGIC PWM

ADAPTIVE ANTI

CROSS-CONDUCTION

Vcc

VccCOMP

BOOT1

HS

LS

LS

HS

UGATE1

PHASE1

LGATE 1

ISEN1

PGNDS1

PGND

PGNDS2

ISEN2

LGATE 2

PHASE2

UGATE2

BOOT2

1/33

L6917B

T

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

Vcc, V

CCDR

V

BOOT-VPHASE

V

UGATE1-VPHASE1

V

UGATE2-VPHASE2

to PGND 15 V

Boot Voltage 15 V

15 V

LGATE1, PHASE1, LGATE2, PHASE2 to PGND -0.3 to Vcc+0.3 V

All other pins to PGND -0.3 to 7 V

V

phase

Sustainable Peak Voltage t < 20ns @ 600kHz 26 V

THERMAL DATA

Symbol Parameter Value Unit

R

th j-amb

T

T

storage

P

Thermal Resistance Junction to Ambient 60 °C/W

Maximum junction temperature 150 °C

max

Storage temperature range -40 to 150 °C

T

Junction Temperature Range -25 to 125 °C

j

Max power dissipation at T

MAX

= 25°C 2 W

amb

PIN CONNECTION

LGATE1

VCCDR

PHASE1

UGATE1

BOOT1

VCC

GND

COMP

FB

FBR

FBG

ISEN1

PGNDS1

2

3

4

5

6

7

8

9

10VSEN

11

12

13

14

SO28

28

27

26

25

24

23

22

21

20

19

18

17

16

15

PGND1

LGA TE2

PHASE2

UGATE2

BOOT2

PGOOD

VID4

VID3

VID2

VID1

VID0

OSC / INH / FAUL

ISEN2

PGNDS2

2/33

L6917B

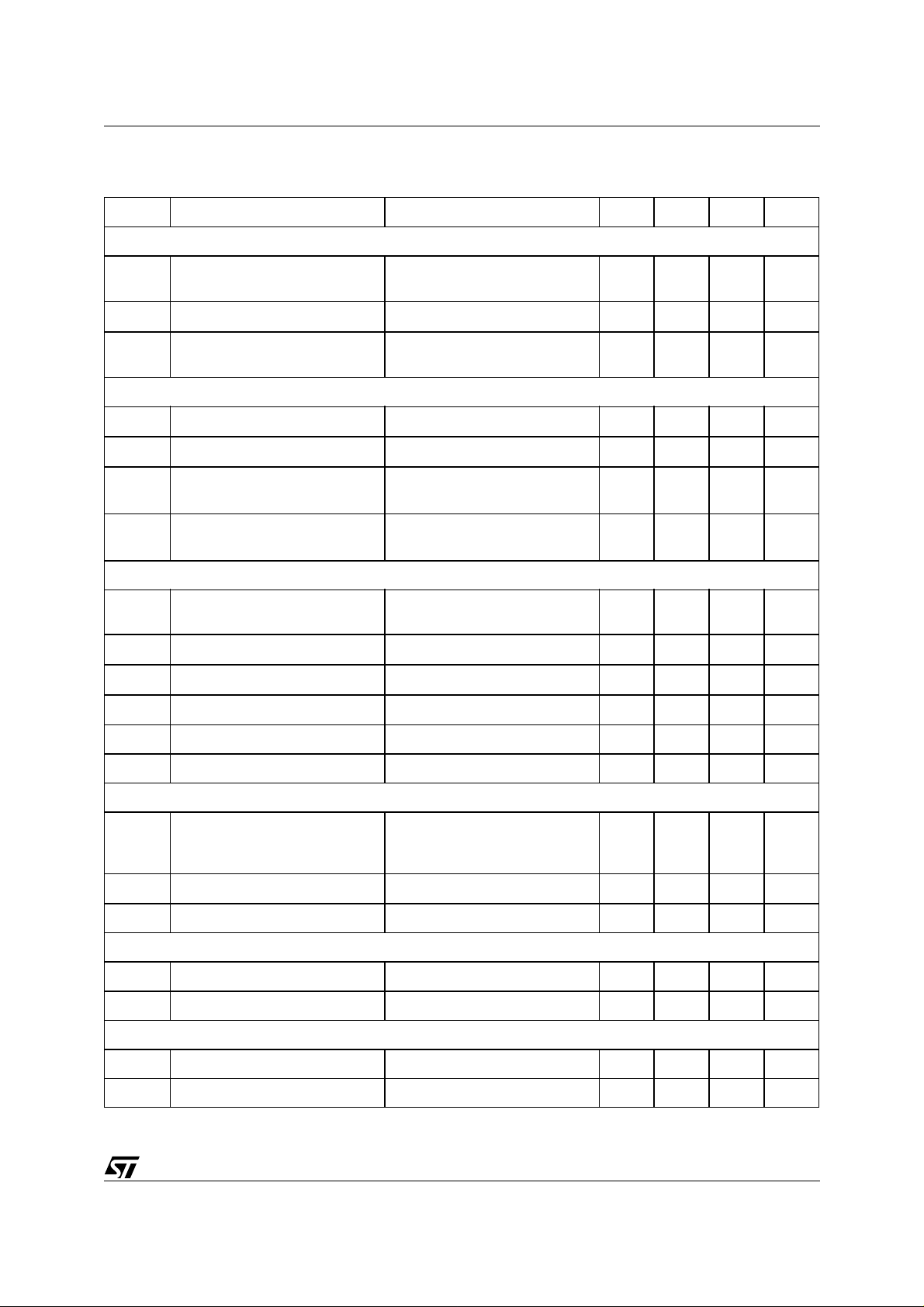

ELECTRICAL CHARACTERISTICS

= 12V ±10%, TJ = 0 to 70°C unless otherwise specified

V

CC

Symbol Parameter Test Condition Min Typ Max Unit

Vcc SUPPLY CURRENT

I

I

CCDR

I

BOOTx

Vcc supply current HGATEx and LGATEx open

CC

V

supply current LGATEx open; V

CCDR

Boot supply current HGATEx open; PHASEx to PGND

POWER-ON

Turn-On V

threshold VCC Rising; V

CC

Turn-Off VCC threshold VCC Falling; V

Turn-On V

CCDR

Threshold

Turn-Off V

CCDR

Threshold

OSCILLATOR/INHIBIT/FAULT

f

OSC

f

OSC,Rosc

Initial Accuracy OSC = OPEN

Total Accuracy RT to GND=74kΩ 450 500 550 kHz

INH Inhibit threshold I

d

Maximum duty cycle OSC = OPEN 70 75 %

MAX

V

CCDR=VBOOT

=12V

=12V 2 3 4 mA

CCDR

0.5 1 1.5 mA

7.5 10 12.5 mA

V

CC=VBOOT

V

CCDR

=12V

Rising

=5V 7.8 9 10.2 V

CCDR

=5V 6.5 7.5 8.5 V

CCDR

4.2 4.4 4.6 V

VCC=12V

V

CCDR

Falling

4.0 4.2 4.4 V

VCC=12V

278

OSC = OPEN; Tj=0°C to 125°C

=5mA 0.8 0.85 0.9 V

SINK

270

300 322

330

kHz

kHz

∆Vosc Ramp Amplitude 1.8 2 2.2 V

FAULT Voltage at pin OSC OVP or UVP Active 4.75 5.0 5.25 V

REFERENCE AND DAC

-0.8 - 0.8 %

I

DAC

Output Voltage

Accuracy

VID0, VID1, VID2, VID3, VID4

see Table1;

FBR = V

; FBG = GND

OUT

VID pull-up Current VIDx = GND 4 5 6 µA

VID pull-up Voltage VIDx = OPEN 3.1 - 3.4 V

ERROR AMPLIFIER

DC Gain 80 dB

SR Slew-Rate COMP=10pF 15 V/µs

DIFFERENTIAL AMPLIFIER (REMOTE BUFFER)

DC Gain 1 V/V

CMRR Common Mode Rejection Ratio 40 dB

3/33

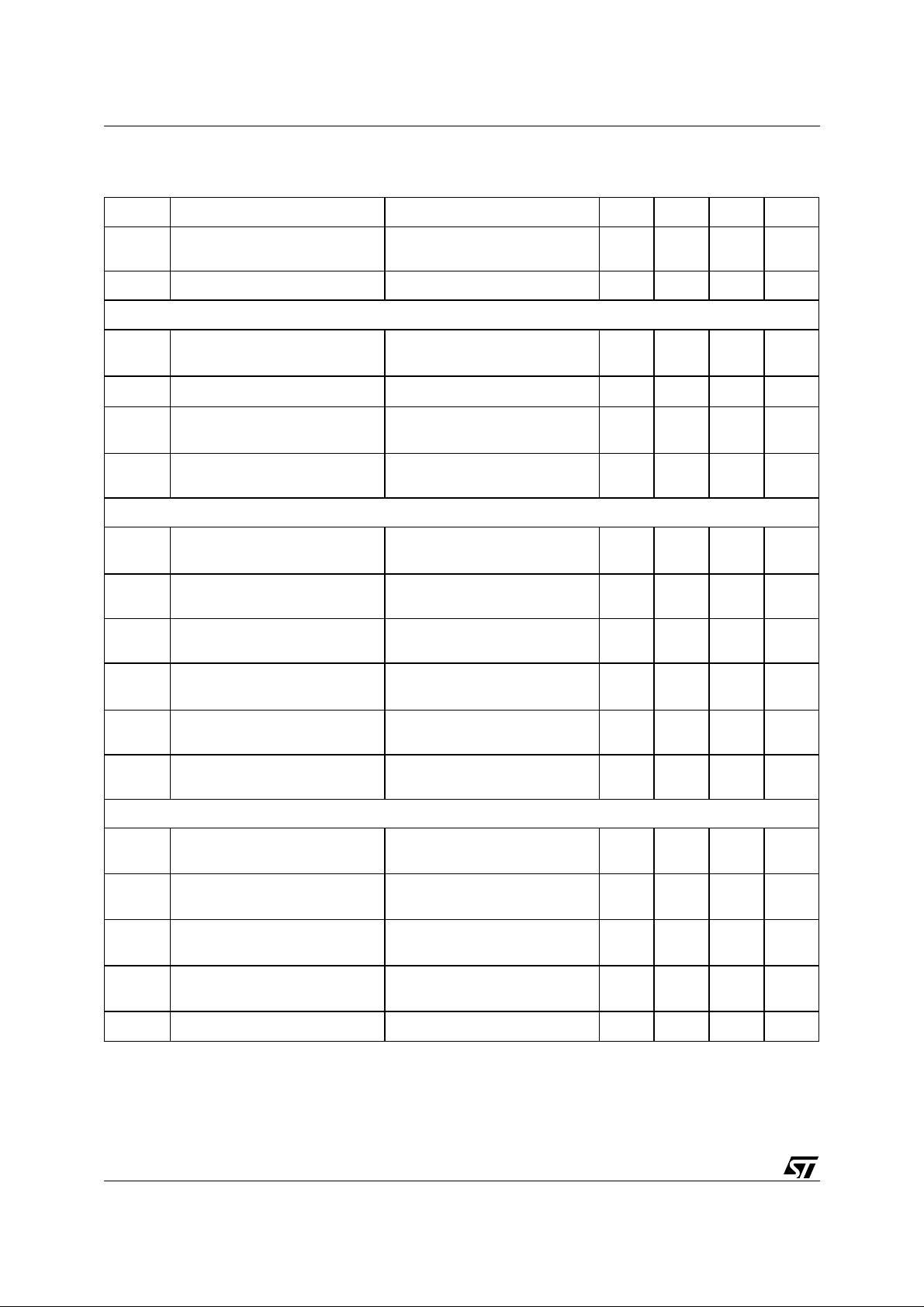

L6917B

ELECTRICAL CHARACTERISTICS

V

= 12V ±10%, TJ = 0 to 70°C unless otherwise specified

CC

(continued)

Symbol Parameter Test Condition Min Typ Max Unit

Input Offset F BR=1 .100V to1.850V;

-12 1 2 mV

FBG=GND

SR Slew Rate VSEN=10pF 15 V/µs

DIFFERENTIAL CURRENT SENSING

,

I

ISEN1

I

ISEN2

I

PGNDSx

I

ISEN1

I

ISEN2

I

Bias Current Iload=0 45 50 55 µA

Bias Current 45 50 55 µA

,

Bias Current at

80 85 90 µA

Over Current Threshold

Active Droop Current Iload<0%

FB

Iload=100% 47.5

0

50

1

52.5

GATE DRIVERS

t

RISE

HGATE

I

HGATEx

High Side

Rise Time

High Side

V

BOOTx-VPHASEx

C

V

to PHASEx=3.3nF

HGATEx

BOOTx-VPHASEx

=10V;

15 30 ns

=10V 2 A

Source Current

µA

µA

R

HGATEx

High Side

Sink Resistance

t

RISE

LGATE

I

LGATEx

Low Side

Rise Time

Low Side

Source Current

R

LGATEx

Low Side

Sink Resistance

P GOOD and OVP/UVP PROTECTIONS

PGOOD Upper Threshold

(V

/DACOUT)

SEN

PGOOD Lower Threshold

/DACOUT)

(V

SEN

OVP Over Voltage Threshold

)

(V

SEN

UVP Under Voltage Trip

/DACOUT)

(V

SEN

V

PGOOD

PGOOD Voltage Low I

V

BOOTx-VPHASEx

V

=10V;

CCDR

C

V

V

V

V

V

V

to PGNDx=5.6nF

LGATEx

=10V 1.8 A

CCDR

=12V 0.7 1.1 1.5 Ω

CCDR

Rising 108 112 116 %

SEN

Falling 84 88 92 %

SEN

Rising 2.0 2.25 V

SEN

Falling 56 60 64 %

SEN

= -4mA 0.3 0.4 0.5 V

PGOOD

=12V; 1.5 2 2.5 Ω

30 55 ns

4/33

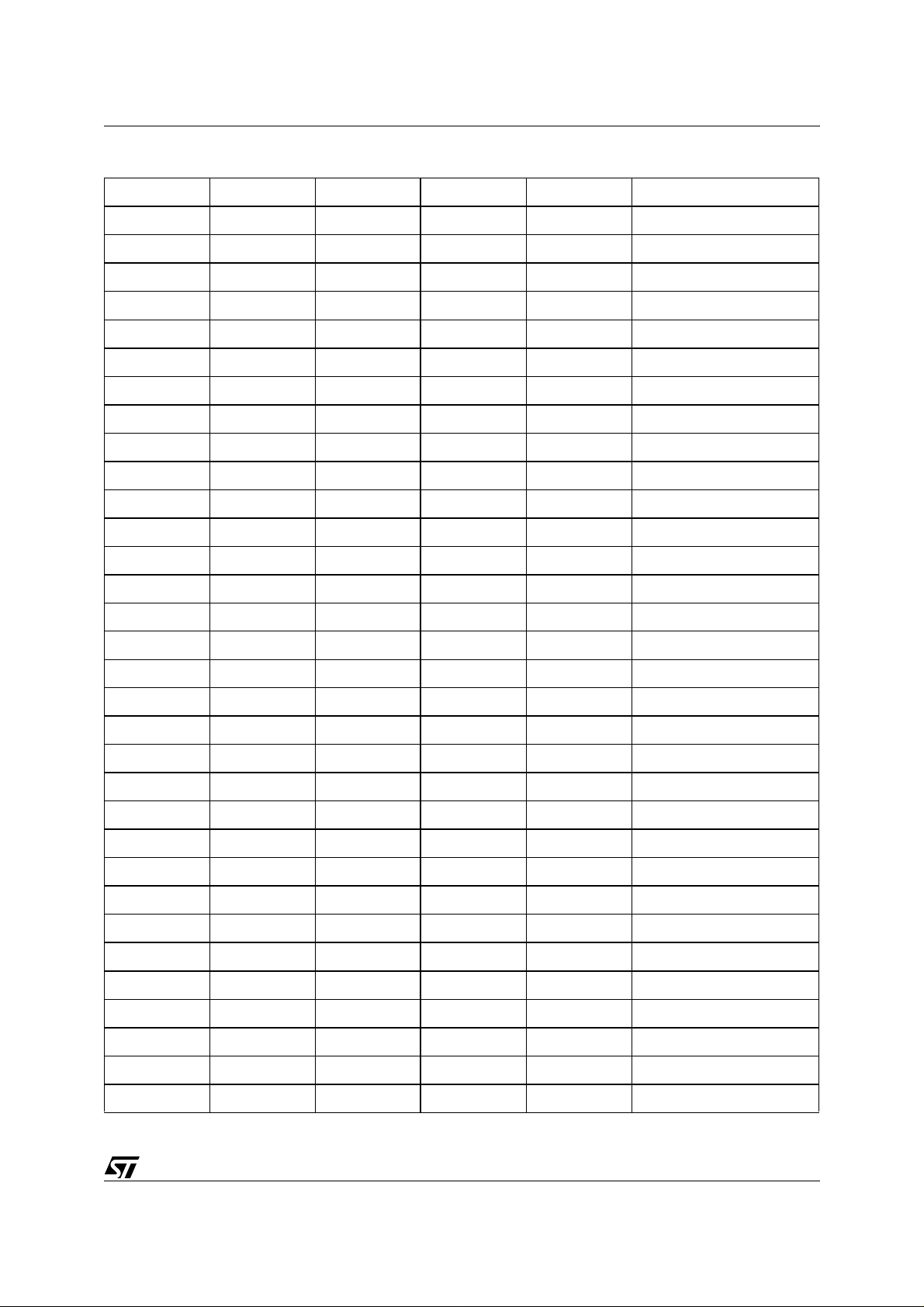

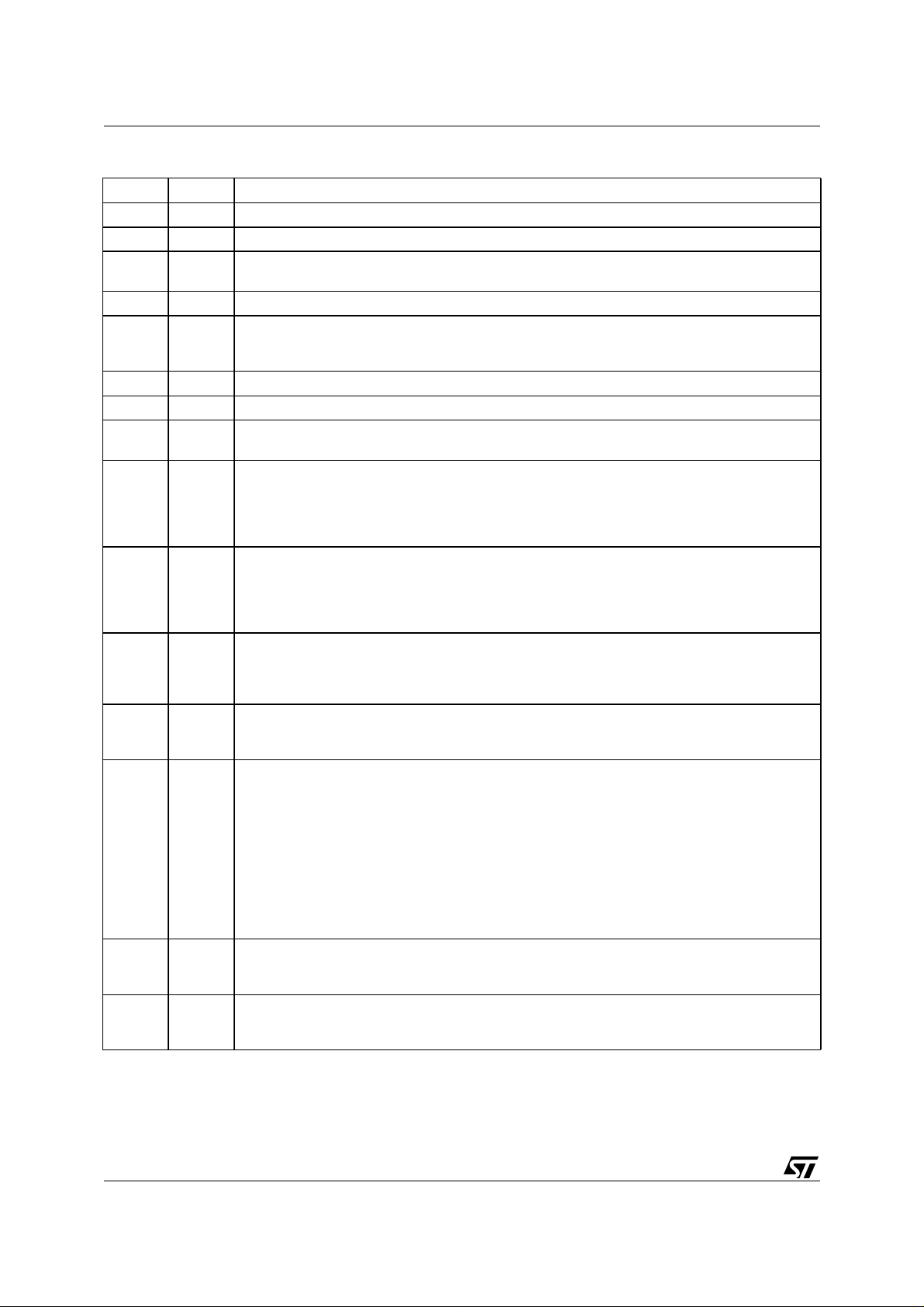

Table 1. VID Settings

VID4 VID3 VID2 VID1 VID0 Output Voltage (V)

1 1 1 1 1 OUTPUT OFF

11110 1.100

11101 1.125

11100 1.150

11011 1.175

11010 1.200

11001 1.225

11000 1.250

10111 1.275

10110 1.300

10101 1.325

10100 1.350

10011 1.375

L6917B

10010 1.400

10001 1.425

10000 1.450

01111 1.475

01110 1.500

01101 1.525

01100 1.550

01011 1.575

01010 1.600

01001 1.625

01000 1.650

00111 1.675

00110 1.700

00101 1.725

00100 1.750

00011 1.775

00010 1.800

00001 1.825

00000 1.850

5/33

L6917B

PIN FUNCTION

N Name Description

1 LGATE1 Channel 1 low side gate driver output.

2 VCCDR Mosfet driver supply. It can be varied from 5V to 12V.

3 PHASE1 This pin is connected to the source of the upper mosfet and provides the return path for the high

side driver of channel 1.

4 UGATE1 Channel 1 high side gate driver output.

5 BOOT1 Channel 1 bootstrap capacitor pin. Through this pin is supplied the high side driver and the upper

mosfet. Connect through a capacitor to the PHASE1 pin and through a diode to Vcc (cathode vs.

boot).

6 VCC Device supply voltage. The operative supply voltage is 12V.

7 GND All the internal references are referred to this pin. Connect it to the PCB signal ground.

8 COMP This pin is connected to the error amplifier output and is used to compensate the control

feedback loop.

9 FB This pin is connected to the error amplifier inverting input and is used to compensate the voltage

10 VSEN Connected to the output voltage it is able to manage Over & Under-voltage conditions and the

11 FBR Remote sense buffer non-inverting input. It has to be connected to the positive side of the load to

12 FBG Remote sense buffer inverting input. It has to be connected to the negative side of the load to

13 ISEN1 Channel 1 current sense pin. The output current may be sensed across a sense resistor or

14

15

(*) Through a resistor Rg.

PGNDS1

PGNDS2

control feedback loop.

A current proportional to the sum of the current sensed in both channel is sourced from this pin

(50µA at full load, 70µA at the Over Current threshold). Connecting a resistor between this pin

and VSEN pin allows programming the droop effect.

PGOOD signal. It is internally connected with the output of the Remote Sense Buffer for Remote

Sense of the regulated voltage.

If no Remote Sense is implemented, connect it directly to the regulated voltage in order to

manage OVP, UVP and PGOOD.

perform a remote sense.

If no remote sense is implemented, connect directly to the output voltage (in this case connect

also the VSEN pin directly to the output regulated voltage).

perform a remote sense.

Pull-down to ground if no remote sense is implemented.

across the low-side mosfet Rds

This pin has to be connected to the low-side mosfet drain or

ON.

to the sense resistor through a resistor Rg in order to program the positive current limit at 140%

as follow:

35µAR

⋅

I

MAX

--------------------------=

R

g

sense

Where 35µA is the current offset information relative to the Over Current condition (offset at OC

threshold minus offset at zero load).

The net connecting the pin to the sense point must be routed as close as possible to the

PGNDS1 net in order to couple in common mode any picked-up noise.

Channel 1 Power Ground sense pin. The net connecting the pin to the sense point (*) must be

routed as close as possible to the ISEN1 net in order to couple in common mode any picked-up

noise.

Channel 2 Power Ground sense pin. The net connecting the pin to the sense point (*) must be

routed as close as possible to the ISEN2 net in order to couple in common mode any picked-up

noise.

6/33

L6917B

PIN FUNCTION

(continued)

N Name Description

16 ISEN2 Channel 2 current sense pin. The output current may be sensed across a sense resistor or

across the low-side mosfet Rds

This pin has to be connected to the low-side mosfet drain or

ON.

to the sense resistor through a resistor Rg in order to program the positive current limit at 140%

as follow:

35µAR

⋅

I

MAX

--------------------------=

R

g

sense

Where 35µA is the current offset information relative to the Over Current condition (offset at OC

threshold minus offset at zero load).

The net connecting the pin to the sense point must be routed as close as possible to the

PGNDS2 net in order to couple in common mode any picked-up noise.

17

OSC/

INH/

FAULT

Oscillator switching frequency pin. Connecting an external resistor from this pin to GND, the

external frequency is increased according to the equation:

f

S

300KHz

14.82 10

-----------------------------+=

R

OSC

6

⋅

KΩ()

Connecting a resistor from this pin to Vcc (12V), the switching frequency is reduced according to

the equation:

f

S

300KHz

12.91 10

-----------------------------–=

R

OSC

7

⋅

KΩ()

If the pin is not connected, the switching frequency is 300KHz.

Forcing the pin to a voltage lower than 0.8V, the device stop operation and enter the inhibit state.

The pin is forced high when an over or under voltage is detected. This condition is latched; to

recover it is necessary turn off and on VCC.

18-22 VID4-0 Voltage IDentification pins. These input are internally pulled-up and TTL compatible. They are

used to program the output voltage as specified in Table 1 and to set the power good thresholds.

Connect to GND to program a ‘0’ while leave floating to program a ‘1’.

23 PGOOD This pin is an open collector output and is pulled low if the output voltage is not within the above

specified thresholds.

If not used may be left floating.

24 BOOT2 Channel 2 bootstrap capacitor pin. Through this pin is supplied the high side driver and the upper

mosfet. Connect through a capacitor to the PHASE2 pin and through a diode to Vcc (cathode vs.

boot).

25 UGATE2 Channel 2 high side gate driver output.

26 PHASE2 This pin is connected to the source of the upper mosfet and provides the return path for the high

side driver of channel 2.

27 LGATE2 Channel 2 low side gate driver output.

28 PGND Power ground pin. This pin is common to both sections and it must be connected through the

closest path to the low side mosfets source pins in order to reduce the noise injection into the

device.

7/33

L6917B

Device Description

The device is an i ntegrated circuit r ealized in BCD technol ogy. It provides c omplete control logic and protections

for a high performance dual-phase step-down DC-DC converter optimized for microprocessor power supply. It

is designed to drive N Channel MOSFETs in a dual-phase synchronous-rectified buck topology. A 180 deg

phase shift is provided between the two phases allowing reduction in the input capaci tor current rippl e, reducing

also the size and the losses. The output voltage of the converter can be precisely regulated, programming the

VID pins, from 1.100V to 1.850V with 25mV binary step s, w ith a ma ximum toler ance of ±0.8% over temper ature

and line voltage variations. The device provides an average current-mode control with fast transient response.

It includes a 300kHz free-r unning oscil lator adjus table up to 600kH z. The error ampli fier features a 15V/

rate that permits high converter bandwidth for fast transient performances. Current information is read across

the lower mosfets r

or across a sense resistor in fully differential mode. The current information corrects

DSON

the PWM output in order to equalize the average current carried by each phase. Cur rent sharing between the

two phases is then limited at ±10% over static and dynamic conditions. The device protects against over-current, with an OC threshold for each phase, entering in constant current mode. Since the current is read across

the low side mosfets, the constant current keeps constant the bottom of the inductors current triangular waveform. When an under voltage is detected the device latches and the FAULT pin is driven high. The device performs also over voltage pr otection that disable immediately the device turning ON the lower driver and driving

high the FAULT pin.

Oscillator

The device has been designed in order to operate an each phase at the same switching frequency of the internal

oscillator. So, input and output resulting frequency is doubled.

The switching frequency is internally fixed to 300kHz. The internal oscillator generates the triangular waveform

for the PWM charging and discharging with a constant c urrent an internal capacit or. The current deliver ed to the

oscillator is typically 25

µ

A and may be varied using an external resistor (R

) connected between OSC pin

OSC

and GND or Vcc. Since the OSC pin is maintained at fixed voltage (typ). 1.235V, the frequency is varied proportionally to the current sunk (forced) from (into) the pin considering the internal gain of 12KHz/

In particular connecting it to GND the frequency is increased (current is sunk from the pin), while connecting ROSC

to Vcc=12V the frequency is reduced (current is forced i nto the pin), accordi ng to the following relationships:

R

OSC

vs. GND: f

S

300kHz

1.237

------------------------------

R

OSC

Ω()

K

12

kHz

-----------⋅+

µ

A

300kHz

14.82 10

------------------------------+==

R

OSC

⋅

K

6

Ω()

µ

s slew

µ

A.

12 1.237

vs. 12V: f

R

OSC

S

300kHz

------------------------------

R

–

OSC

Ω()

K

kHz

-----------

⋅–

12

µ

A

300kHz

12.918 10

--------------------------------–==

R

OSC

⋅

Ω()

K

7

Note that forcing a 25µA current into this pin, the device stops switching because no current is delivered to the

oscillator.

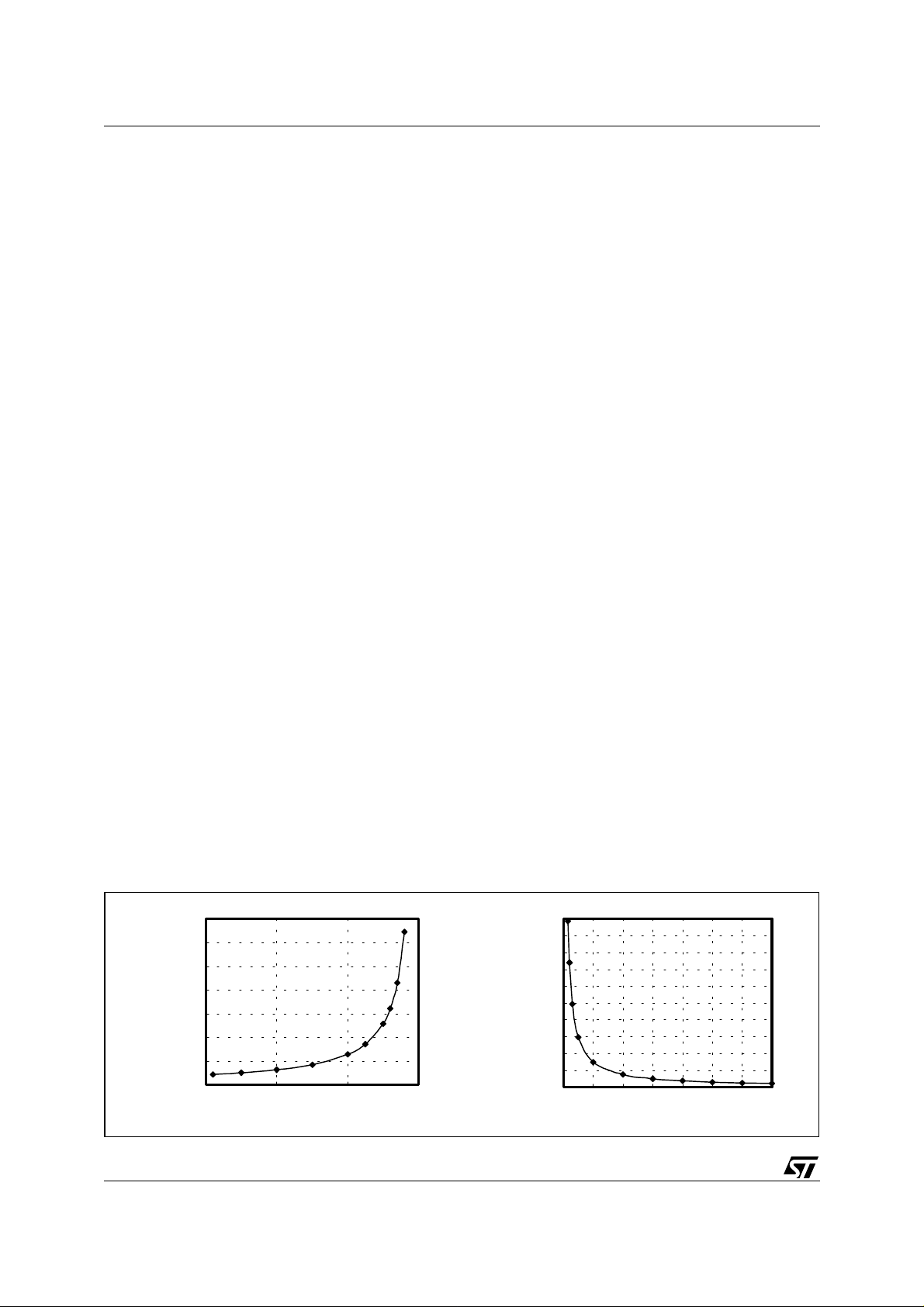

Figure 1. R

) vs. 12V

Ω

Rosc(K

8/33

vs. Switching Frequency

OSC

7000

6000

5000

4000

3000

2000

1000

0

0 100 200 300

Frequency (KH z )

1000

900

800

700

600

) vs. GND

500

Ω

400

300

200

Rosc(K

100

0

300 400 500 600 700 800 900 1000

Frequency (KHz)

L6917B

Digital to Analog Converter

The built-in digital to analog converter allows the adjustment of the output voltage from 1.100V to 1.850V with

25mV as shown in the previous table 1. The internal reference is trimmed to ensure the precision of 0.8% and

a zero temperature coef ficient aroun d 70°C. The inter nal referenc e voltage for the regulation is pr ogrammed by

the voltage identification (VID) pins. These are TTL compatible inputs of an internal DA C that is realized by

means of a series of resistor s providing a parti tion of the inter nal voltage reference. The V ID code drives a multiplexer that selects a voltage on a precise point of the divider. The DAC output is delivered to an amplifier obtaining the VPROG voltage reference (i.e. the set-point of the error amplifier). Internal pull-ups are provided

(realized with a 5

the pin floating, while to program a logic "0" it is enough to short the pin to GND. VID code “11111” programs

the NOCPU state: all mosfets are turned OFF and the condition is latched.

The voltage identification (VID) pin configuration also sets the power-good thresholds (PGOOD) and the overvoltage protection (OVP) thresholds.

Soft Start and INHIBIT

At start-up a ramp is generated increasing the loop reference from 0V to the final value programmed by VID in

2048 clock periods as shown in figure 2.

Before soft start, the lower power MOS are turned ON after that V

to discharge the output capacitor and to protect the load from high side mosfet failures. Once soft start begins,

the reference is increased; when it reaches the bottom of the oscillator triangular waveform (1V typ) also the

upper MOS begins to swi tch and the output volta ge star ts to increase w ith c losed l oop regulation.. At the end of

the digital soft start, the Power Good comparator is enabled and the PGOOD signal is then driven high (See fig.

2). The Under Voltage comparator enabled when the reference voltage reaches 0.8V.

The Soft-Start will not take place, if both V

ing normal operation, if any under-voltage is detected on one of the two supplies the device shuts down.

Forcing the OSC/INH/FAULT pin to a voltage lower than 0.8V the device enter in INHIBIT mode: all the power

mosfets are turned off until this condition is removed. When this pin is freed, the OSC/INH/FAULT pin reaches

the band-gap voltage and the soft start begins.

µ

A current generator up to 3.3V max); in this way, to program a logic "1" it is enough to leave

reaches 2V (independently by Vcc value)

CCDR

and VCCDR pins are not abov e their own turn- on thresholds. Dur-

CC

Figure 2. Soft Start

VIN=V

CCDR

V

LGATEx

V

OUT

PGOOD

Turn ON threshold

2V

t

t

t

2048 Clock Cycles

Timing Diagram Acquisition:

t

CH1 = PGOOD; CH2 = V

; CH4 = LGATEx

OUT

9/33

L6917B

Driver Section

The integrated high-current drivers allow using different types of power MOS (also multiple MOS to reduce the

RDSON), maintaining fast switching transition.

The drivers for the high-side mosfets use BOOTx pins for supply and PHASEx pins for return. The drivers for

the low-side mosfets use VCCDRV pin for supply and PGND pin for return. A minimum voltage of 4.6V at VCCDRV pin is required to start operations of the device.

The controller embodies a sophisticated anti-shoot- through system to minimize low side body diode conduction

time maintaining good efficiency saving the use of Schottky diodes. The dead time is reduced to few nanoseconds assuring that high-side and low-side mosfets are never switched on simultaneously: when the high-side

mosfet turns off, the voltage on its source begins to fall; when the voltage reach es 2V, the low-side mosfet gate

drive is applied with 30ns delay. When the low-side mosfet turns off, the voltage at LGATEx pin is sensed. When

it drops below 1V, the high-side mosfet gate drive is applied with a delay of 30ns. If the current flowing in the

inductor is negativ e, the sourc e of high -side mos f et will nev er dr op. To all ow the tur ning on of the l ow-side mosfet even in this case, a watchdog controller is enabled: if the source of the high-side mosfet don't drop for more

than 240ns, the low side mosfet is switched on so allowing the negative current of the inductor to recirculate.

This mechanism allows the system to regulate even if the current is negative.

The BOOTx and VCCDR pins are separated from IC's power supply (VCC pin) as well as signal ground (SGND

pin) and power ground (PGND pin) in order to maximize the switching noise immunity. The separated supply

for the diff erent drivers gives high flexibility in mosfet choice, allow ing the use of logic- level mosf et. Several combination of supply can be chosen to optimize performance and efficiency of the application. Power conversion

is also flexible, 5V or 12V bus can be chosen freely.

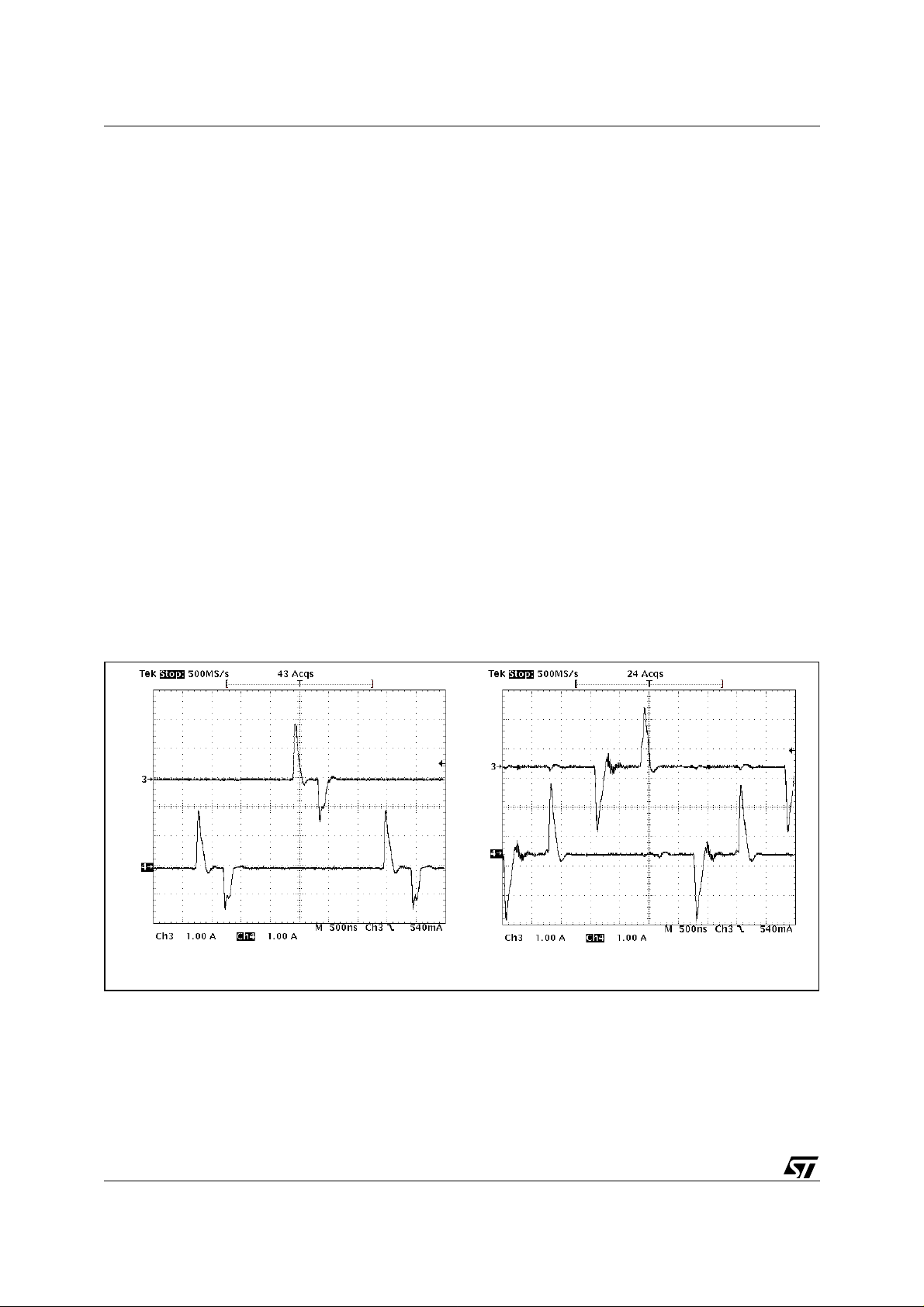

The peak current is shown for both the upper and the lower driver of the two phases in figure 3. A 10nF capacitive load has been used. For the upper drivers, the source current is 1.9A while the sink current is 1.5A with

V

BOOT-VPHASE

VCCDR = 1 2V.

= 12V; similarly, for the lower drivers , the s our ce c urrent is 2.4A while the sink cur rent is 2A w ith

Figure 3. Drivers peak current: High Side (left) and Low Side (right)

CH3 = HGATE1; CH4 = HGATE2 CH3 = LGATE1; CH4 = LGATE2

Current Reading and Over Current

The current flowing trough each phase is read using the voltage drop across the low side mosfets r

across a sense resistor (R

) and internally converted into a current. The transconductance ratio is issued

SENSE

DSON

or

by the external resistor Rg placed outsi de the chip between ISENx and PGNDSx pins toward the reading points.

The full differential current readi ng rejects noi se and allow s to plac e sensing el ement in different lo cations w ithout affecting the measurement's accuracy. The current reading circuitry reads the current during the time in

10/33

Loading...

Loading...